MITSUBISHI GALANT 1989 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 1131 of 1273

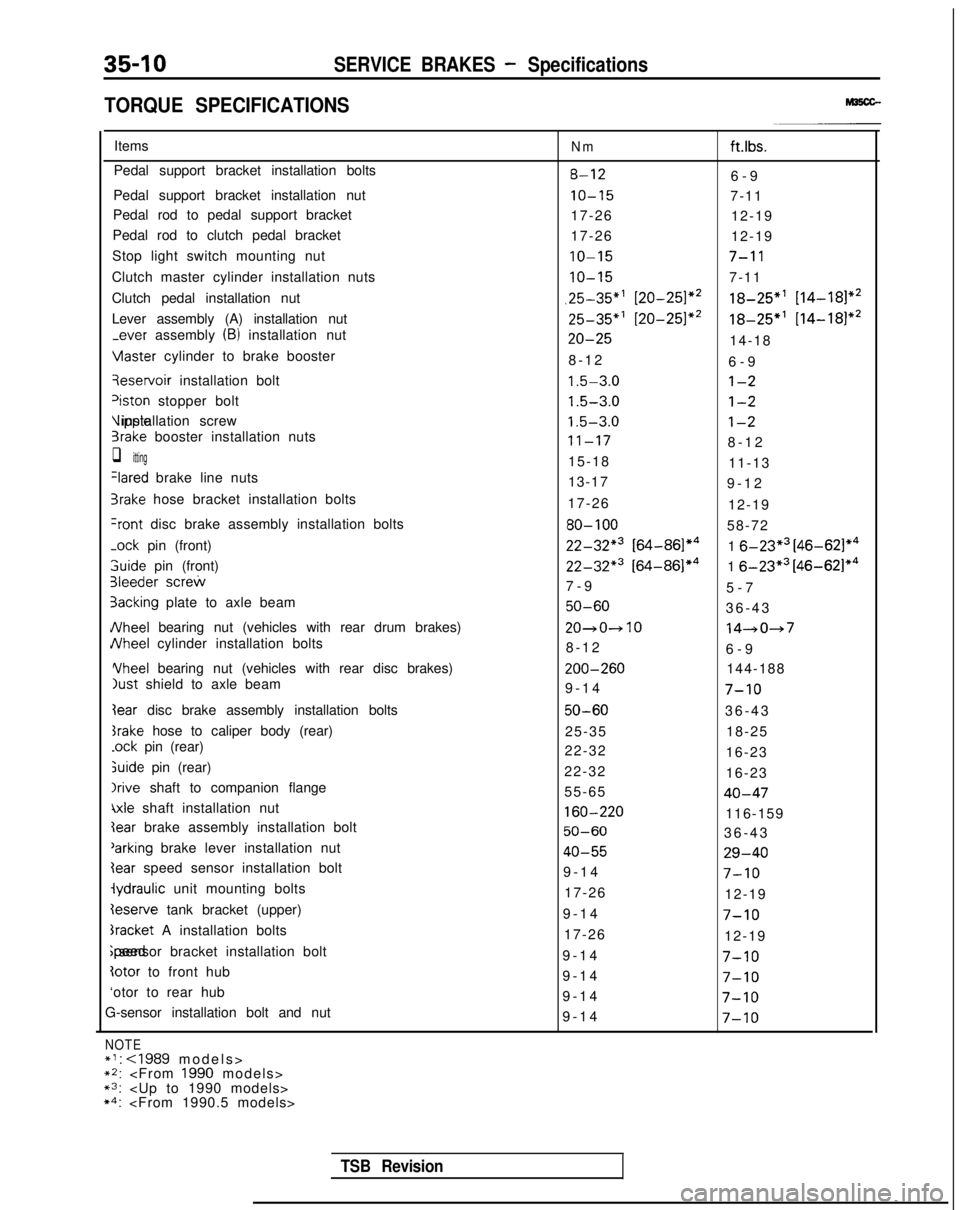

35-10SERVICE BRAKES - Specifications

TORQUE SPECIFICATIONS

Items

Pedal support bracket installation bolts

Pedal support bracket installation nut

Pedal rod to pedal support bracket

Pedal rod to clutch pedal bracket

Stop light switch mounting nut

Clutch master cylinder installation nuts

Clutch pedal installation nut

Lever assembly (A) installation nut

-ever assembly (B) installation nut Vlaster

cylinder to brake booster qeservoir

installation bolt

‘iston stopper bolt Vipple installation screw

3rake booster installation nuts

q itting

Ilared brake line nuts

3rake hose bracket installation bolts

+ont disc brake assembly installation bolts

-ock

pin (front) 3uide

pin (front)

31eeder screw

3acking plate to axle beam

JVheel bearing nut (vehicles with rear drum brakes)

JVheel cylinder installation bolts Yheel

bearing nut (vehicles with rear disc brakes)

just shield to axle beam

Iear disc brake assembly installation bolts

srake hose to caliper body (rear)

.ock pin (rear)

&ride pin (rear)

Irive shaft to companion flange

\xle shaft installation nut

Ieserve tank bracket (upper)

bracket A installation bolts ;peed sensor bracket installation bolt

totor to front hub

‘otor to rear hub

G-sensor installation bolt and nut

NOTE*I:

~2:

Nmft.lbs.

8-126-

9

IO-157-11

17-26 12-19

17-26 12-19

IO-157-l 1

IO-157-11

,25-35”’ [20-251*218-25”’ [14-181*2

25-35*’ [20-251*218-25*’

[14-181*2

20-2514-18

8-1

2

6-9

1.5-3.0l-2

1.5-3.0l-2

1.5-3.0l-2

11-178-1

2

15-18 11-13

13-17 9-12

17-26 12-19

80-10058-72

22-32*3 [64-86]*41 6-23*3 [46-621*4

22-32*3 [64-86]*41 6-23*3 [46-62]*4

7-

9

5-7

50-6036-4

3

20~0~1014-047

8-1

2

6-9 ZOO-260

144-188

9-14

7-10

50-6036-4

3

25-35 18-25

22-32 16-23

22-32 16-23

55-65

40-47

160-220116-159

50-6036-4

3

40-5529-40

9-1

4

7-10

17-26

12-19

9-1

4

7-10

17-26

12-19

9-1

4

7-10

9-1

4

7-10

9-1

4

7-10

9-1

4

7-10

TSB Revision

Page 1132 of 1273

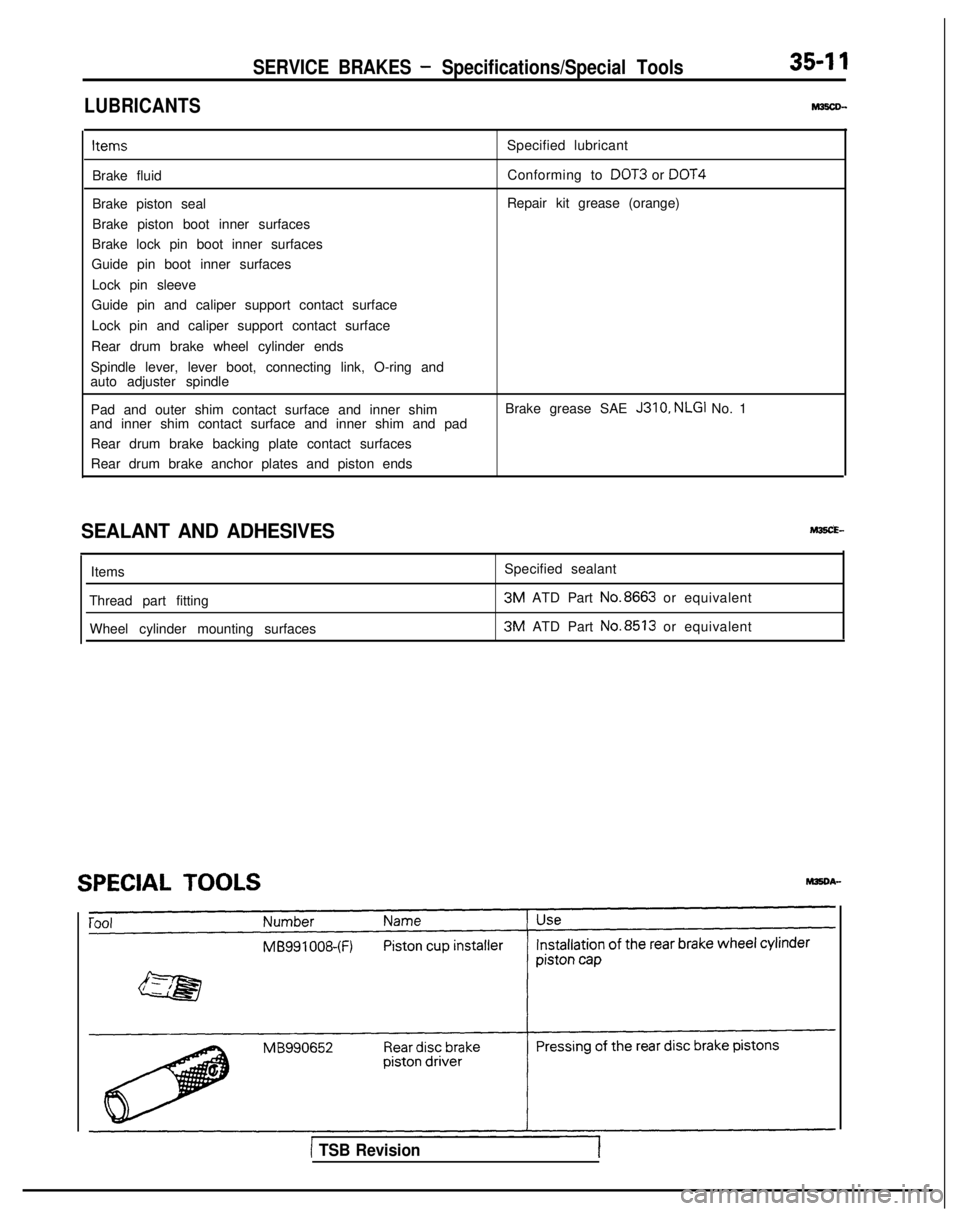

SERVICE BRAKES - Specifications/Special Tools35-l 1

LUBRICANTS

Items

Brake fluid

Brake piston seal

Brake piston boot inner surfaces

Brake lock pin boot inner surfaces

Guide pin boot inner surfaces

Lock pin sleeve

Guide pin and caliper support contact surface

Lock pin and caliper support contact surface

Rear drum brake wheel cylinder ends

Spindle lever, lever boot, connecting link, O-ring and

auto adjuster spindle Specified lubricant

Conforming to

DOT3 or DOT4

Repair kit grease (orange)

Pad and outer shim contact surface and inner shim

and inner shim contact surface and inner shim and pad

Rear drum brake backing plate contact surfaces

Rear drum brake anchor plates and piston ends Brake grease SAE J310,

NLGI No. 1

SEALANT AND ADHESIVES

,

Items

Specified sealant

Thread part fitting 3M

ATD Part No.8663

or equivalent

Wheel cylinder mounting surfaces 3M

ATD Part No.8513

or equivalent

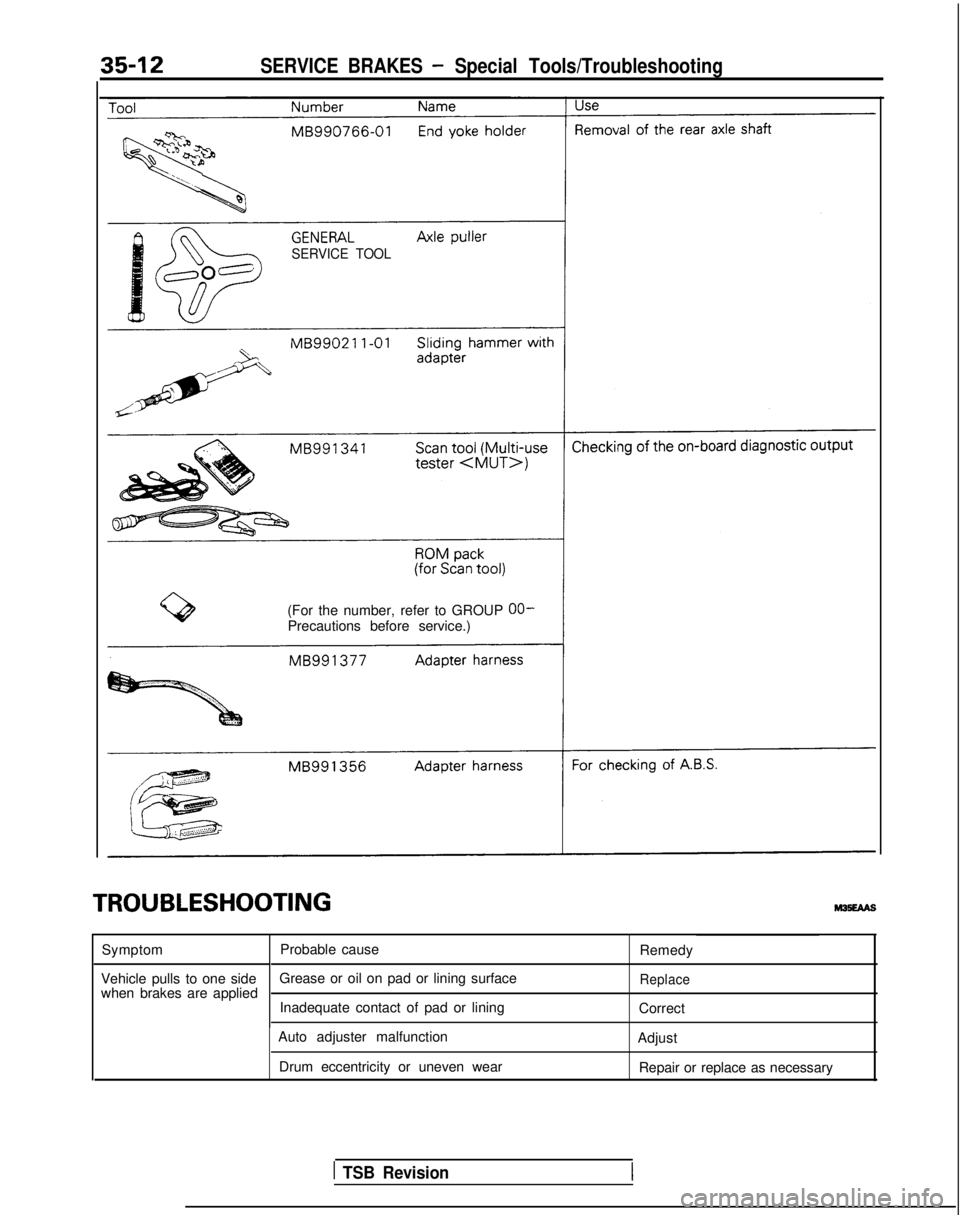

SPECIAL TOOLS

[ TSB Revision

Page 1133 of 1273

SERVICE BRAKES - Special Tools/Troubleshooting

SERVICE TOOL

(For the number, refer to GROUP OO-Precautions before service.)

TROUBLESHOOTING

Symptom

Vehicle pulls to one side

when brakes are applied Probable cause

Grease or oil on pad or lining surface

Inadequate contact of pad or lining

Auto adjuster malfunction

Drum eccentricity or uneven wear Remedy

Replace

Correct

Adjust Repair or replace as necessary

1 TSB Revision

Page 1134 of 1273

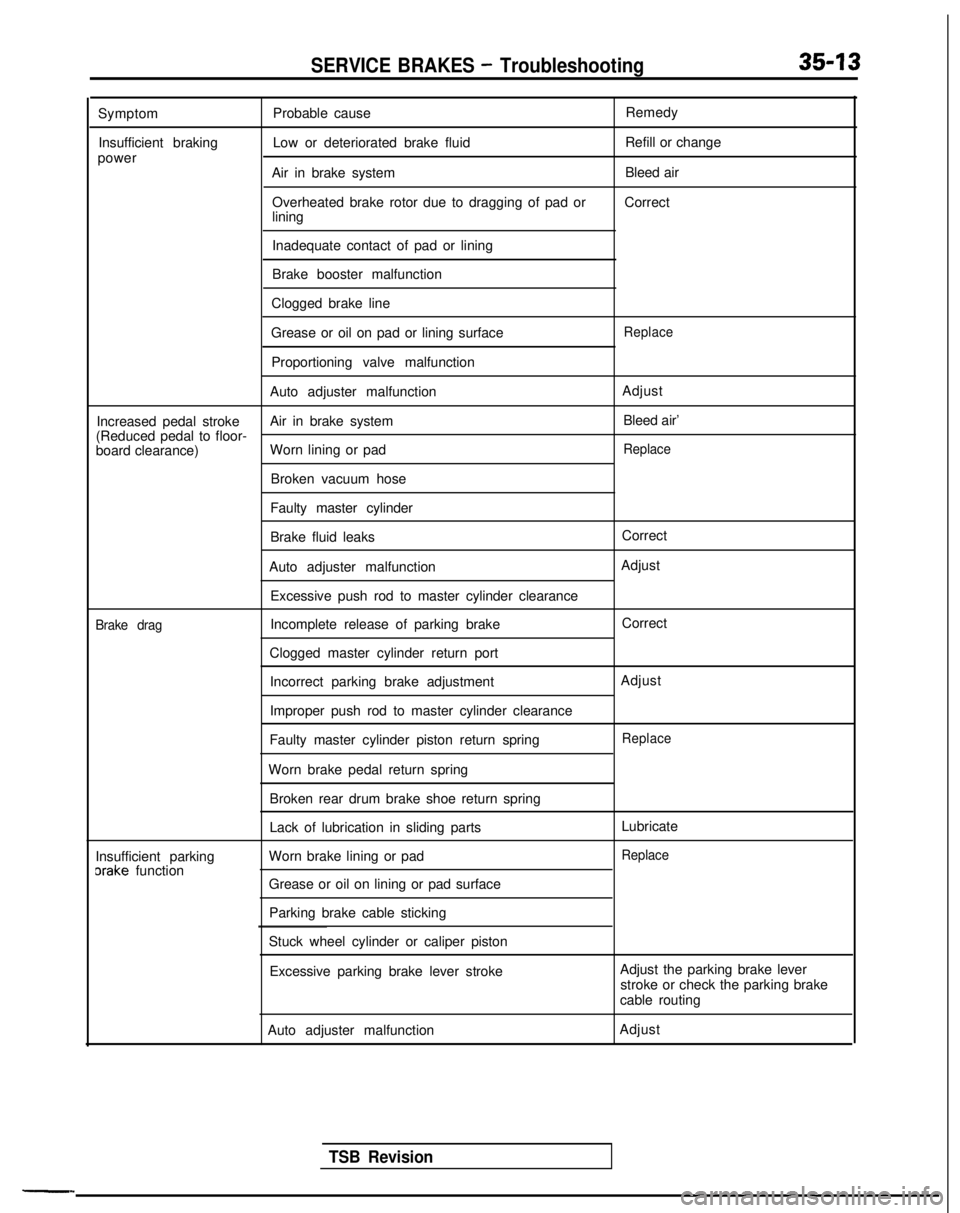

SERVICE BRAKES - Troubleshooting35-13

SymptomInsufficient braking

power Probable cause

Low or deteriorated brake fluid

Air in brake system Overheated brake rotor due to dragging of pad or

lining Remedy

Refill or change

Bleed air

Correct

Inadequate contact of pad or lining

Brake booster malfunction

Clogged brake line

Grease or oil on pad or lining surface

Replace

Proportioning valve malfunction

Auto adjuster malfunction Adjust

Increased pedal stroke Air in brake system Bleed air’

(Reduced pedal to floor-

board clearance) Worn lining or pad

Replace

Broken vacuum hose

Faulty master cylinder

Brake fluid leaks Correct

Auto adjuster malfunction Adjust

Excessive push rod to master cylinder clearance

Brake dragIncomplete release of parking brake Correct

Clogged master cylinder return port Incorrect parking brake adjustment Adjust

Improper push rod to master cylinder clearance

Faulty master cylinder piston return spring

Replace

Worn brake pedal return spring Broken rear drum brake shoe return spring

Lack of lubrication in sliding parts Lubricate

Insufficient parking Worn brake lining or pad

Replace

Drake function

Grease or oil on lining or pad surface

Parking brake cable sticking

Stuck wheel cylinder or caliper piston

Excessive parking brake lever stroke Adjust the parking brake lever

stroke or check the parking brake

cable routing

Auto adjuster malfunction Adjust

TSB Revision

-..

Page 1135 of 1273

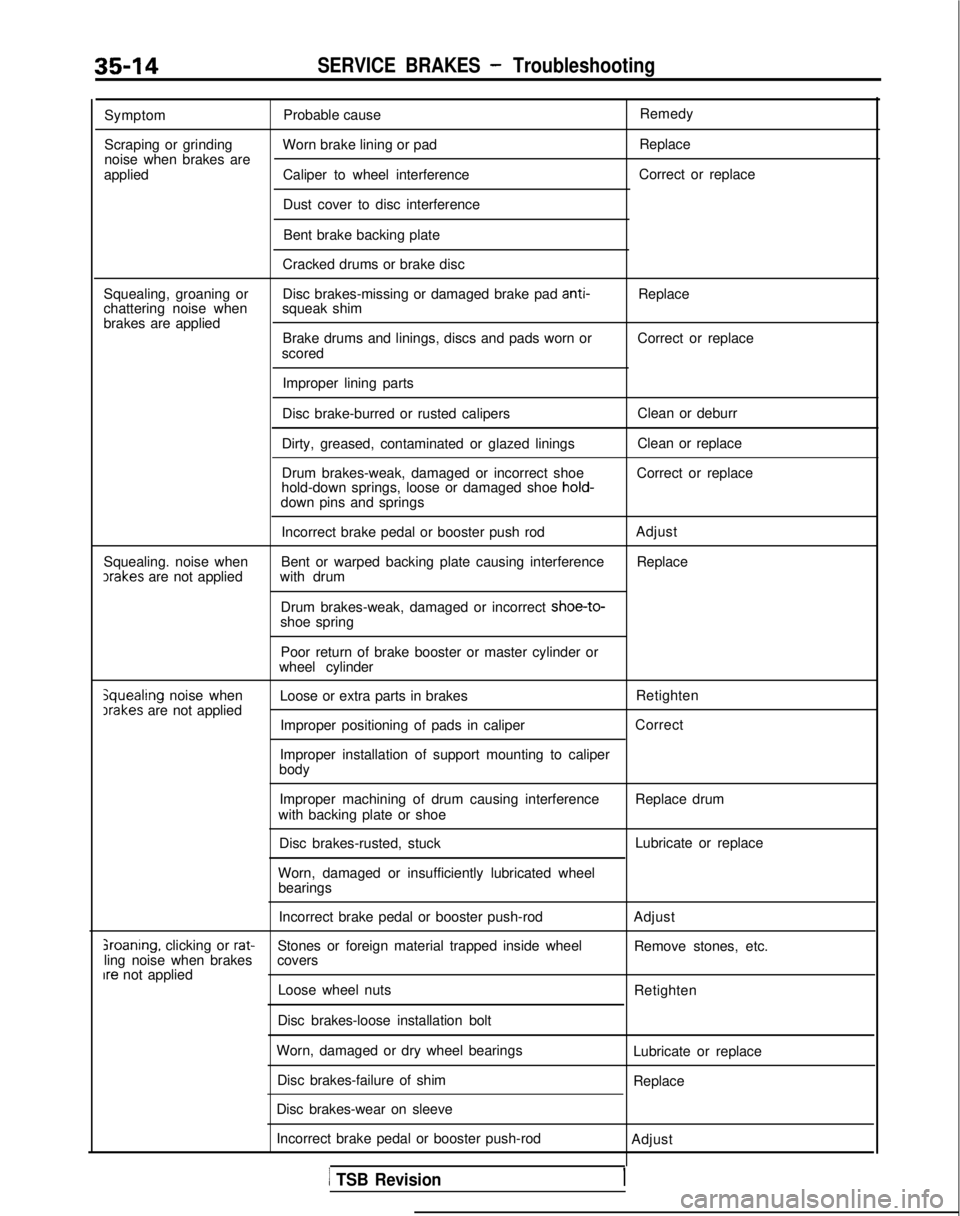

35-14SERVICE BRAKES - Troubleshooting

Symptom

Scraping or grinding

noise when brakes are

applied Probable cause

Worn brake lining or pad

Caliper to wheel interference

Dust cover to disc interference Remedy

Replace

Correct or replace

Bent brake backing plate

Cracked drums or brake disc

Squealing, groaning or

chattering noise when

brakes are applied Disc brakes-missing or damaged brake pad anti-

squeak shim Replace

Brake drums and linings, discs and pads worn or

scored Correct or replace

Improper lining parts

Disc brake-burred or rusted calipers

Dirty, greased, contaminated or glazed linings

Drum brakes-weak, damaged or incorrect shoe

hold-down springs, loose or damaged shoe hold-

down pins and springs Clean or deburr

Clean or replace

Correct or replace

Squealing. noise when ,rakes

are not applied Incorrect brake pedal or booster push rod

Bent or warped backing plate causing interference

with drum

Drum brakes-weak, damaged or incorrect shoe-to-

shoe spring Adjust

Replace

jquealing noise when Irakes

are not applied Poor return of brake booster or master cylinder or

wheel cylinder

Loose or extra parts in brakes Retighten

Improper positioning of pads in caliper

Improper installation of support mounting to caliper

body Correct

Improper machining of drum causing interference

with backing plate or shoe

Disc brakes-rusted, stuck

Worn, damaged or insufficiently lubricated wheel bearings Replace drum

Lubricate or replace

Incorrect brake pedal or booster push-rod Adjust

sroaning. clicking or rat-Stones or foreign material trapped inside wheel

Remove stones, etc.

ling noise when brakes covers

Ire not applied

Loose wheel nuts Retighten

Disc brakes-loose installation bolt

Worn, damaged or dry wheel bearings Disc brakes-failure of shim

Disc brakes-wear on sleeve Lubricate or replace

Replace

Incorrect brake pedal or booster push-rod Adjust

1 TSB Revision

Page 1136 of 1273

SERVICE BRAKES - Anti-lock Braking System Troubleshooting35-15

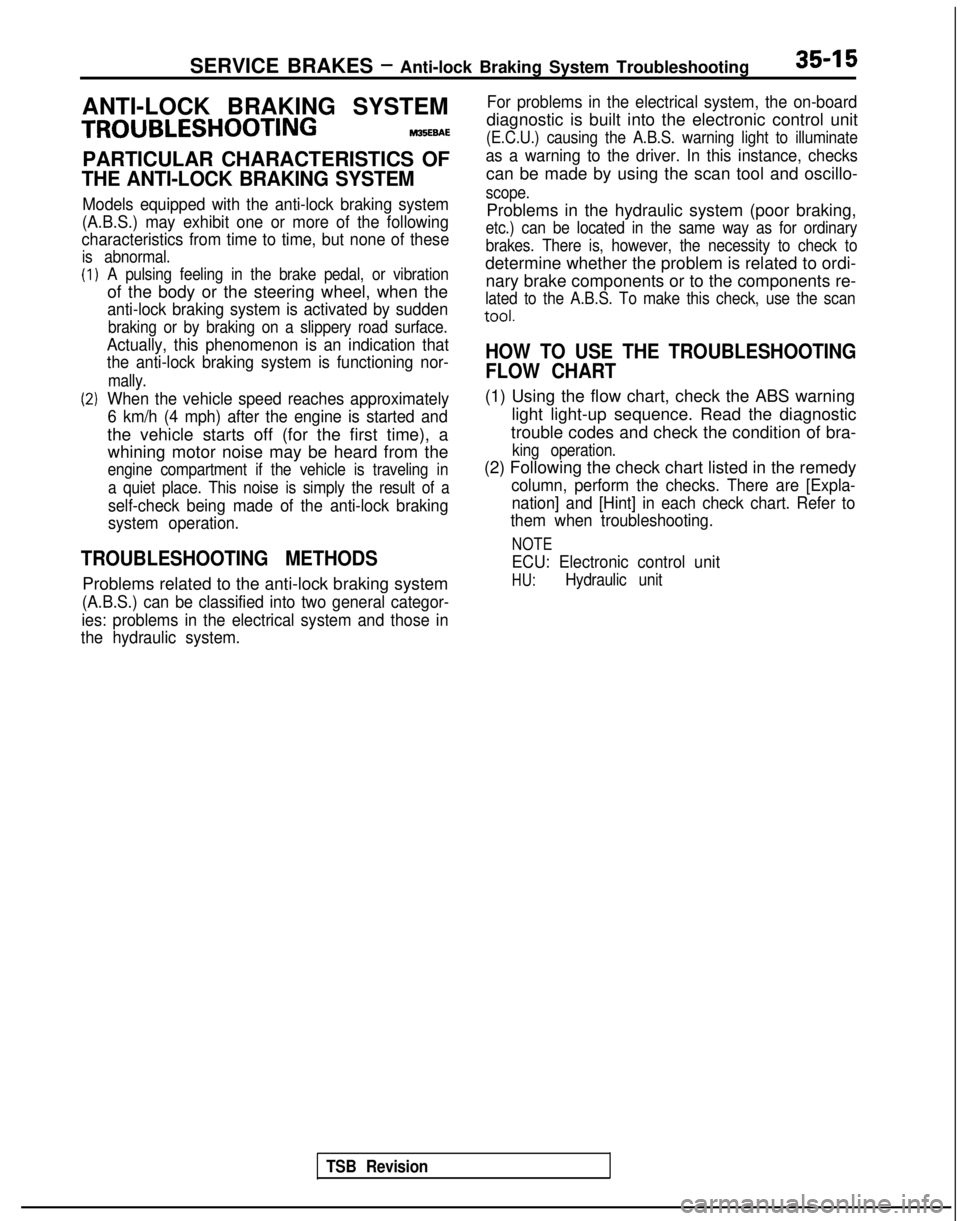

ANTI-LOCK BRAKING SYSTEM

TROUBLESHOOTINGM35EElAE

PARTICULAR CHARACTERISTICS OF

THE ANTI-LOCK BRAKING SYSTEM

Models equipped with the anti-lock braking system

(A.B.S.) may exhibit one or more of the following

characteristics from time to time, but none of these

is abnormal.

(1)

(2)

A pulsing feeling in the brake pedal, or vibration

of the body or the steering wheel, when the

anti-lock braking system is activated by sudden

braking or by braking on a slippery road surface.

Actually, this phenomenon is an indication that

the anti-lock braking system is functioning nor-

mally.

When the vehicle speed reaches approximately

6 km/h (4 mph) after the engine is started and

the vehicle starts off (for the first time), awhining motor noise may be heard from the

engine compartment if the vehicle is traveling in

a quiet place. This noise is simply the result of a

self-check being made of the anti-lock braking

system operation.

TROUBLESHOOTING METHODS

Problems related to the anti-lock braking system

(A.B.S.) can be classified into two general categor-

ies: problems in the electrical system and those in

the hydraulic system. For problems in the electrical system, the on-board

diagnostic is built into the electronic control unit

(E.C.U.) causing the A.B.S. warning light to illuminate

as a warning to the driver. In this instance, checks

can be made by using the scan tool and oscillo-

scope.

Problems in the hydraulic system (poor braking,

etc.) can be located in the same way as for ordinary

brakes. There is, however, the necessity to check to

determine whether the problem is related to ordi-

nary brake components or to the components re-

lated to the A.B.S. To make this check, use the scan

tool.

HOW TO USE THE TROUBLESHOOTING

FLOW CHART

(1) Using the flow chart, check the ABS warning

light light-up sequence. Read the diagnostic

trouble codes and check the condition of bra-

king operation.

(2) Following the check chart listed in the remedy

column, perform the checks. There are [Expla- nation] and [Hint] in each check chart. Refer to

them when troubleshooting.

NOTE

ECU: Electronic control unit

HU:Hydraulic unit

TSB Revision

Page 1137 of 1273

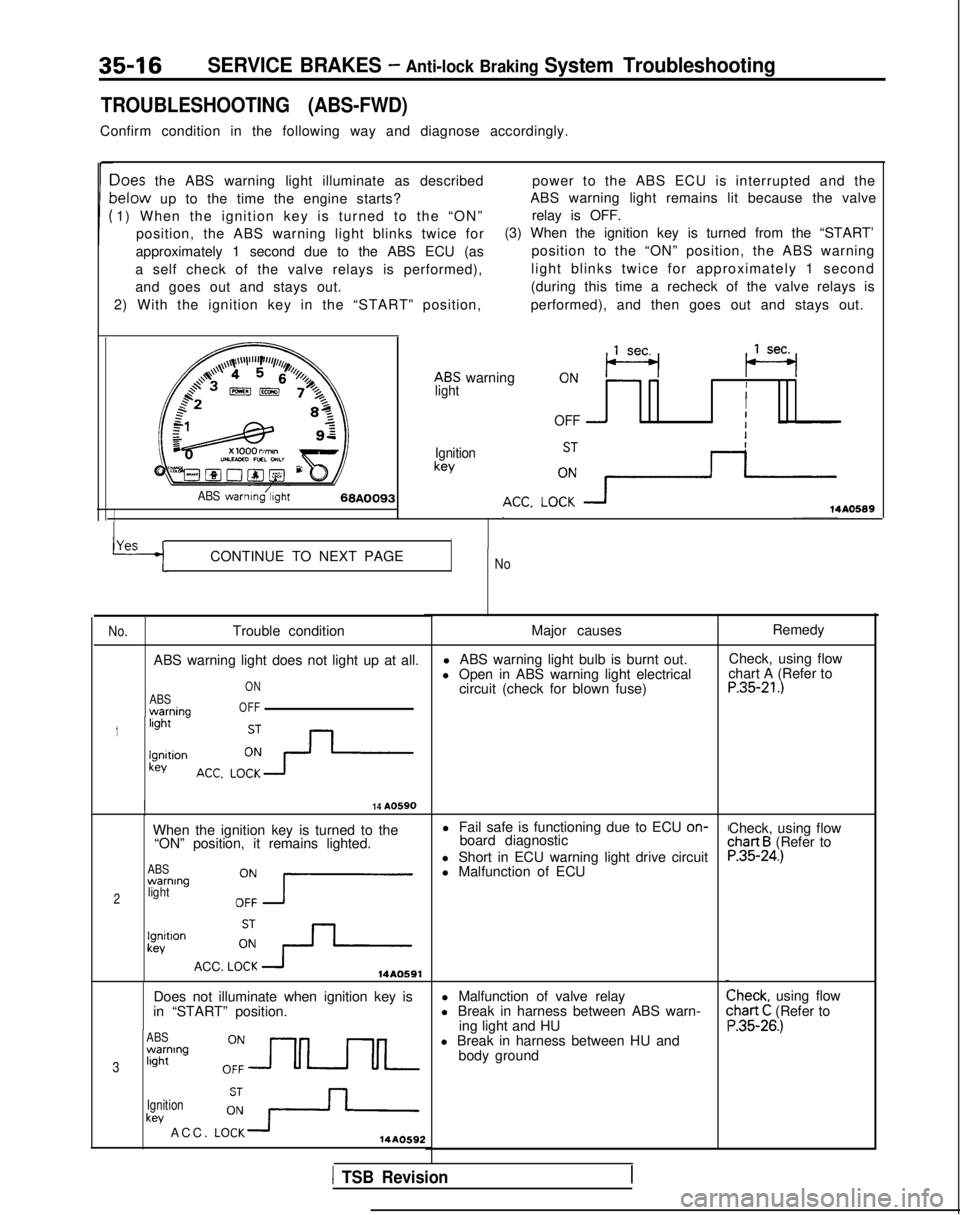

35-16SERVICE BRAKES - Anti-lock Braking System Troubleshooting

TROUBLESHOOTING (ABS-FWD)

Confirm condition in the following way and diagnose accordingly.

Ioes the ABS warning light illuminate as describedpower to the ABS ECU is interrupted and the

lelow up to the time the engine starts?ABS warning light remains lit because the valve

1) When the ignition key is turned to the “ON” relay is OFF.

position, the ABS warning light blinks twice for (3) When the ignition key is turned from the “START’

approximately 1 second due to the ABS ECU (as position to the “ON” position, the ABS warning

a self check of the valve relays is performed), light blinks twice for approximately 1 second

and goes out and stays out. (during this time a recheck of the valve relays is

2) With the ignition key in the “START” position, performed), and then goes out and stays out.

ABS warning

,,lseq (se+

lightII

OFF -I

Ignitionkey

ABS warnmg/;,ght68A009314A0589

YAS rICONTINUE TO NEXT PAGENo

No.

Trouble condition

ABS warning light does not light up at all.

ABSwarnina

ON

OFF

1light -

lgnltionkey

I14 A0590

When the ignition key is turned to the l Fail safe is functioning due to ECU on-

“ON” position, it remains lighted. board diagnostic

ABSwarning

2lightOZ7

l Short in ECU warning light drive circuit

l Malfunction of ECU

lgnitlonkev

ACC. LOi+14A0591

Does not illuminate when ignition key is

in “START” position.

ABSwarning

3light

Ignition

key ACC. LO:+14AO592

Major causes

l ABS warning light bulb is burnt out.

l Open in ABS warning light electrical circuit (check for blown fuse)

l Malfunction of valve relay

l Break in harness between ABS warn- ing light and HU

l Break in harness between HU and body ground Remedy

Check, using flow

chart A (Refer to

P.35-21.)

Check, using flowchart B (Refer toP.35-24.)

Check, using flow:hart C (Refer to ‘.35-26.)

1 TSB Revision

Page 1138 of 1273

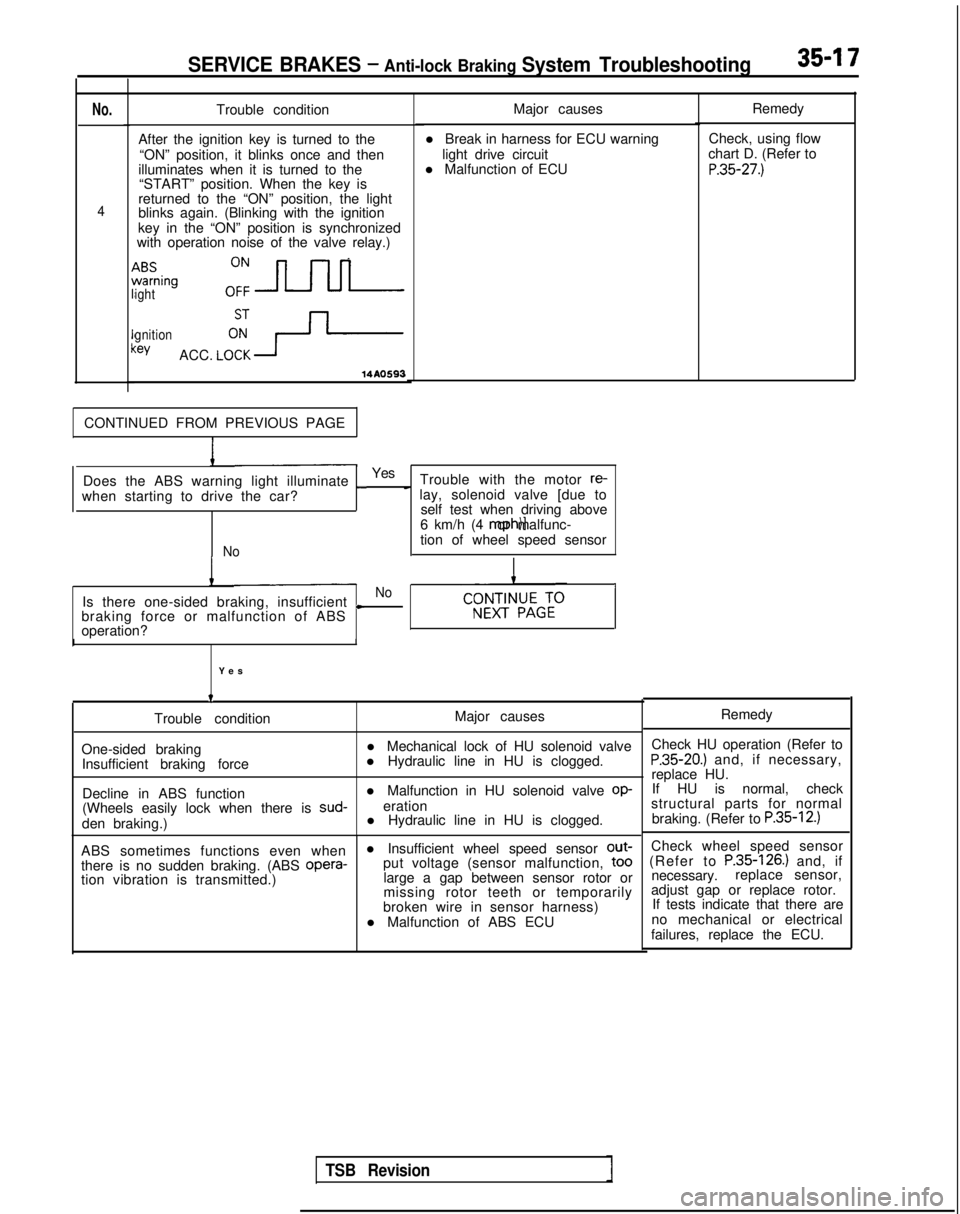

SERVICE BRAKES - Anti-lock Braking System Troubleshooting35-I 7

No.

4

Trouble condition

After the ignition key is turned to the “ON” position, it blinks once and then

illuminates when it is turned to the “START” position. When the key is

returned to the “ON” position, the light

blinks again. (Blinking with the ignition

key in the “ON” position is synchronized

with operation noise of the valve relay.)

ABSwarning

ighto:=

gnition:eyACC. LCFY-

14AO593

Major causes

l Break in harness for ECU warning light drive circuit

l Malfunction of ECU

CONTINUED FROM PREVIOUS PAGE

Does the ABS warning light illuminate

_Yes Trouble with the motor re-

when starting to drive the car?

c lay, solenoid valve [due to self test when driving above

6 km/h (4 mph)] or malfunc-

Notion of wheel speed sensor

I

Is there one-sided braking, insufficientNo

L

braking force or malfunction of ABS

operation?

I

Yes

t

Trouble condition

One-sided braking Insufficient braking force

Decline in ABS function

I

Major causes

l Mechanical lock of HU solenoid valve

l Hydraulic line in HU is clogged.

l Malfunction in HU solenoid valve

op-

(Wheels easily lock when there is sud-

eration

den braking.) l Hydraulic line in HU is clogged.

ABS sometimes functions even when l Insufficient wheel speed sensor out-

there is no sudden braking. (ABS opera-

put voltage (sensor malfunction,

to0

tion vibration is transmitted.)

large a gap between sensor rotor or

missing rotor teeth or temporarily

broken wire in sensor harness)

l Malfunction of ABS ECU Remedy

Check, using flow

chart D. (Refer to

P.35-27.)

Remedy

Check HU operation (Refer to

P.35-20.) and, if necessary,

replace HU. If HU is normal, check

structural parts for normal

braking. (Refer to

P.35-12.)

Check wheel speed sensor

(Refer to P.35-126.) and, if

necessary. replace sensor,

adjust gap or replace rotor. If tests indicate that there are

no mechanical or electrical

failures, replace the ECU.

TSB Revision

Page 1139 of 1273

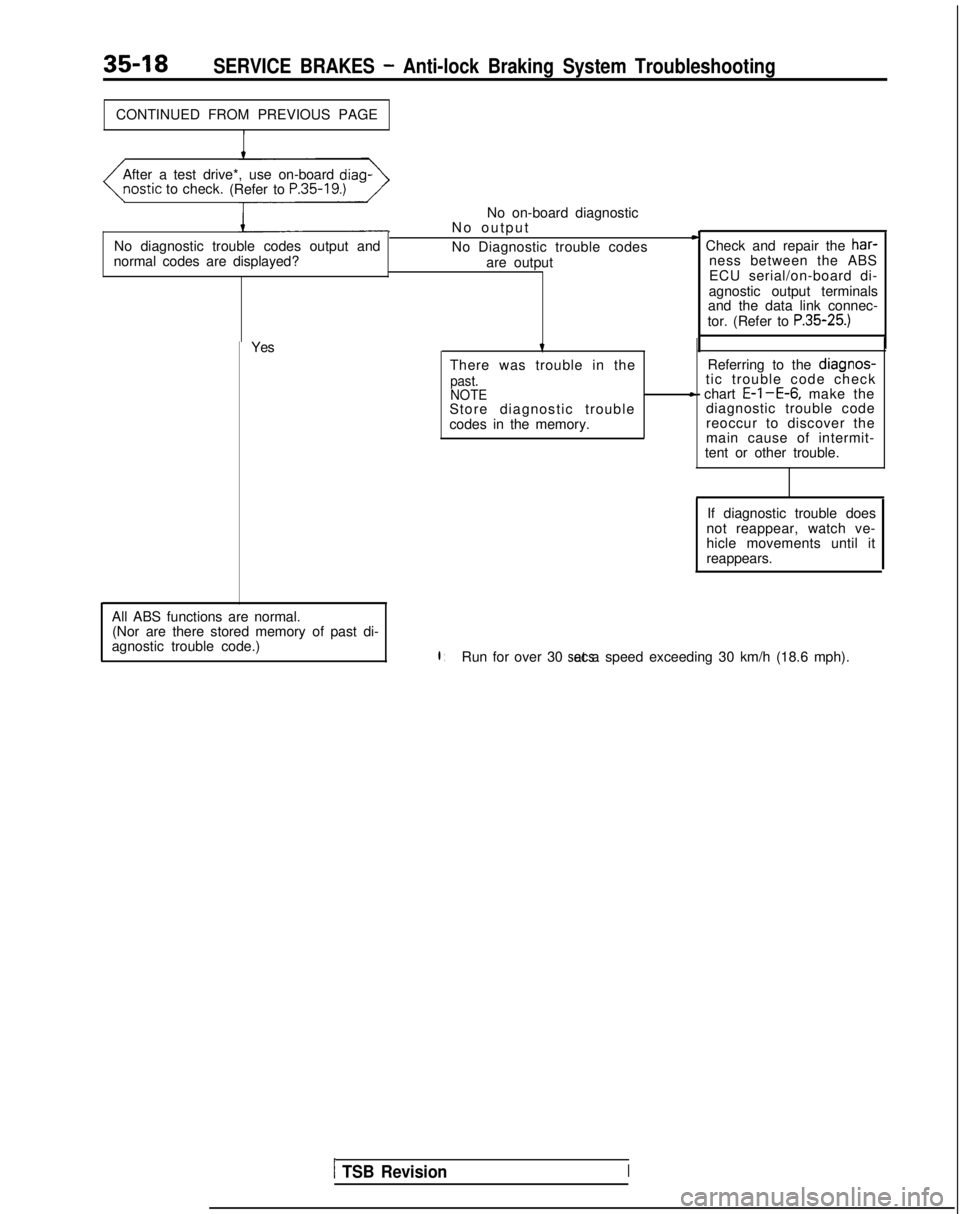

35-18SERVICE BRAKES - Anti-lock Braking System Troubleshooting

CONTINUED FROM PREVIOUS PAGEAfter a test drive*, use on-board diag-

ostic

to check.

(Refer to

P.35-19.)

No diagnostic trouble codes output and

normal codes are displayed? No on-board diagnostic

No outpu

t

No Diagnostic trouble codes are output

D Check and repair the har-

ness between the ABS

ECU serial/on-board di-

agnostic output terminals

and the data link connec-

tor. (Refer to

P.35-25.)

Yes

All ABS functions are normal. (Nor are there stored memory of past di-

agnostic trouble code.)t

There was trouble in the

past.

NOTE

Store diagnostic trouble

codes in the memory. Referring to the

diagnos-tic trouble code checkc chart E-l-E-6, make the

diagnostic trouble code

reoccur to discover the

main cause of intermit-

tent or other trouble.

If diagnostic trouble does

not reappear, watch ve-

hicle movements until it

reappears.

l :Run for over 30 sets. at a speed exceeding 30 km/h (18.6 mph).

1 TSB RevisionI

Page 1140 of 1273

SERVICE BRAKES - Anti-lock Braking System Troubleshooting35-19

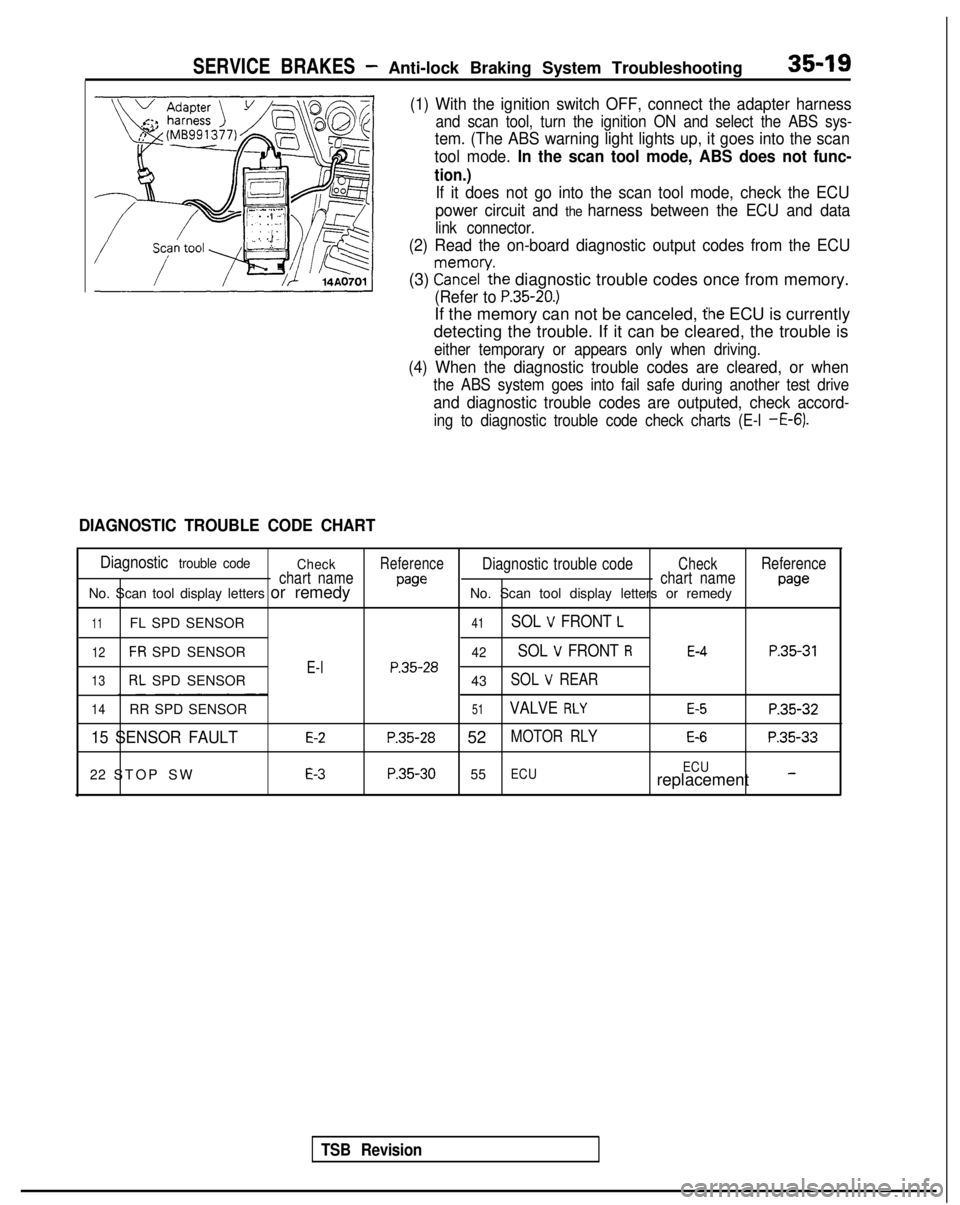

(1) With the ignition switch OFF, connect the adapter harness

and scan tool, turn the ignition ON and select the ABS sys-

tem. (The ABS warning light lights up, it goes into the scan

tool mode.

In the scan tool mode, ABS does not func-

tion.)

If it does not go into the scan tool mode, check the ECU

power circuit and

the harness between the ECU and data

link connector.

(2) Read the on-board diagnostic output codes from the ECU

(3) ?a\?zl’ythe diagnostic trouble codes once from memory.

(Refer to P.35-20.)

If the memory can not be canceled, the ECU is currently

detecting the trouble. If it can be cleared, the trouble is

either temporary or appears only when driving.

(4) When the diagnostic trouble codes are cleared, or when

the ABS system goes into fail safe during another test drive

and diagnostic trouble codes are outputed, check accord-

ing to diagnostic trouble code check charts (E-l -E-6).

DIAGNOSTIC TROUBLE CODE CHART

Diagnostic trouble code CheckReferenceDiagnostic trouble codeCheckReference

chart name

pawchart namepawNo. Scan tool display letters or remedy No. Scan tool display letters or remedy

11FL SPD SENSOR41SOL V FRONT L

12FR SPD SENSOR42SOL V FRONT RE-4P.35-31

E-lP.35-2813RL SPD SENSOR

43SOL V REAR

14RR SPD SENSOR51VALVE RLYE-5P.35-32

15 SENSOR FAULTE-2P.35-28 52MOTOR RLYE-6P.35-33

22 STOP SWE-3P.35-30 55ECU ECUreplacement -

TSB Revision