engine MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 1195 of 1216

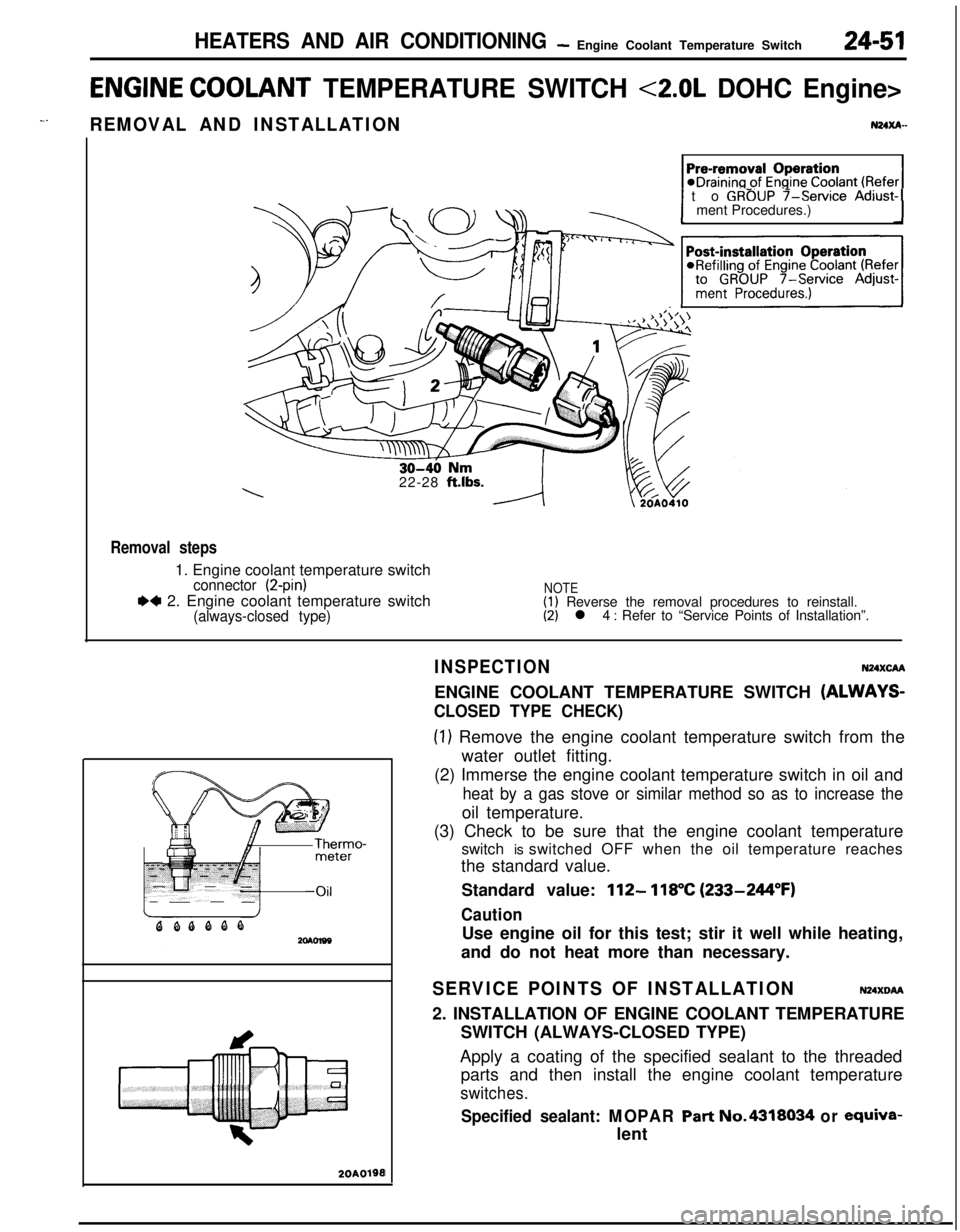

HEATERS AND AIR CONDITIONING- Engine Coolant Temperature Switch24-51

ENGINE COOLANT TEMPERATURE SWITCH <2.0L DOHC Engine>

-.REMOVAL AND INSTALLATIONN24xA-

1 to GROUP f-service Adjust-1ment Procedures.)

22-28

ft.lbs.

Removal steps1. Engine coolant temperature switch

connector (2-pin)

.4 2. Engine coolant temperature switch(always-closed type)

NOTE(1) Reverse the removal procedures to reinstall.(2) l 4 : Refer to “Service Points of Installation”.

20A0190I

INSPECTIONN24XcAAENGINE COOLANT TEMPERATURE SWITCH

(ALWAYS-

CLOSED TYPE CHECK)

(1) Remove the engine coolant temperature switch from the

water outlet fitting.

(2) Immerse the engine coolant temperature switch in oil and

heat by a gas stove or similar method so as to increase theoil temperature.

(3) Check to be sure that the engine coolant temperature

switch is switched OFF when the oil temperature reaches

the standard value.

Standard value:

112- 118°C (233-244°F)

CautionUse engine oil for this test; stir it well while heating,

and do not heat more than necessary.

SERVICE POINTS OF INSTALLATIONN24XDM2. INSTALLATION OF ENGINE COOLANT TEMPERATURE

SWITCH (ALWAYS-CLOSED TYPE)

Apply a coating of the specified sealant to the threaded

parts and then install the engine coolant temperature

switches.

Specified sealant: MOPAR Part No.4318034 or ewiva-lent

Page 1197 of 1216

.^

EMISSION CONTROL

SYSTEMS

CONTENTSN25AA-

CATALYTICCONVERTER...............................20CRANKCASE EMISSION CONTROL

SYSTEM...........................................................7Components Location

...................................7Crankcase Ventilation System

Inspection......................................................8Positive Crankcase Ventilation Valve

...........8EVAPORATIVE EMISSION CONTROL

SYSTEM...........................................................9

AirConditionerSwitch.................................14Air Flow Sensor, Engine Coolant

Temperature Sensor and Intake Air

Temperature Sensor

.....................................14

Canister.........................................................14Components Location

...................................9

FuelFillerCapInspection............................14Overfill Limiter (Two-way Valve)

..................14

PurgeControlSolenoidValve......................13Purge Control

SystemInspection................11

PurgeControlValve

SYSTEM...........................................................15Air-fuel Ratio Control (MPI) System

............20Components Location

...................................15EGR Control Solenoid Valve

.................................................19

EGR

SystemInspection...............................17EGR Temperature Sensor

......19

EGR Valve.....................................................18

Therm0 Valve

SPECIFICATIONS.............................................2General Specifications

..................................2

Sealant..........................................................2Service Specifications

...................................2

TorqueSpecifications...................................2

TROUBLESHOOTING......................................3

VACUUMHOSES...........................................4

VacuumHosesRouting...............................4

Page 1198 of 1216

EMISSION CONTROL SYSTEMS - Specifications

SPECIFICATIONS

GENERAL SPECIFICATIONSN25CA-ItemsSpecifications

.,:..rCrankcase emission control systemClosed type with positive crankcase ventilation valve”I

‘:Evaporative emission control systemCanister storage type

CanisterCharcoal type

Exhaust emission control system

Exhaust gas recirculation system

EGR valveVacuum-activated diaphragm type

Therm0 valveBimetal type

EGR temperature sensor

EGR control solenoid valve

Duty cycle solenoid valve

Catalytic converterMonolith type

LocationUnder floor

SERVICE SPECIFICATIONSN25CB-

ItemsSpecifications

Purge-control solenoid valve coil resistance

&236-44 [at 20°C (68”F)I

Therm0 valve closing temperature“C (“F)65 (149)

EGR temperature sensor resistance

kQ60-83 [at 50°C (122”F)]11-14 [at

100°C (212”F)]EGR control solenoid valve coil resistance

S236-44 [at 20°C (68”F)]

TORQUE SPECIFICATIONSN25CC-

ItemsPositive crankcase ventilation valve

EGR valve installation bolt

<2.0L DOHC Engine>

Therm0 valve

EGR temperature sensor

Nmftlbs.8-12

6-8.5

IO-157.2-1015-22

10-15.5

20-4015-30

10-127.3-8.6

SEALANT

Items

Therm0 valve thread portionSpecified sealant

MOPAR Part No.4318034 or equivalent

Page 1199 of 1216

-.

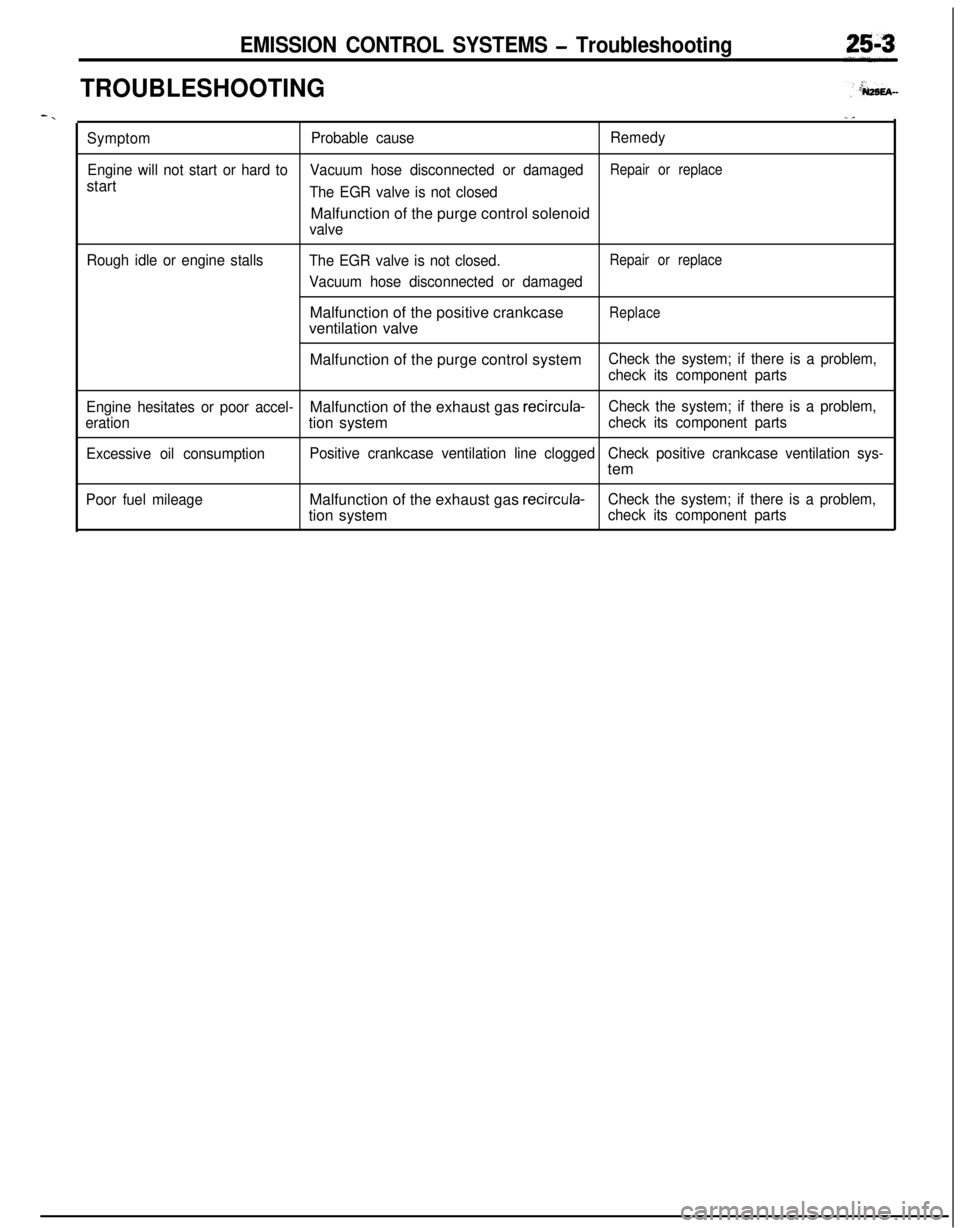

EMISSION CONTROL SYSTEMS - Troubleshooting

TROUBLESHOOTING

., ,_

SymptomProbable causeRemedy

Engine will not start or hard toVacuum hose disconnected or damaged

Repair or replacestart

The EGR valve is not closedMalfunction of the purge control solenoid

valve

Rough idle or engine stalls

The EGR valve is not closed.

Repair or replace

Vacuum hose disconnected or damagedMalfunction of the positive crankcase

ventilation valve

ReplaceMalfunction of the purge control system

Check the system; if there is a problem,

check its component parts

Engine hesitates or poor accel-Malfunction of the exhaust gas

recircula-Check the system; if there is a problem,

erationtion systemcheck its component parts

Excessive oil consumptionPositive crankcase ventilation line cloggedCheck positive crankcase ventilation sys-tem

Poor fuel mileageMalfunction of the exhaust gas recircula-Check the system; if there is a problem,tion systemcheck its component parts

Page 1200 of 1216

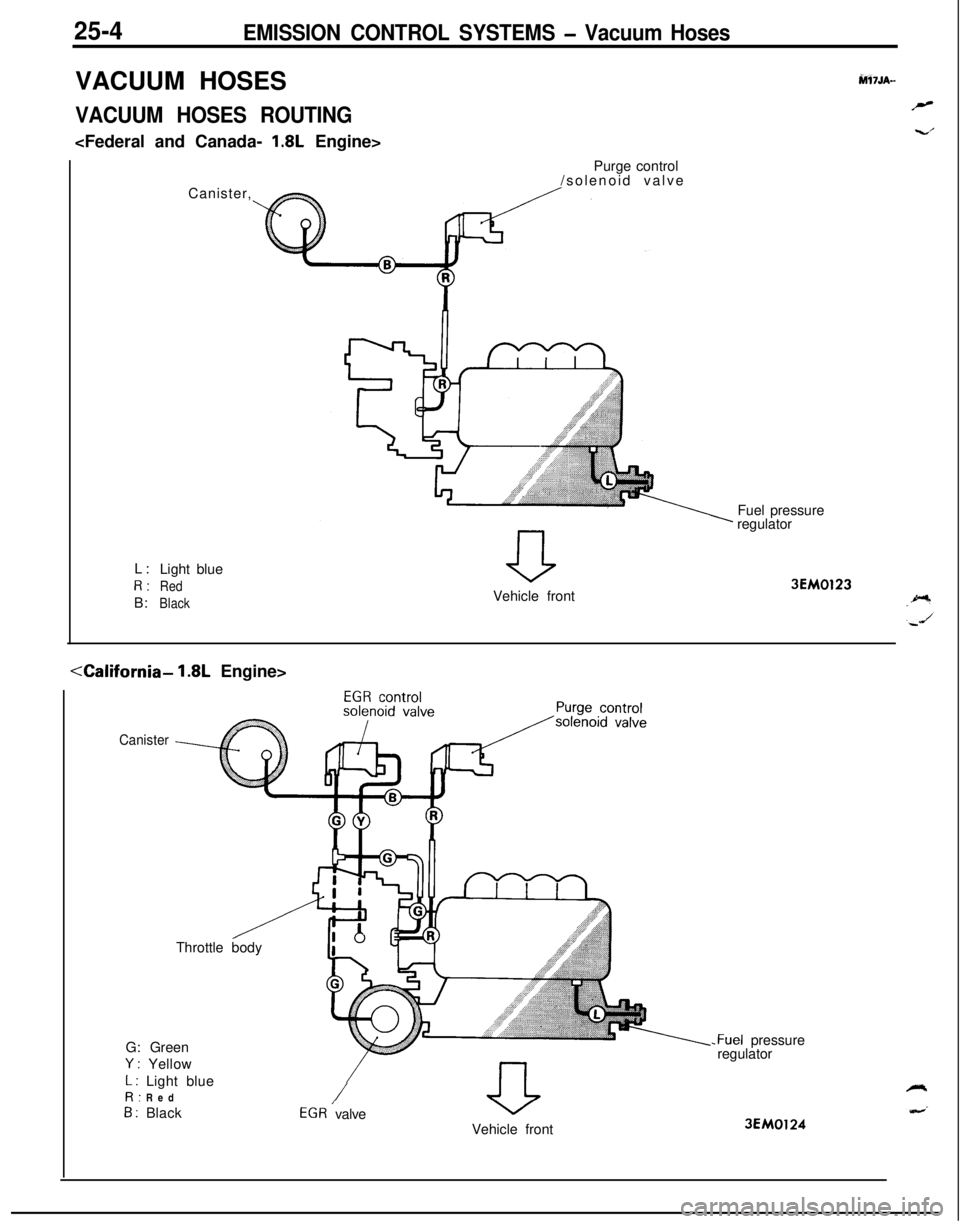

25-4EMISSION CONTROL SYSTEMS - Vacuum HosesVACUUM HOSES

VACUUM HOSES ROUTING

hW7JA-

r”

w..’L:

Light blueR:

RedB:

BlackCanister,Purge control

/solenoid valve

Fuel pressure

regulator

Vehicle front

3EM0123

<-LCalifornia- 1.8L Engine>

CanisterThrottle body

aVehicle front G: Green

Y : Yellow

L : Light blueR: Red

B : Black/EGR valve

-Fuel pressure

regulator

3EM0124

Page 1201 of 1216

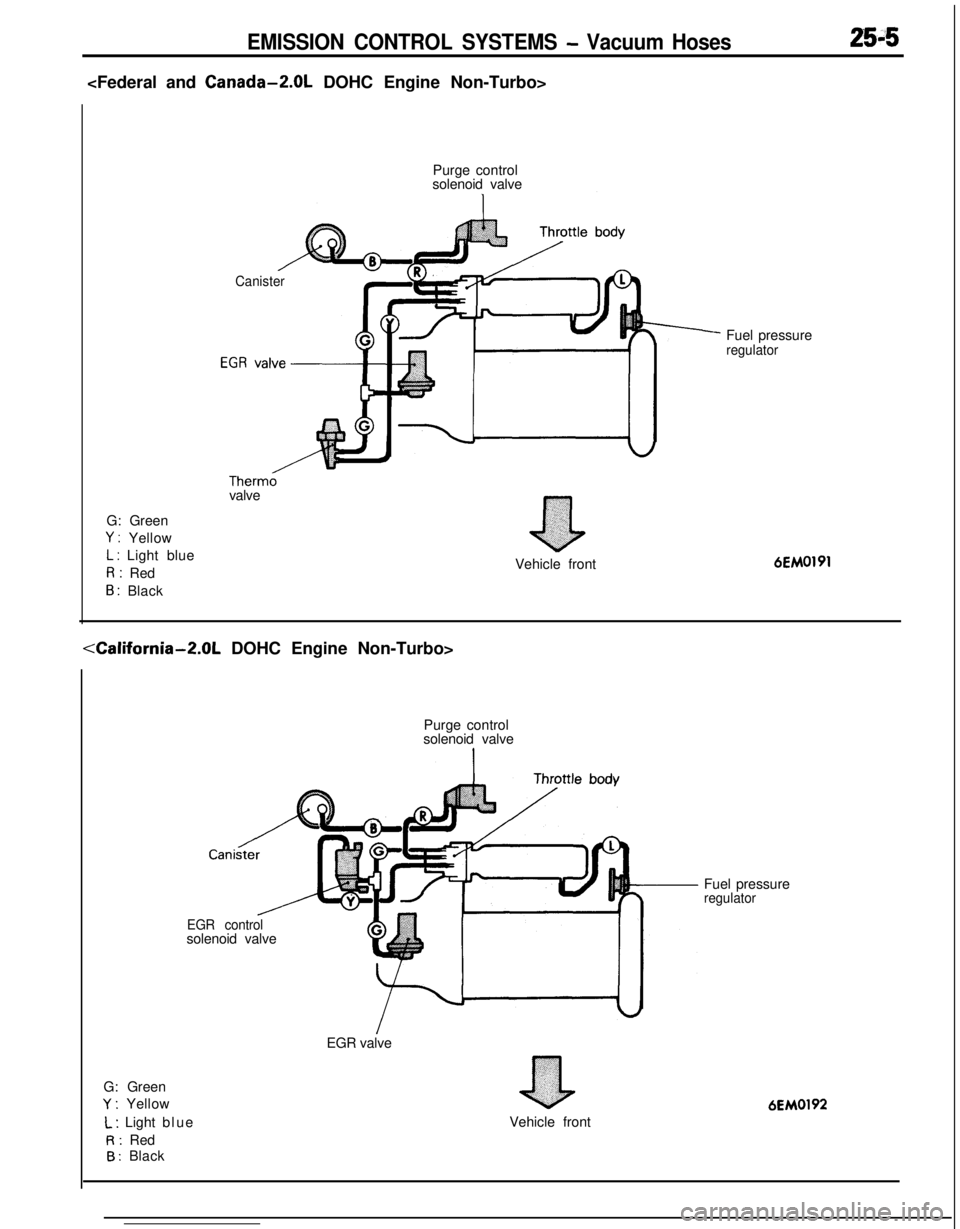

EMISSION CONTROL SYSTEMS - Vacuum Hoses2515

Purge control

solenoid valve

Canister

Therm0valve

G: Green

Y : Yellow

L : Light blueR: Red

B : Black

nVehicle frontFuel pressure

regulator6EM0191

G: Green

Y : YellowPurge control

solenoid valve

Cani

EGR controlsolenoid valve

EGR valve

L : Light blue

R: Red

B : BlackVehicle frontFuel pressure

regulator

6EM0192

Page 1202 of 1216

25-6EMISSION CONTROL SYSTEMS - Vacuum Hoses

G: Green

Y : Yellow

L : Light blueR: Red

B : Black

W: White

Purge control valvg

Purge controlFuel pressure control,solenoid valve/solenoid valve

Therm0 valve’

el pressure regulator

Turbocharger

vvasre gate actuator Waste gate control

solenoid valveVehicle front

6EM0222

G: Green

Y : Yellow

L : Lrght blueR: Red

B : Black

W: White

1sPurge control valve

&+

Air cleanerFuel pressure control

solenoid valve.

Purge control

solenoid valve\Fuel pressure regulator

Waste gate control

solenord valve

Waste gate actuatorv.,~~‘~y:‘;7Vehicle front

6EM0223

Page 1203 of 1216

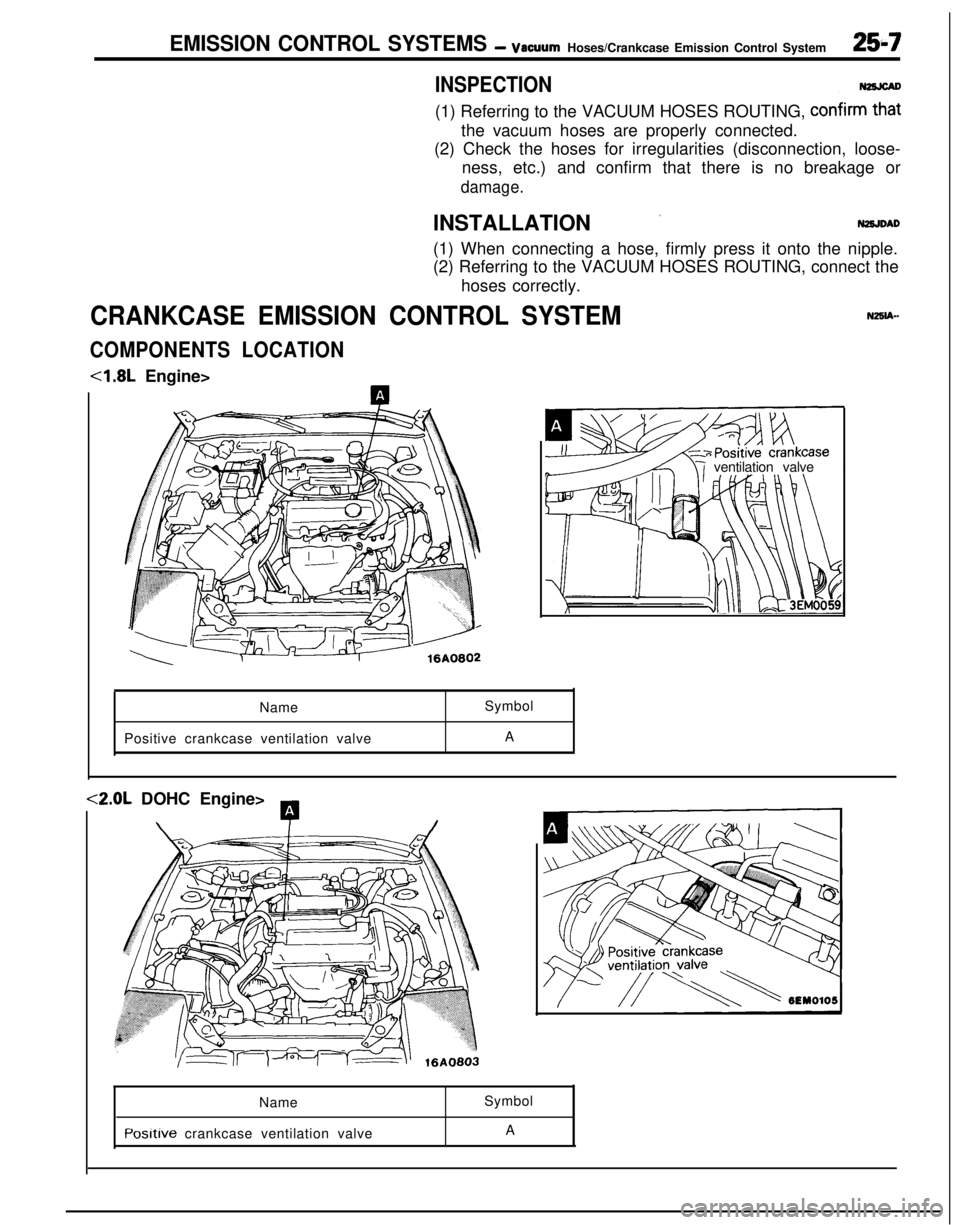

EMISSION CONTROL SYSTEMS - vacuumHoses/Crankcase Emission Control System25-7

INSPECTION(1) Referring to the VACUUM HOSES ROUTING,

confirm2the vacuum hoses are properly connected.

(2) Check the hoses for irregularities (disconnection, loose-

ness, etc.) and confirm that there is no breakage or

damage.INSTALLATION

’N2SJDAD(1) When connecting a hose, firmly press it onto the nipple.

(2) Referring to the VACUUM HOSES ROUTING, connect the

hoses correctly.

CRANKCASE EMISSION CONTROL SYSTEM

COMPONENTS LOCATION<1.8L Engine>

ventilation valve

NameSymbol

Positive crankcase ventilation valveA<2.0L DOHC Engine>

A

\T/Name

Posltive crankcase ventilation valveSymbol

A

Page 1204 of 1216

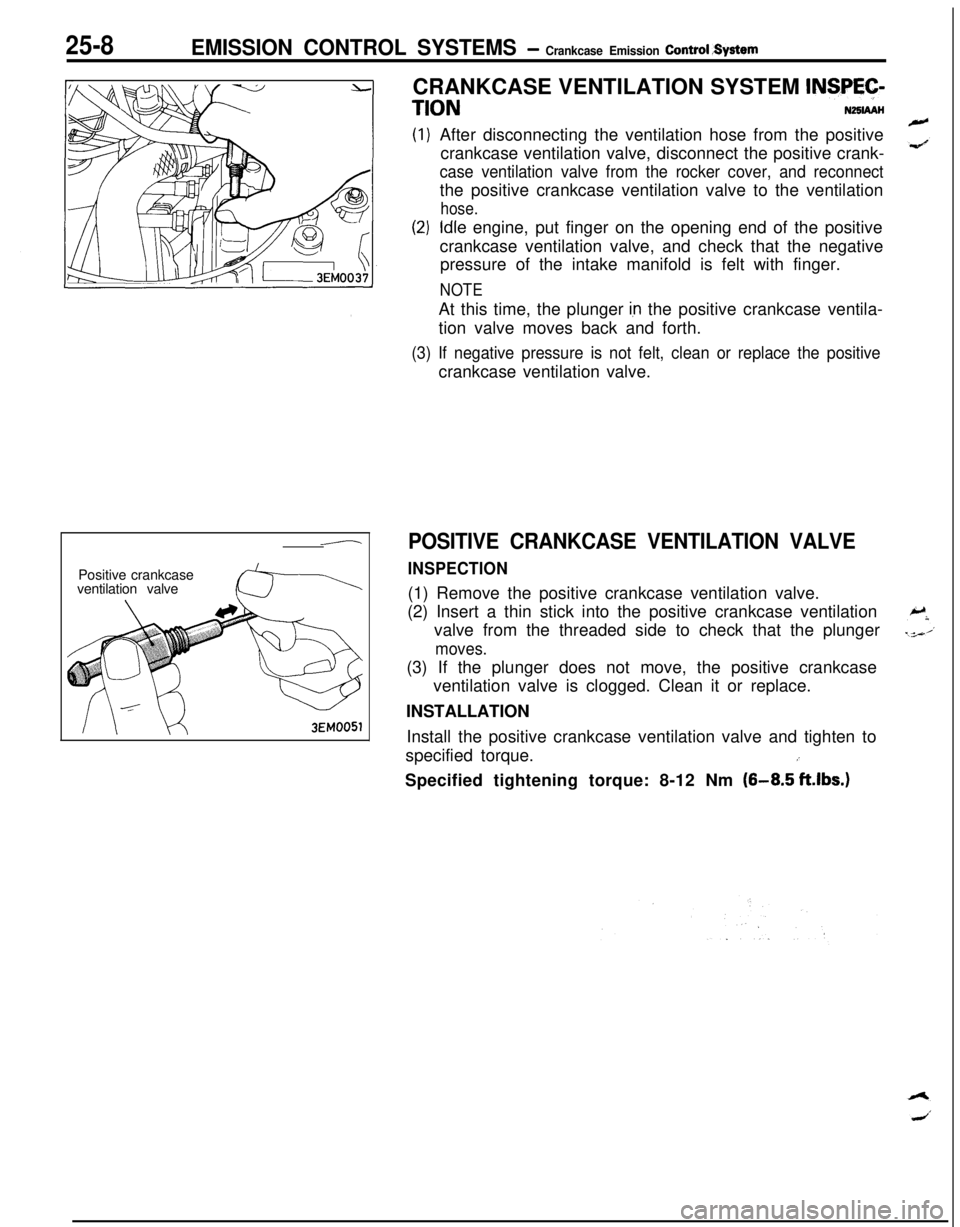

25-8EMISSION CONTROL SYSTEMS - Crankcase Emission Control System

-Positive crankcase

ventilation valve3EM0051CRANKCASE VENTILATION SYSTEM

INSPEC-

TIONNZSIAAHAfter disconnecting the ventilation hose from the positive

crankcase ventilation valve, disconnect the positive crank-

case ventilation valve from the rocker cover, and reconnectthe positive crankcase ventilation valve to the ventilation

hose.

Idle engine, put finger on the opening end of the positive

crankcase ventilation valve, and check that the negative

pressure of the intake manifold is felt with finger.

NOTEAt this time, the plunger

Ian the positive crankcase ventila-

tion valve moves back and forth.

(3) If negative pressure is not felt, clean or replace the positivecrankcase ventilation valve.

POSITIVE CRANKCASE VENTILATION VALVE

INSPECTION(1) Remove the positive crankcase ventilation valve.

(2) Insert a thin stick into the positive crankcase ventilation

valve from the threaded side to check that the plunger

moves.(3) If the plunger does not move, the positive crankcase

ventilation valve is clogged. Clean it or replace.

INSTALLATION

Install the positive crankcase ventilation valve and tighten to

specified torque.

iSpecified tightening torque: 8-12 Nm

(8-8.5 ft.lbs.)

Page 1205 of 1216

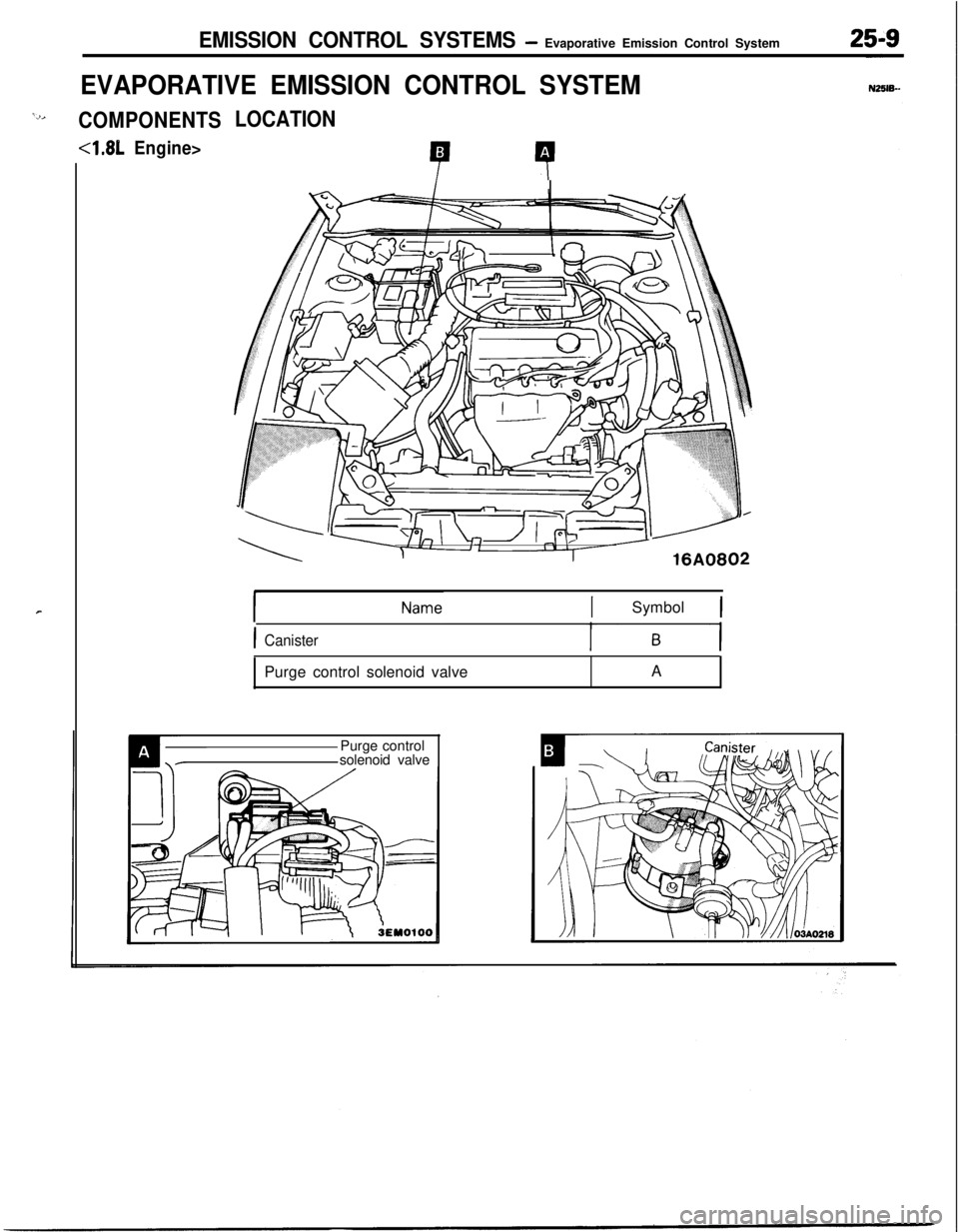

EMISSION CONTROL SYSTEMS- Evaporative Emission Control System

EVAPORATIVE EMISSION CONTROL SYSTEM

‘2,COMPONENTS

4.81,Engine>

r

LOCATION

P 4

xl-#i

ISymbol 1

ICanisterPurge control solenoid valveA

Purge control

solenoid valve