MITSUBISHI ECLIPSE 1990 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 221 of 391

POWER STEERING - Oil Pump

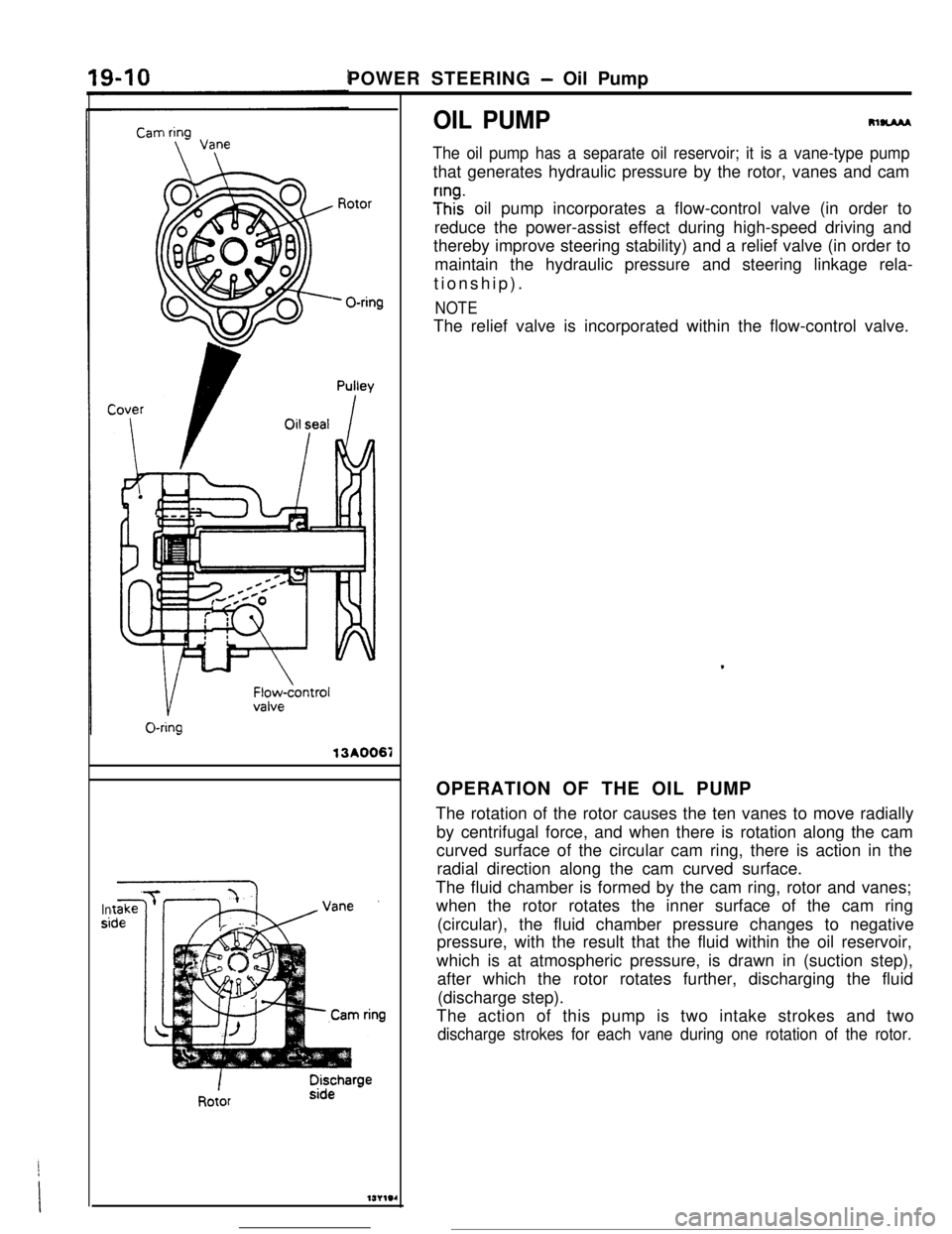

OIL PUMP13A0067

Insi

m-

The oil pump has a separate oil reservoir; it is a vane-type pumpthat generates hydraulic pressure by the rotor, vanes and cam

;Inhz oil pump incorporates a flow-control valve (in order to

reduce the power-assist effect during high-speed driving and

thereby improve steering stability) and a relief valve (in order to

maintain the hydraulic pressure and steering linkage rela-

tionship).

NOTEThe relief valve is incorporated within the flow-control valve.

.OPERATION OF THE OIL PUMP

The rotation of the rotor causes the ten vanes to move radially

by centrifugal force, and when there is rotation along the cam

curved surface of the circular cam ring, there is action in the

radial direction along the cam curved surface.

The fluid chamber is formed by the cam ring, rotor and vanes;

when the rotor rotates the inner surface of the cam ring

(circular), the fluid chamber pressure changes to negative

pressure, with the result that the fluid within the oil reservoir,

which is at atmospheric pressure, is drawn in (suction step),

after which the rotor rotates further, discharging the fluid

(discharge step).

The action of this pump is two intake strokes and two

discharge strokes for each vane during one rotation of the rotor.

Page 222 of 391

POWER STEERING - Oil Pump

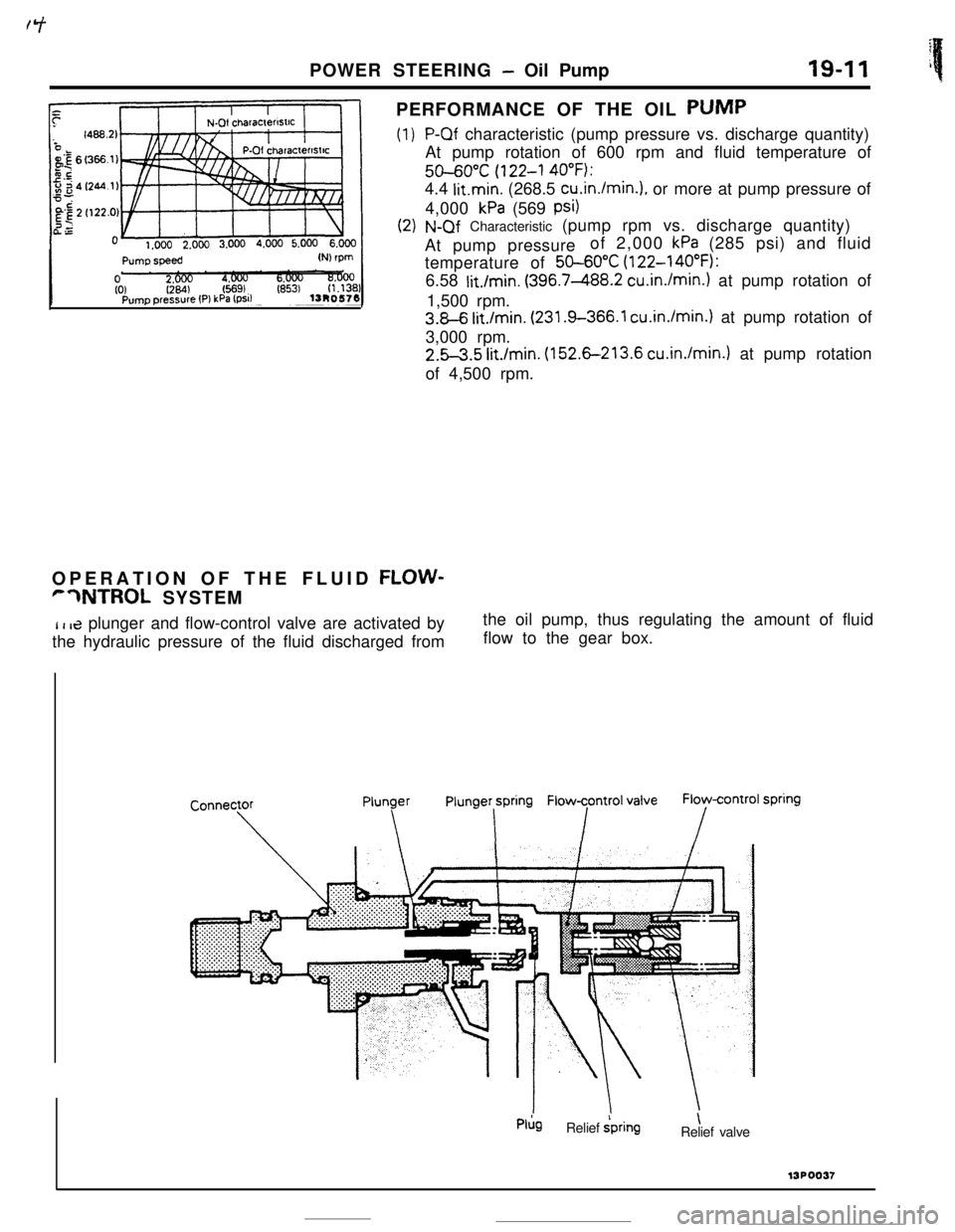

PERFORMANCE OF THE OIL PUMP

(1)

19-11 i

P-Qf characteristic (pump pressure vs. discharge quantity)

At pump rotation of 600 rpm and fluid temperature of

50-6O”C (122-l 40°F):4.4

litmin. (268.5 cu.in./min.), or more at pump pressure of

4,000

kPa (569 psi)

N-Qf Characteristic (pump rpm vs. discharge quantity)

At pump pressureof 2,000

kPa (285 psi) and fluid

temperature of

50-60X (122-140°F):

6.58

lit./min. (396.7-488.2 cu.in./min.) at pump rotation of

1,500 rpm.

3.8-6 lit./min. (231.9-366.1 cu.in./min.) at pump rotation of

3,000 rpm.

2.5-3.5 Mnin. (152.6-213.6 cu.in./min.) at pump rotation

of 4,500 rpm.

OPERATION OF THE FLUID

FLOW-

r7NTROL SYSTEM

I t 13 plunger and flow-control valve are activated bythe oil pump, thus regulating the amount of fluid

the hydraulic pressure of the fluid discharged fromflow to the gear box.

Pl;lgRelief ipring\

Relief valve13POO37

Page 223 of 391

19-12POWER STEERING - Oil Pump

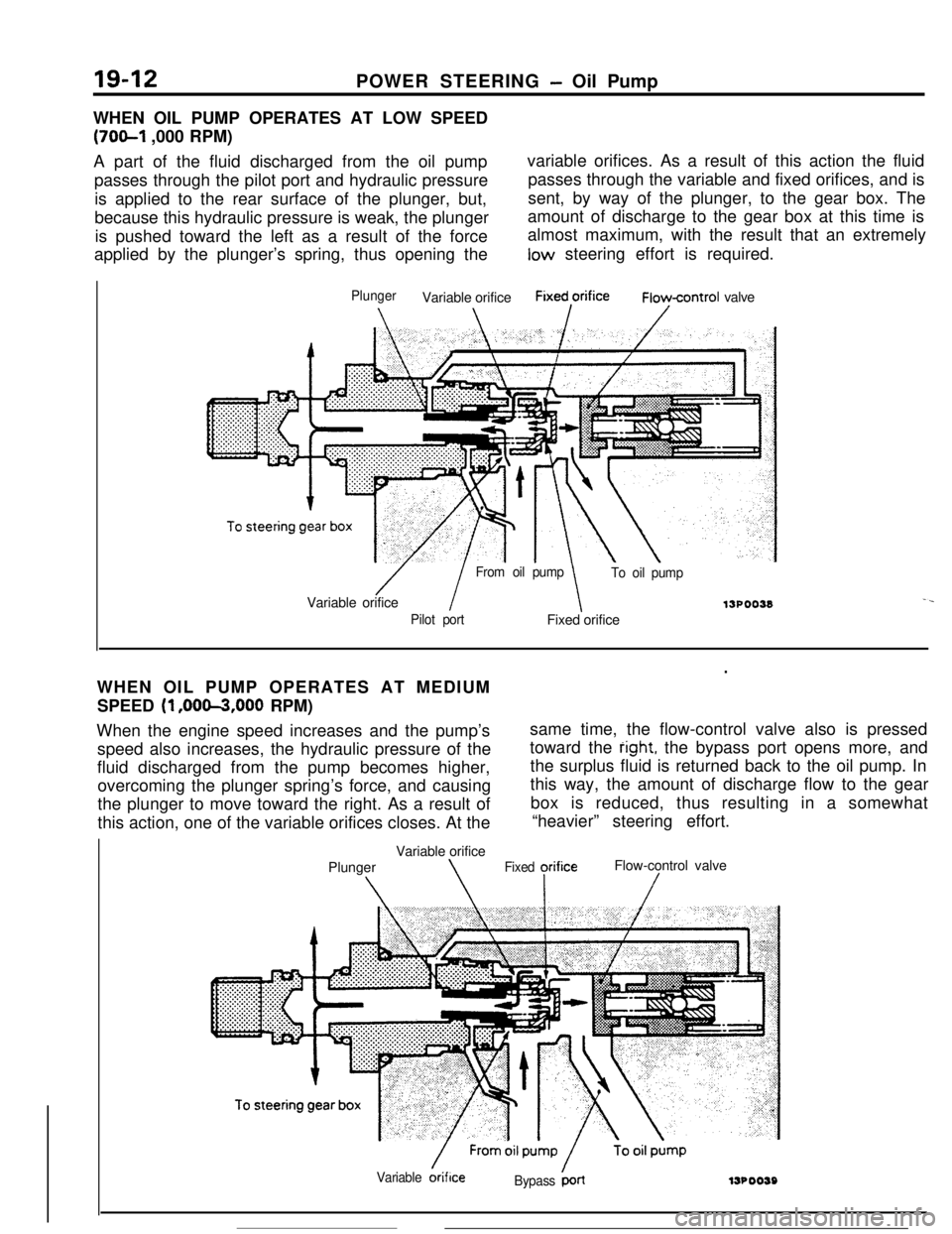

WHEN OIL PUMP OPERATES AT LOW SPEED

(70&l ,000 RPM)

A part of the fluid discharged from the oil pumpvariable orifices. As a result of this action the fluid

passes through the pilot port and hydraulic pressurepasses through the variable and fixed orifices, and is

is applied to the rear surface of the plunger, but,sent, by way of the plunger, to the gear box. The

because this hydraulic pressure is weak, the plungeramount of discharge to the gear box at this time is

is pushed toward the left as a result of the forcealmost maximum, with the result that an extremely

applied by the plunger’s spring, thus opening thelow steering effort is required.

PlungerVariable orificeFixed,orificeFioycontrol valve

/ I

From oil pump

To oil pumpVariable orifice

13POO38-.

Pilot portFixed orifice

.WHEN OIL PUMP OPERATES AT MEDIUM

SPEED

(1 ,OOm,OOO RPM)

When the engine speed increases and the pump’ssame time, the flow-control valve also is pressed

speed also increases, the hydraulic pressure of thetoward the

right, the bypass port opens more, and

fluid discharged from the pump becomes higher,the surplus fluid is returned back to the oil pump. In

overcoming the plunger spring’s force, and causingthis way, the amount of discharge flow to the gear

the plunger to move toward the right. As a result ofbox is reduced, thus resulting in a somewhat

this action, one of the variable orifices closes. At the“heavier” steering effort.

Variable orifice

PlungerFlow-control valve

\\Fixed yrifice/

Variable &iflceBypass ‘LrllJPOO59

Page 224 of 391

i t-7POWER STEERING

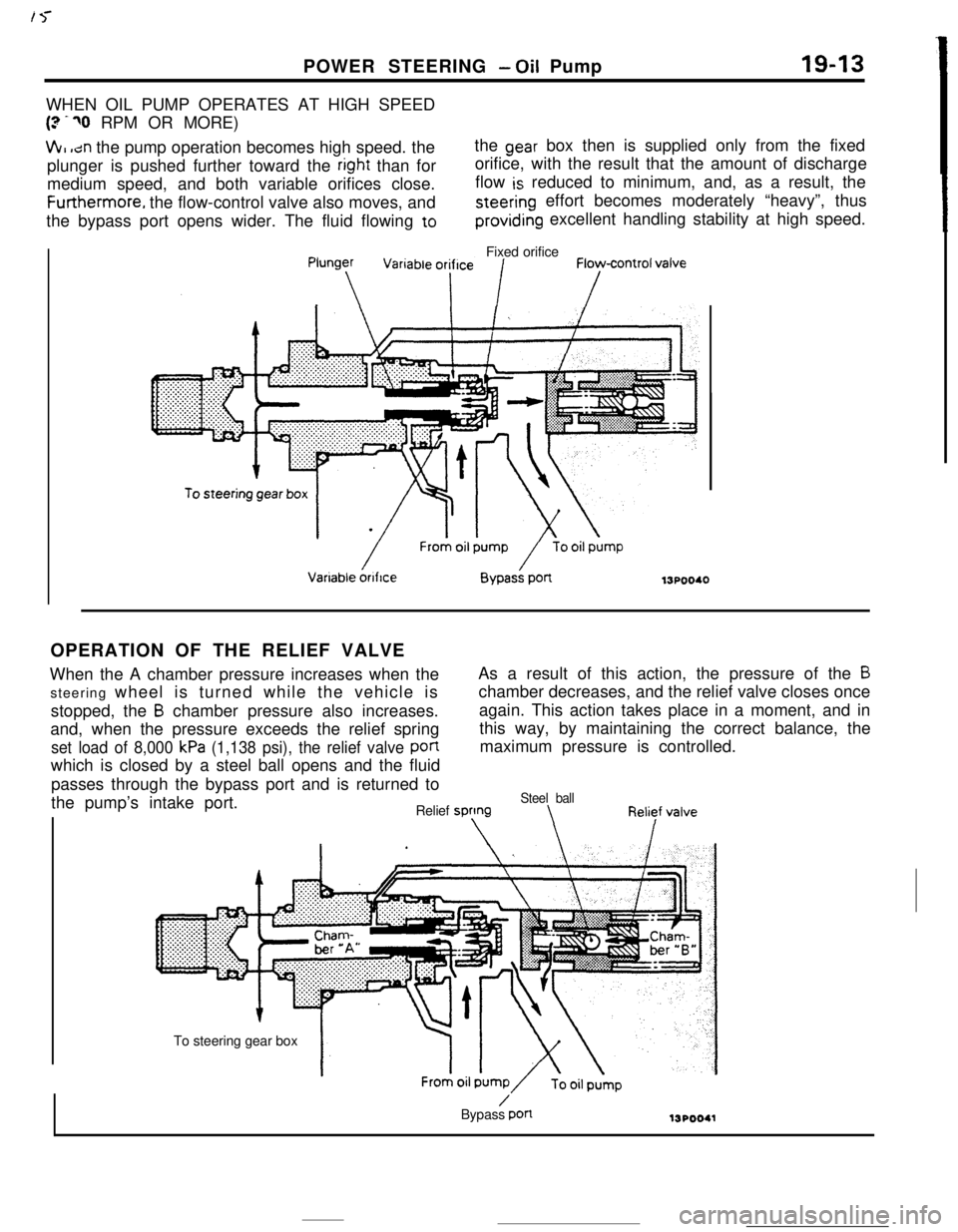

- Oil Pump19-13WHEN OIL PUMP OPERATES AT HIGH SPEED

(? -70 RPM OR MORE)

VII, ,dn the pump operation becomes high speed. thethe gear box then is supplied only from the fixed

plunger is pushed further toward the

right than fororifice, with the result that the amount of discharge

medium speed, and both variable orifices close.flow

is reduced to minimum, and, as a result, theFurthermore. the flow-control valve also moves, and

steering effort becomes moderately “heavy”, thus

the bypass port opens wider. The fluid flowing to

providing excellent handling stability at high speed.

Fixed orifice13POO40

OPERATION OF THE RELIEF VALVE

When the A chamber pressure increases when theAs a result of this action, the pressure of the

Bsteering wheel is turned while the vehicle ischamber decreases, and the relief valve closes once

stopped, the

B chamber pressure also increases.again. This action takes place in a moment, and in

and, when the pressure exceeds the relief springthis way, by maintaining the correct balance, the

set load of 8,000 kPa (1,138 psi), the relief valve panmaximum pressure is controlled.

which is closed by a steel ball opens and the fluid

passes through the bypass port and is returned to

the pump’s intake port.

Steel ballRelief sprtngTo steering gear box

/Bypass pan

WPOO41

Page 225 of 391

21-l

k

TRANSAXLE

‘TORQUE CONVERTE R....................................22

TRANSAXLZ MECHANIS M............................ 23

EndClutch<.................................................. 27

Front Clutch’.................................................... 25

KickdownBrake............................................ 28

Low-reverse Brake........................................30

One-way Clutch............................................ 31

CObROL................................ 15I

VISCOUS COUPLING (VCU). . . . . . . . . . . . . . . . . . . . . . . . 12

Page 226 of 391

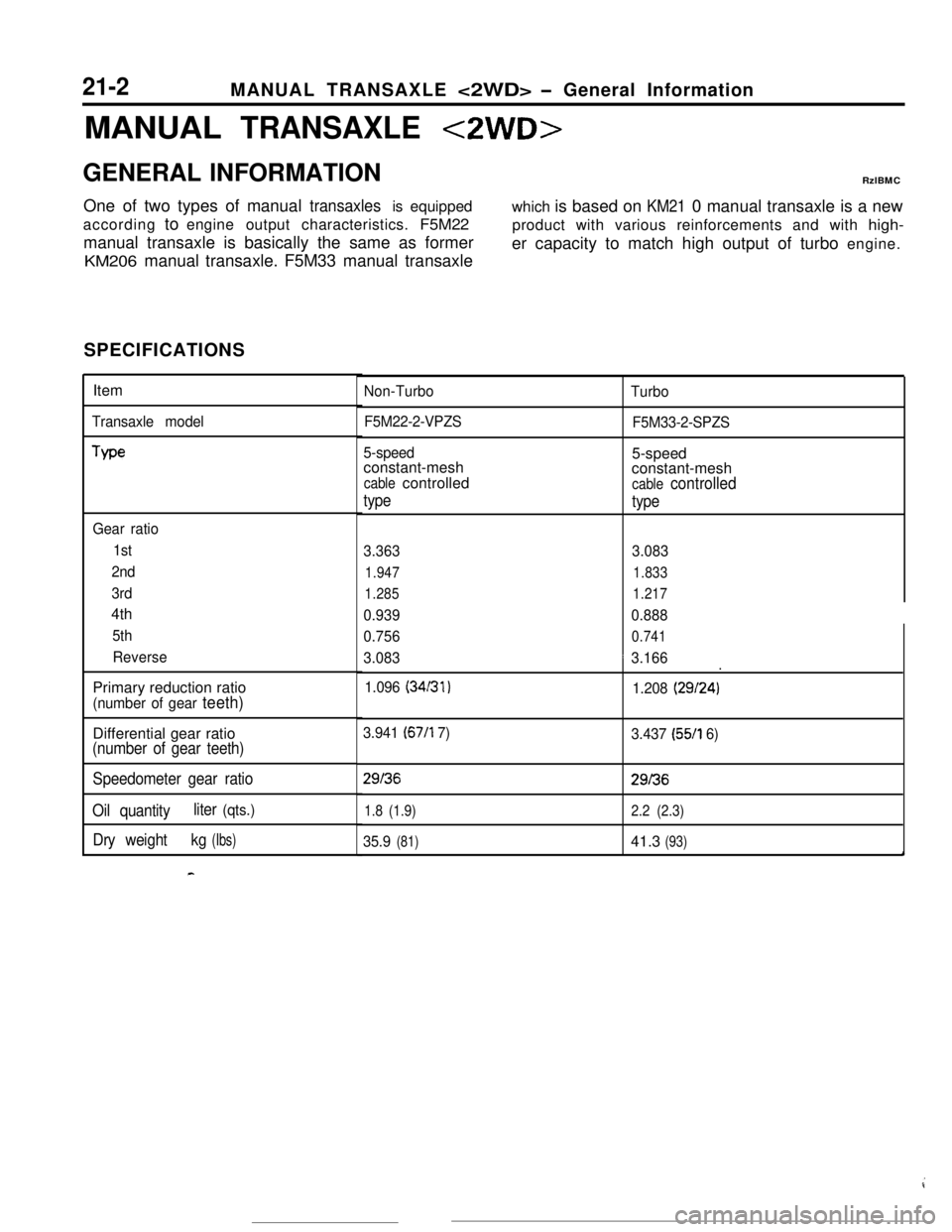

21-2 MANUAL TRANSAXLE

GENERAL INFORMATION

We

Gear ratio

(34131)

3.941 (67/l 7)

29f36

1.8 (1.9)

o 3.166.

(29f24)

3.437 (55/l 6)

29f36

2.2 (2.3)

4

Page 227 of 391

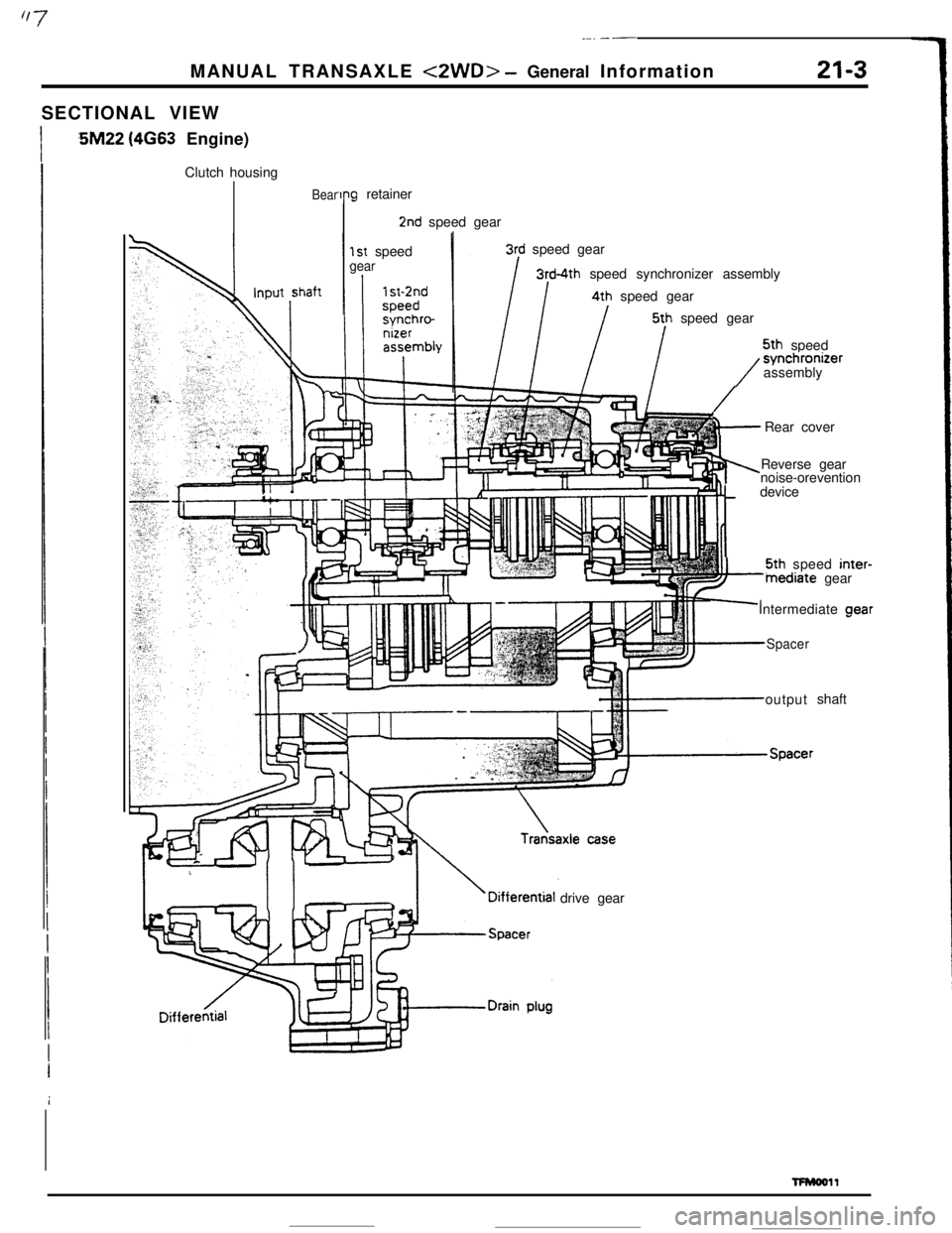

_-. ---MANUAL TRANSAXLE

<2WD> - General Information21-3SECTIONAL VIEW

:5M22 (4663 Engine)

Clutch housing

Bear‘Ing retainer

2nd speed gear

1st speedgear

3rd speed gear

3rd-4th speed synchronizer assembly4th speed gear5th speed gear5th speed

/synchronizer

assembly

ii+-Rear cover

Reverse gear

noise-orevention

tdevice5th speed inter-

inediate gear

Intermediate aear

Spaceroutputshaft

drive gear

TFMooll

Page 228 of 391

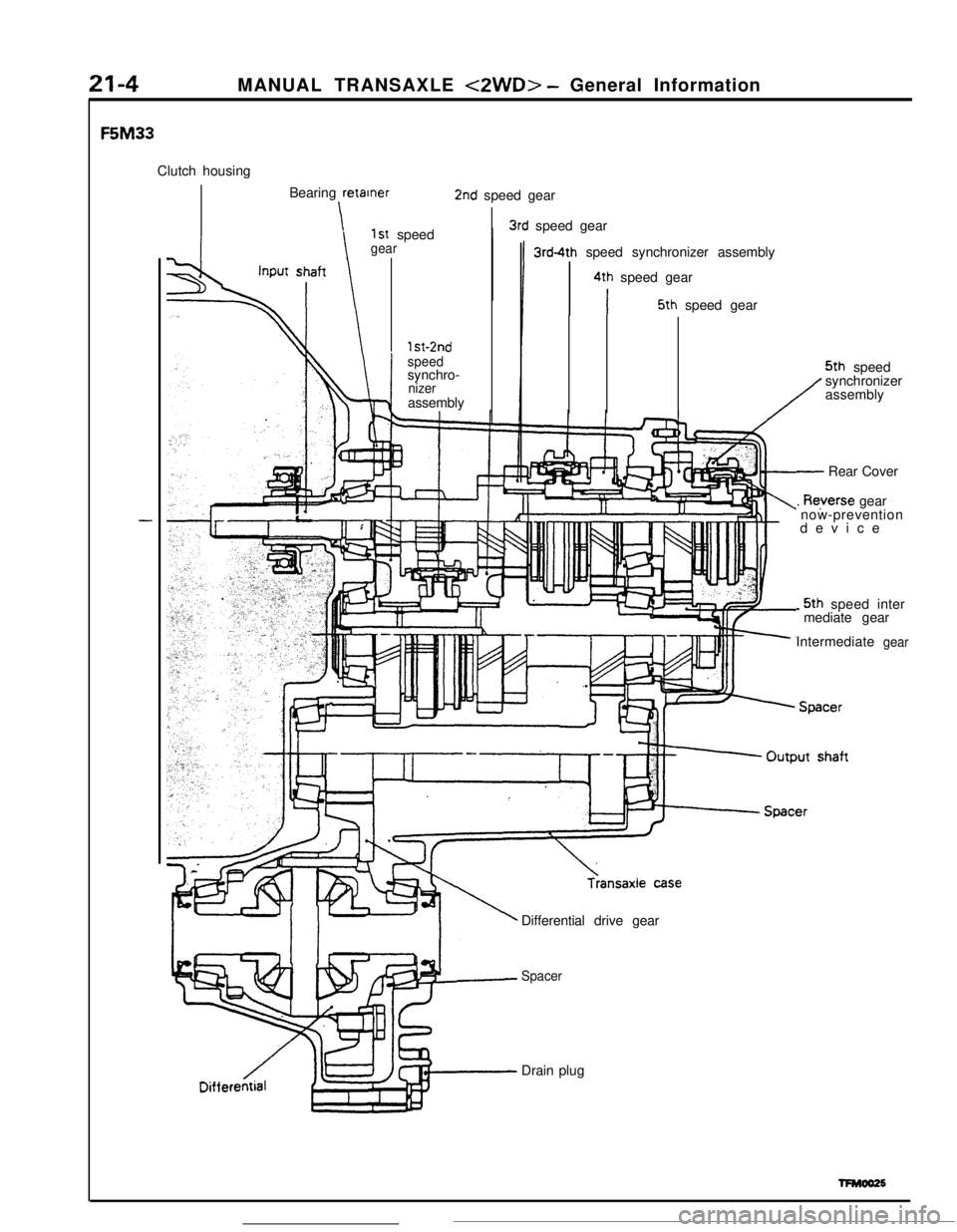

MANUAL TRANSAXLE <2WD> - General InformationF5M33

Clutch housing

Bearing retainer

\1st speedgear

2nd speed gear

I3rd speed gear

3rd-4th speed synchronizer assembly

4th speed gear

I5th speed gear

1 st-2nd

speedsynchro-

nizerassembly5th speed

synchronizer

assembly

- Rear Cover

. Reyerse gear

now-prevention

device

-5th speed inter

mediate gear

Intermediate

Differential drive gear

SpacerDrain plug

gear

Page 229 of 391

MANUAL TRANSAXLE <2WD> - Transaxle Control

21-5

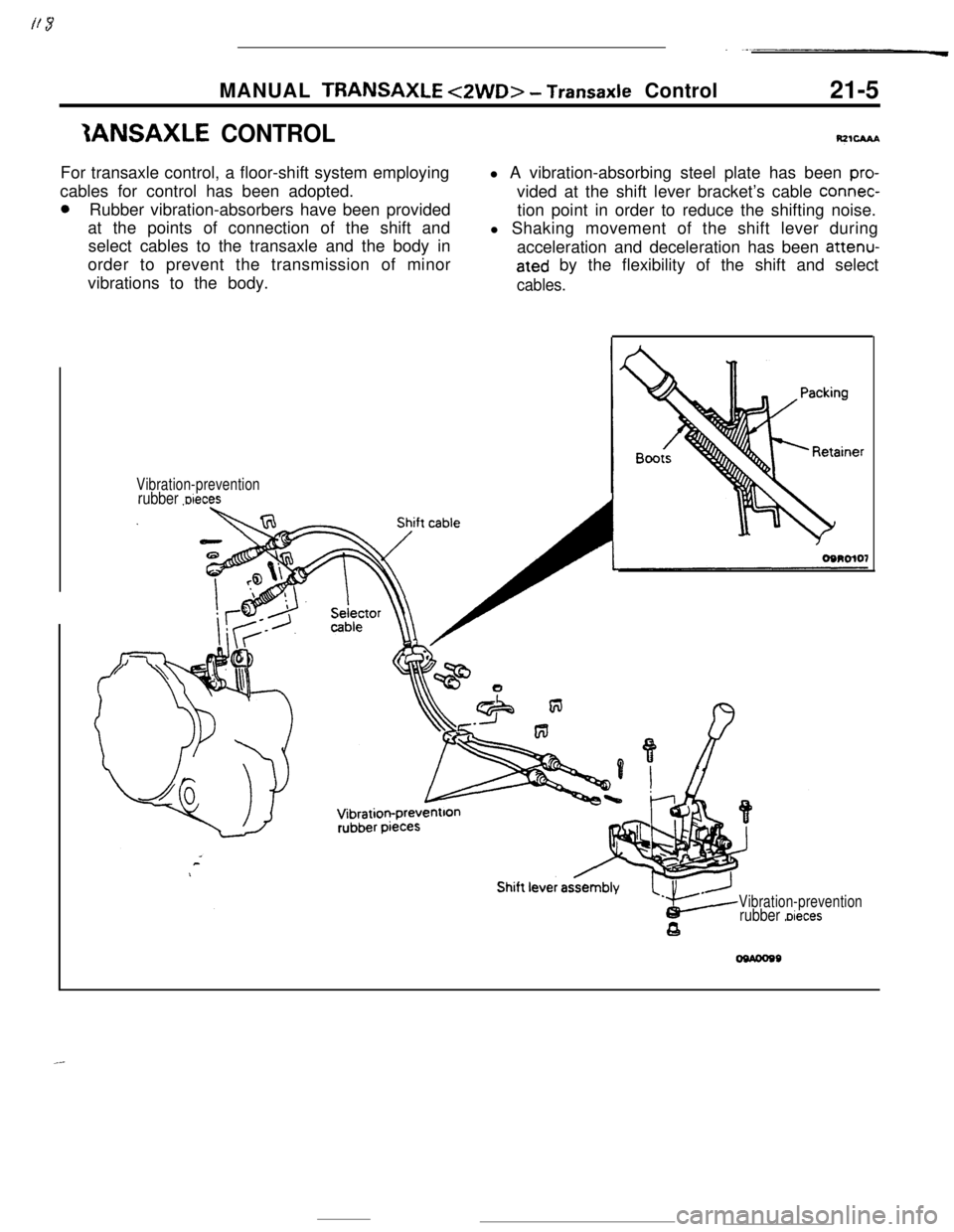

IANSAXLE CONTROLFor transaxle control, a floor-shift system employing

cables for control has been adopted.

0Rubber vibration-absorbers have been provided

at the points of connection of the shift and

select cables to the transaxle and the body in

order to prevent the transmission of minor

vibrations to the body.l A vibration-absorbing steel plate has been

pro-vided at the shift lever bracket’s cable connec-

tion point in order to reduce the shifting noise.

l Shaking movement of the shift lever during

acceleration and deceleration has been attenu-

ated by the flexibility of the shift and select

cables.

Vibration-preventionrubber Dieces

Vibration-preventionrubber Dieces

Page 230 of 391

MANUAL TRANSAXLE <4WD> - General Information

MANUAL TRANSAXLE <4WD>

GENERAL INFORMATION

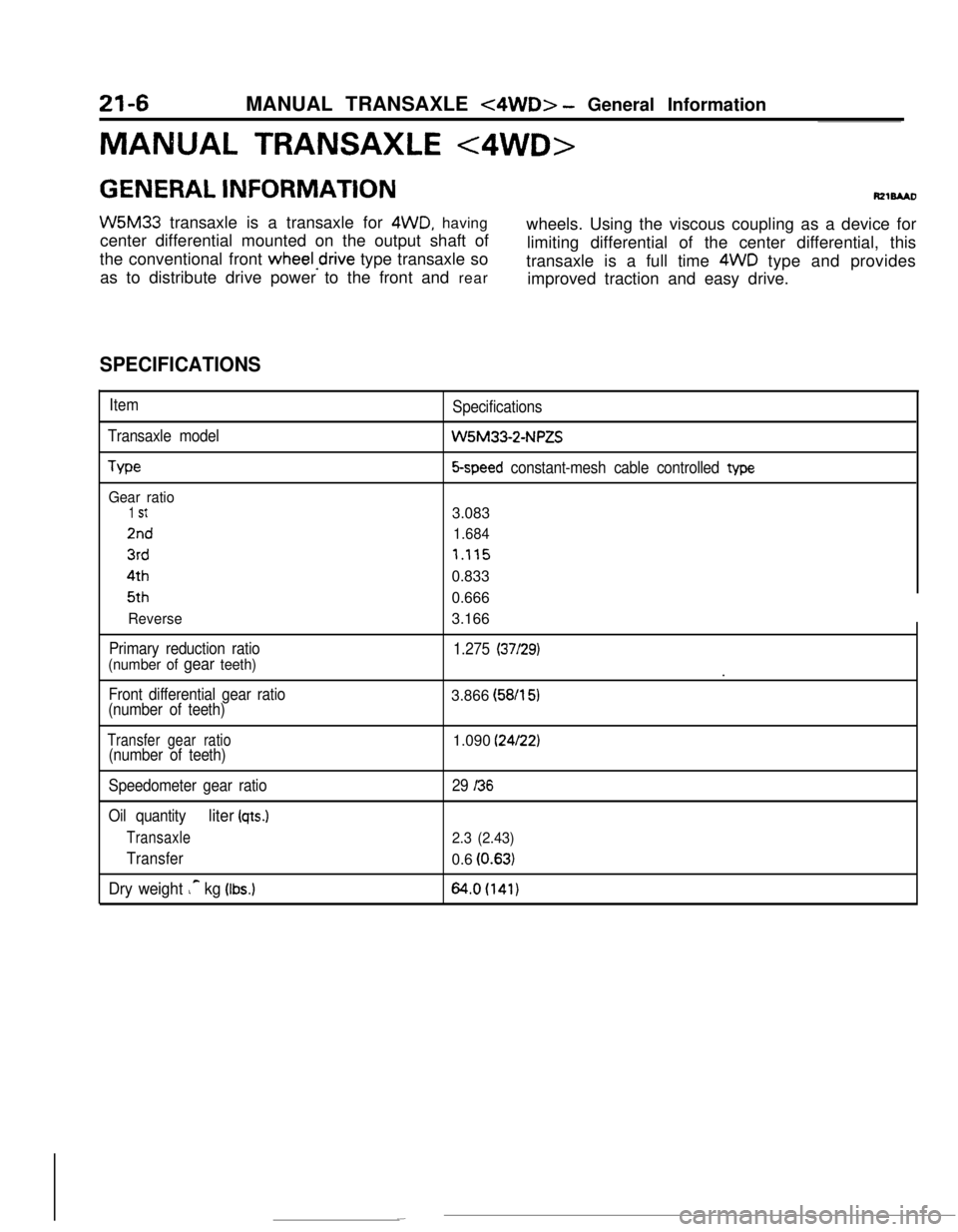

W5M33 transaxle is a transaxle for 4WD, having

center differential mounted on the output shaft ofwheels. Using the viscous coupling as a device for

the conventional front

wheeledrive type transaxle solimiting differential of the center differential, this

as to distribute drive power to the front and reartransaxle is a full time 4WD type and provides

improved traction and easy drive.

SPECIFICATIONS

Item

Transaxle model

We

Gear ratio

1 St

2nd

3rd4th5th

Reverse

Primary reduction ratio

(number of gear teeth)

Front differential gear ratio

(number of teeth)Specifications

W5M33-2-NPZS

5-speed constant-mesh cable controlled type3.083

1.684

7.1150.833

0.666

3.166

1.275 (37/29).

3.866 (58/l

51

Transfer gear ratio(number of teeth)1.090 (24/22)

Speedometer gear ratio

Oil quantity

liter (qts.)

Transaxle

Transfer

Dry weight ic kg (Ibs.)

29 I36

2.3 (2.43)0.6

(0.63)

64.0(141)