MITSUBISHI ECLIPSE 1990 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 201 of 391

.-_. -

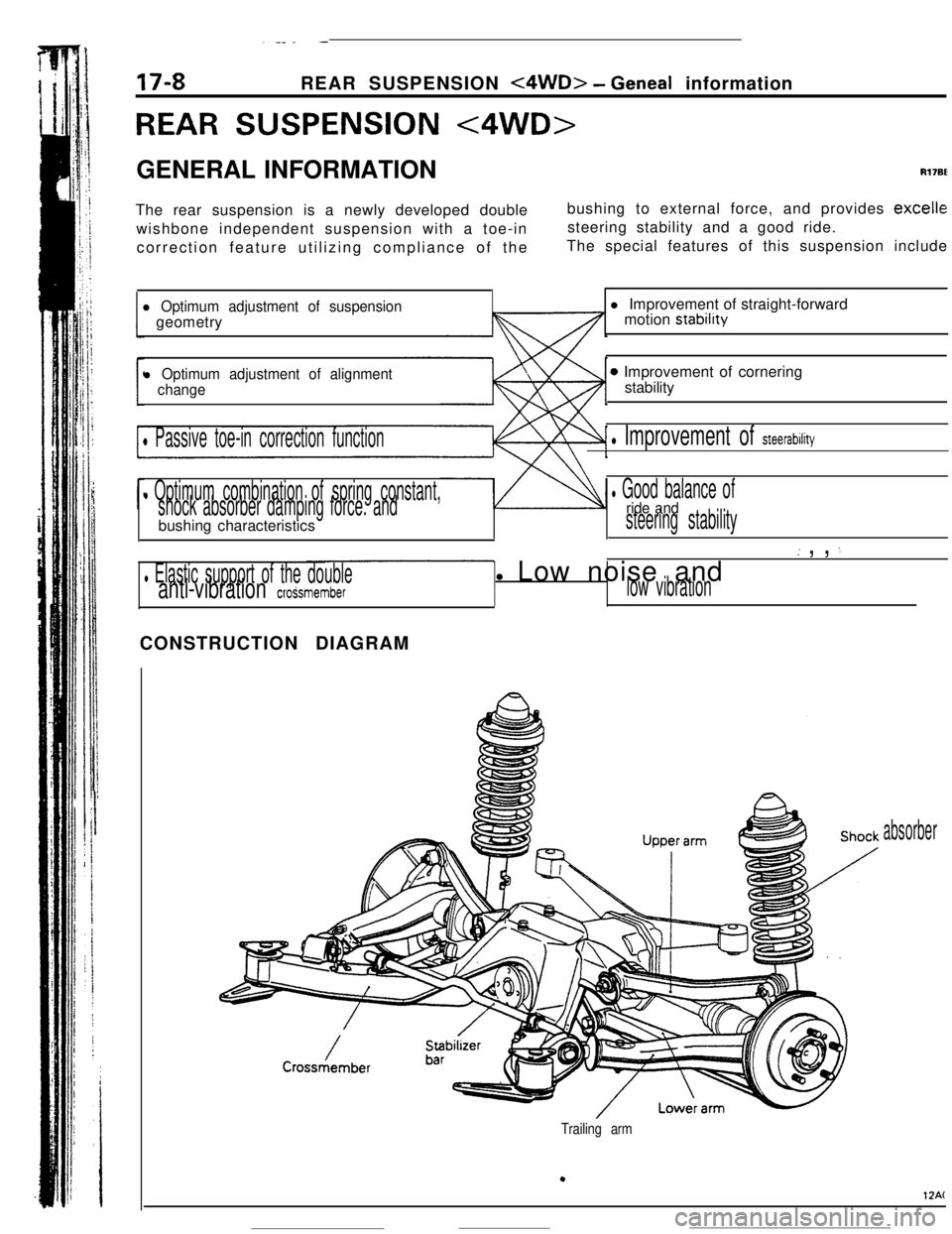

17-8REAR SUSPENSION <4WD> - Geneal information

REAR SUSPENSION <4WD>GENERAL INFORMATION

Rl7BEThe rear suspension is a newly developed double

wishbone independent suspension with a toe-in

correction feature utilizing compliance of thebushing to external force, and provides

excellesteering stability and a good ride.

The special features of this suspension include

l Optimum adjustment of suspensiongeometry

l Optimum adjustment of alignment

change

0 Passive toe-in correction function

l Optimum combination of spring constant,

shock absorber damping force. andbushing characteristics

l Elastic support of the doubleanti-vibration croSsmemberl Improvement of straight-forward

motion stability

0 Improvement of cornering

stability

l Improvement of steerability

l Good balance ofride andsteering stability

( , , :l Low noise and

low vibrationCONSTRUCTION DIAGRAM

absorber

Trailing arm

.

12AC

Page 202 of 391

_ -. ..__ .-

REAR SUSPENSION

<4WD> - Geneal (nformation

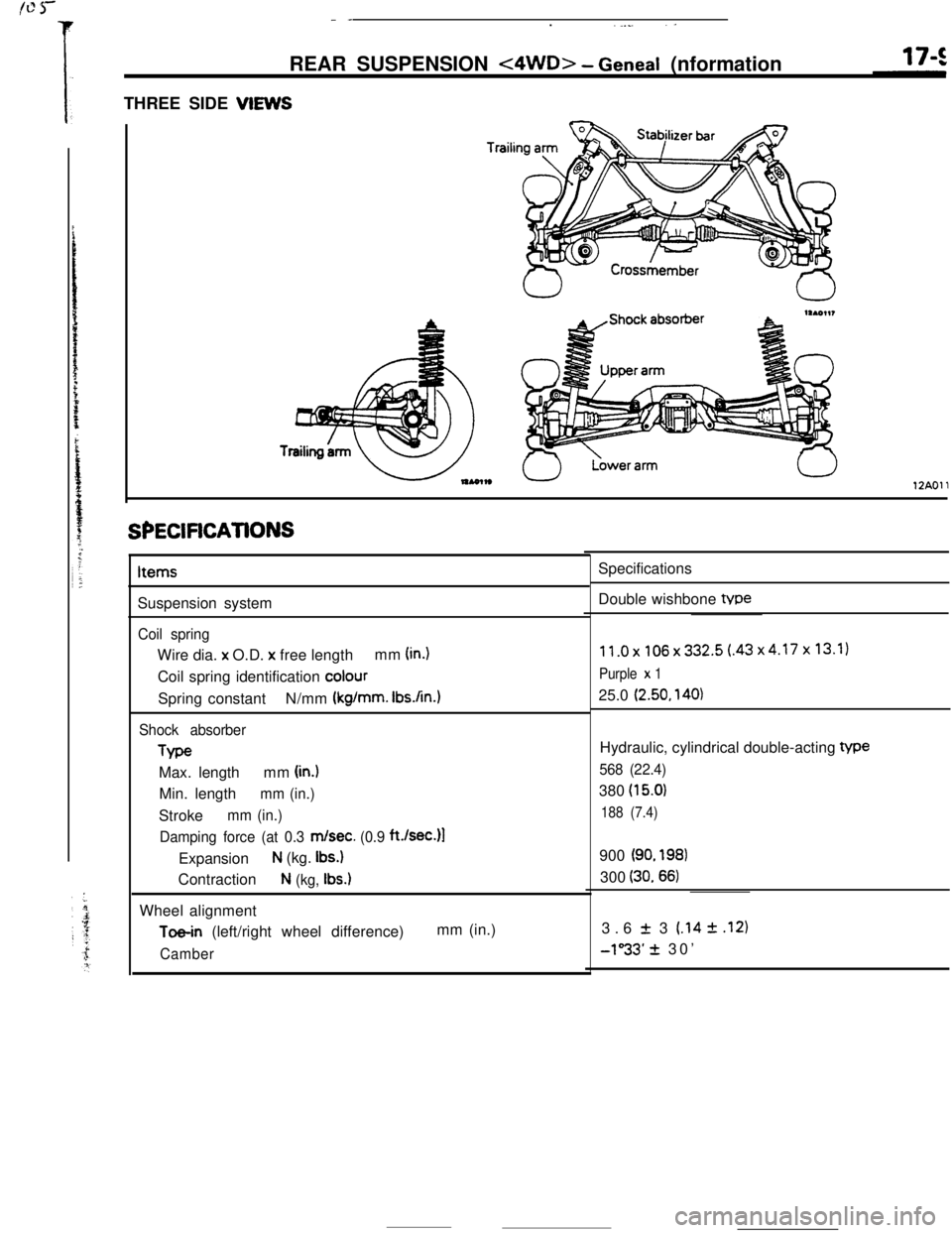

THREE SIDE VIEWS

Trailil

12AOll

SPECiFiCATiONSItems

Suspension system

Coil springWire dia. x O.D.

x free lengthmm (in.)Coil spring identification

colourSpring constantN/mm

(kg/mm. Ibs.An.1

Shock absorberType

Max. lengthmm

(in.)Min. length

mm (in.)Stroke

mm (in.)

Damping force (at 0.3

m/set. (0.9 ft./sec.)l

Expansion

N (kg. Ibs.)Contraction

N (kg, Ibs.)Wheel alignment

Toe-in (left/right wheel difference)mm (in.)

CamberSpecifications

Double wishbone tvpe

11.0x106x332.5(.43x4.17x13.1)

Purple x 125.0

(2.50, 140)Hydraulic, cylindrical double-acting

We

568 (22.4)380

(15.0)

188 (7.4)900

(90. 198)300

(30.66)3.6

f 3 (.14 2 .I21

-1”33’ + 30’

Page 203 of 391

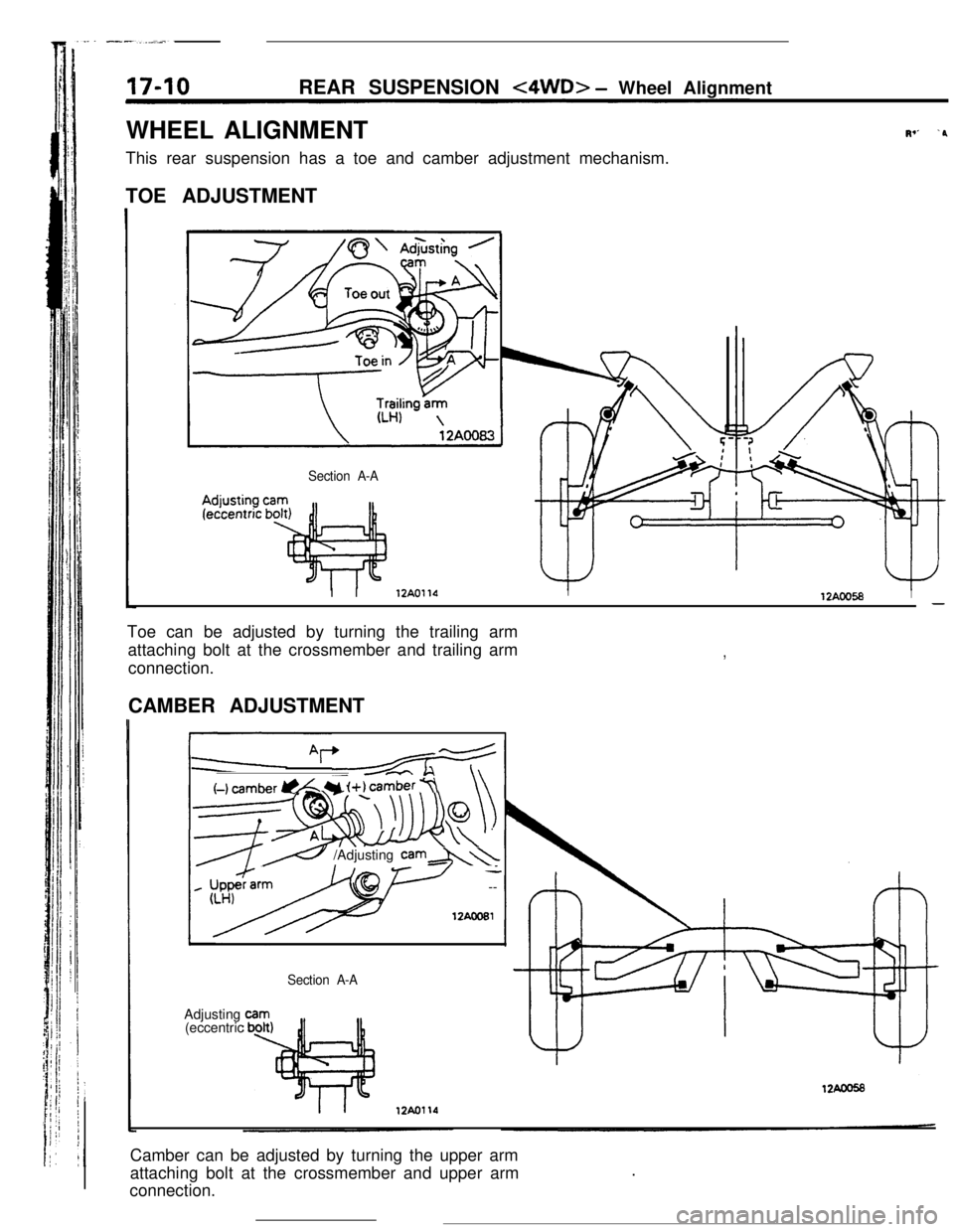

REAR SUSPENSION <4WD> - Wheel Alignment

WHEEL ALIGNMENT

This rear suspension has a toe and camber adjustment mechanism.

TOE ADJUSTMENT

Section A-A

Iv’ ‘PI I

12AOllOI12AOO58I-Toe can be adjusted by turning the trailing arm

attaching bolt at the crossmember and trailing arm

connection.

,CAMBER ADJUSTMENT

I

(-1 cam&r @L Y i+) camber 7\\

__cc \

----7--w

’ --

12AcoEl

e /Adjusting cam&\\Adjusting

(eccentric

Section A-ACamber can be adjusted by turning the upper arm

attaching bolt at the crossmember and upper arm

connection..

Page 204 of 391

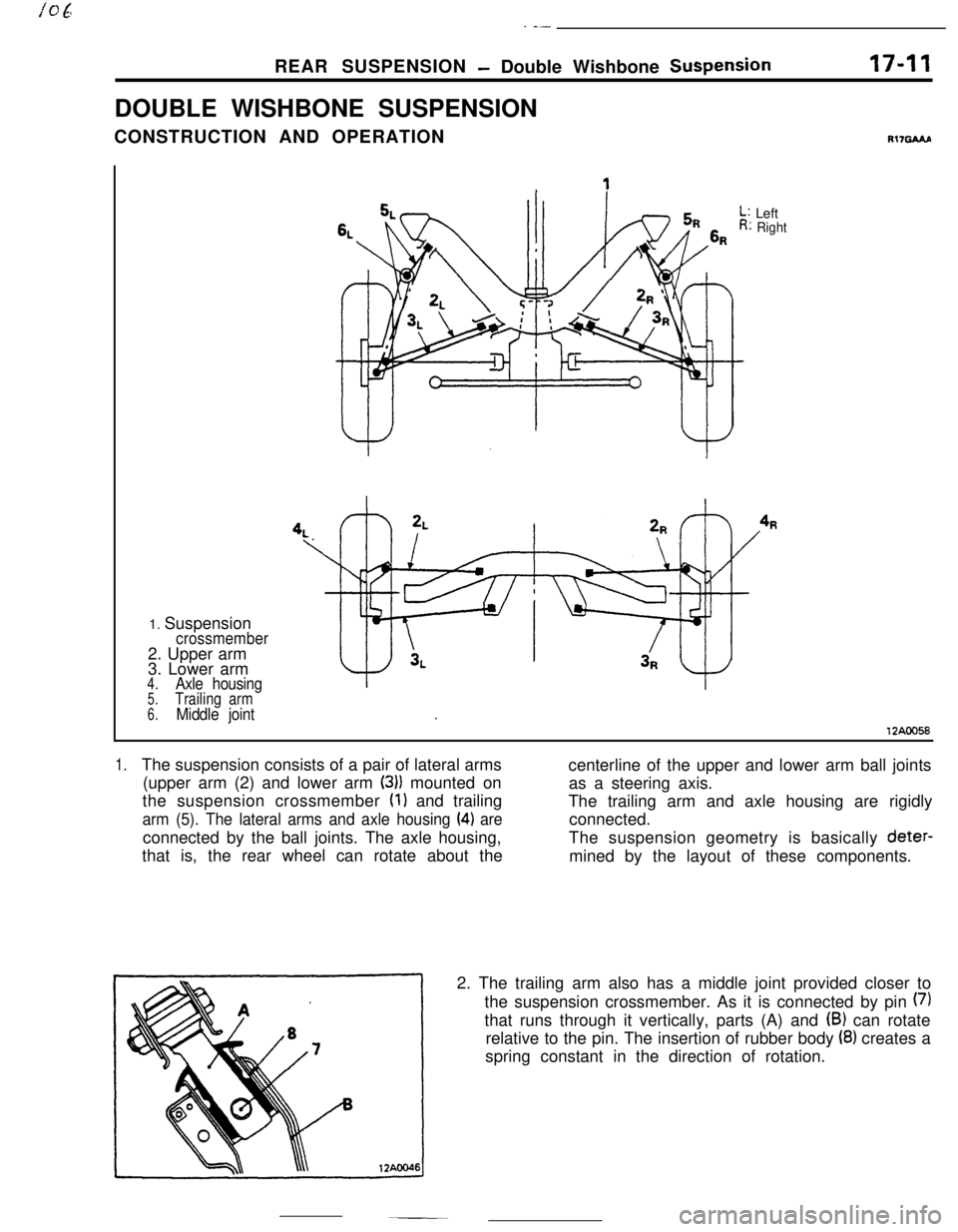

. -.-REAR SUSPENSION

- Double Wishbone SuspensionDOUBLE WISHBONE SUSPENSION

CONSTRUCTION AND OPERATION17-11

R17GAAP1. Suspension

crossmember2. Upper arm

3. Lower arm

4.Axle housing5.Trailing arm

6.Middle jointLeft

Right

12AOO58

1.The suspension consists of a pair of lateral arms

centerline of the upper and lower arm ball joints

(upper arm (2) and lower arm

(3)) mounted on

as a steering axis.

the suspension crossmember

(1) and trailing

The trailing arm and axle housing are rigidly

arm (5). The lateral arms and axle housing (4) areconnected.

connected by the ball joints. The axle housing,The suspension geometry is basically deter-

that is, the rear wheel can rotate about the

mined by the layout of these components.

2. The trailing arm also has a middle joint provided closer to

the suspension crossmember. As it is connected by pin

(7)that runs through it vertically, parts (A) and

(B) can rotate

relative to the pin. The insertion of rubber body

(8) creates a

spring constant in the direction of rotation.

Page 205 of 391

17-12REAR SUSPENSION - Double Wishbone Suspension

12AWY

lZAOOS!

When cornering. I.to the right

I Toe-inToe angle

ReboundBump-

PositiveCamber(to body)

- Camber to ground: 0

Bump

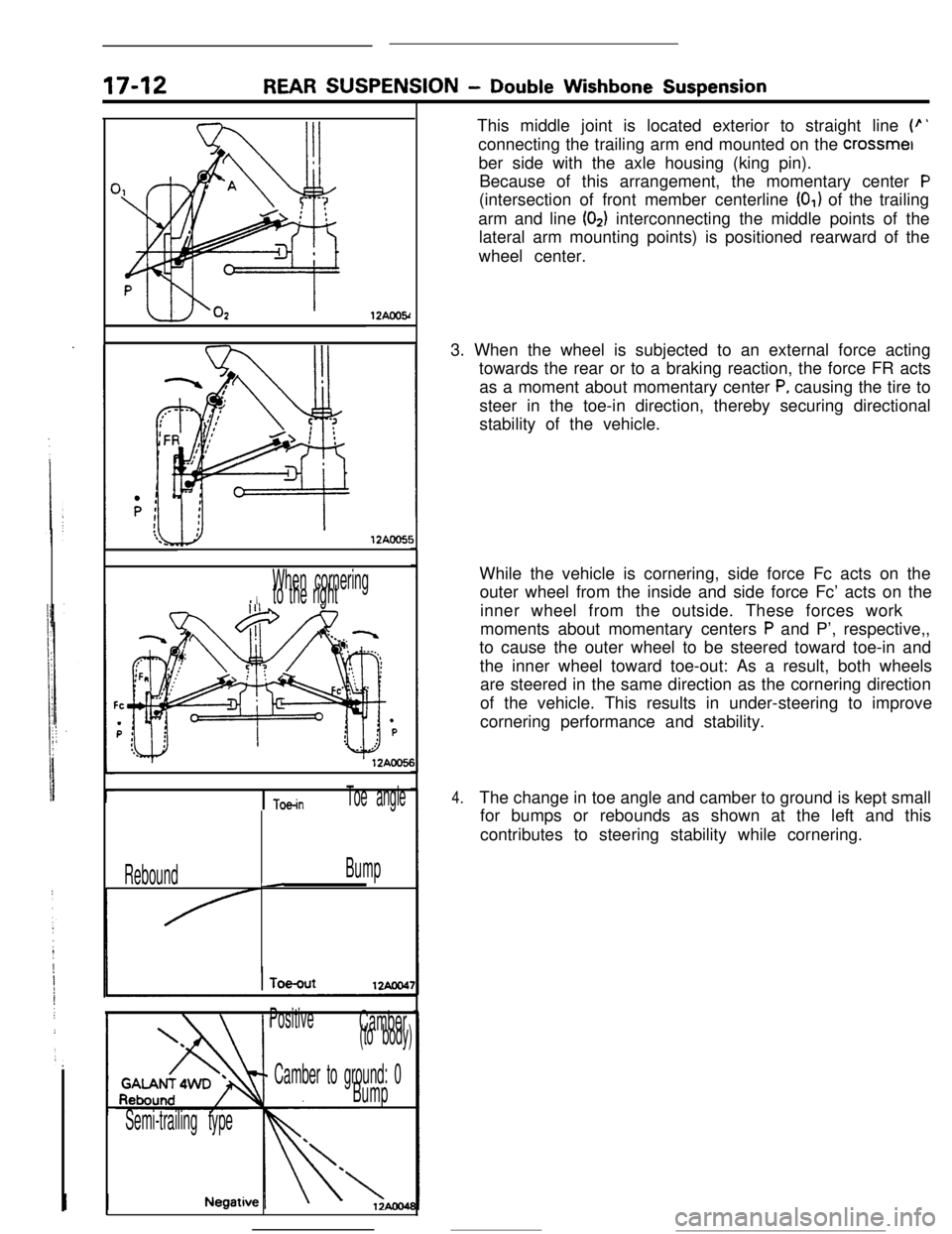

Semi-trailing typeThis middle joint is located exterior to straight line

(p’connecting the trailing arm end mounted on the crossmet

ber side with the axle housing (king pin).

Because of this arrangement, the momentary center

P(intersection of front member centerline

(0,) of the trailing

arm and line

(02) interconnecting the middle points of the

lateral arm mounting points) is positioned rearward of the

wheel center.

3. When the wheel is subjected to an external force acting

towards the rear or to a braking reaction, the force FR acts

as a moment about momentary center

P, causing the tire to

steer in the toe-in direction, thereby securing directional

stability of the vehicle.

While the vehicle is cornering, side force Fc acts on the

outer wheel from the inside and side force Fc’ acts on the

inner wheel from the outside. These forces work

moments about momentary centers

P and P’, respective,,

to cause the outer wheel to be steered toward toe-in and

the inner wheel toward toe-out: As a result, both wheels

are steered in the same direction as the cornering direction

of the vehicle. This results in under-steering to improve

cornering performance and stability.

4.The change in toe angle and camber to ground is kept small

for bumps or rebounds as shown at the left and this

contributes to steering stability while cornering.

Page 206 of 391

-

REAR SUSPENSION -Double Wishbone Suspension17-13

Member supponbushingI

12AOO5

Upper arm

Link diagram of ordinarydouble wishbone suspension system

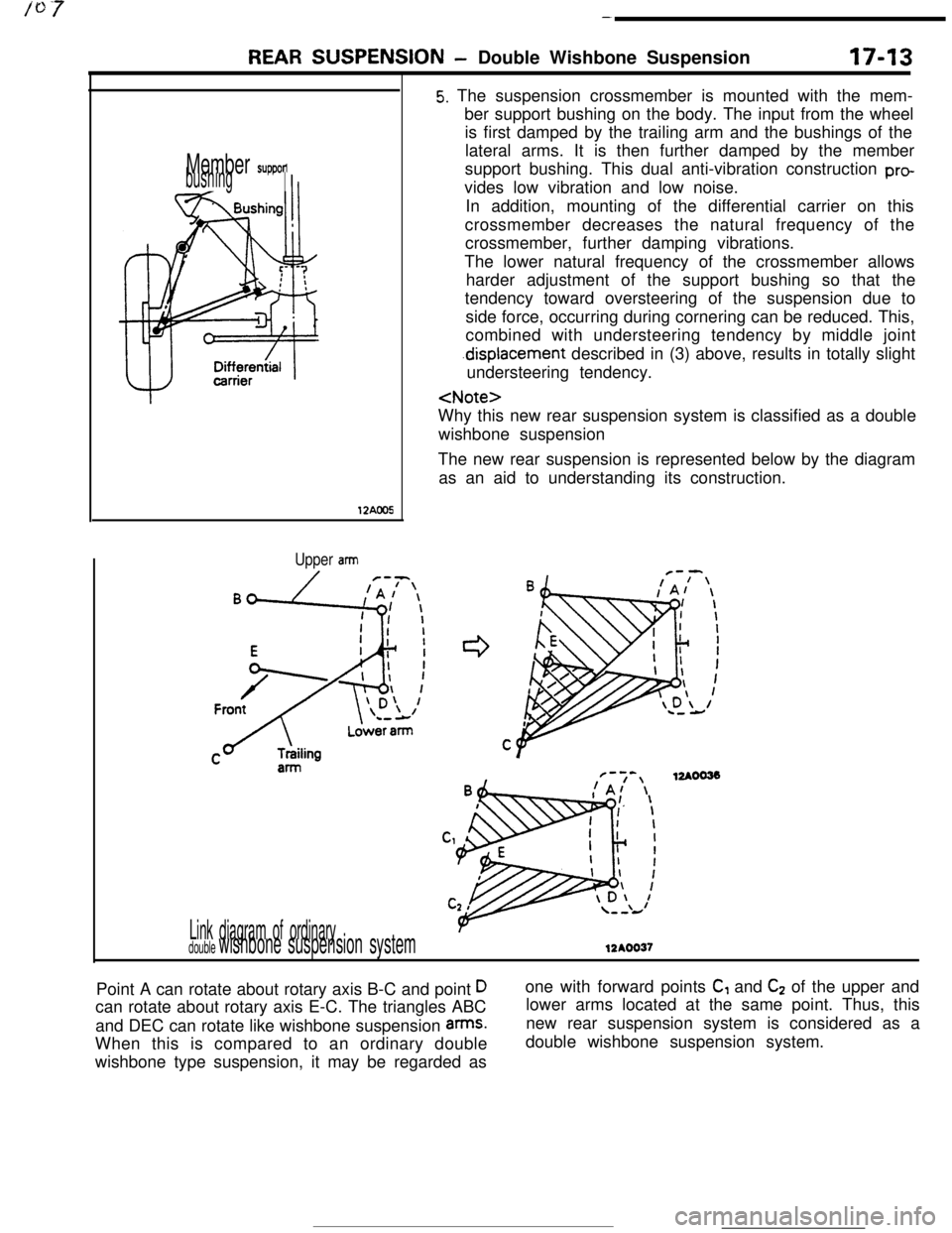

5. The suspension crossmember is mounted with the mem-

ber support bushing on the body. The input from the wheel

is first damped by the trailing arm and the bushings of the

lateral arms. It is then further damped by the member

support bushing. This dual anti-vibration construction

provides low vibration and low noise.

In addition, mounting of the differential carrier on this

crossmember decreases the natural frequency of the

crossmember, further damping vibrations.

The lower natural frequency of the crossmember allows

harder adjustment of the support bushing so that the

tendency toward oversteering of the suspension due to

side force, occurring during cornering can be reduced. This,

combined with understeering tendency by middle joint

.displacement described in (3) above, results in totally slight

understeering tendency.

wishbone suspension

The new rear suspension is represented below by the diagram

as an aid to understanding its construction.

F-7-,12AOO33!A/ \

12AOO37Point A can rotate about rotary axis B-C and point

Dcan rotate about rotary axis E-C. The triangles ABC

and DEC can rotate like wishbone suspension

arms.When this is compared to an ordinary double

wishbone type suspension, it may be regarded asone with forward points

C, and C2 of the upper and

lower arms located at the same point. Thus, this

new rear suspension system is considered as a

double wishbone suspension system.

Page 207 of 391

17-14REAR SUSPENSION - Double Wishbone Suwension

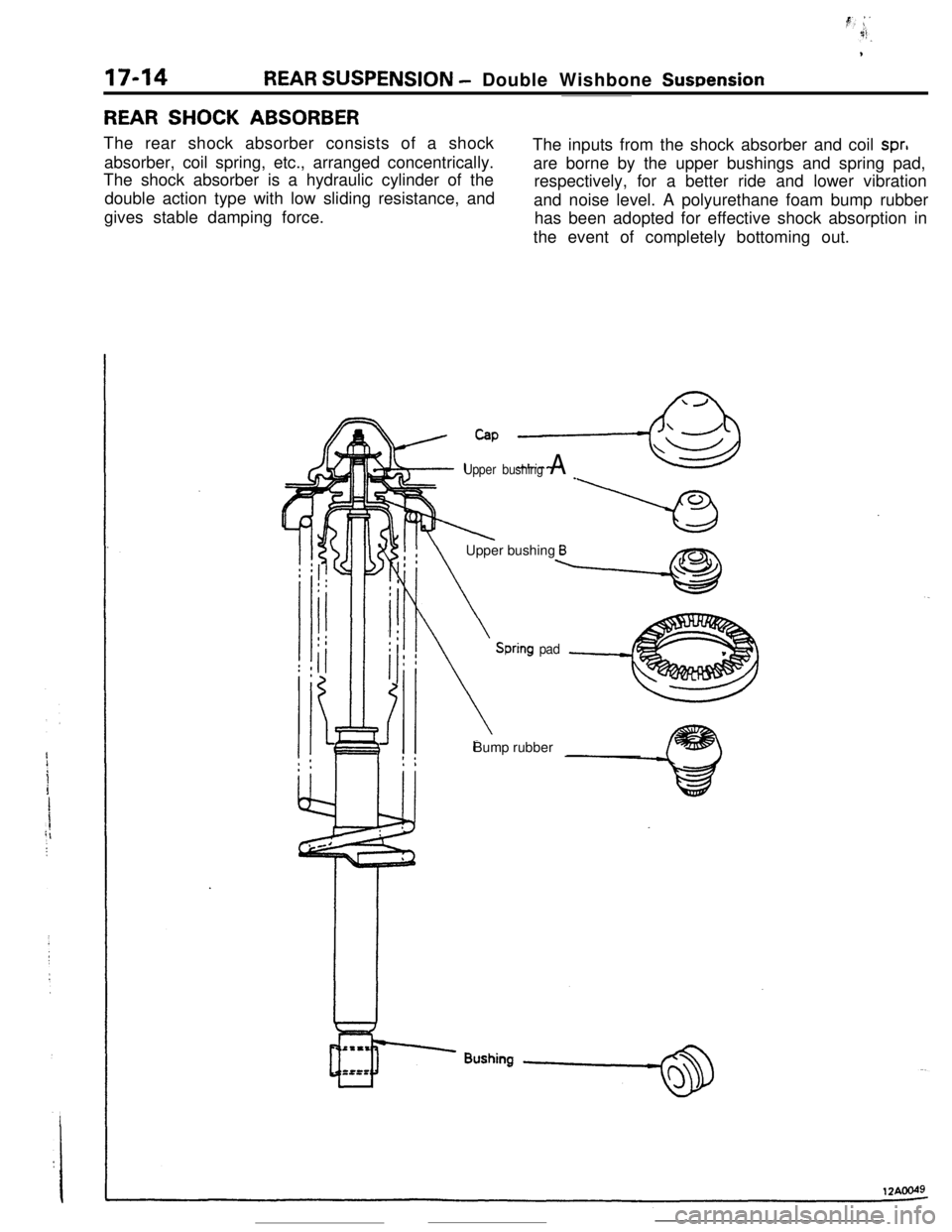

REAR SHOCK ABSORBERThe rear shock absorber consists of a shock

absorber, coil spring, etc., arranged concentrically.

The shock absorber is a hydraulic cylinder of the

double action type with low sliding resistance, and

gives stable damping force.The inputs from the shock absorber and coil

spr,are borne by the upper bushings and spring pad,

respectively, for a better ride and lower vibration

and noise level. A polyurethane foam bump rubber

has been adopted for effective shock absorption in

the event of completely bottoming out.

Cap ,-&

Upper bushing A _

IlXk!! \Upper bushing Bx?nb

Spring padBump rubber

Page 208 of 391

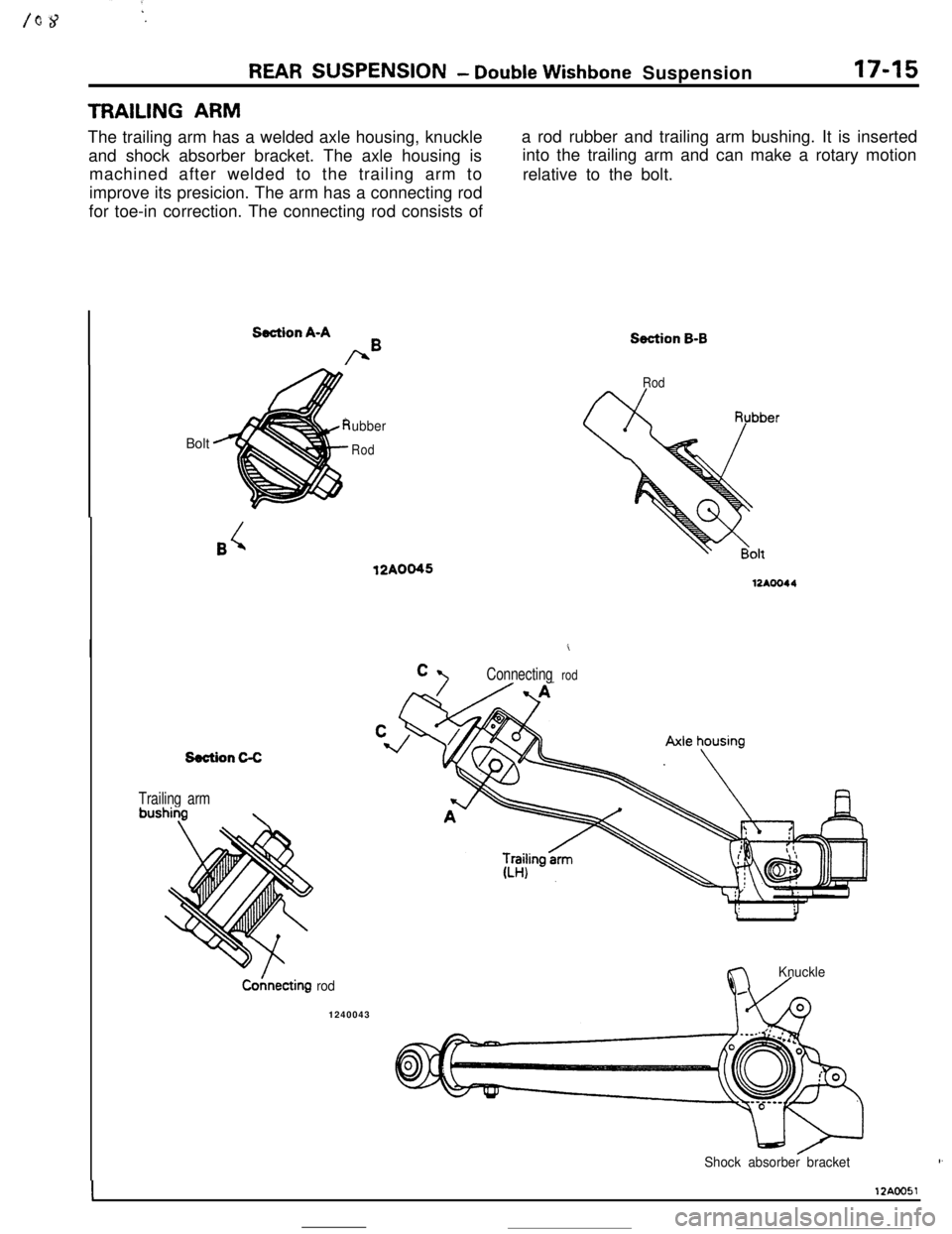

REAR SUSPENSION- Double Wishbone Suspension17-15TRAILING ARM

The trailing arm has a welded axle housing, knuckle

and shock absorber bracket. The axle housing is

machined after welded to the trailing arm to

improve its presicion. The arm has a connecting rod

for toe-in correction. The connecting rod consists ofa rod rubber and trailing arm bushing. It is inserted

into the trailing arm and can make a rotary motion

relative to the bolt.

Section A-A

bBBolt

ubber

RodRod12A0045

Ii

Connecting rod

Section C-C

Trailing armbushiyg

\Co;lnecting

rod1240043

Section B-B

Knuckleii-l /

Shock absorber bracket,,

I12ACO51

Page 209 of 391

1

1746REAR SUSPENSION - Double Wishbone Suspension

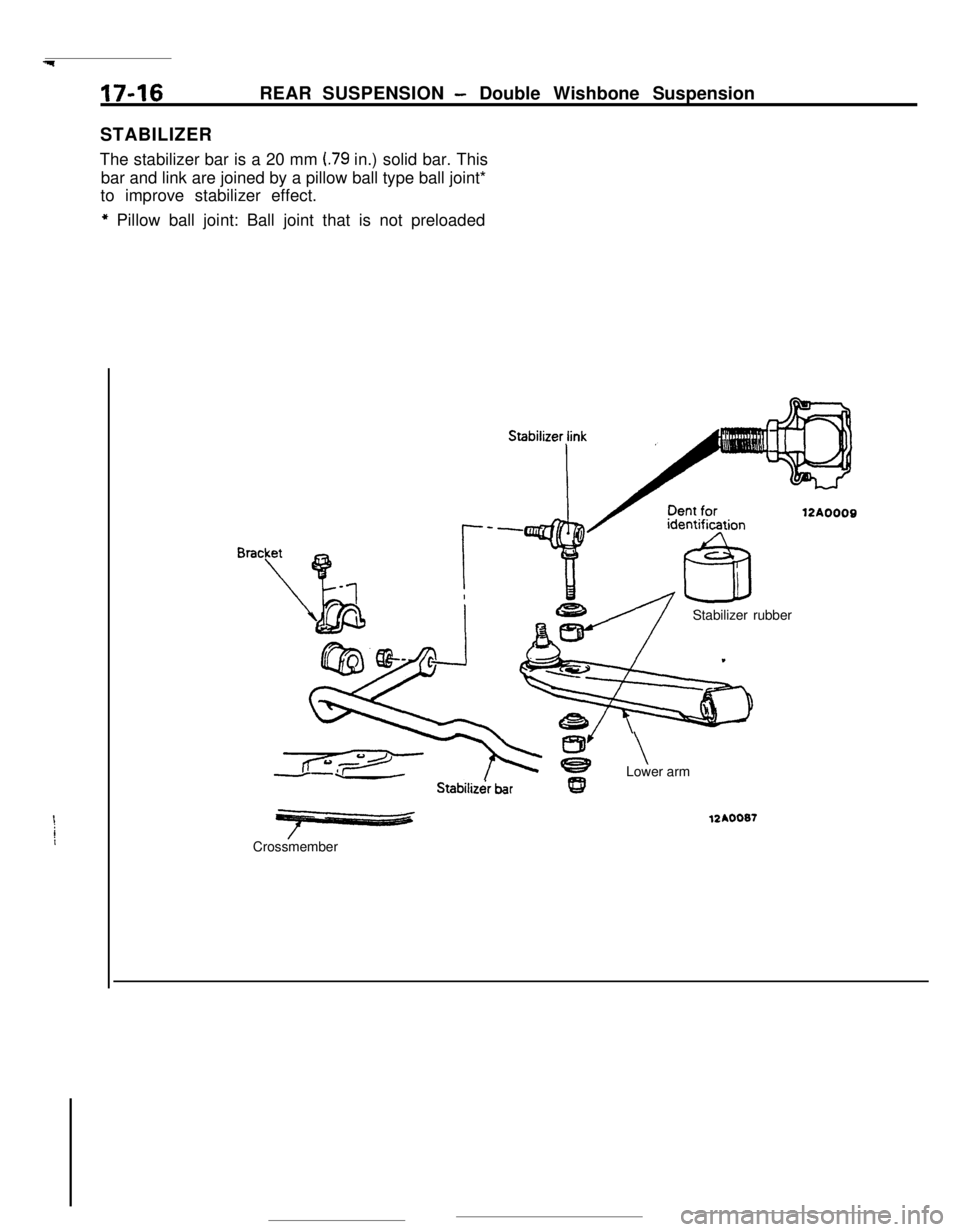

STABILIZER

The stabilizer bar is a 20 mm

I.79 in.) solid bar. This

bar and link are joined by a pillow ball type ball joint*

to improve stabilizer effect.

* Pillow ball joint: Ball joint that is not preloaded

12A0009

!!IStabilizer rubberStabiliz&

barCrossmemberz

\Lower arm

12A0087

Page 210 of 391

19-I

POWER

_

GENERAL INFORMATION

.._ . . . . .

OIL PUMP ........................................................10POWER STEERING GEAR BOX