MITSUBISHI ENDEAVOR 2004 Service Repair Manual

ENDEAVOR 2004

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57105/w960_57105-0.png

MITSUBISHI ENDEAVOR 2004 Service Repair Manual

Trending: oil level, fuse box location, thermostat, light, fuse diagram, speed sensor, wipers

Page 3491 of 3870

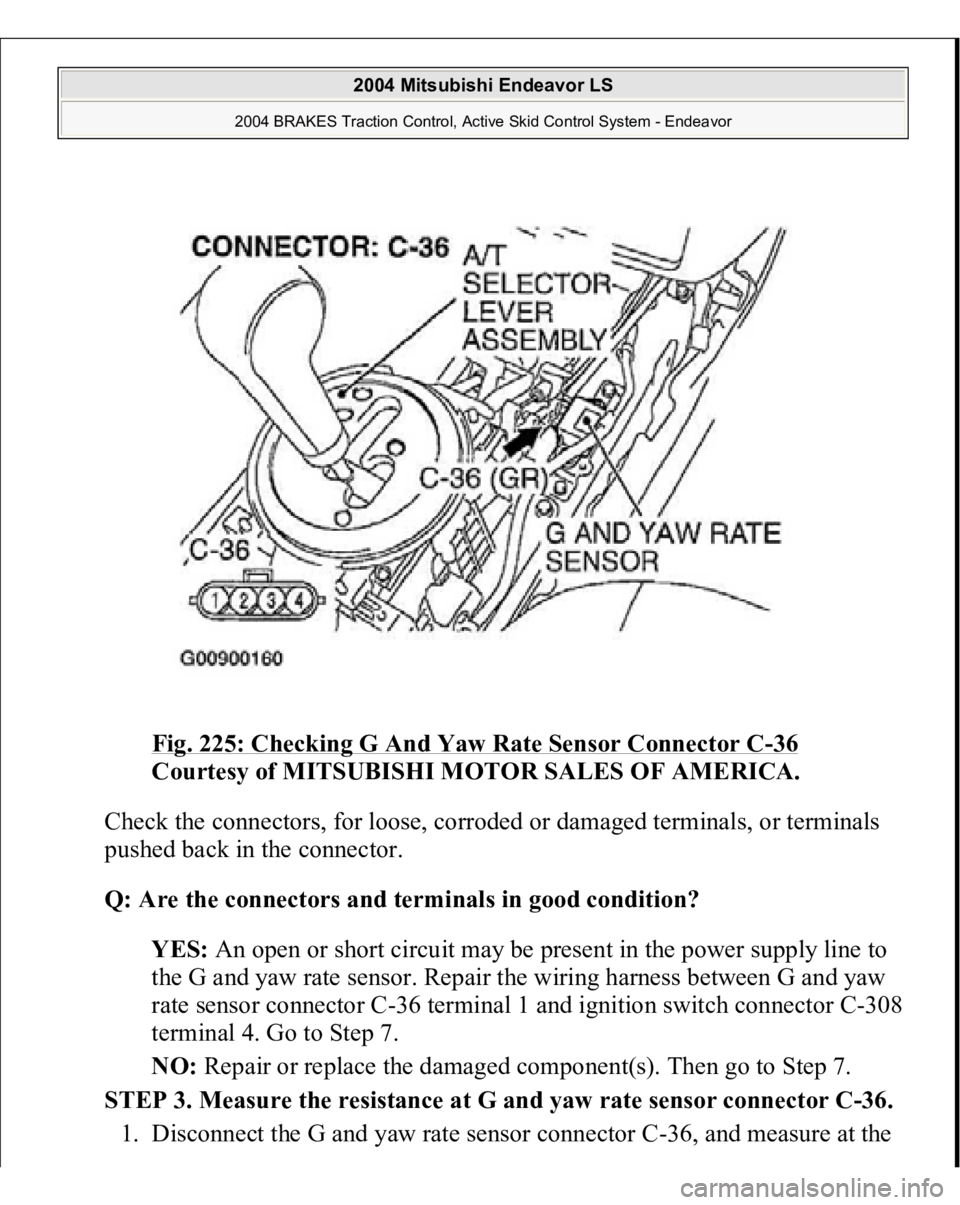

Fig. 225: Checking G And Yaw Rate Sensor Connector C

-36

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

Check the connectors, for loose, corroded or damaged terminals, or terminals

pushed back in the connector.

Q: Are the connectors and terminals in good condition?

YES: An open or short circuit may be present in the power supply line to

the G and yaw rate sensor. Repair the wiring harness between G and yaw

rate sensor connector C-36 terminal 1 and ignition switch connector C-308

terminal 4. Go to Step 7.

NO: Repair or replace the damaged component(s). Then go to Step 7.

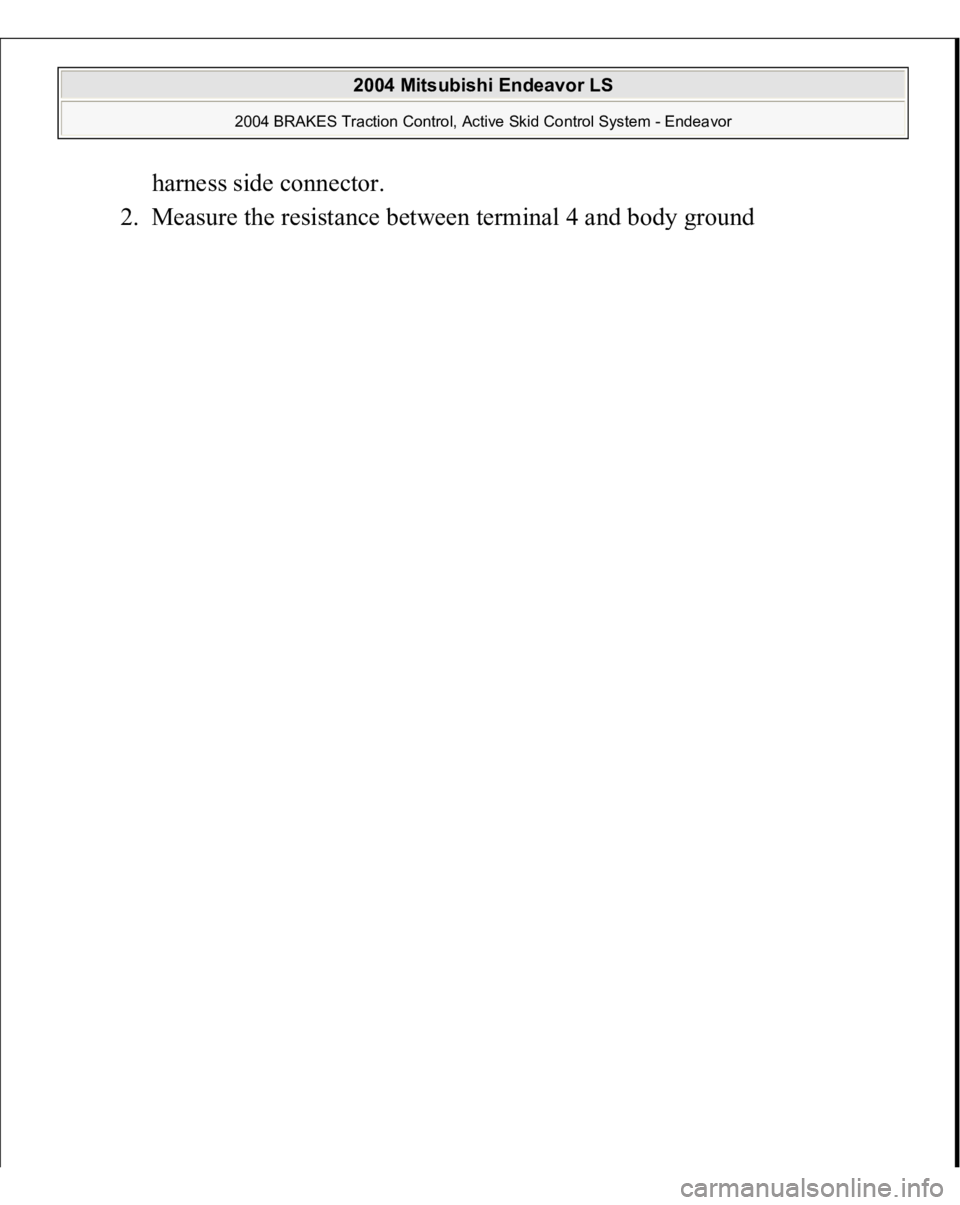

STEP 3. Measure the resistance at G and yaw rate sensor connector C-36.

1. Disconnect the G and

yaw rate sensor connector C-36, and measure at the

2004 Mitsubishi Endeavor LS

2004 BRAKES Traction Control, Active Skid Control System - Endeavor

Page 3492 of 3870

harness side connector.

2. Measure the resistance between terminal 4 and bod

y ground

2004 Mitsubishi Endeavor LS

2004 BRAKES Traction Control, Active Skid Control System - Endeavor

Page 3493 of 3870

Fig. 226: Measuring Resistance At G And Yaw Rate Sensor

2004 Mitsubishi Endeavor LS

2004 BRAKES Traction Control, Active Skid Control System - Endeavor

Page 3494 of 3870

Connector C

-36 (Step 3)

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

Q: Is the measured resistance 2 ohms or less?

YES: Go to Step 5.

NO: Go to Step 4.

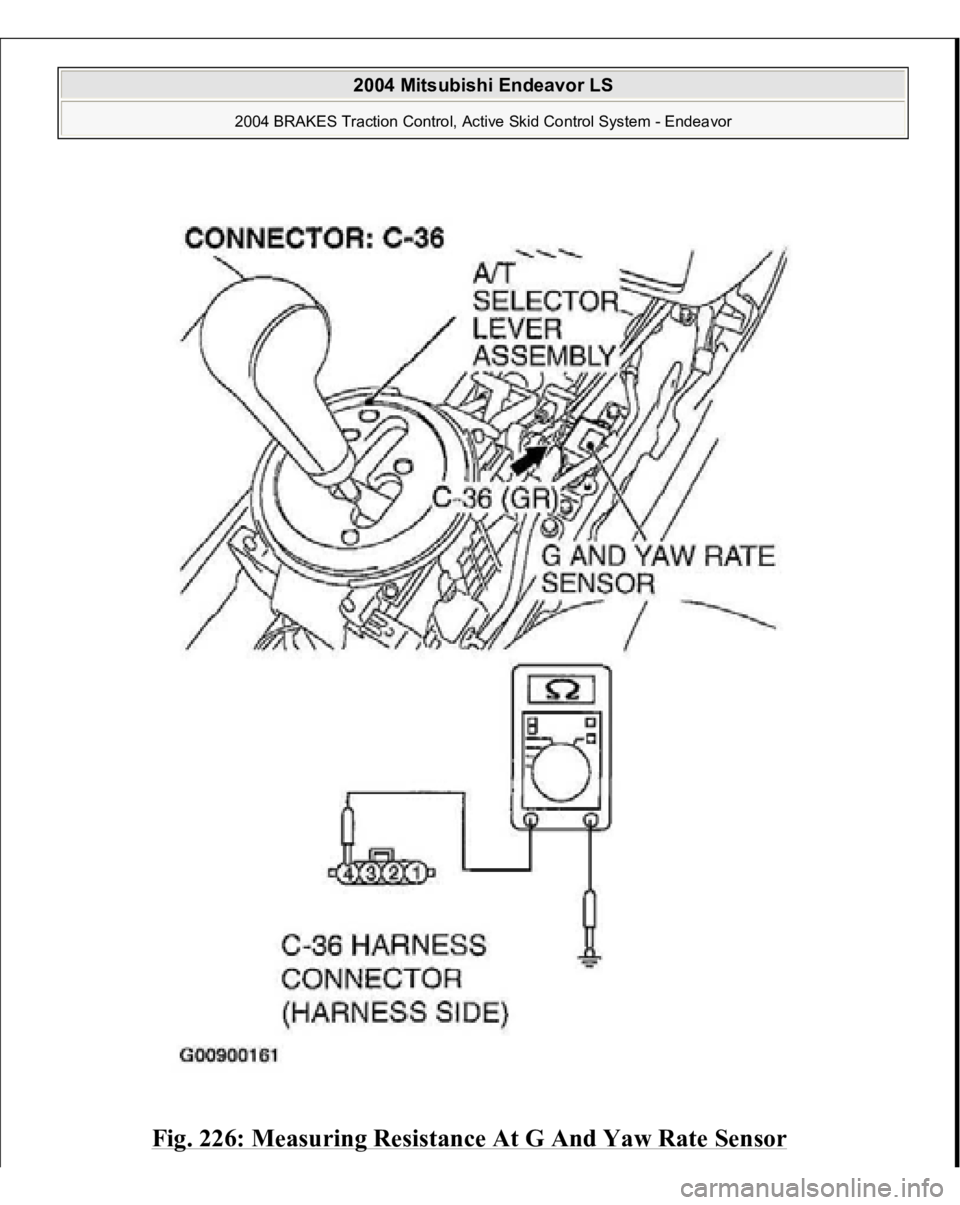

STEP 4. Check G and yaw rate sensor connector C-36 for loose, corroded

or damaged terminals, or terminals pushed back in the connector.

Fig. 227: Checking G And Yaw Rate Sensor Connector C

-36

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

Q: Are the connectors and terminals in good condition?

YES: An o

pen circuit ma

y be

present in the

ground circuit. Re

pair the

2004 Mitsubishi Endeavor LS

2004 BRAKES Traction Control, Active Skid Control System - Endeavor

Page 3495 of 3870

wiring harness between G and yaw rate sensor connector C-36 terminals 4

and the body ground. Then go to Step 7.

NO: Repair or replace the damaged component(s). Then go to Step 7.

STEP 5. Check the battery.

Check the battery (Refer toBATTERY TEST

).

Q: Is the battery in good condition?

YES: Go to Step 6.

NO: Charge or replace the battery. Then go to Step 7.

STEP 6. Check the charging system.

Check the charging system (Refer to GENERATORS & REGULATORS

).

Q: Is the charging system in good condition?

YES: Replace the G and yaw rate sensor (Refer to G AND YAW RATE

SENSOR

). Then go to Step 7.

NO: Repair or replace the charging system component(s). Then go to Step

7.

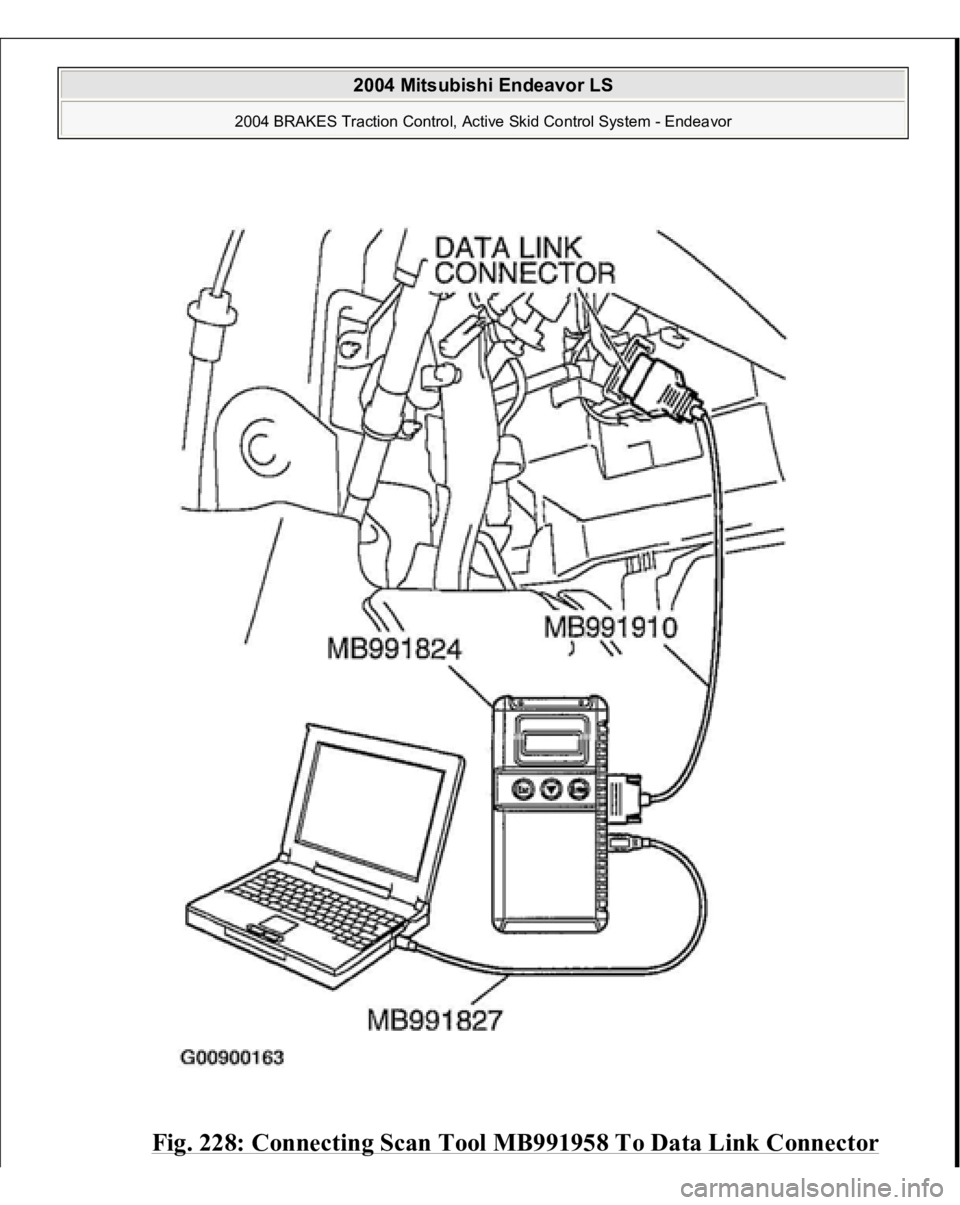

STEP 7. Using scan tool MB991958, read the TCL/ASC diagnostic trouble

code.

1. Connect scan tool MB991958 to the data link connec

tor. CAUTION: To prevent damage to scan tool always turn the

ignition switch to "LOCK" (OFF) position before

connecting or disconnecting scan tool.

2004 Mitsubishi Endeavor LS

2004 BRAKES Traction Control, Active Skid Control System - Endeavor

Page 3496 of 3870

Fig. 228: Connecting Scan Tool MB991958 To Data Link Connector

2004 Mitsubishi Endeavor LS

2004 BRAKES Traction Control, Active Skid Control System - Endeavor

Page 3497 of 3870

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA

.

2. Turn the ignition switch to the "ON" position.

3. Read the TCL/ASC diagnostic trouble code.

Q: Is the DTC U1105 (current trouble) set?

YES: Diagnose the TCL/ASC by referring to DTC U1105: YR/G CAN

TIMEOUT/NOT EQUIPPED

.

NO: The procedure is complete.

INSPECTION PROCEDURE 11: TCL/ASC System dose not Operate. COMMENT The fall-safe function is probably canceling TCL/ASC system. In this case, scan

tool MB991958 can be used to Retest each system by checking the diagnostic

trouble codes. TROUBLESHOOTING HINTS (The most likely causes for this case:)

Malfunction of the CAN bus line. Malfunction of the TCL/ASC-ECU.

DIAGNOSIS Required Special Tools:

MB991958: Scan Tool (MUT-III Sub Assembly)

MB991824: Vehicle Communication Interface (V.C.I.) MB991827: MUT-III USB Cable MB991910: MUT-III Main Harness A

STEP 1. Hydraulic unit check

Refer to POINTS IN WAVEFORM MEASUREMENT

.

Q: Is the hydraulic unit normal?

2004 Mitsubishi Endeavor LS

2004 BRAKES Traction Control, Active Skid Control System - Endeavor

Page 3498 of 3870

YES: Go to Step 2.

NO: Connect the brake pipes correctly, repair the external brake lines, or

replace the hydraulic unit.

STEP 2. Verify that the condition described by the customer exists.

Q: Can any faults be found with the brake operation?

YES: Check the brake system related components except the ASC system.

NO: The procedure is complete.

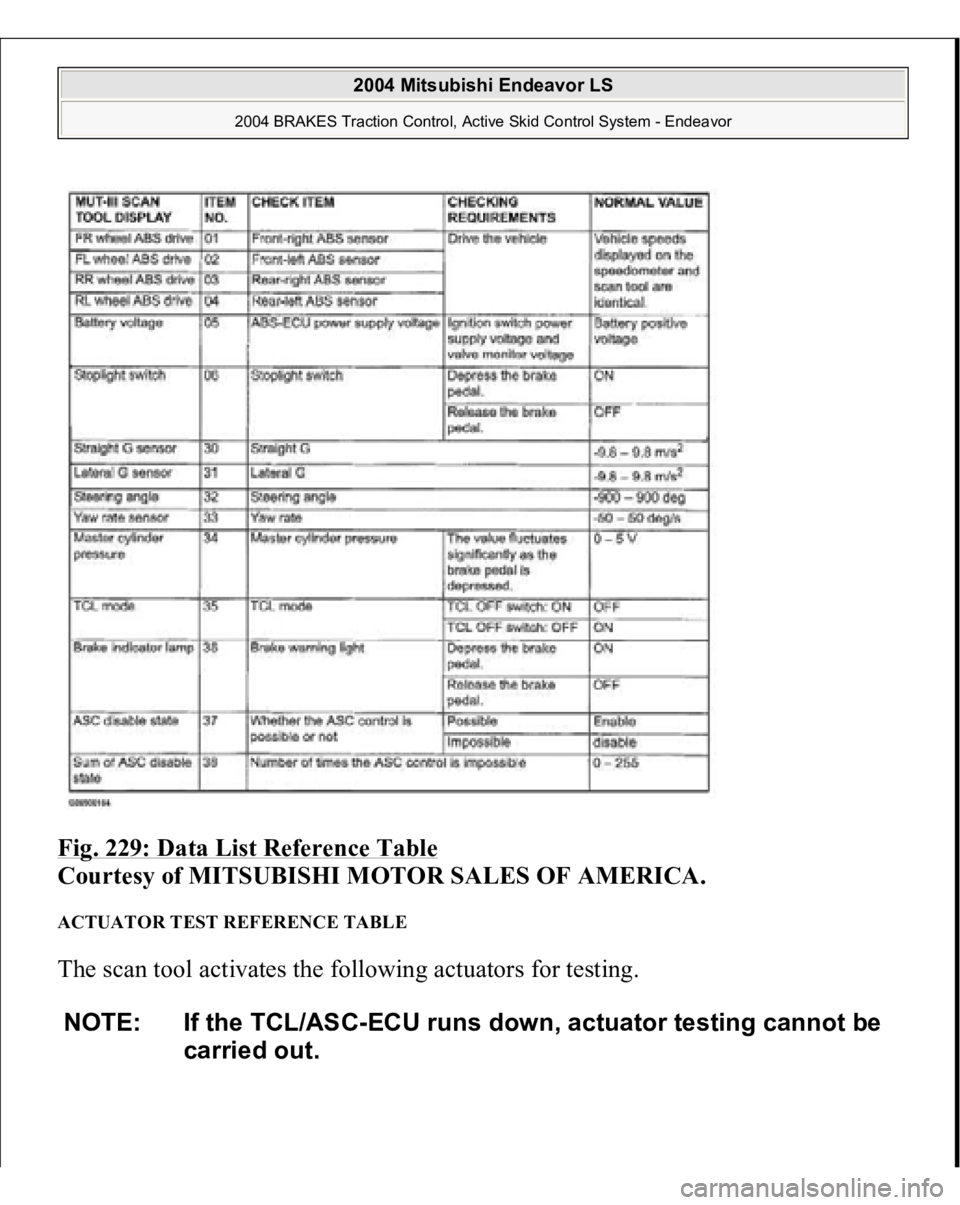

DATA LIST REFERENCE TABLE The following items can be read by the scan tool from the TCL/ASC-ECU input

data.

2004 Mitsubishi Endeavor LS

2004 BRAKES Traction Control, Active Skid Control System - Endeavor

Page 3499 of 3870

Fig. 229: Data List Reference Table

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

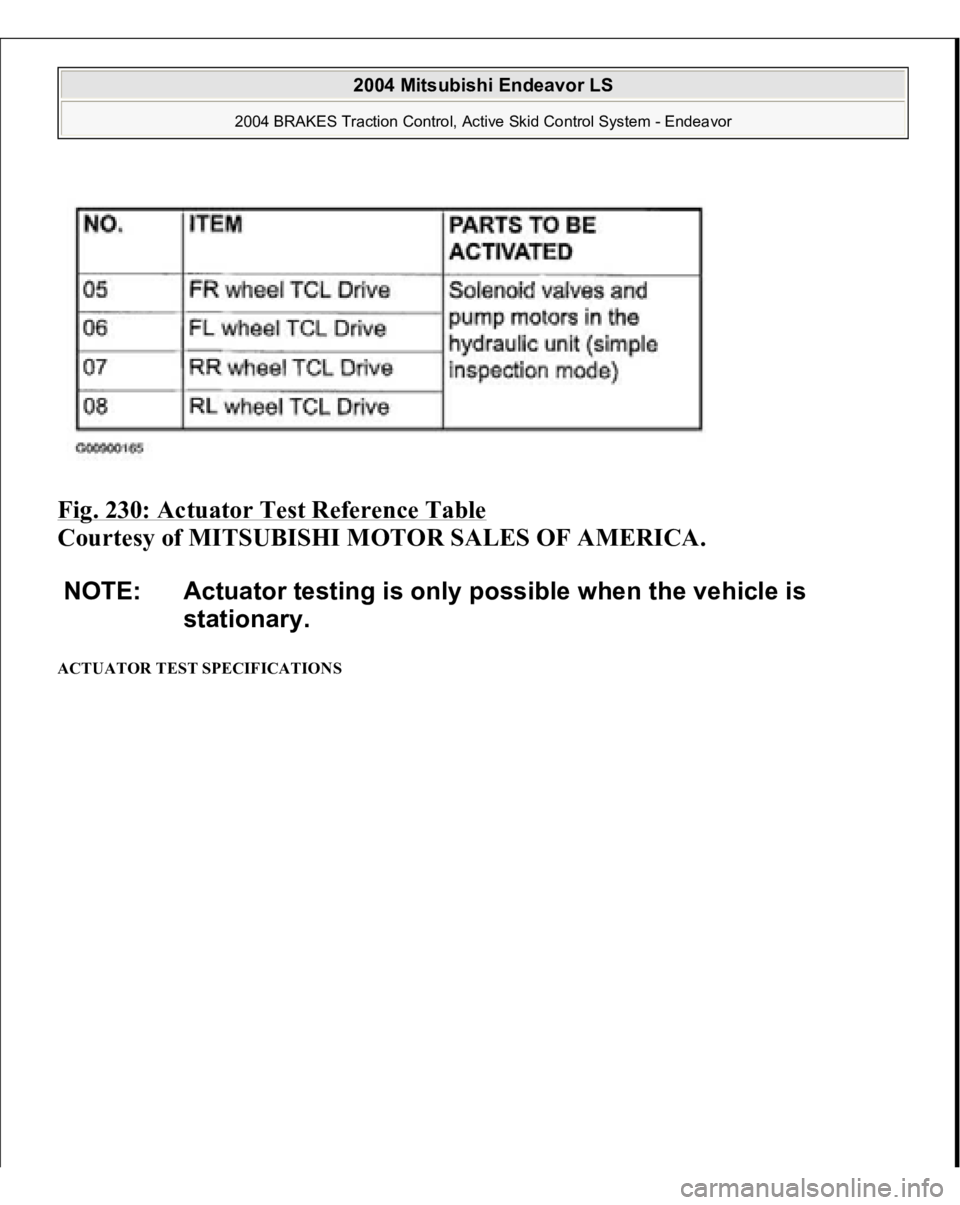

ACTUATOR TEST REFERENCE TABLE The scan tool activates the following actuators for testing. NOTE: If the TCL/ASC-ECU runs down, actuator testing cannot be

carried out.

2004 Mitsubishi Endeavor LS

2004 BRAKES Traction Control, Active Skid Control System - Endeavor

Page 3500 of 3870

Fig. 230: Actuator Test Reference Table

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

ACTUATOR TEST SPECIFICATIONS NOTE: Actuator testing is only possible when the vehicle is

stationary.

2004 Mitsubishi Endeavor LS

2004 BRAKES Traction Control, Active Skid Control System - Endeavor

Trending: change key battery, recommended oil, test oxygen, steering wheel adjustment, AUX, horn, cruise control