MITSUBISHI GALANT 1989 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 1091 of 1273

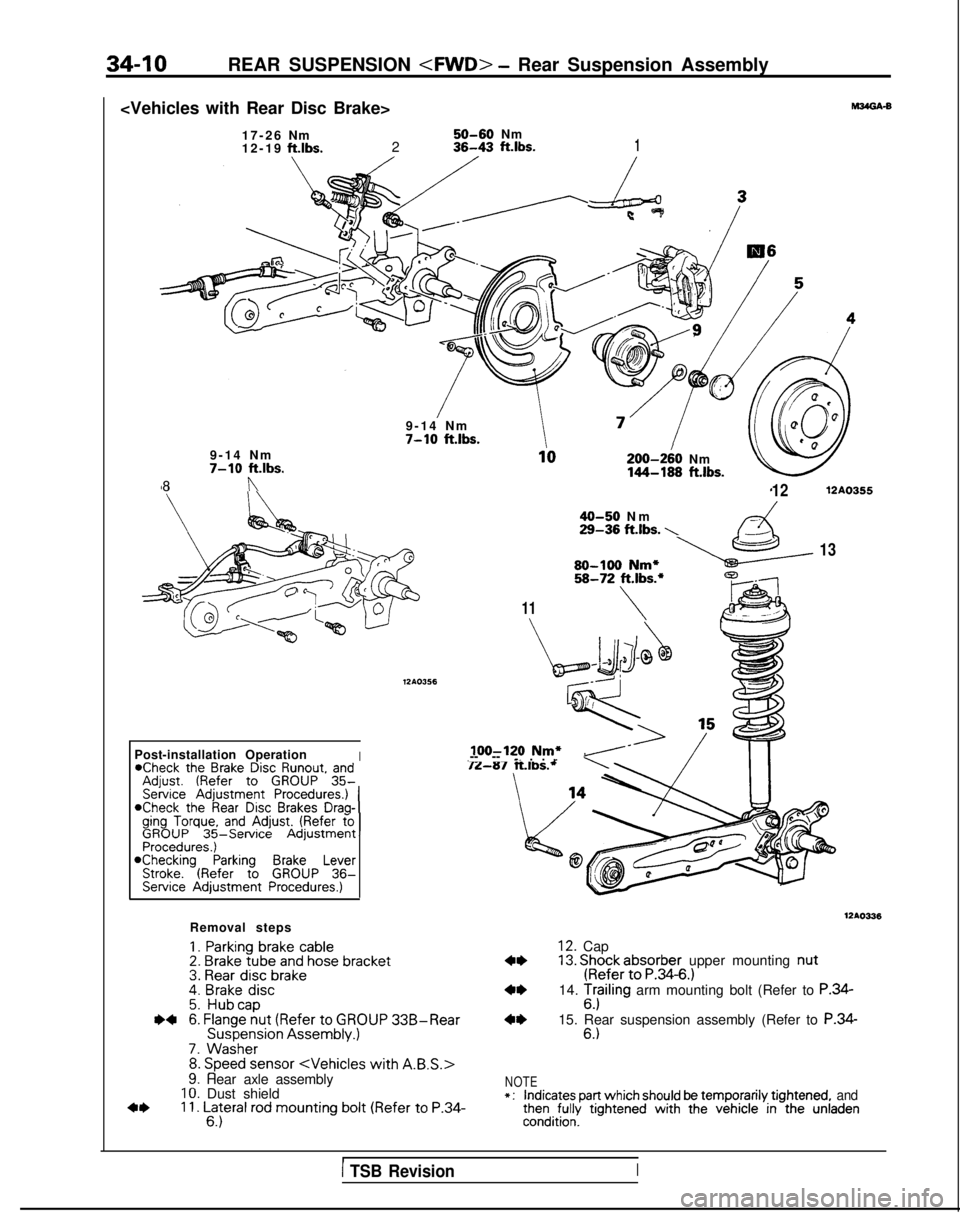

34-10REAR SUSPENSION

6

Nm

50-60Nm

12-1

9

ft.lbs.236-43 ft.lbs.1

9-14 N

m

7-10 ft.lbs.

200-240

Nm

144-188 ft.lbs.

9-14 Nm7-10 ft.lbs.

8

n

11

40-50 N

m

29-36 ft.lbs. \

1212AO355

1380-100 Nm*58-72 ft.lbs.*

\

Iloo-120 Nm*.-- -- _. . . ”Post-installation Operation*Check the Brake Disc Runout. andAdiust. (Refer to GROUP 35-

*Check the Rear Disc Brakes Draq-Iging Torque, and Adjust. (Refer foGROUP

35-ServiceAdjustmentISehice

Adjustment Procedures.) 1

Procedures.)@Checking Parking Brake LeverStroke. (Refer to GROUP 36-Service Adjustment Procedures.)

Removal steps

1. Parking

brake cable2.

Brake tube and hose bracket3. Rear

disc

brake4. Brake

disc5.

Hubcap~~6. Flange

nut

(Refer

to

GROUP 33B-Rear Suspension

Assembly.)

7.

Washer8. Speed sensor

WA0336

12. Cap13. Shock absorber

upper mounting nut

(Refer

to P.34-6.)14. Tr$ling arm mounting bolt (Refer to P.34-6.)15. Rear suspension assembly (Refer to P.34-6.)

c*

Y. Hear axle assembly10. Dust shield11. Lateral

rod mounting

bolt (Refer

to

P.34-6.)

NOTE*:indicates part which should be temporarily tightened, andthen fully tightened with

the vehicle in the unladencondition.

1 TSB RevisionI

Page 1092 of 1273

REAR SUSPENSION

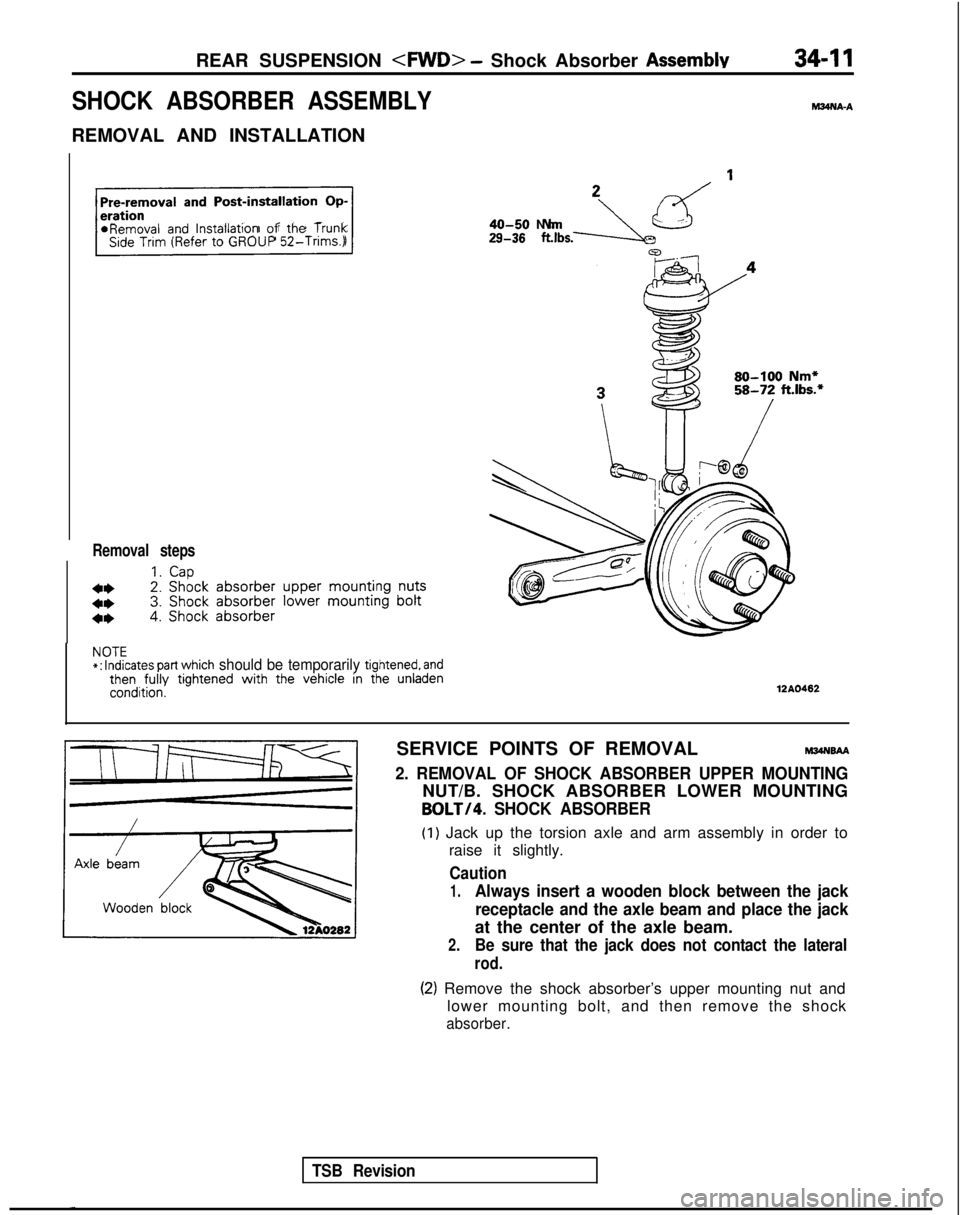

SHOCK ABSORBER ASSEMBLY

REMOVAL AND INSTALLATION

hl34NA-A

Pre-removal

and Post-installation Op-

r

*Removal and lnstallatlon of the TrunkSide Trim (Refer to GROUP

52-Trims.)

Removal steps

1.Cap

4*2. Shock

absorber

upper

mounting

nuts

4*3. Shock

absorber

lower mounting

bolt

4*4. Shock absorber

29-38 .,bs.-JLzd ’40-50 N

m

80-100 Nm*58-72 ft.lbs.*

NOTE*:

Indicates part which should be temporarily tightened, andthen fully

tightened with

the vehicle in the unladencondition.12AO462

TSB Revision

SERVICE POINTS OF REMOVALM34NsAA

2. REMOVAL OF SHOCK ABSORBER UPPER MOUNTING

NUT/B. SHOCK ABSORBER LOWER MOUNTING

BOLT/4. SHOCK ABSORBER

(1) Jack up the torsion axle and arm assembly in order to

raise it slightly.

Caution

1.Always insert a wooden block between the jack

receptacle and the axle beam and place the jack

at the center of the axle beam.

2.Be sure that the jack does not contact the lateral

rod.

(2) Remove the shock absorber’s upper mounting nut and lower mounting bolt, and then remove the shock

absorber.

Page 1093 of 1273

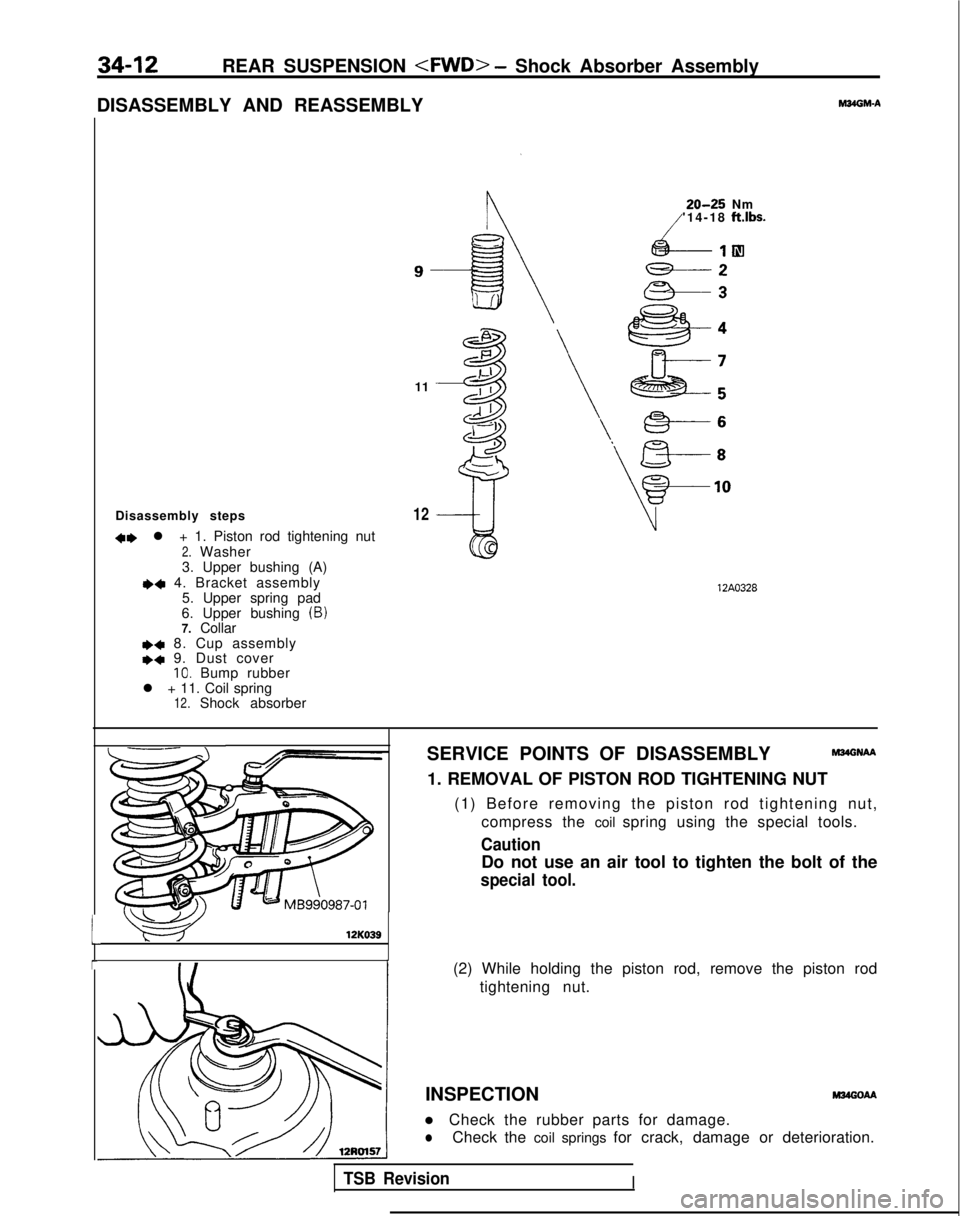

34-12REAR SUSPENSION

DISASSEMBLY AND REASSEMBLY

M34GM-A

i

r

Disassembly steps

+e l + 1. Piston rod tightening nut2.Washer

3. Upper bushing (A)

1)4 4. Bracket assembly 5. Upper spring pad

6. Upper bushing

(B)

7.CollarI)+ 8. Cup assemblyea 9. Dust cover10.Bump rubber

l + 11. Coil spring

12.Shock absorber

9-

11

12

-Y

-R\-

Ef‘i I

\

2%P

2

I--’

,:1

4

q

-=L

57

-IdC

\

20-25 Nm

'14-18 ft.lbs.

@%9--s-

12A0328

WY

12KO39

SERVICE POINTS OF DISASSEMBLY

M34GNAA

1. REMOVAL OF PISTON ROD TIGHTENING NUT

(1) Before removing the piston rod tightening nut,compress the coil spring using the special tools.

Caution

Do not use an air tool to tighten the bolt of the

special tool.

TSB Revision

I

(2) While holding the piston rod, remove the piston rod tightening nut.

INSPECTION

M34GOAA

l Check the rubber parts for damage.

lCheck the coil springs for crack, damage or deterioration.

Page 1094 of 1273

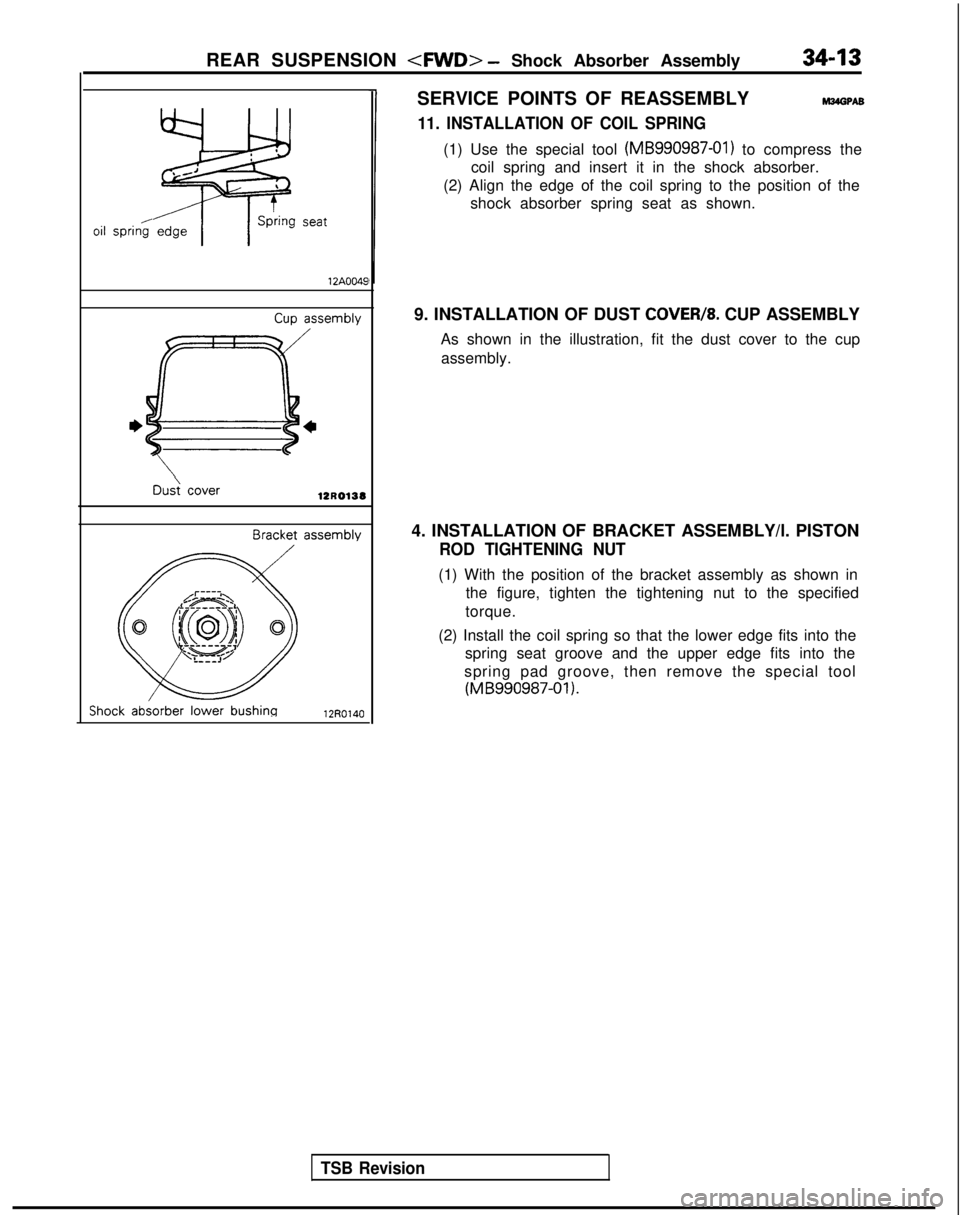

REAR SUSPENSION

oil

springseat

12A0049

Cup assembly

DE> cover

Bracket assembly

Shock absorber

lower bushing

12R0140SERVICE POINTS OF REASSEMBLY

M34GPA3

11. INSTALLATION OF COIL SPRING

(1) Use the special tool (MB990987-01) to compress the

coil spring and insert it in the shock absorber.

(2) Align the edge of the coil spring to the position of the shock absorber spring seat as shown.

9. INSTALLATION OF DUST

COVEl?/8. CUP ASSEMBLY

As shown in the illustration, fit the dust cover to the cup assembly.

4. INSTALLATION OF BRACKET ASSEMBLY/l. PISTON

ROD TIGHTENING NUT

(1) With the position of the bracket assembly as shown in the figure, tighten the tightening nut to the specified

torque.

(2) Install the coil spring so that the lower edge fits into the spring seat groove and the upper edge fits into the

spring pad groove, then remove the special tool (MB990987-01).

TSB

Revision

Page 1095 of 1273

34-14

REAR SUSPENSION

LATERAL ROD

REMOVAL AND INSTALLATIONMMOA-

Removal steps

I. LateralI)+ 2. Lateralside)3. Lateral

4. Lateral rod mounting

bolt (body side)rod mounting

bolt (axle beam

rodrod bushing

80-100 Nm*~ / 58-72 ft.lbs.*

100-120 Nm*72-87 ft.lbs.*

%!A0232

NOTE *:Indicates part which should be temporarily tightened, andthen

fully

tightened with

the vehicle in the unladencondition.

INSPECTION

l Check the lateral rod for damage or deformation.

0Check the bushings for cracking, deterioration, or unusual

wear.

NOTE

For information concerning the replacement of the lateral

rod bushing, refer to

P.34-8.

Lateral rodnounting b,yltAxle beamr

I

SERVICE POINTS OF INSTALLATIONm4oDAA

2. INSTALLATION OF LATERAL ROD MOUNTING BOLT

(AXLE BEAM SIDE)

Install the lateral rod mounting bolt from the direction

shown in the illustration.

1 TSB Revision

Page 1096 of 1273

REAR SUSPENSION

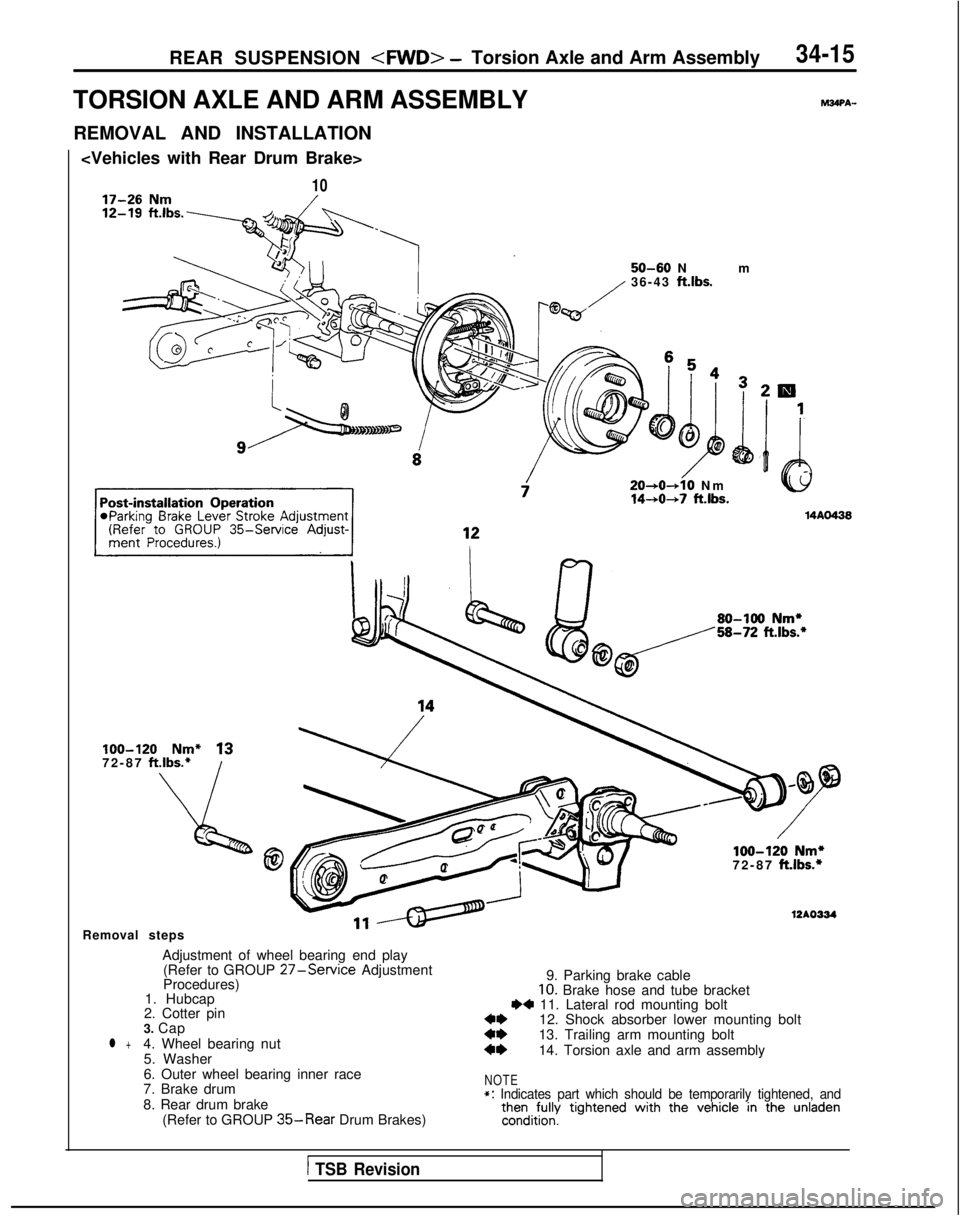

TORSION AXLE AND ARM ASSEMBLYPAWPA-

REMOVAL AND INSTALLATION

10

50-60 N

m

36-43

ft.lbs.

20+0-+10 N

m

14-+0+7 ftlbs.

100-120 Nm* 1372-87 ft.lbs.*

loo-120 Nm*72-87 ft.lbs.*

Removal steps

Adjustment of wheel bearing end play

12AO334

(Refer to GROUP 27-Service Adjustment

Procedures) 9. Parking brake cable

1. Hubcap

10. Brake hose and tube bracket

2. Cotter pinI)+ 11. Lateral rod mounting bolt

3. Cap 12. Shock absorber lower mounting bolt

l +4. Wheel bearing nut::13. Trailing arm mounting bolt

5. Washer4*14. Torsion axle and arm assembly

6. Outer wheel bearing inner race

7. Brake drum

NOTE

8. Rear drum brake *: Indicates part which should be temporarily tightened, and

(Refer to GROUP 35-Rear Drum Brakes)then

fully

tightened with

the vehicle in the unladencondition.

1 TSB Revision

Page 1097 of 1273

34-16 REAR SUSPENSION

L

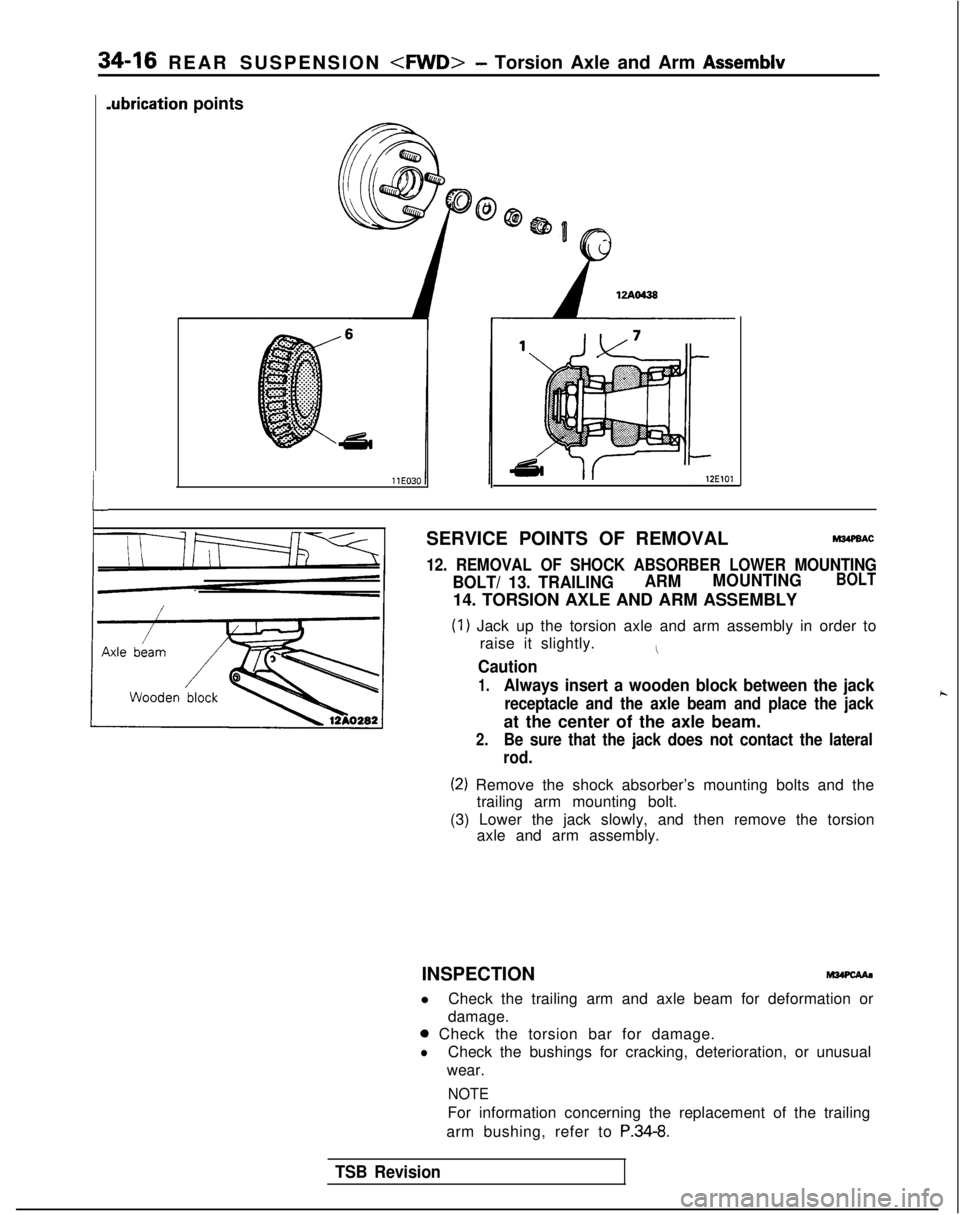

.ubrication points

12ElOl

SERVICE POINTS OF REMOVALM34PBAC

12. REMOVAL OF SHOCK ABSORBER LOWER MOUNTING

BOLT/ 13. TRAILINGARM

MOUNTINGBOLT

14. TORSION AXLE AND ARM ASSEMBLY

(1) Jack up the torsion axle and arm assembly in order to

raise it slightly.

I

Caution

1.Always insert a wooden block between the jack

receptacle and the axle beam and place the jackh

at the center of the axle beam.

2.Be sure that the jack does not contact the lateral

rod.

(2) Remove the shock absorber’s mounting bolts and the trailing arm mounting bolt.

(3) Lower the jack slowly, and then remove the torsion axle and arm assembly.

INSPECTION

l Check the trailing arm and axle beam for deformation or

damage.

0 Check the torsion bar for damage.

lCheck the bushings for cracking, deterioration, or unusual

wear.

NOTE

For information concerning the replacement of the trailing

arm bushing, refer to

P.34-8.

TSB Revision

Page 1098 of 1273

REAR SUSPENSION

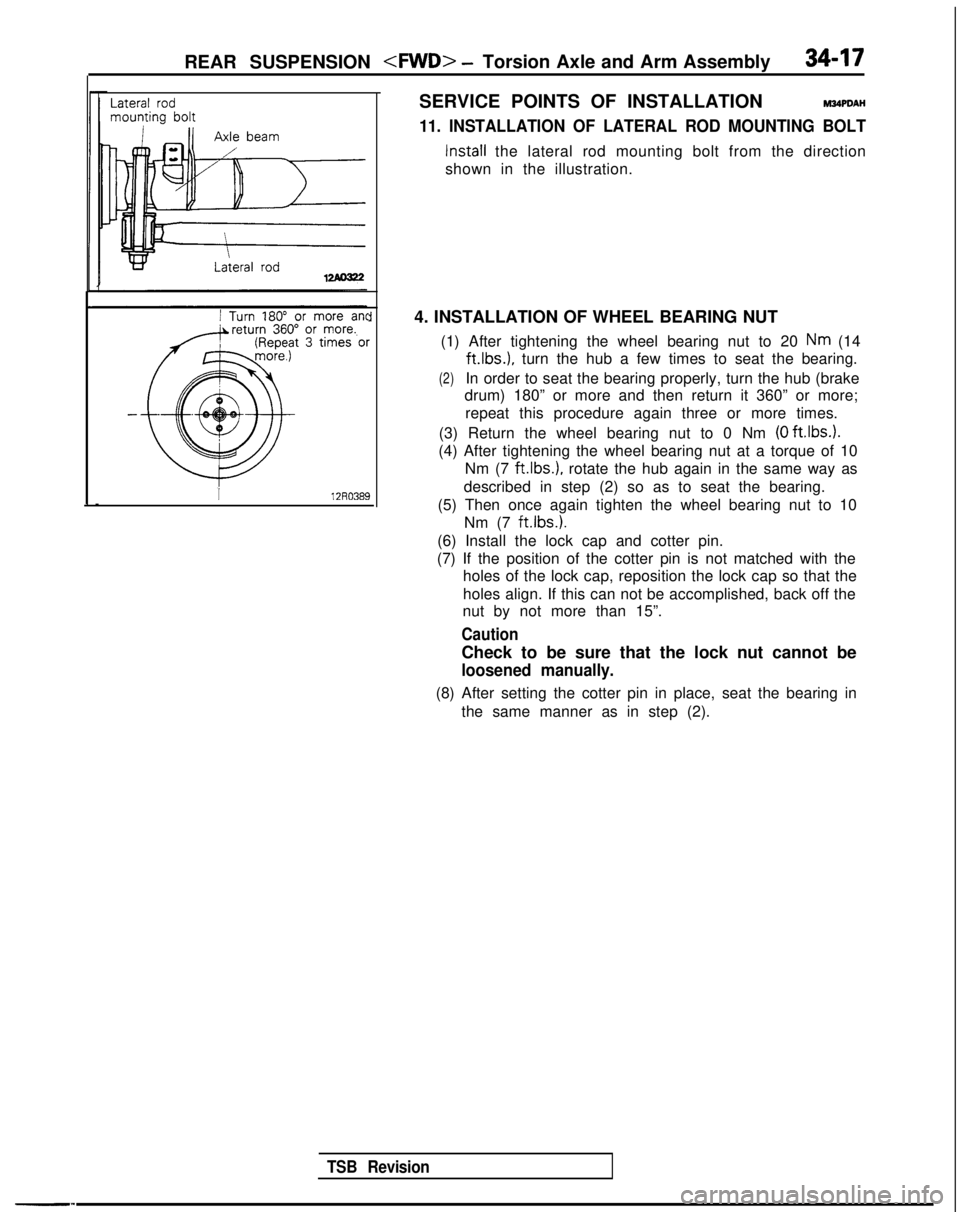

Lateral rodmounting bolt

1 Turn 180” or more ant1

TSB Revision

SERVICE POINTS OF INSTALLATIONMtOPDAH

11. INSTALLATION OF LATERAL ROD MOUNTING BOLT

Install the lateral rod mounting bolt from the direction

shown in the illustration.

4. INSTALLATION OF WHEEL BEARING NUT (1) After tightening the wheel bearing nut to 20

Nm (14 ft.lbs.),

turn the hub a few times to seat the bearing.

(2)In order to seat the bearing properly, turn the hub (brake

drum) 180” or more and then return it 360” or more;

repeat this procedure again three or more times.

(3) Return the wheel bearing nut to 0 Nm

(0 ftlbs.).

(4) After tightening the wheel bearing nut at a torque of 10 Nm (7

ftlbs.), rotate the hub again in the same way as

described in step (2) so as to seat the bearing.

(5) Then once again tighten the wheel bearing nut to 10 Nm (7 ft.lbs.).

(6) Install the lock cap and cotter pin.

(7) If the position of the cotter pin is not matched with the holes of the lock cap, reposition the lock cap so that the

holes align. If this can not be accomplished, back off the

nut by not more than 15”.

Caution

Check to be sure that the lock nut cannot be

loosened manually.

(8) After setting the cotter pin in place, seat the bearing in

the same manner as in step (2).

Page 1099 of 1273

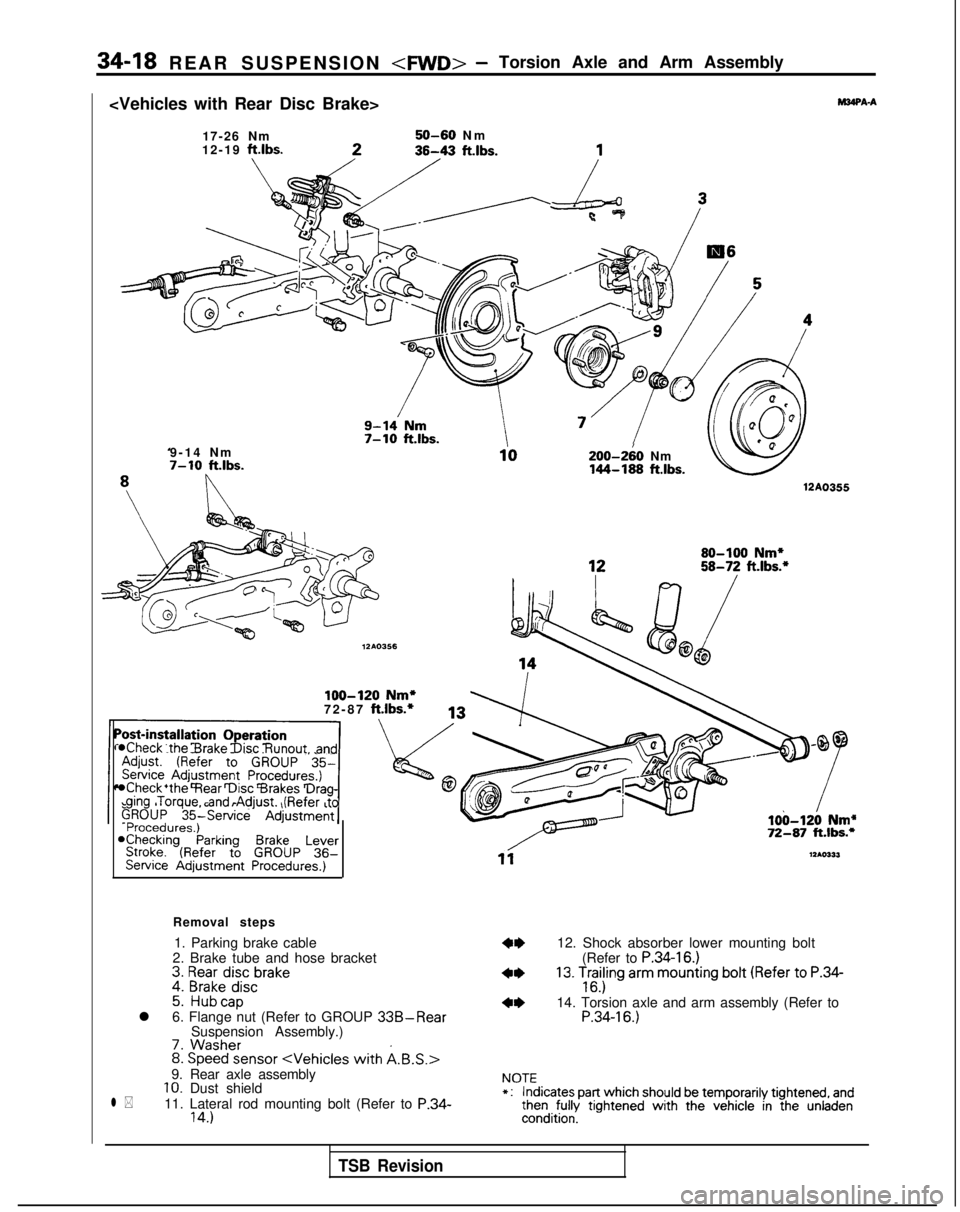

34-18 REAR SUSPENSION

WA-A

17-26 Nm

12-19 ftlbs.50-60 N

m

9-14 Nm

7-10 ft.lbs.200-2iO Nm144-189 ftlbs.

12A0355

loo-120 Nm*72-87 ft.lbs.*

*Check the Brake Disc Runout. and

*Check the Rear Disc Brakes Drag-ging Torque, and Adjust. (Refer to

Procedures.)*Checking Parking Brake LeverStroke. (Refer to GROUP 36-Service Adjustment Procedures.)

Removal steps

1. Parking brake cable

2. Brake tube and hose bracket

*I)12. Shock absorber lower mounting bolt

3. Rear disc

brake

(Refer to P.34-16.)

4. Brake disc4*13. Trailing

arm

mounting

bolt (Refer

to

P.34-

5. Hubcap16.)

l

6. Flange nut (Refer to GROUP 33B-Rear4*14. Torsion axle and arm assembly (Refer to

Suspension Assembly.)P.34-16.)

7. Washer

l *

8.

Speed sensor

11. Lateral rod mounting bolt (Refer to P.34-14.)

NOTE*:Indicates part which should be temporarily tightened, andthen fully tightened with the vehicle in the unladencondition.

TSB Revision

Page 1100 of 1273

REAR SUSPENSION

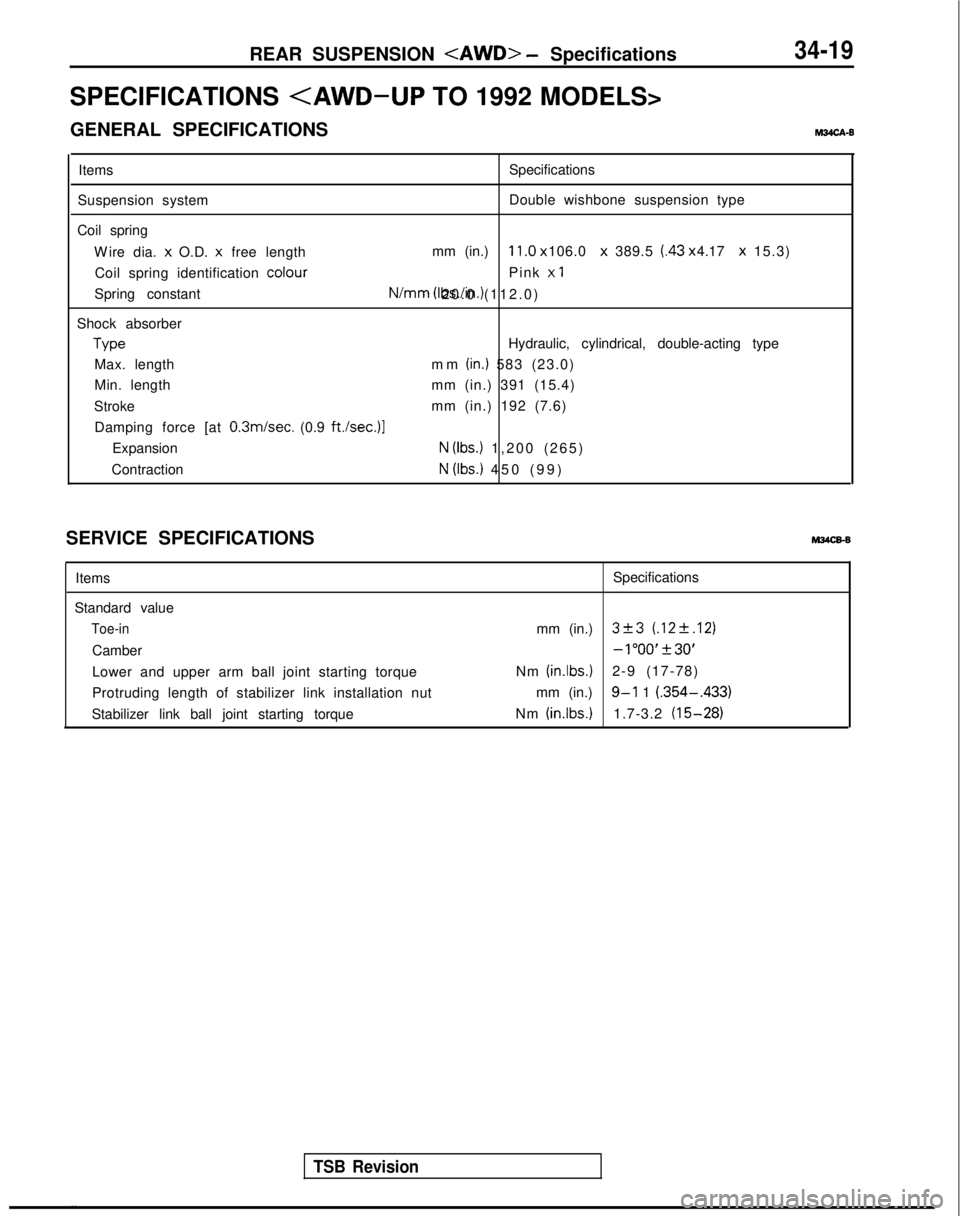

SPECIFICATIONS

GENERAL SPECIFICATIONS M34cA-0

Items Specifications

Suspension system Double wishbone suspension type

Coil spring Wire dia. x

O.D. x

free length mm (in.)

11.0 x 106.0 x

389.5 (.43 x 4.17 x

15.3)

Coil spring identification colour

Pink x

1

Spring constant N/mm

(Ibs./in.) 20.0 (112.0)

Shock absorber Type

Hydraulic, cylindrical, double-acting type

Max. length mm

(in.) 583 (23.0)

Min. length mm (in.) 391 (15.4)

Stroke mm (in.) 192 (7.6)

Damping force [at 0.3m/sec.

(0.9

ft./sec.)l

ExpansionN (Ibs.) 1,200 (265

)

Contraction

N (Ibs.) 450 (99

)

SERVICE SPECIFICATIONS Items

Standard value

Toe-in

Camber mm (in.)

Lower and upper arm ball joint starting torque

Protruding length of stabilizer link installation nut

Stabilizer link ball joint starting torque Nm

(inlbs.)

mm (in.)

Nm

(inlbs.)

Specifications

TSB Revision

. .

3+3 (.12+.12)

-1”00’+30’

2-9 (17-78)

9-l 1 (.354-.433)

1.7-3.2 (15-28)