MITSUBISHI COLT 2006 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 2006, Model line: COLT, Model: MITSUBISHI COLT 2006Pages: 364, PDF Size: 11.65 MB

Page 241 of 364

ELECTRICAL POWER STEERING

POWER STEERING37-8

ELECTRICAL PARTS AND FUNCTIONS

Parts nameDescription about function

SensorVehicle speed sensor (ABS-ECU)Sends the vehicle speed signal to the electric power

steering-ECU.

Torque sensorDetects a steering force, converts it into the voltage signal,

and then sends the signal to the electric power

steering-ECU.

ActuatorMotorGenerates assist torque by the steering operation to the

steering gear using the signals sent from the electric power

steering-ECU.

Electric power steering warning

lampWarns a driver of the system malfunction using the signal

sent from the electric power steering-ECU.

Electric power steering-ECUControl the actuator (motor) based on the signal sent from

sensor.

Controls the self-diagnostic fu nction and fail-safe function.

Controls diagnostic function (Compatible with M.U.T.-III).

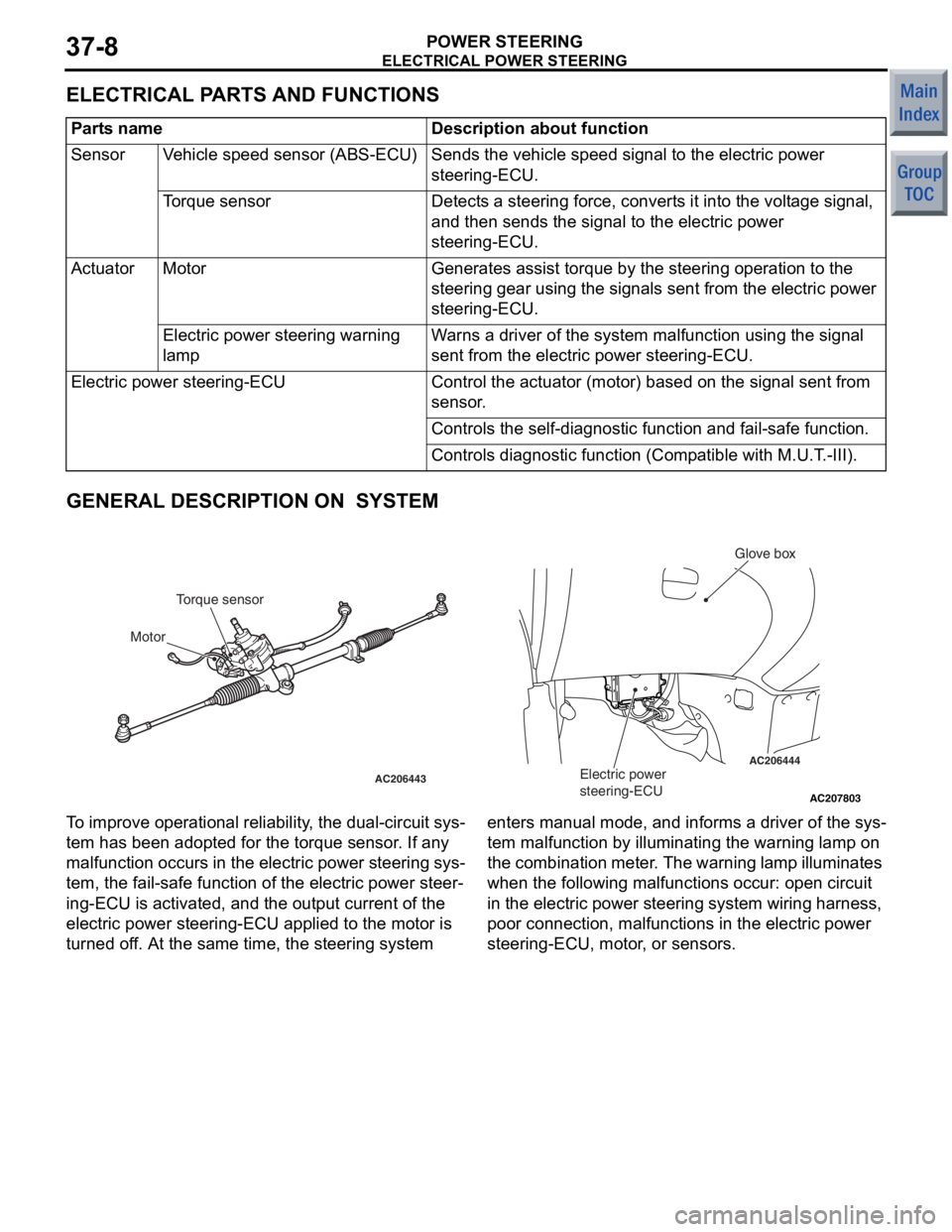

GENERAL DESCRIPTION ON SYSTEM

AC207803

AC206444

AC206443

AB

Electric power

steering-ECU

Glove box

Torque sensor

Motor

T o improve opera t iona l reliabi lity , th e dual-circuit sys-

tem ha s be en ad opted f o r the t o rque sensor . If a n y

malfunct

i on occurs in the electric power st eering sys

-

tem, the fail-sa f e fun c tio n of th e ele c tric power steer-

ing-ECU is activated, and the ou tput current of the

electric power steerin

g-ECU a pplied to the motor is

turned o

f f. At th e sa me time, the steerin g syste m enters man ual mode, and informs a dr iver of the sys

-

tem malfu

n ction by illuminating th e warnin g lamp on

the

comb in at io n me te r . Th e warn in g la mp il lu min a te s

wh

en the following malfu n ct ions occur: ope n circuit

in the

e l ectric power stee ring system wiring harness,

poor connectio

n , ma lfunction s in the e l ectric power

steering-ECU, mo

tor , or sensors.

Page 242 of 364

ELECTRICAL POWER STEERING

POWER STEERING37-9

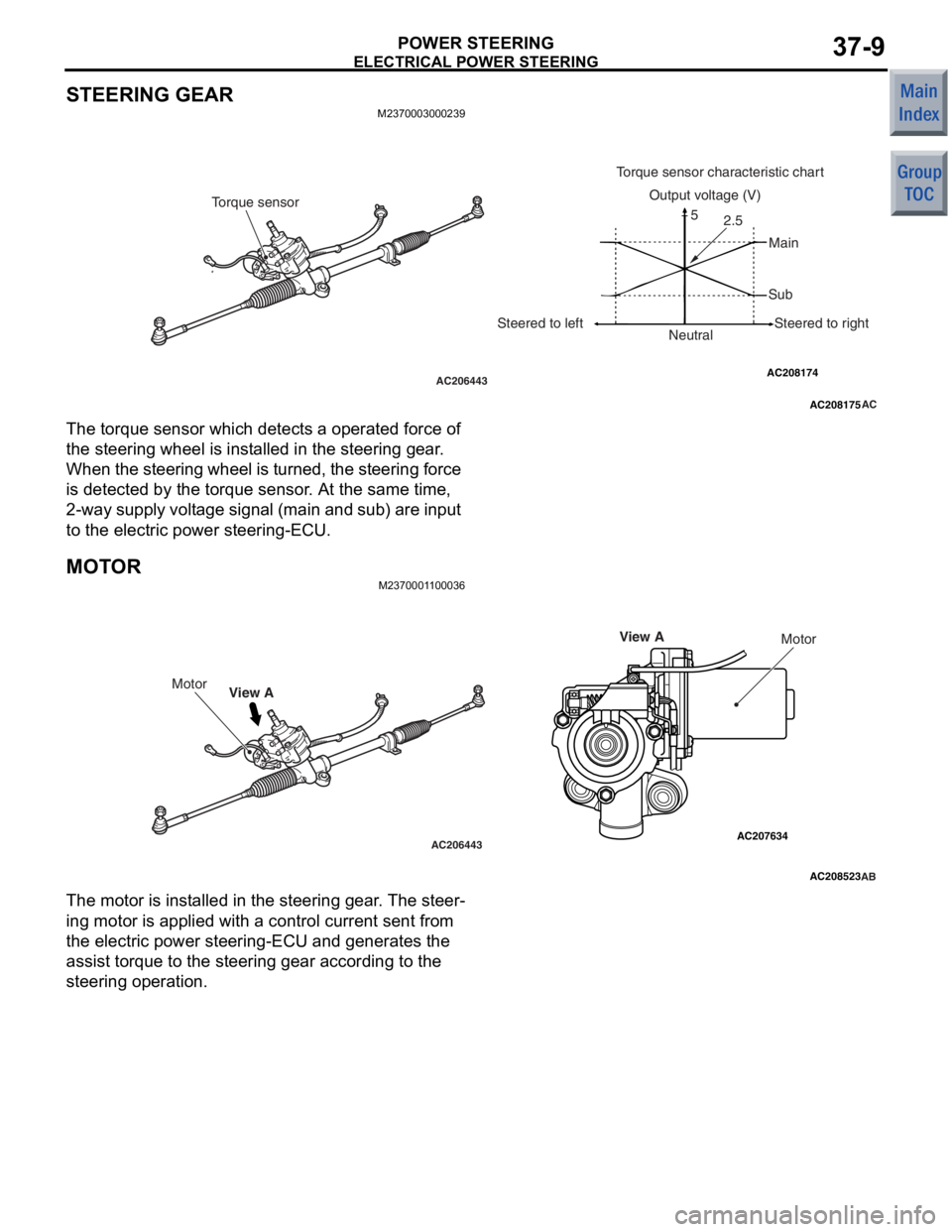

STEERING GEAR

M2370003000239

AC208175

AC208174AC206443AC

NeutralSub

Torque sensor

Steered to leftMain

Steered to right

Output voltage (V)

Torque sensor characteristic chart

52.5

The torqu e sensor which detect s a opera t ed force of

the steerin

g wheel is inst alled in the stee ring g ear .

Whe

n th e st eer in g whe e l is tu rn ed , t h e ste e ring f o rce

is d

e tected by the to rque sensor . At the same time,

2-way supp

ly volt a ge signa l (main and sub ) are input

to the e

l ectric power steerin g-ECU.

MOT O RM237000 1 1 0003 6

AC208523

AC206443

AC207634

AB

View AMotor

Motor

View A

The mot

o r is inst alled in th e steering gea r . The ste e r-

ing motor is applied with a con t rol current sent from

the electric po

we r stee ring-ECU and genera t es t he

assist

torque to the steering ge ar according to the

steering op

eratio n.

Page 243 of 364

ELECTRICAL POWER STEERING

POWER STEERING37-10

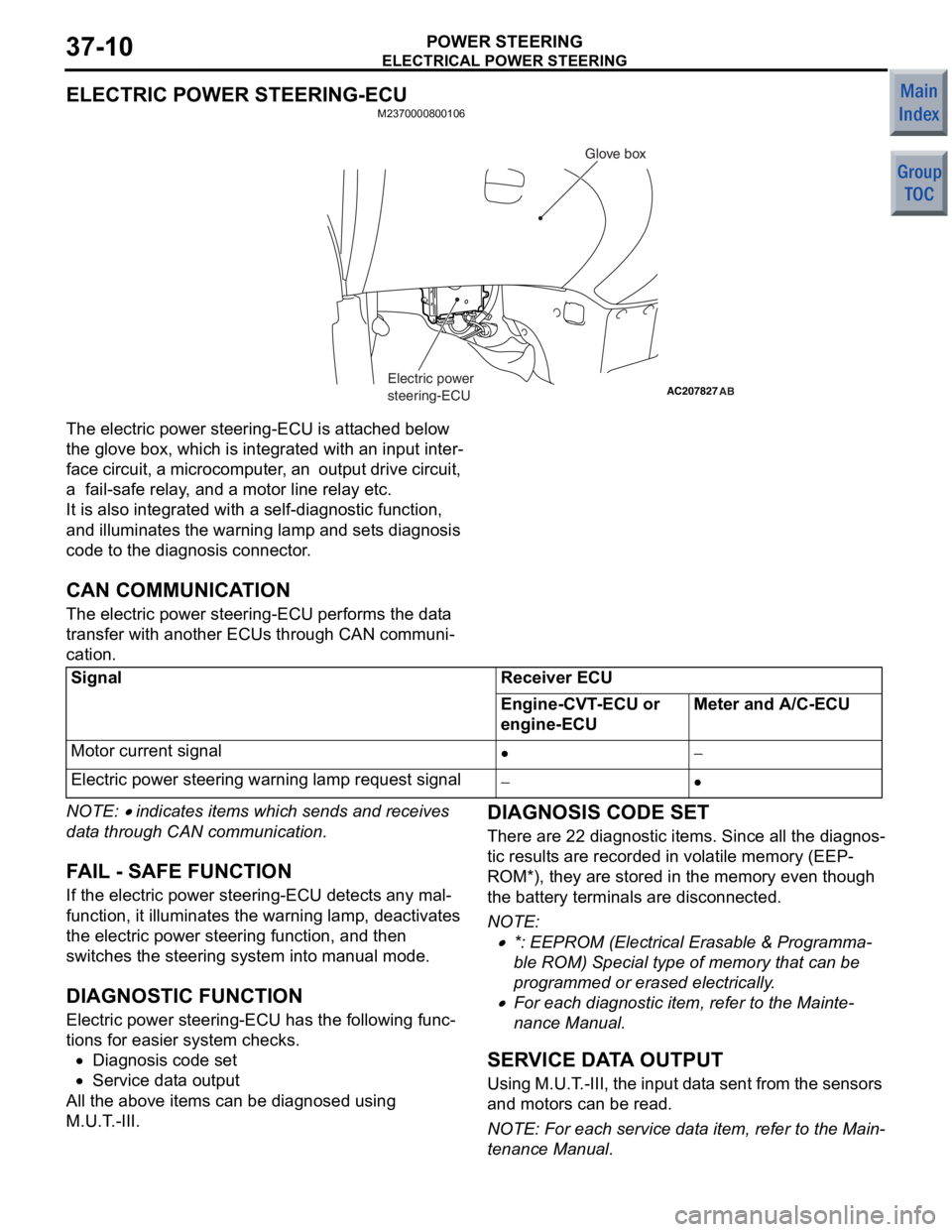

ELECTRIC POWER STEERING-ECU

M2370000800106

AC207827AB

Glove box

Electric power

steering-ECU

The electric powe r stee ring-ECU is att a ch ed below

the glove

box, wh ich is integ r ated wit h an input inter

-

face circu i t, a microco m p u ter , an outp u t d r ive circuit,

a fail-sa

f e rela y , and a mot o r line relay et c.

It is also integrated with a self-diag nostic fu nction,

and illuminate

s the warn ing lamp an d set s d i agno sis

code

to the diagn osis connector .

CAN COMMUNICATION

The electric powe r stee ring-ECU perfo rms the da t a

transf

e r with a nother ECUs through CAN communi

-

cation.

SignalReceiver ECU

Engine-CVT-ECU or

engine-ECUMeter and A/C-ECU

Motor current signal•−

Electric power steering warning lamp request signal−•

NOTE: • ind i ca tes items which sends and re ceives

dat

a throu gh CAN communicat i on.

FA IL - SAFE FUNCTION

If the e l ectric power st eering - ECU de tect s any mal-

functi on, it illuminat es th e warnin g lamp, de activate s

the electric po

we r stee ring f unct i on, a nd the n

switches

the steerin g system in to ma nual mode .

DIAGNOSTIC FUNCTION

Electric po wer ste e ring -ECU has the following fu nc-

tions for easie r system ch ecks.

•Diagnosis code set

•Service dat a outp u t

All the above ite m s can be diagnosed using

M.U.T

. -III.

DIAGNOSIS CODE SET

There a r e 22 d i agno stic ite m s. Since all the d i agn os-

tic result s are recorded in volatile memory (EEP-

ROM*), they a r e sto r ed in the memo ry even th ough

the bat

tery t e rminals are d i sconne cted.

NOTE: .

•*: EEPROM (E lectrical Erasable & Programma-

ble ROM) Special ty pe o f me mory that can b e

prog

rammed or erase d ele c trically .

•For each diag nostic item, refer to the Mainte-

nance Manua l.

SERV ICE DA T A OUTPUT

Usin g M. U. T . -II I , t h e i n p u t d a t a s e n t f r om t h e se ns ors

and motors can

be rea d .

NOTE: For e a ch service dat a it em, re fer to th e Ma in-

tenance Manual.

Page 244 of 364

ELECTRICAL POWER STEERING

POWER STEERING37-11

OPERATION

M2370000700110

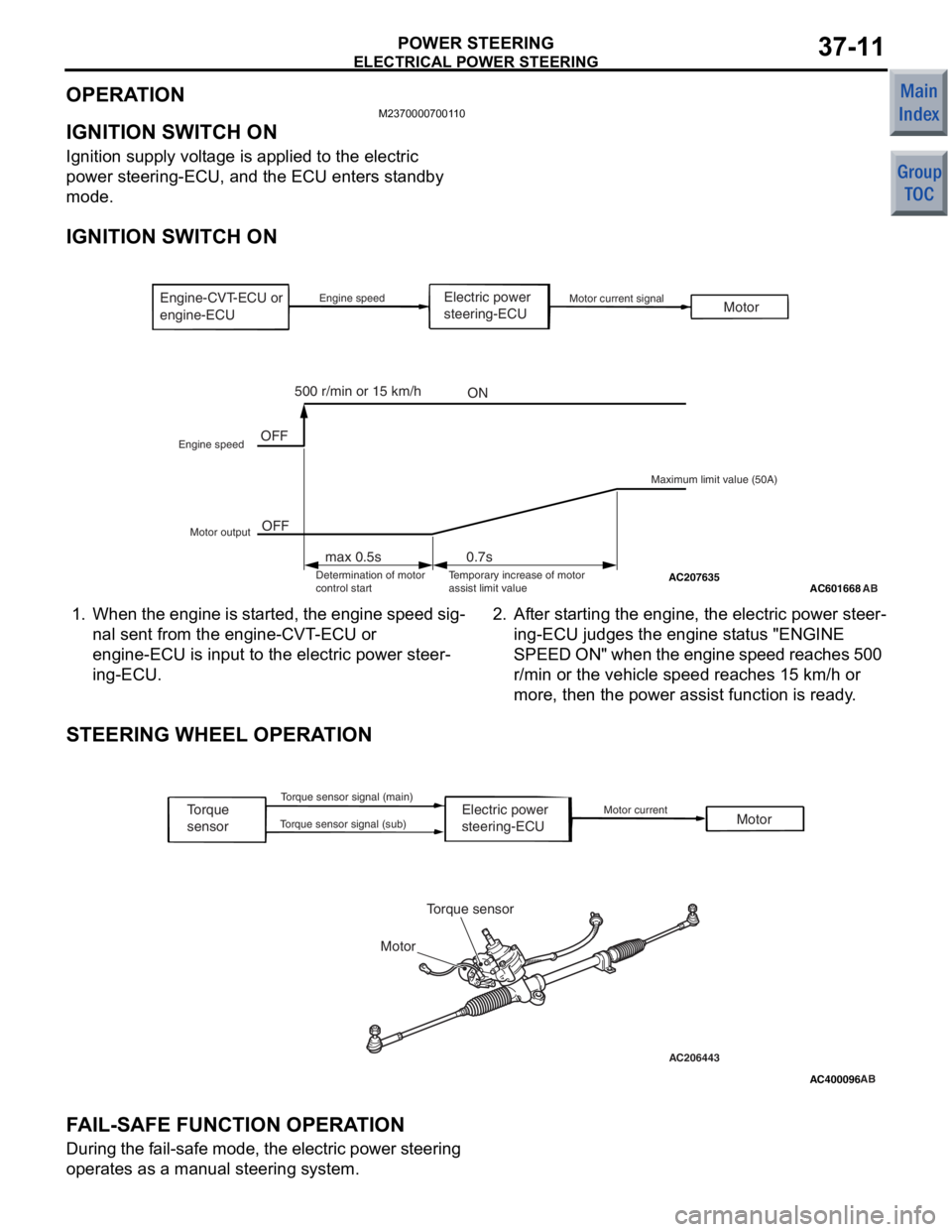

IGNITION SWITCH ON

Ignition supply voltage is applied to the electric

power steering-ECU, and the ECU enters standby

mode.

IGNITION SWITCH ON

AC601668AC207635 AB

Electric power

steering-ECU

OFF

OFF MotorMotor current signal

Maximum limit value (50A)

Engine speed

Engine speed

ON

500 r/min or 15 km/h

max 0.5s 0.7s

Motor output Determination of motor

control start Temporary increase of motor

assist limit value

Engine-CVT-ECU or

engine-ECU

1.

Whe n th e e ngine is st arted, the en gine sp eed sig-

nal sent from the en gine -CVT -ECU or

eng

ine-ECU is inp u t to th e ele c tric power steer

-

ing-ECU.

2. Af ter st a r ting the engine, the electric power ste e r-

ing-ECU judges the engin e st atu s "ENGINE

SPEED ON"

when the engine speed reaches 500

r/min or

the vehicle speed reaches 1 5 km/h or

more, the

n the p o wer assist functio n is ready .

STEERING WHEEL OPERAT ION

AC400096

AC206443AB

Electric power

steering-ECU

Torque

sensor

Torque sensor

Motor Motor

Motor current

Torque sensor signal (main)

Torque sensor signal (sub)

F A IL- S AFE FUNCTION OPERA T ION

Duri ng t h e f a il -s af e m o d e , t h e el ect r ic powe r st ee rin g

operate

s as a manual ste e ring system.

Page 245 of 364

GROUP 36

PARKING BRAKES

CONTENTS

GENERAL INFORMATION . . . . . . . .36-2

STRUCTURAL DESCRIPTION

OPERATIONAL DESCRIPTION

Page 246 of 364

GENERAL INFORMATION

PARKING BRAKES36-2

GENERAL INFORMATION

M2360000100656

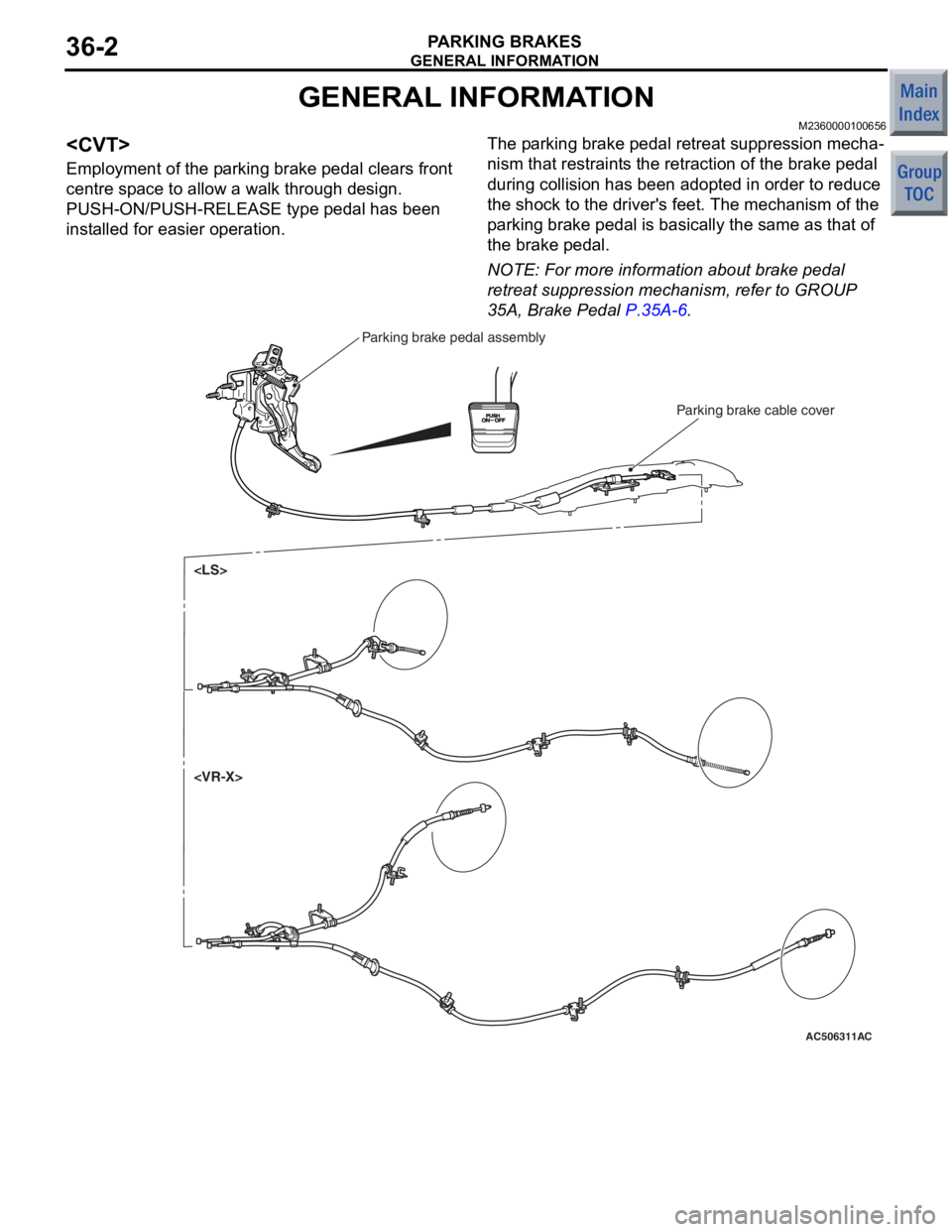

Employment of the parking brake pedal clears front

centre space to allow a walk through design.

PUSH-ON/PUSH-RELEASE type pedal has been

installed for easier operation.

The parking brake pedal retreat suppression mecha-

nism that restraints the retraction of the brake pedal

during collision has been adopted in order to reduce

the shock to the driver's feet. The mechanism of the

parking brake pedal is basically the same as that of

the brake pedal.

NOTE: For more information about brake pedal

retreat suppression mechanism, refer to GROUP

35A, Brake Pedal

P.35A-6.

AC506311AC

Parking brake cable cover

Parking brake pedal assembly

Page 247 of 364

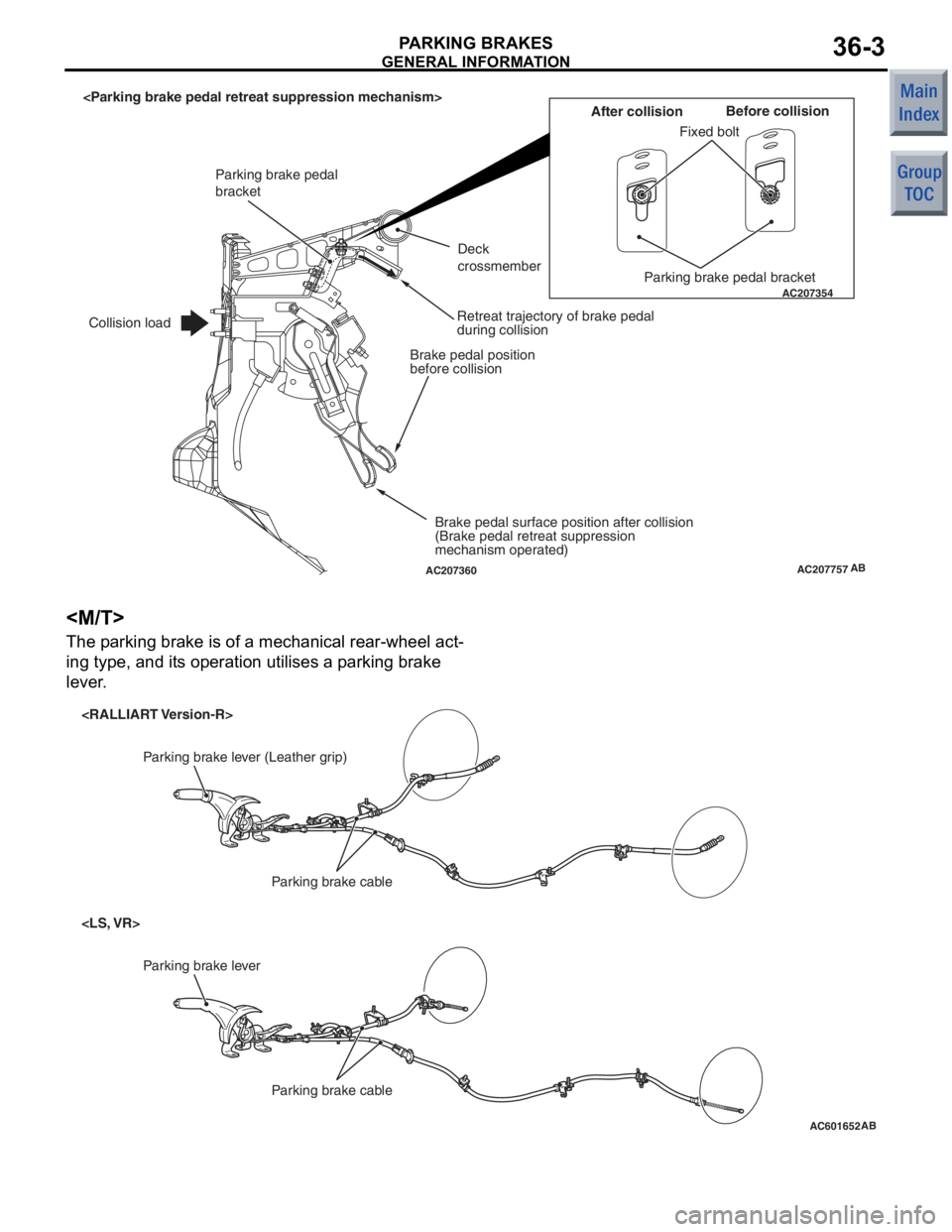

AC207757

AC207354

AC207360AB

Fixed boltBefore collision

After collision

Parking brake pedal bracket

Deck

crossmember

Retreat trajectory of brake pedal

during collision

Brake pedal position

before collision

Brake pedal surface position after collision

(Brake pedal retreat suppression

mechanism operated)

Parking brake pedal

bracket

Collision load

GENERAL INFORMA

T ION

PA R K ING BR AKES36-3

The pa rking b r ake is o f a me chan ica l rea r-wh eel a c t-

ing type, and it s operat ion u t ilises a p a rking b r ake

leve

r .

AC601652

Parking brake lever

Parking brake cable

Parking brake lever (Leather grip)Parking brake cable

AB

Page 248 of 364

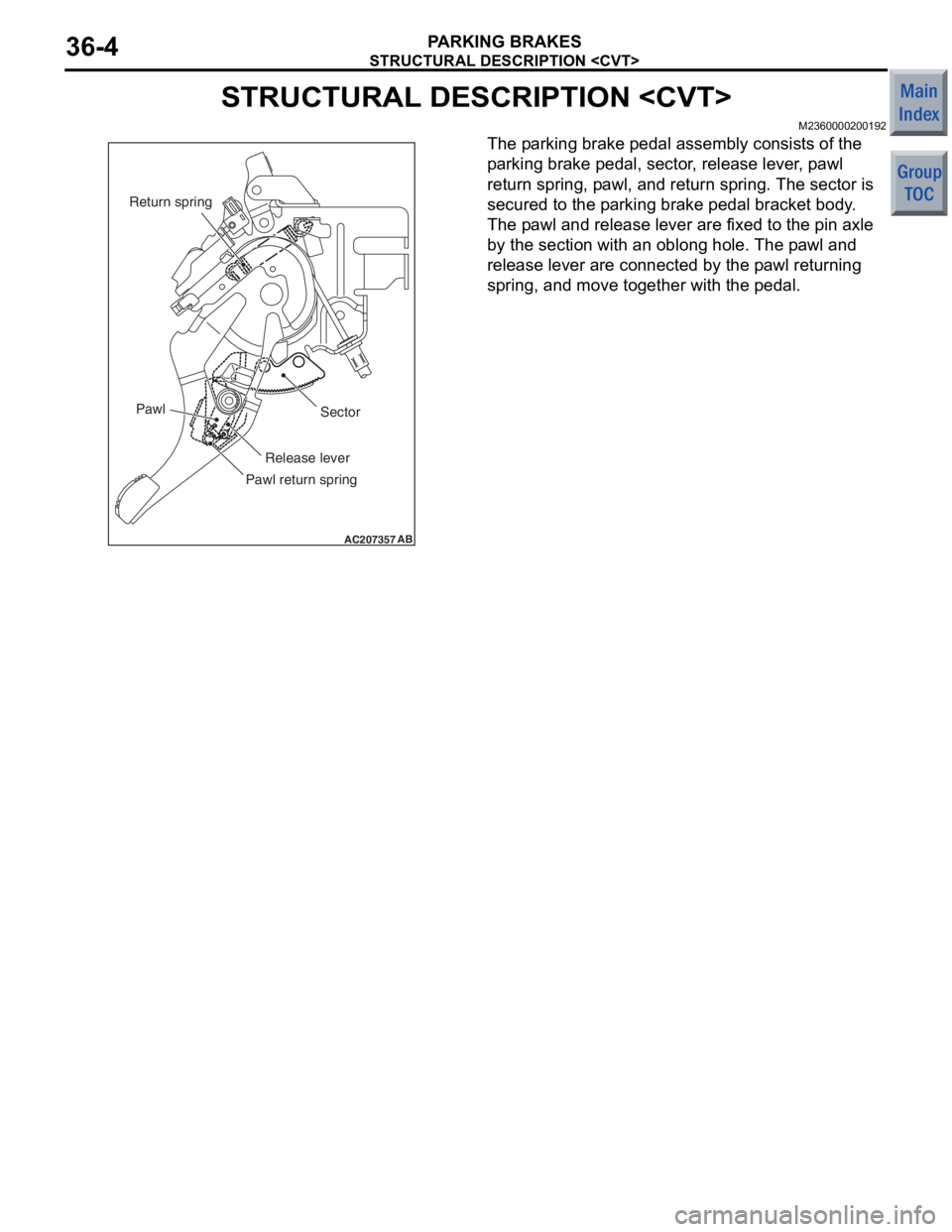

STRUCTURAL DESCRIPTION

PARKING BRAKES36-4

STRUCTURAL DESCRIPTION

M2360000200192

AC207357AB

PawlSector

Release lever

Pawl return spring

Return spring

The pa rking b r ake pedal assemb ly consist s of the

p

a r k ing brake peda l, secto r , rele ase leve r , p a wl

return sprin

g , p a wl, an d return spring. Th e sector is

secured to

the p a rking b r ake pedal bracket b ody .

The p

a wl a nd release lever are f i xe d to the pin axle

by th

e sectio n with a n oblong ho le. Th e p a wl and

release lever

are co nnected by the p a wl returning

spring, an

d move tog e ther with the pedal.

Page 249 of 364

OPERATIONAL DESCRIPTION

PARKING BRAKES36-5

OPERATIONAL DESCRIPTION

M2360000300207

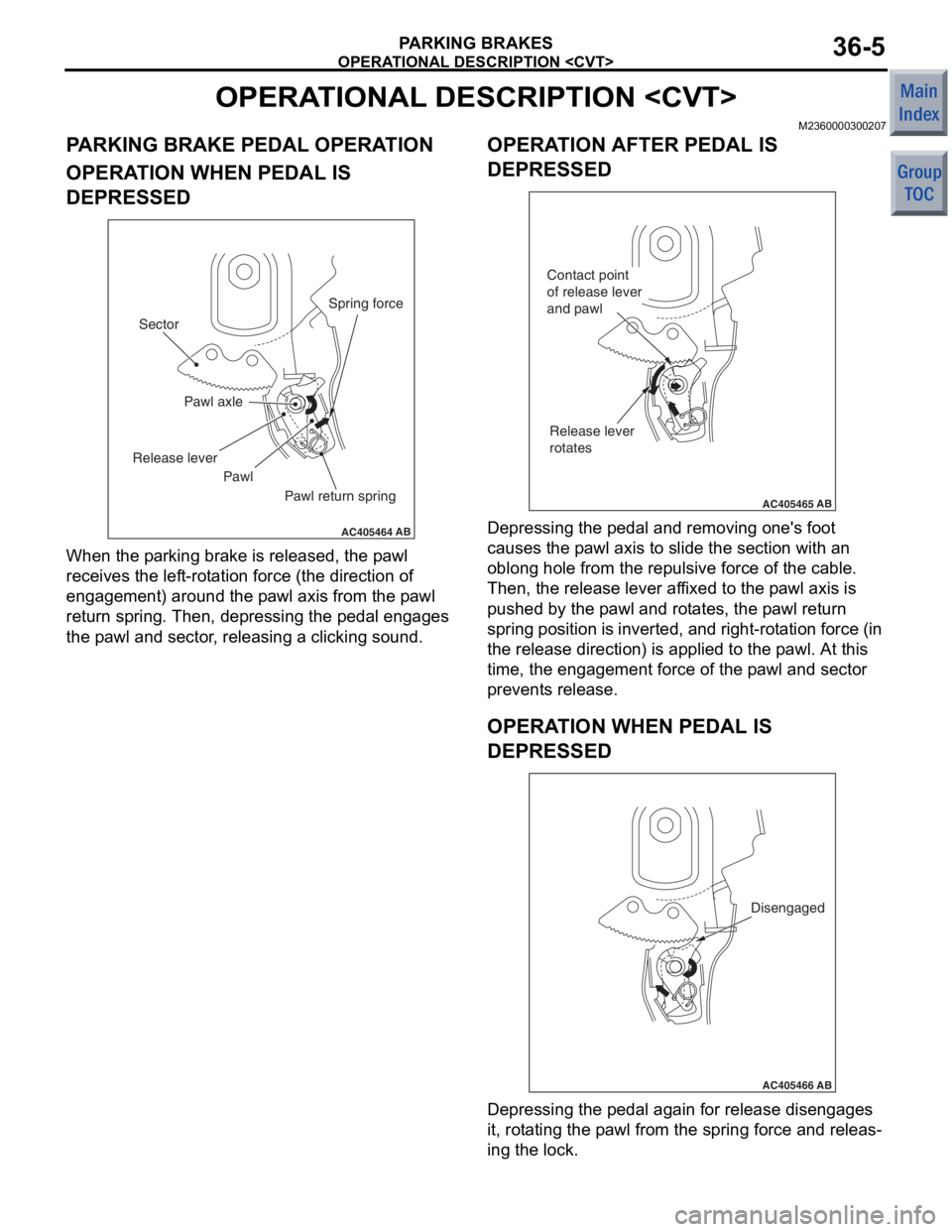

PARKING BRAKE PEDAL OPERATION

OPERATION WHEN PEDAL IS

DEPRESSED

AC405464

Pawl axle

AB

Sector

Release lever

Pawl Pawl return springSpring force

When th

e p a rking bra k e is released, the p a wl

receives the lef

t -rot a tion force (the d i rection o f

engage

ment ) around the p a wl axis from the p a wl

return sprin

g . Then , depre ssing th e peda l eng ages

the p

a wl an d se ctor , relea s ing a clickin g so und.

OPERAT ION AFTER PEDAL IS

DEPRESSED

AC405465

Contact point

of release lever

and pawl

Release lever

rotates

AB

De pressing the pe dal a nd removing on e's fo ot

causes

the p a wl axis to slid e the sect ion with an

oblon

g hole from the re pulsive force of th e cab l e.

Then, t

he release lever af fixe d to th e p a wl axis is

push

ed by the p a wl and rot a te s, the p a wl return

spring position

is inverted, an d r i ght-ro t a t i on force (in

the release dire

ctio n) is appl ied to the p a wl. At this

time

, the e ngage ment force of the p a wl and sect or

preve

n t s release .

OPERAT ION W H EN PEDAL IS

DEPRESSED

AC405466AB

Disengaged

Depressing the pe dal a gain for release disengag es

it, rot

a ting the p a wl from the sprin g force and releas

-

ing the lock.

Page 250 of 364

OPERATIONAL DESCRIPTION

PARKING BRAKES36-6

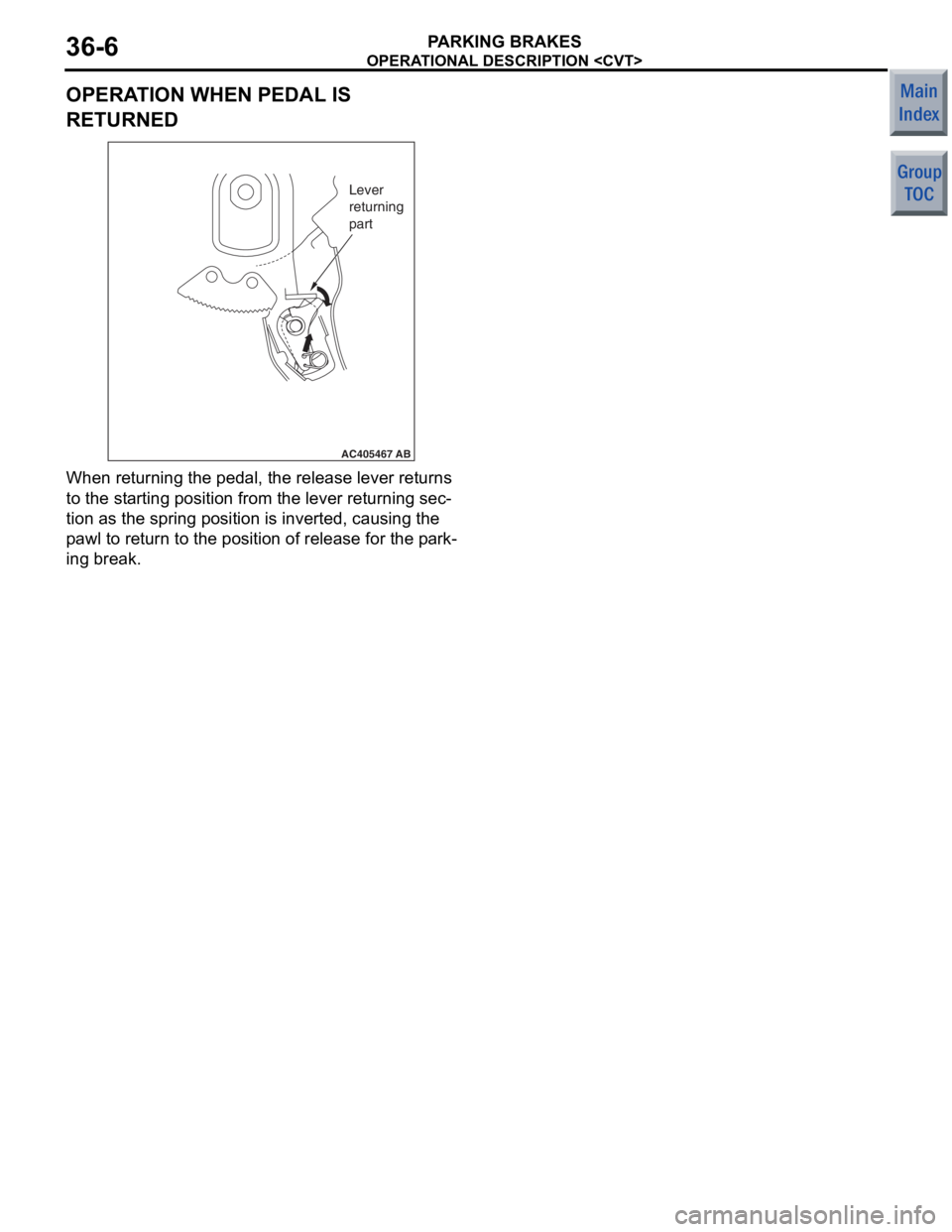

OPERATION WHEN PEDAL IS

RETURNED

AC405467

Lever

returning

part

AB

When returnin g the p edal, the release lever ret u rns

to the st

arting position from the lever returning se c

-

tion as the spring po sition is inverte d , ca using the

p

a wl to retu rn to th e positio n of release for th e p a rk

-

ing br eak.