MITSUBISHI GALANT 1989 Service Repair Manual

GALANT 1989

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57312/w960_57312-0.png

MITSUBISHI GALANT 1989 Service Repair Manual

Trending: kickdown, tyre pressure, wheel, traction control, fuses, tire pressure, radio

Page 611 of 1273

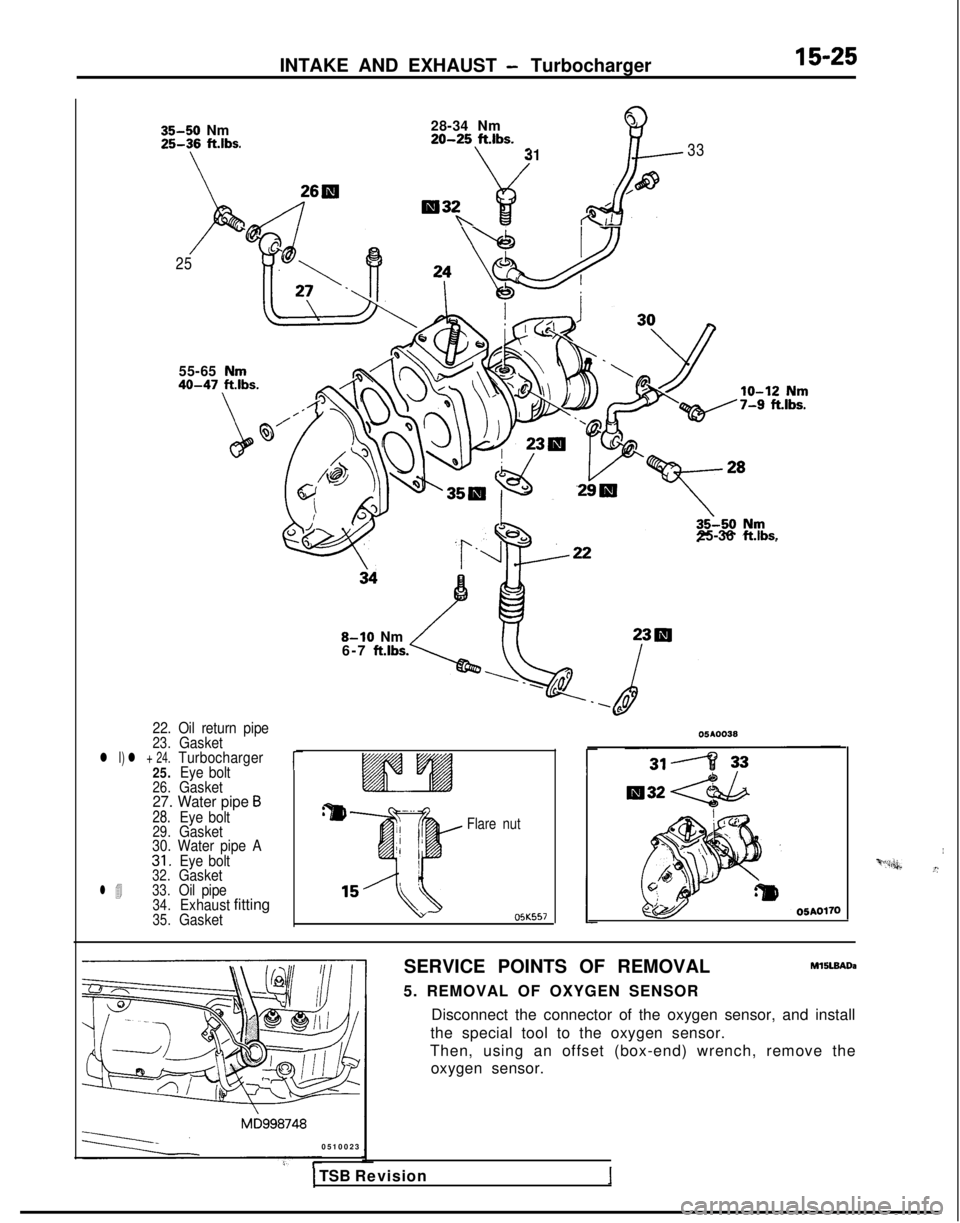

INTAKE AND EXHAUST - Turbocharger15-25

35-50 Nm

25-3\6 fubs*

28-34 Nm

920-25 ftlbs.

3133

26H,a

/IW32Rk .p&

/25

55-65

40-47

25-36 ftlbs.

22. Oil return pipe23.Gasketl I) l + 24.Turbocharger

25. Eye bolt

26.Gasket27. Water pipe B28.Eye bolt29.Gasket

30. Water pipe A

31.Eye bolt32.Gasketl 433.Oil pipe34.Exhaustfitting35.Gasket

r

8-10 Nm

6-7 ft.lbs.

Flare nut OJK557

SERVICE POINTS OF REMOVAL

M15lBAoa

5. REMOVAL OF OXYGEN SENSOR Disconnect the connector of the oxygen sensor, and install

the special tool to the oxygen sensor.

Then, using an offset (box-end) wrench, remove the oxygen sensor.

0510023

I‘“*“n,&.”

1 TSB Revision

Page 612 of 1273

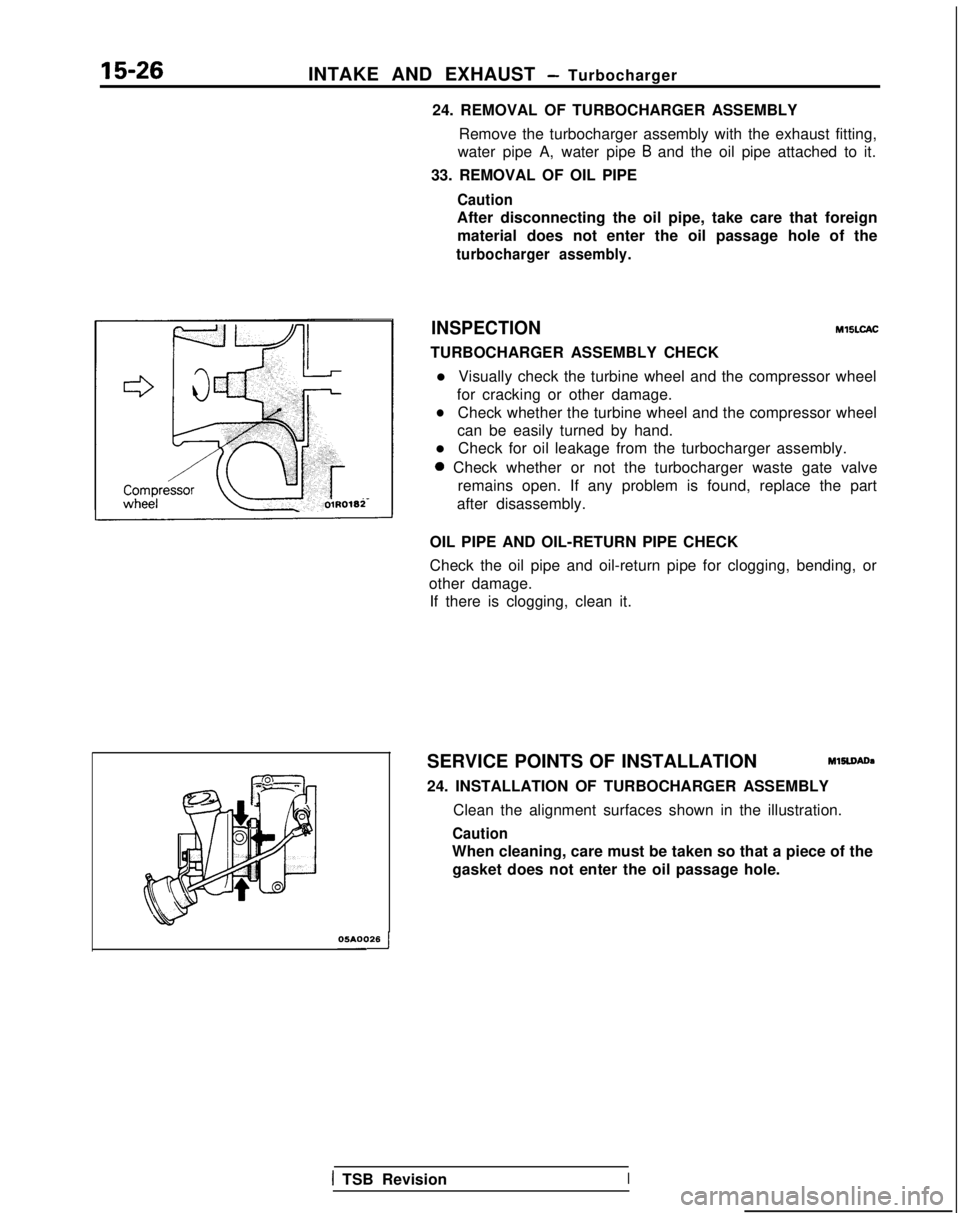

15-26INTAKE AND EXHAUST - Turbocharger

24. REMOVAL OF TURBOCHARGER ASSEMBLY Remove the turbocharger assembly with the exhaust fitting,

water pipe A, water pipe

B and the oil pipe attached to it.

33. REMOVAL OF OIL PIPE

Caution

After disconnecting the oil pipe, take care that foreign material does not enter the oil passage hole of the

turbocharger assembly.

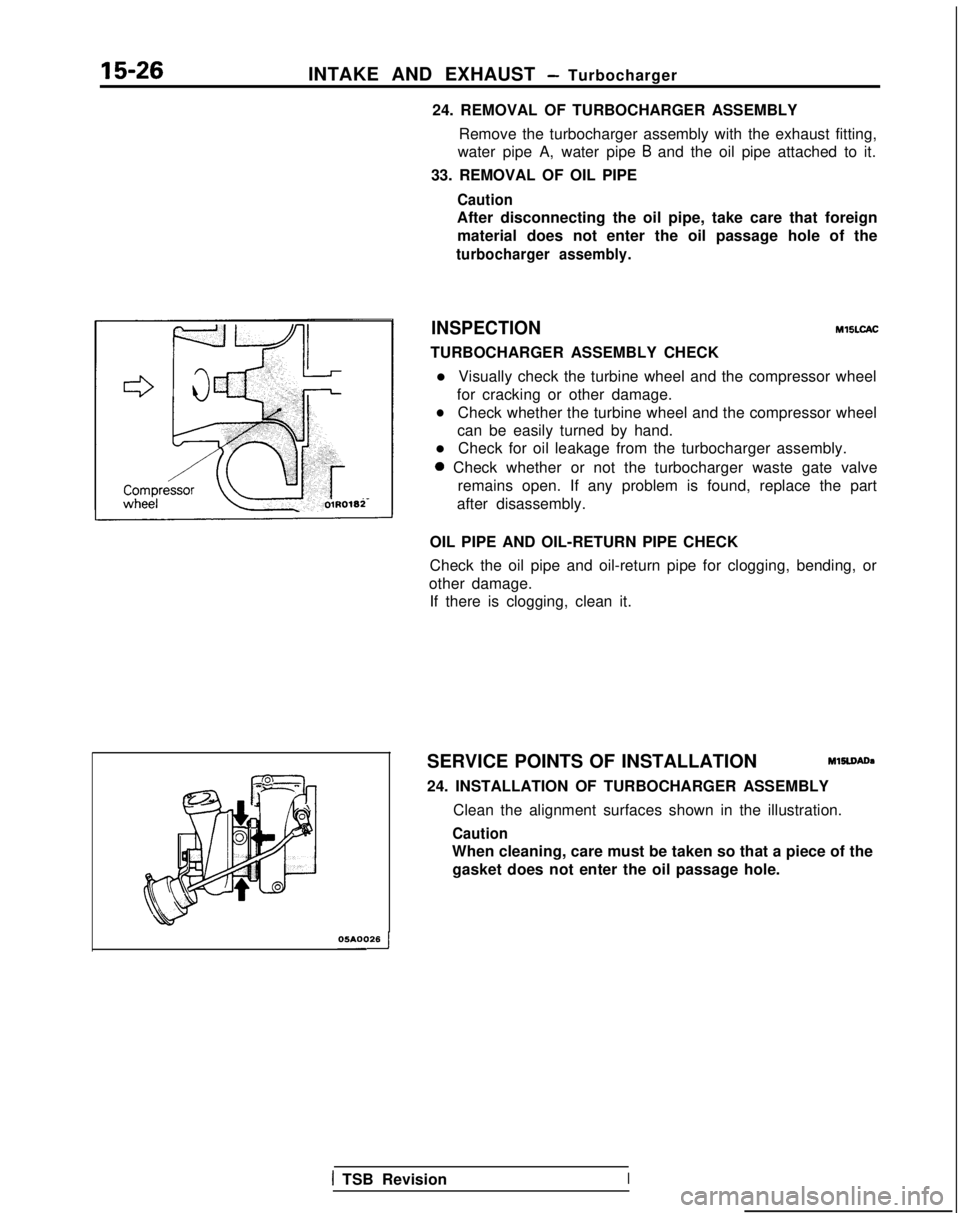

INSPECTIONMlSLCAC

TURBOCHARGER ASSEMBLY CHECK

l Visually check the turbine wheel and the compressor wheel for cracking or other damage.

lCheck whether the turbine wheel and the compressor wheel

can be easily turned by hand.

l Check for oil leakage from the turbocharger assembly. 0

Check whether or not the turbocharger waste gate valve

remains open. If any problem is found, replace the part

after disassembly.

OIL PIPE AND OIL-RETURN PIPE CHECK

Check the oil pipe and oil-return pipe for clogging, bending, or

other damage. If there is clogging, clean it.

SERVICE POINTS OF INSTALLATION M15lDADa

24. INSTALLATION OF TURBOCHARGER ASSEMBLY Clean the alignment surfaces shown in the illustration.

Caution

When cleaning, care must be taken so that a piece of thegasket does not enter the oil passage hole.

1 TSB RevisionI

Page 613 of 1273

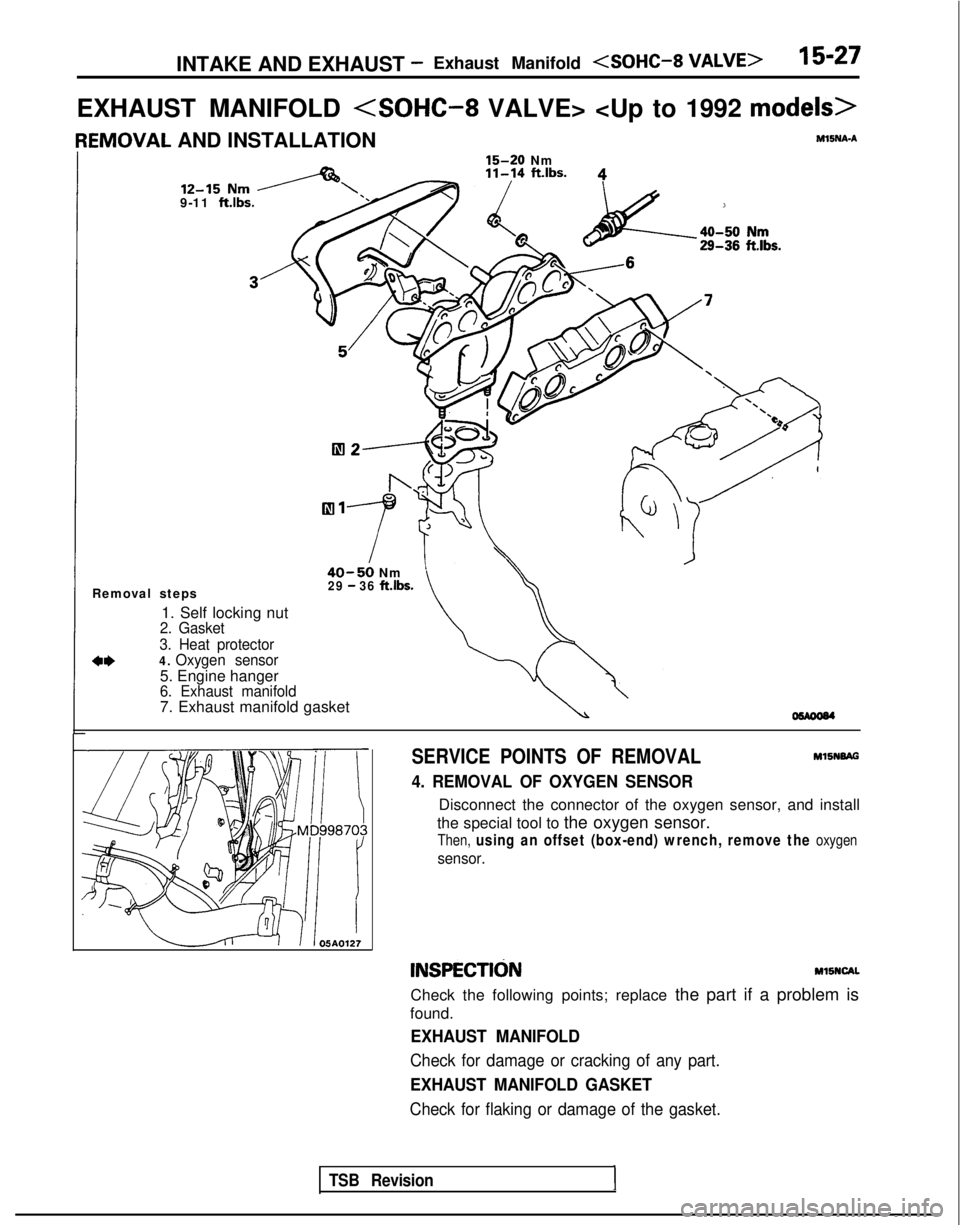

INTAKE AND EXHAUST -Exhaust Manifold (SOHC-8 VALVE>15-27

EXHAUST MANIFOLD

models>

IEMOVAL AND INSTALLATIONYSNA-A

15-20

Nm

9-11 ftlbs.

40-50 Nm

Removal steps29 - 36 ft.lbs.

1. Self locking nut2. Gasket

3. Heat protector

a*4. Oxygen sensor

5. Engine hanger6. Exhaust manifold7. Exhaust manifold gasket

SERVICE POINTS OF REMOVAL MlSNBAG

4. REMOVAL OF OXYGEN SENSOR

Disconnect the connector of the oxygen sensor, and install

the special tool to the oxygen sensor.

Then, using an offset (box-end) wrench, remove the oxygen

sensor.

INSPECTldNMllNCAL

Check the following points; replace the part if a problem is

found.

EXHAUST MANIFOLD

Check for damage or cracking of any part.

EXHAUST MANIFOLD GASKET

Check for flaking or damage of the gasket.

TSB Revision1

Page 614 of 1273

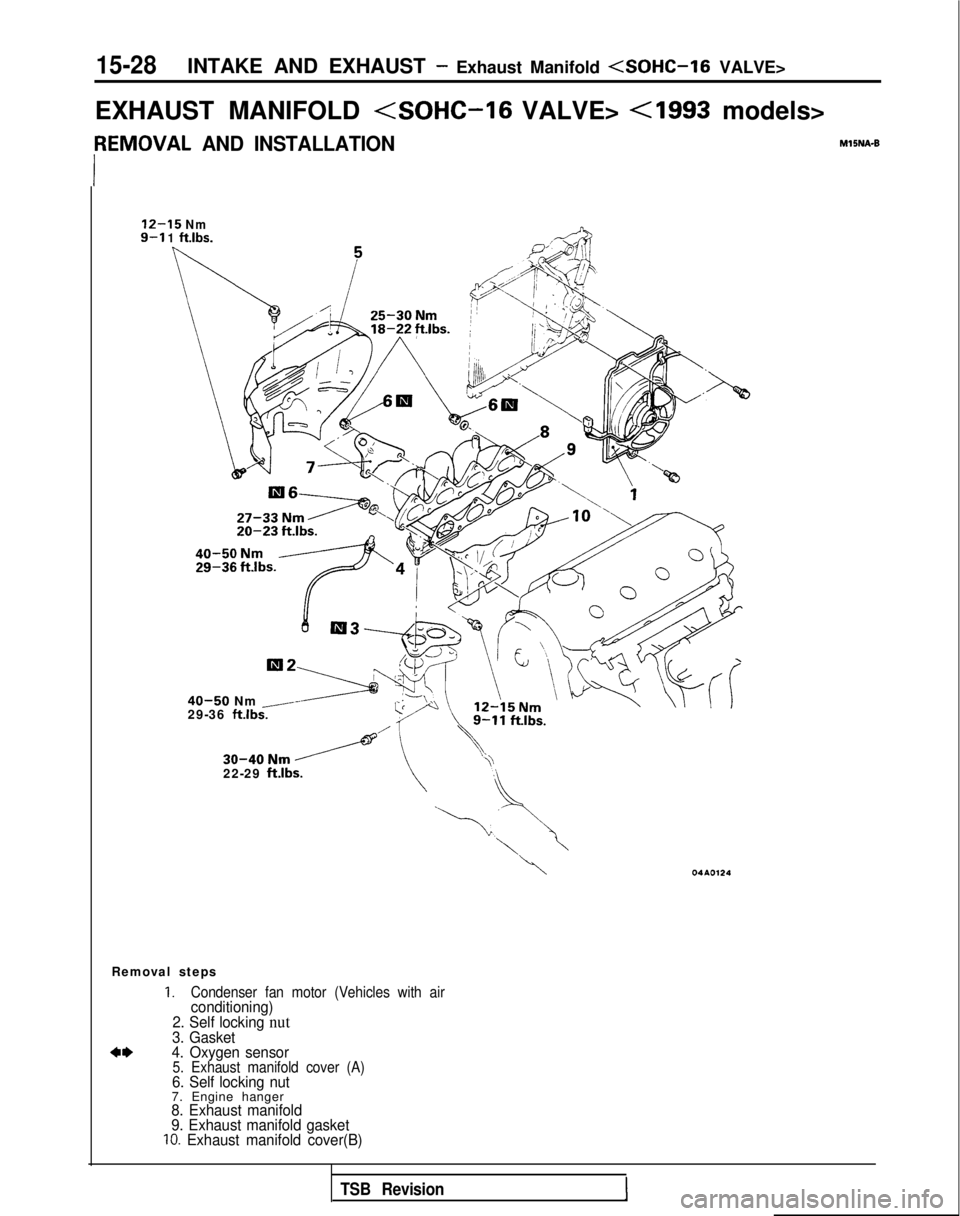

15-28INTAKE AND EXHAUST - Exhaust Manifold

EXHAUST MANIFOLD

PEMOVAL AND INSTALLATION MlSNA-B

.15 Nm

1 ft.lbs.

7-l

40-50Nm ----‘--A

40-50 Nm /-29-36 ft.lbs.

30-40Nmj’22-29 ft.lbs.

Removal steps

1.Condenser fan motor (Vehicles with airconditioning)

2. Self locking nut

3. Gasket

4*4. Oxygen sensor5. Exhaust manifold cover (A)6. Self locking nut7. Engine hanger8. Exhaust manifold

9. Exhaust manifold gasket

IO. Exhaust manifold cover(B)

TSB Revision1

Page 615 of 1273

INTAKE AND EXHAUST - Exhaust Manifold 15-29

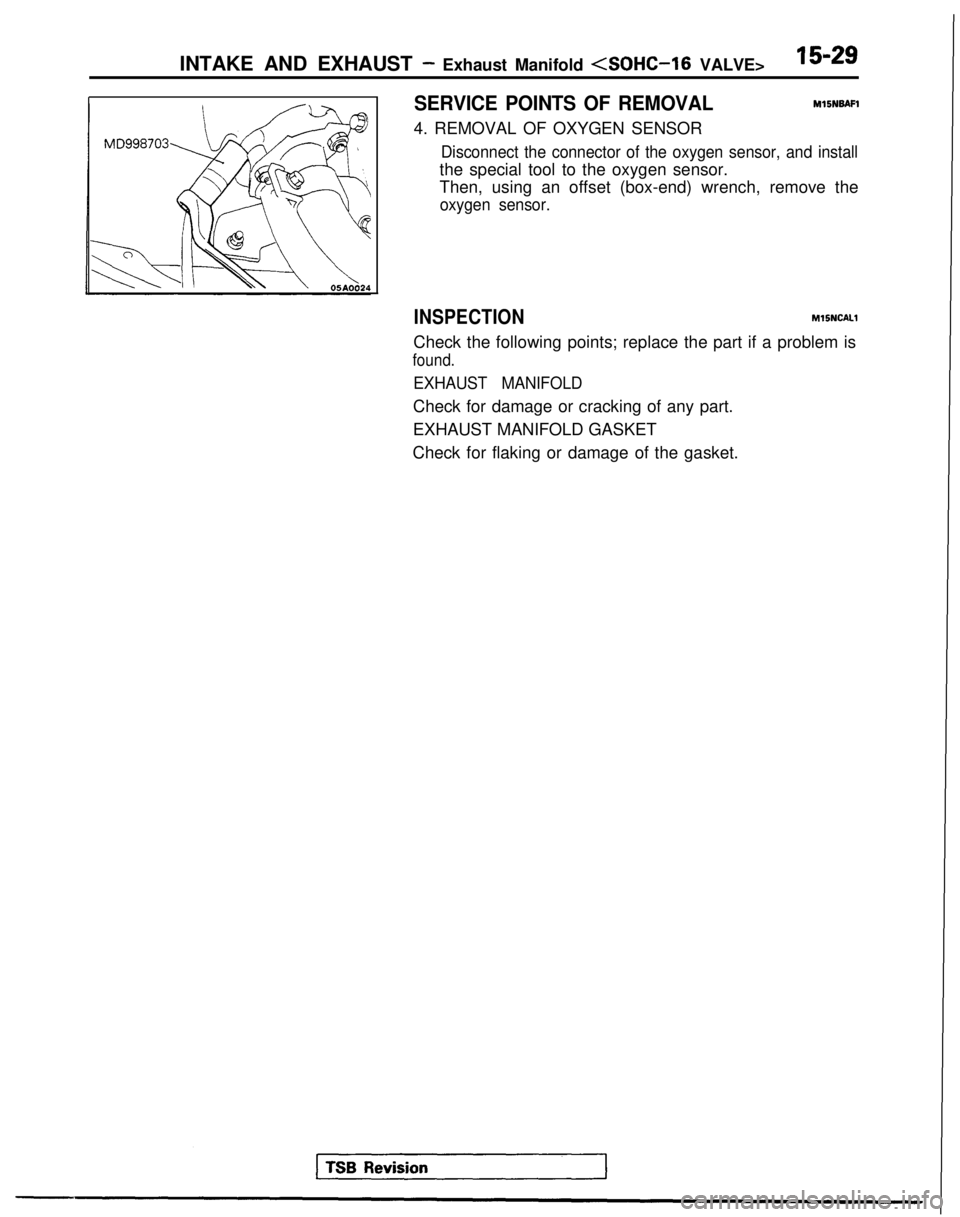

SERVICE POINTS OF REMOVAL

MlBNBAFl

4. REMOVAL OF OXYGEN SENSOR

Disconnect the connector of the oxygen sensor, and install

the special tool to the oxygen sensor.

Then, using an offset (box-end) wrench, remove the

oxygen sensor.

INSPECTION MlSNCALl

Check the following points; replace the part if a problem is

found.

EXHAUST MANIFOLD

Check for damage or cracking of any part.

EXHAUST MANIFOLD GASKET

Check for flaking or damage of the gasket.

Page 616 of 1273

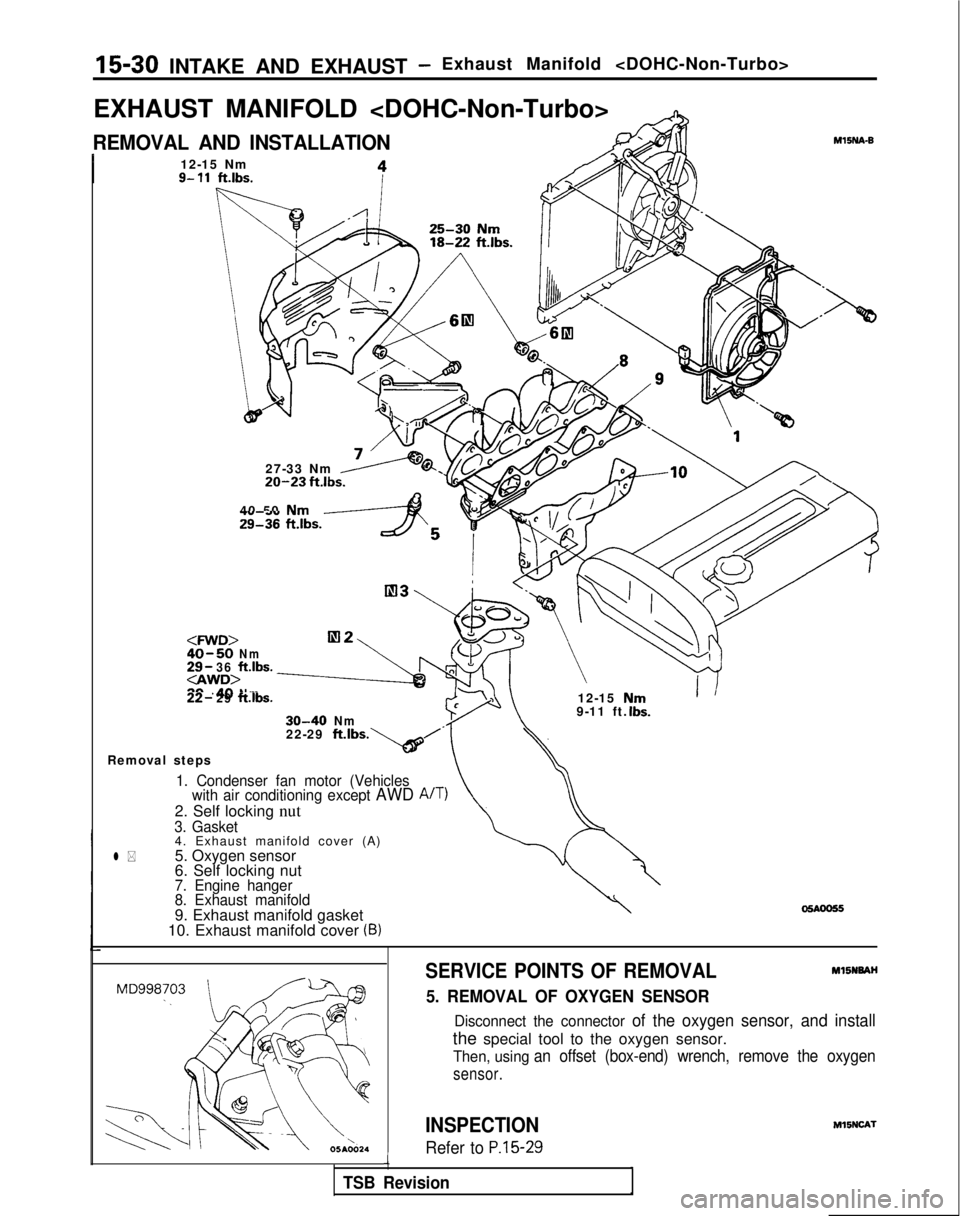

15-30 INTAKE AND EXHAUST -Exhaust Manifold

EXHAUST MANIFOLD

REMOVAL AND INSTALLATION

I12-15 Nm9- 11ft.lbs.

27-33 Nm20-23 fklbs.

40 50 Nm29136 ft.lbs.yAS

40-50Nm29- 36ft.lbs.30-40Nm22- 29ft.lbs.12-15 1

30-40Nm9-11 ft.

\

UrnIbs.

MlINA-B

22-29 ft.lbs

Removal steps*b’.

1. Condenser fan motor (Vehicles with air conditioning except AWD A/T)

2. Self locking nut3. Gasket4. Exhaust manifold cover (A)

l *5. Oxygen sensor

6. Self locking nut

7. Engine hanger

8. Exhaust manifold

9. Exhaust manifold gasket

10. Exhaust manifold cover (B)

SERVICE POINTS OF REMOVALMl5NNAH

5. REMOVAL OF OXYGEN SENSOR

Disconnect the connector of the oxygen sensor, and install

the special tool to the oxygen sensor.

Then, using an offset (box-end) wrench, remove the oxygen

sensor.

INSPECTION

Refer to P.15-29i

TSB Revision M15NCA-l

Page 617 of 1273

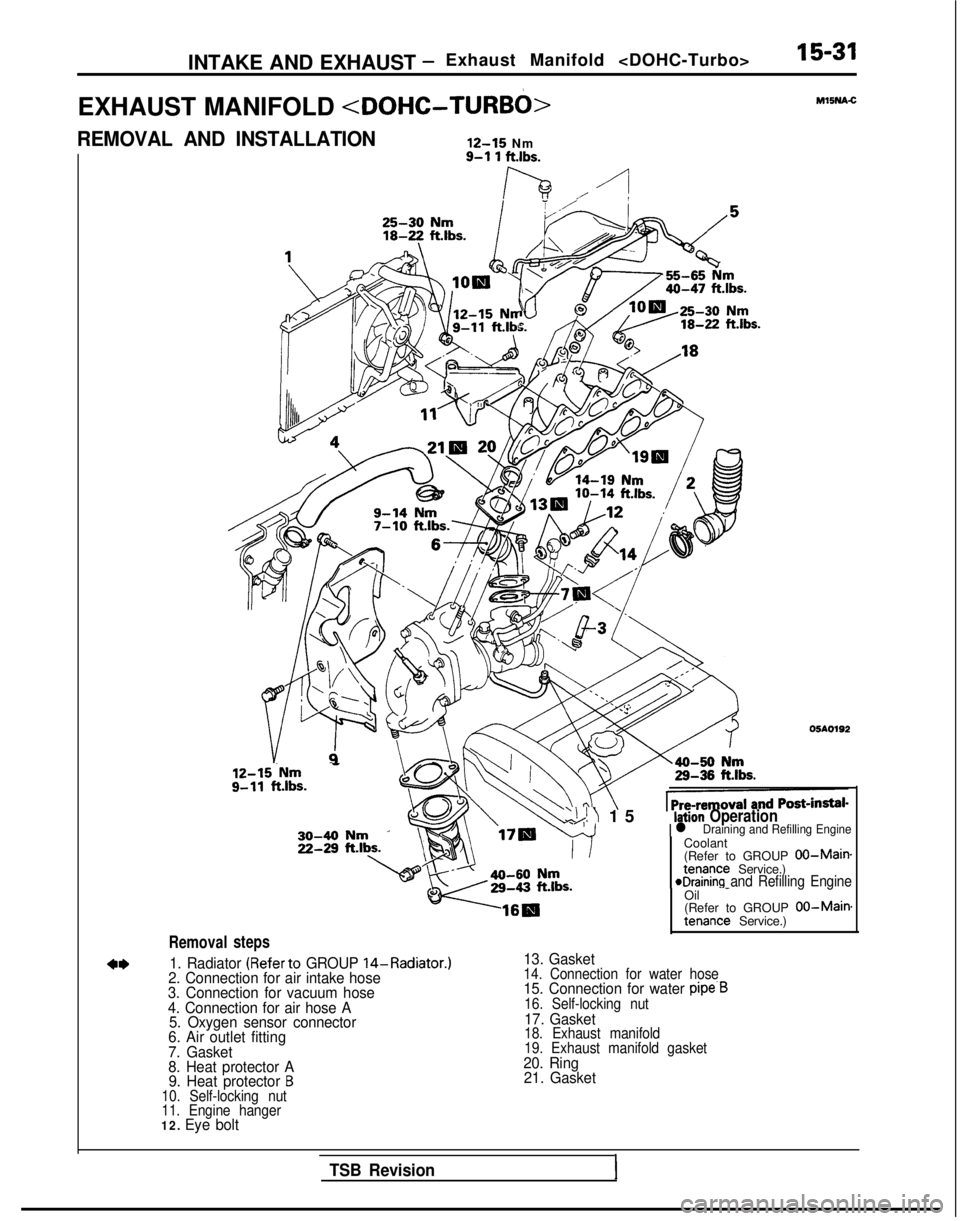

INTAKE AND EXHAUST -Exhaust Manifold 15-31

EXHAUST MANIFOLD

REMOVAL AND INSTALLATION

12-15

Nm

Removal

12-15.Nm - g-11

ft.lbs.

steps

9-l 1 ftlbs.

lh ./-I

‘Uc Ml5NA.C

05AO192

Coolant

(Refer to GROUP

00-Maimtenance Service.)eDraining and Refilling Engine

1. Radiator (Referto GROUP 14-Radiator.)

2. Connection for air intake hose

3. Connection for vacuum hose

4. Connection for air hose A 5. Oxygen sensor connector

6. Air outlet fitting

7. Gasket

8. Heat protector A 9. Heat protector

B10. Self-locking nut

11. Engine hanger

12. Eye bolt

‘\!I 1

5

Ilation Operationl Draining and Refilling Engine

Oil

-

(Refer to GROUP 00-Main.tenance Service.)

13. Gasket14. Connection for water hose15. Connection for water pipe.B16. Self-locking nut17. Gasket18. Exhaust manifold

19. Exhaust manifold gasket

20. Ring

21. Gasket

TSB Revision1

Page 618 of 1273

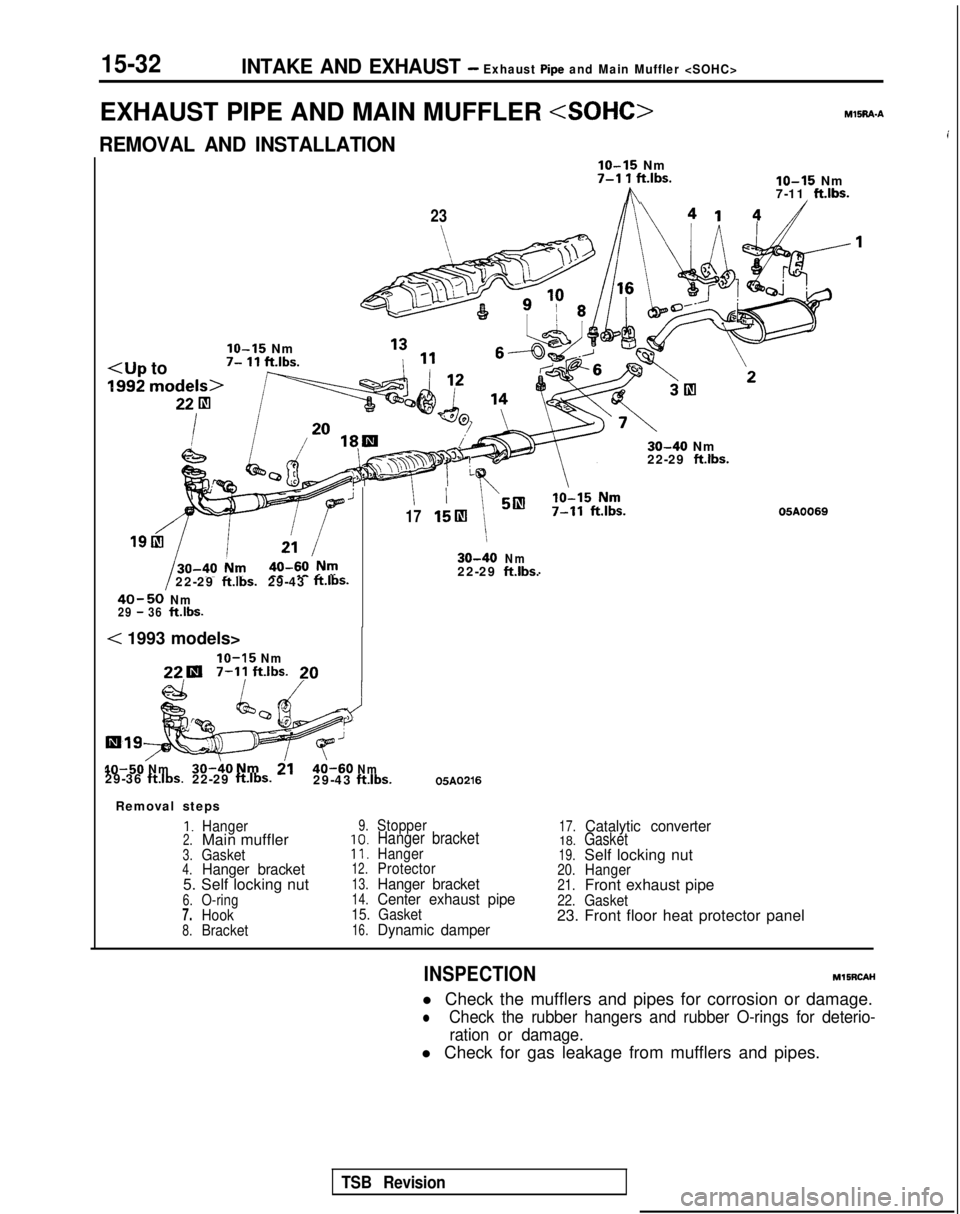

15-32INTAKE AND EXHAUST - Exhaust Pipe and Main Muffler

EXHAUST PIPE AND MAIN MUFFLER M15RA.A

iREMOVAL AND INSTALLATION

IO-15 Nm7-l 1 ft.lbs.

h

lo-15 Nm

7-11 ft.lbs.

IO-15 Nm7- 11 ft.lbs.

23 30-40

Nm

22-29

ft.lbs.

’1715lIl 30-40

Nm

22-29ftlbs.29-43ft.lbs.22-29ft.lbs.

40-50Nm29 - 36ftlbs.

05A0069

< 1993 models>

IO-15 Nm22.1

7-11

ftlbs.20

40-50

Nm30-40Nm2140-60Nm29-36ft.lbs.22-29 ft.lbs.29-43

ftlbs.05A0216

Removal steps

1.Hanger2.Main muffler3.Gasket4.Hanger bracket5. Self locking nut6.O-ring7.Hook8.Bracket

9.Stopper

10.Hanger bracket11.Hanger12.Protector13.Hanger bracket14.Center exhaust pipe15. Gasket16.Dynamic damper

17.Catalytic converter18.Gasket19.Self locking nut20.Hanger21.Front exhaust pipe22.Gasket23. Front floor heat protector panel

INSPECTION

MlSRCAH

l Check the mufflers and pipes for corrosion or damage.

lCheck the rubber hangers and rubber O-rings for deterio- ration or damage.

l Check for gas leakage from mufflers and pipes.

TSB Revision

Page 619 of 1273

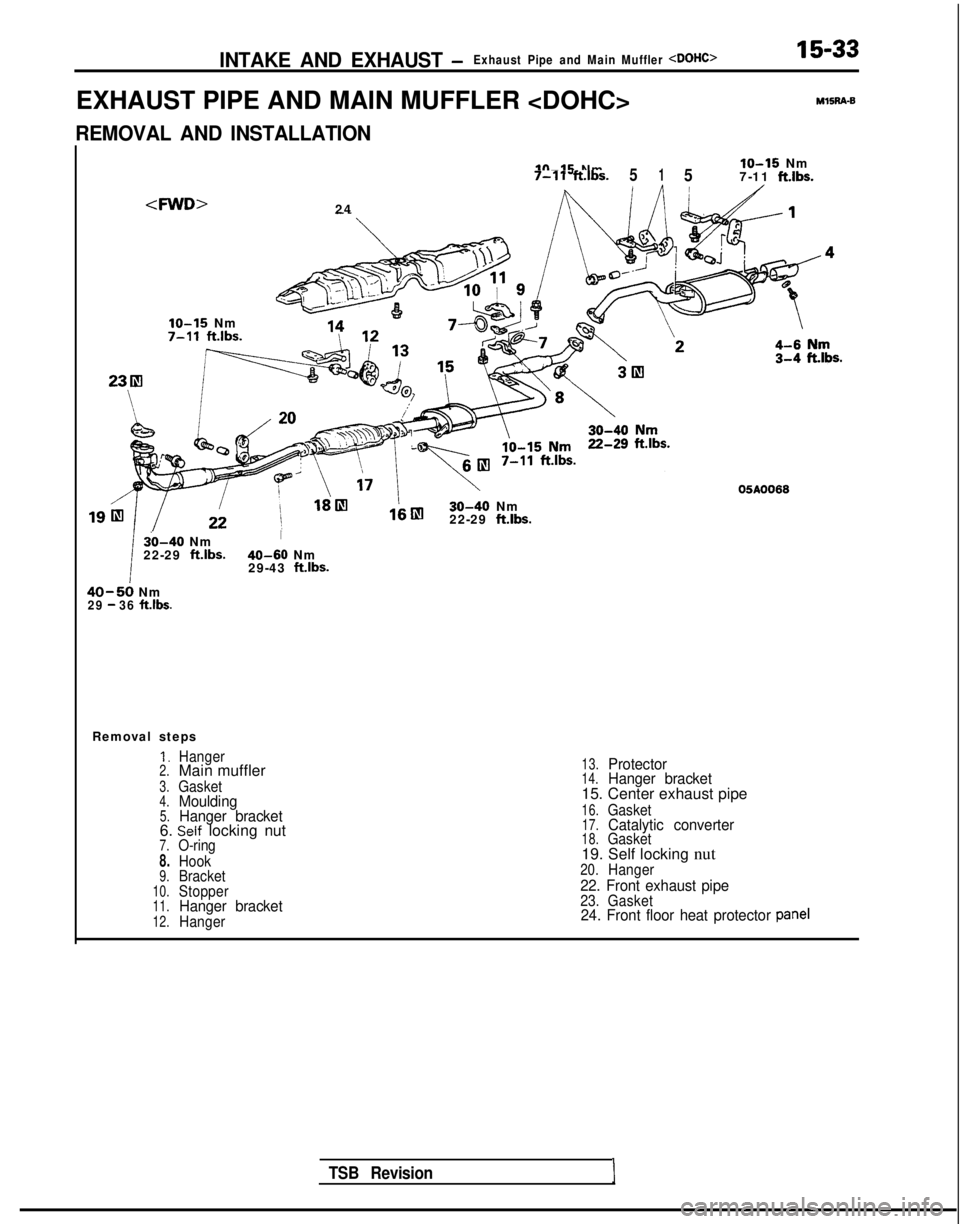

INTAKE AND EXHAUST -Exhaust Pipe and Main Muffler

EXHAUST PIPE AND MAIN MUFFLER

15-33M15R4-8

REMOVAL AND INSTALLATION

24

IO-15 Nmlo-15 Nm

7-11ft.lbs.5157-11ft.lbs.,

,IO-15

Nm 7-11

ft.lbs.

30-40 Nm

22-29 ft.lbs.

30-40 NmI

22-29 ft.lbs. 40-60

Nm

29-43 ftlbs.

40-50 Nm29 - 36 ft.lbs.

Removal steps

1.Hanger2.Main muffler

3.Gasket4.Moulding5.Hanger bracket6. Self locking nut7.O-ring

8.Hook9.Bracket10.Stopper11.Hanger bracket12.Hanger

13.Protector14.Hanger bracket15. Center exhaust pipe

16.Gasket17.Catalytic converter18.Gasket19. Self locking nut20.Hanger

22. Front exhaust pipe23. Gasket24. Front floor heat protector panel

TSB RevisionI

Page 620 of 1273

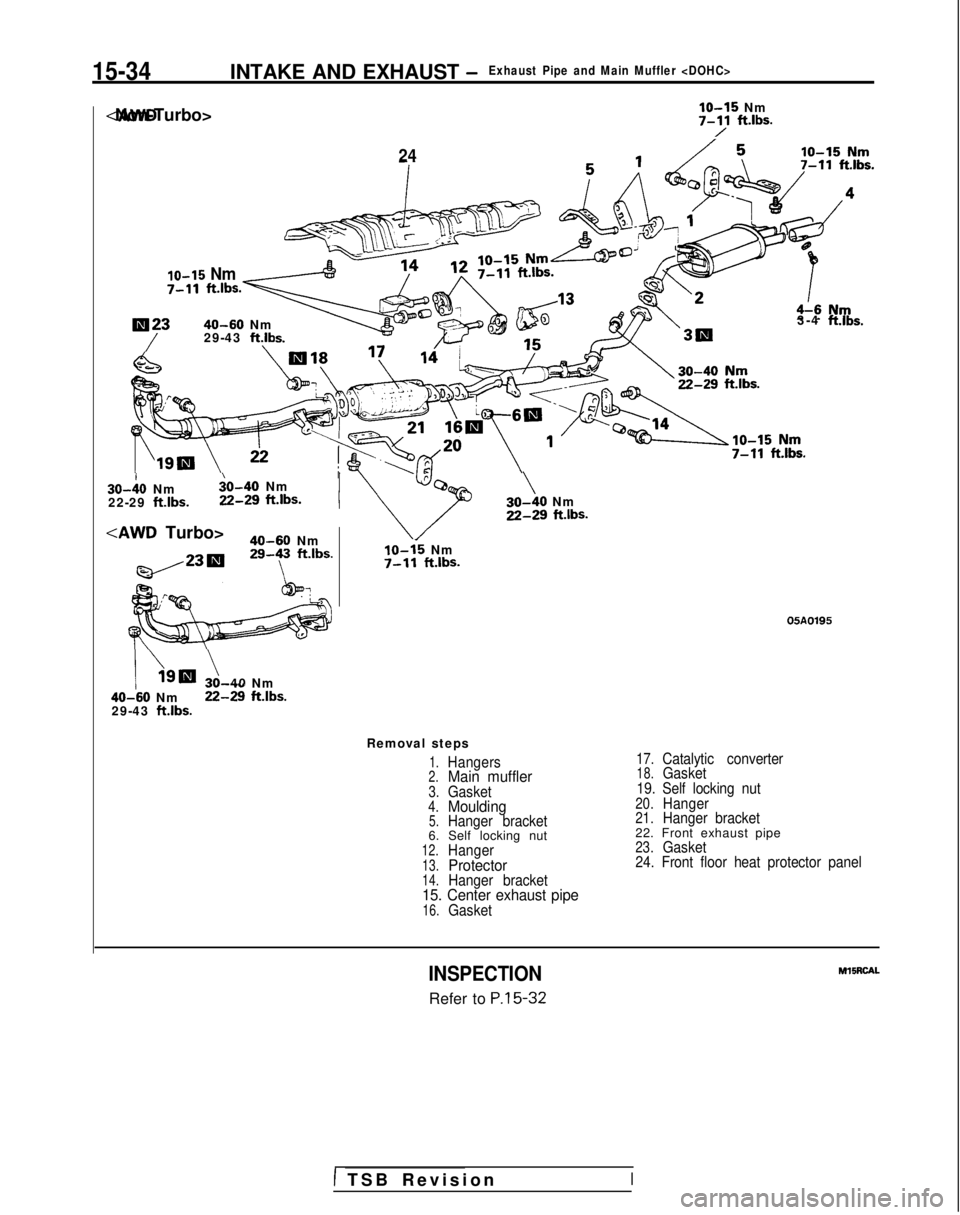

15-34INTAKE AND EXHAUST -Exhaust Pipe and Main Muffler

lo-15 Nm

7-Y ft*lbs.

10-15 Nm

7-11

ft.lbs

24

lN2340-60 Nm

/29-43 ft.lb

3-4 ft.lbs. 30-10

Nm

$0-40 Nm

22-29

ft.lbs. 22-29

ft.lbs.I

Turbo>

40-60 Nm29-y ft.lbs.

/\Ignr ?,40 Nm 40-60

Nm 22-29

ft.lbs.29-43 ft.lbs.

\30-40 NmZ-29 ft.lbs.

IO-15 Nm7-11 ft.lbs.

05A0195

Removal steps

1.Hangers2.Main muffler3.Gasket4.Moulding5.Hanger bracket6. Self locking nut12.Hanger13.Protector14.Hanger bracket15. Center exhaust pipe16.Gasket

17.Catalytic converter18.Gasket

19. Self locking nut

20.Hanger21.Hanger bracket22. Front exhaust pipe23.Gasket

24. Front floor heat protector panel

INSPECTION

Refer to P.15-32 MllRCAL

1 TSB Revisio

n

I

Trending: tow bar, spark plugs replace, traction control, fuel tank capacity, four wheel drive, ECO mode, Electric window