MITSUBISHI 380 2005 Workshop Manual

Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1091 of 1500

DOOR

BODY42-24

SYMPTOM CHARTM1423007000303

SYMPTOM PROCEDURES

INSPECTION PROCEDURE 1: Water Leak Through Door Window Glass

DIAGNOSIS

STEP 1. Check the window glass runchannel.

Q: Is the window glass runchannel in good condition?

YES :

Go to Step 2.

NO : Replace the runchannel, then go to Step 4.

STEP 2. Check the door window glass

installation.

Q: Is the door window glass installed correctly?

YES :

Go to Step 3.

NO : Reinstall the door window glass. (Refer to

P.42-39). Then go to Step 4.

STEP 3. Check the clearance at the top of the

door window glass.

Q: Is the clearance at the top of the door window

glass correct?

YES :

Go to Step 4.

NO : Adjust the door window glass. Refer to

P.42-31. Then go to Step 4.

STEP 4. Retest the system.

Q: Is any water leaking?

YES :

Return to Step 1.

NO : The procedure is complete.

INSPECTION PROCEDURE 2: Door Window Glass Malfunction

DIAGNOSIS

STEP 1. Check the door window glass

installation condition.

Q: Is the door window installed correctly?

YES :

Go to Step 2.

NO : Reinstall the door window glass. (Refer to

P.42-39). Then go to Step 4.

STEP 2. Check the door sash.

Q: Is the door sash in good condition?

YES :

Go to Step 3.

NO : Repair or replace door sash, then go to Step

4. SYMPTOM INSPECTION

PROCEDUREREFERENCE PAGE

Water leak through door window glass 1

P.42-24

Door window glass malfunction 2

P.42-24

Water leak through door edge 3

P.42-25

Water leak from door center 4

P.42-25

Door hard to open 5

P.42-25

Door does not open or close completely 6

P.42-26

Uneven gap between body 7

P.42-26

Wind noise around door 8

P.42-26

Page 1092 of 1500

DOOR

BODY42-25

STEP 3. Inspect the window regulator assembly.

Q: Is the window regulator assembly in good

condition?

YES :

Go to Step 4.

NO : Repair or replace the window regulator

assembly, then go to Step 4.

STEP 4. Retest the system.

Q: Does the door window operate correctly?

YES :

The procedure is complete.

NO : Return to Step 1.

INSPECTION PROCEDURE 3: Water Leak Through Door Edge

DIAGNOSIS

STEP 1. Check the weatherstrip.

Q: Is the weatherstrip in good condition?

YES :

Go to Step 2.

NO : Replace the weatherstrip, then go to Step 3.

STEP 2. Check the door fit (alignment).

Q: Is the door fit (alignment) correct?

YES :

Go to Step 3.

NO : Adjust the door fit (Refer to P.42-30). Then

go to Step 3.

STEP 3. Retest the system.

Q: Is any water leaking?

YES :

Return to Step 1.

NO : The procedure is complete.

INSPECTION PROCEDURE 4: Water Leak from Door Center

DIAGNOSIS

STEP 1. Check the drain hole.

Q: Is the drain hole clogged?

YES :

Clean the drain hole, then go to Step 3.

NO : Go to Step 2.

STEP 2. Check the weatherstrip.

Q: Is the weatherstrip in good condition?

YES :

Go to Step 3.

NO : Repair or replace the weatherstrip, then go

to Step 3.

STEP 3. Retest the system.

Q: Is any water leaking?

YES :

Return to Step 1.

NO : The procedure is complete.

INSPECTION PROCEDURE 5: Door Hard to Open

DIAGNOSIS

STEP 1. Adjust the latch and striker engagement.

Refer to P.42-30.

Q: Is the latch and striker engagement adjusted?

YES :

Go to Step 2.

NO : Adjust the latch and striker. (Refer to

P.42-30). Then go to Step 4.

STEP 2. Check for lock cable damage.

Q: Is the lock rod damaged?

YES :

Repair or replace the lock cable, then go to

St e p 4.

NO : Go to Step 3.

Page 1093 of 1500

DOOR

BODY42-26

STEP 3. Check the door handle flexibility

(amount of movement of handle required to open

door).

Q: Is the door handle flexibility good?

YES :

Go to Step 4.

NO : Check the door outside handle and inside

handle (Refer to P.42-35 and P.42-35).

Then go to Step 4.

STEP 4. Retest the system.

Q: Does the door open easily?

YES :

The procedure is complete.

NO : Return to Step 1.

INSPECTION PROCEDURE 6: Door Does Not Open or Close Completely

DIAGNOSIS

STEP 1. Check the door hinge position.

Q: Is the door hinge correct?

YES :

Go to Step 2.

NO : Adjust the door hinge (Refer to P.42-30).

Then go to Step 4.

STEP 2. Check the door for damage.

Q: Is the door in good condition?

YES :

Go to Step 3.

NO : Repair or replace the door, then go to Step

4.

STEP 3. Check lubrication.

Q: Are the door check and door hinge sufficiently

lubricated?

YES :

Go to Step 4.

NO : Apply grease, then go to Step 4.

STEP 4. Retest the system.

Q: Does the door open and close completely?

YES :

The procedure is complete.

NO : Return to Step 1.

INSPECTION PROCEDURE 7: Uneven Gap Between Body

.DIAGNOSIS

Adjust the door fit (Refer to P.42-30). Then check

that the gap has been improved.

INSPECTION PROCEDURE 8: Wind Noise Around Door

DIAGNOSIS

STEP 1. Check the weatherstrip for holding

condition.

Q: Is the weatherstrip holding firmly?

YES :

Go to Step 2.

NO : Adjust fit of door (Refer to P.42-32). Then

go to Step 5.

STEP 2. Check the weatherstrip for installation

condition.

Q: Is the weatherstrip installed properly?

YES :

Go to Step 3.

NO : Repair or replace the weatherstrip. Then go

to Step 5.

Page 1094 of 1500

DOOR

BODY42-27

STEP 3. Check the clearance.

Q: Are the door glass and door weatherstrip holder

installed properly?

YES :

Go to Step 4.

NO : Adjust the door glass and the weatherstrip

holder (Refer to P.42-32). Then go to Step

5.

STEP 4. Check the door for deformation.

Q: Is the door deformed?

YES :

Replace the door. then go to Step 5.

NO : Go to Step 5.

STEP 5. Retest the system.

Q: Has the wind noise been improved?

YES :

Return to Step 1.

NO : This diagnosis complete.

HOW TO LOCATE WIND NOISEM1421004200227

1. Attach cloth tape to every place, such as panel seams,

projections, molding seams, glass and body seams, etc.

which might conceivably be the source of wind noise.

2. Then make a road test to check that the places not covered

by tape are not sources of wind noise.

3. Remove the strips of tape one by one, making a road test

after each is removed, until a wind noise source is

discovered.

4. When such a place is found, cover it again and repeat the

procedure to check if there are any other noise source.

5. If no others are found, the last remaining tape is the only

source.

Page 1095 of 1500

DOOR

BODY42-28

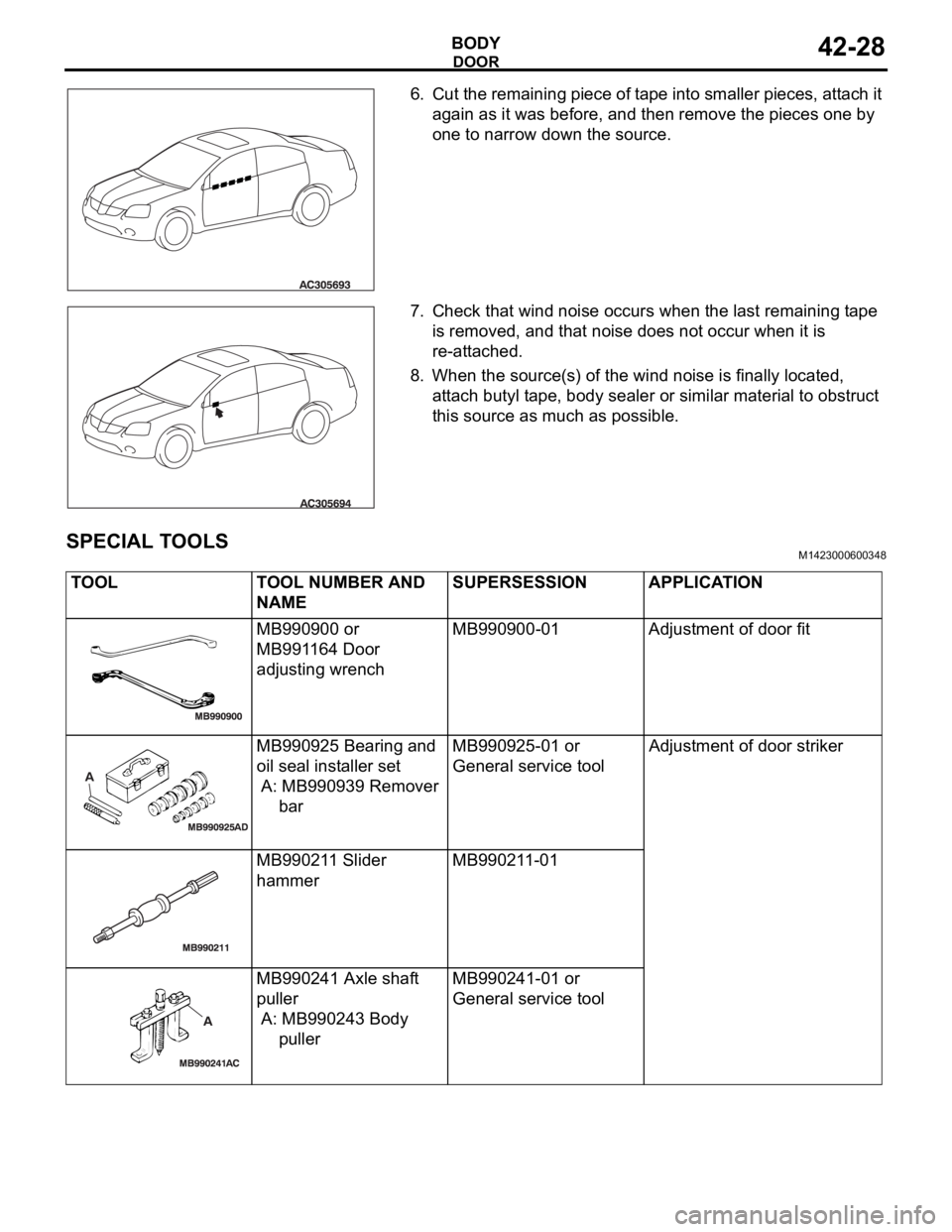

6. Cut the remaining piece of tape into smaller pieces, attach it

again as it was before, and then remove the pieces one by

one to narrow down the source.

7. Check that wind noise occurs when the last remaining tape

is removed, and that noise does not occur when it is

re-attached.

8. When the source(s) of the wind noise is finally located,

attach butyl tape, body sealer or similar material to obstruct

this source as much as possible.

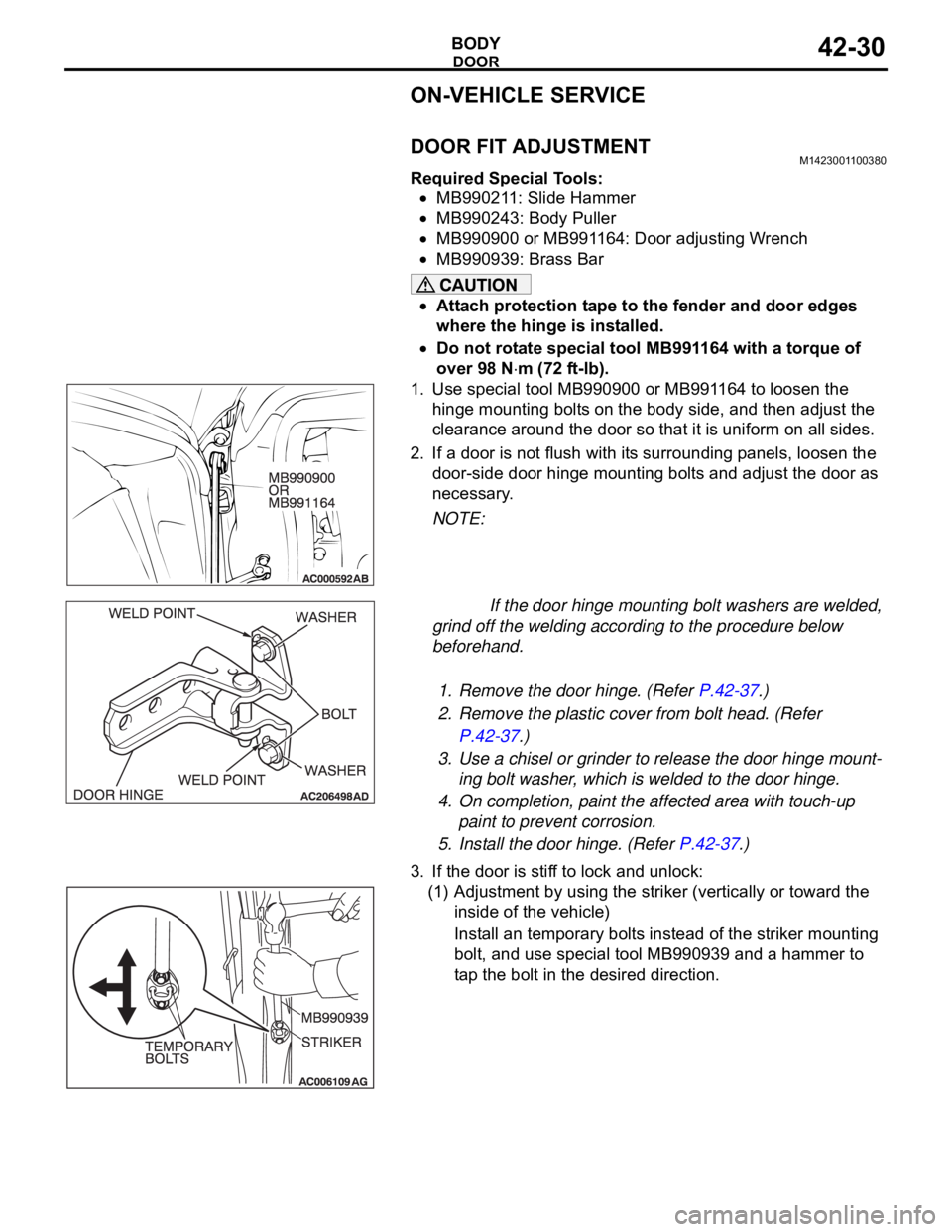

SPECIAL TOOLSM1423000600348

TOOL TOOL NUMBER AND

NAMESUPERSESSION APPLICATION

MB990900 or

MB991164 Door

adjusting wrenchMB990900-01 Adjustment of door fit

MB990925 Bearing and

oil seal installer set

A: MB990939 Remover

barMB990925-01 or

General service toolAdjustment of door striker

MB990211 Slider

hammerMB990211-01

MB990241 Axle shaft

puller

A: MB990243 Body

pullerMB990241-01 or

General service tool

Page 1096 of 1500

DOOR

BODY42-29

MB990480 Glass holder General service tool Removal of power window

regulator assembly

MB991223 Harness set

A: MB991219 Test

harness

B: MB991220 LED

harness

C: MB991221 LED

harness adapter

D: MB991222 ProbeGeneral service tools Measurement of terminal

voltage

A: Connector pin contact

pressure inspection

B: Power circuit inspection

C: Power circuit inspection

D: Commercial tester

connection

MB990784 Ornament

removerGeneral service tool Removal of power window

switch panel assembly TOOL TOOL NUMBER AND

NAMESUPERSESSION APPLICATION

Page 1097 of 1500

DOOR

BODY42-30

ON-VEHICLE SERVICE

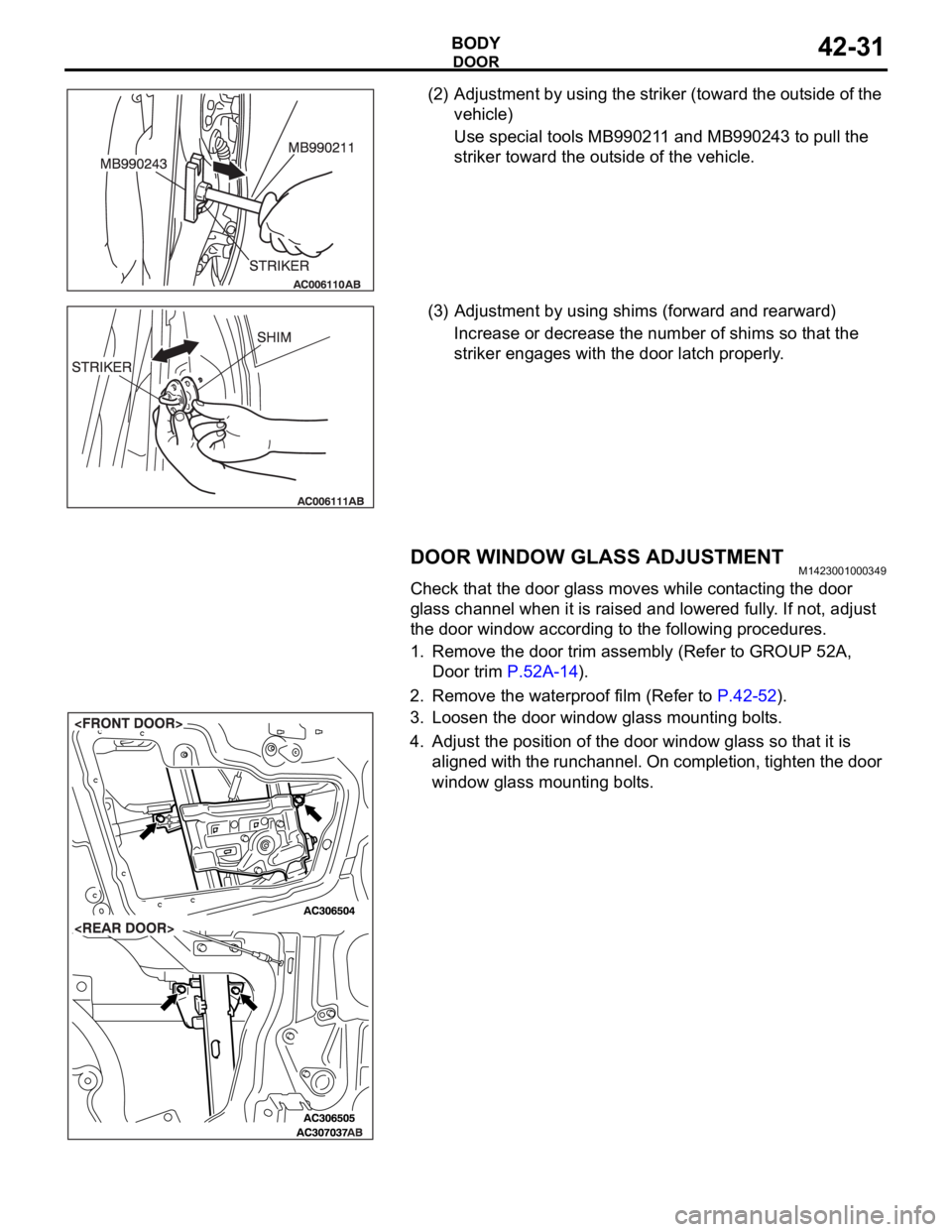

DOOR FIT ADJUSTMENTM1423001100380

Required Special Tools:

MB990211: Slide Hammer

MB990243: Body Puller

MB990900 or MB991164: Door adjusting Wrench

MB990939: Brass Bar

Attach protection tape to the fender and door edges

where the hinge is installed.

Do not rotate special tool MB991164 with a torque of

over 98 N

m (72 ft-lb).

1. Use special tool MB990900 or MB991164 to loosen the

hinge mounting bolts on the body side, and then adjust the

clearance around the door so that it is uniform on all sides.

2. If a door is not flush with its surrounding panels, loosen the

door-side door hinge mounting bolts and adjust the door as

necessary.

NOTE:

If the door hinge mounting bolt washers are welded,

grind off the welding according to the procedure below

beforehand.

.

1. Remove the door hinge. (Refer P.42-37.)

2. Remove the plastic cover from bolt head. (Refer

P.42-37.)

3. Use a chisel or grinder to release the door hinge mount-

ing bolt washer, which is welded to the door hinge.

4. On completion, paint the affected area with touch-up

paint to prevent corrosion.

5. Install the door hinge. (Refer P.42-37.)

3. If the door is stiff to lock and unlock:

(1) Adjustment by using the striker (vertically or toward the

inside of the vehicle)

Install an temporary bolts instead of the striker mounting

bolt, and use special tool MB990939 and a hammer to

tap the bolt in the desired direction.

Page 1098 of 1500

DOOR

BODY42-31

(2) Adjustment by using the striker (toward the outside of the

vehicle)

Use special tools MB990211 and MB990243 to pull the

striker toward the outside of the vehicle.

(3) Adjustment by using shims (forward and rearward)

Increase or decrease the number of shims so that the

striker engages with the door latch properly.

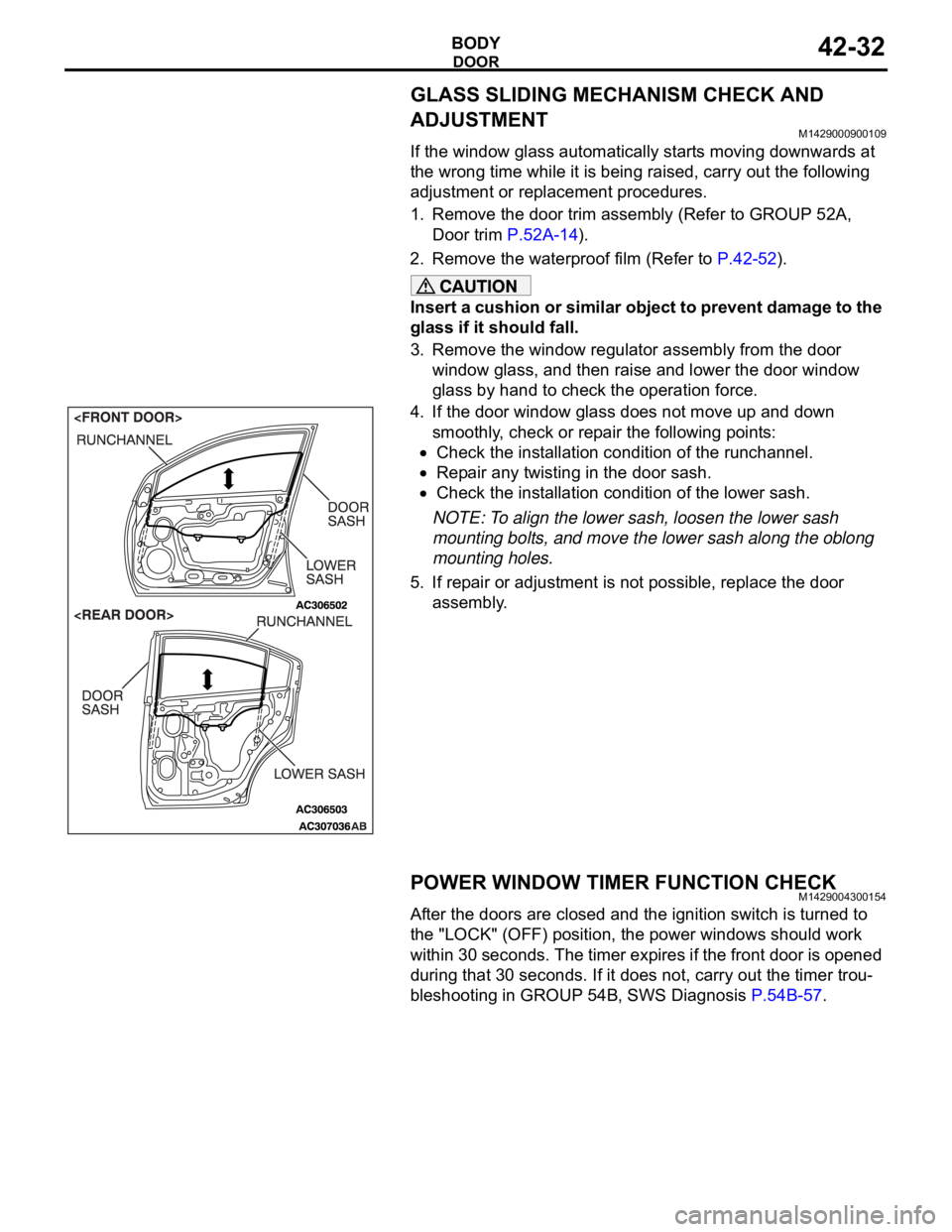

DOOR WINDOW GLASS ADJUSTMENTM1423001000349

Check that the door glass moves while contacting the door

glass channel when it is raised and lowered fully. If not, adjust

the door window according to the following procedures.

1. Remove the door trim assembly (Refer to GROUP 52A,

Door trim P.52A-14).

2. Remove the waterproof film (Refer to P.42-52).

3. Loosen the door window glass mounting bolts.

4. Adjust the position of the door window glass so that it is

aligned with the runchannel. On completion, tighten the door

window glass mounting bolts.

Page 1099 of 1500

DOOR

BODY42-32

GLASS SLIDING MECHANISM CHECK AND

ADJUSTMENT

M1429000900109

If the window glass automatically starts moving downwards at

the wrong time while it is being raised, carry out the following

adjustment or replacement procedures.

1. Remove the door trim assembly (Refer to GROUP 52A,

Door trim P.52A-14).

2. Remove the waterproof film (Refer to P.42-52).

Insert a cushion or similar object to prevent damage to the

glass if it should fall.

3. Remove the window regulator assembly from the door

window glass, and then raise and lower the door window

glass by hand to check the operation force.

4. If the door window glass does not move up and down

smoothly, check or repair the following points:

Check the installation condition of the runchannel.

Repair any twisting in the door sash.

Check the installation condition of the lower sash.

NOTE: To align the lower sash, loosen the lower sash

mounting bolts, and move the lower sash along the oblong

mounting holes.

5. If repair or adjustment is not possible, replace the door

assembly.

POWER WINDOW TIMER FUNCTION CHECKM1429004300154

After the doors are closed and the ignition switch is turned to

the "LOCK" (OFF) position, the power windows should work

within 30 seconds. The timer expires if the front door is opened

during that 30 seconds. If it does not, carry out the timer trou-

bleshooting in GROUP 54B, SWS Diagnosis P.54B-57.

Page 1100 of 1500

DOOR

BODY42-33

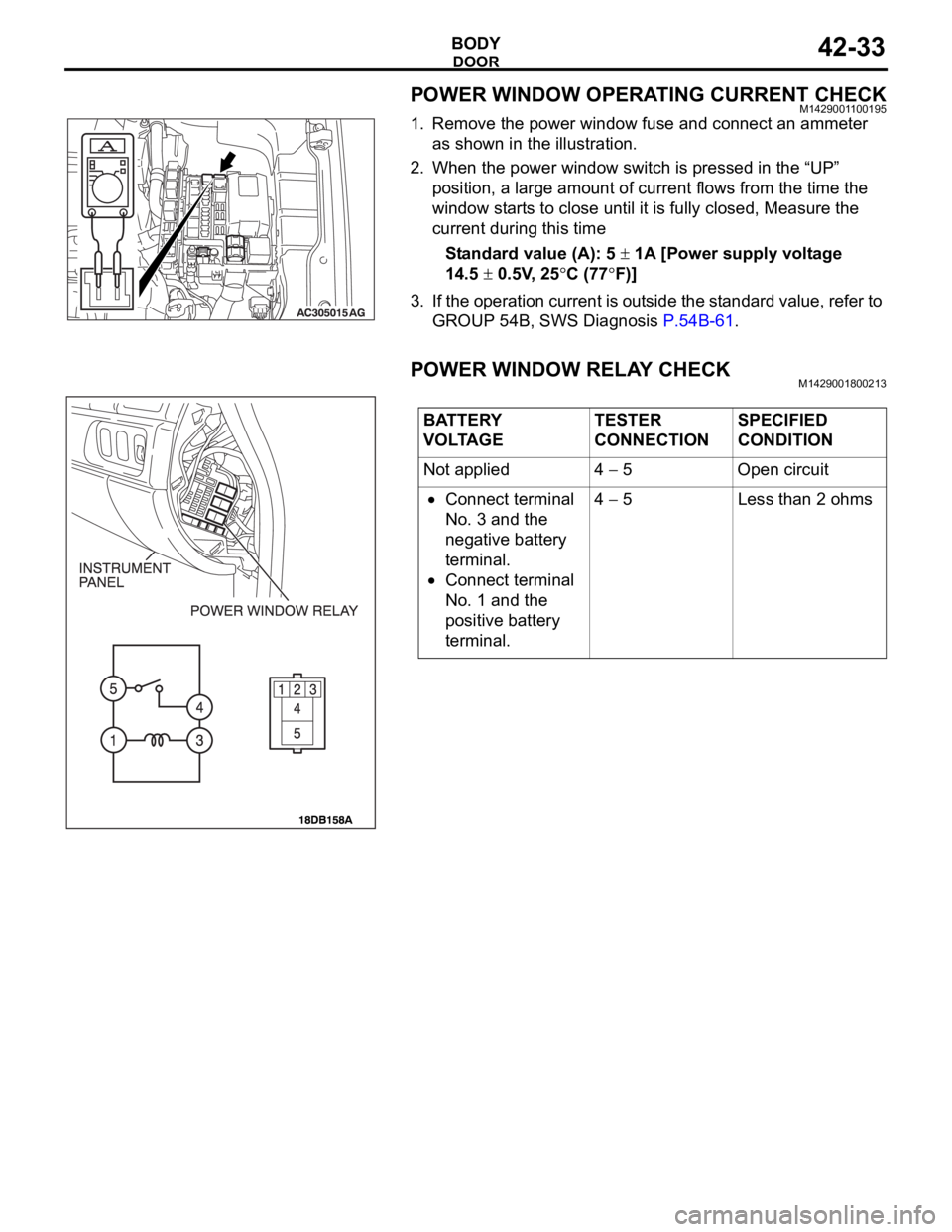

POWER WINDOW OPERATING CURRENT CHECKM1429001100195

1. Remove the power window fuse and connect an ammeter

as shown in the illustration.

2. When the power window switch is pressed in the “UP”

position, a large amount of current flows from the time the

window starts to close until it is fully closed, Measure the

current during this time

Standard value (A): 5

1A [Power supply voltage

14.5

0.5V, 25C (77F)]

3. If the operation current is outside the standard value, refer to

GROUP 54B, SWS Diagnosis P.54B-61.

POWER WINDOW RELAY CHECKM1429001800213

BATTERY

VOLTAGETESTER

CONNECTIONSPECIFIED

CONDITION

Not applied 4

5 Open circuit

Connect terminal

No. 3 and the

negative battery

terminal.

Connect terminal

No. 1 and the

positive battery

terminal.4

5 Less than 2 ohms