MITSUBISHI 3000GT 1991 Owner's Guide

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 31 of 1146

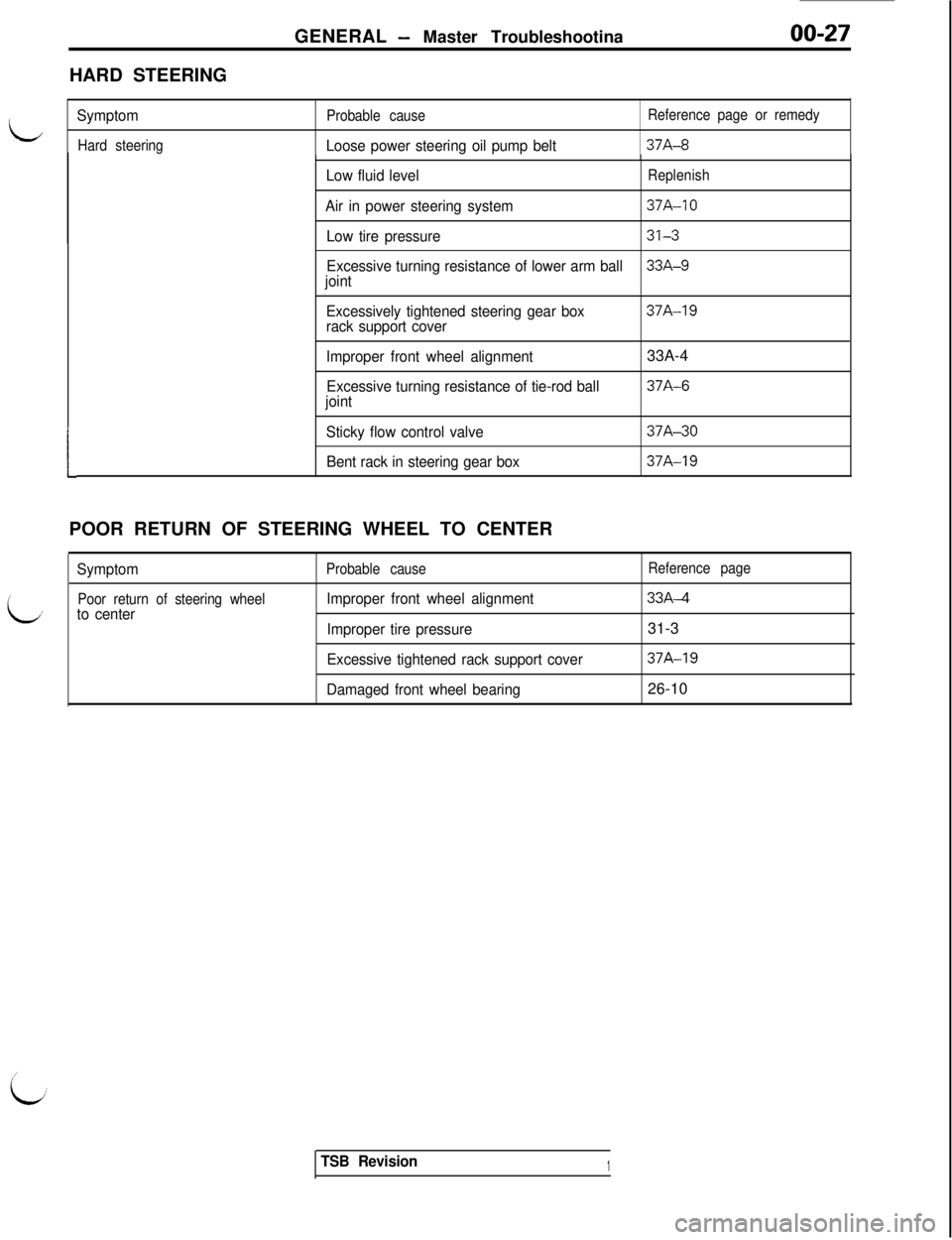

GENERAL - Master Troubleshootina00-27HARD STEERING

L

L

Symptom

Hard steeringProbable causeLoose power steering oil pump belt

Reference page or remedy37A-8

1POOR RETURN OF STEERING WHEEL TO CENTER

Symptom

Poor return of steering wheelto center

Probable cause

Improper front wheel alignment

Improper tire pressure

Excessive tightened rack support cover

Damaged front wheel bearing

Reference page33A-4

31-3

37A-1926-10

Low fluid levelReplenish

Air in power steering system37A-10

Low tire pressure

313

Excessive turning resistance of lower arm ball33A-9joint

Excessively tightened steering gear box

rack support cover

37A-19

Improper front wheel alignment

Excessive turning resistance of tie-rod ball

joint

Sticky flow control valve

Bent rack in steering gear box33A-437A-6

37A-30

37A-19

TSB Revision1

Page 32 of 1146

00-28GENERAL - Master Troubleshooting

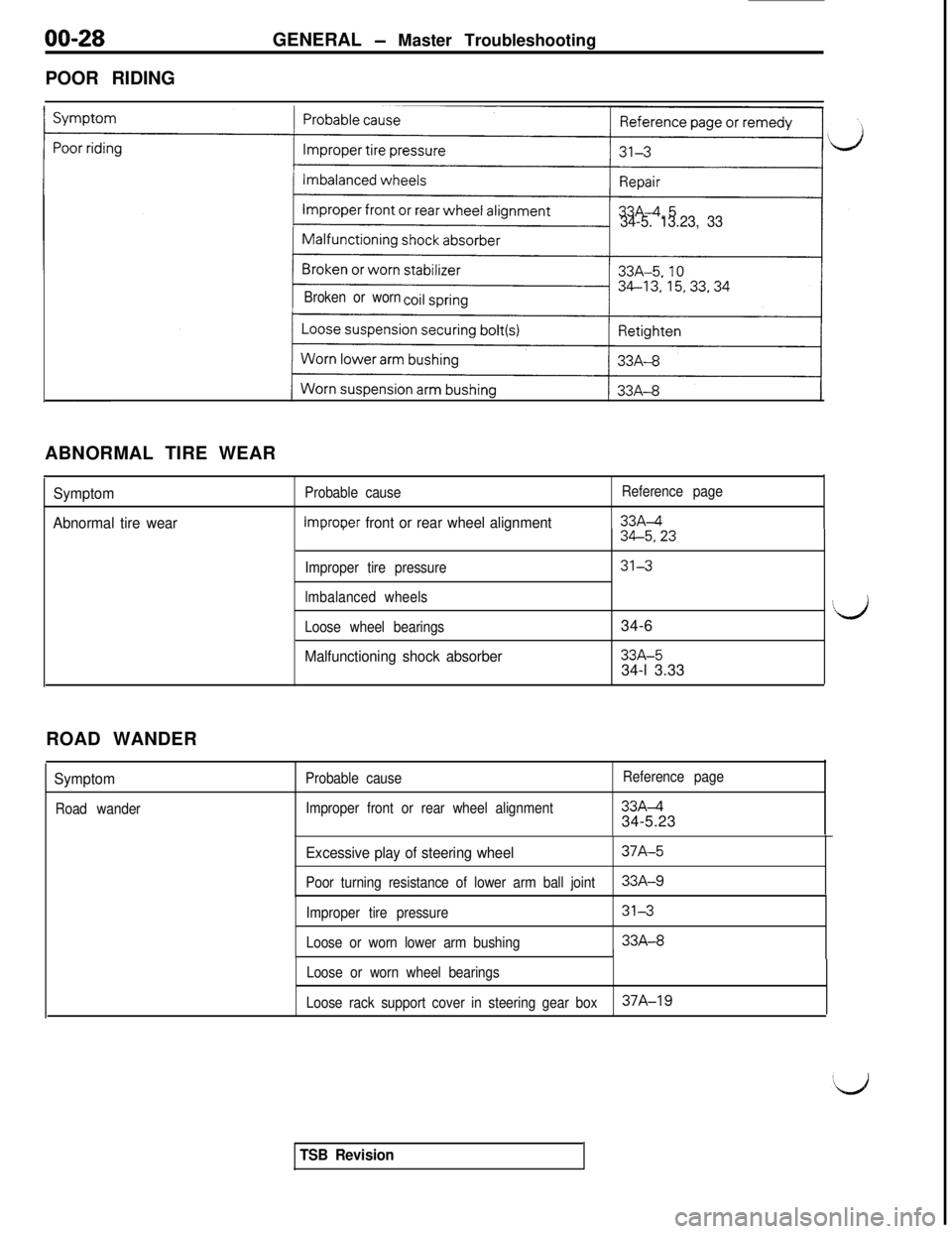

POOR RIDING

34-5. 13.23, 33

Broken or wornABNORMAL TIRE WEAR

Symptom

Abnormal tire wearProbable cause

lmorooer front or rear wheel alignment, ,

Improper tire pressure

lmbalanced wheels

Loose wheel bearings

Malfunctioning shock absorber

Reference page

33Ad34-5,23

31334-6

LJ33A-5

34-l 3.33

ROAD WANDER

Symptom

Road wanderProbable cause

Improper front or rear wheel alignmentReference page33A&34-5.23

Excessive play of steering wheel

Poor turning resistance of lower arm ball joint37A-533A-9

Improper tire pressure

Loose or worn lower arm bushing31333A-8

III

Loose or worn wheel bearings

Loose rack support cover in steering gear box37A-19

TSB Revision

Page 33 of 1146

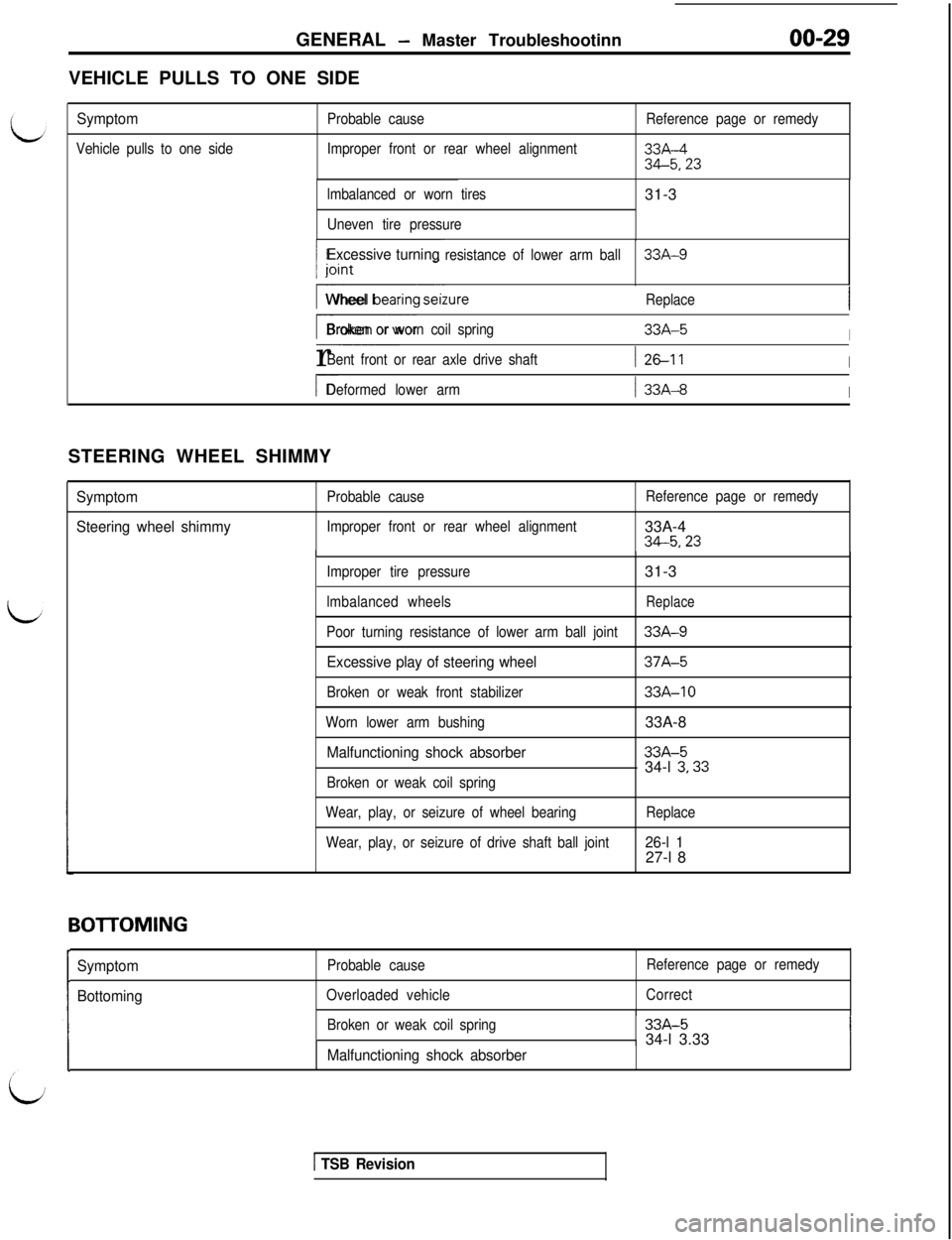

GENERAL - Master Troubleshootinn

VEHICLE PULLS TO ONE SIDE

Symptom

Vehicle pulls to one sideProbable cause

Improper front or rear wheel alignmentReference page or remedy33A-4

34-5,23

lmbalanced or worn tires

Uneven tire pressure31-3

Excessive turningresistance of lower arm ball33A-9

I--_Wheel beanng serzureReplace

I---Broken or worn coil spring33A-5Ir

~~~~~~Bent front or rear axle drive shaft126-11I

I-Deformed lower arm1 33A-8I

Improper tire pressure31-3

lmbalanced wheelsReplace

Poor turning resistance of lower arm ball joint33A-9

Excessive play of steering wheel37A-5

Broken or weak front stabilizer33A-10

Worn lower arm bushing33A-8

Malfunctioning shock absorber33A-5

34-l 3,33

Broken or weak coil spring

Wear, play, or seizure of wheel bearing

Wear, play, or seizure of drive shaft ball jointReplace

26-l 127-l 8 STEERING WHEEL SHIMMY

SymptomProbable cause

Steering wheel shimmyImproper front or rear wheel alignmentReference page or remedy33A-434-5,23

Boll-OMING

Symptom

BottomingProbable cause

Overloaded vehicleReference page or remedy

Correct

Broken or weak coil spring33A-5

34-l 3.33

IMalfunctioning shock absorber

1 TSB Revision

Page 34 of 1146

00-30GENERAL - Master Troubleshooting

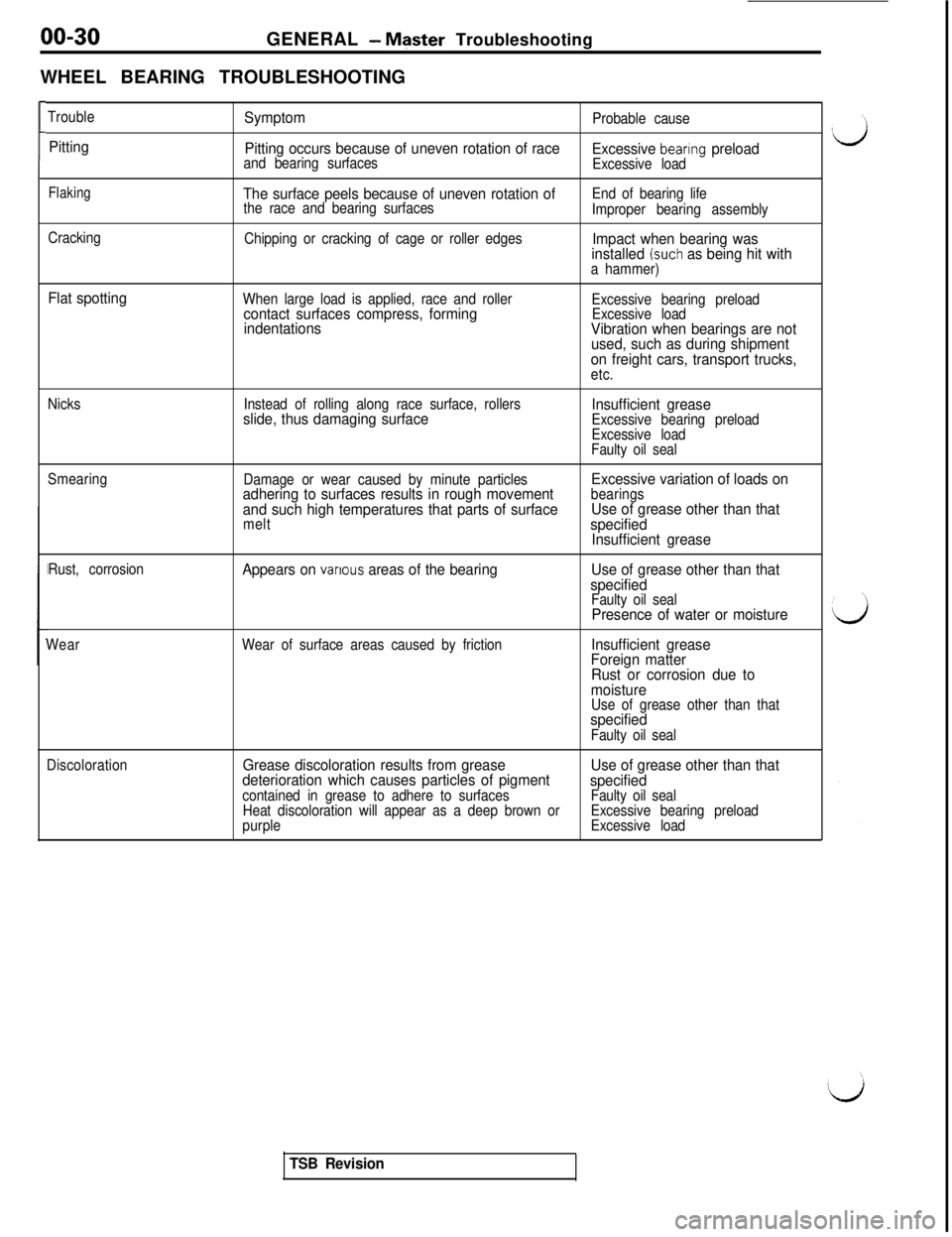

WHEEL BEARING TROUBLESHOOTING

1

Trouble

PittingSymptom

Pitting occurs because of uneven rotation of race

and bearing surfacesProbable causeExcessive bearing preloadExcessive load

FlakingThe surface peels because of uneven rotation ofthe race and bearing surfacesEnd of bearing life

Improper bearing assembly

Cracking

Chipping or cracking of cage or roller edges

Impact when bearing was

installed (such as being hit witha hammer)

Flat spottingWhen large load is applied, race and rollercontact surfaces compress, forming

indentationsExcessive bearing preload

Excessive load

Vibration when bearings are not

used, such as during shipment

on freight cars, transport trucks,

etc.

NicksInstead of rolling along race surface, rollers

slide, thus damaging surfaceInsufficient greaseExcessive bearing preload

Excessive load

Faulty oil seal

Smearing

Damage or wear caused by minute particles

adhering to surfaces results in rough movement

and such high temperatures that parts of surface

melt

Excessive variation of loads onbearingsUse of grease other than that

specified

Insufficient grease

Rust, corrosionAppears on various areas of the bearingUse of grease other than that

specified

Faulty oil sealPresence of water or moisture

WearWear of surface areas caused by frictionInsufficient grease

Foreign matter

Rust or corrosion due to

moisture

Use of grease other than thatspecifiedFaulty oil seal

Discoloration

Grease discoloration results from grease

deterioration which causes particles of pigment

contained in grease to adhere to surfaces

Heat discoloration will appear as a deep brown or

purple

Use of grease other than that

specified

Faulty oil seal

Excessive bearing preload

Excessive load

TSB Revision

Page 35 of 1146

GENERAL - Lubrication and Maintenance00-31LUBRICATION AND MAINTE-

NANCEMOOPA- -

iiMaintenance and lubrication service recommenda-

tions have been compiled to provide maximum

protection for the vehicle owner’s investment

against all reasonable types of driving conditions.

Since these conditions vary with the individual

vehicle owner’s driving habits, the area in which the

vehicle is operated and the type of driving to which

the vehicle is subjected, it is necessary to prescribe

lubrication and maintenance service on a time

frequency as well as mileage interval basis.

Oils, lubricants and greases are classified and

graded according to standards recommended by the

Society of Automotive Engineers

(SAE), the Amer-

ican Petroleum Institute (API) and the National

Lubricating Grease Institute

(NLGI).MAINTENANCE SCHEDULES

Information for service maintenance is provided

under “SCHEDULED MAINTENANCE TABLE”.

Three schedules are provided; one for “Required

Maintenance”, one for “General Maintenance” and

one for “Severe Usage Service”.

Item numbers in the “SCHEDULED MAINTE-

NANCE TABLE” correspond to the item numbers in

the “MAINTENANCE SERVICE” section.

LSEVERE SERVICE

Vehicles operating under severe service conditions

will require more frequent service.

Component service information is included in

appropriate units for vehicles operating under one or

more of the following conditions:

1. Police, taxi, or commercial type operation

2. Operation of Vehicle

(1) Short-trip operation at freezing temperature

(engine not thoroughly warmed up)

(2) More than 50% operation in heavy city

traffic during hot weather above 32°C

(90°F)(3) Extensive idling

(4) Driving in sandy areas

(5) Driving in salty areas

(6) Driving in dusty conditions

ENGINE OIL

The SAE grade number indicates the viscosity of

engine oils, for example, SAE 30, which is a single

grade oil. Engine oils are also identified by a dual

number, for example, SAE 1 OW-30, which indicates

a multigrade oil.

The API classification system defines oil perform-

ance in terms of engine usage. Only engine oil

idesigned “For Service SG” or “For Service

SGXD”,when available, should be used. These oils contain

sufficient chemical additives to provide maximumengine protection. Both the SAE grade and the API

designation can be found on the container.

Caution

Test results submitted to EPA have shown thatlaboratory animals develop skin cancer after

prolonged contact with used engine oil. Accor-dingly, the potential exists for humans to de-

velop a number of skin disorders, including

cancer, from such exposure to used engine oil.

Care should be taken, therefore, when changing

engine oil, to minimize the amount and length ofexposure time to used engine oil on your skin.

Protective clothing and gloves, that cannot be

penetrated by oil, should be worn. The skin

should be thoroughly washed with soap and

water, or use waterless hand cleaner, to removeany used engine oil. Do not use gasoline,

thinners, or solvents.GEAR

LUEiRlCANTSThe SAE grade number also indicates the viscosity

of Multi-Purpose Gear Lubricants.

The API classification system defines gear lubri-

cants in terms of usage. Typically gear lubricants

conforming to API GL-4 or GL-5 with a viscosity of

SAE

75W-85W are recommended for manual trans-

axle.

LUBRICANTS

- GREASES

Semi-solid lubricants, bear the

NLGI designation and

are further classified as grades 0, 1, 2, 3 etc.

Whenever “Chassis Lubricant” is specified,

Multi-Purpose Grease,

NLGI grade 2, should be used.

FUEL USAGE STATEMENT

Use premium unleaded gasoline having a minimum

octane rating of 91,

(R + M)/2. However, it is also

possible to use unleaded gasoline with an octane

rating of at least 87.

Unleaded gasolines only must be used in vehicles

equipped with catalyst emission control systems.

All vehicles, so equipped, have labels located on the

instrument panel and on the back of fuel filler lid that

state, “UNLEADED GASOLINE ONLY”. These vehi-

cles also have fuel filler tubes especially designed to

accept the smaller diameter unleaded gasoline

dispensing nozzles only.

MATERIALS ADDED TO FUEL

Indiscriminate use of fuel system cleaning agents

should be avoided. Many of these materials in-

tended for gum and varnish removal may contain

highly active solvents or similar ingredients that can

be harmful to gasket and diaphragm materials used

in fuel system component parts.

1 TSB Revision

Page 36 of 1146

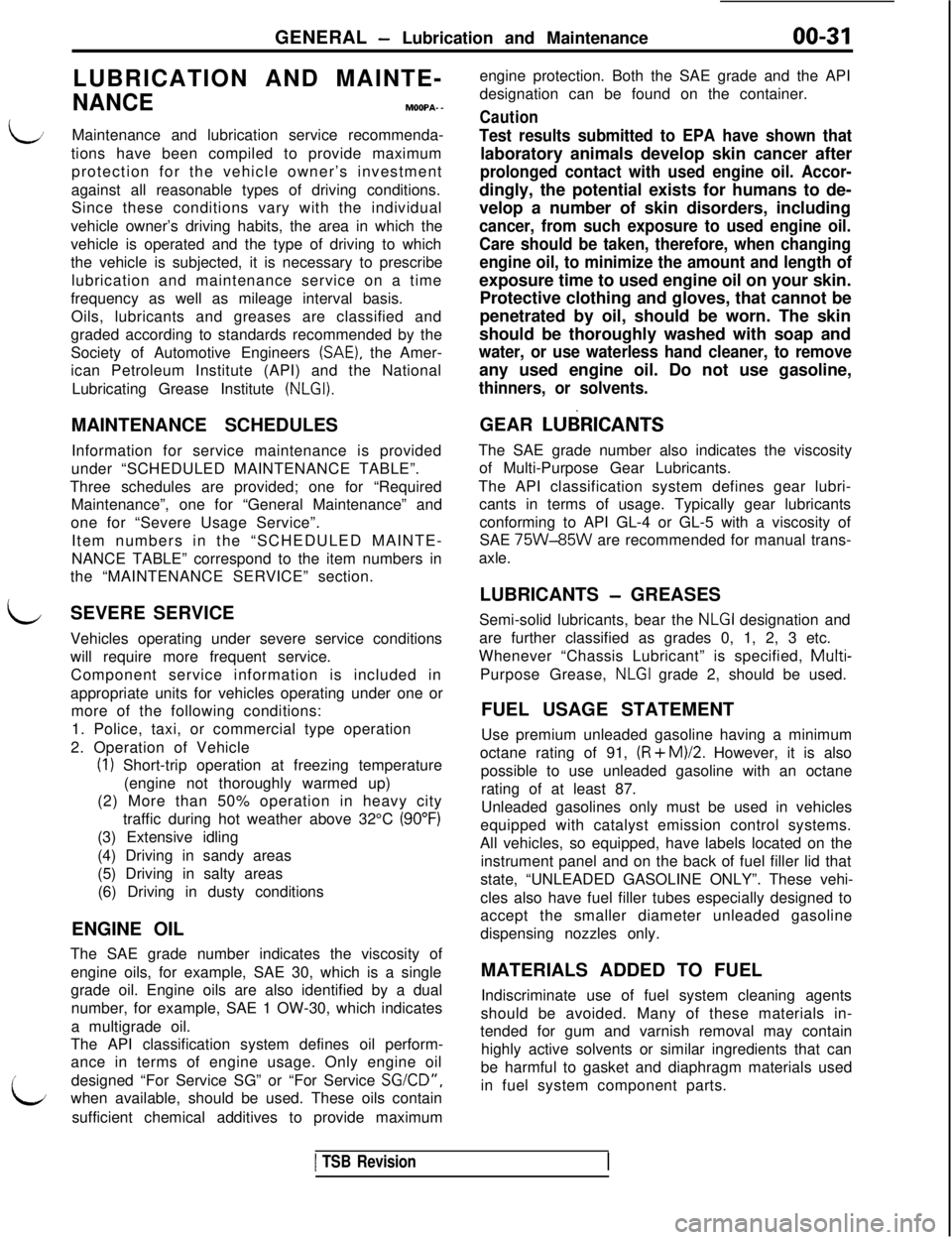

00-32 GENERAL - Recommended Lubricants and Lubricant Capacities Table

RECOMMENDED LUBRICANTS AND LUBRICANT CAPACITIES TABLE

MOORA- -RECOMMENDED LUBRICANTS

\L/

DIA-QUEEN LONG-LIFE COOLANT (Part No. 0103044) orLUBRICANT CAPACITIES TABLE

Description

Engine oil

Crankcase

(excluding oil filter and oil cooler)

Oil filter

Oil cooler (Turbo)

Cooling system (including heater and coolant

reserve system)

Manual transaxle

Transfer

Automatic transaxle

Rear axle

Power steering

<2ws>

<4ws>

Fuel tank

Metric measureU.S. measure

4.0 liters4.2 qts.

0.3 liter1/2qt. s

0.21 liter112 qt.

8.0 liters8.5 qts.

2.3 liters2.4 qts.

2.4 liters

2.5 qts.

0.27 liter.29 qt.

7.5 liters

7.9 qts.

1

.I liters1.16qts.

0.9 liter

.95 qt.

1.5 liters1.59 qts.

75 liters

19.8 gals.

TSB Revision1

d

Page 37 of 1146

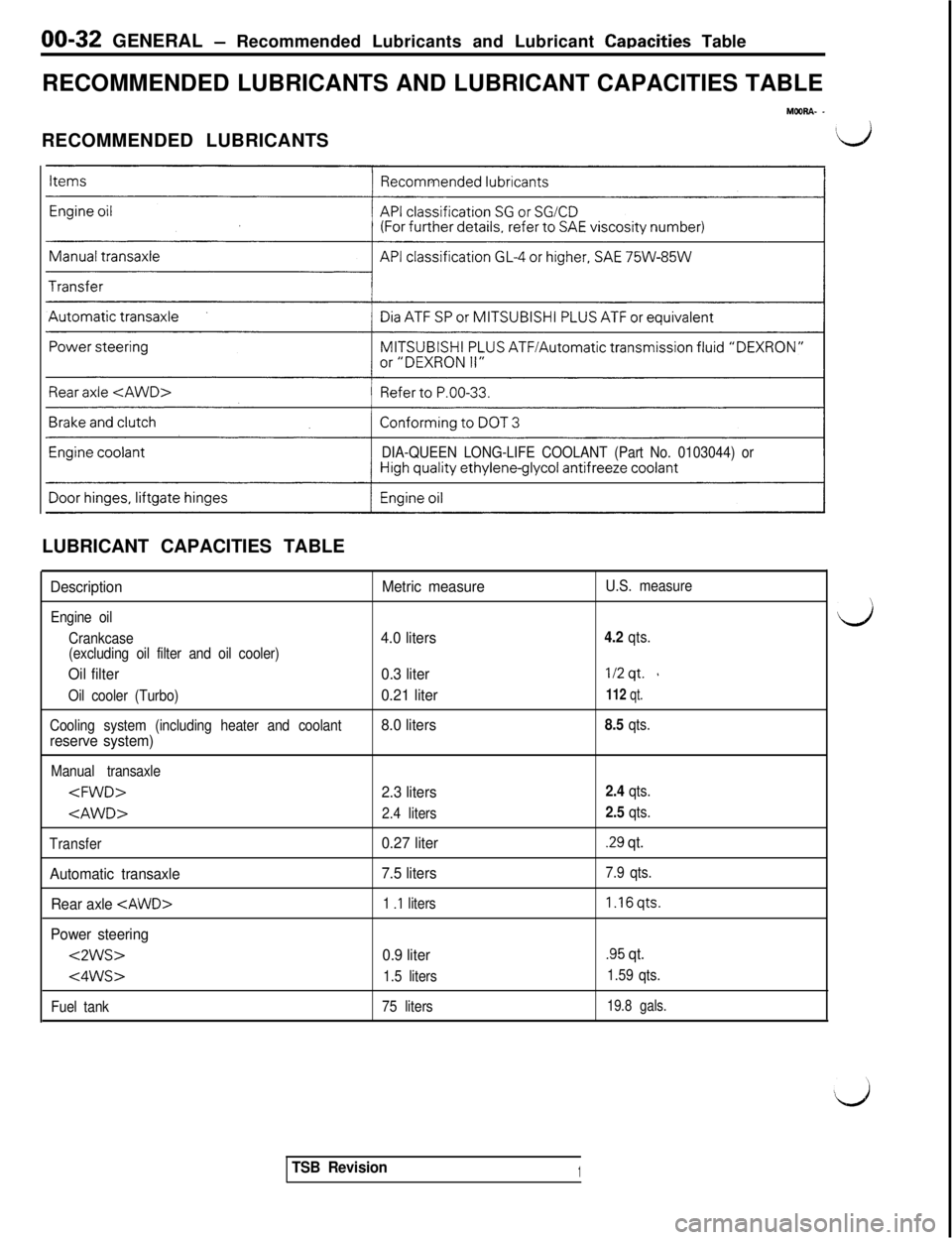

GENERAL - Recommended Lubricants and Lubricant Capacities Table 00-334027

8016

60

1050032

-1014

-155

-20-4-23-10

-29-20104

6SAE 5W-20 Not recommended for sustainedhigh speed vehicle operation.

** SAE 5W-30 may be used for operation in verycold weather areas where the lowest atmos-pheric temperature is below -23°C (-10°F).SELECTION OF LUBRICANTS

ENGINE OILEngine oil should be used which conform to the requirements

of the API classification “For Service SG” or “For Service

SGKD”, and have the proper SAE grade number for the

expected temperature range.

Caution

Nondetergent or straight mineral oil must never be used.

Energy Conserving OilIn order to improve fuel economy and conserve energy new,

lower friction engine oils have been developed. These oils are

readily available and can be identified by such labels as “Energy

Conserving

II”,“Energy Saving”,

“Improved Fuel Economy”,

etc.

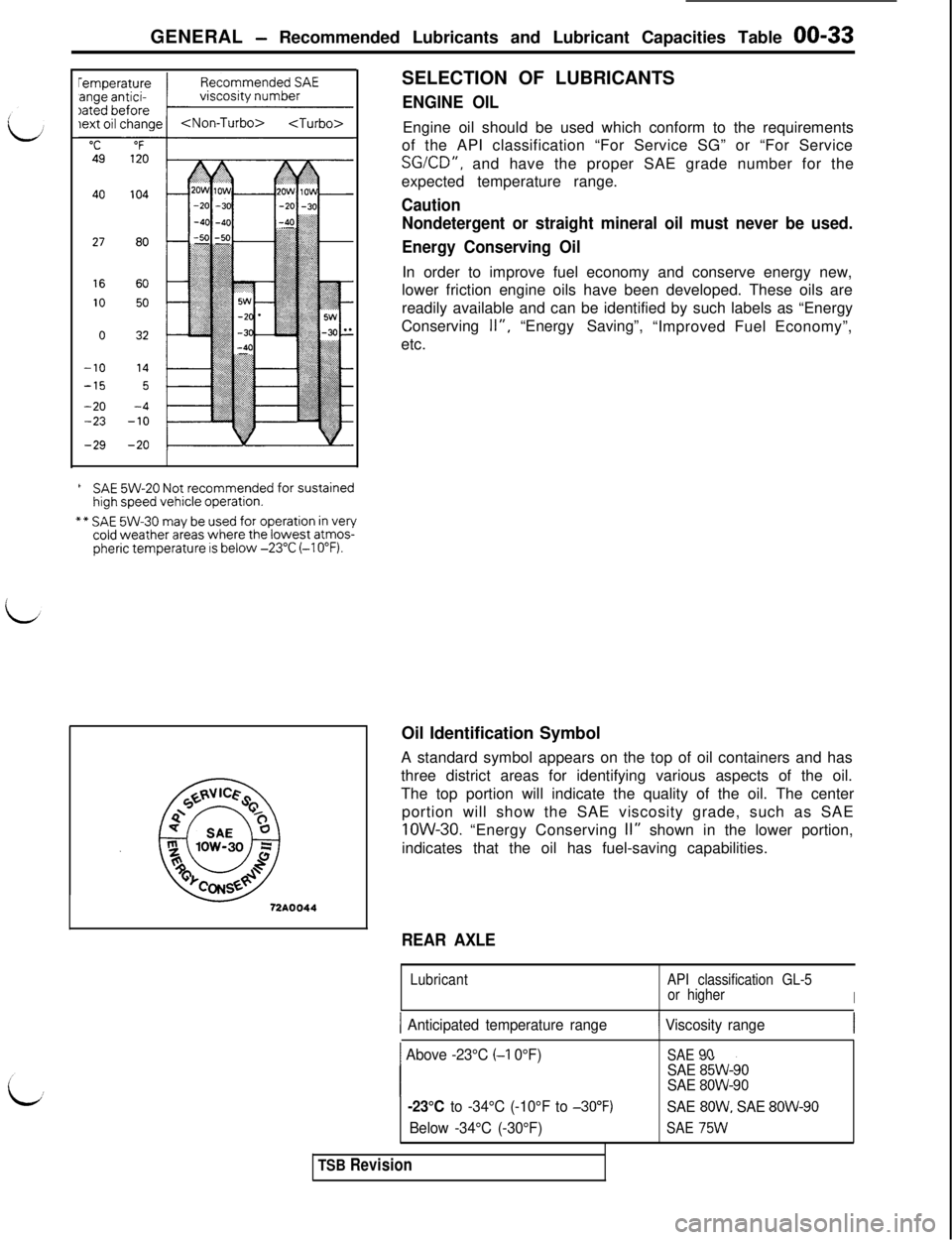

Oil Identification Symbol

A standard symbol appears on the top of oil containers and has

three district areas for identifying various aspects of the oil.

The top portion will indicate the quality of the oil. The center

portion will show the SAE viscosity grade, such as SAEIOW-30. “Energy Conserving

II” shown in the lower portion,

indicates that the oil has fuel-saving capabilities.

72AOO.34

REAR AXLE

LubricantAPI classification GL-5

or higher

I

1 Anticipated temperature range

1 Above -23°C k-1 0°F)

1 Viscosity range

-23°C to -34°C (-10°F to -30°F)

Below -34°C (-30°F)

SAE 90SAE 85W-90SAE 8OW-90

SAE 80W. SAE 8OW-90

SAE 75W

TSB Revision

Page 38 of 1146

00-34 GENERAL - Recommended Lubricants and Lubricant Capacities Table

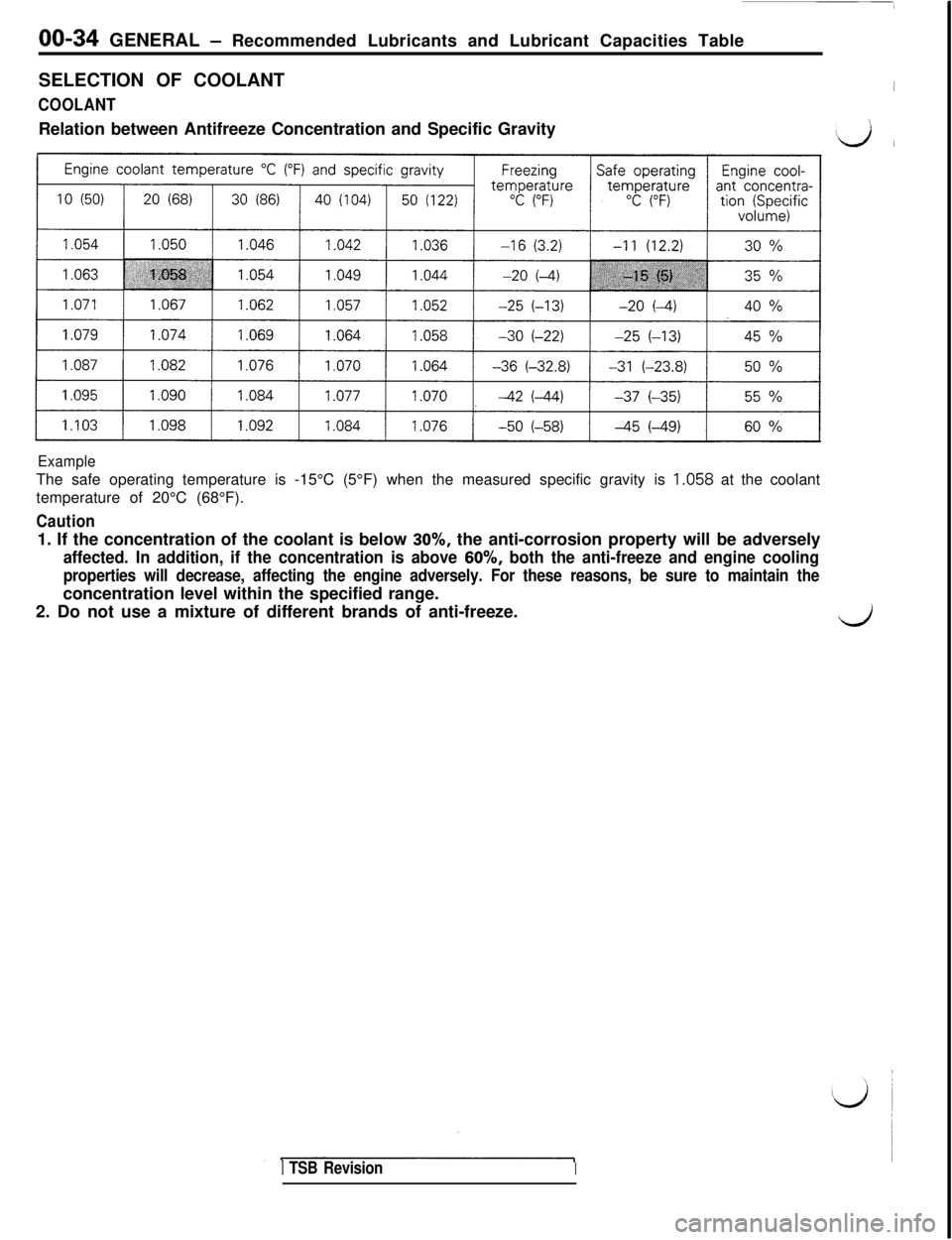

SELECTION OF COOLANT

COOLANTRelation between Antifreeze Concentration and Specific Gravity

I

\

‘d I

ExampleThe safe operating temperature is -15°C (5°F) when the measured specific gravity is 1.058 at the coolant

temperature of 20°C (68°F).

Caution1. If the concentration of the coolant is below 30%, the anti-corrosion property will be adversely

affected. In addition, if the concentration is above 60%, both the anti-freeze and engine cooling

properties will decrease, affecting the engine adversely. For these reasons, be sure to maintain theconcentration level within the specified range.

2. Do not use a mixture of different brands of anti-freeze.

-/‘.

1 TSB RevisionI

Page 39 of 1146

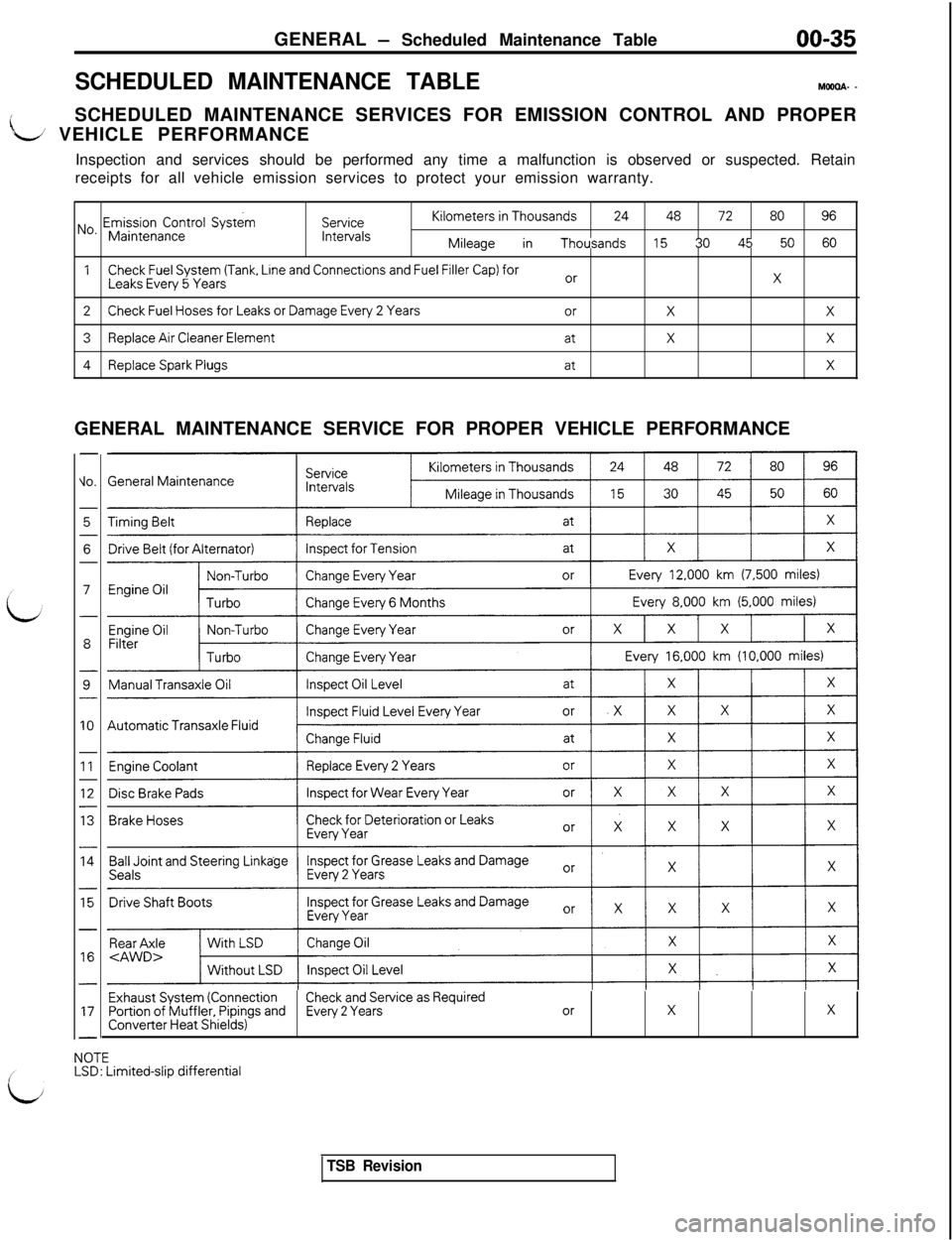

GENERAL - Scheduled Maintenance Table00-35

SCHEDULED MAINTENANCE TABLE

MOOOA- _SCHEDULED MAINTENANCE SERVICES FOR EMISSION CONTROL AND PROPER

L VEHICLE PERFORMANCE

Inspection and services should be performed any time a malfunction is observed or suspected. Retain

receipts for all vehicle emission services to protect your emission warranty.

No, Emission Control SystemServiceKilometersinThousands 24 48 72 80 96

MaintenanceIntervalsMileage in Thousands 15 30 45 50 60

1Check Fuel System (Tank. Line and Connections and Fuel Filler Cap) forLeaks Every 5 Yearsorx

2Check Fuel Hoses for Leaks or Damage Every 2 YearsorXX

3Replace Air Cleaner ElementatXX

4Replace Spark PlugsatXGENERAL MAINTENANCE SERVICE FOR PROPER VEHICLE PERFORMANCE

-

10.

-

5-

6-

7

-

8

-

9-

10

-

11-

12-

13

-

14

-

15

-

16

-

17

-

General Maintenance

Automatic Transaxle Fluid

Exhaust System (ConnectionCheck and Service as RequiredPortion of Muffler, Pipings andEvery 2 YearsorXXConverter Heat Shields)

NOTELSD: Limited-slip differential

TSB Revision

Page 40 of 1146

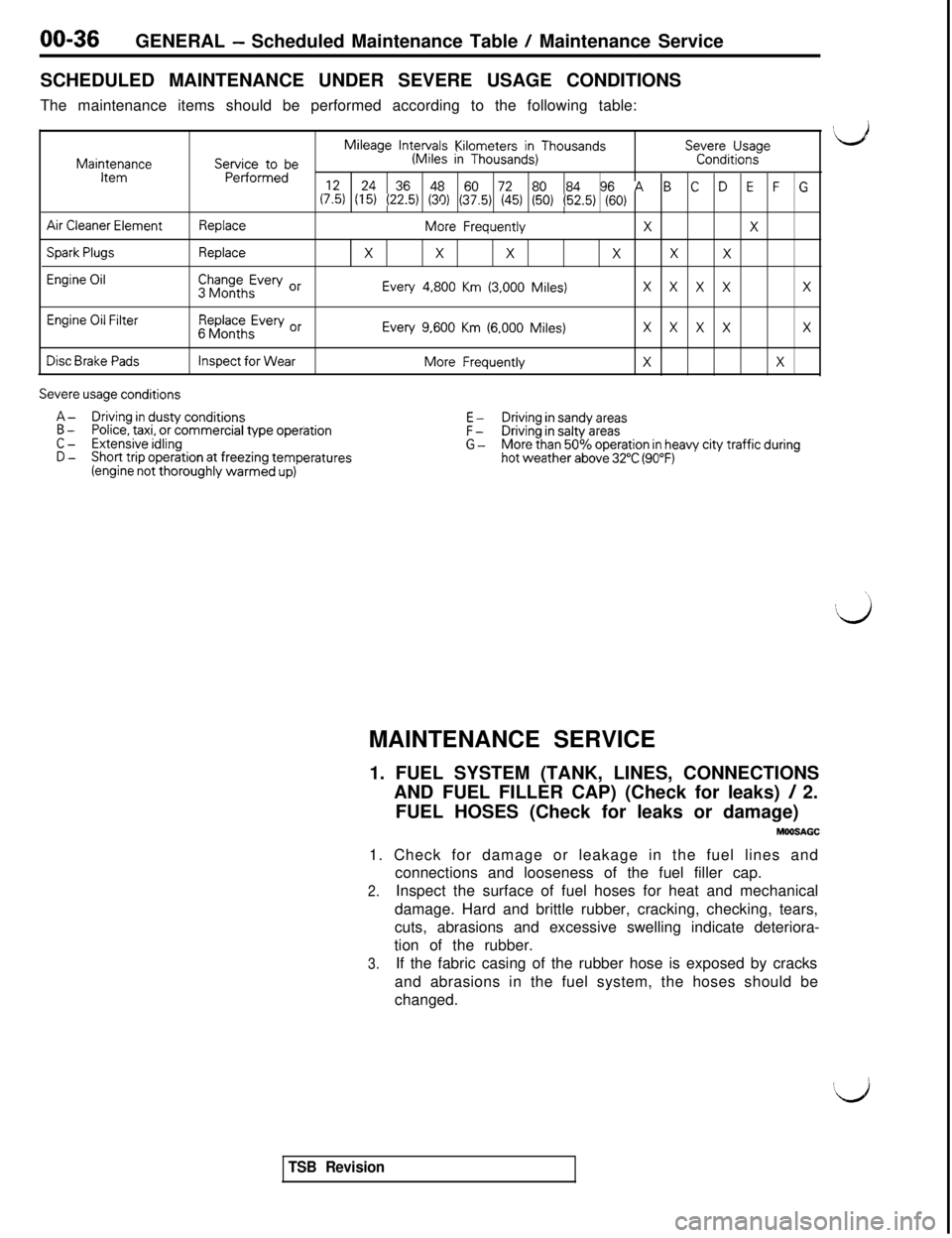

00-36GENERAL - Scheduled Maintenance Table / Maintenance Service

SCHEDULED MAINTENANCE UNDER SEVERE USAGE CONDITIONS

The maintenance items should be performed according to the following table:

Mileage Intervals Kilometers in ThousandsSevere Usage

MaintenanceService to be(Miles in Thousands)Conditions

itemPerformed

(6 (15) (22.5) (30) (37.5) (45) (50) (52.5) (60)24 36 48 60 72 80 84 96 A B C D E F G

Air Cleaner ElementReplaceMore FrequentlyXX

Spark PlugsReplaceXXXXXX

Engine OilChange Every Or3 MonthsEvery 4,800 Km (3,000 Miles)x x x xX

Engine Oil FilterReplace Every or6 MonthsEvery 9,600 Km (6.000 Miles)x x x xX

Disc Brake PadsInspect for WearMore FrequentlyXX

Severe usage conditions

A-Driving in dusty conditionsE -B -Police, taxi, or commercial type operationF -Driving in sandy areas

C -Extensive idlingG -Driving in salty areas

D -Short trip operation at freezing temperaturesMore than 50% operation in heavy city traffic during

(engine not thoroughly warmed up)hot weather above 32°C (90°F)MAINTENANCE SERVICE

1. FUEL SYSTEM (TANK, LINES, CONNECTIONS

AND FUEL FILLER CAP) (Check for leaks)

/ 2.

FUEL HOSES (Check for leaks or damage)MWShGC

1. Check for damage or leakage in the fuel lines and

connections and looseness of the fuel filler cap.

2.Inspect the surface of fuel hoses for heat and mechanical

damage. Hard and brittle rubber, cracking, checking, tears,

cuts, abrasions and excessive swelling indicate deteriora-

tion of the rubber.

3.If the fabric casing of the rubber hose is exposed by cracks

and abrasions in the fuel system, the hoses should be

changed.

TSB Revision