MITSUBISHI GALANT 1989 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 1111 of 1273

34-30REAR SUSPENSION

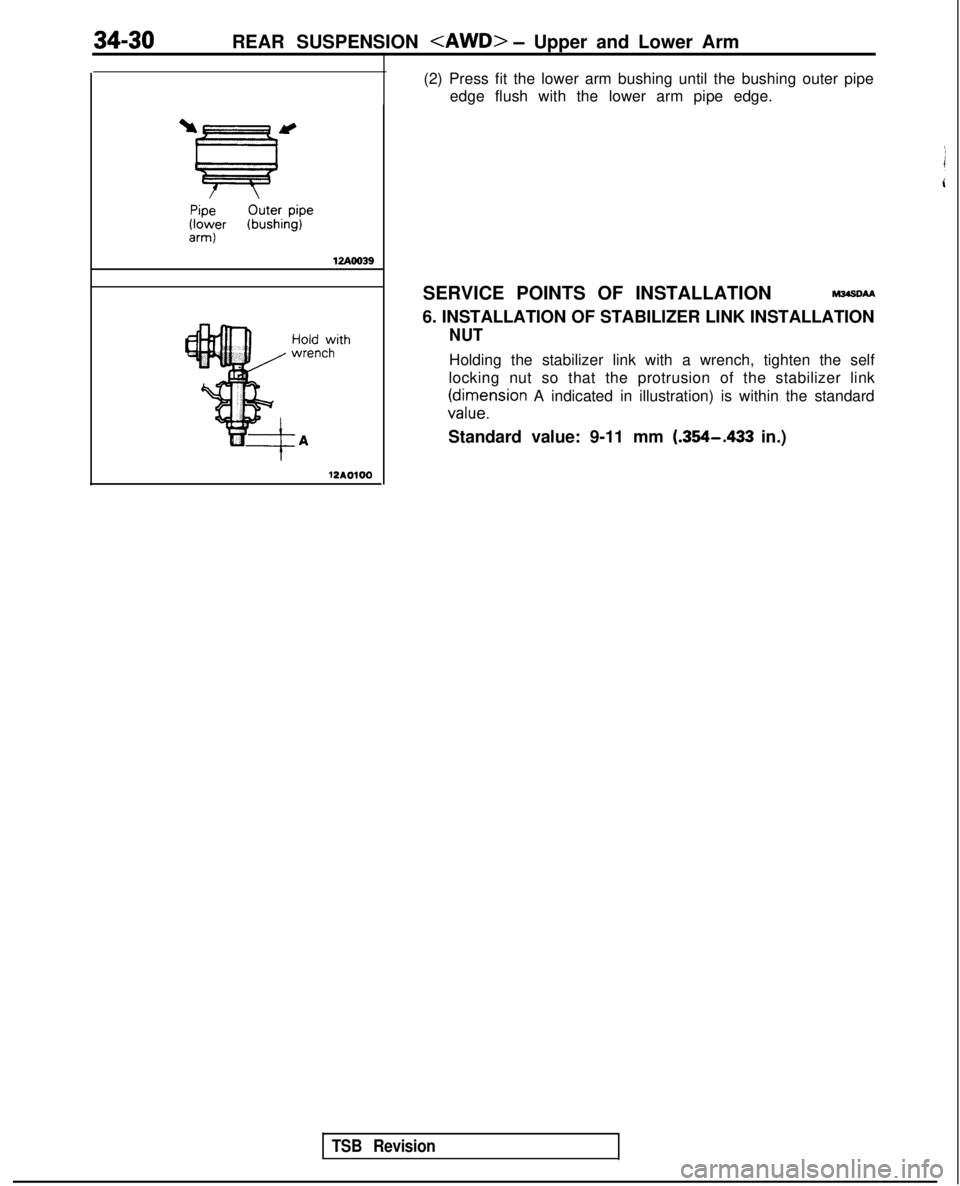

PipeOuter pipe(lower (bushing)arm)

12AOO39

12A0100

(2) Press fit the lower arm bushing until the bushing outer pipeedge flush with the lower arm pipe edge.

SERVICE POINTS OF INSTALLATION

M34sDAA

6. INSTALLATION OF STABILIZER LINK INSTALLATION

NUT

Holding the stabilizer link with a wrench, tighten the self

locking nut so that the protrusion of the stabilizer link

(cil;l,nsion A indicated in illustration) is within the standard

Standard value: 9-11 mm

(.364-433 in.)

TSB Revision

Page 1112 of 1273

REAR SUSPENSION

TRAILING ARM

REMOVAL AND INSTALLATION

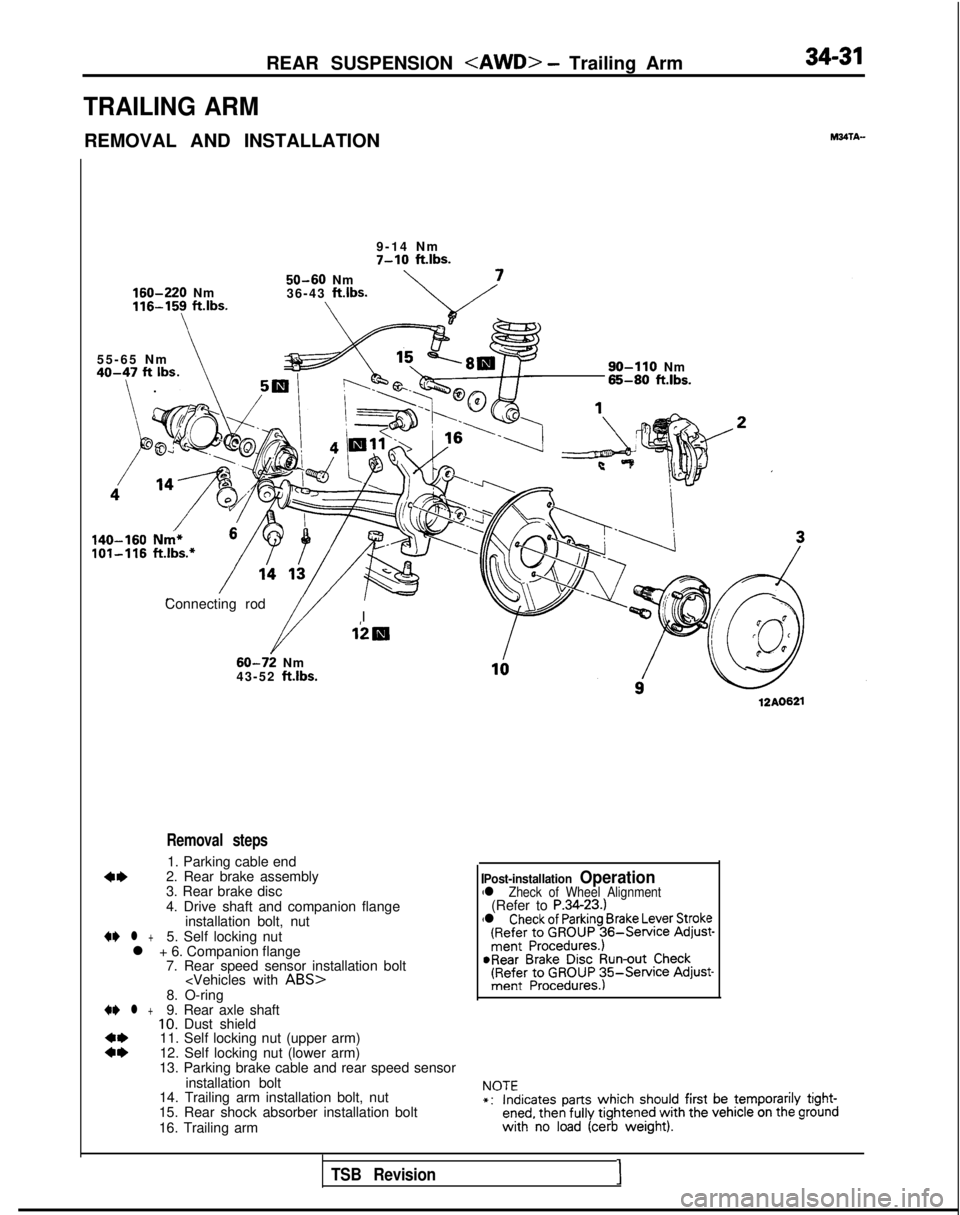

160-220 Nm116-15y

ft.lbs.

9-14 Nm

7-10 ftlbs.

50-60 Nm

36-43 ft.lbs.

\

55-65 N

m

40-47 ft Ibs\ . .\~- -

140-160 Nm*101-116 ft.lbs.*

Connecting rod// I

Yli0

60-7i Nm

43-52 ft.lbs.

90-110 Nm65-80 ftlbs.

Removal steps

1. Parking cable end

4*2. Rear brake assembly

3. Rear brake disc

4. Drive shaft and companion flange

installation bolt, nut

4I) l +5. Self locking nut

l + 6. Companion flange 7. Rear speed sensor installation bolt

::11. Self locking nut (upper arm)

12. Self locking nut (lower arm)

13. Parking brake cable and rear speed sensor

installation bolt

14. Trailing arm installation bolt, nut

15. Rear shock absorber installation bolt

16. Trailing arm

12AO621

Post-installation Operationl Zheck of Wheel Alignment(Refer to P.3423.)l Check of Parking Brake Lever Stroke(Refer to GROUP 36-Service

Adjust-ment Procedures.)@Rear Brake Disc Run-out Check(Refer to GROUP 35Service Adjust-ment Procedures.)

NOTE*:Indicates parts which should

first

be temporarily tight-ened, then fully

tightened with

the vehicle on the ground with

no load (cerb weight).

TSB Revision I

Page 1113 of 1273

34-32REAR SUSPENSION

12AOO64

MB991 113-01

12AOO96-

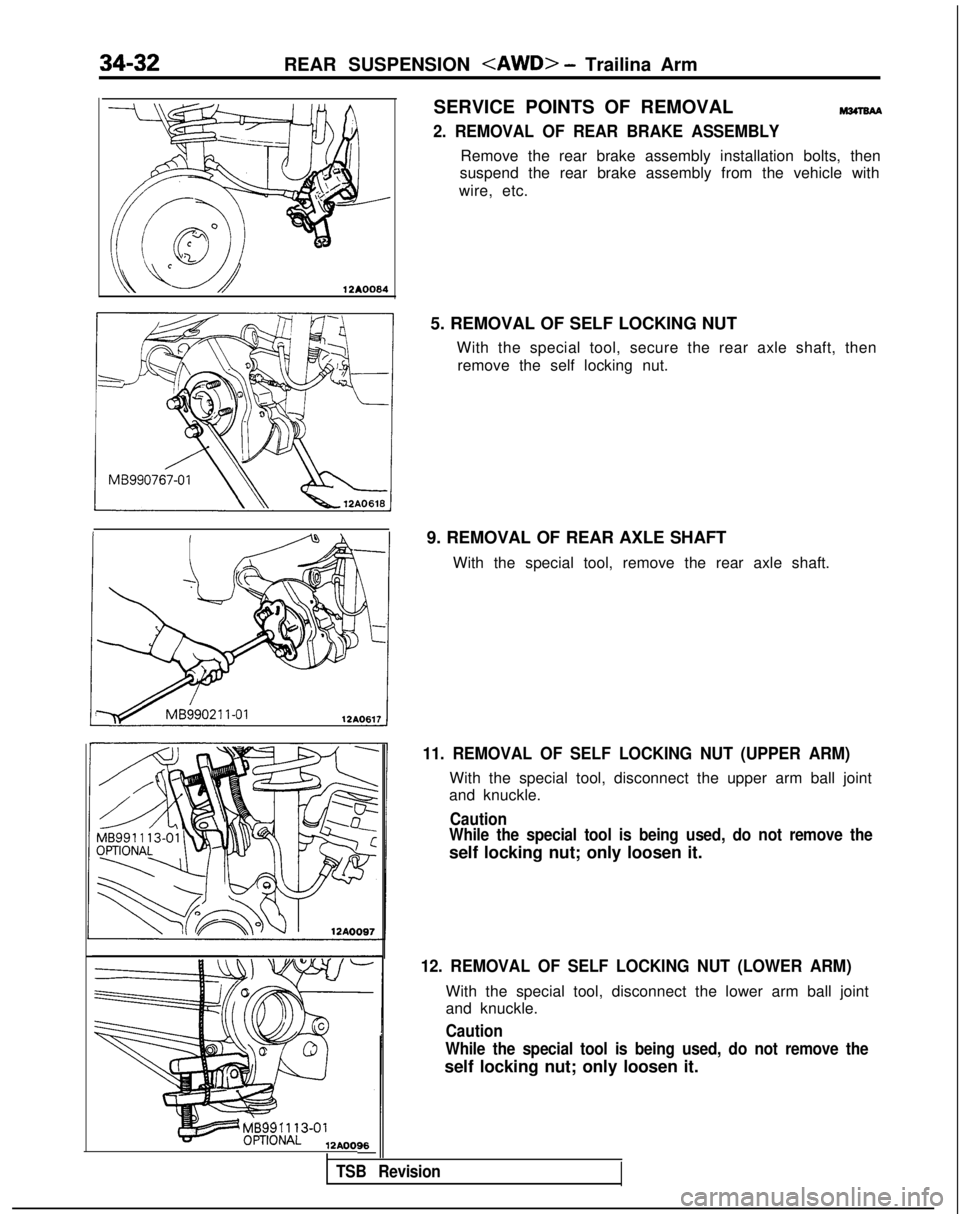

SERVICE POINTS OF REMOVAL

2. REMOVAL OF REAR BRAKE ASSEMBLY

Remove the rear brake assembly installation bolts, then

suspend the rear brake assembly from the vehicle with

wire, etc.

5. REMOVAL OF SELF LOCKING NUT With the special tool, secure the rear axle shaft, thenremove the self locking nut.

9. REMOVAL OF REAR AXLE SHAFT With the special tool, remove the rear axle shaft.

11. REMOVAL OF SELF LOCKING NUT (UPPER ARM)

With the special tool, disconnect the upper arm ball joint

and knuckle.

Caution

While the special tool is being used, do not remove the

self locking nut; only loosen it.

12. REMOVAL OF SELF LOCKING NUT (LOWER ARM)

With the special tool, disconnect the lower arm ball joint

and knuckle.

Caution

While the special tool is being used, do not remove the

self locking nut; only loosen it.

TSB Revision

Page 1114 of 1273

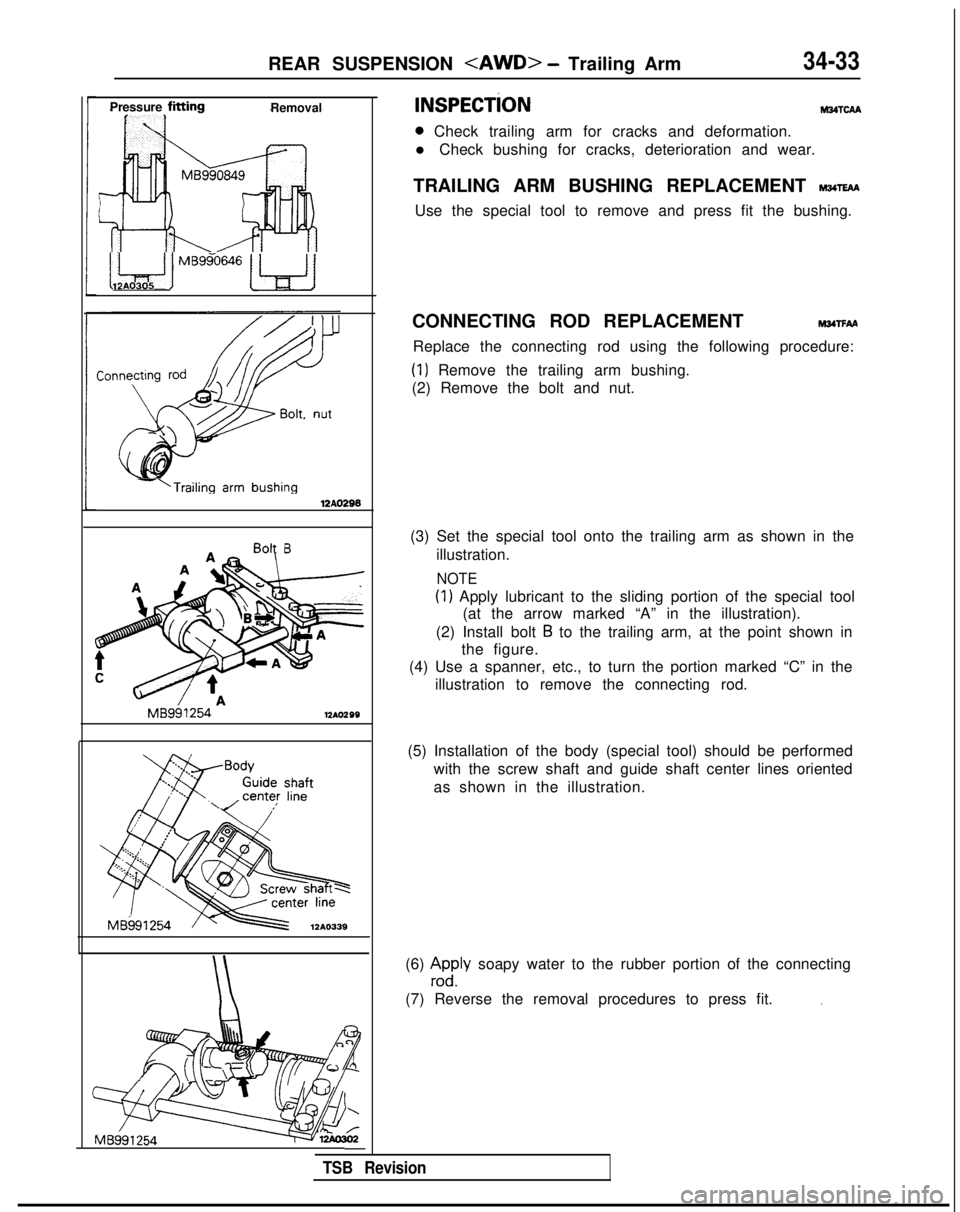

Pressure fittingRemoval

REAR SUSPENSION

M34TCAA

0 Check trailing arm for cracks and deformation.

l Check bushing for cracks, deterioration and wear.

TRAILING ARM BUSHING REPLACEMENT

wm

Use the special tool to remove and press fit the bushing.

i Le$ iMBggo646w12AO305

-‘Trailing arm

bushing12AO296

Bolt B

MB991254

12AO299

Body

Guide

shaftcenter line.\/ ’

MB991254

12A0339

MB991

254-

CONNECTING ROD REPLACEMENTMwrFAA

Replace the connecting rod using the following procedure:

(1) Remove the trailing arm bushing.

(2) Remove the bolt and nut.

(3) Set the special tool onto the trailing arm as shown in the illustration.

NOTE

(1) Apply lubricant to the sliding portion of the special tool(at the arrow marked “A” in the illustration).

(2) Install bolt

B to the trailing arm, at the point shown in

the figure.

(4) Use a spanner, etc., to turn the portion marked “C” in the

illustration to remove the connecting rod.

(5) Installation of the body (special tool) should be performed with the screw shaft and guide shaft center lines oriented

as shown in the illustration.

(6)

zdyly soapy water to the rubber portion of the connecting

(7) Reverse the removal procedures to press fit.

I

TSB Revision

Page 1115 of 1273

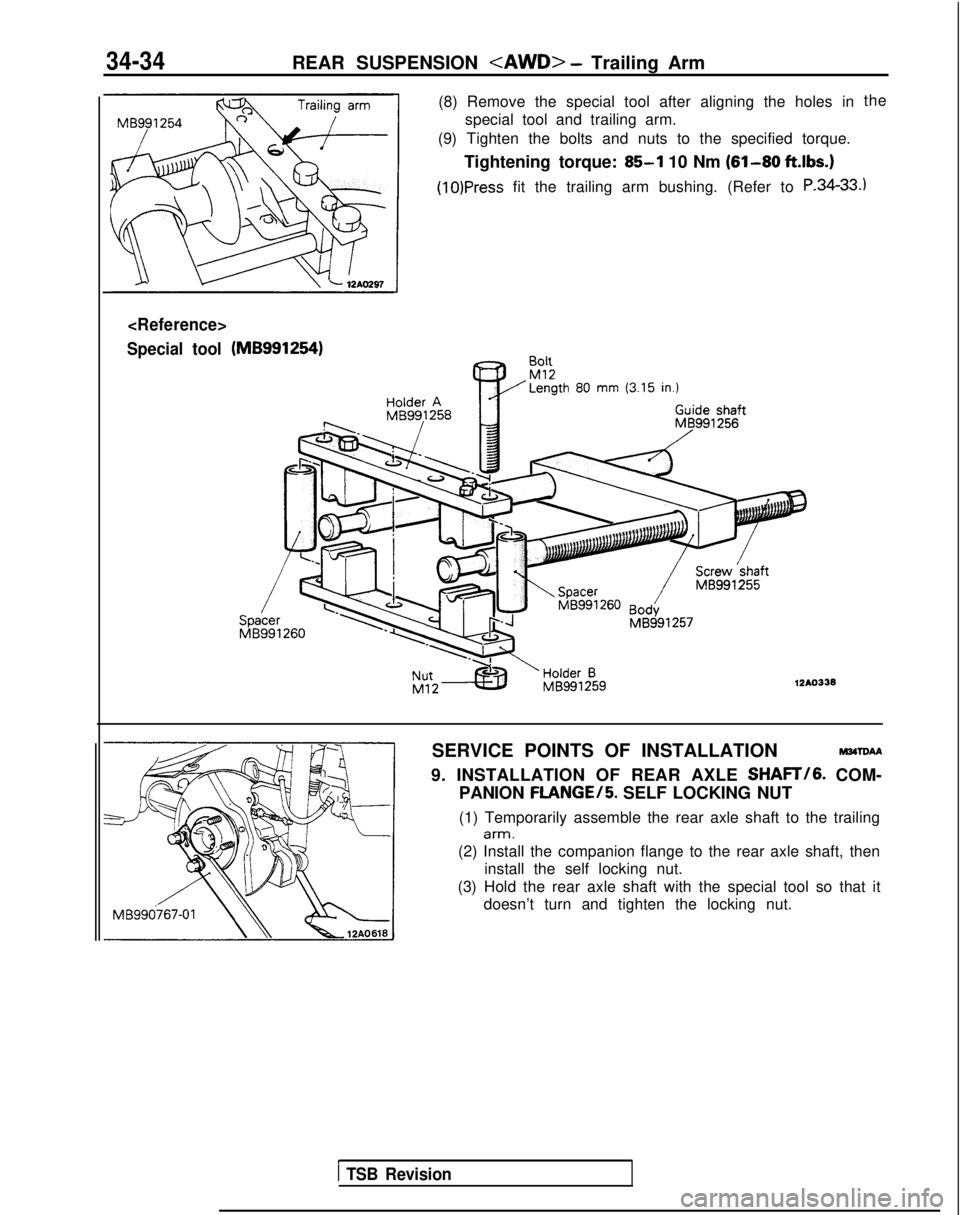

34-34REAR SUSPENSION

Special tool

(8) Remove the special tool after aligning the holes in special tool and trailing arm.

(9) Tighten the bolts and nuts to the specified torque.

Tightening torque:

85-l 10 Nm (61-80 ft.lbs.)

(10)Press fit the trailing arm bushing. (Refer to P.34-33

(MB991254)- Rnl1

Holder AMB991258

I”..Ml2 Length

80 mm

(3.15

in.) Guide

shaftMB991 256/

/

Screw

‘shaft MB991255

%’ Body

MB991 257

12AO336

the

.I

SERVICE POINTS OF INSTALLATIONM34ToAA

9. INSTALLATION OF REAR AXLE SHAFT/G. COM-

PANION

FLANGE/5. SELF LOCKING NUT

(1) Temporarily assemble the rear axle shaft to the trailing

arm.

(2) Install the companion flange to the rear axle shaft, then install the self locking nut.

(3) Hold the rear axle shaft with the special tool so that it doesn’t turn and tighten the locking nut.

1 TSB Revision

Page 1116 of 1273

REAR SUSPENSION

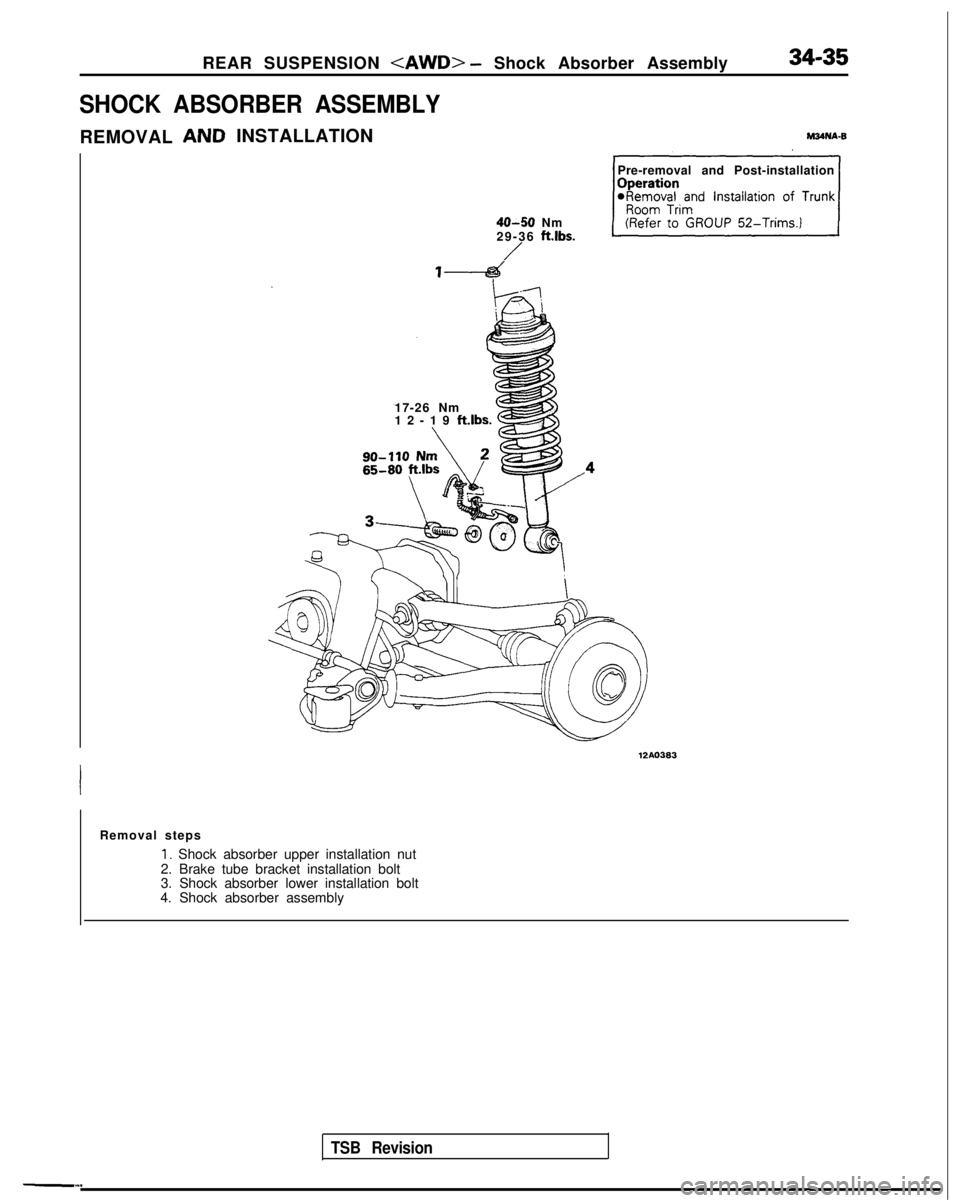

SHOCK ABSORBER ASSEMBLY

INSTALLATION

REMOVAL

17-26 Nm

12-19 ft.lbs.

6

Pre-removal and Post-installation

40-50 Nm

29-36 ftlbs.

/

TSB Revision

12AO383

Removal steps

I. Shock absorber upper installation nut

2. Brake tube bracket installation bolt

3. Shock absorber lower installation bolt

4. Shock absorber assembly

Page 1117 of 1273

34-36REAR SUSPENSION

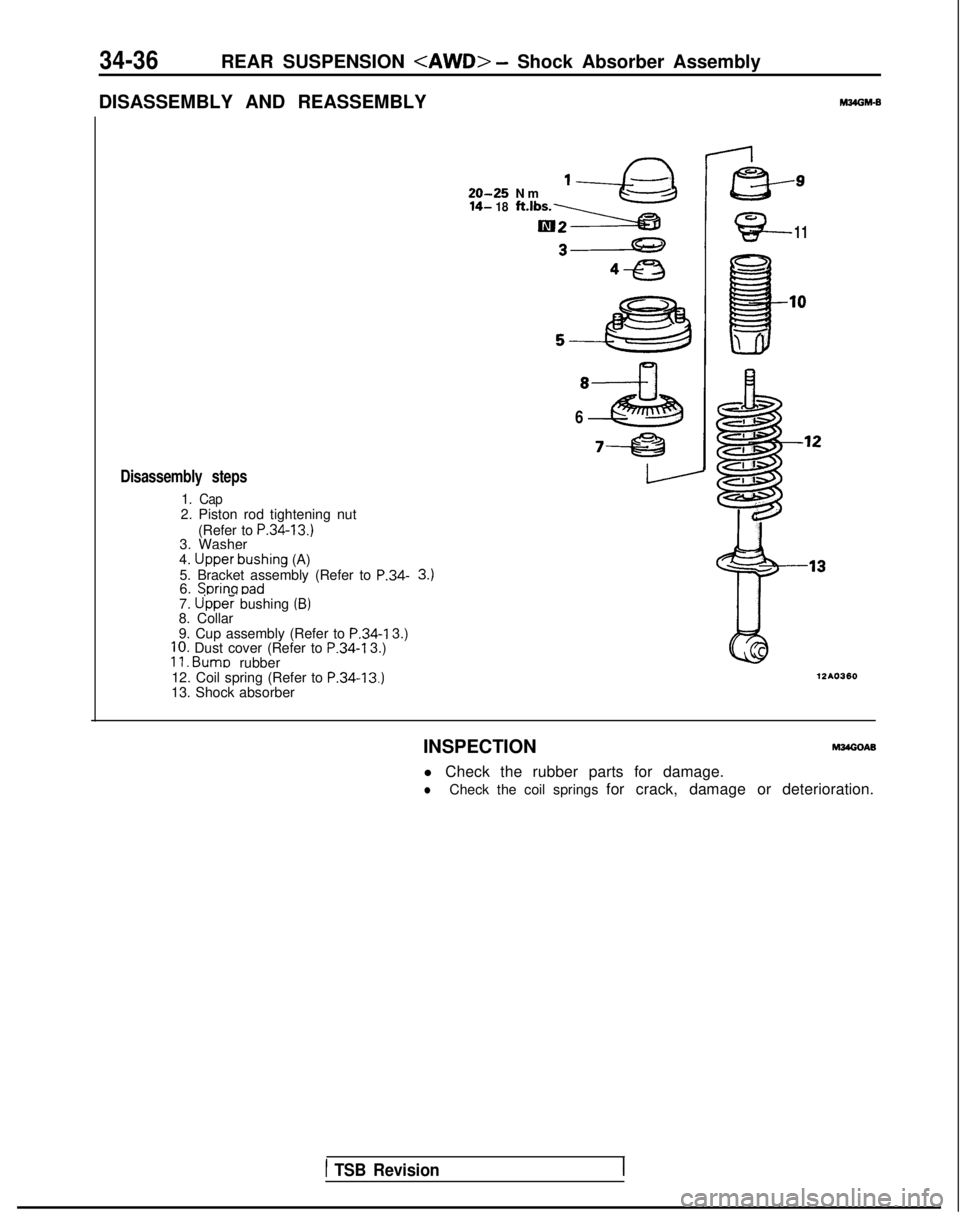

DISASSEMBLY AND REASSEMBLY

M34OM-B

Disassembly steps

1. Cap2. Piston rod tightening nut (Refer to

P.34-13.)3. Washer

4. Upper-bushing (A)

5. Bracket assembly (Refer to P.34-6. Sorina oad

20-25 N

m

14- 18

1-a

ft.‘bs-BS-

3J

e3

7. U’pper bushing (B)8. Collar

9. Cup assembly (Refer to

P.34-I

3.)

10. Dust cover (Refer to P.34-I

3.)11. Bums

rubber

12. Coil spring (Refer to P.34-13,)13. Shock absorber

INSPECTION

I-

B-9

G?-11

8

6

~-EB

12AO360

l Check the rubber parts for damage.

lCheck the coil springs for crack, damage or deterioration.

1 TSB Revision

Page 1118 of 1273

REAR SUSPENSION

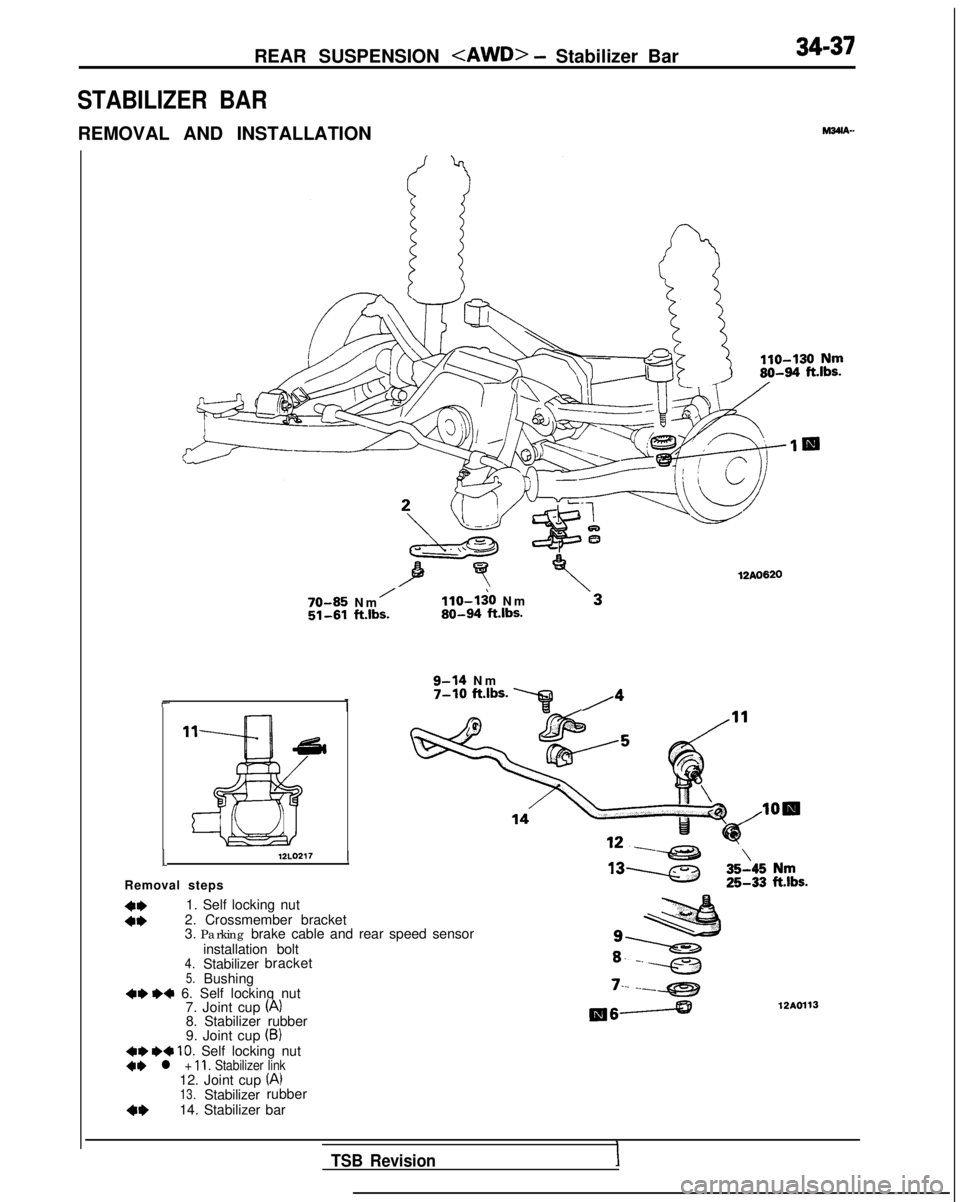

STABILIZER BAR

REMOVAL AND INSTALLATION

34-37

M36lA-

12AO620

70-85 N

m

/llo-li0 N

m

51-61 ft.lbs.80-94

ft.lbs.

9-14 N

m

7-10 ft.lbs. ‘q,4I-

112L0217

Removal steps

*I)1. Self locking nut

4*2. Crossmember bracket

3. Parking brake cable and rear speed sensor

installation bolt

4.Stabilizer bracket5.Bushing+e I)+ 6. Self locking nut

7. Joint cup (A)8. Stabilizer rubber

9. Joint cup (B)+e e+ 10. Self locking nut+e l + 11. Stabilizer link12. Joint cup (A)

13.Stabilizer rubber

4w14. Stabilizer bar

7-- --e

IllSA12A0113

TSB Revision

Page 1119 of 1273

34-38

REAR SUSPENSION

II12AO109

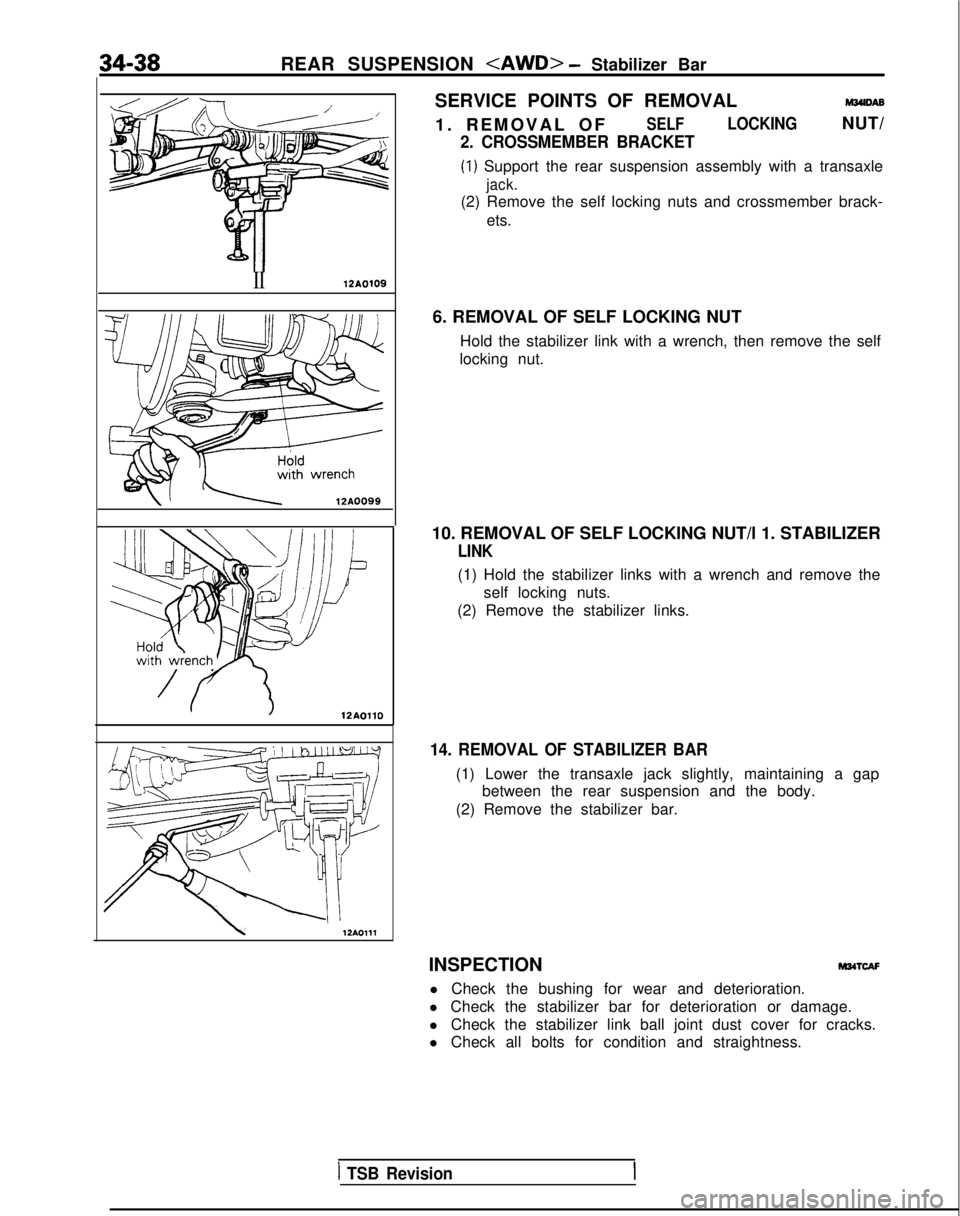

/ 12AOllOSERVICE POINTS OF REMOVAL

M34lDAB

1. REMOVAL O

F

SELFLOCKINGNUT/

2. CROSSMEMBER BRACKET

(1) Support the rear suspension assembly with a transaxle

jack.

(2) Remove the self locking nuts and crossmember brack-

ets.

6. REMOVAL OF SELF LOCKING NUT Hold the stabilizer link with a wrench, then remove the self

locking nut.

10. REMOVAL OF SELF LOCKING NUT/l 1. STABILIZER

LINK

(1) Hold the stabilizer links with a wrench and remove the self locking nuts.

(2) Remove the stabilizer links.

14. REMOVAL OF STABILIZER BAR

(1) Lower the transaxle jack slightly, maintaining a gap between the rear suspension and the body.

(2) Remove the stabilizer bar.

INSPECTION

M34TcAF

l Check the bushing for wear and deterioration.

l Check the stabilizer bar for deterioration or damage.

l Check the stabilizer link ball joint dust cover for cracks.

l Check all bolts for condition and straightness.

1 TSB Revision

Page 1120 of 1273

REAR SUSPENSION

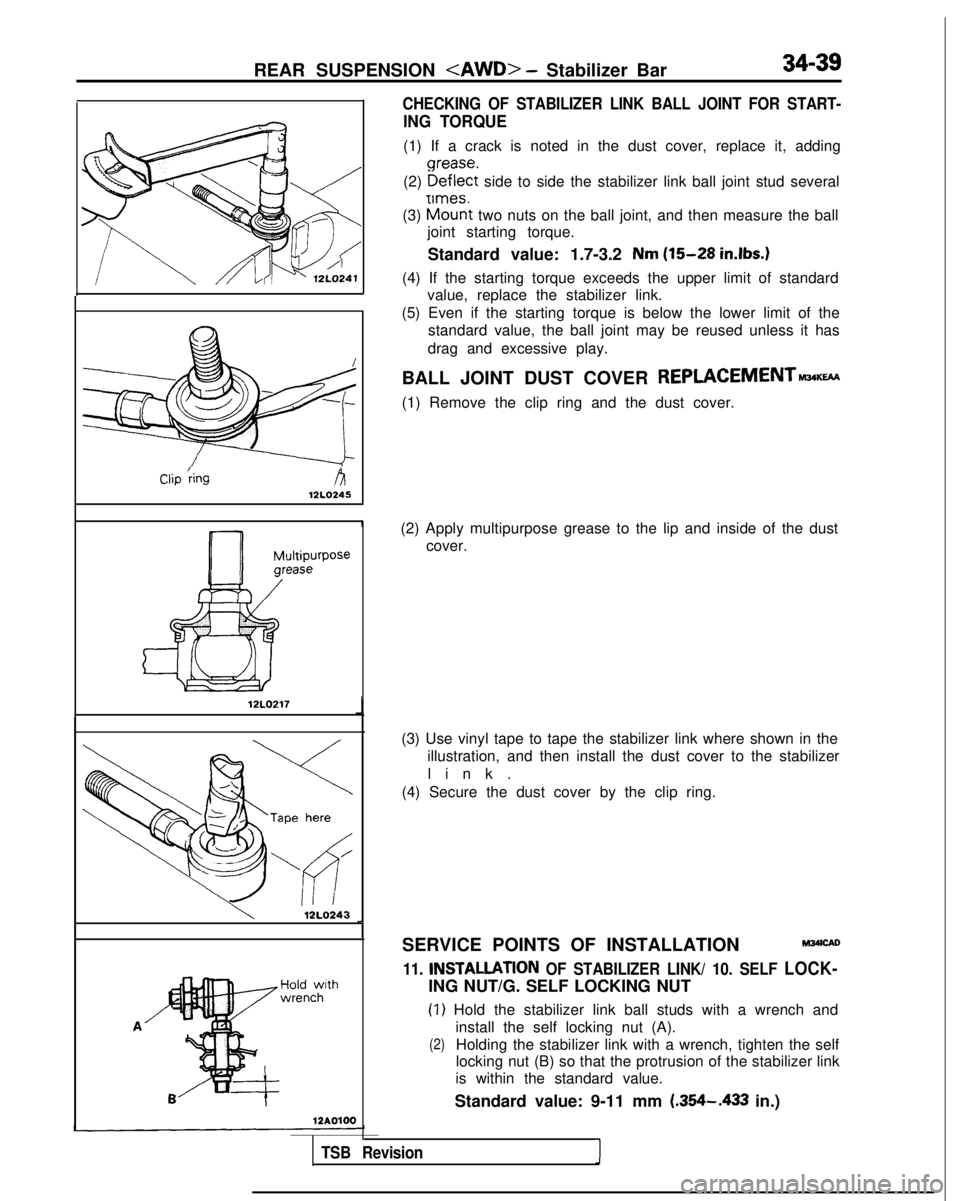

CHECKING OF STABILIZER LINK BALL JOINT FOR START-

ING TORQUE

(1) If a crack is noted in the dust cover, replace it, adding

(2)

gz;zEt side to side the stabilizer link ball joint stud several

(3)

h!z% two nuts on the ball joint, and then measure the ball

joint starting torque.

Standard value: 1.7-3.2

Nm (15-28 in.lbs.1

(4) If the starting torque exceeds the upper limit of standard value, replace the stabilizer link.

(5) Even if the starting torque is below the lower limit of the standard value, the ball joint may be reused unless it has

drag and excessive play. Clip

kgA12LO245

I

12LO217J

12LO243J

Hold

withwrench 12AOlOOBALL JOINT DUST COVER

REPLACEMENT-w

(1) Remove the clip ring and the dust cover.

(2) Apply multipurpose grease to the lip and inside of the dust cover.

(3) Use vinyl tape to tape the stabilizer link where shown in the illustration, and then install the dust cover to the stabilizer

link

.

(4) Secure the dust cover by the clip ring.

SERVICE POINTS OF INSTALLATION

11. INSTALLATlON OF STABILIZER LINK/ 10. SELF LOCK-

ING NUT/G. SELF LOCKING NUT

(1) Hold the stabilizer link ball studs with a wrench and install the self locking nut (A).

(2)Holding the stabilizer link with a wrench, tighten the self

locking nut (B) so that the protrusion of the stabilizer link

is within the standard value.

Standard value: 9-11 mm (.354-.433

in.)

TSB Revision1