MITSUBISHI 3000GT 1991 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 691 of 1146

REAR SUSPENSION

0 camber

“\

er

ewer arm (L.H.)A-L!?., ’ cLr”“l‘412F002E

SERVICE ADJUSTMENT PROCEDURES

REAR WHEEL ALIGNMENT INSPECTIONM34FAAH

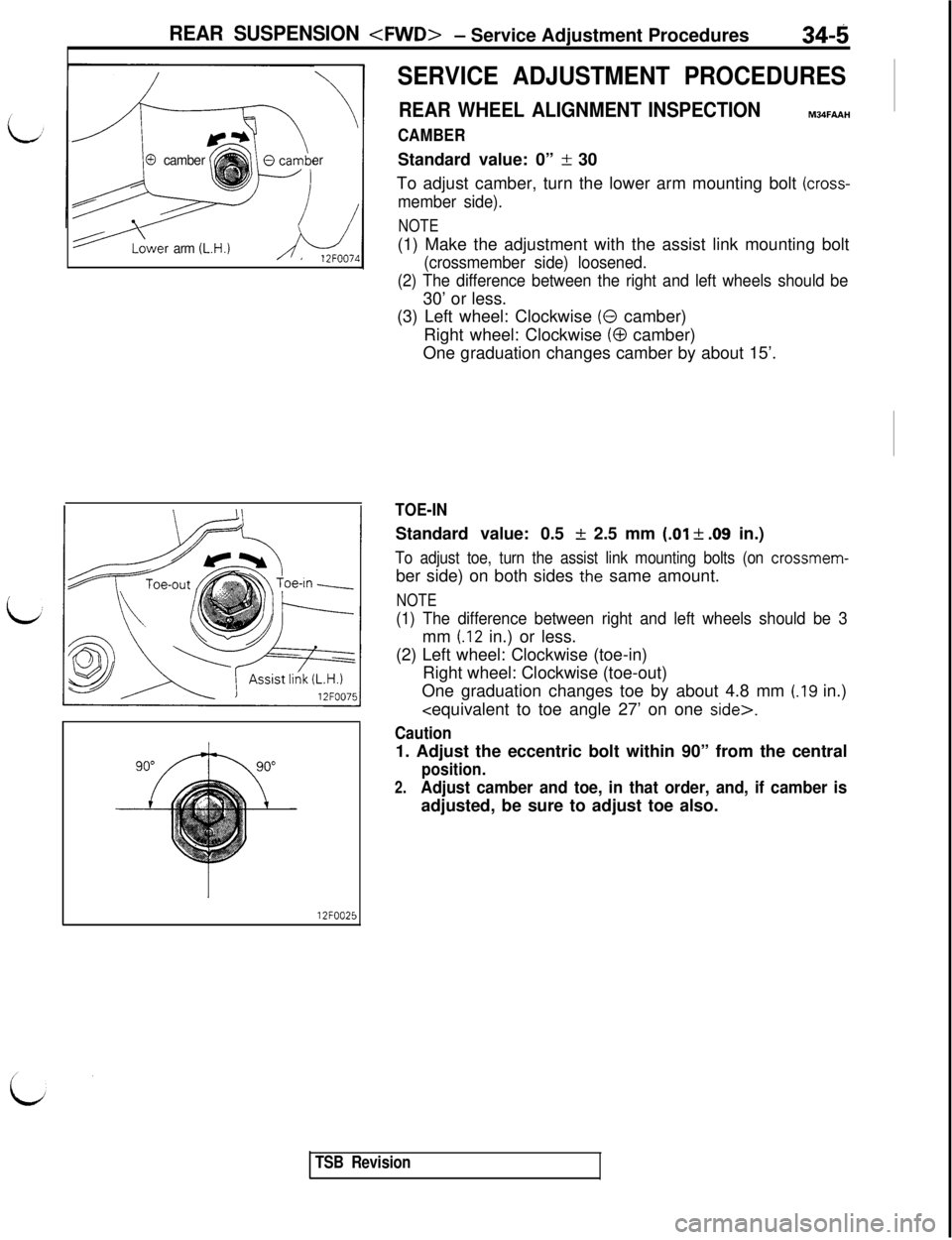

CAMBERStandard value: 0” + 30

To adjust camber, turn the lower arm mounting bolt

(cross-

member side).

NOTE(1) Make the adjustment with the assist link mounting bolt

(crossmember side) loosened.

(2) The difference between the right and left wheels should be30’ or less.

(3) Left wheel: Clockwise

(0 camber)

Right wheel: Clockwise

(0 camber)

One graduation changes camber by about 15’.

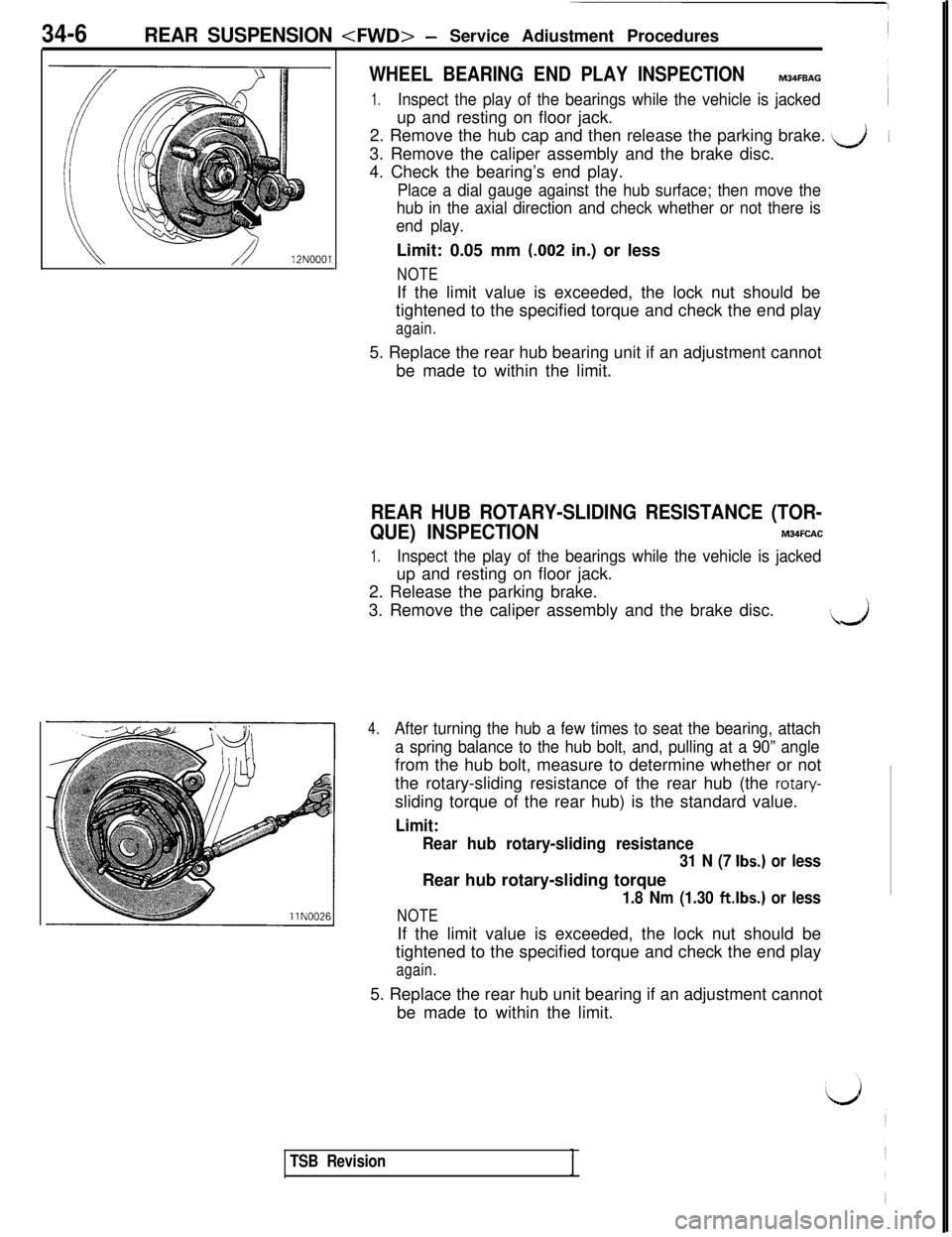

TOE-INStandard value: 0.5

-+ 2.5 mm (.Ol + .09 in.)

To adjust toe, turn the assist link mounting bolts (on crossmem-ber side) on both sides

t,he same amount.

NOTE

(1) The difference between right and left wheels should be 3mm (.I2 in.) or less.

(2) Left wheel: Clockwise (toe-in)

Right wheel: Clockwise (toe-out)

One graduation changes toe by about 4.8 mm

(.19 in.)

Caution1. Adjust the eccentric bolt within 90” from the central

position.

2.Adjust camber and toe, in that order, and, if camber isadjusted, be sure to adjust toe also.

TSB Revision

Page 692 of 1146

34-6REAR SUSPENSION

WHEEL BEARING END PLAY INSPECTIONM34FBAG

1.Inspect the play of the bearings while the vehicle is jackedup and resting on floor jack.

2. Remove the hub cap and then release the parking brake.

s&i3. Remove the caliper assembly and the brake disc.

4. Check the bearing’s end play.

Place a dial gauge against the hub surface; then move the

hub in the axial direction and check whether or not there is

end play.Limit: 0.05 mm

(.002 in.) or less

NOTEIf the limit value is exceeded, the lock nut should be

tightened to the specified torque and check the end play

again.5. Replace the rear hub bearing unit if an adjustment cannot

be made to within the limit.

REAR HUB ROTARY-SLIDING RESISTANCE (TOR-

QUE) INSPECTION

M34FCAC

1.Inspect the play of the bearings while the vehicle is jackedup and resting on floor jack.

2. Release the parking brake.

3. Remove the caliper assembly and the brake disc.

..J

4.After turning the hub a few times to seat the bearing, attach

a spring balance to the hub bolt, and, pulling at a 90” anglefrom the hub bolt, measure to determine whether or not

the rotary-sliding resistance of the rear hub (the

rotary-sliding torque of the rear hub) is the standard value.

Limit:

Rear hub rotary-sliding resistance

31 N (7 Ibs.) or lessRear hub rotary-sliding torque

1.8 Nm (1.30 ftlbs.) or less

NOTEIf the limit value is exceeded, the lock nut should be

tightened to the specified torque and check the end play

again.5. Replace the rear hub unit bearing if an adjustment cannot

be made to within the limit.

TSB Revision

Page 693 of 1146

REAR SUSPENSION

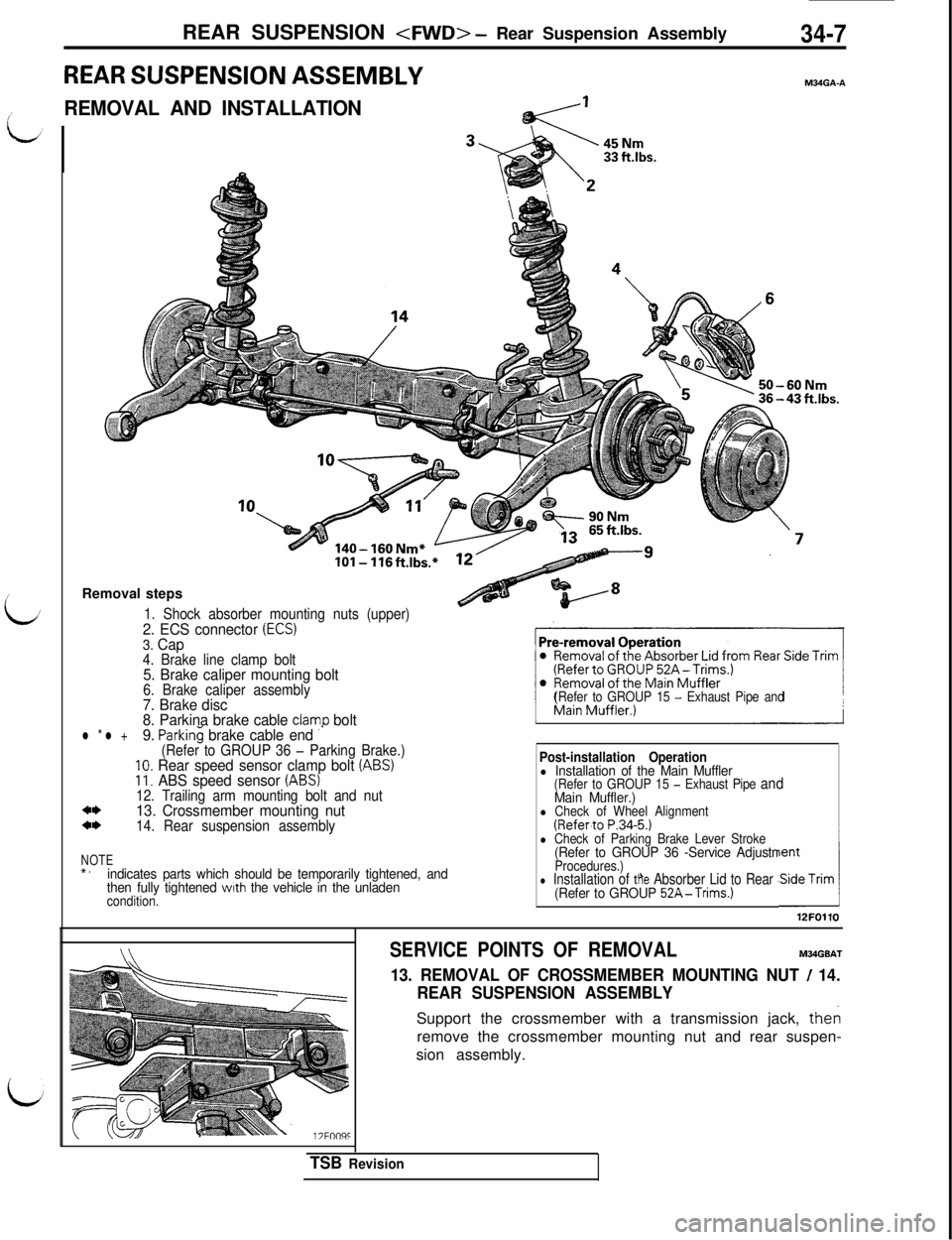

REAR SUSPENSION ASSEMBLYM34GA-A

L/

REMOVAL AND INSTALLATION

140- 160 Nm*IOI- 116ftlbs.

Removal steps

1. Shock absorber mounting nuts (upper)2. ECS connector (ECS)3. Cap4. Brake line clamp bolt5. Brake caliper mounting bolt6. Brake caliper assembly7. Brake disc

8. Parkina brake cable clamo bolt

(Refer to GROUP 15 - Exhaust Pipe and

l * l +9. ParkinG brake cable end ”(Refer to GROUP 36 - Parking Brake.)10. Rear speed sensor clamp bolt (ABS)11. ABS speed sensor (ABS)12. Trailing arm mounting bolt and nut*I)13. Crossmember mounting nut*I)14. Rear suspension assembly

NOTE*.indicates parts which should be temporarily tightened, and

then fully tightened with the vehicle in the unladencondition.

Post-installation Operationl Installation of the Main Muffler(Refer to GROUP 15 - Exhaust Pipe andMain Muffler.)l Check of Wheel Alignment(Refer.to P.34-5.)l Check of Parking Brake Lever Stroke(Refer to GROUP 36 -Service AdjustmentProcedures.)l Installation of the Absorber Lid to Rear Side Trim(Refer to GROUP 52A-Trims.)A12FOllO

SERVICE POINTS OF REMOVALM34GBAT

13. REMOVAL OF CROSSMEMBER MOUNTING NUT / 14.

REAR SUSPENSION ASSEMBLYSupport the crossmember with a transmission jack, then

remove the crossmember mounting nut and rear suspen-

sion assembly.

TSB Revision

Page 694 of 1146

34-8REAR SUSPENSION

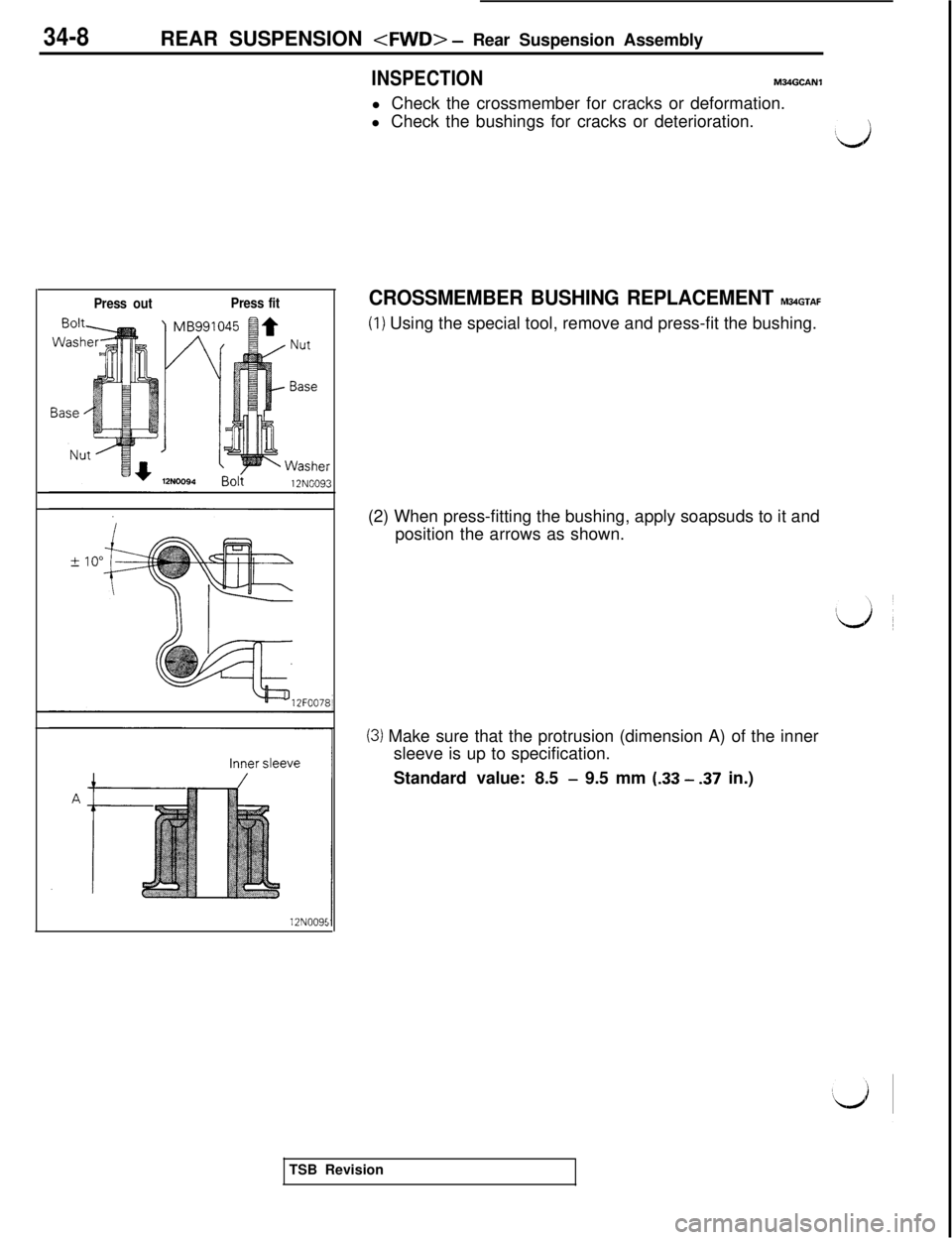

INSPECTIONM34GcANll Check the crossmember for cracks or deformation.

l Check the bushings for cracks or deterioration.

;d

Press outPress fit12N009fCROSSMEMBER BUSHING REPLACEMENT M34GTAF

(1) Using the special tool, remove and press-fit the bushing.

(2) When press-fitting the bushing, apply soapsuds to it and

position the arrows as shown.

(3) Make sure that the protrusion (dimension A) of the inner

sleeve is up to specification.

Standard value: 8.5

- 9.5 mm (.33 - .37 in.)

TSB Revision

Page 695 of 1146

REAR SUSPENSION

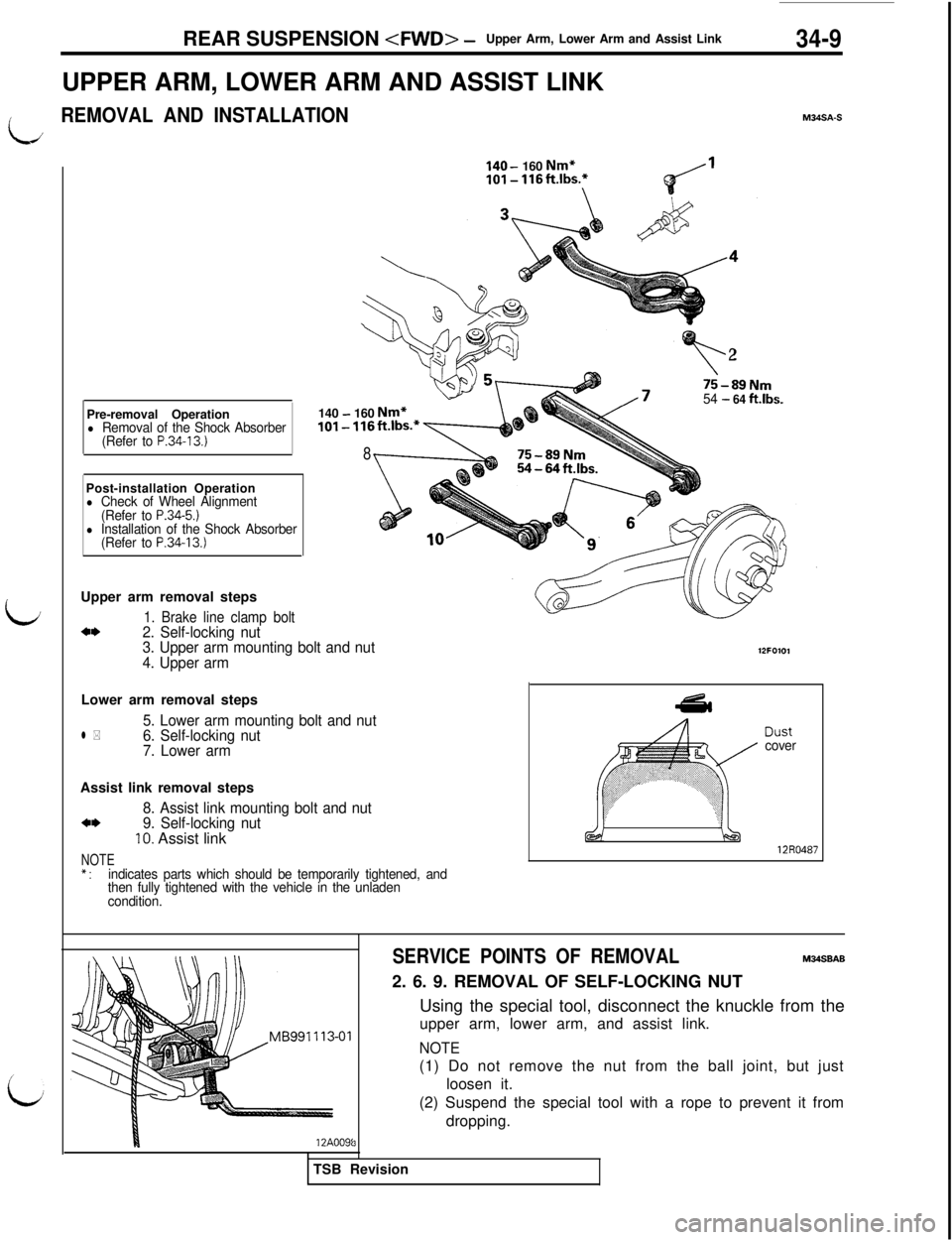

iREMOVAL AND INSTALLATION

LPre-removal Operation

l Removal of the Shock Absorber

(Refer to P.34-13.)Post-installation Operation

l Check of Wheel Alignment

(Refer to P.34-5.)l Installation of the Shock Absorber

(Refer to P.34-13.)Upper arm removal steps

1. Brake line clamp bolta*2. Self-locking nut

140- 160 Nm*IOl-116ft.lbs.”\

\

2

/7

75-89Nm54 - 64 ft.lbs.

140 - 160 Nm*101 - 116ft.lbs.*

8

3. Upper arm mounting bolt and nut

4. Upper armLower arm removal steps

5. Lower arm mounting bolt and nutl *6. Self-locking nut

7. Lower armAssist link removal steps

8. Assist link mounting bolt and nut4*9. Self-locking nut10. Assist link

NOTE*:indicates parts which should be temporarily tightened, and

then fully tightened with the vehicle in the unladen

condition.

M34SA-S

Dustcover

rz412R0487

12A009$3TSB Revision

SERVICE POINTS OF REMOVALMSBAB2. 6. 9. REMOVAL OF SELF-LOCKING NUT

Using the special tool, disconnect the knuckle from the

upper arm, lower arm, and assist link.

NOTE(1) Do not remove the nut from the ball joint, but just

loosen it.

(2) Suspend the special tool with a rope to prevent it from

dropping.

Page 696 of 1146

REAR SUSPENSION

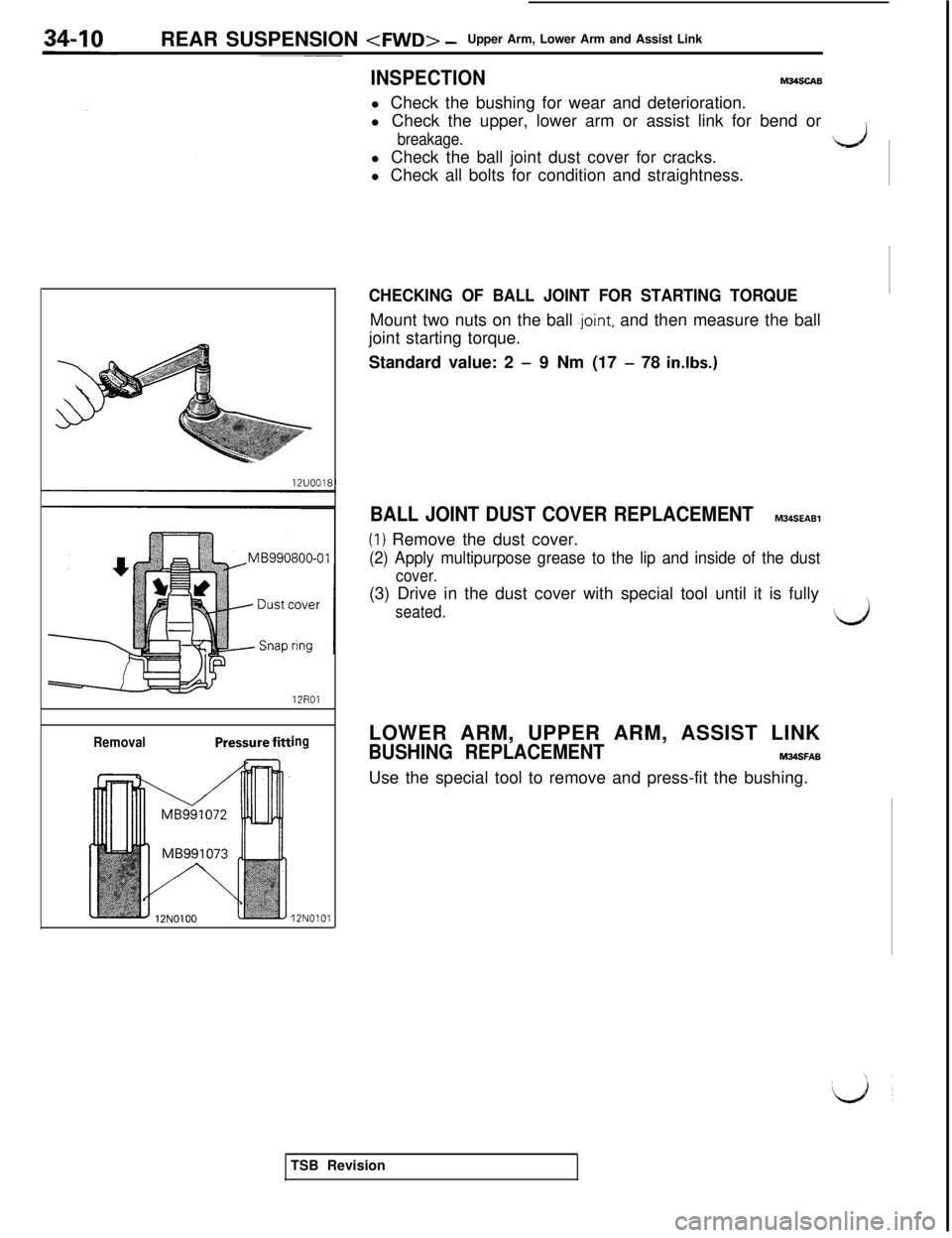

INSPECTIONM34SCABl Check the bushing for wear and deterioration.

l Check the upper, lower arm or assist link for bend or

breakage.l Check the ball joint dust cover for cracks.

l Check all bolts for condition and straightness.d12ROl

Removaling12NOlOl

CHECKING OF BALL JOINT FOR STARTING TORQUEMount two nuts on the ball

.joint, and then measure the ball

joint starting torque.

Standard value: 2

- 9 Nm (17 - 78 in.lbs.)

BALL JOINT DUST COVER REPLACEMENTM34SEABl

(1) Remove the dust cover.

(2) Apply multipurpose grease to the lip and inside of the dust

cover.(3) Drive in the dust cover with special tool until it is fully

seated.‘dLOWER ARM, UPPER ARM, ASSIST LINK

BUSHING REPLACEMENTM34SFABUse the special tool to remove and press-fit the bushing.

TSB Revision

Page 697 of 1146

REAR SUSPENSION

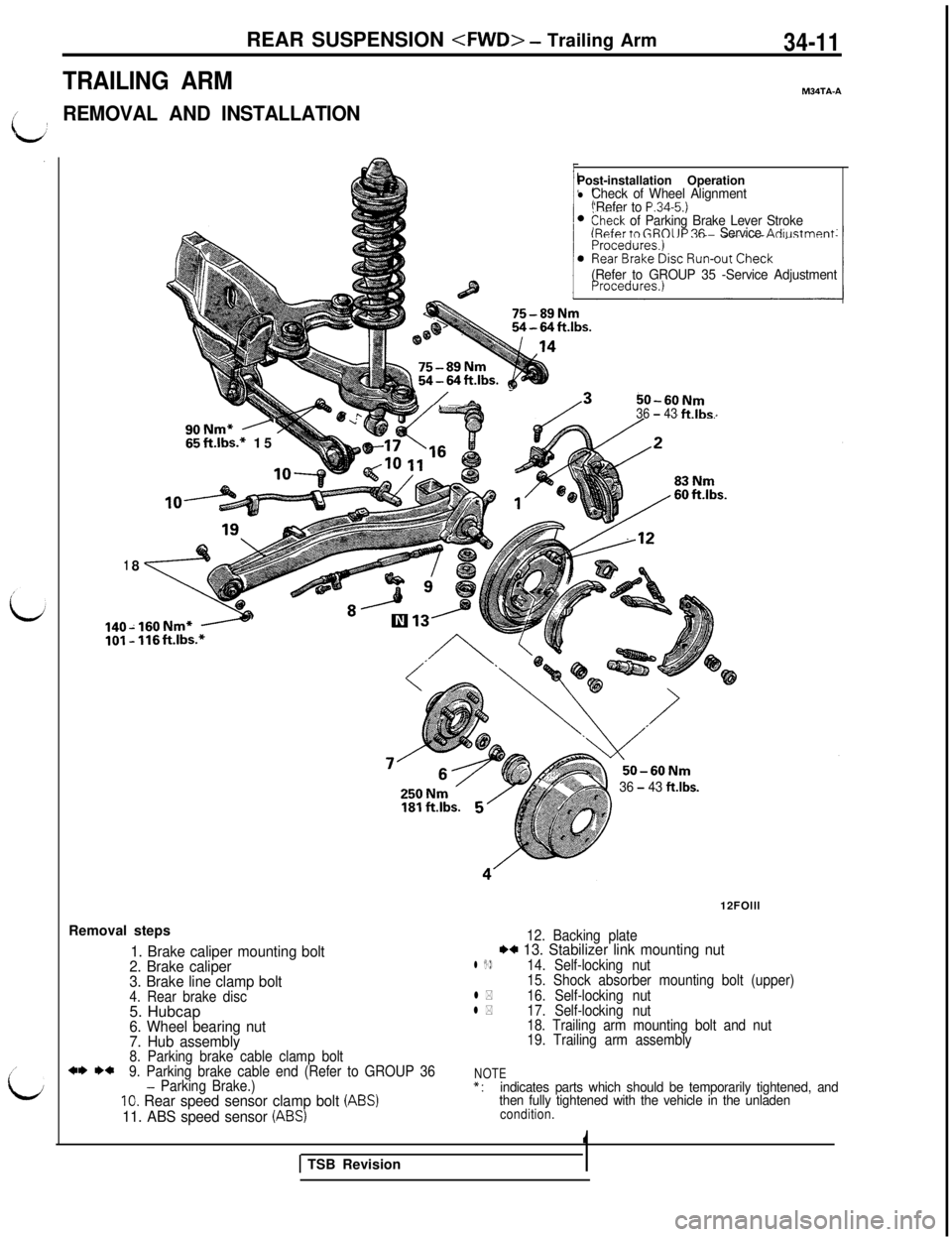

TRAILING ARMM34TA-A

t’REMOVAL AND INSTALLATION

,’

i;

18

90Nm* A65ft.lbs.* 15Post-installation Operation

lCheck of Wheel Alignment

‘Refer to P.34-5.)>heck of Parking Brake Lever Stroke(Refer tn GROIJP 36 - Service Adiustment

r/A -50-60Nm36 - 43ftlbs.

(Refer to GROUP 35 -Service Adjustment

-160Nm* -- 116ft.lbs.*Removal steps

1. Brake caliper mounting bolt

2. Brake caliper

3. Brake line clamp bolt

4. Rear brake disc5. Hubcap

6. Wheel bearing nut

7. Hub assembly

8. Parking brake cable clamp bolt*I) I)*9. Parking brake cable end (Refer to GROUP 36- Parking Brake.)IO. Rear speed sensor clamp bolt (ABS)

11. ABS speed sensor (ABS)

36 - 43 ftlbs.12FOlll

12. Backing plateI)+ 13. Stabilizer link mounting nutl I)14. Self-locking nut

15. Shock absorber mounting bolt (upper)

l *16. Self-locking nutl *17. Self-locking nut

18. Trailing arm mounting bolt and nut

19. Trailing arm assembly

NOTE*:indicates parts which should be temporarily tightened, and

then fully tightened with the vehicle in the unladen

condition.

1 TSB Revision1

Page 698 of 1146

34-12REAR SUSPENSION

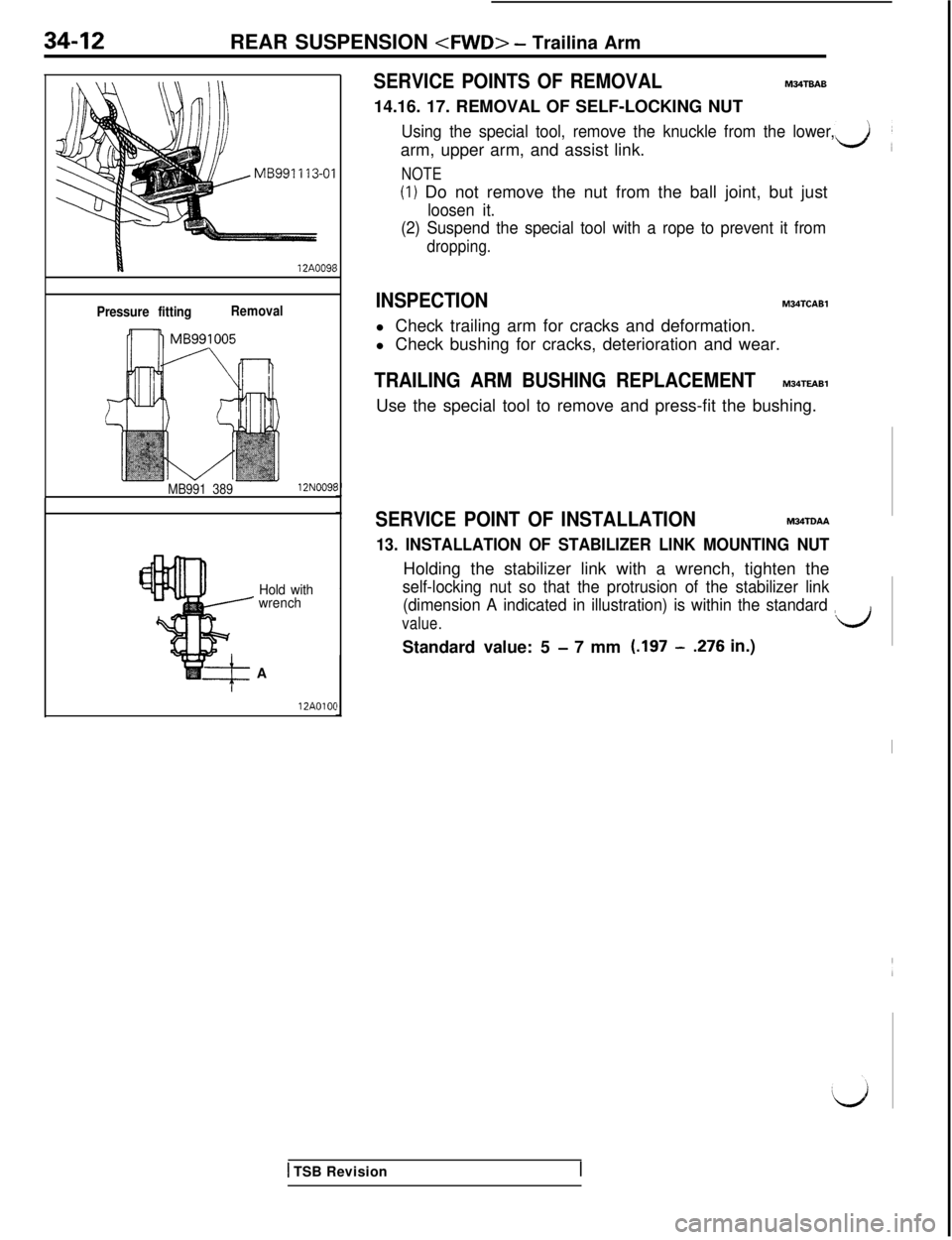

I12A009E

Pressure fittingRemoval

MB991 38912N009t

_ Hold with

wrenchA12AOlOC

SERVICE POINTS OF REMOVALM34TBAB14.16. 17. REMOVAL OF SELF-LOCKING NUT

Using the special tool, remove the knuckle from the lower,arm, upper arm, and assist link.

NOTE

(1) Do not remove the nut from the ball joint, but just

loosen it.

(2) Suspend the special tool with a rope to prevent it from

dropping.

INSPECTIONM34TCABl

l Check trailing arm for cracks and deformation.

l Check bushing for cracks, deterioration and wear.

TRAILING ARM BUSHING REPLACEMENTM34TEABl

Use the special tool to remove and press-fit the bushing.

SERVICE POINT OF INSTALLATIONM34lDAA

13. INSTALLATION OF STABILIZER LINK MOUNTING NUTHolding the stabilizer link with a wrench, tighten the

self-locking nut so that the protrusion of the stabilizer link

(dimension A indicated in illustration) is within the standard

,,

value.dStandard value: 5

- 7 mm

1 TSB Revision

(.197 -.276 in.)I

Page 699 of 1146

REAR SUSPENSION

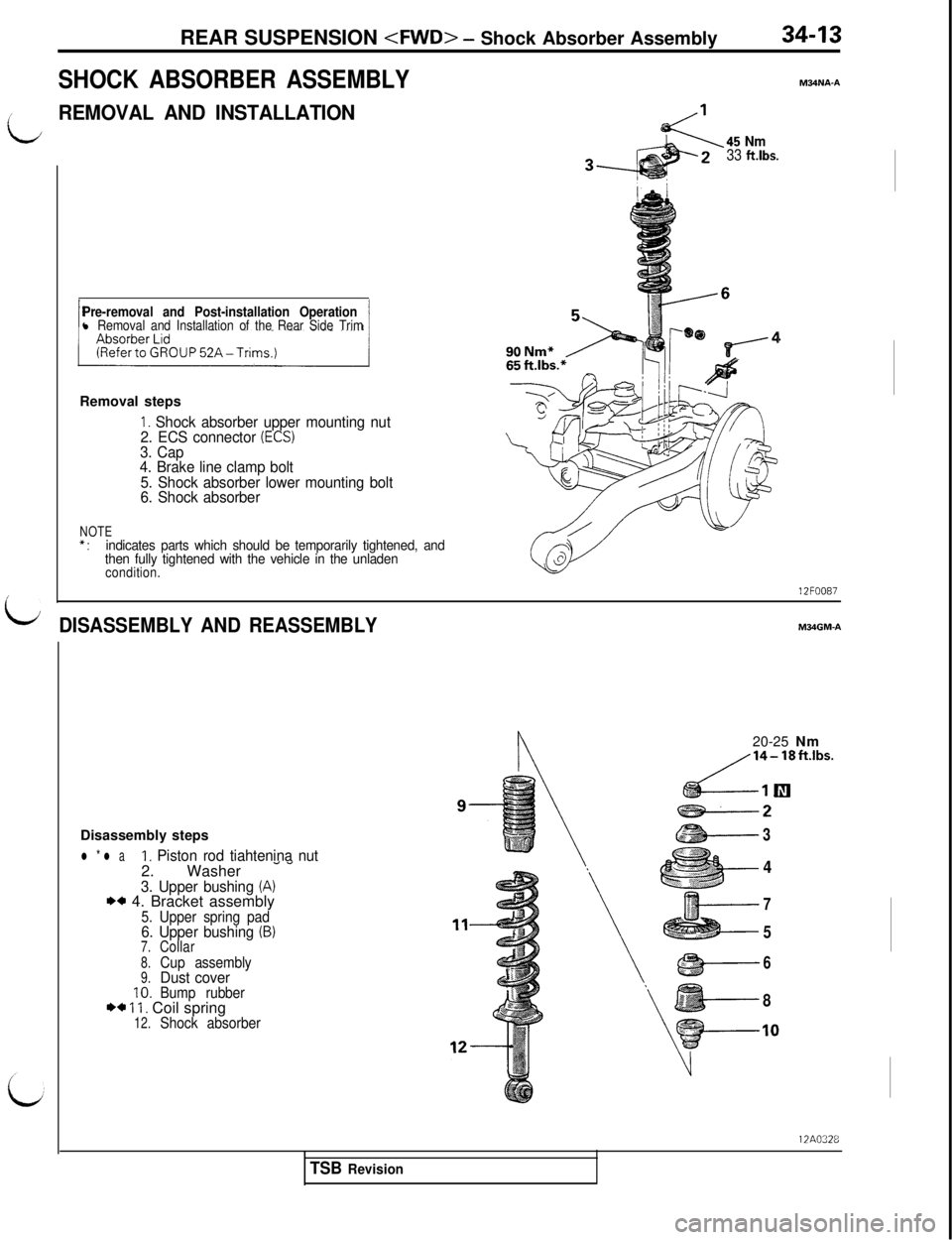

SHOCK ABSORBER ASSEMBLYM34NA-A

iREMOVAL AND INSTALLATION

L

i

Pre-removal and Post-installation Operationl Removal and Installation of the Rear Side TrimRemoval steps

1. Shock absorber upper mounting nut

2. ECS connector (ECS)3. Cap

4. Brake line clamp bolt

5. Shock absorber lower mounting bolt

6. Shock absorber

NOTE*:indicates parts which should be temporarily tightened, and

then fully tightened with the vehicle in the unladen

condition.

45 Nm33 ft.lbs.12FOO87

DISASSEMBLY AND REASSEMBLYM34GMA

20-25 Nm

Disassembly steps

l * l a1, Piston rod tiahtenina nut2. Washer d u3. Upper bushing (A)** 4. Bracket assembly5. Upper spring pad6. Upper bushing (B)7.Collar

8.Cup assembly9.Dust cover10.Bump rubber+* 11. Coil spring12.Shock absorber

3

4

7

5

6

8

10

1280325:

TSB Revision

Page 700 of 1146

34-14REAR SUSPENSION

12K(u9

‘7

Coil

,’I

seat12A0049

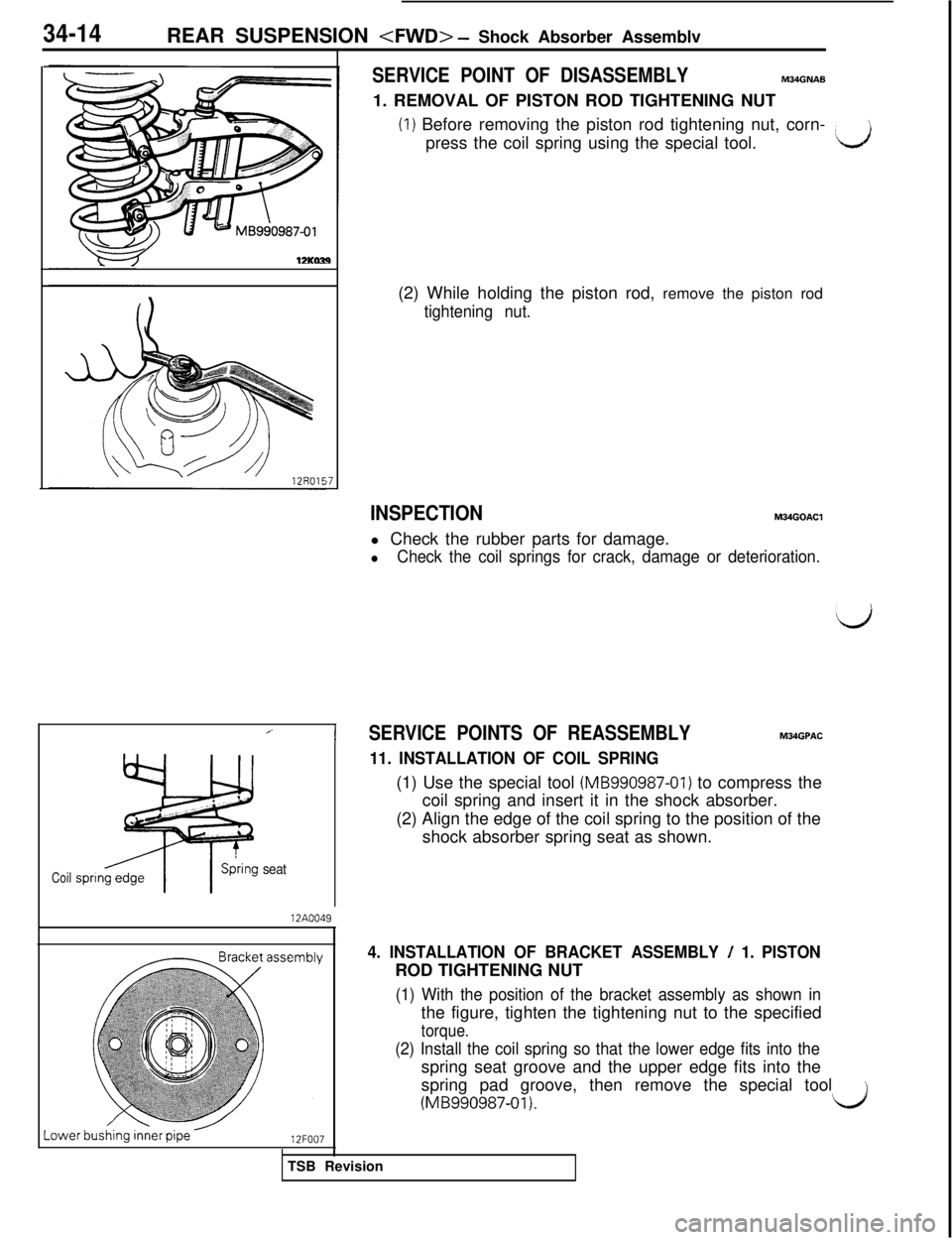

SERVICE POINT OF DISASSEMBLYM34GNAB1. REMOVAL OF PISTON ROD TIGHTENING NUT

(1) Before removing the piston rod tightening nut, corn-

press the coil spring using the special tool.

d(2) While holding the piston rod, remove the piston rod

tightening nut.

INSPECTIONM34GOACl

l Check the rubber parts for damage.

lCheck the coil springs for crack, damage or deterioration.

SERVICE POINTS OF REASSEMBLYM34GPAC

11. INSTALLATION OF COIL SPRING(1) Use the special tool

(MB990987-01) to compress the

coil spring and insert it in the shock absorber.

(2) Align the edge of the coil spring to the position of the

shock absorber spring seat as shown.

4. INSTALLATION OF BRACKET ASSEMBLY / 1. PISTONROD TIGHTENING NUT

(1) With the position of the bracket assembly as shown inthe figure, tighten the tightening nut to the specified

torque.

(2) Install the coil spring so that the lower edge fits into thespring seat groove and the upper edge fits into the

spring pad groove, then remove the special tool

’

(MB990987-01).L/iTSB Revision