engine MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 955 of 1216

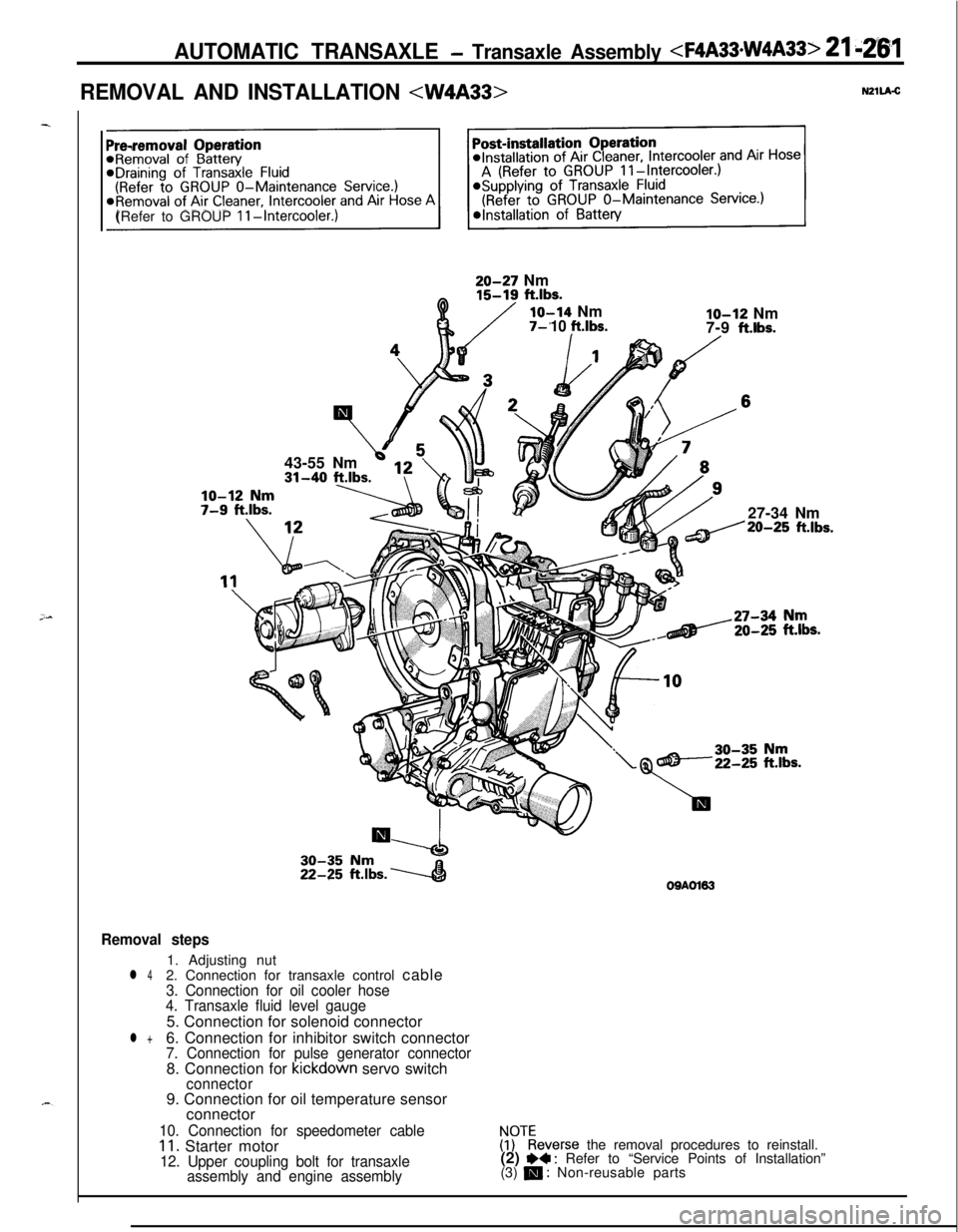

AUTOMATIC TRANSAXLE - Transaxle Assembly

REMOVAL AND INSTALLATION

(Refer to GROUP

II-Intercooler.)43-55 Nm

\i 513 \20-27 Nm

Q15-19 ft.lbs.

lo-14 NmIO-12 Nm10 ft.lbs.7-9 ftlbs.

/27-34 Nm

ft.lbs.

Y

Es.

Removal steps1. Adjusting nut

l 42. Connection for transaxle control cable3. Connection for oil cooler hose

4. Transaxle fluid level gauge5. Connection for solenoid connector

l +6. Connection for inhibitor switch connector7. Connection for pulse generator connector8. Connection for kickdown servo switch

connector9. Connection for oil temperature sensor

OQAOl63connector

10. Connection for speedometer cable11. Starter motor12. Upper coupling bolt for transaxle

assembly and engine assembly

irkeverse the removal procedures to reinstall.

(2) I)+ : Refer to “Service Points of Installation”

(3) m : Non-reusable parts

Page 1040 of 1216

5 22-2WHEELS AND TIRES - Specifications

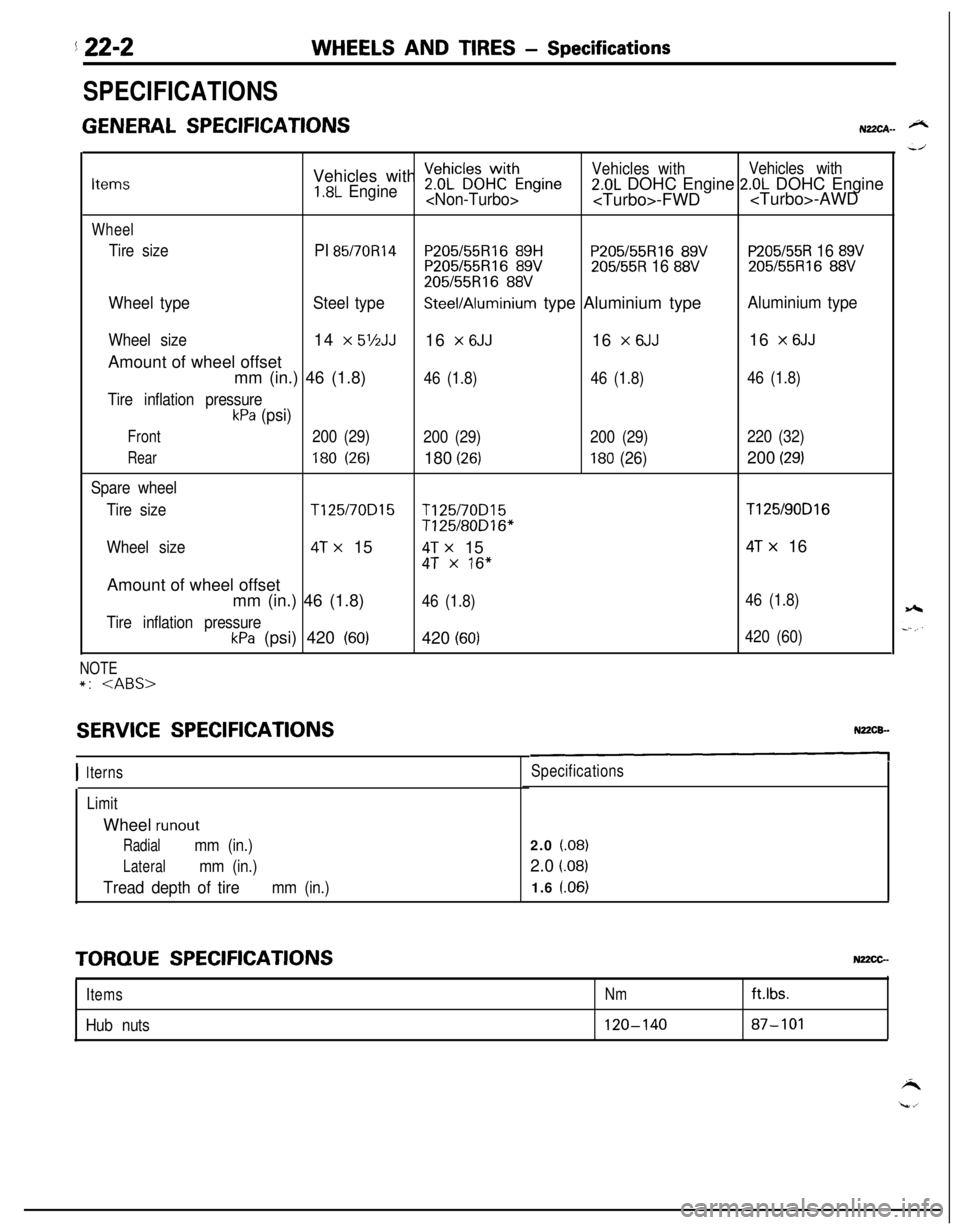

SPECIFICATIONS

GENERAL SPECIFICATIONSN22CA- @NVehicles with

~eDhL”~~HWCthEngineVehicles withVehicles withItems1.8L Engine2.0L DOHC Engine 2.0L DOHC Engine

Wheel

Tire sizePI 85/70R14P205155Rl6 89HP205/55R16 89VP205/55R 16 89VP205155R16 89V205/55R 16 88V205/55R16 88V

205/55R16 88V

Wheel typeSteel typeSteel/Aluminium type Aluminium typeAluminium type

Wheel size14 x 5’/2JJ16 x 6JJ16 x 6JJ16 x 6JJAmount of wheel offset

mm (in.) 46 (1.8)

46 (1.8)46 (1.8)46 (1.8)

Tire inflation pressure

kPa (psi)

Front200 (29)

200 (29)200 (29)220 (32)

Rear180 (26)180 (26)180 (26)200 (29)

Spare wheel

Tire size

T125/70D15T125/70D15T125/90D16

T125/80D16*

Wheel size

4T x 154T x 154T x 16

4T x 16”Amount of wheel offset

mm (in.) 46 (1.8)

46 (1.8)46 (1.8)

Tire inflation pressure

kPa (psi) 420 (60)420 (60)420 (60)

NOTE*:

SERVICE SPECIFICATIONS

I 1terns

LimitWheel

runout

Radialmm (in.)

Lateralmm (in.)

Tread depth of tiremm (in.)

Specifications2.0

(.08)2.0

i.08)1.6 l.06)

TORQUE SPECIFICATIONSNz2cG-

ItemsNm

Hub nuts120-140ftlbs.87-101

Page 1145 of 1216

24-l

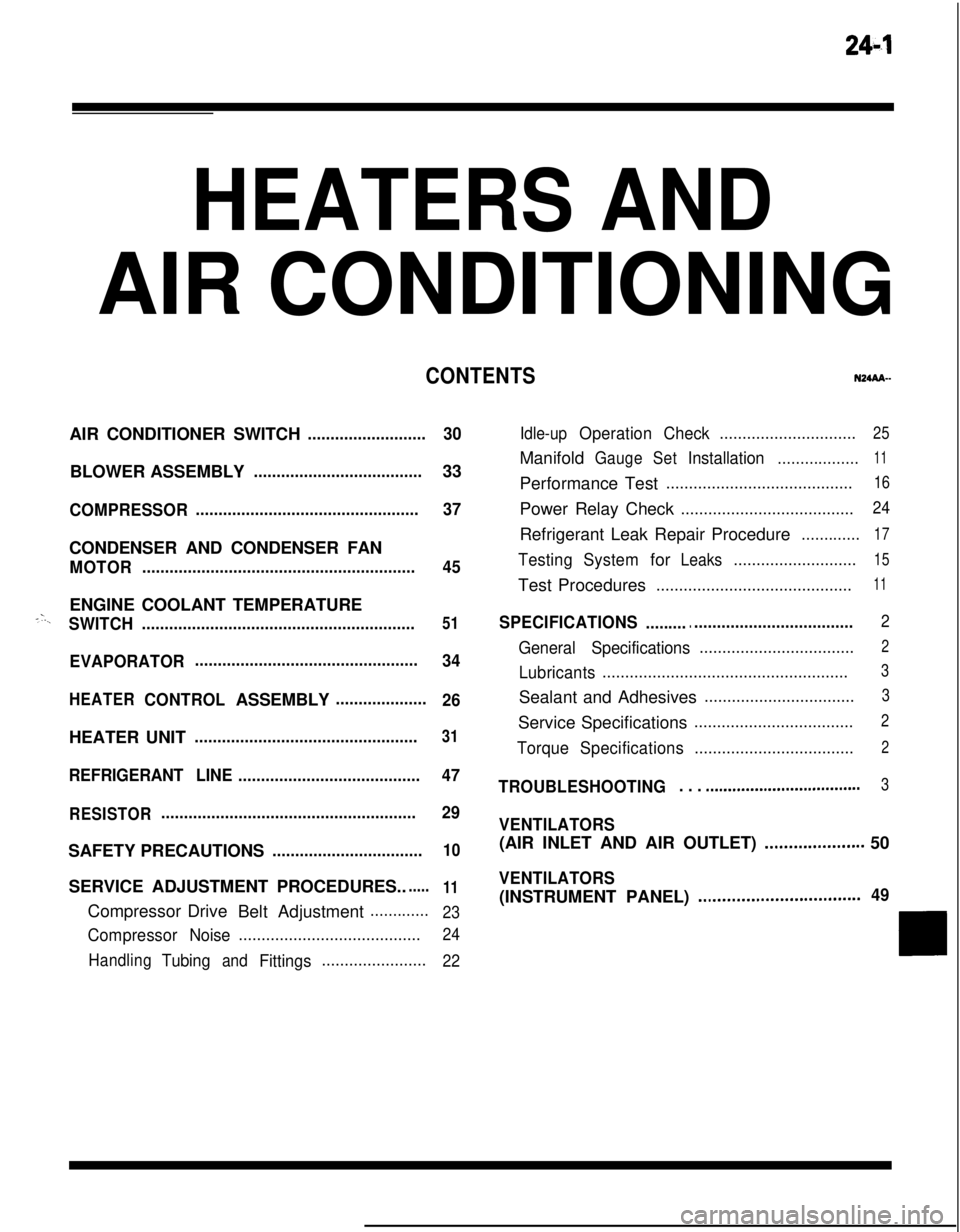

HEATERS ANDAIR CONDITIONING

CONTENTSN24M--AIR CONDITIONER SWITCH

..........................30BLOWER ASSEMBLY

.....................................33

COMPRESSOR.................................................37CONDENSER AND CONDENSER FAN

MOTOR............................................................45ENGINE COOLANT TEMPERATURE

-‘-.,SWITCH............................................................51

EVAPORATOR.................................................

34

HEATERCONTROLASSEMBLY....................

26HEATER UNIT

.................................................31

REFRIGERANTLINE........................................47

RESISTOR........................................................29SAFETY PRECAUTIONS

.................................10SERVICE ADJUSTMENT PROCEDURES..

.....11Compressor Drive

Belt Adjustment

.............

23

CompressorNoise........................................24

Handling

TubingandFittings.......................22Idle-up

OperationCheck..............................25Manifold

GaugeSetInstallation..................11Performance Test

.........................................16Power Relay Check

......................................24Refrigerant Leak Repair Procedure

.............17

TestingSystemforLeaks...........................15Test Procedures

...........................................11

SPECIFICATIONS.............................................2

General Specifications..................................2

Lubricants......................................................3Sealant and Adhesives

.................................3Service Specifications

...................................2

TorqueSpecifications...................................2

TROUBLESHOOTING. . . ..a................................3

VENTILATORS(AIR INLET AND AIR OUTLET)

..,....s............. 50

VENTILATORS(INSTRUMENT PANEL)

..,...................*...........49

Page 1146 of 1216

24-2HEATERS AND AIR CONDITIONING - Specifications

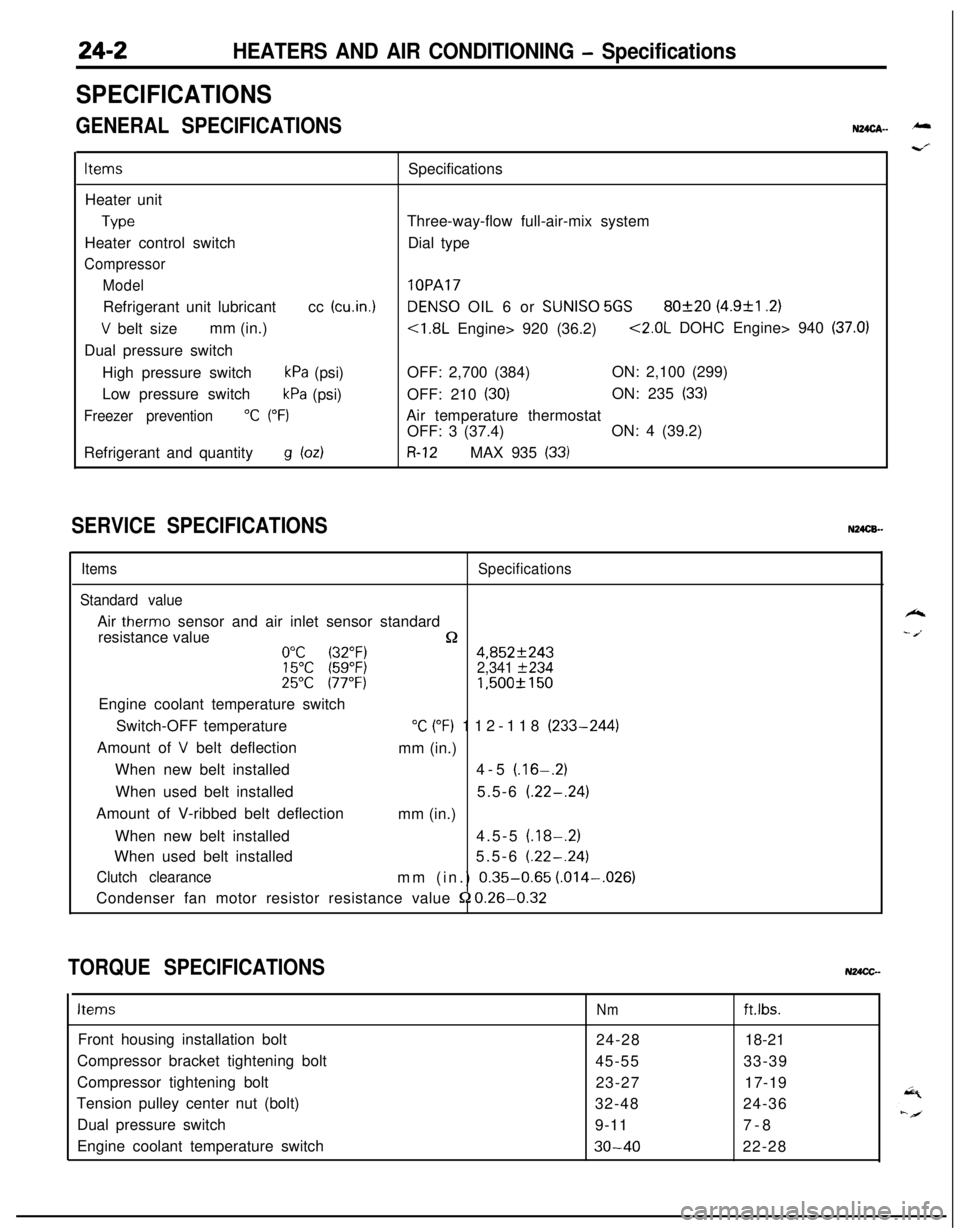

SPECIFICATIONS

GENERAL SPECIFICATIONSN24cA- -

ItemsSpecifications

Heater unit

TypeThree-way-flow full-air-mix system

Heater control switchDial type

Compressor

Model

lOPARefrigerant unit lubricantcc

(cu.in.1DENS0 OIL 6 or SUNISO 5GS80f20 (4.9&l .2)

V belt sizemm (in.)<1.8L Engine> 920 (36.2)<2.0L DOHC Engine> 940 (37.0)Dual pressure switch

High pressure switch

kPa (psi)OFF: 2,700 (384)ON: 2,100 (299)

Low pressure switch

kPa (psi)OFF: 210 (30)ON: 235 (33)

Freezer prevention“C (“F)Air temperature thermostat

OFF: 3 (37.4)ON: 4 (39.2)

Refrigerant and quantity

g bdR-12MAX 935 (33)

SERVICE SPECIFICATIONSN24CB.-

ItemsSpecifications

Standard valueAir

therm0 sensor and air inlet sensor standard

resistance value

n0°C (32°F)4,852f24315°C (59°F)2,341 f23425°C 177°F)1,500f 150Engine coolant temperature switch

Switch-OFF temperature

“C (“F) 112-118 (233-244)

Amount of

V belt deflection

mm (in.)

When new belt installed4-5

(.16-.2)When used belt installed5.5-6

(.22-.24)Amount of V-ribbed belt deflection

mm (in.)

When new belt installed4.5-5

(.18-.2)When used belt installed5.5-6

(.22-.24)

Clutch clearancemm (in.) 0.35-0.65 (.014-,026)

Condenser fan motor resistor resistance value

52 0.26-0.32

TORQUE SPECIFICATIONSN24CC-

ItemsNmft.lbs.Front housing installation bolt

24-2818-21

Compressor bracket tightening bolt

45-5533-39

Compressor tightening bolt

23-2717-19

Tension pulley center nut (bolt)

32-4824-36

Dual pressure switch

9-117-8

Engine coolant temperature switch

30-4022-28

k

- /.

Page 1147 of 1216

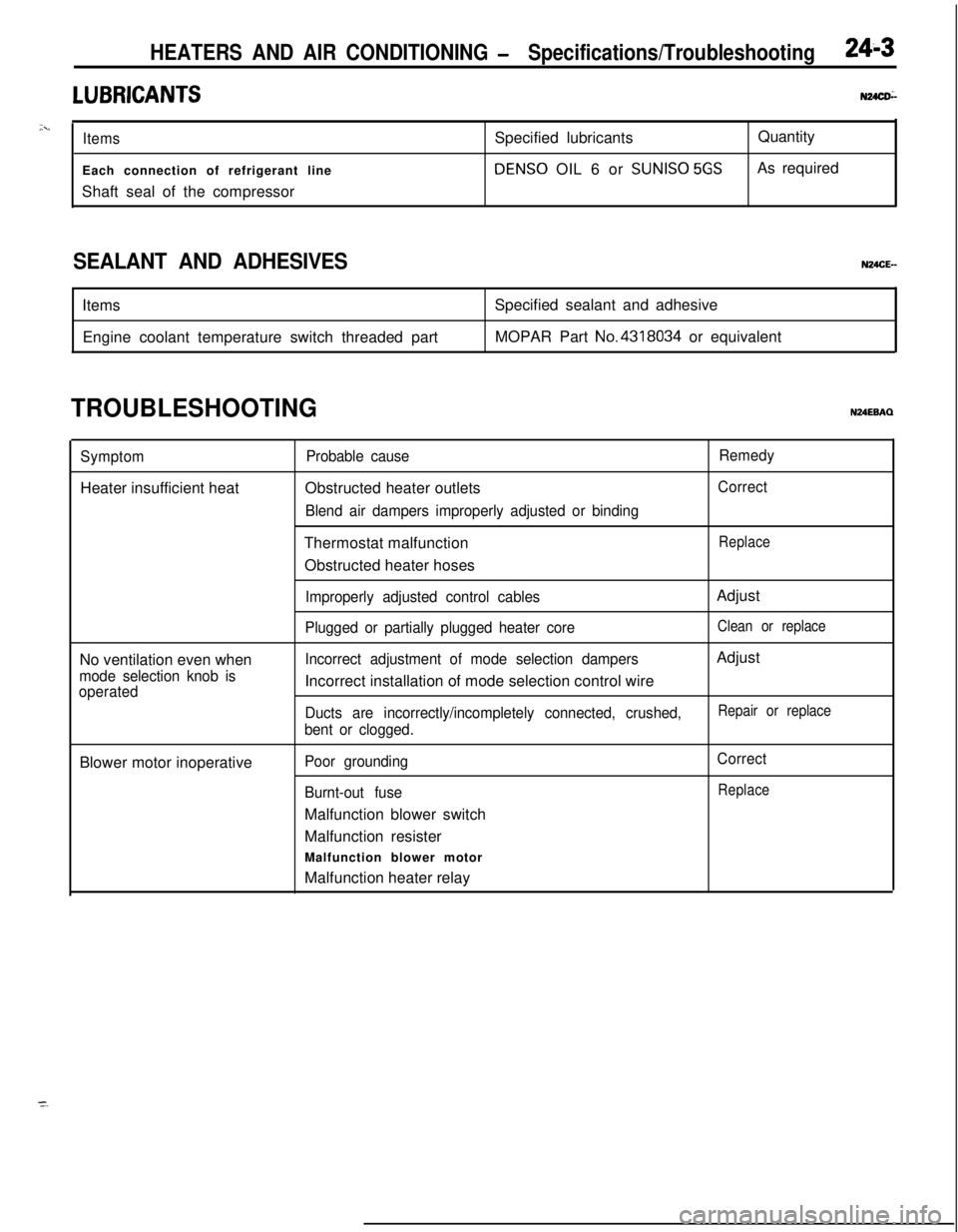

HEATERS AND AIR CONDITIONING - Specifications/Troubleshooting24-3LUBRICANTS

u24as-

;xiItemsSpecified lubricantsQuantity

Each connection of refrigerant lineDENS0 OIL 6 or

SUNISO 5GSAs required

Shaft seal of the compressor

SEALANT AND ADHESIVES, Items

Engine coolant temperature switch threaded partSpecified sealant and adhesive

MOPAR Part No.4318034 or equivalentN24CE-

TROUBLESHOOTINGN24EBAQ

SymptomHeater insufficient heat

No ventilation even when

mode selection knob is

operatedBlower motor inoperative

Probable causeObstructed heater outlets

Blend air dampers improperly adjusted or bindingThermostat malfunction

Obstructed heater hoses

Improperly adjusted control cables

Plugged or partially plugged heater core

Incorrect adjustment of mode selection dampersIncorrect installation of mode selection control wire

Ducts are incorrectly/incompletely connected, crushed,

bent or clogged.

Poor grounding

Burnt-out fuseMalfunction blower switch

Malfunction resister

Malfunction blower motor

Malfunction heater relay

Remedy

Correct

ReplaceAdjust

Clean or replaceAdjust

Repair or replace

Correct

Replace

Page 1149 of 1216

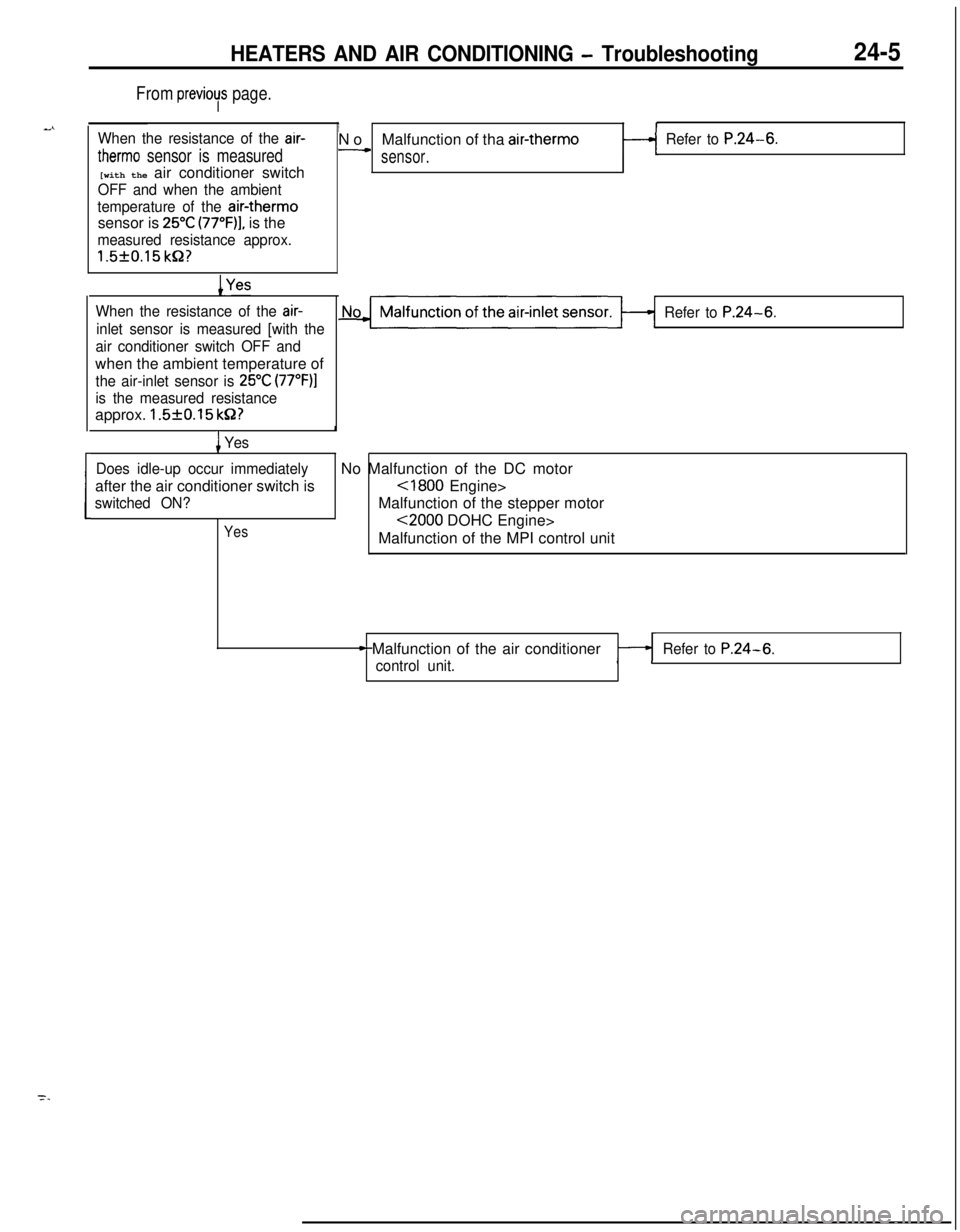

HEATERS AND AIR CONDITIONING - Troubleshooting24-5

From previoys page.

When the resistance of the air-

therm0 sensor is measured[with the air conditioner switch

OFF and when the ambient

temperature of the

air-therm0sensor is

25°C (77“F)], is the

measured resistance approx.

1.5f0.15 kP?

INoMalfunction of tha air-therm0Refer to P.24-6.-sensor.

Refer to P.24-6.

1Yes

When the resistance of the air-

inlet sensor is measured [with the

air conditioner switch OFF andwhen the ambient temperature of

the air-inlet sensor is 25°C (77”F)l

is the measured resistanceapprox.

1.5f0.15 k&2?I

1 Yes

Does idle-up occur immediatelyNo Malfunction of the DC motor

after the air conditioner switch is

cl800 Engine>

switched ON?Malfunction of the stepper motor

Yes~2000 DOHC Engine>

Malfunction of the MPI control unit

* Malfunction of the air conditioner

control unit.Refer to P.24-6.

Page 1152 of 1216

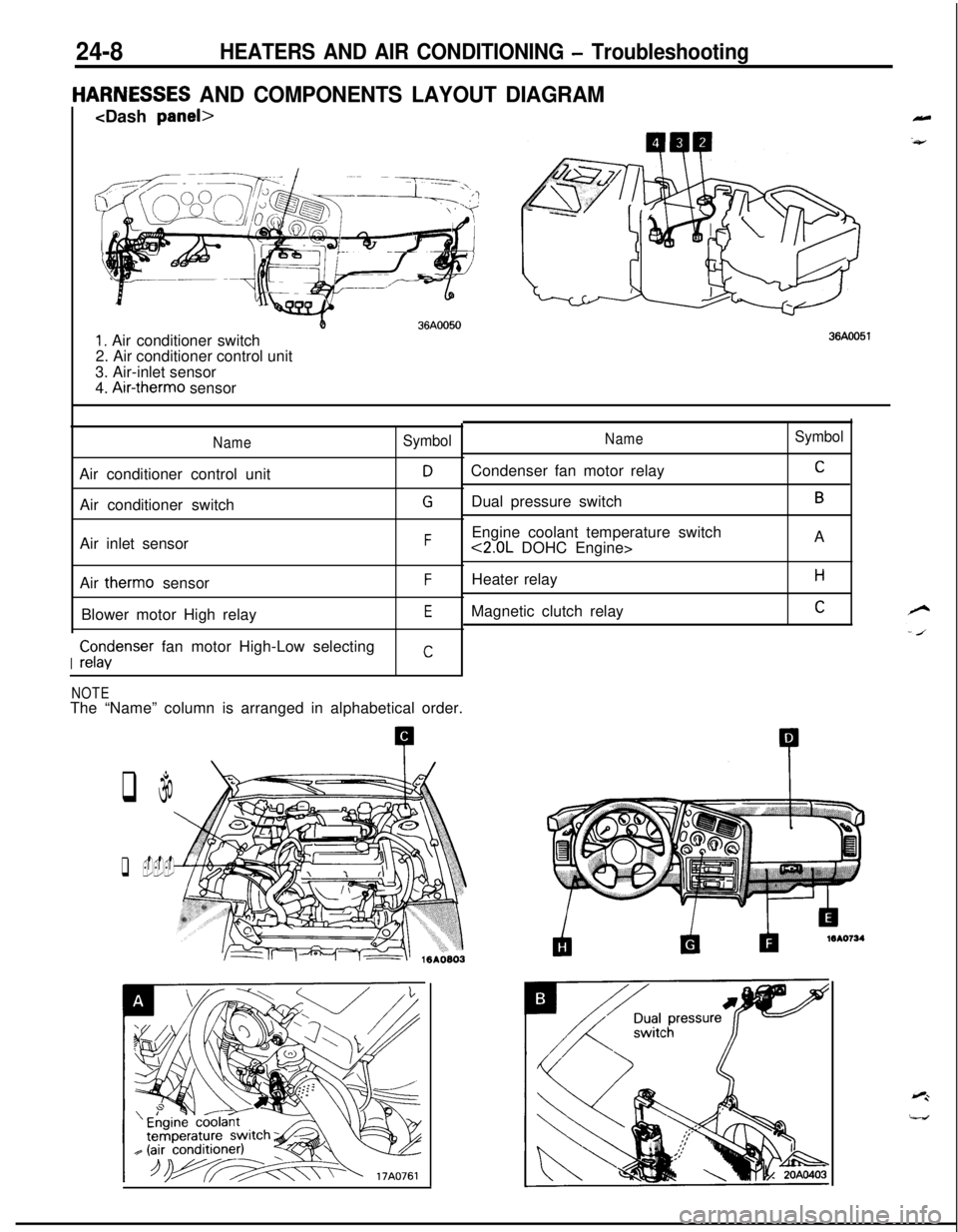

24-8HEATERS AND AIR CONDITIONING - Troubleshooting

IARNESSES AND COMPONENTS LAYOUT DIAGRAM

1. Air conditioner switch

2. Air conditioner control unit

3. Air-inlet sensor

4.

Air-therm0 sensor

36AOO51

NameSymbolAir conditioner control unit

DAir conditioner switch

GAir inlet sensor

FAir

therm0 sensorFBlower motor High relay

E

IrrIor:enser fan motor High-Low selecting

C

NameCondenser fan motor relay

Dual pressure switch

Engine coolant temperature switch

<2.0L DOHC Engine>

Heater relay

Magnetic clutch relay

Symbol

C

BA

H

C

NOTEThe “Name” column is arranged in alphabetical order.

q \

q ---

Page 1155 of 1216

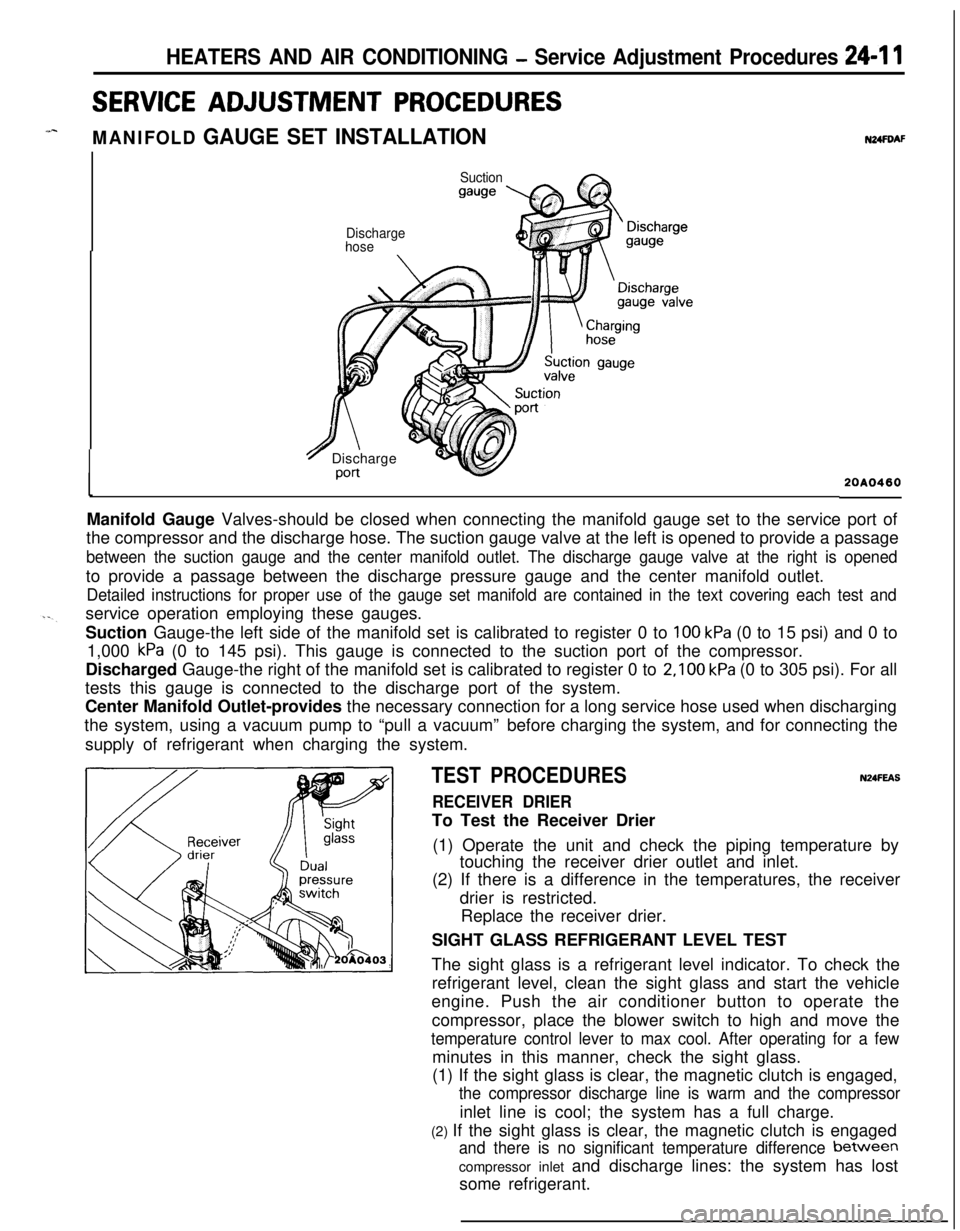

HEATERS AND AIR CONDITIONING - Service Adjustment Procedures 24-I 1

SERVICE ADJUSTMENT PROCEDURES

MANIFOLD GAUGE SET INSTALLATION

Suction

gauge

N24FDAF

Discharge

hose

7 Discharge

Port20A0460Manifold Gauge Valves-should be closed when connecting the manifold gauge set to the service port of

the compressor and the discharge hose. The suction gauge valve at the left is opened to provide a passage

between the suction gauge and the center manifold outlet. The discharge gauge valve at the right is openedto provide a passage between the discharge pressure gauge and the center manifold outlet.

Detailed instructions for proper use of the gauge set manifold are contained in the text covering each test andservice operation employing these gauges.

Suction Gauge-the left side of the manifold set is calibrated to register 0 to

100 kPa (0 to 15 psi) and 0 to

1,000

kPa (0 to 145 psi). This gauge is connected to the suction port of the compressor.

Discharged Gauge-the right of the manifold set is calibrated to register 0 to

2,100 kPa (0 to 305 psi). For all

tests this gauge is connected to the discharge port of the system.

Center Manifold Outlet-provides the necessary connection for a long service hose used when discharging

the system, using a vacuum pump to “pull a vacuum”before charging the system, and for connecting the

supply of refrigerant when charging the system.

TEST PROCEDURESN24FEAS

RECEIVER DRIERTo Test the Receiver Drier

(1) Operate the unit and check the piping temperature by

touching the receiver drier outlet and inlet.

(2) If there is a difference in the temperatures, the receiver

drier is restricted.

Replace the receiver drier.

SIGHT GLASS REFRIGERANT LEVEL TEST

The sight glass is a refrigerant level indicator. To check the

refrigerant level, clean the sight glass and start the vehicle

engine. Push the air conditioner button to operate the

compressor, place the blower switch to high and move the

temperature control lever to max cool. After operating for a fewminutes in this manner, check the sight glass.

(1) If the sight glass is clear, the magnetic clutch is engaged,

the compressor discharge line is warm and the compressorinlet line is cool; the system has a full charge.

(2) If the sight glass is clear, the magnetic clutch is engaged

and there is no significant temperature difference between

compressor inlet and discharge lines: the system has lost

some refrigerant.

Page 1156 of 1216

24-12 HEATERS AND AIR CONDITIONING - Service Adjustment Procedures

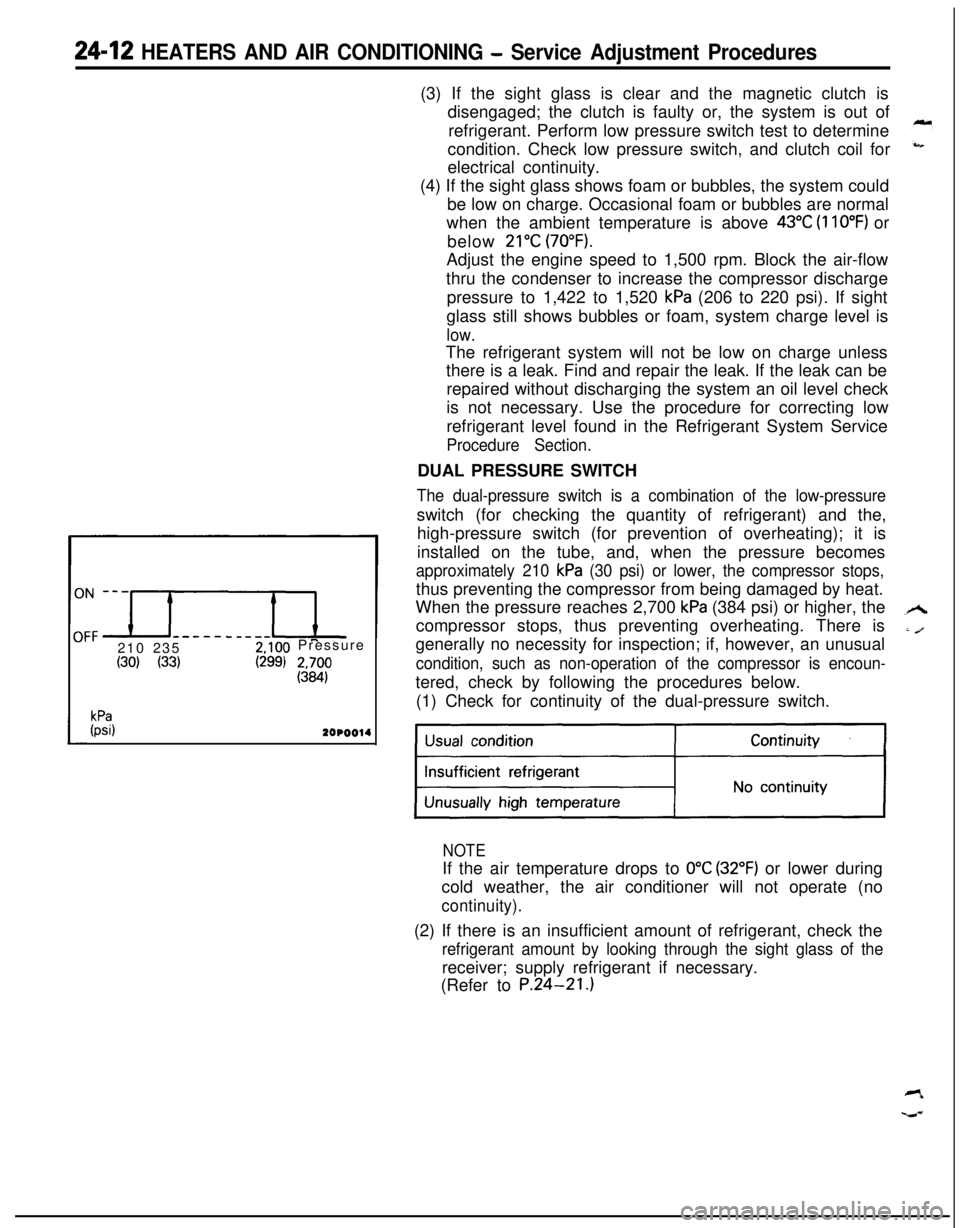

------__--210 2352,100 Pressure

(30) (33)(299) 2&

kPa(psi)2OPOO14(3) If the sight glass is clear and the magnetic clutch is

disengaged; the clutch is faulty or, the system is out of

refrigerant. Perform low pressure switch test to determine

condition. Check low pressure switch, and clutch coil for

electrical continuity.

(4) If the sight glass shows foam or bubbles, the system could

be low on charge. Occasional foam or bubbles are normal

when the ambient temperature is above

43°C (110°F) or

below

21°C (70°F).Adjust the engine speed to 1,500 rpm. Block the air-flow

thru the condenser to increase the compressor discharge

pressure to 1,422 to 1,520

kPa (206 to 220 psi). If sight

glass still shows bubbles or foam, system charge level is

low.The refrigerant system will not be low on charge unless

there is a leak. Find and repair the leak. If the leak can be

repaired without discharging the system an oil level check

is not necessary. Use the procedure for correcting low

refrigerant level found in the Refrigerant System Service

Procedure Section.DUAL PRESSURE SWITCH

The dual-pressure switch is a combination of the low-pressureswitch (for checking the quantity of refrigerant) and the,

high-pressure switch (for prevention of overheating); it is

installed on the tube, and, when the pressure becomes

approximately 210 kPa (30 psi) or lower, the compressor stops,thus preventing the compressor from being damaged by heat.

When the pressure reaches 2,700

kPa (384 psi) or higher, the

compressor stops, thus preventing overheating. There is

generally no necessity for inspection; if, however, an unusual

condition, such as non-operation of the compressor is encoun-tered, check by following the procedures below.

(1) Check for continuity of the dual-pressure switch.

NOTEIf the air temperature drops to

0°C (32°F) or lower during

cold weather, the air conditioner will not operate (no

continuity).(2) If there is an insufficient amount of refrigerant, check the

refrigerant amount by looking through the sight glass of thereceiver; supply refrigerant if necessary.

(Refer to P.24-21.)

Page 1157 of 1216

HEATERS AND AIR CONDITIONING - Service Adjustment Procedures 249*I3

--Air-therm0

sensor

Air inlet

sensor

E>aporator(3)

Set the gauge manifold in place and check whether or not

the pressure at the high-pressure side has become the

dual-pressure switch activation pressure.

(4) Replace the switch if, under ordinary conditions, there is no

continuity.Caution

The condition can be considered to be satisfactory if

there is continuity.

Never increase the pressure in a deliberate attempt to

obtain an abnormally high temperature, because to do

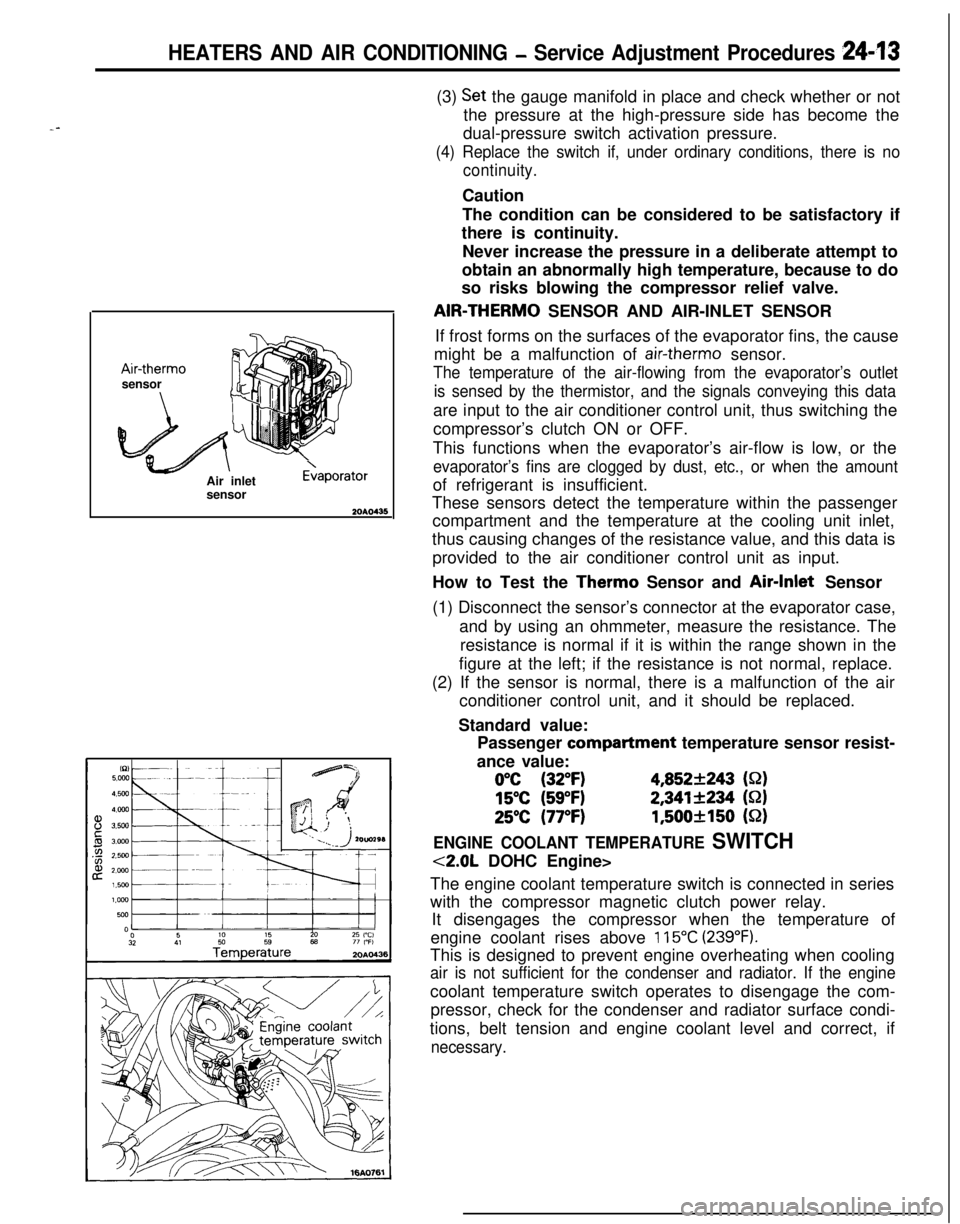

so risks blowing the compressor relief valve.AIR-THERM0 SENSOR AND AIR-INLET SENSOR

If frost forms on the surfaces of the evaporator fins, the cause

might be a malfunction of

air-therm0 sensor.

The temperature of the air-flowing from the evaporator’s outlet

is sensed by the thermistor, and the signals conveying this dataare input to the air conditioner control unit, thus switching the

compressor’s clutch ON or OFF.

This functions when the evaporator’s air-flow is low, or the

evaporator’s fins are clogged by dust, etc., or when the amountof refrigerant is insufficient.

These sensors detect the temperature within the passenger

compartment and the temperature at the cooling unit inlet,

thus causing changes of the resistance value, and this data is

provided to the air conditioner control unit as input.

How to Test the Therm0 Sensor and Air-Inlet Sensor

(1) Disconnect the sensor’s connector at the evaporator case,

and by using an ohmmeter, measure the resistance. The

resistance is normal if it is within the range shown in the

figure at the left; if the resistance is not normal, replace.

(2) If the sensor is normal, there is a malfunction of the air

conditioner control unit, and it should be replaced.

Standard value:

Passenger compartment temperature sensor resist-

ance value:

0°C (32°F)4,852+243 (S-2)

15°C (59°F)2,341+234 (S-2)

25°C (77°F)1,500+150 (52)

ENGINE COOLANT TEMPERATURE SWITCH

<2.0L DOHC Engine>

The engine coolant temperature switch is connected in series

with the compressor magnetic clutch power relay.

It disengages the compressor when the temperature of

engine coolant rises above

115°C (239°F).This is designed to prevent engine overheating when cooling

air is not sufficient for the condenser and radiator. If the enginecoolant temperature switch operates to disengage the com-

pressor, check for the condenser and radiator surface condi-

tions, belt tension and engine coolant level and correct, if

necessary.