engine MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 869 of 1216

AUTOMATIC TRANSAXLE - TroubleshootingBased upon use of the troubleshooting

guide, the probable location of the prob-

lem should be estimated.

Checks should be made of fluid levels

and the condition of the ATF, as well as

bles; adjustments should then be made if

If a presumption has been made that

there is an abnormal condition some-

check the fault code, in order to determinethe probable location of the problem, by

When the abnormal system is discovered,

check each element (sensors, etc.) one byone, and make repairs as necessary.

“~^II_When the abnormal condition is pre-

sumed to be in the

orI-pressure-controlsystem, check by making an oil-pressure

If the problem is unusually dirty ATF,

of the clutch or brakes, or an abnormal

condition of the transaxle itself,

disassem-TROUBLESHOOTING

”N21EeAYFunctional malfunctions of the ELC4A/T can lead to other

problems, such as those described below:

(1) Improper maintenance and/or adjustments

(2) Malfunctions of the electronic control functions

(3) Malfunctions of mechanical functions

(4) Malfunctions of hydraulic control functions

(5) Malfunctions of engine performance

etc.In order to properly determine (“Troubleshoot”) the source of

these malfunctions, it is first essential to methodically ques-

tion the user concerning the details of the problem, such qs

the condition of the problem, the situation at the time the

problem occurred, and any other relevant information, all in as

much detail as possible. The user

shoutd also be asked

whether or not the problem has occurred more than once,

and under what conditions.

Subsequently, certain tests should be conducted in a certain

order, as described at the left.

Page 879 of 1216

AUTOMATIC TRANSAXLE - Troubleshooting21483

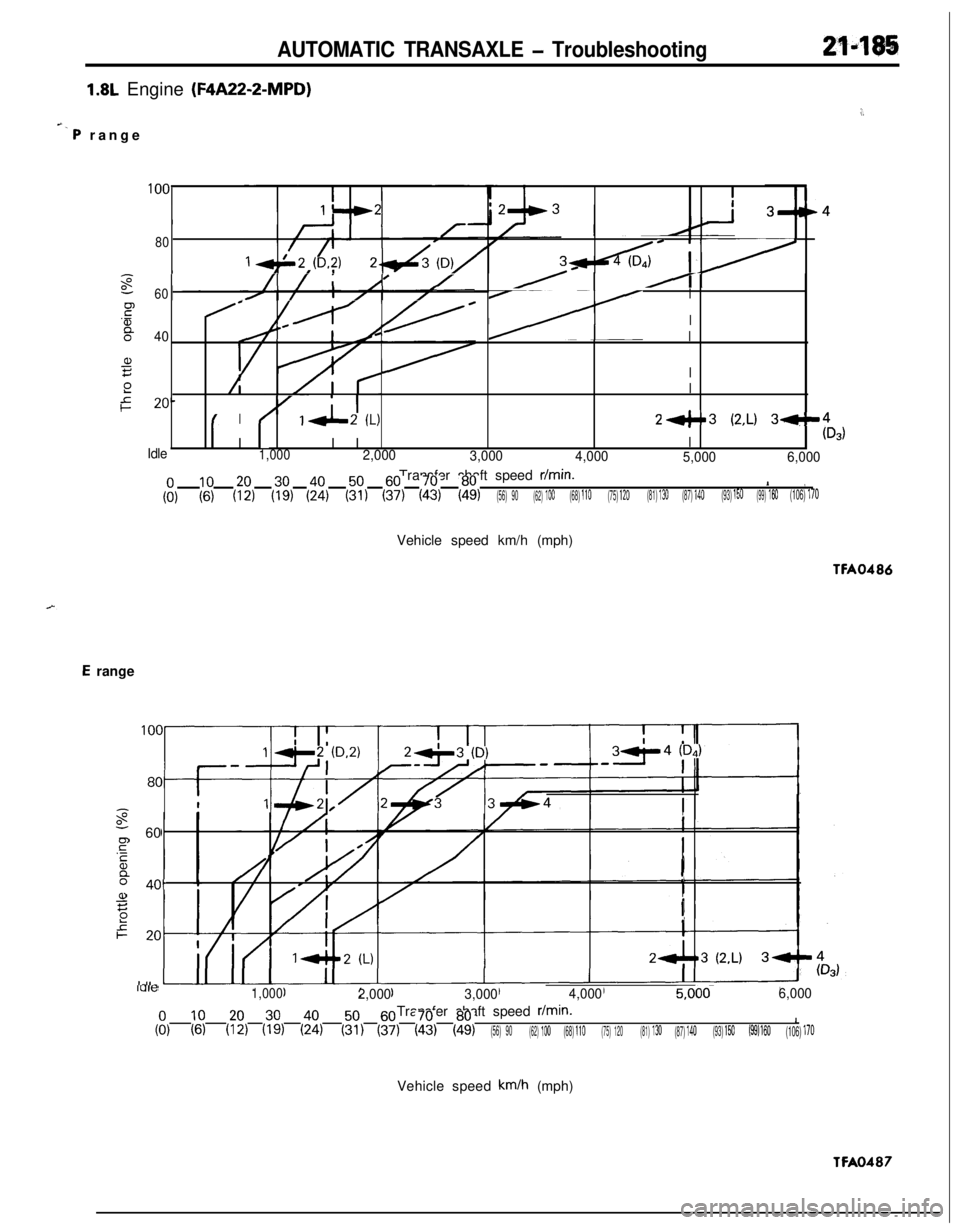

1.8L Engine (F4A22-2-MPD)

+. P range

:,

100II

80c I

I/zb/I/i A’/-60II

Fe

'!zI:I40Jk///@ /'

a,IzI

2Ie20-I

I/' IA (L)24.3 (2,L) 3-14

I(Ds)

IdleI II I1,0002,000

3,000

4,000

5,0006,000Transfer shaft speed

r/min.1I1,

(ii);$(::I(7:)(4:)(::)(i;)(ii)(ii)(56) 90(62) 100(68) 110(75) 120(81) 130(87) 140(93) 150(99) 160(106) 170Vehicle speed km/h (mph)TFA0486

E range

I

- 60I

PI40.

!

a,It:!

ILIlt?1,0002,0003,0004,0005,000~6,000Transfer shaft speed

r/min.1,1I.$1('69(::,(%(%,$7)(i?)(ii,&(56) 90(62) 100(68) 110(75) 120(81) 130(87) 140(93) 150(99) 160(106) 170Vehicle speed

km/h (mph)TFA0487

Page 880 of 1216

21-186AUTOMATIC TRANSAXLE - Troubleshooting

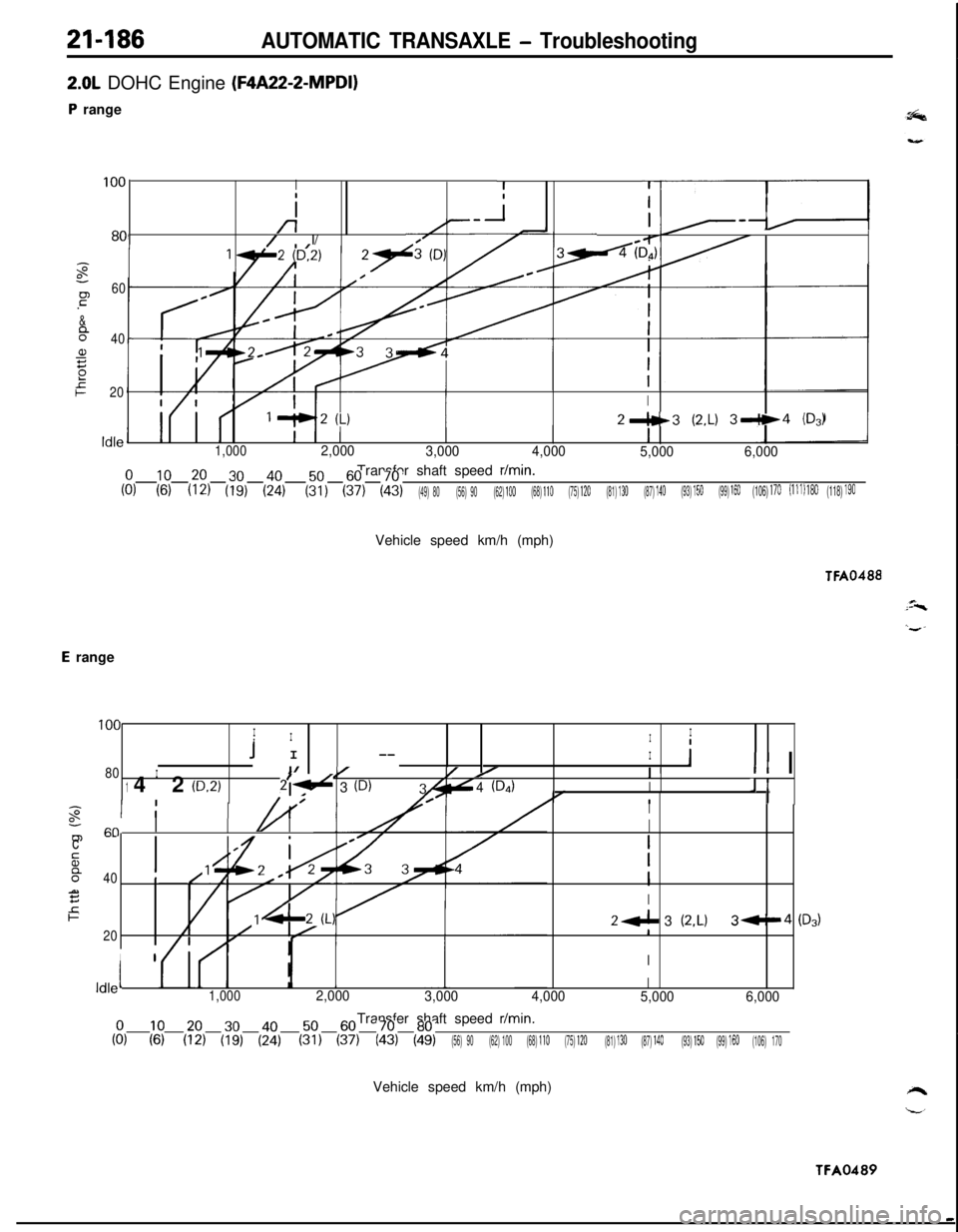

2.0L DOHC Engine (F4A22-2-MPDI)

P range

II

i

-

-z2-I

100I

i

801/ I/

;

P60.-

&

840a,s2

e20I

2"c3 (2.L) 39+4 (DA

Idle1,0002,000

3,0004,000

5,0006,000Transfer shaft speed

r/min.Iiik?66)&(35:)(t;,(ii,(49) 80(56) 90(62) 100(68) 110(75) 120(81) 130(87) 140(93) 150(99) 160(106) 170(111) 180(118) 190Vehicle speed km/h (mph)

TFA0488

E range

100IIIII

I

1I --IiI/80I II/ /Y/I II142(D-2)214 3 (D)4(DAIJ/ /I1

I! I

IIo-/A’III-“1m--c

sI

O"40!al5I

2F24 3(2,L)3-1420I

I1I

ldlelI1,0002,000

3,0004,000

5,0006,000Transfer shaft speed

r/min.I1Iii,('$(:;,(%)(;:)&(:?,(&(::I(56) 90(62) 100(68) 110(75) 120(81) 130(87) 140(93) 150(99) 160(106) 170Vehicle speed km/h (mph)

P3)TFA0489

Page 881 of 1216

AUTOMATIC TRANSAXLE - Troubleshooting

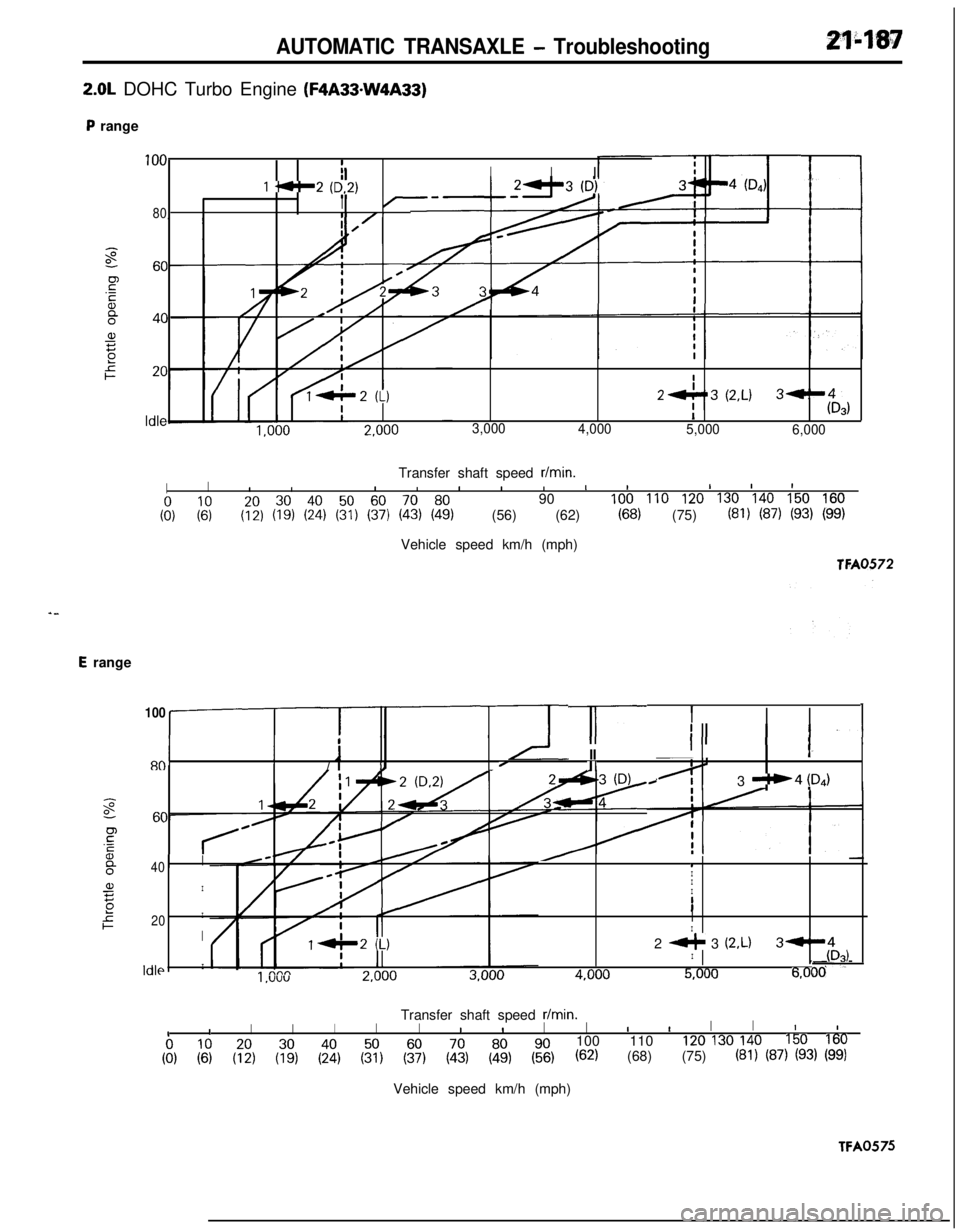

2.0L DOHC Turbo Engine (F4A33-W4A33)

P range

100I

1 .*-2 (6.2,

IIII

80I

I27’3 (2.L)3-I

I$3,

3,000

4,000

5,000

6,000Transfer shaft speed

r/min.

IIIIIIIIII11II

coo, ;fi90

100 110 120 130 140 150 160

(:;j (::j (i:, (?, (!;I (ii, (% (56) (62) (68) (75) (81) (87) (93) (99,Vehicle speed km/h (mph)

TFA0572

E range

l-r

1I

I II

II1

I I-IIIIII-80/IL/IIc

3 --4 !D,)

100

:40I1IaI

EI

I

,o

f20IIIII

I2 +- 3 (2.L)3--I, (4D3,11 nnn'1 nnnA nnn!i nnn6.01Idk

I .vvvL,““”L),““”7,““”-,---~, DOTransfer shaft speed

r/min.

IIIIIIIIIIIIIIIII

(E, (69 (:;, (% (4:) (% (% (ii, (ii, (%100 110

120 130 140150 160

(62) (68) (75) (81) (87) (93, (99,Vehicle speed km/h (mph)

TFA0575

Page 882 of 1216

21-188AUTOMATIC TRANSAXLE - Troubleshooting

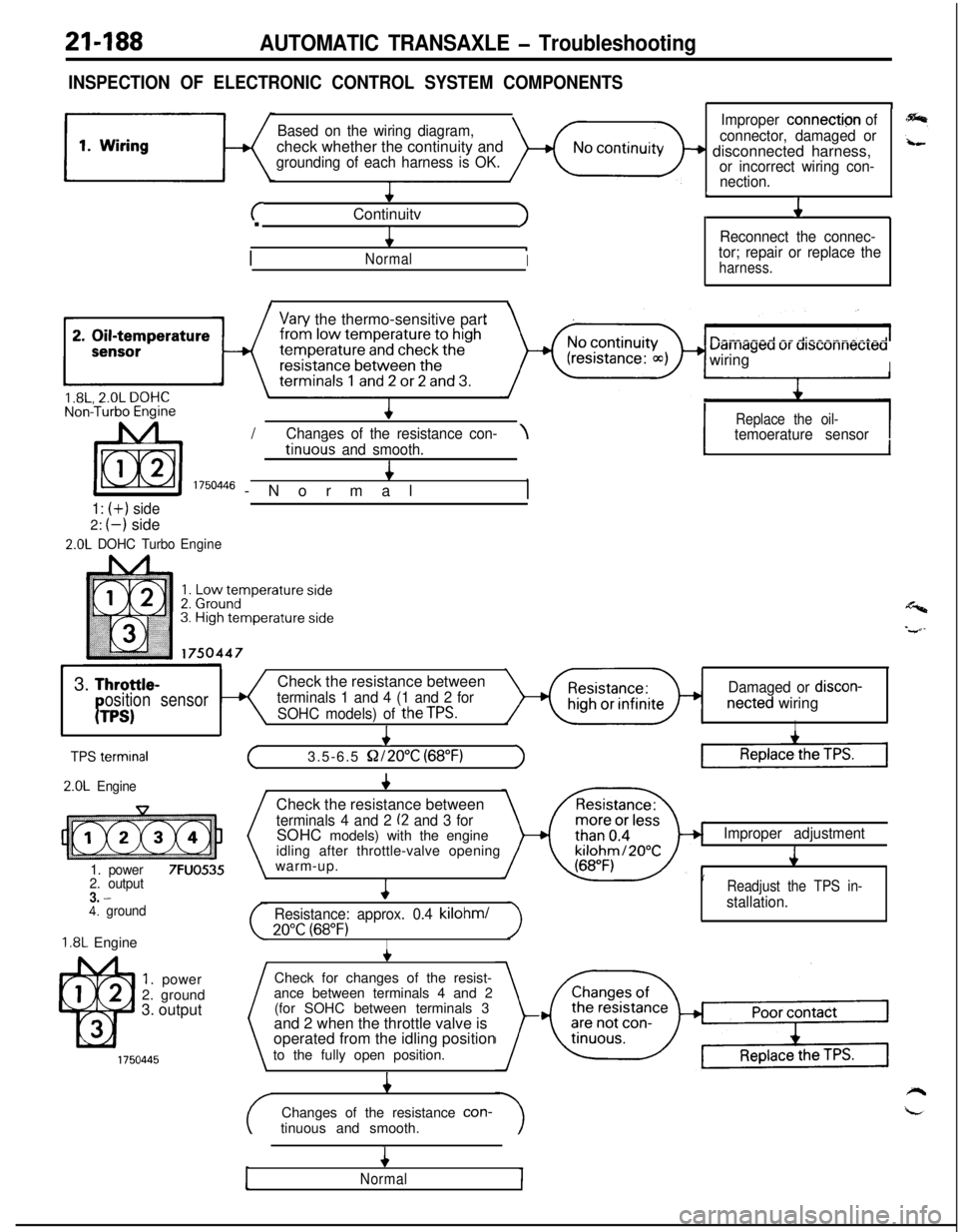

INSPECTION OF ELECTRONIC CONTROL SYSTEM COMPONENTS

Based on the wiring diagram,check whether the continuity and

grounding of each harness is OK.

+

cContinuitvJ.

4

/

.NormalI

1

Improper connection of

connector, damaged or

+ disconnected harness,or incorrect wiring con-

nection.

L

J1

Reconnect the connec-

tor; repair or replace the

harness.

I\

Vary the thermo-sensitive part

uarriageu ur ursconnecreawiring

I/

IReplace the oil-Chanaes of the resistance con-\temoerature sensortinuo& and smooth.4

I 1750446 -Normal,

1: (+) side2:

(-) side

2.0L DOHC TurboEngine

1I

Y3.

Throttle-Check the resistance betweenosition sensorterminals 1 and 4 (1 and 2 forDamaged or discon-

PTPS)SOHC models) of theTPS.netted wiringI

I

TPS termrnal

2.0L Engine

1. power

7FUO5352. output3. -4. ground

1.8L Engine

1. power

2. ground

3. output

+

(3.5-6.5 S2/2O”C (68°F)1Check the resistance between

terminals 4 and 2 (2 and 3 forSOHC models) with the engine

idling after throttle-valve opening

warm-up.

4

Resistance: approx. 0.4 kilohml

20°C (68°F)I

Improper adjustment

J

’Readjust the TPS in-

stallation.Check for changes of the resist-

ance between terminals 4 and 2

(for SOHC between terminals 3

and 2 when the throttle valve is

operated from the idling position

to the fully open position.

4Changes of the resistance con-

tinuous and smooth.

4

Normal

Page 883 of 1216

AUTOMATIC TRANSAXLE - Troubleshooting21-189

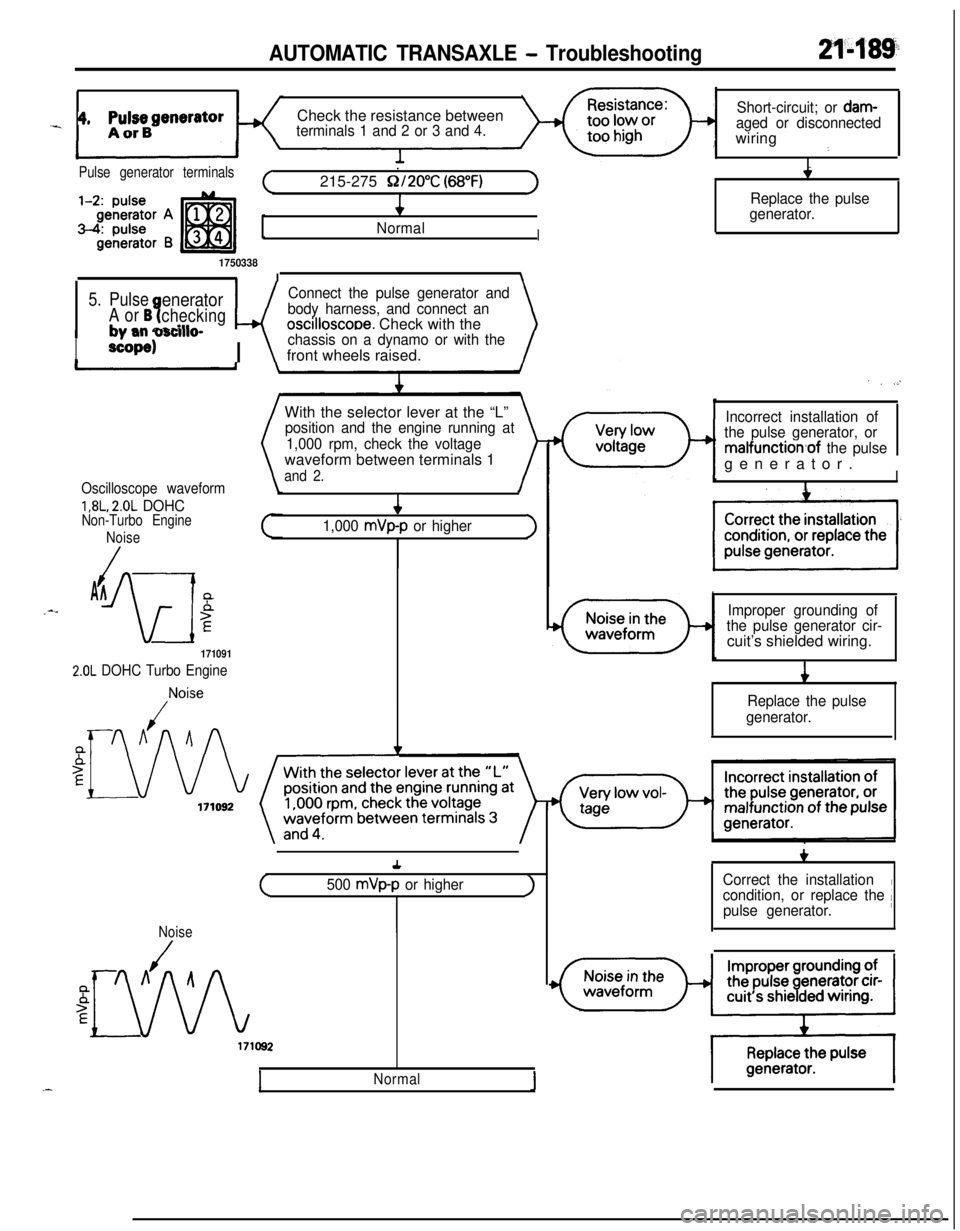

_ 4, ppBgeneratorCheck the resistance betweenterminals 1 and 2 or 3 and 4.Short-circuit; or

dam-aged or disconnectedwiring

:

I

.

4

/

NormalI

1750338II\

Pulse generator terminals.(215-275 Q/2O”C (68°F)1

5. PulseeneratorConnect the pulse generator and

A or B?checkingwbody harness, and connect an

+ mm narillroscilloscooe. Check with the\

I

#, -mm v3nlwdP

scope)I \

chassis on a dynamo or with thefront wheels raised.

With the selector lever at the “L”

position and the engine running at

1,000 rpm, check the voltagewaveform between terminals 1

and 2.

Oscilloscope waveform

1,8L, 2.0L DOHCNon-Turbo Engine

Noise

/AA_--

iw

5E4

1,000 mVp-p or higher>

171091

2.0L DOHC Turbo Engine

,Noise

Replace the pulse

generator.

. . .,’

Incorrect installation of

the pulse generator, or

malfunction,of the pulsegenerator.

II

Improper grounding of

the pulse generator cir-cuit’s shielded wiring.

i

Replace the pulse

generator.+

(500 mVp-p or higherJ

Noise

Normal1

+,I

Correct the installation

condition, or replace the /pulse generator.

Page 885 of 1216

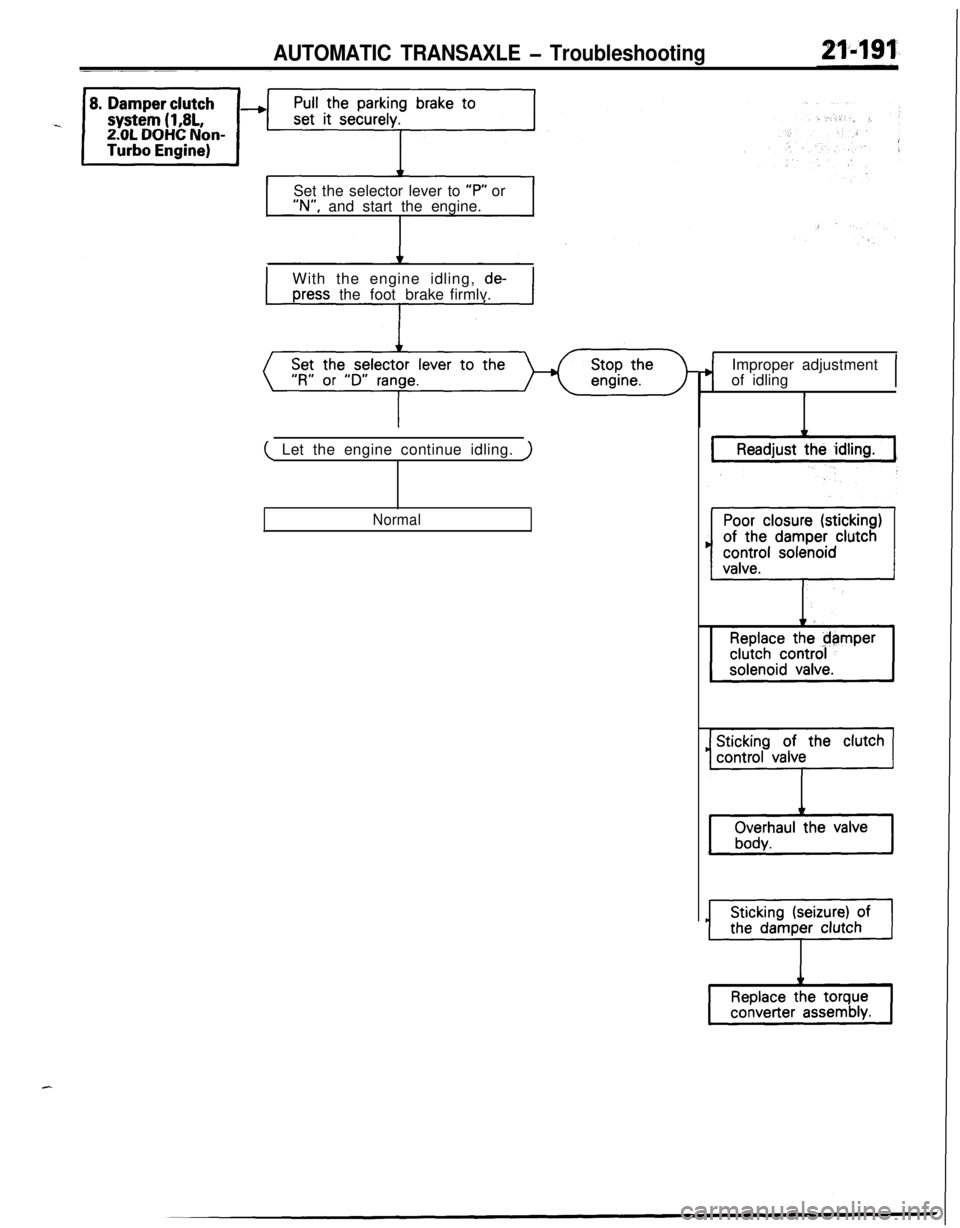

AUTOMATIC TRANSAXLE - TroubleshootingSet the selector lever to “P” or“N”, and start the engine.

IWith the engine idling,

de-

Dress the footbrake firmlv.I

( Let the engine continue idling. )

NormalImproper adjustment

of idling

I

Page 886 of 1216

21-192AUTOMATIC TRANSAXLE - Troubleshooting

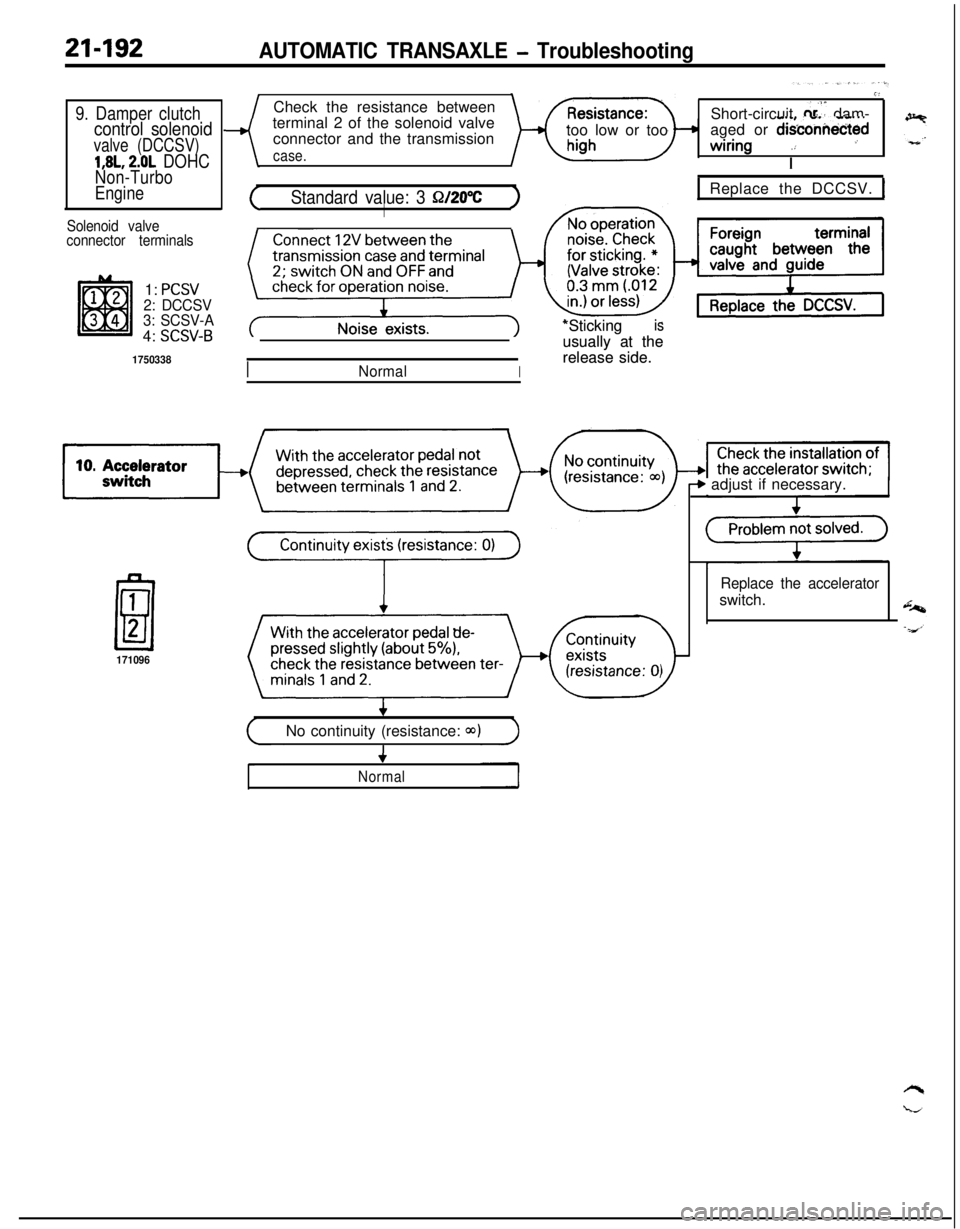

9. Damper clutchcontrol solenoid

valve (DCCSV)

1,8L, 2.0L DOHC

Non-Turbo

Engine

Solenoid valve

connector terminals1:

PCSV2: DCCSV

3: SCSV-A4:

SCSV-B

1750338Check the resistance between

terminal 2 of the solenoid valve

connector and the transmission

case.too low or too

G’Short-circuit

0,s” dam-

aged or d&connectedwiring

.: ’

I

(Standard value: 3 Q/20%)I

INormalI*Sticking *Sticking

is isusually at the usually at the

release side. release side.

1 Replace the DCCSV. 1

171096

b adjust if necessary.

Replace the acceleratorswitch.

(No continuity (resistance: Q)))4

Normal

Page 888 of 1216

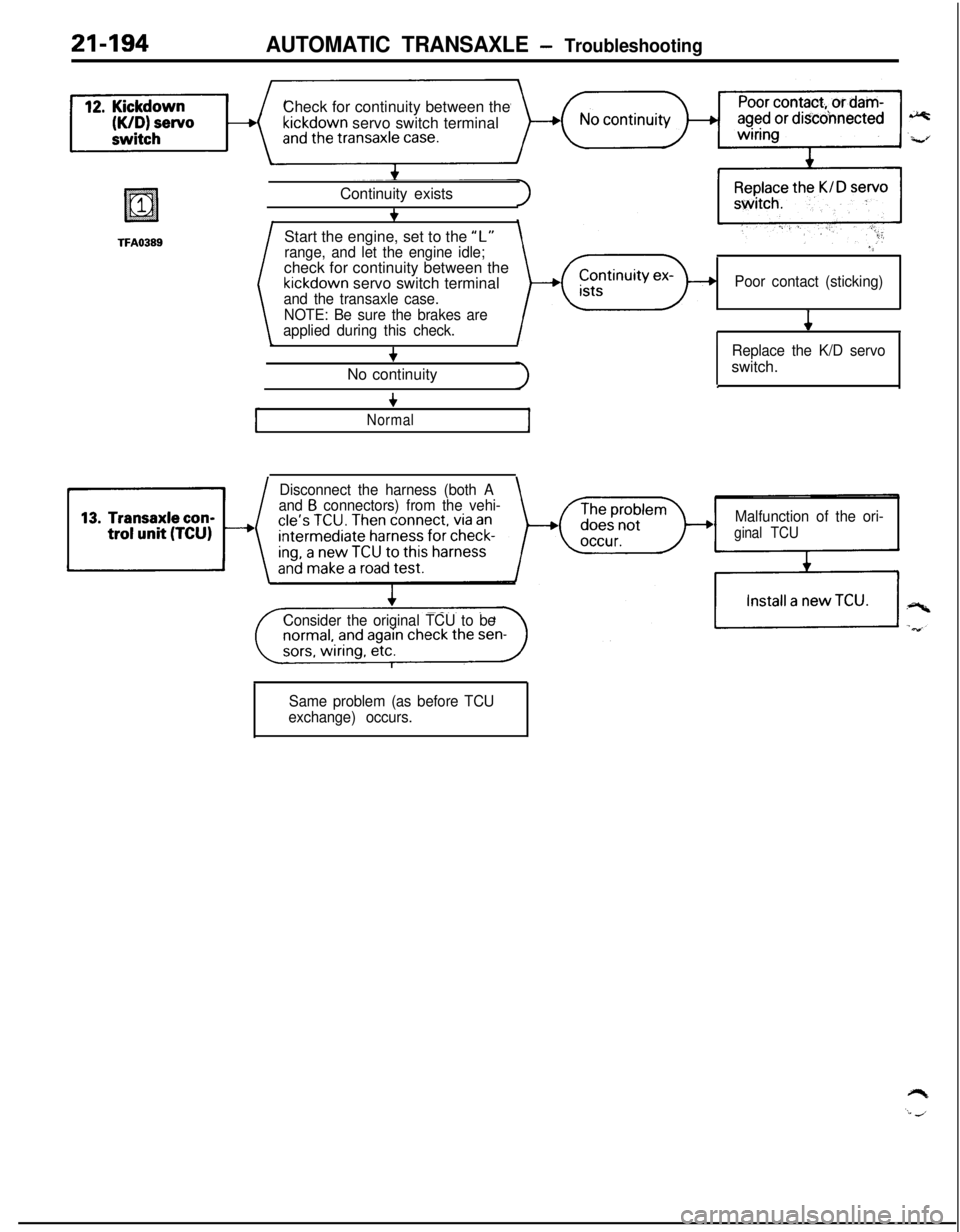

21-194AUTOMATIC TRANSAXLE - TroubleshootingCheck for continuity between the

kickdown servo switch terminal

TFA0389Start the engine, set to the “L”Continuity exists

+

range, and let the engine idle;check for continuity between the

kickdown servo switch terminaland the transaxle case.

NOTE: Be sure the brakes are

applied during this check.

+No continuity

“‘

Poor contact (sticking)

4

Replace the K/D servoswitch.

.

+

Normal

Disconnect the harness (both A

and B connectors) from the vehi-

Malfunction of the ori-

ginal TCU

Consider the original TCU to be

Same problem (as before TCU

exchange) occurs.

Page 889 of 1216

AUTOMATIC TRANSAXLE - Troubleshooting21'495

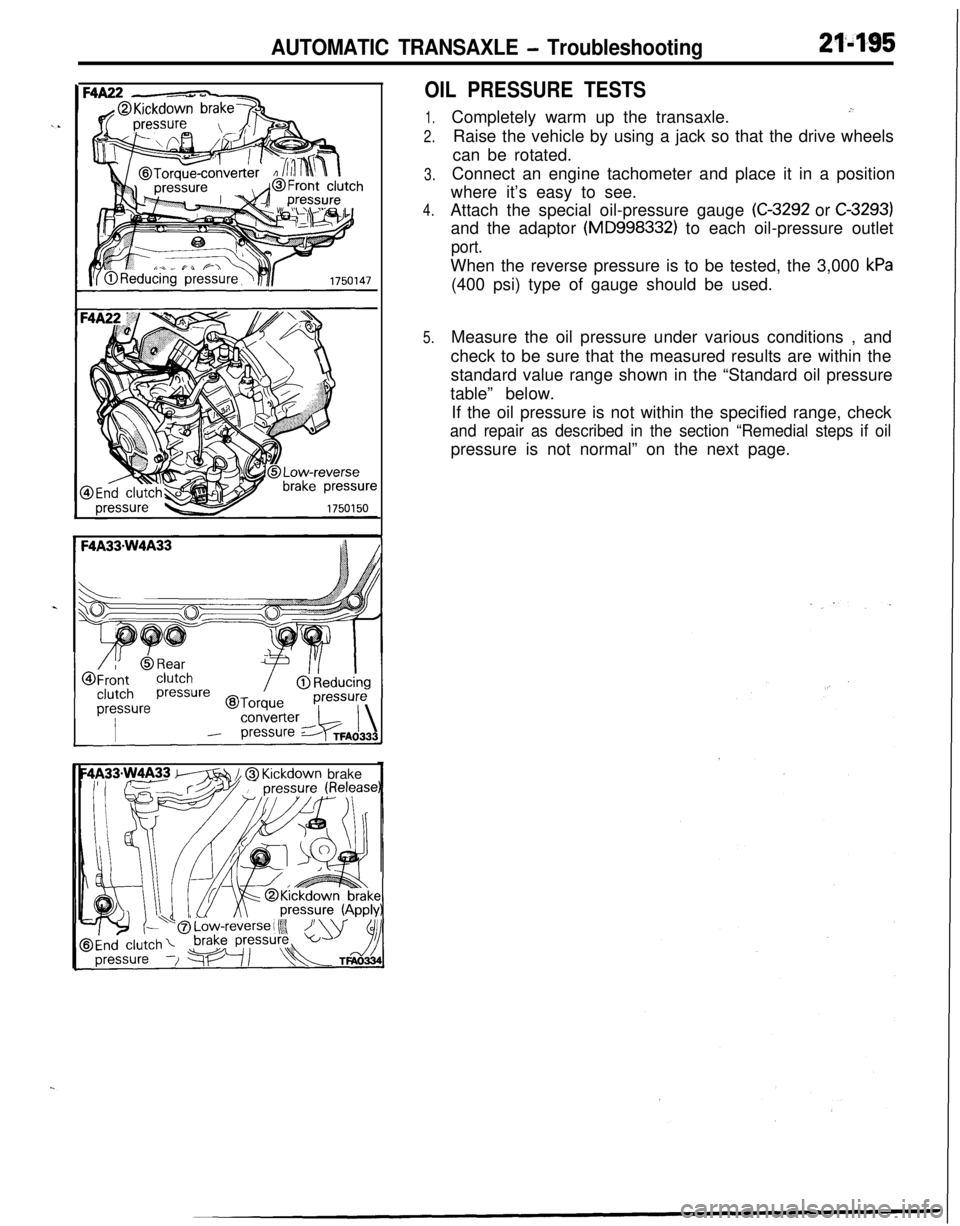

OIL PRESSURE TESTS

1.

2.

3.

4.

5.Completely warm up the transaxle.

.”Raise the vehicle by using a jack so that the drive wheels

can be rotated.

Connect an engine tachometer and place it in a position

where it’s easy to see.

Attach the special oil-pressure gauge

(C-3292 or C-3293)and the adaptor

(MD998332) to each oil-pressure outlet

port.When the reverse pressure is to be tested, the 3,000

kPa(400 psi) type of gauge should be used.

Measure the oil pressure under various conditions , and

check to be sure that the measured results are within the

standard value range shown in the “Standard oil pressure

table” below.

If the oil pressure is not within the specified range, check

and repair as described in the section “Remedial steps if oilpressure is not normal” on the next page.

m // @ Kickdown brake