MITSUBISHI ECLIPSE 1990 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 161 of 391

FUEL SYSTEM -Idle Speed Control14-49

Servo ControlServo control includes feedback control and position

ontrol. In feedback control, the engine control uniti;onstantly calculates the actual idle speed, and if

the

value differs from the target idle speed, the unit

drives the stepper motor to adjust actual speed to

Feedback ControlWhile the engine runs at idle speed, the stepper

motor is activated to keep the engine speed at the

preset target idle speed by controlling the bypass air

volume.

The target idle speed that is optimum for each

operating condition (including air conditioner switch

ON/OFF) has been preset. This engine speed

feedback control is provided under stabilized idling

conditions and not when any of the following

conditions occur.

l When the vehicle is moving at 2.5 km/h (1.6

mph) or more.the target value. In position control, the idle speed

control

is adjusted to the target position to cope

with air conditioner and other load changes. Position

control is also performed when cranking the engine

and decelerating.

lWhen the idle switch is turned from OFF to ON,

and while the idle switch is in the OFF position.

lWhen the air conditioner switch is turned from

ON to OFF, or vice versa.

l When power steering oil pressure switch is

turned from ON to OFF, or vice versa.

l When the ignition switch is turned from ST to

IG, or vice versa.

l While the dash pot control is in operation.

lWhen the inhibitor switch is switched from “N”

range to “D” range or vice versa.

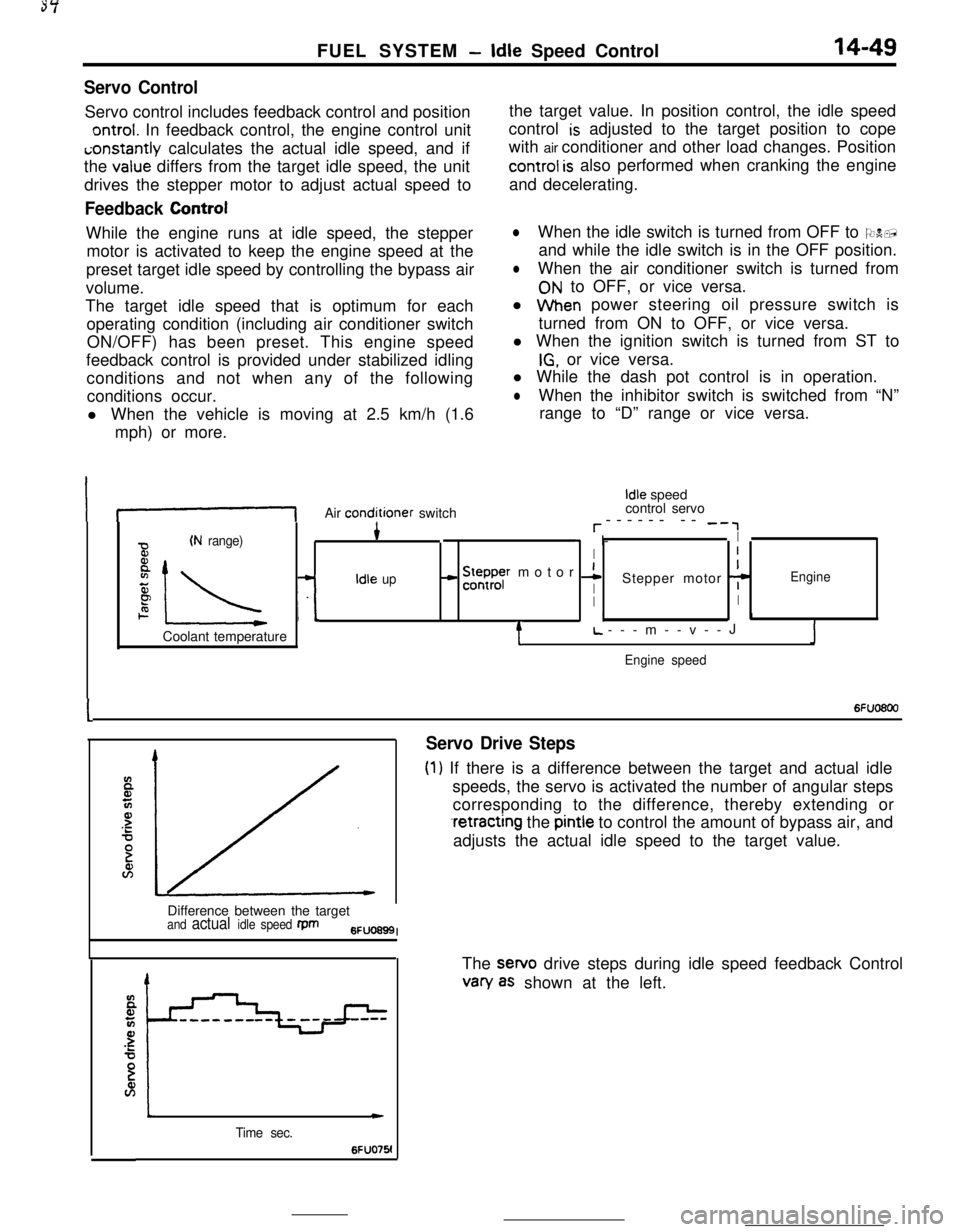

If-1Air conditioner switch

Idle speed

control servo

r------ -- -‘,

(N range)4* I-I

BI

8

IL -L

- !5ysr motor 1I

zIdle upIStepper motor 7Engine

PII2. I.1Coolant temperature

tL.---m--v--JJ

Engine speed

I6Fuo6oo

Servo Drive Steps

(1) If there is a difference between the target and actual idle

speeds, the servo is activated the number of angular steps

corresponding to the difference, thereby extending or

.retracting the pintle to control the amount of bypass air, and

adjusts the actual idle speed to the target value.

Difference between the target

and actual idle speed fpm6FUO699I

Time sec.

c

6FUO76!The sewo drive steps during idle speed feedback Control

van/ as shown at the left.

Page 162 of 391

14-50FUEL SYSTEM- Idle Speed Control

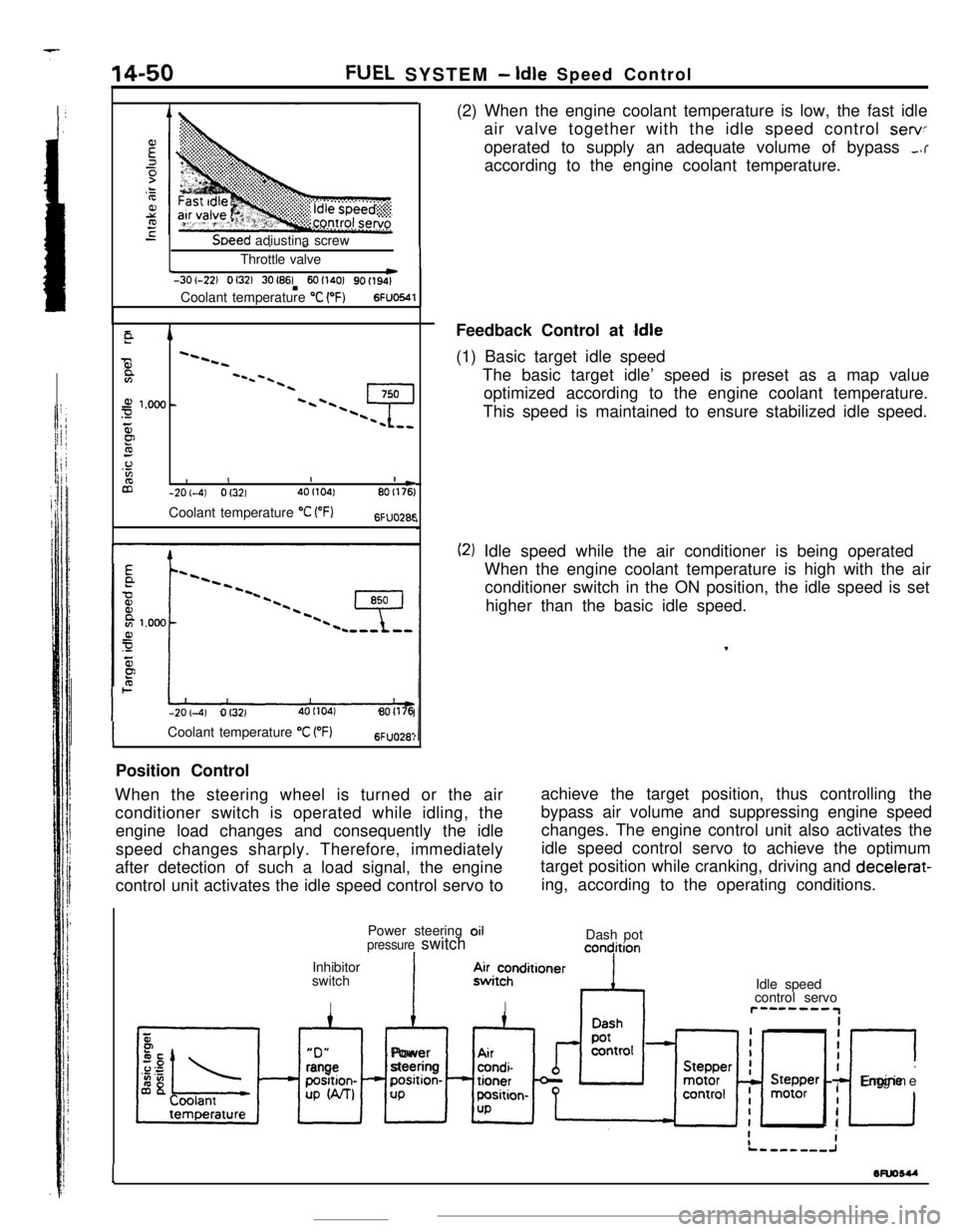

SDeed adiustina screwI -Throttle valve

Lw-3O(-22) 0132) 30(86! 601140) 9ofl94)Coolant temperature

“C (OF)6FUO641

E94

72--2--I

Q--.-.-z

3201.000 --4-\-\

5P9.o%IIIaI L-2O(-41 Of3214Of104)801176)Coolant temperature

“C VF)6FU028E

-201-4) Of3214OI104180(176(2) When the engine coolant temperature is low, the fast idle

air valve together with the idle speed control

servoperated to supply an adequate volume of bypass

,.raccording to the engine coolant temperature.

Feedback Control at

Idle(1) Basic target idle speed

The basic target idle’ speed is preset as a map value

optimized according to the engine coolant temperature.

This speed is maintained to ensure stabilized idle speed.

(2) Idle speed while the air conditioner is being operated

When the engine coolant temperature is high with the air

conditioner switch in the ON position, the idle speed is set

higher than the basic idle speed.

,

ICoolant temperature “C VF)6FUO28:Position Control

When the steering wheel is turned or the air

conditioner switch is operated while idling, theachieve the target position, thus controlling the

engine load changes and consequently the idlebypass air volume and suppressing engine speed

changes. The engine control unit also activates the

speed changes sharply. Therefore, immediately

after detection of such a load signal, the engine

control unit activates the idle speed control servo toidle speed control servo to achieve the optimum

target position while cranking, driving and decelerat-

ing, according to the operating conditions.

Power steering oil

pressure switchIInhibitor

switch

IDash pot

concjition“D”

xl

rangeposition-

UP W-U

IAlPower

steeringposition-

UP.4~i~hnditioner

IIdle speed

control servor”--““IiiI

I

c

IEngine

I

I

1wuosu

-

Page 163 of 391

FUEL SYSTEM -Idle Speed Control14-51

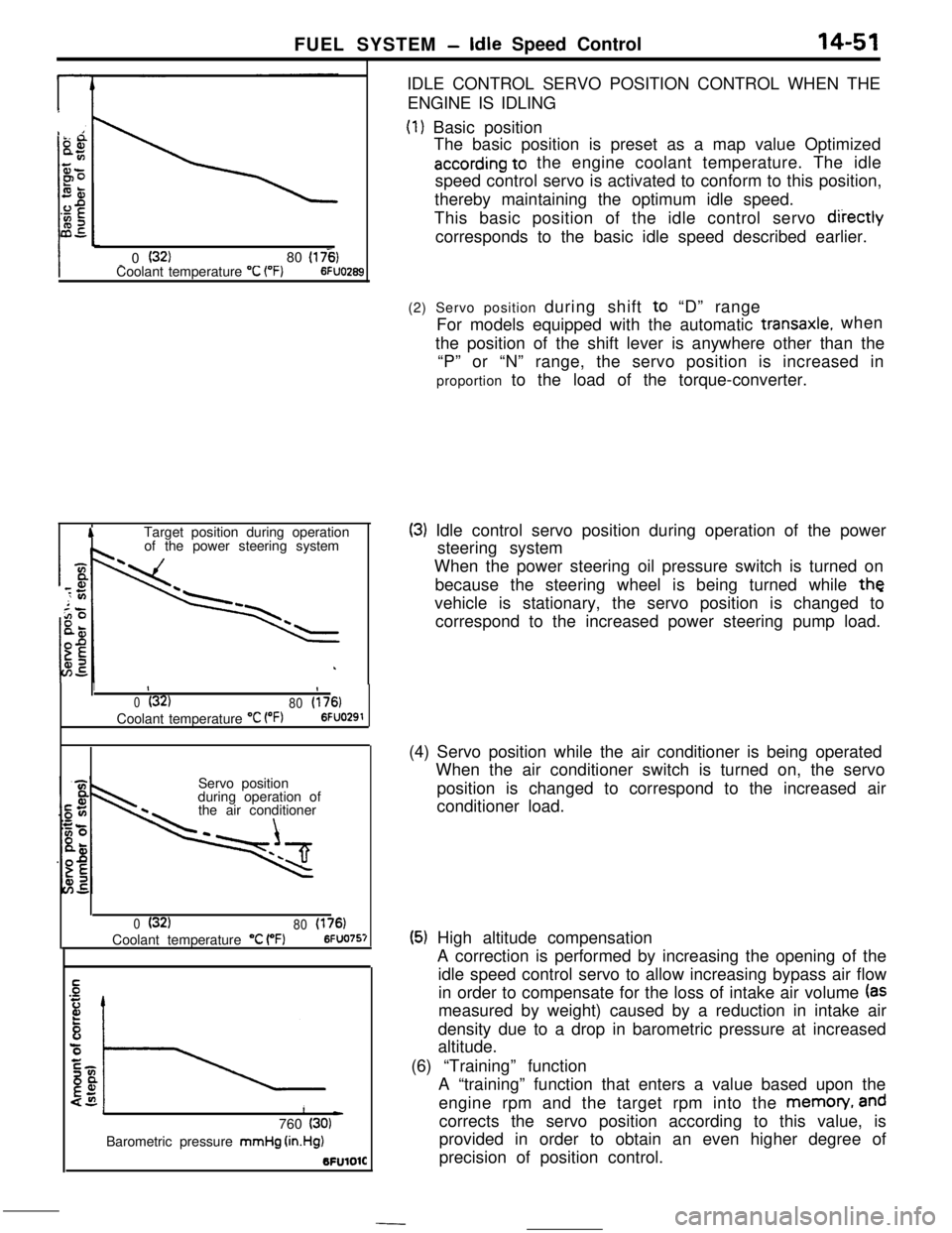

_ 0 (32)80 (175)Coolant temperature “C (“F)6FUO2653

ATarget position during operation

of the power steering systemIDLE CONTROL SERVO POSITION CONTROL WHEN THE

ENGINE IS IDLING

(1) Basic position

The basic position is preset as a map value Optimized

according to the engine coolant temperature. The idle

speed control servo is activated to conform to this position,

thereby maintaining the optimum idle speed.

This basic position of the idle control servo

diiectlycorresponds to the basic idle speed described earlier.

1II

0(32)

80(176)Coolant temperature

“C VW6FUO291Servo position

during operation of

the air conditioner

0(32)

80(176)Coolant temperature “C (“F)6FUO757

1L)760 (30)Barometric pressure mmHg

(in.Hg)BFUlOlC(2) Servo position during shift to “D” range

For models equipped with the automatic

transaxle.when

the position of the shift lever is anywhere other than the

“P” or “N” range, the servo position is increased in

proportion to the load of the torque-converter.

(3) Idle control servo position during operation of the power

steering system

When the power steering oil pressure switch is turned on

because the steering wheel is being turned while

thevehicle is stationary, the servo position is changed to

correspond to the increased power steering pump load.

(4) Servo position while the air conditioner is being operated

When the air conditioner switch is turned on, the servo

position is changed to correspond to the increased air

conditioner load.

(5) High altitude compensation

A correction is performed by increasing the opening of the

idle speed control servo to allow increasing bypass air flow

in order to compensate for the loss of intake air volume

(asmeasured by weight) caused by a reduction in intake air

density due to a drop in barometric pressure at increased

altitude.

(6) “Training” function

A “training” function that enters a value based upon the

engine rpm and the target rpm into the memon/,

andcorrects the servo position according to this value, is

provided in order to obtain an even higher degree of

precision of position control.

Page 164 of 391

--

14-52FUEL SYSTEM - Idle Speed Control

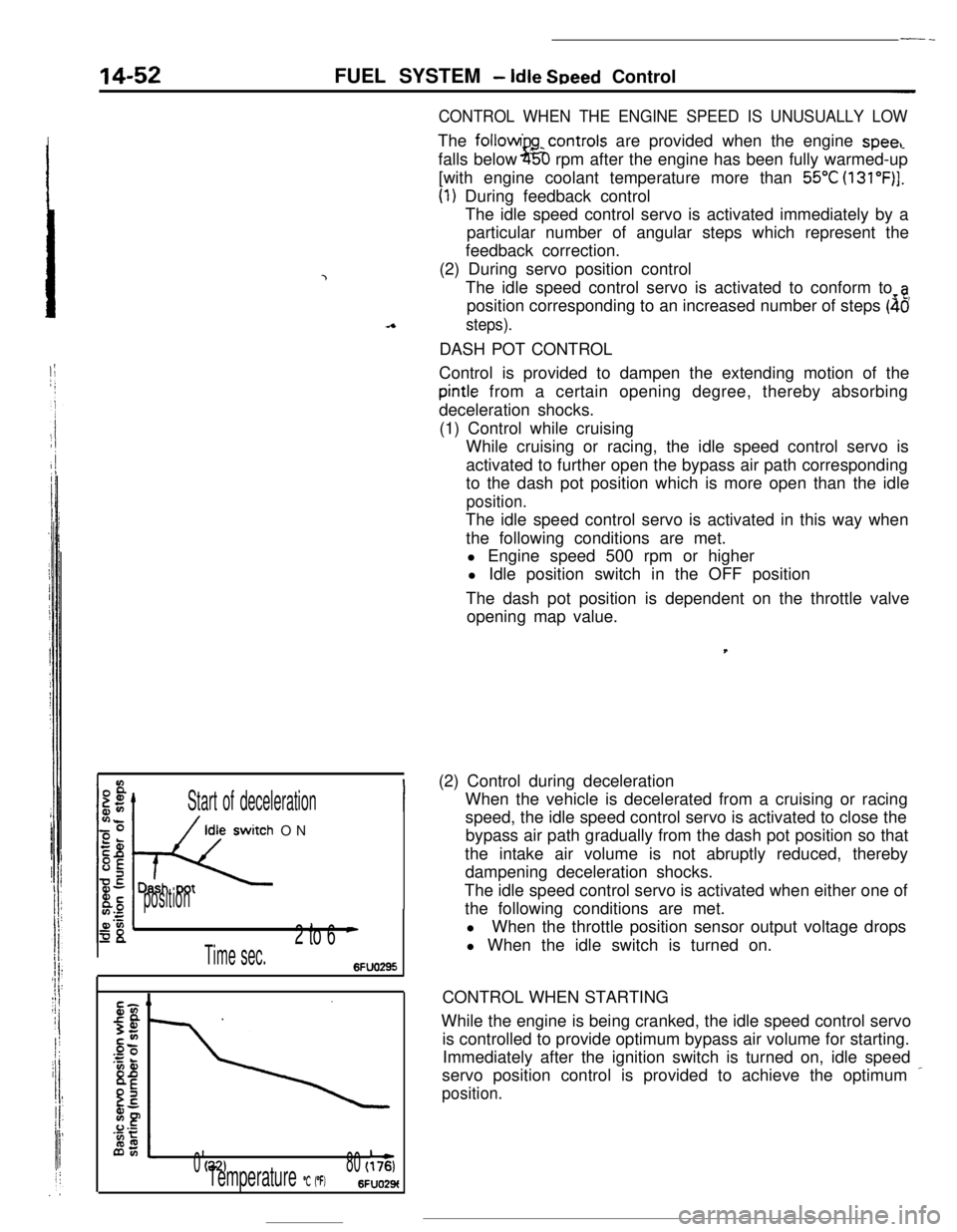

4

Start of deceleration

DLhq ON

position

I*2 to 6

Time sec.6FUO295

II)

0(32180(176)Temperature “C 1°F)6FUO29t

CONTROL WHEN THE ENGINE SPEED IS UNUSUALLY LOWThe followi

gcontrols are provided when the engine speecfalls below

i5;D rpm after the engine has been fully warmed-up

[with engine coolant temperature more than

55°C (131”F)].

(1) During feedback control

The idle speed control servo is activated immediately by a

particular number of angular steps which represent the

feedback correction.

(2) During servo position control

The idle speed control servo is activated to conform to

aposition corresponding to an increased number of steps

(46

steps).DASH POT CONTROL

Control is provided to dampen the extending motion of the

pintle from a certain opening degree, thereby absorbing

deceleration shocks.

(1) Control while cruising

While cruising or racing, the idle speed control servo is

activated to further open the bypass air path corresponding

to the dash pot position which is more open than the idle

position.The idle speed control servo is activated in this way when

the following conditions are met.

l Engine speed 500 rpm or higher

l Idle position switch in the OFF position

The dash pot position is dependent on the throttle valve

opening map value.,

(2) Control during deceleration

When the vehicle is decelerated from a cruising or racing

speed, the idle speed control servo is activated to close the

bypass air path gradually from the dash pot position so that

the intake air volume is not abruptly reduced, thereby

dampening deceleration shocks.

The idle speed control servo is activated when either one of

the following conditions are met.

lWhen the throttle position sensor output voltage drops

l When the idle switch is turned on.

CONTROL WHEN STARTING

While the engine is being cranked, the idle speed control servo

is controlled to provide optimum bypass air volume for starting.

Immediately after the ignition switch is turned on, idle speed

servo position control is provided to achieve the optimum

_

position.

Page 165 of 391

FUEL SYSTEM -Idle Speed Control I Power Supply Control14-53

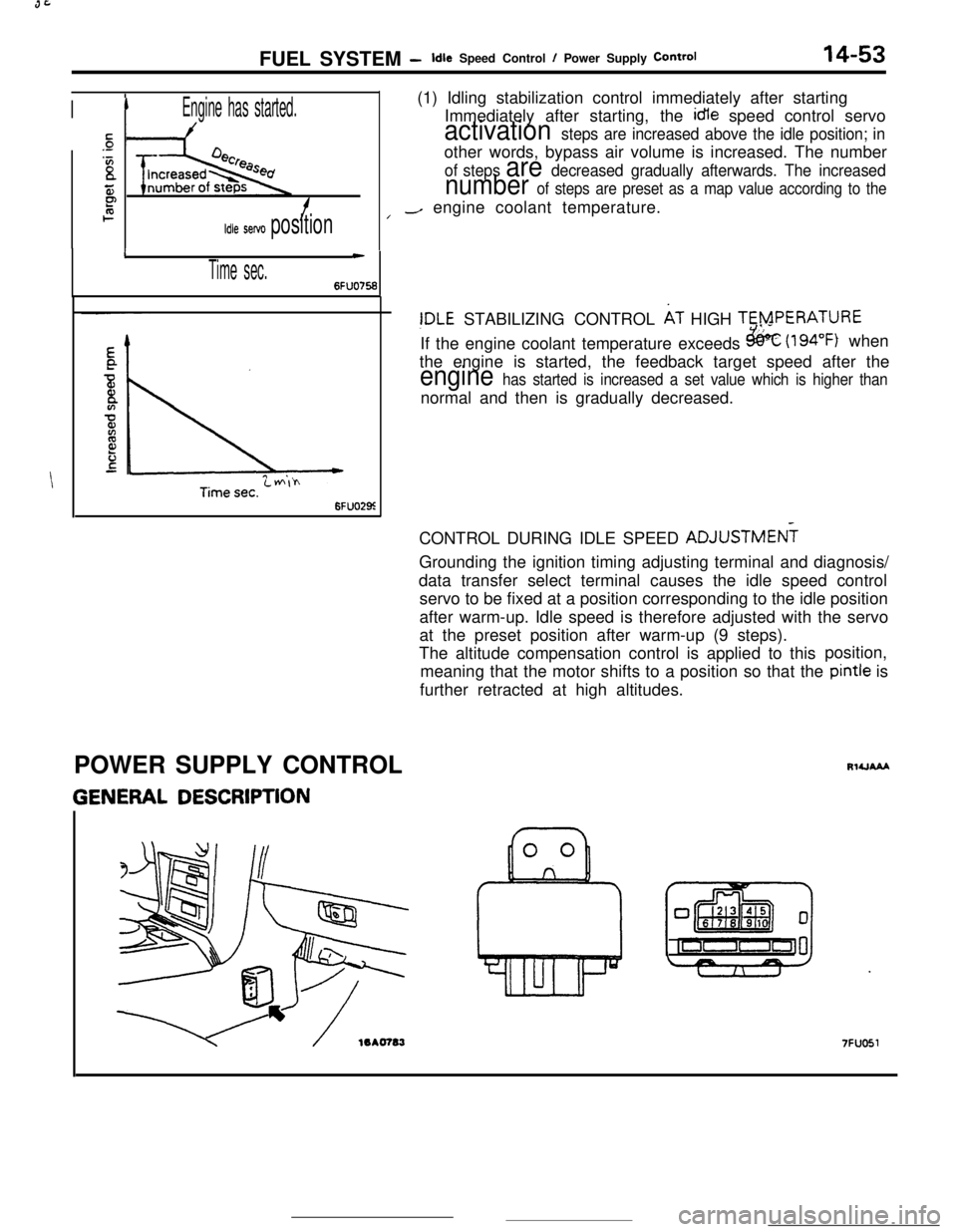

IIEngine has started.(1) Idling stabilization control immediately after starting

Immediately after starting, the idle speed control servo

sactivation steps are increased above the idle position; in.-

‘Bother words, bypass air volume is increased. The numberof steps are decreased gradually afterwards. The increased

55number of steps are preset as a map value according to theP2f/-/ engine coolant temperature.

Idle servo position

I

Time sec.

c

6FUO756

6FUO29z

!DLE STABILIZING CONTROL AT HIGH TERPERATURE

If the engine coolant temperature exceeds

&k (194°F) when

the engine is started, the feedback target speed after the

engine has started is increased a set value which is higher thannormal and then is gradually decreased.

CONTROL DURING IDLE SPEED ADJUSTMEN?

Grounding the ignition timing adjusting terminal and diagnosis/

data transfer select terminal causes the idle speed control

servo to be fixed at a position corresponding to the idle position

after warm-up. Idle speed is therefore adjusted with the servo

at the preset position after warm-up (9 steps).

The altitude compensation control is applied to thisposition,

meaning that the motor shifts to a position so that the pintle is

further retracted at high altitudes.

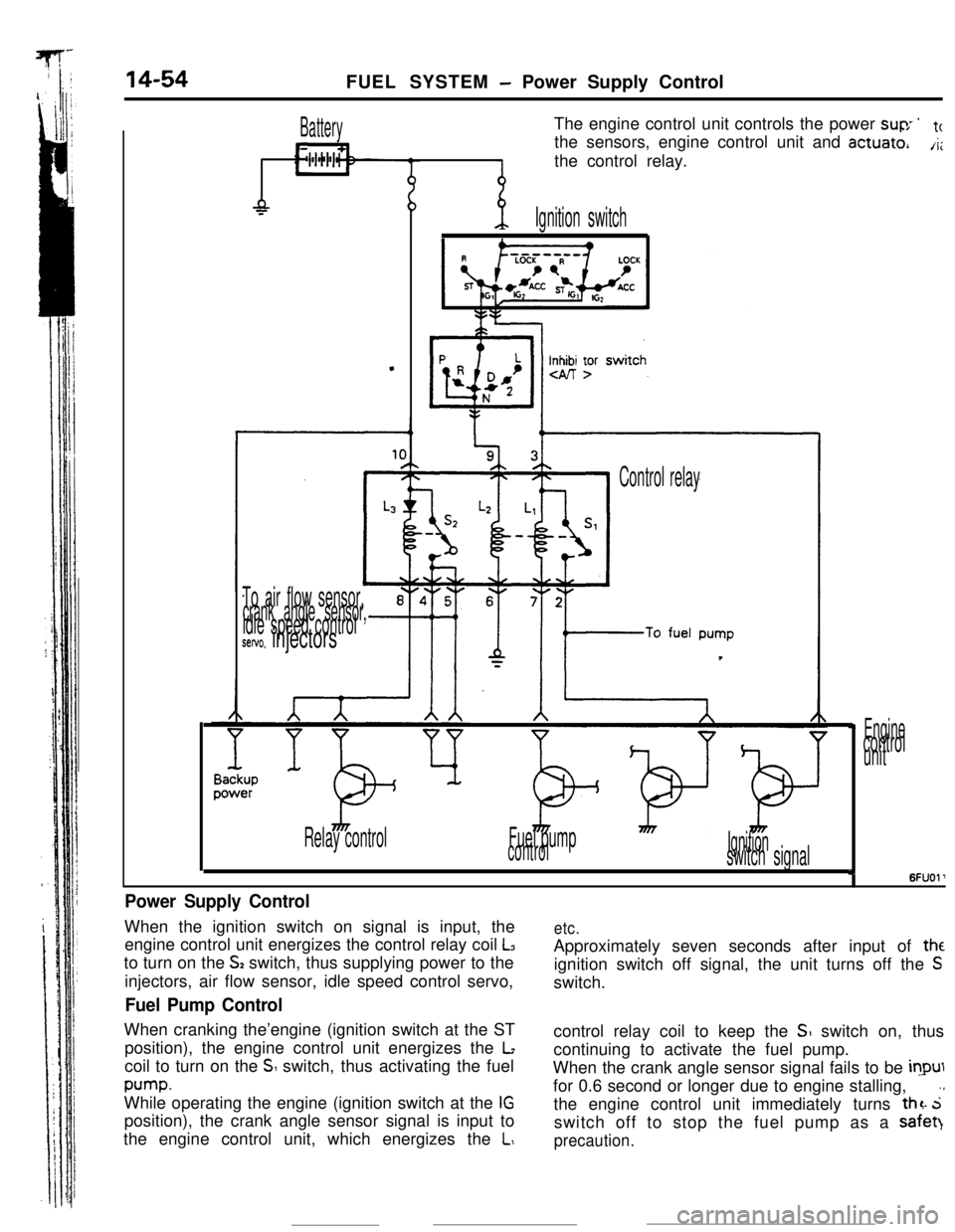

POWER SUPPLY CONTROL

GENERAL DESCRIPTION

RlUAAA

7FUO51

Page 166 of 391

FUEL SYSTEM- Power Supply Control

Battery

L11The engine control unit controls the power

suv ’tcthe sensors, engine control unit and

actuate,A;the control relay.

-P

.

-p.Ignition switch

Inn yr

To air flow sensor,crank angle sensor,idle speed controlsetvo. injectors

Control relay

Relay controlFuel pump

controlIgnitionswitch signal

Enginecontrol

unit

I6FUOl’

Power Supply ControlWhen the ignition switch on signal is input, the

engine control unit energizes the control relay coil

L3to turn on the

S2 switch, thus supplying power to the

injectors, air flow sensor, idle speed control servo,

Fuel Pump ControlWhen cranking the’engine (ignition switch at the ST

position), the engine control unit energizes the

Lcoil to turn on the

S switch, thus activating the fuel

pump.While operating the engine (ignition switch at the

IGposition), the crank angle sensor signal is input to

the engine control unit, which energizes the

L,

etc.Approximately seven seconds after input of

theignition switch off signal, the unit turns off the

Sswitch.

control relay coil to keep the

SI switch on, thus

continuing to activate the fuel pump.

When the crank angle sensor signal fails to be

inputfor 0.6 second or longer due to engine stalling,

.,the engine control unit immediately turns

thz. 5switch off to stop the fuel pump as a safet)

precaution.

Page 167 of 391

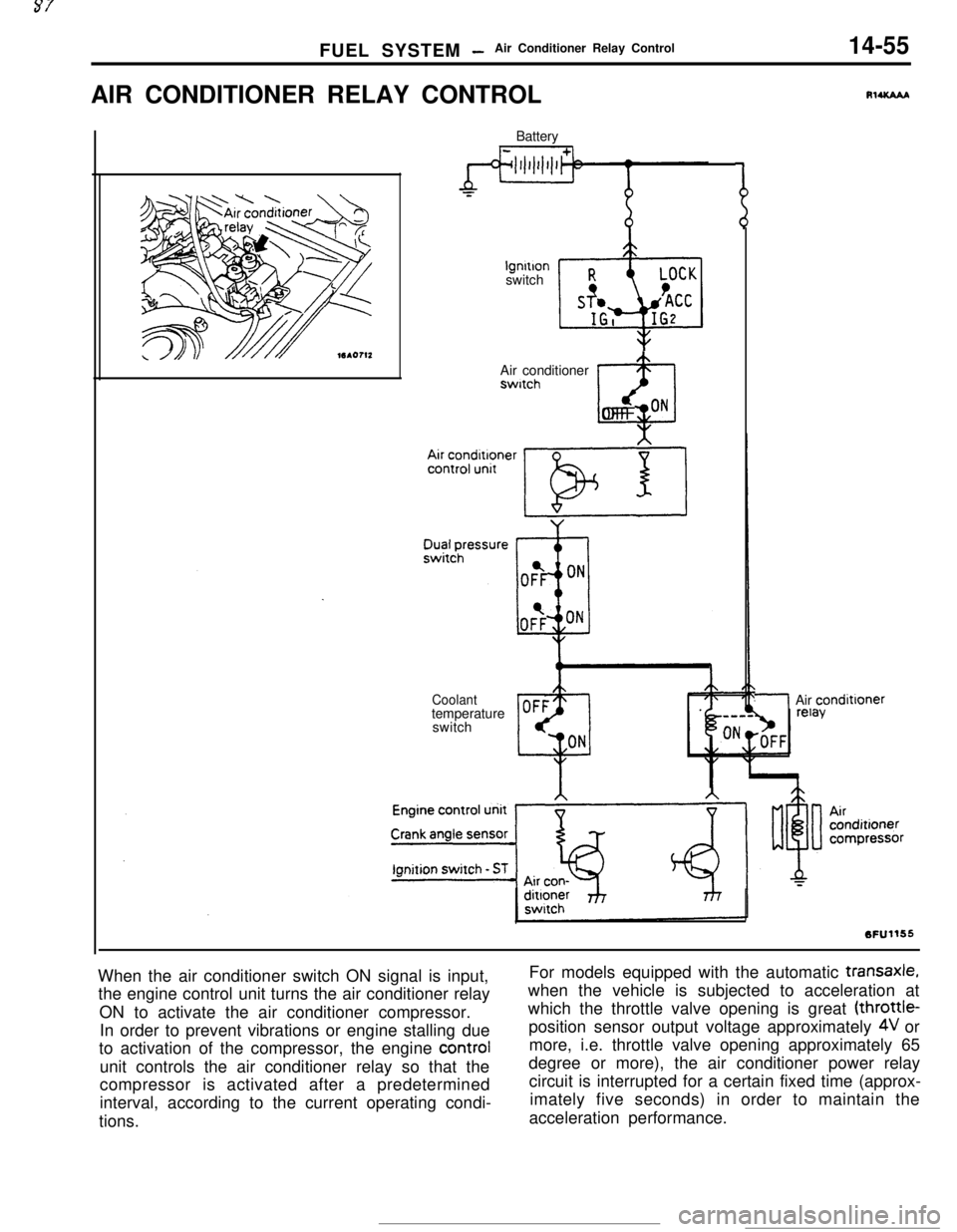

FUEL SYSTEM -Air Conditioner Relay Control14-55AIR CONDITIONER RELAY CONTROL

Batterylgnltlon

switch

Air conditionerswitch

@OFF ON

Coolanttemperature

switch

RlUCAAA

/Air condittoner

When the air conditioner switch ON signal is input,

the engine control unit turns the air conditioner relay

ON to activate the air conditioner compressor.

In order to prevent vibrations or engine stalling due

to activation of the compressor, the engine control

unit controls the air conditioner relay so that the

compressor is activated after a predetermined

interval, according to the current operating condi-

tions.For models equipped with the automatic

transaxle,when the vehicle is subjected to acceleration at

which the throttle valve opening is great (throttle-

position sensor output voltage approximately

4V or

more, i.e. throttle valve opening approximately 65

degree or more), the air conditioner power relay

circuit is interrupted for a certain fixed time (approx-

imately five seconds) in order to maintain the

acceleration performance.

Page 168 of 391

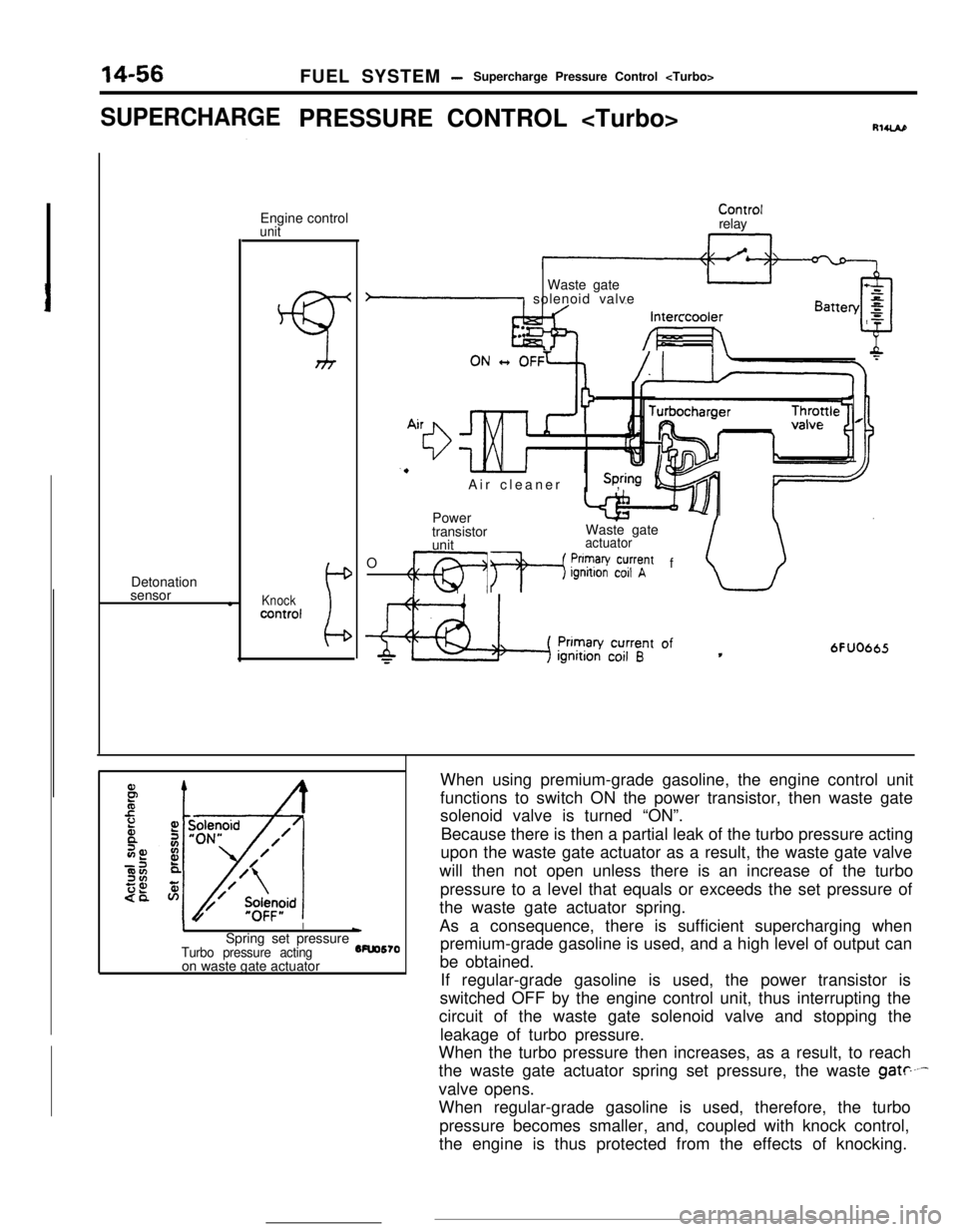

14-56FUEL SYSTEM -Supercharge Pressure Control

SUPERCHARGEPRESSURE CONTROL

sensor

lEngine control

unit

Knockcontrol

ControlrelayIntercooler

h&l --/I- h

.. .Waste gate

P solenoid valve

Air cleaner,

Power

transistorWaste gate

unit

actuatorOf

CT1 +p$?V~~~t

6FUO665

II\Spring set pressure

Turbo pressure acting5Fuo570

on waste gate actuatorWhen using premium-grade gasoline, the engine control unit

functions to switch ON the power transistor, then waste gate

solenoid valve is turned “ON”.

Because there is then a partial leak of the turbo pressure acting

upon the waste gate actuator as a result, the waste gate valve

will then not open unless there is an increase of the turbo

pressure to a level that equals or exceeds the set pressure of

the waste gate actuator spring.

As a consequence, there is sufficient supercharging when

premium-grade gasoline is used, and a high level of output can

be obtained.

If regular-grade gasoline is used, the power transistor is

switched OFF by the engine control unit, thus interrupting the

circuit of the waste gate solenoid valve and stopping the

leakage of turbo pressure.

When the turbo pressure then increases, as a result, to reach

the waste gate actuator spring set pressure, the waste

gate----valve opens.

When regular-grade gasoline is used, therefore, the turbo

pressure becomes smaller, and, coupled with knock control,

the engine is thus protected from the effects of knocking.

Page 169 of 391

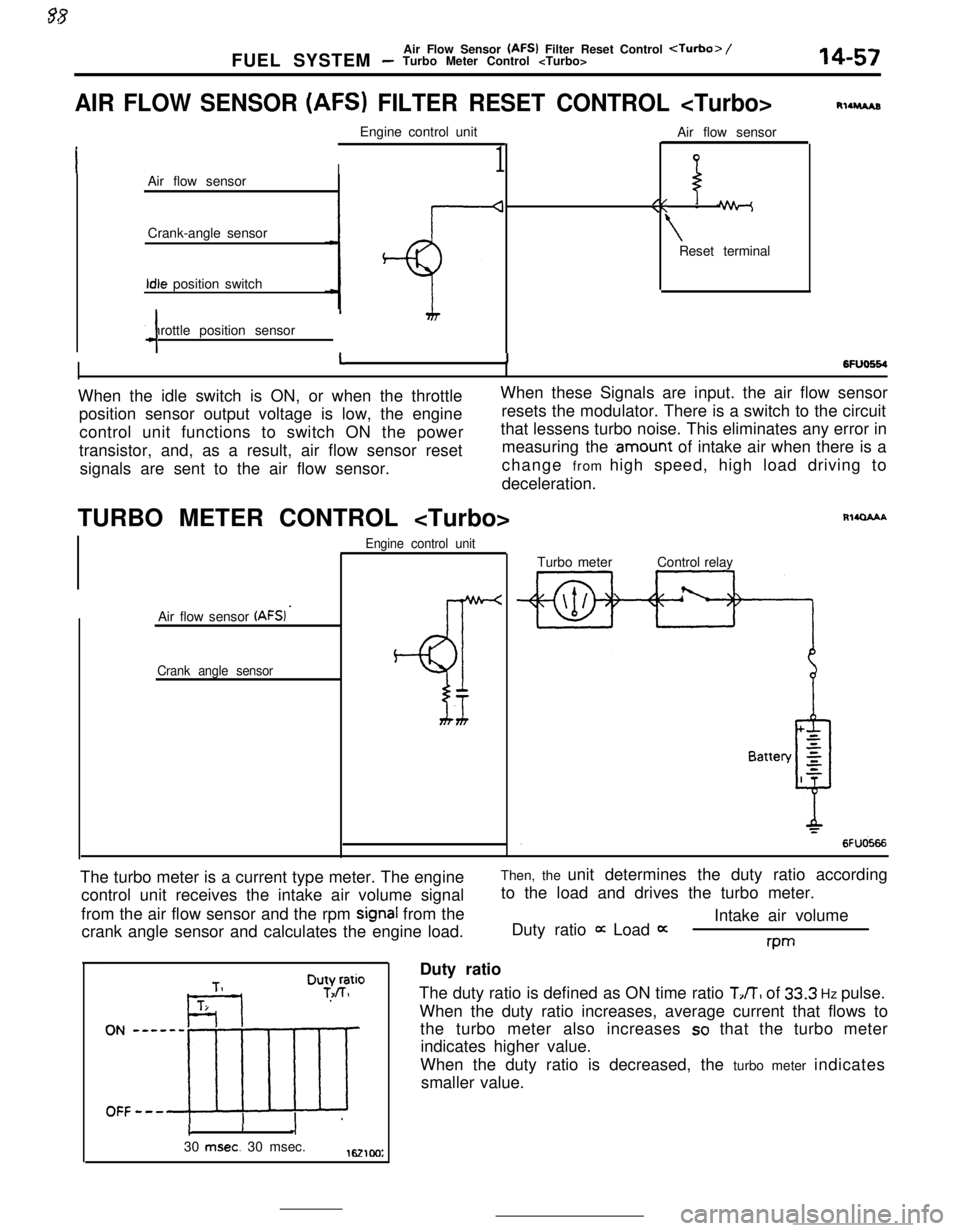

FUEL SYSTEMAir Flow Sensor (AFSI Filter Reset Control

AIR FLOW SENSOR (AFS) FILTER RESET CONTROL

I1Air flow sensor

Crank-angle sensorIdle position switch

Throttle position sensor

4Air flow sensor

//\\ -

\Reset terminal

RllruAs

6FlJo664I11When the idle switch is ON, or when the throttleWhen these Signals are input. the air flow sensor

position sensor output voltage is low, the engineresets the modulator. There is a switch to the circuit

control unit functions to switch ON the powerthat lessens turbo noise. This eliminates any error in

transistor, and, as a result, air flow sensor resetmeasuring the

.amount of intake air when there is a

signals are sent to the air flow sensor.change from high speed, high load driving to

deceleration.

TURBO METER CONTROL

Air flow sensor

(AFSI ’

Crank angle sensorEngine control unit

BT

Rl4QAAATurbo meterControl relay

The turbo meter is a current type meter. The engine

control unit receives the intake air volume signal

from the air flow sensor and the rpm

signal from the

crank angle sensor and calculates the engine load.Then, the unit determines the duty ratio according

to the load and drives the turbo meter.

Intake air volume

Duty ratio

it Load 0:rwDuty ratio

The duty ratio is defined as ON time ratio

TJT, of 33.3 Hz pulse.

When the duty ratio increases, average current that flows to

the turbo meter also increases

so that the turbo meter

indicates higher value.

When the duty ratio is decreased, the turbo meter indicates

smaller value.

cI30

msec. 30 msec.1621cm:

Page 170 of 391

._ ..-

14-58

.-FUEL SYSTEM

- Accelerator Components

-7

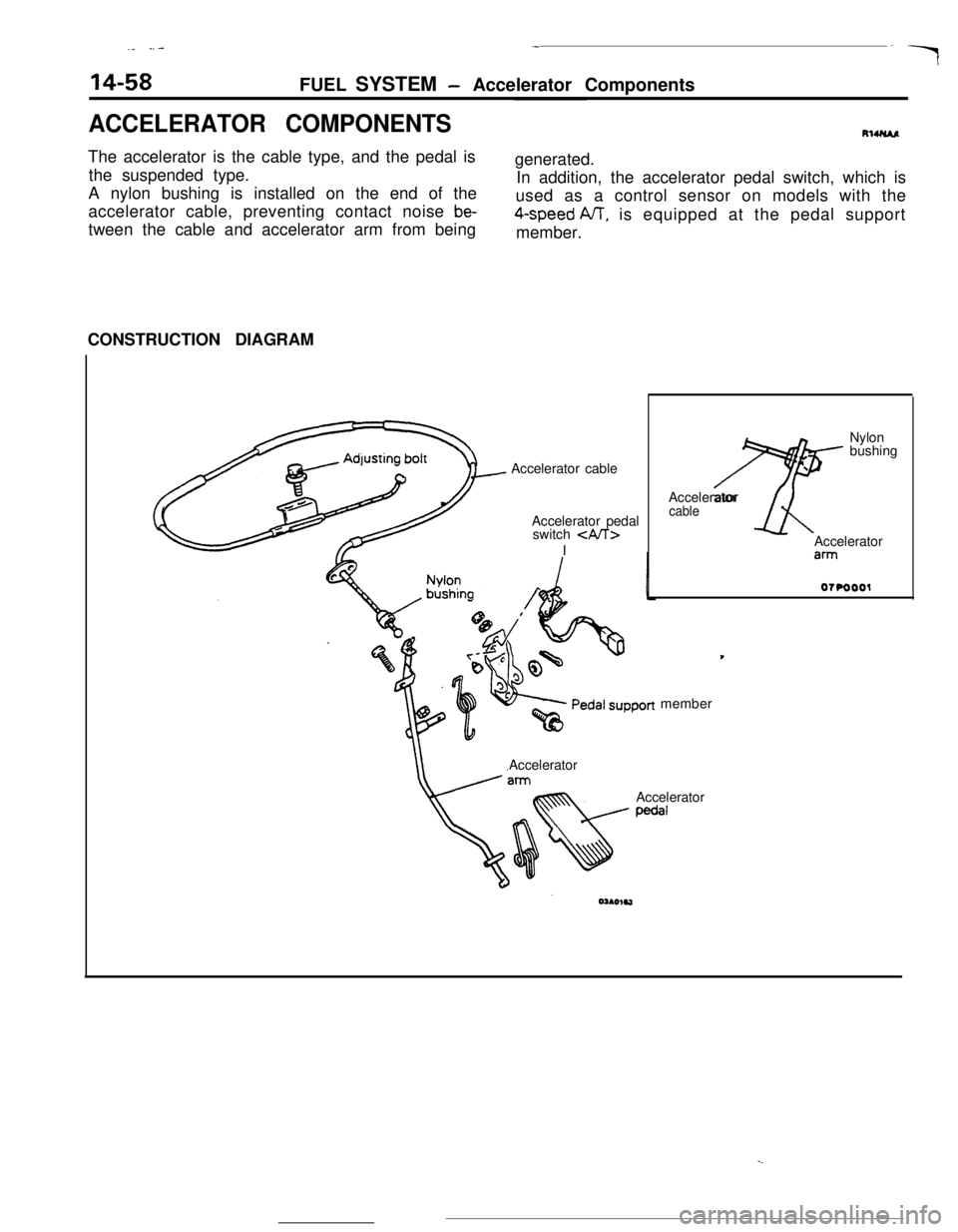

ACCELERATOR COMPONENTSRlUUAAThe accelerator is the cable type, and the pedal is

the suspended type.

A nylon bushing is installed on the end of the

accelerator cable, preventing contact noise

be-tween the cable and accelerator arm from beinggenerated.

In addition, the accelerator pedal switch, which is

used as a control sensor on models with the4-speed NT, is equipped at the pedal support

member.

CONSTRUCTION DIAGRAM

Accelerator cable

Accelerator pedal

switch

\Accelerator

cableAccelerator

ahmember

Accelerator

Accelerator

pedal