MITSUBISHI ECLIPSE 1990 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 231 of 391

--.-.--_ _ _-MANUAL TRANSAXLE

<4WD> - General Information

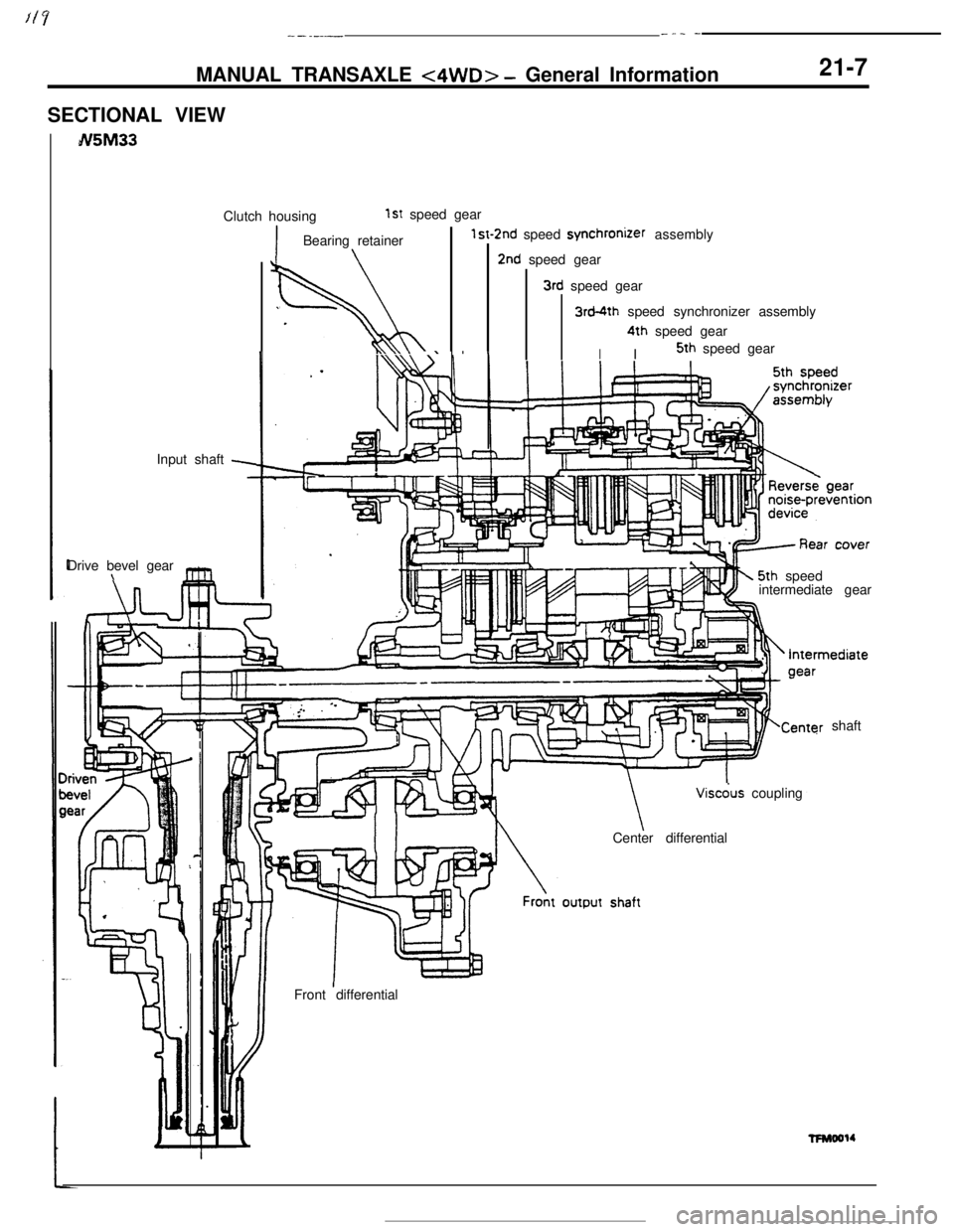

SECTIONAL VIEWN5M3321-7Clutch housing

1st speed gear

Input shaft

-Drive bevel gear

\r

l!

.IBearing retainer\

St-1

w

.

I,..\\I \ I I

2nd speed synchronizer assembly

2nd speed gear

3rd speed gear

3rd-4th speed synchronizer assembly

I4th speed gear

I5th speed gear

5th speed

intermediate gear

shaft

Center differential

Front differentialViscdus coupling

wMool4

Page 232 of 391

_.c.

21-8MANUAL TRANSAXLE <4WD> - General Information4WD SYSTEM

Viscous couplingCenter differential

cous coupling

kCenth differential

I

IFro& differential

Rear differential

I

I

I [[lll,i, ‘- h-

1 p’f’ ,* , l/i\

/IViscous couplingL

(Option)

3

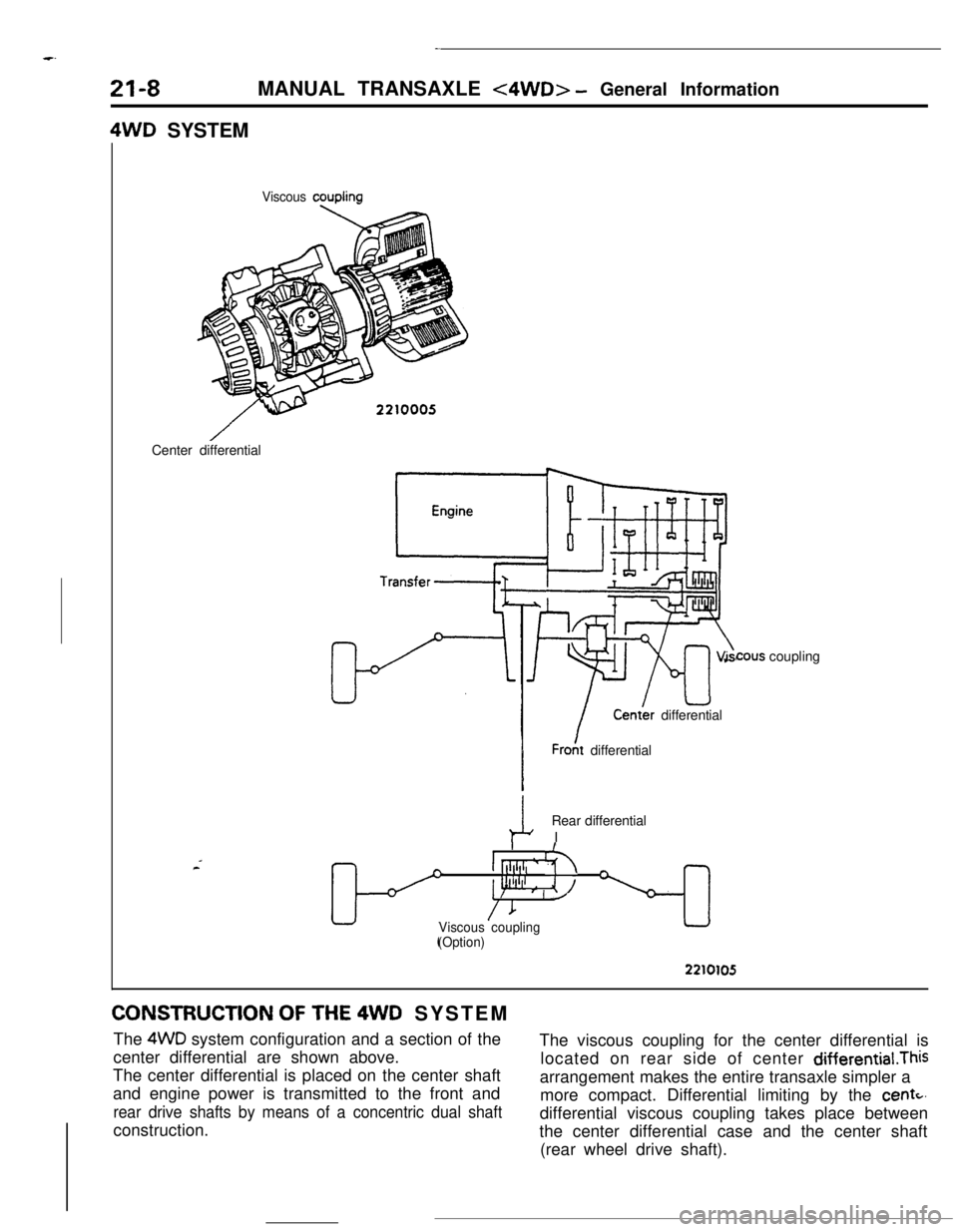

2210105CONSTRUCTION

OF THE 4WD SYSTEM

The 4WD system configuration and a section of the

center differential are shown above.The viscous coupling for the center differential is

The center differential is placed on the center shaftlocated on rear side of center differential.This

and engine power is transmitted to the front andarrangement makes the entire transaxle simpler a

rear drive shafts by means of a concentric dual shaftmore compact. Differential limiting by the

centc,construction.differential viscous coupling takes place between

the center differential case and the center shaft

(rear wheel drive shaft).

Page 233 of 391

-MANUAL TRANSAXLE

<4WD> - General information

21-9

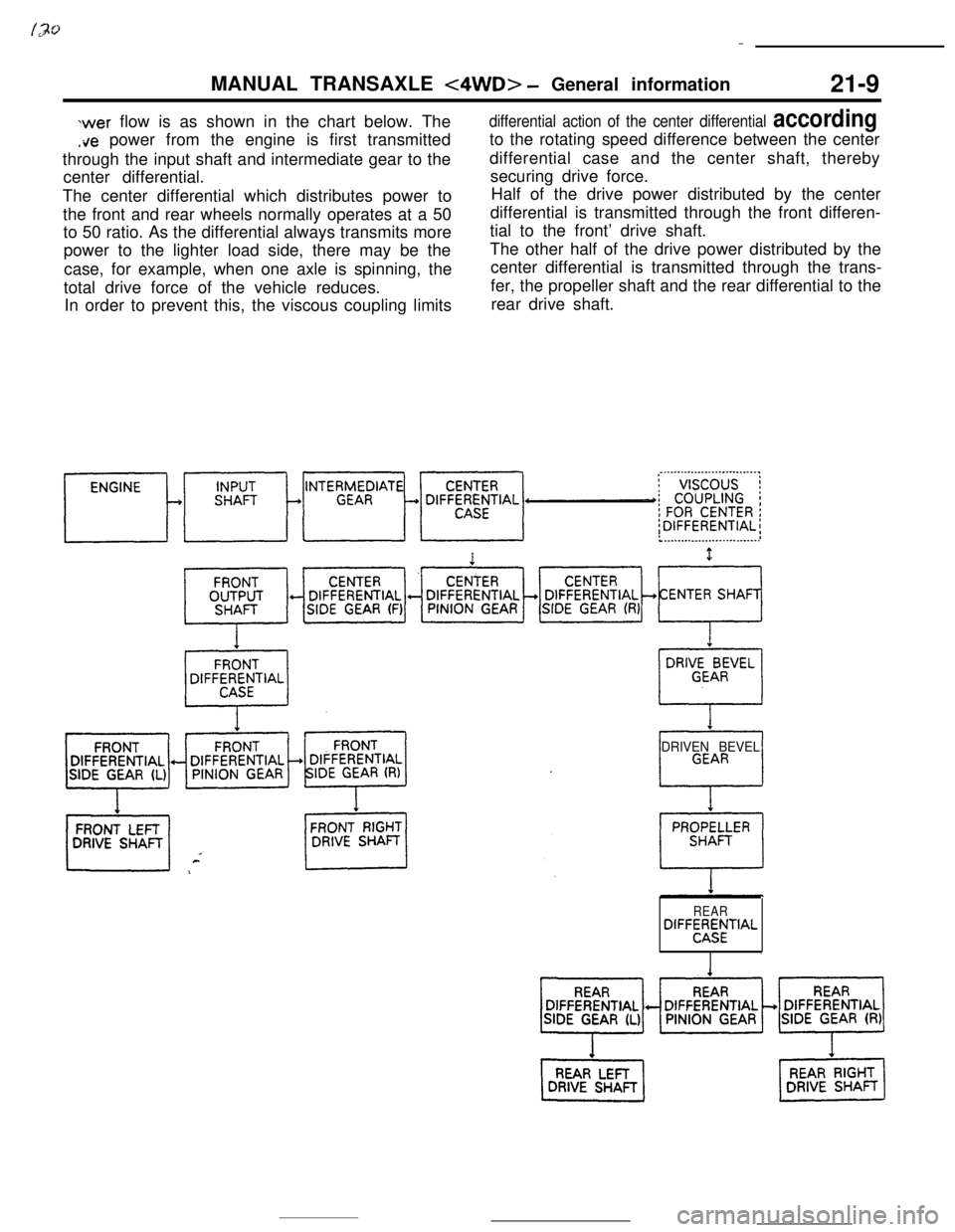

wer flow is as shown in the chart below. The

.ire power from the engine is first transmitted

through the input shaft and intermediate gear to the

center differential.

The center differential which distributes power to

the front and rear wheels normally operates at a 50

to 50 ratio. As the differential always transmits more

power to the lighter load side, there may be the

case, for example, when one axle is spinning, the

total drive force of the vehicle reduces.

In order to prevent this, the viscous coupling limits

differential action of the center differential accordingto the rotating speed difference between the center

differential case and the center shaft, thereby

securing drive force.

Half of the drive power distributed by the center

differential is transmitted through the front differen-

tial to the front’ drive shaft.

The other half of the drive power distributed by the

center differential is transmitted through the trans-

fer, the propeller shaft and the rear differential to the

rear drive shaft.

DRIVEN BEVEL

REARDIFF~;MfTIAL

,

Page 234 of 391

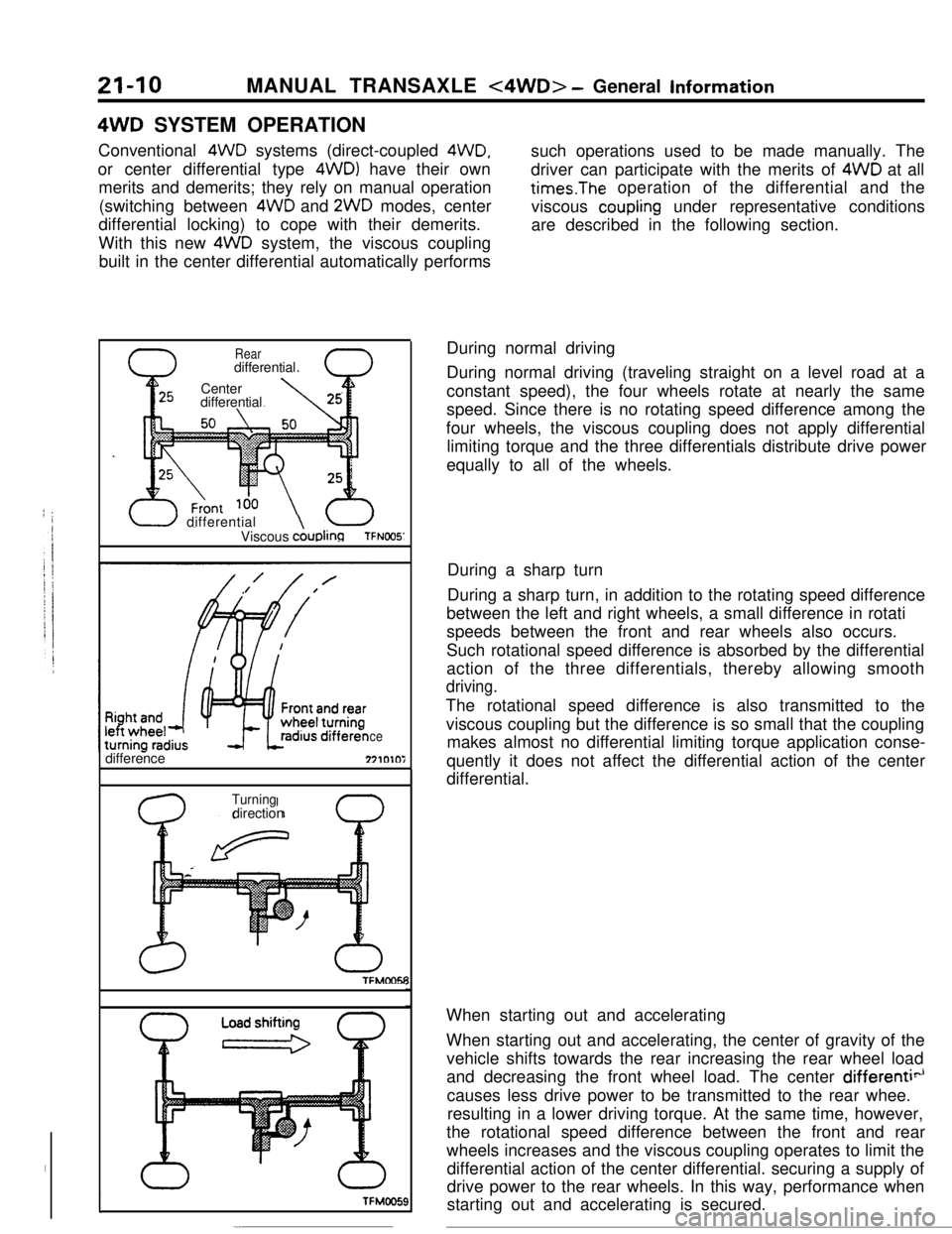

21-10MANUAL TRANSAXLE <4WD> - General Information4WD SYSTEM OPERATION

Conventional 4WD systems (direct-coupled

4WD,or center differential type 4WDl have their own

merits and demerits; they rely on manual operation

(switching between 4WD and 2WD modes, center

differential locking) to cope with their demerits.

With this new 4WD system, the viscous coupling

built in the center differential automatically performssuch operations used to be made manually. The

driver can participate with the merits of 4WD at alltimes.The operation of the differential and the

viscous

coupling under representative conditions

are described in the following section.

I

Reardifferential

Center

differential

U differential

Viscous AuDk?TFNOO5’difference

ce271010i

TFMMYTFMMY

0

Turningdirection

ITFMOO!X

-.During normal driving

During normal driving (traveling straight on a level road at a

constant speed), the four wheels rotate at nearly the same

speed. Since there is no rotating speed difference among the

four wheels, the viscous coupling does not apply differential

limiting torque and the three differentials distribute drive power

equally to all of the wheels.

During a sharp turn

During a sharp turn, in addition to the rotating speed difference

between the left and right wheels, a small difference in rotati

speeds between the front and rear wheels also occurs.

Such rotational speed difference is absorbed by the differential

action of the three differentials, thereby allowing smooth

driving.The rotational speed difference is also transmitted to the

viscous coupling but the difference is so small that the coupling

makes almost no differential limiting torque application conse-

quently it does not affect the differential action of the center

differential.

When starting out and accelerating

When starting out and accelerating, the center of gravity of the

vehicle shifts towards the rear increasing the rear wheel load

and decreasing the front wheel load. The center

differenti”causes less drive power to be transmitted to the rear whee.

resulting in a lower driving torque. At the same time, however,

the rotational speed difference between the front and rear

wheels increases and the viscous coupling operates to limit the

differential action of the center differential. securing a supply of

drive power to the rear wheels. In this way, performance when

starting out and accelerating is secured.

Page 235 of 391

MANUAL TRANSAXLE <4WD> - General Information21-I 1When driving on rough roads. . .In case either a front or rear wheel starts spinning on a slippery

or muddy road or when the vehicle is stuck in mud and one tire

spins, the drive power will be decreased by differential action.

However, as this also causes a sharp increase of speed

difference of the viscous coupling, a large differential limiting

torque is now applied, with more power transmitted to the tires

that are not spinning so that the vehicle can drive through or

getout of mud.A

Page 236 of 391

21-12MANUAL TRANSAXLE <4WD> - Viscous Coupling (VCU)

VISCOUS COUPLING (VCU)

RZlL

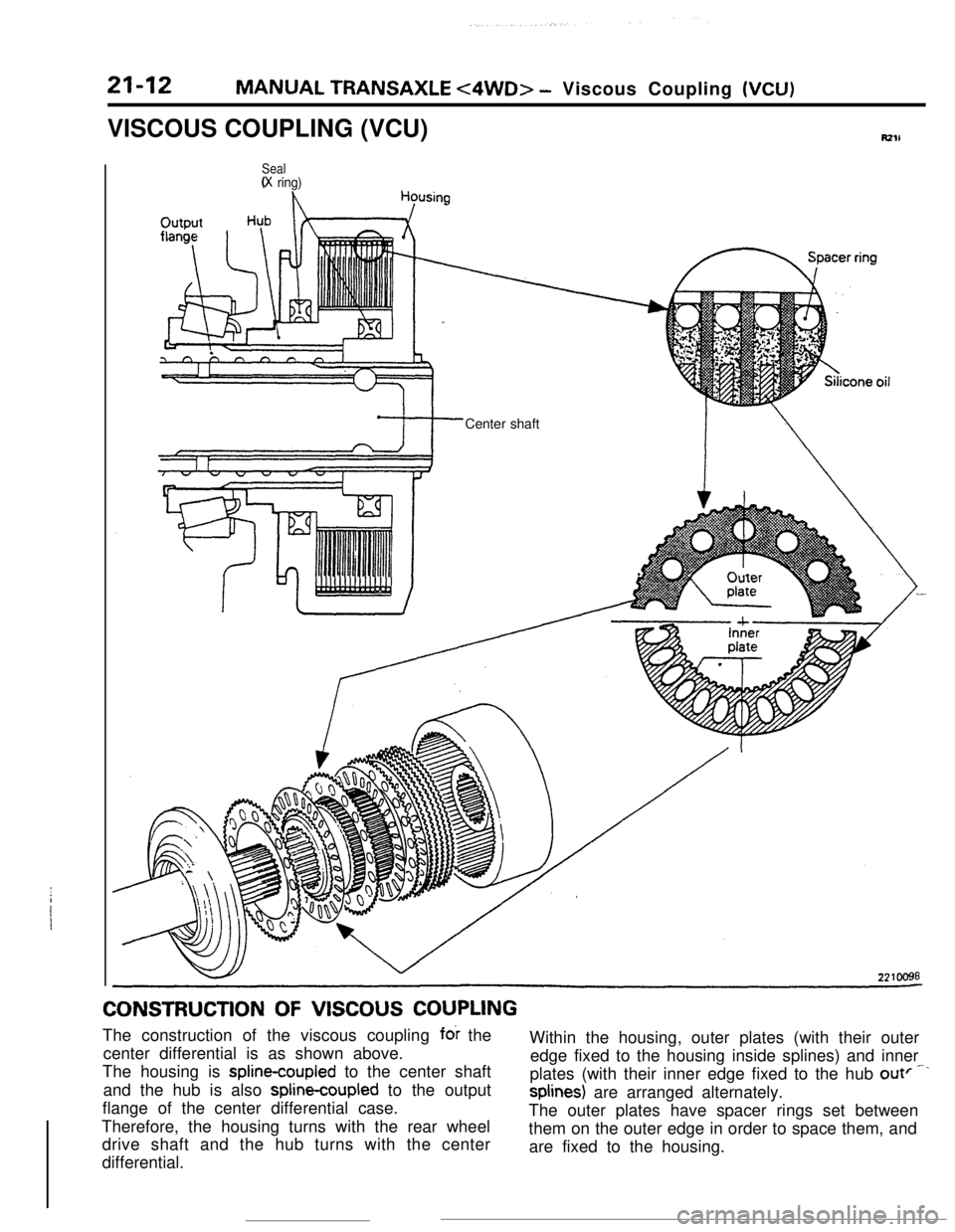

Seal(X ring)Center shaftCONSTRUCTION

OF VISCOUS COUPLINGThe construction of the viscous coupling

fck the

Within the housing, outer plates (with their outer

center differential is as shown above.

edge fixed to the housing inside splines) and inner

The housing is splinecoupled to the center shaft

plates (with their inner edge fixed to the hub

outF--and the hub is also

spline-coupled to the outputsplines) are arranged alternately.

flange of the center differential case.

The outer plates have spacer rings set between

Therefore, the housing turns with the rear wheel

them on the outer edge in order to space them, and

drive shaft and the hub turns with the center

are fixed to the housing.

differential.

Page 237 of 391

MANUAL TRANSAXLE <4WD> - Viscous Coupling .(VClJ)21-13In contrast, the inner plates have no such spacer rings, and

each can slide to some extent over the hub spline shaft

between the outer plates.

The space between the housing and outer and inner plates is

filled with mixture of silicone oil and air.

Plate A

Moving atvelocity V*

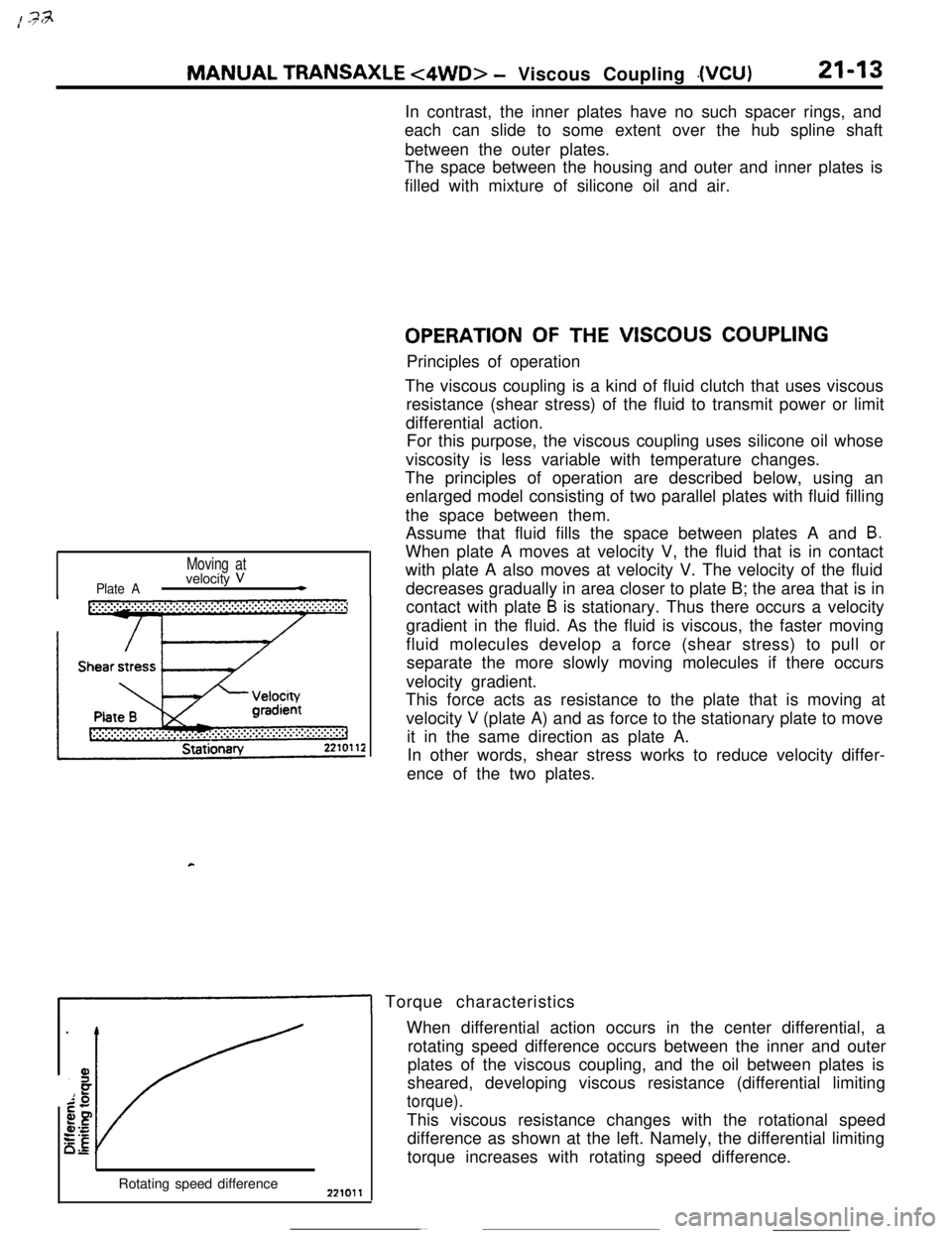

OPERATION OF THE VISCOUS COUPLINGPrinciples of operation

The viscous coupling is a kind of fluid clutch that uses viscous

resistance (shear stress) of the fluid to transmit power or limit

differential action.

For this purpose, the viscous coupling uses silicone oil whose

viscosity is less variable with temperature changes.

The principles of operation are described below, using an

enlarged model consisting of two parallel plates with fluid filling

the space between them.

Assume that fluid fills the space between plates A and

B.When plate A moves at velocity V, the fluid that is in contact

with plate A also moves at velocity V. The velocity of the fluid

decreases gradually in area closer to plate B; the area that is in

contact with plate

B is stationary. Thus there occurs a velocity

gradient in the fluid. As the fluid is viscous, the faster moving

fluid molecules develop a force (shear stress) to pull or

separate the more slowly moving molecules if there occurs

velocity gradient.

This force acts as resistance to the plate that is moving at

velocity

V (plate A) and as force to the stationary plate to move

it in the same direction as plate A.

In other words, shear stress works to reduce velocity differ-

ence of the two plates.

1 Torque characteristics

Rotating speed differenceWhen differential action occurs in the center differential, a

rotating speed difference occurs between the inner and outer

plates of the viscous coupling, and the oil between plates is

sheared, developing viscous resistance (differential limiting

torque).This viscous resistance changes with the rotational speed

difference as shown at the left. Namely, the differential limiting

torque increases with rotating speed difference.

Page 238 of 391

21-14MANUAL TRANSAXLE t4WD> - Viscous Coupling (VCU)

Rotating speed difference

Transmitted

torque

TemperatureII I

t

/

IIc

P&e surface‘II I

preTYl-LLL

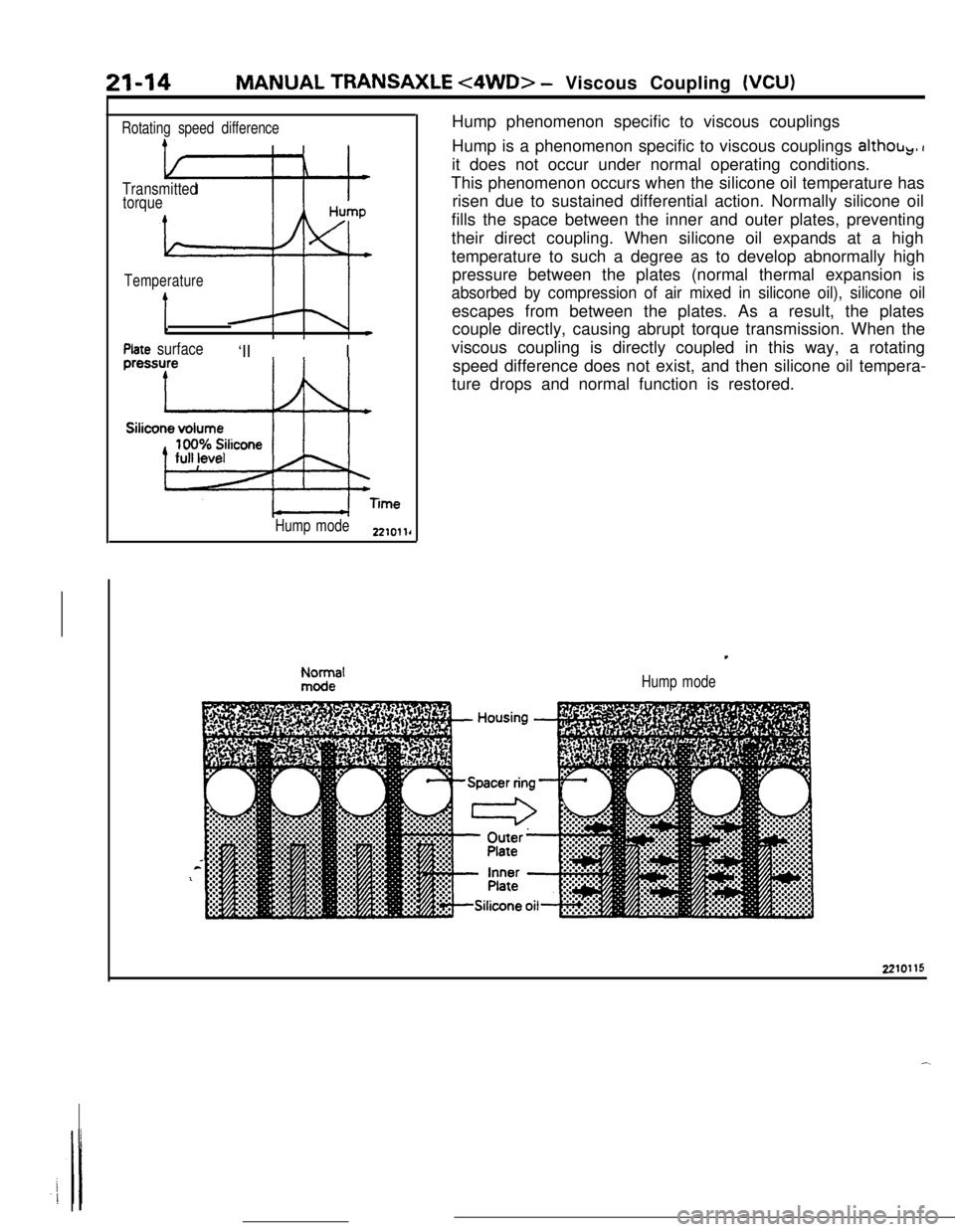

Hump mode2210llrHump phenomenon specific to viscous couplings

Hump is a phenomenon specific to viscous couplings

althob,, Iit does not occur under normal operating conditions.

This phenomenon occurs when the silicone oil temperature has

risen due to sustained differential action. Normally silicone oil

fills the space between the inner and outer plates, preventing

their direct coupling. When silicone oil expands at a high

temperature to such a degree as to develop abnormally high

pressure between the plates (normal thermal expansion is

absorbed by compression of air mixed in silicone oil), silicone oilescapes from between the plates. As a result, the plates

couple directly, causing abrupt torque transmission. When the

viscous coupling is directly coupled in this way, a rotating

speed difference does not exist, and then silicone oil tempera-

ture drops and normal function is restored.

Hump mode2210115

Page 239 of 391

MANUAL TRANSAXLE <4WD> - Transaxle Control

TRANSAXLE CONTROL,

4~ construction and operation, refer to TRANSAX-LE CONTROL of 2WD system.

21-15

RZlCMB

Page 240 of 391

_-

21-16AUTOMATIC TRANSAXLE - General InformationAUTOMATIC

TRANSAXLE

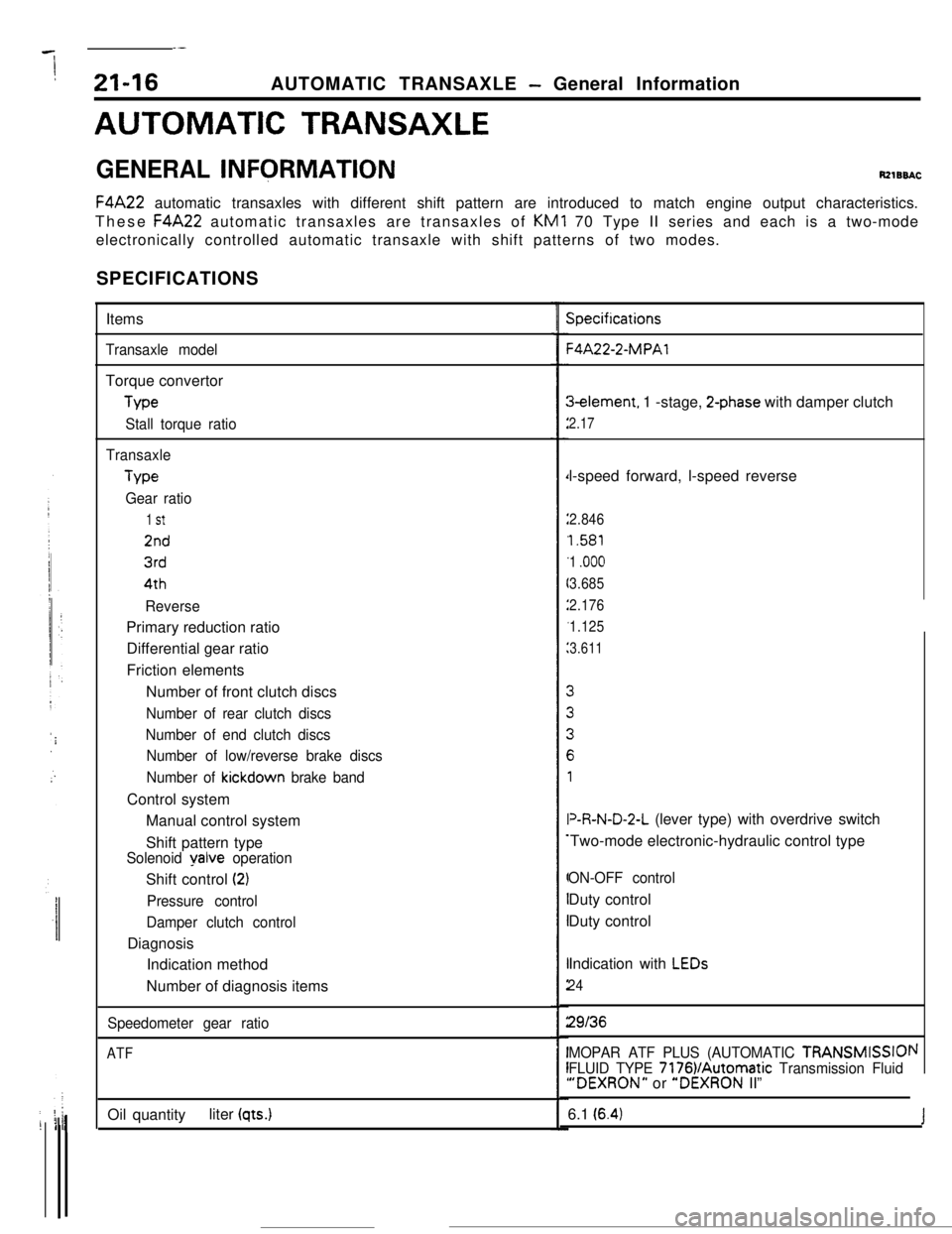

GENERAL INFQRMATIONRzlBBACF4A22 automatic transaxles with different shift pattern are introduced to match engine output characteristics.

These F4A22 automatic transaxles are transaxles of KM1 70 Type II series and each is a two-mode

electronically controlled automatic transaxle with shift patterns of two modes.

SPECIFICATIONS

Items

Transaxle modelTorque convertor

Me

Stall torque ratio

TransaxleType

Gear ratio

1 St

2nd

3rd4th

ReversePrimary reduction ratio

Differential gear ratio

Friction elements

Number of front clutch discs

Number of rear clutch discs

Number of end clutch discs

Number of low/reverse brake discs

Number of

kickdown brake bandControl system

Manual control system

Shift pattern type

Solenoid yalve operationShift control

(2)

Pressure control

Damper clutch controlDiagnosis

Indication method

Number of diagnosis items

Speedometer gear ratio

ATFOil quantityliter

(qts.)

Specifications-4A22-2-MPAl3element, 1 -stage,

2-phase with damper clutch

2.17l-speed forward, l-speed reverse

2.846

1.581

1

.ooo

3.685

2.176

1.125

3.611V&N-D-2-L (lever type) with overdrive switch

Two-mode electronic-hydraulic control type

ON-OFF controlDuty control

Duty control

Indication with

LEDs

24

29136

MOPAR ATF PLUS (AUTOMATIC TRANSMISSIOI

FLUID TYPE 7176VAutomatic Transmission Fluid“DEXRON” or “DEXRON II”

\I6.1

(6.4)J