MITSUBISHI 3000GT 1991 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 671 of 1146

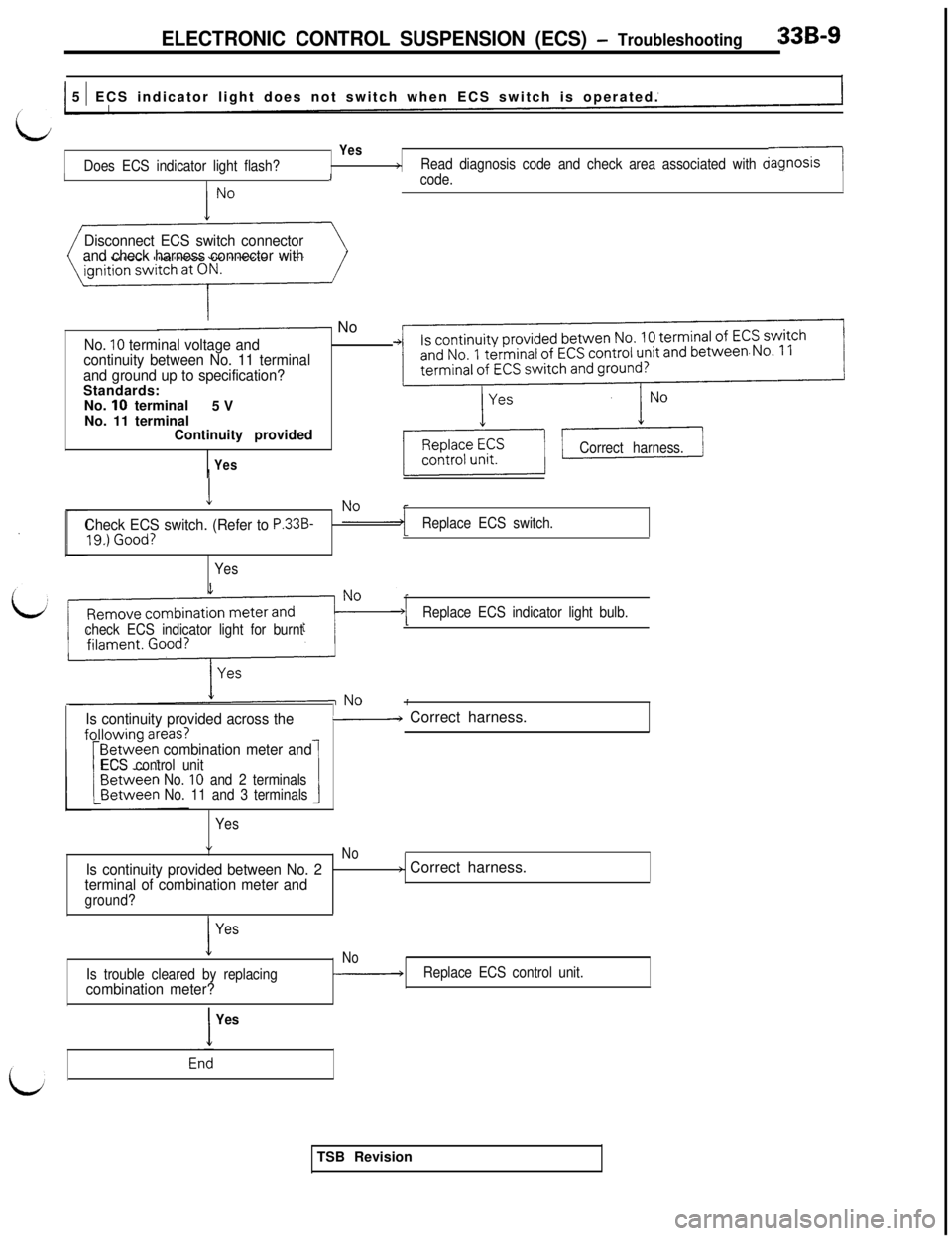

ELECTRONIC CONTROL SUSPENSION (ECS) - Troubleshooting:33B-9

1 5 1 ECS indicator light does not switch when ECS switch is operated.

Yes

Does ECS indicator light flash?+Read diagnosis code and check area associated with dralgnosrs.---IIIcode.

Disconnect ECS switch connector

and check harness connector with

- No

No. 10 terminal voltage and

continuity between No. 11 terminal

and ground up to specification?Standards:

No.

10 terminal

5 V

No. 11 terminal

Continuity provided

YesCorrect harness.

Check ECS switch. (Refer to P.33B-

YesReplace ECS switch.

check ECS indicator light for burntReplace ECS indicator light bulb.

Is continuity provided across the- Correct harness.

combination meter andECS control unit

No. 10 and 2 terminals

No. 11 and 3 terminals

Yes

”No

Is continuity provided between No. 2> Correct harness.

terminal of combination meter andground?

I

Yes

No

Is trouble cleared by replacingcombination meter?

-Replace ECS control unit.

IYesTSB Revision

Page 672 of 1146

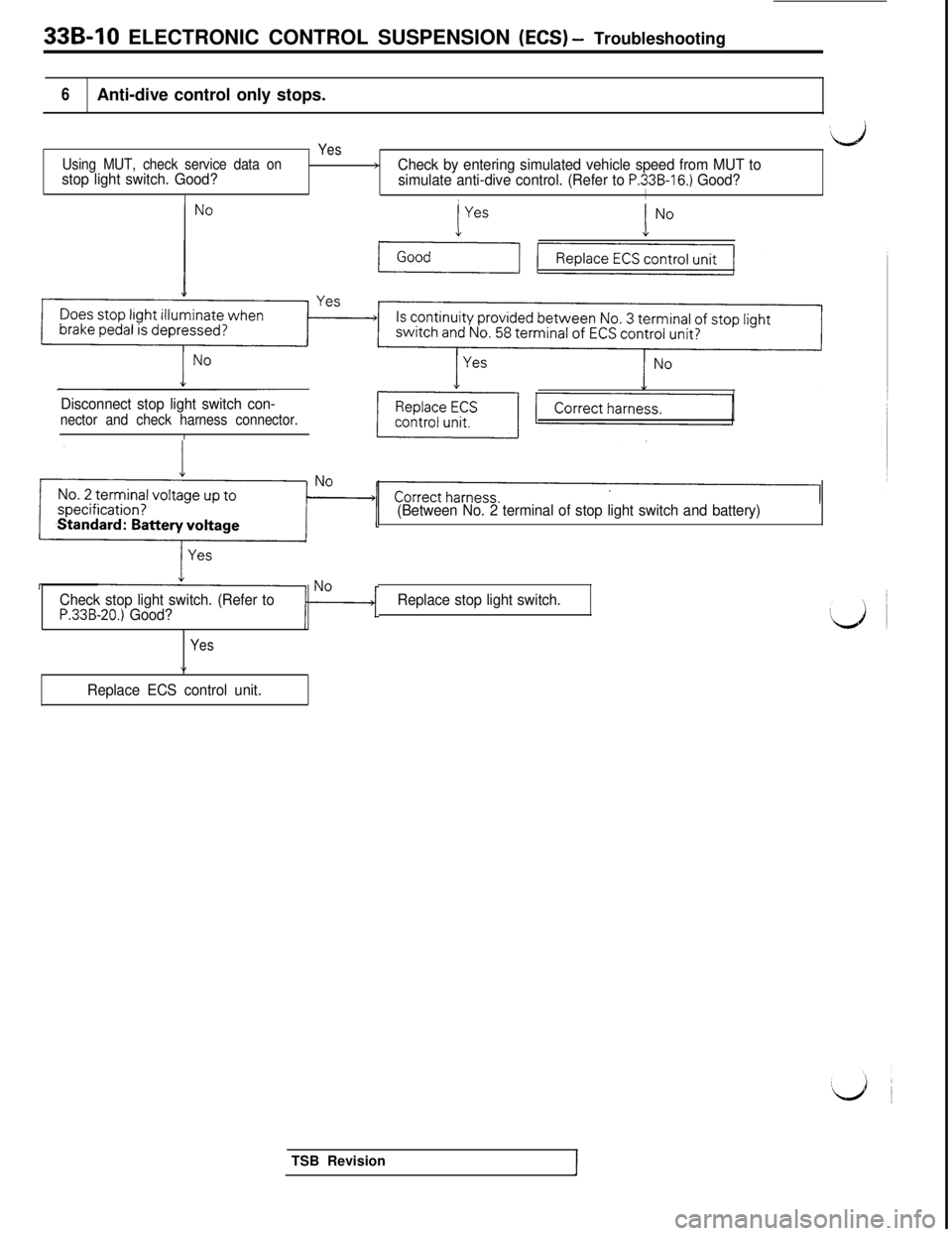

33B-10 ELECTRONIC CONTROL SUSPENSION (ECS) - Troubleshooting

6Anti-dive control only stops.

Yes

Using MUT, check service data on

stop light switch. Good?>Check by entering simulated vehicle speed from MUT to

simulate anti-dive control. (Refer to P.33B-16.) Good?

,I

ch

Disconnect stop light switch con-

nector and check harness connector.f

(Between No. 2 terminal of stop light switch and battery)

Check stop light switch. (Refer to

P.33B-20.) Good?

Yes

”

Replace ECS control unit.Replace stop light switch.TSB Revision

Page 673 of 1146

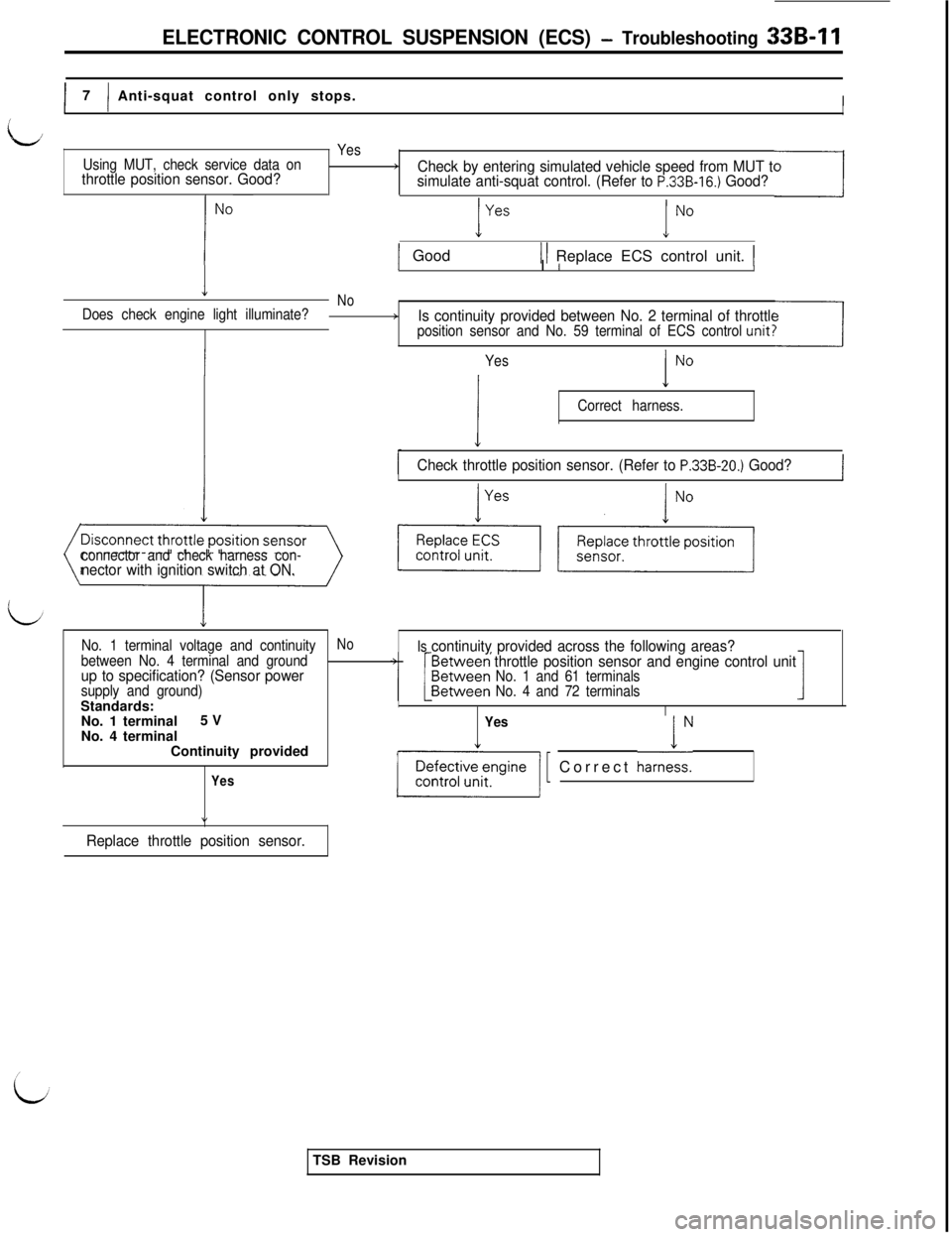

ELECTRONIC CONTROL SUSPENSION (ECS) - Troubleshooting 33B-11

I I7

Anti-squat control only stops.III

L,

I

Using MUT, check service data onthrottle position sensor. Good?

Yes

rCheck by entering simulated vehicle speed from MUT to

simulate anti-squat control. (Refer to P.33B-16.) Good?!

1 Good1 ) Replace ECS control unit. 1

I

1I II

NoDoes check engine light illuminate?>Is continuity provided between No. 2 terminal of throttleposition sensor and No. 59 terminal of ECS controlunityII

Yes

i

Correct harness.

1Check throttle position sensor. (Refer to P.33B-20.) Good?III1

connector and check harness con-nector with ignition switch at ON.

No. 1 terminal voltage and continuityNo

Is

between No. 4 terminal and groundcontinuity provided across the following areas?

up to specification? (Sensor powerthrottle position sensor and engine control unit

No. 1 and 61 terminals

supply and ground)

No. 4 and 72 terminalsStandards:

INo. 1 terminal5 V

YesNo. 4 terminal

Continuity provided

Yes-1 1 Correct harnei:

”

Replace throttle position sensor.TSB Revision

Page 674 of 1146

33B-12ELECTRONIC CONTROL SUSPENSION (EC9 - i?:~~u:‘?s*men*

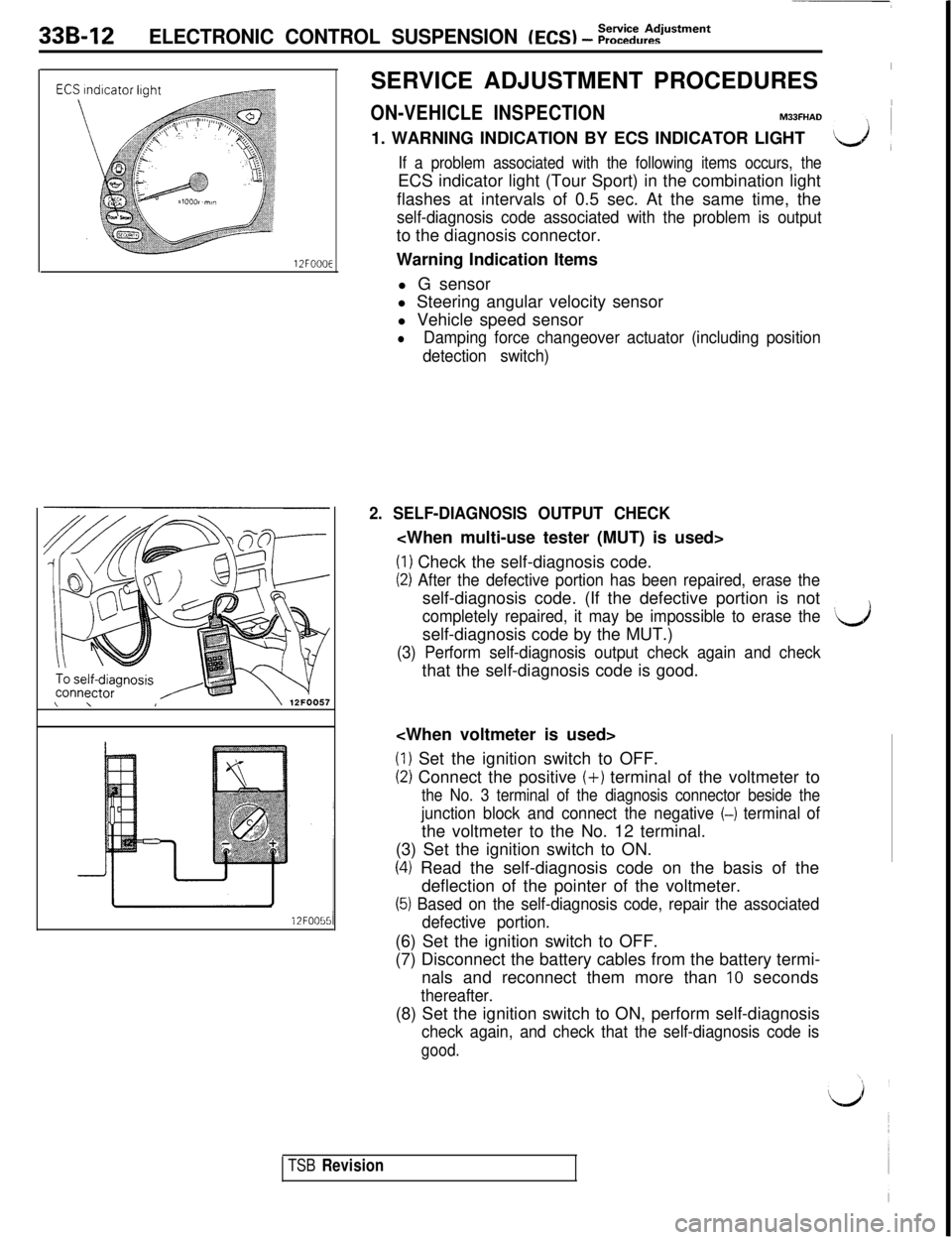

12FOOOESERVICE ADJUSTMENT PROCEDURES

I

ON-VEHICLE INSPECTIONIM33FHAD1. WARNING INDICATION BY ECS INDICATOR LIGHT

If a problem associated with the following items occurs, theECS indicator light (Tour Sport) in the combination light

flashes at intervals of 0.5 sec. At the same time, the

self-diagnosis code associated with the problem is outputto the diagnosis connector.

Warning Indication Items

l G sensor

l Steering angular velocity sensor

l Vehicle speed sensor

lDamping force changeover actuator (including position

detection switch)

2. SELF-DIAGNOSIS OUTPUT CHECK

(I) Check the self-diagnosis code.

(2) After the defective portion has been repaired, erase theself-diagnosis code. (If the defective portion is not

completely repaired, it may be impossible to erase the’self-diagnosis code by the MUT.)d

(3) Perform self-diagnosis output check again and checkthat the self-diagnosis code is good.

(1) Set the ignition switch to OFF.

(2) Connect the positive (+) terminal of the voltmeter to

the No. 3 terminal of the diagnosis connector beside the

junction block and connect the negative (--) terminal ofthe voltmeter to the No. 12 terminal.

(3) Set the ignition switch to ON.

(4) Read the self-diagnosis code on the basis of the

deflection of the pointer of the voltmeter.

(5) Based on the self-diagnosis code, repair the associated

defective portion.(6) Set the ignition switch to OFF.

(7) Disconnect the battery cables from the battery termi-

nals and reconnect them more than

10 seconds

thereafter.(8) Set the ignition switch to ON, perform self-diagnosis

check again, and check that the self-diagnosis code is

good.

TSB Revision

Page 675 of 1146

![MITSUBISHI 3000GT 1991 Service Manual Service AdjustmentELECTRONIC CONTROL SUSPENSION (ECS) - Procedures33B-13Fail Safe and Diagnosis List

Output Code

Diagnosis Item

Fail SafeCode No.Indication Pattern

0[Good]

[Good]

l-l

11G sensor defect MITSUBISHI 3000GT 1991 Service Manual Service AdjustmentELECTRONIC CONTROL SUSPENSION (ECS) - Procedures33B-13Fail Safe and Diagnosis List

Output Code

Diagnosis Item

Fail SafeCode No.Indication Pattern

0[Good]

[Good]

l-l

11G sensor defect](/img/19/57085/w960_57085-674.png)

Service AdjustmentELECTRONIC CONTROL SUSPENSION (ECS) - Procedures33B-13Fail Safe and Diagnosis List

Output Code

Diagnosis Item

Fail SafeCode No.Indication Pattern

0[Good]

[Good]

l-l

11G sensor defective*l Ride controls (pinching and bouncingcontrol, bad road detection control) sl:op.

21Steering angularvelocity sensor open-circuited*

l Anti-roll control stops.

24Vehicle speed sensor*nn open-crrcurtedl Steering stability controls (anti-roll, high

speed sensitive controls) and attitude

controls (anti-dive, anti-squat) stop.l Shock absorber damping force fixed

F. L. damping forcefl-~-~-j 11c$i;z;;Fr actuator

R. R. damping force

I /

64 j-jMJ-~-~-~ ~t$ec~Z$rn&ftYrrZ& /

NOTE(1)Control stop, warning indication and fixed damping force return to normal when the ignition switch is set to OFF.

When any of the problems marked* occurs, if no subsequent problem occurs (for example, when the problem IStransient) normal operation will be restored even if the ignition switch is not set to OFF.(2)Even if control stop warning indication and fixed damping force return to normal as described above, the

self-diagnosis code’is stored in the memory in the ECS control unrt.

(3)The self-diagnosis code can be force-cleared by use of the MUT or by stopping the power supply to the ECS controlunit. In addition

it is automatically cleared if the ON/OFF control of the ignition swatch is repeated 60 times after the

self-diagnosis code has been output, provided that no new self-diagnosis code is output during the period.TSB Revision

Page 676 of 1146

339-l 4ELECTRONIC CONTROL SUSPENSION (ECS) - ~;:i%?tment

Self-Diagnosis Determination Conditions

Code No.What is DefectiveSelf-Diagnosis Determination Conditions

11G sensor defectiveWhen sensor input of 0.5 or less or 4.5 V or more lasts for morethan 10 seconds.

21Steering angular velocity

sensor open-circuitedOpen circuit detected on the basis of difference in voltage level of

sensor signal.

24Vehicle speed sensor

defectiveWhen throttle opening of 30% (1.5 V) or more lasts for more than 60

seconds with the ignition switch at ON and if there is no input from the

vehicle speed sensor during the period, it is regarded as a problem.61

- 64Damping force changeoveractuator defectiveIf no damping force changeover is made in a second after actuatordrive signal has been output (position detection switch output patterndoes not change to that of target damping force), it is regarded as

a problem.3. SERVICE DATA OUTPUT CHECK

Using the MUT, check the service data.

Service Data Inspection List

Item No.

11

14

21

sensorST2 ON ON

OFFOFF

1 TSB Revision

Page 677 of 1146

I,

ELECTRONIC CONTROL SUSPENSION (ECS) - ;;~i%:~ustment339-15

Item No.Check

PointCheck ConditionSoundness Determination Value

24

Check by actually operating

vehicle.Speedometer indication and

MUT indication coincide.

26

61

62

63

64Vehicle

speed

sensorstop

lightswitch

F.R.actuator

F.L.actuator

R.R.actuator

R.L.actuatorDepress brake pedal.

ON

Do not depress brake pedal.OFF

Tour mode with vehicle stationarySOFT

Sport mode with vehicle stationaryHARD

Tour mode with vehicle stationarySOFT

Sport mode with vehicle stationaryHARD

Tour mode with vehicle stationarySOFT

Sport mode with vehicle stationaryHARD

Tour mode with vehicle stationarySOFT

Sport mode with vehicle stationaryHARD4. ACTUATOR CHECK

(I) Using the MUT, force-drive the actuator and fix the damping force changeover.

(2) Check service data (Item No. 61 through 64) to verify that the actuator has been force-driven.

NOTE

lAll of the four actuators in the shock absorbers are simultaneously changed over by forced drive.

lThe damping force changed over and fixed by forced drive is cleared by the following three conditions.1. Ignition switch OFF

2. Vehicle speed 3 km/h (1.9 mph) or more

3. MUT disconnected

Actuator Check List

Item No.Check Point

Check ConditionMUT Service Data Item

No. 61 - 64 Indicated

01Damping force SOFT

03Damping force MEDIUM

04Damping force HARD

Vehicle in stationary

conditionSOFT

MEDIUM

HARD

i

TSB Revision

Page 678 of 1146

339-l 6ELECTRONIC CONTROL SUSPENSION (ECS) - ;;:%,:?‘Stment5. CONTROL FUNCTION SIMULATION CHECK

Using the MUT, check all control functions during operationwith the vehicle in stationary condition.

5-1. Anti-Roll Control Function Check:d

(1) Raise the front wheels on a jack and have them supportedby rigid racks.

(2) Place the steering wheel in straight ahead position.

(3) Select the Tour mode by the ECS switch.

(4) Enter a simulated vehicle speed of 100 km/h (62 mph) fromthe MUT.

(5) Using the MUT, check the indications of service data itemsNo. 61 through 64.

MUT indication: SOFT

12FOO64(6) Turn the steering wheel clockwise or counterclockwise

from the straight ahead position.

(7) Using the MUT, check that the indications of service dataitems No. 61 through 64 change over.

Approx. 0.2 seconds for 90” rotation

(8) Check that the original damping force indication (SOFT) isrestored a second later.

5-2. Anti-Dive Control Function Check

(1) Select the Tour mode by the ECS switch.

(2) Enter a simulated vehicle speed of 100 km/h (62 mph) fromthe MUT.

(3) Using the MUT, check the indications of service data itemsNo. 61 through 64.

MUT indication: SOFT

(4) Depress the brake pedal and simultaneously change the

entered simulated vehicle speed by the MUT. (Change thespeed in 0.4 seconds after depressing the brake pedal.)

(5) Using the MUT, check that the indications of service dataitems No. 61 through 64 change over.

Changing entered simulated

vehicle speedMUT indication

100 km/h (62 mph) to 80 km/h (50 mph)HARD

(6) Check that the original damping force indication (SOFT) isrestored a second later.

Ls5-3. Anti-Squat Control Function Check

(1) Select the Tour mode by the ECS switch.

(2) Enter a simulated vehicle speed of 30 km/h (19 mph) fromthe

MUT.

(3) Using the MUT, check the indications of service data itemsNo. 61 through 64.

MUT indication: SOFT

l/i

TSB Revision

Page 679 of 1146

ELECTRONIC CONTROL SUSPENSION (ECS) - :;:~u:~men*33B17(4) Check that when the accelerator

dedal is operated, the

indications of service data items No. 61 through 64 on theMUT change as shown in the following table.

(5) With the simulated vehicle speed at 60 km/h (37’ mph) and

90 km/h (56 mph), similarly operate the accelerator pedaland check that the MUT indications change over.

Accelerator operating condition

EnE~~esismp~~ed ~;zz-KzxJ130km/h(19mph)

1HARDIMEDllJMI

1 60 km/h (37 mph)1MEDIUMIMEDllJMI

1 90 km/h (56 mph)1SOFTIMEDLJMI(6) Check that when the accelerator pedal is released, the

original damping force (SOFT) is restored in less than a

second.5-4. High Speed Sensitive Control Function

Chleck(I) Select the Tour mode by the ECS switch.

(2) Check that when the entered simulated vehicle speed is

changed by the MUT, the indications of service data itemsNo. 61 through 64 change.

(If the simulated vehicle speed is continuously cihanged by

the

Q and .!J keys of the MUT, however, the indications of

service data items No. 61 through 64 do not change duringthe period the

0 or a key is pressed.)

Changing entered simulated

vehicle speedMUT indication

Acceleration 129 km/h (80 mph)to 130 km/h (81 mph)SOFT + MEDIUM

Deceleration 120 km/h (75 mph)

to 119 km/h (74 mph)MEDIUM +, SOFT

5-5. Pitching and Bouncing Control Function Check

(1) Select the Tour mode by the ECS switch.

(2) Using the MUT, check the indications of service data itemsNo. 61 through 64.

MUT indication: SOFT

(3) Remove the G sensor, slowly shake it up and down througha space of about 5 cm (1.9 in.) with the connector

connected, and check that the indications of service dataitems No. 61 through 64 change.

G sensor status

IMUT indicationI

Shake up and down at a speed of arou.nd trip in a second.HARD(4) Check that when the G sensor is held stationary, the

original damping force indication (SOFT) is restored.

TSB Revision

Page 680 of 1146

33B-18ELECTRONIC CONTROL SUSPENSION (EC9 - ~::::u:?‘s*men*

\/I

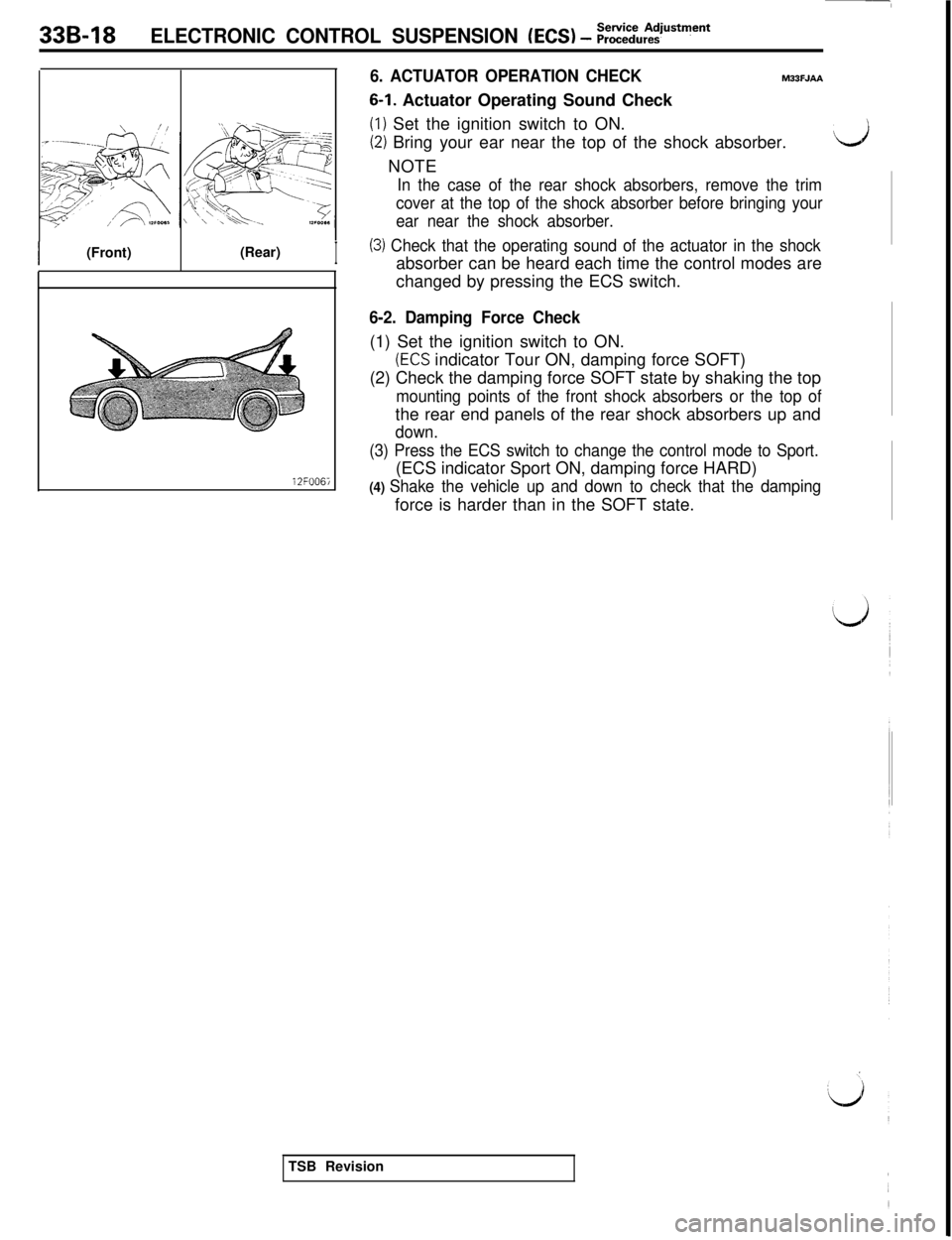

I(Front)(Rear)I

12FOOG

6. ACTUATOR OPERATION CHECKM33FJAA

6-1. Actuator Operating Sound Check

(I) Set the ignition switch to ON.

(2) Bring your ear near the top of the shock absorber.dNOTE

In the case of the rear shock absorbers, remove the trim

cover at the top of the shock absorber before bringing your

ear near the shock absorber.

(3) Check that the operating sound of the actuator in the shockabsorber can be heard each time the control modes are

changed by pressing the ECS switch.

6-2. Damping Force Check(1) Set the ignition switch to ON.

(ECS indicator Tour ON, damping force SOFT)

(2) Check the damping force SOFT state by shaking the top

mounting points of the front shock absorbers or the top ofthe rear end panels of the rear shock absorbers up and

down.

(3) Press the ECS switch to change the control mode to Sport.(ECS indicator Sport ON, damping force HARD)

(4) Shake the vehicle up and down to check that the dampingforce is harder than in the SOFT state.

TSB Revision