MITSUBISHI GALANT 1989 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 601 of 1273

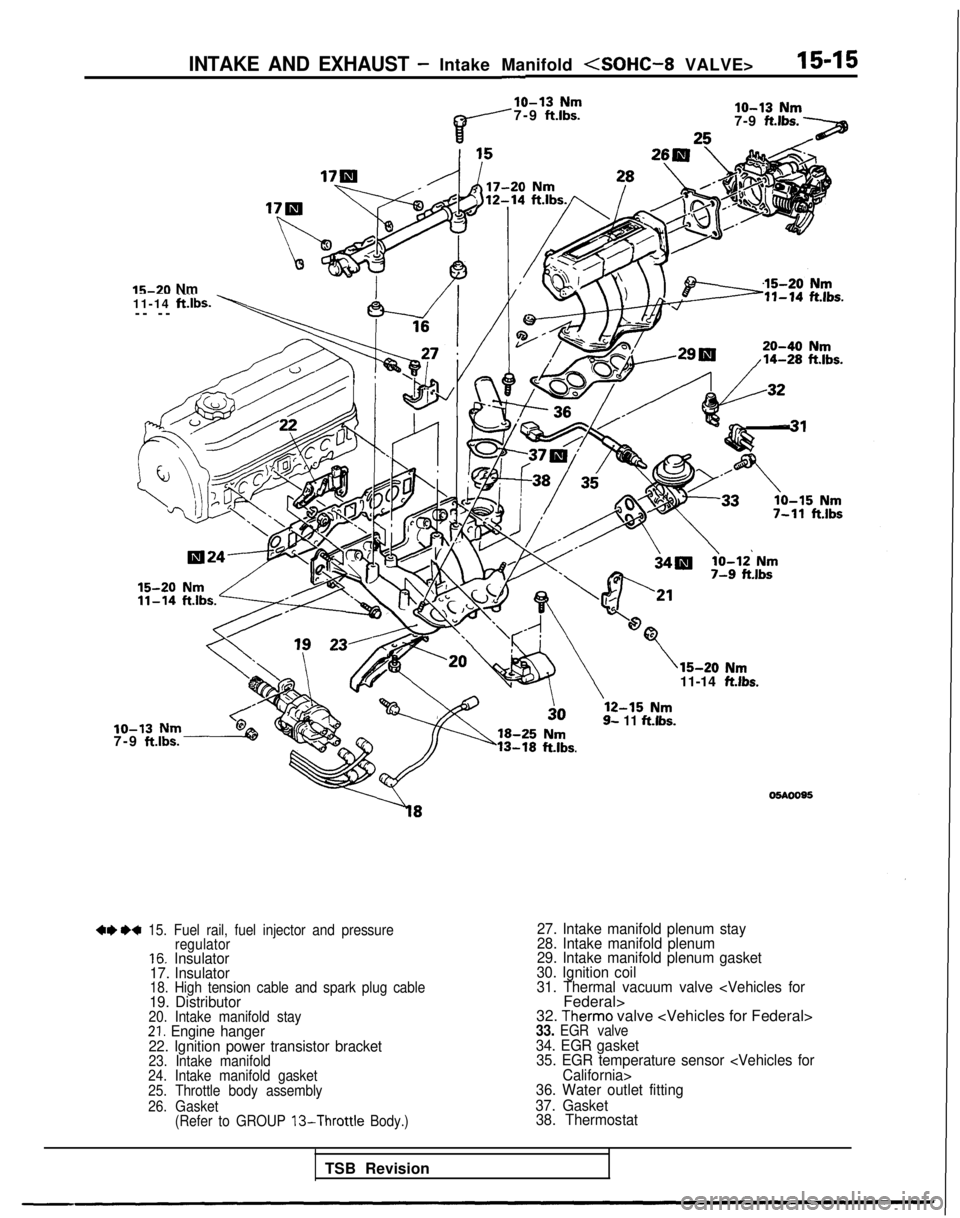

INTAKE AND EXHAUST -Intake Manifold

lo-13 Nm

r

7-9 ftlbs.IO-13 Nm7-9 ftlbs.

IS-20 Nm

11-14 ft Ibs-- -- --I-

7-11 ft.lbs

‘S-20 Nm11-14 ftlbs.

9- 11

ftlbs.lo-13 Nm7-9

ftlbs.

20-40 Nm,14-28 ft.lbs.

osAooss

--l8

++ ** 15. Fuel rail, fuel injector and pressure

regulator

16. Insulator

17. Insulator

18. High tension cable and spark plug cable19. Distributor20. Intake manifold stay21. Engine hanger

22. Ignition power transistor bracket

23. Intake manifold

24. Intake manifold gasket

25. Throttle body assembly

26. Gasket (Refer to GROUP

13-Throttle Body.)

27. Intake manifold plenum stay

28. Intake manifold plenum

29. Intake manifold plenum gasket

30. Ignition coil

31. Thermal vacuum valve

32. Therm0 valve

35. EGR temperature sensor

36. Water outlet fitting

37. Gasket 38. Thermostat

TSB Revision

Page 602 of 1273

15-16INTAKE AND EXHAUST- Intake Manifold

05AOO89

I05A0081

(

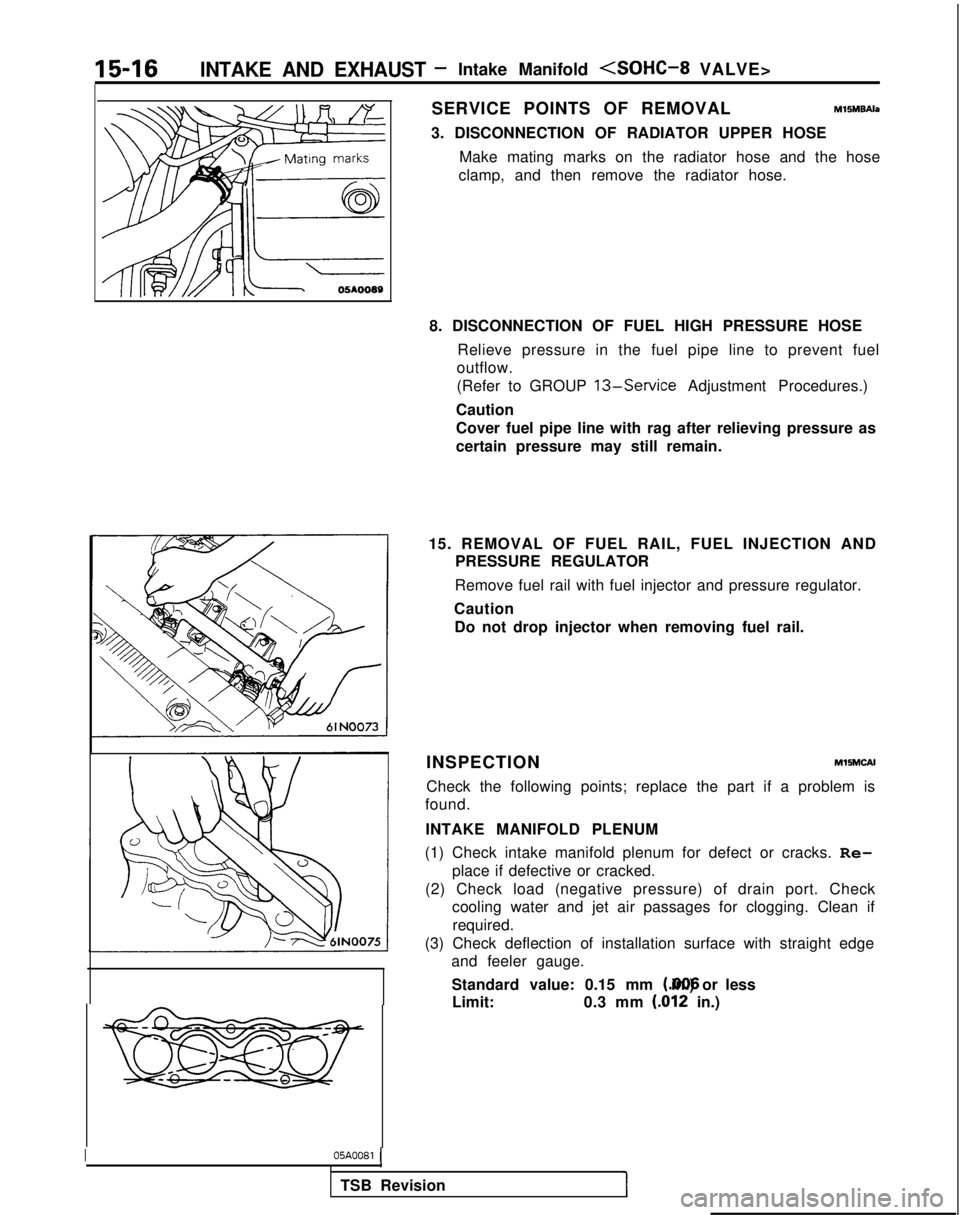

SERVICE POINTS OF REMOVALM15M9Ah

3. DISCONNECTION OF RADIATOR UPPER HOSE

Make mating marks on the radiator hose and the hose

clamp, and then remove the radiator hose.

8. DISCONNECTION OF FUEL HIGH PRESSURE HOSE Relieve pressure in the fuel pipe line to prevent fuel

outflow.

(Refer to GROUP

13-Service Adjustment Procedures.)

Caution

Cover fuel pipe line with rag after relieving pressure as

certain pressure may still remain.

15. REMOVAL OF FUEL RAIL, FUEL INJECTION AND PRESSURE REGULATOR

Remove fuel rail with fuel injector and pressure regulator.

Caution Do not drop injector when removing fuel rail.

INSPECTION

MlSMCAI

Check the following points; replace the part if a problem is

found.

INTAKE MANIFOLD PLENUM

(1) Check intake manifold plenum for defect or cracks. Re- place if defective or cracked.

(2) Check load (negative pressure) of drain port. Check cooling water and jet air passages for clogging. Clean if

required.

(3) Check deflection of installation surface with straight edge and feeler gauge.

Standard value: 0.15 mm (.006 in.) or less

Limit: 0.3 mm

(.012 in.)

1

TSB Revision

Page 603 of 1273

INTAKE AND EXHAUST -Intake Manifold

15-17

\

05A0074

TSB Revision

I

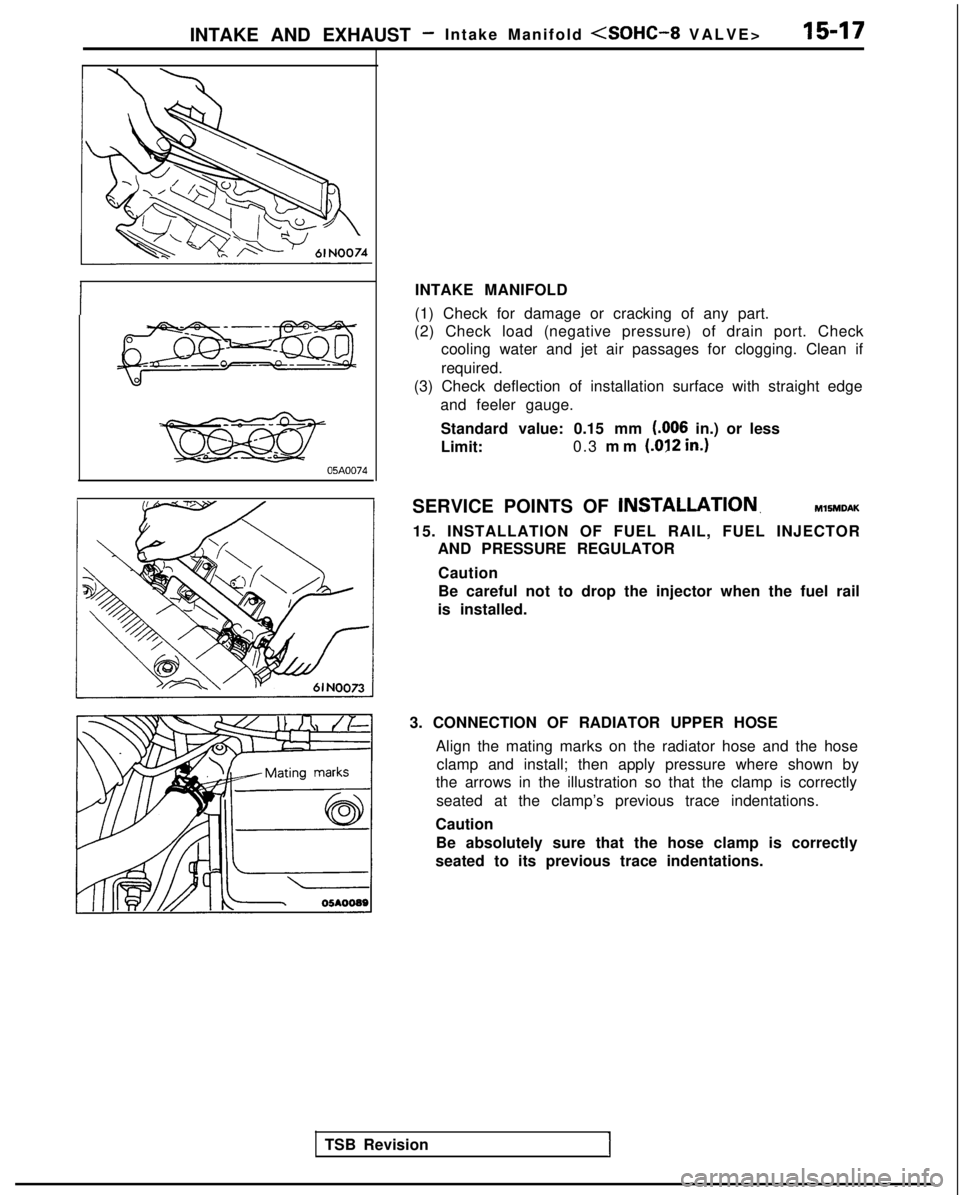

INTAKE MANIFOLD

(1) Check for damage or cracking of any part.

(2) Check load (negative pressure) of drain port. Check cooling water and jet air passages for clogging. Clean if

required.

(3) Check deflection of installation surface with straight edge

and feeler gauge.

Standard value: 0.15 mm I.006

in.) or less

Limit: 0.3

mm

(.012 in.1

SERVICE POINTS OF INSTALLATION,MlSMDAK

15. INSTALLATION OF FUEL RAIL, FUEL INJECTOR

AND PRESSURE REGULATOR

Caution

Be careful not to drop the injector when the fuel rail

is installed.

3. CONNECTION OF RADIATOR UPPER HOSE Align the mating marks on the radiator hose and the hoseclamp and install; then apply pressure where shown by

the arrows in the illustration so that the clamp is correctly

seated at the clamp’s previous trace indentations.

Caution Be absolutely sure that the hose clamp is correctly

seated to its previous trace indentations.

Page 604 of 1273

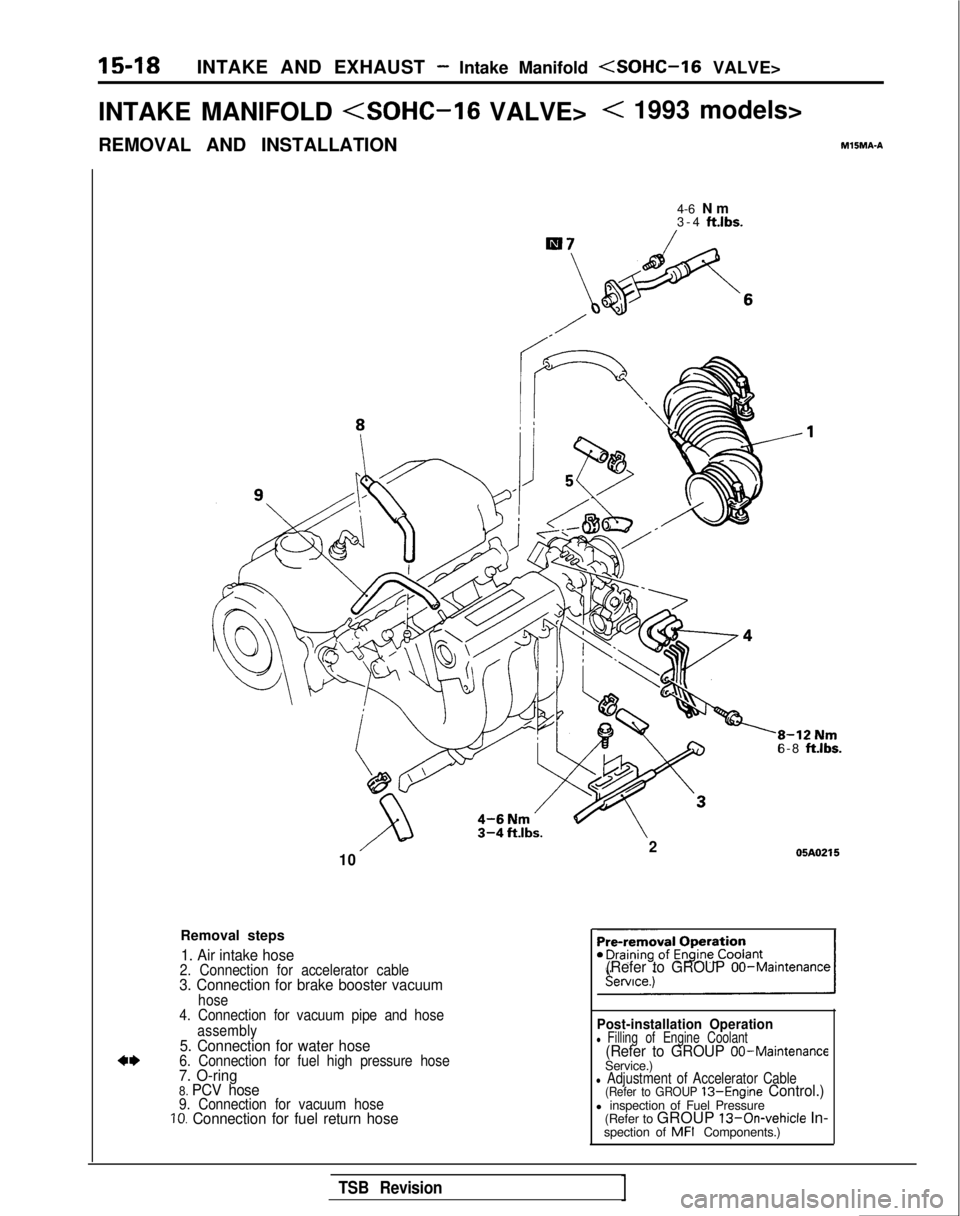

15-18INTAKE AND EXHAUST - Intake Manifold (SOHC-16 VALVE>

INTAKE MANIFOLD

REMOVAL AND INSTALLATION< 1993 models>

?.llSt.lA-A

4-6 N

m

3-4

ft.lbs.

7#jfi6

/ '

6-8 ft.lbs.

2

10OSAO215

Removal steps

1. Air intake hose2. Connection for accelerator cable3. Connection for brake booster vacuumhose

4. Connection for vacuum pipe and hose

assembly

5. Connection for water hose6. Connection for fuel high pressure hose7. O-ring8. PCV hose9. Connection for vacuum hoseIO. Connection for fuel return hose (Refer to GROUP

OO-Maintenance

Post-installation Operationl

Filling of Engine Coolant(Refer to GROUP 00-MaintenanceService.)l Adjustment of Accelerator Cable(Refer to GROUP 13-Engine Control.)l inspection of Fuel Pressure

(Refer to GROUP 13-On-vehicle In-

spection of MFI

Components.)

TSB Revision

Page 605 of 1273

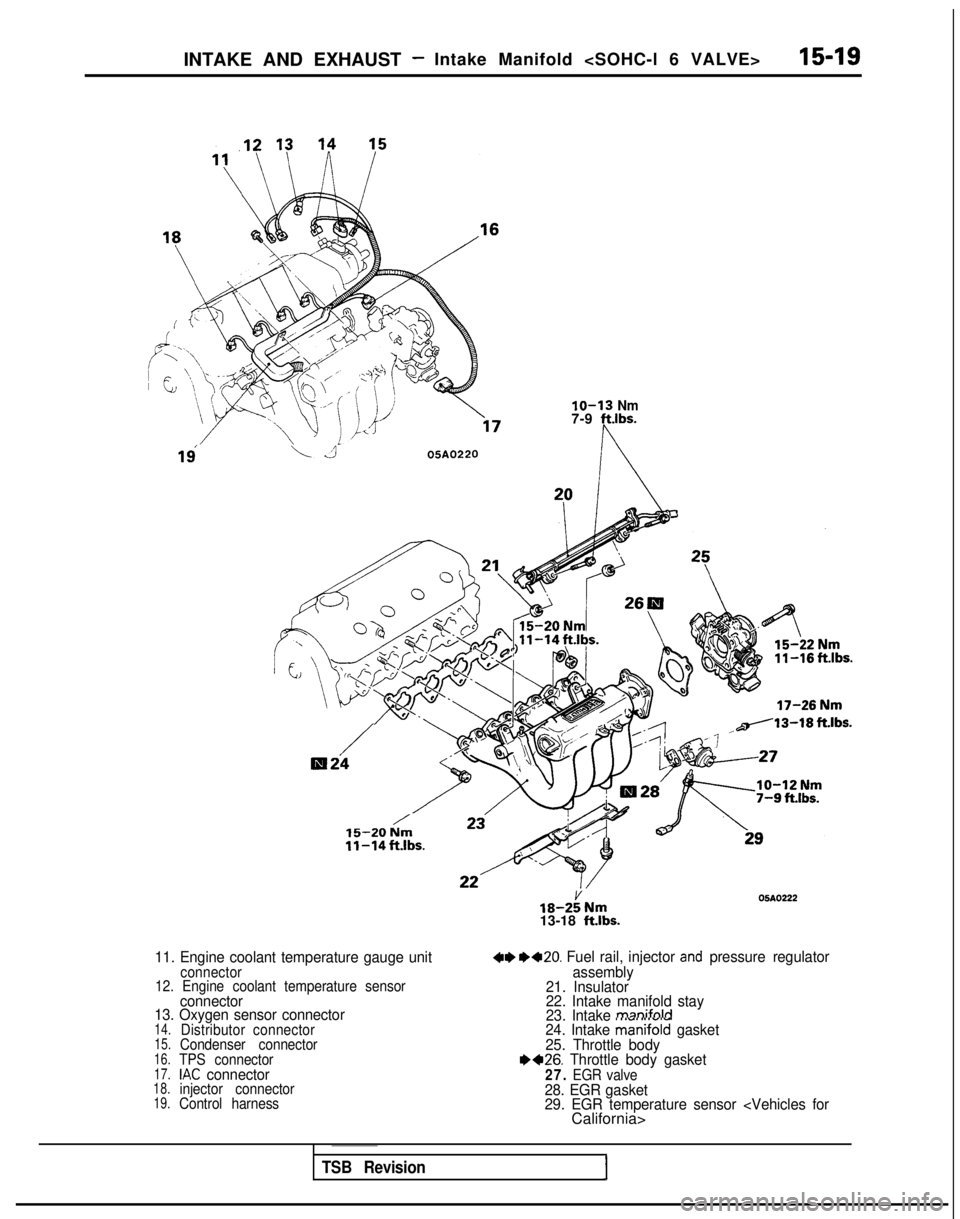

INTAKE AND EXHAUST -Intake Manifold

16

\305A0220

lo-13 Nm7-9 ft.lbs.

/R24

,,/13-18 ft.lbs.

’15-20 Nm11-14ft.lbs.

11. Engine coolant temperature gauge unitconnector

12. Engine coolant temperature sensor

connector

13. Oxygen sensor connector

14.Distributor connector15.Condenser connector16.TPS connector17.IAC connector18.injector connector19.Control harness

18-2iNm13-18 ft.lbs.

05AO222

4I) 1)+20. Fuel rail, injector and pressure regulator

assembly

21. Insulator

22. Intake manifold stay

23. Intake

manifold24. Intake manifoii gasket

25. Throttle body

1)+26. Throttle body gasket27. EGR valve28. EGR gasket

29. EGR temperature sensor

TSB RevisionI

Page 606 of 1273

15-20INTAKE AND EXHAUST - Intake Manifold (SOHC-16 VALVE>

05AO217

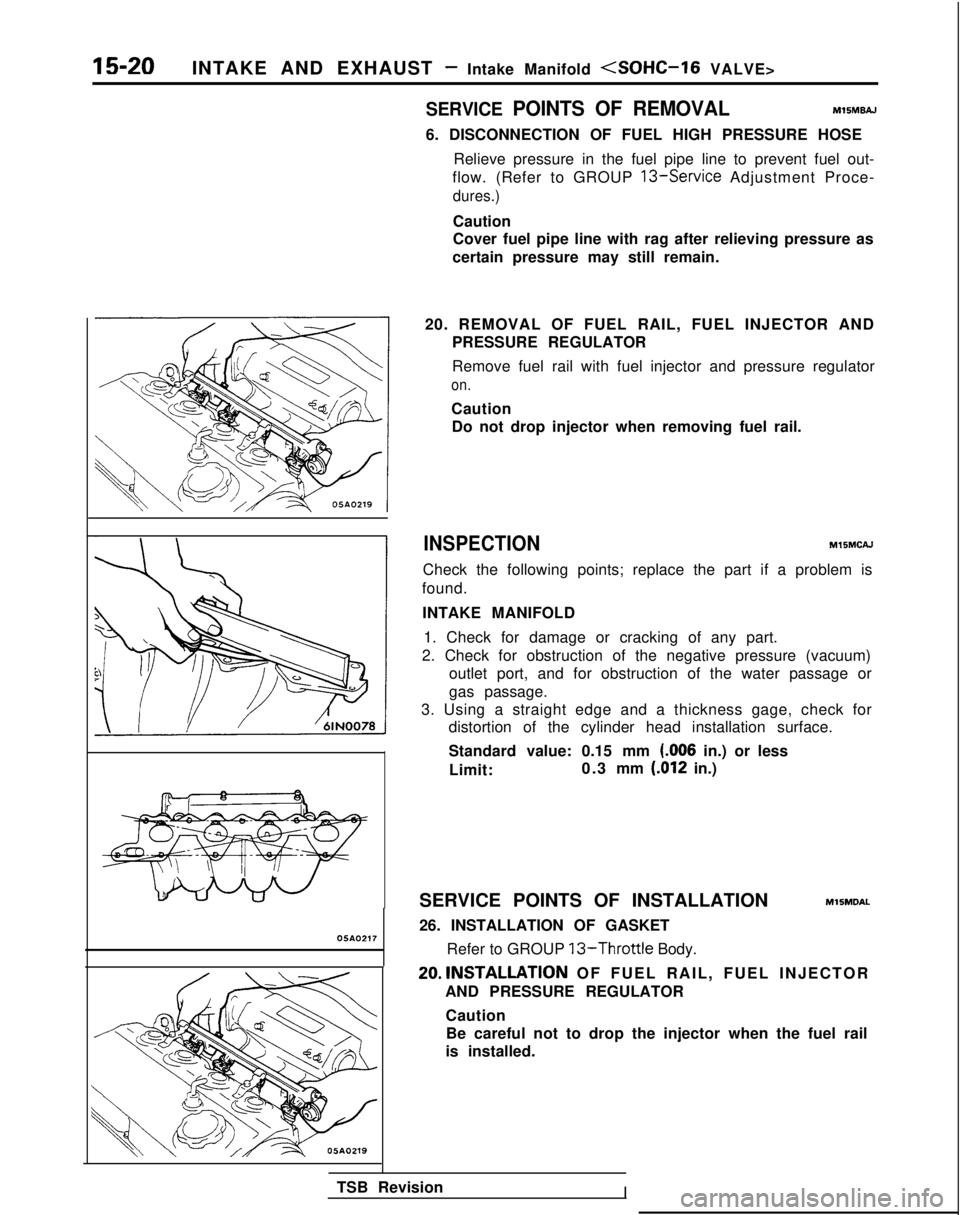

SERVICE POINTS OF REMOVALMlSMBAJ

6. DISCONNECTION OF FUEL HIGH PRESSURE HOSERelieve pressure in the fuel pipe line to prevent fuel out-

flow. (Refer to GROUP

13-Service Adjustment Proce-

dures.)

Caution

Cover fuel pipe line with rag after relieving pressure as

certain pressure may still remain.

20. REMOVAL OF FUEL RAIL, FUEL INJECTOR AND PRESSURE REGULATOR

Remove fuel rail with fuel injector and pressure regulator

on.

CautionDo not drop injector when removing fuel rail.

INSPECTIONMlSMCAJ

Check the following points; replace the part if a problem is

found.

INTAKE MANIFOLD 1. Check for damage or cracking of any part.

2. Check for obstruction of the negative pressure (vacuum) outlet port, and for obstruction of the water passage or

gas passage.

3. Using a straight edge and a thickness gage, check for distortion of the cylinder head installation surface.

Standard value: 0.15 mm

(006 in.) or less

Limit: 0.3 mm

(.012 in.)

SERVICE POINTS OF INSTALLATION

MllMDAL

26. INSTALLATION OF GASKET Refer to GROUP

13-Throttle Body.

20.lNSTALLATlON OF FUEL RAIL, FUEL INJECTOR

AND PRESSURE REGULATOR

CautionBe careful not to drop the injector when the fuel rail

is installed.

TSB Revision

I

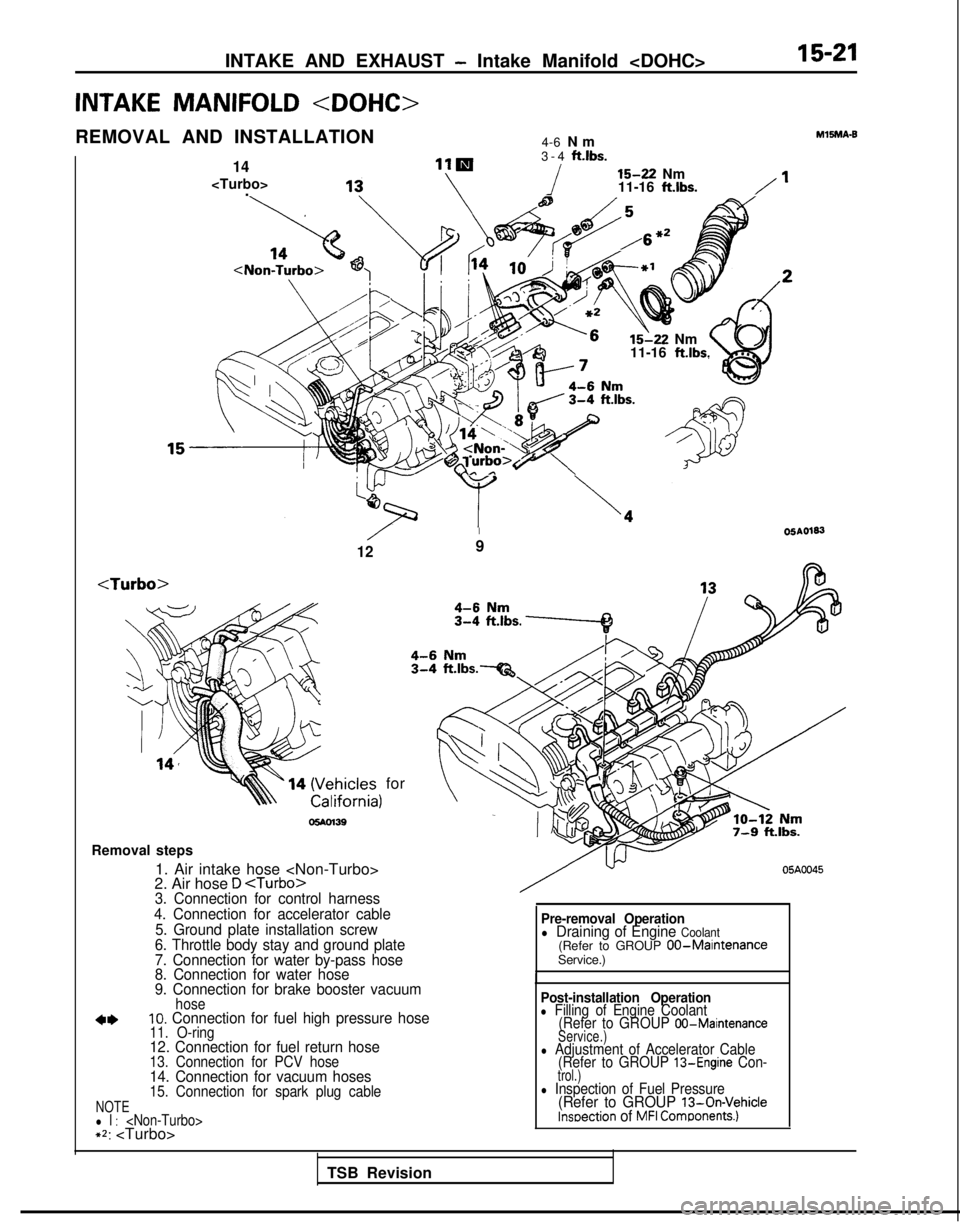

Page 607 of 1273

INTAKE AND EXHAUST - Intake Manifold

INTAKE MANIFOLD

REMOVAL AND INSTALLATION 4-6 Nm

14

. 3-4

ft.lbs.

i 15-22

Nm

11-16 ft.lbs./’

/6 *= 15-22

Nm

11-16

ft.lbs.

‘urbo>fl\sT

M15MA-9

/I05AO183

129

for

o!wn39

Removal steps 1. Air intake hose

2. Air hose

D

4. Connection for accelerator cable 5. Ground plate installation screw

6. Throttle body stay and ground plate

7. Connection for water by-pass hose

8. Connection for water hose

9. Connection for brake booster vacuum

hose10. Connection for fuel high pressure hose11. O-ring12. Connection for fuel return hose13. Connection for PCV hose14. Connection for vacuum hoses15. Connection for spark plug cableNOTEl l :

05A0045

Pre-removal Operationl Draining of Engine Coolant(Refer to GROUP 00-MaintenanceService.)

Post-installation Operationl Filling of Engine Coolant (Refer to GROUP 00-Maintenance

Service.)

l Adjustment of Accelerator Cable (Refer to GROUP 13-Engine Con-trol.)l Inspection of Fuel Pressure(Refer to GROUP 13-On-Vehiclelnseection of MFI Comgonents.)

TSB Revision

Page 608 of 1273

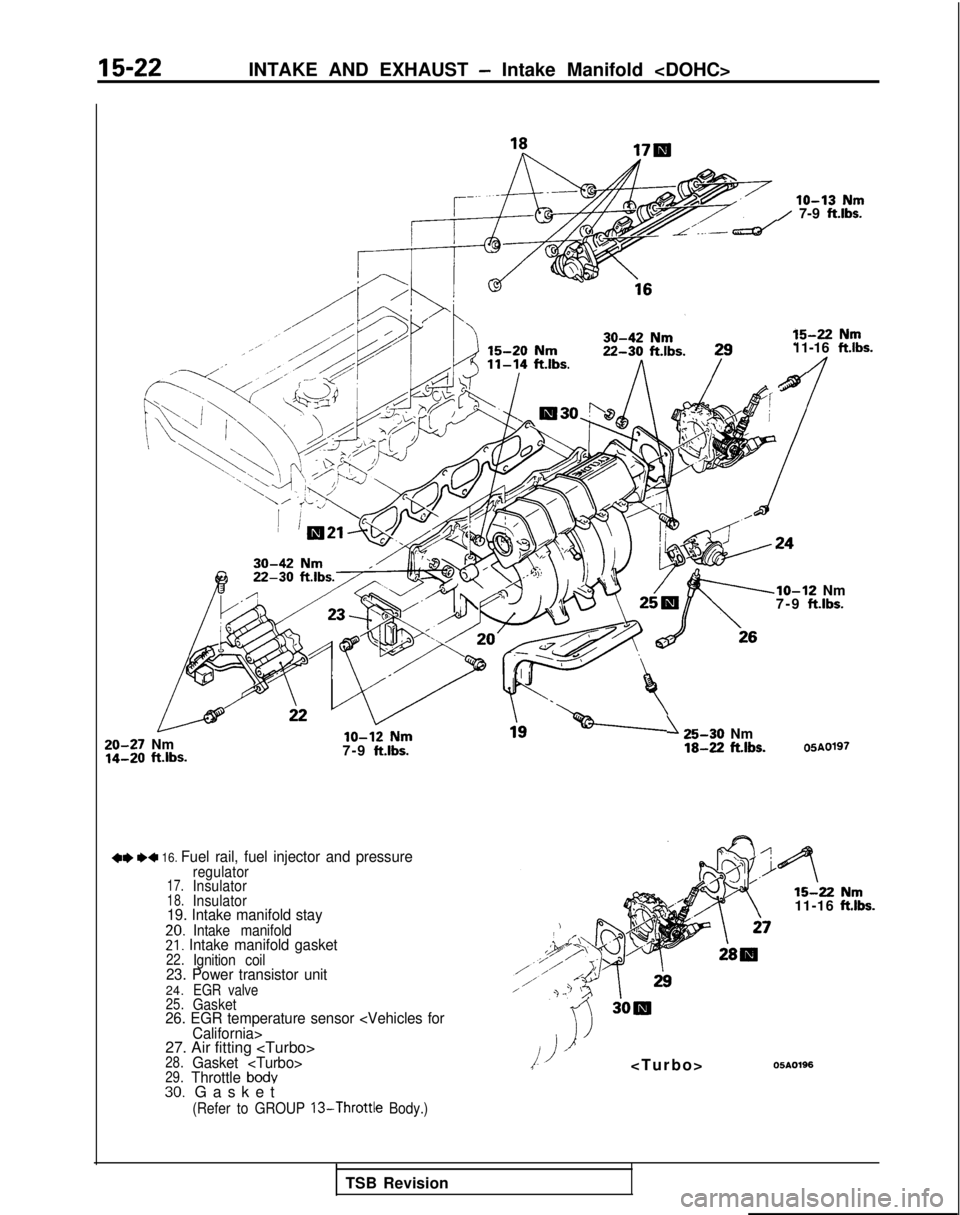

15-22INTAKE AND EXHAUST - Intake Manifold

lo-13 Nm/ 7-9 ftlbs.

15-22 Nm11-16

ftlbs.

n

20-27 Nm14-20 ft.lbs.7-9

ftlbs.

+e I)4 16. Fuel rail, fuel injector and pressureregulator17.Insulator18.Insulator19. Intake manifold stay20.Intake manifold21. Intake manifold gasket22.Ignition coil23. Power transistor unit24.EGR valve

25.Gasket26. EGR temperature sensor

27. Air fitting

t

(Refer to GROUP 13-Throttle

Body.)

lo-12 Nm

7-9 ft.lbs.

125-30 Nm18-22 ftlbs.05AQ197

15-2211-16

OSAO196

TSB Revision

Page 609 of 1273

INTAKE AND EXHAUST - Intake Manifold

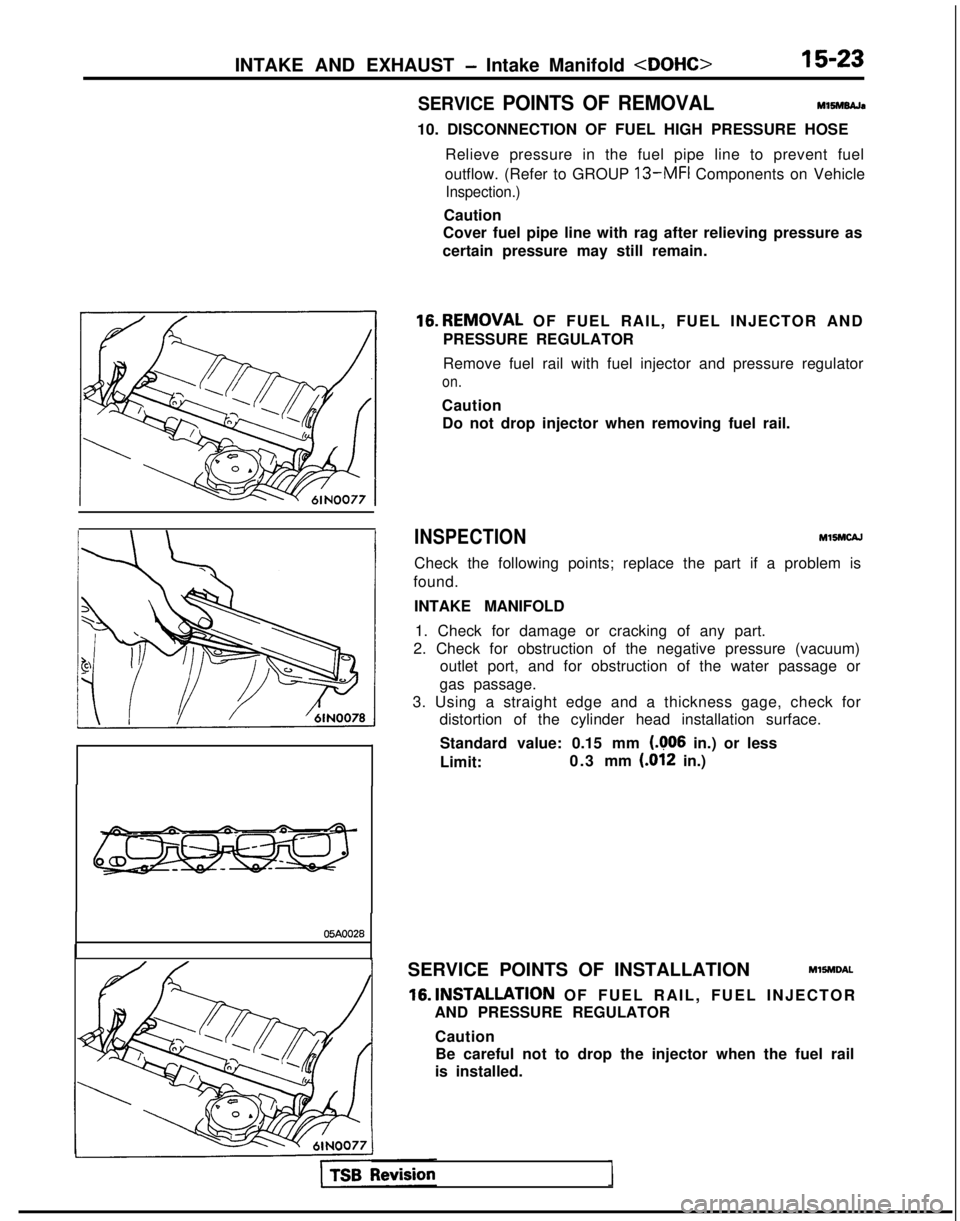

SERVICE POINTS OF REMOVAL

M1SMEAJa

10. DISCONNECTION OF FUEL HIGH PRESSURE HOSE Relieve pressure in the fuel pipe line to prevent fuel

outflow. (Refer to GROUP

13-MFI Components on Vehicle

Inspection.)

Caution

Cover fuel pipe line with rag after relieving pressure as

certain pressure may still remain.

16.REMOVAL OF FUEL RAIL, FUEL INJECTOR AND

PRESSURE REGULATOR

Remove fuel rail with fuel injector and pressure regulator

on.

Caution Do not drop injector when removing fuel rail.

INSPECTION MlSMCAJ

Check the following points; replace the part if a problem is

found.

INTAKE MANIFOLD1. Check for damage or cracking of any part.

2. Check for obstruction of the negative pressure (vacuum) outlet port, and for obstruction of the water passage or

gas passage.

3. Using a straight edge and a thickness gage, check for distortion of the cylinder head installation surface.

Standard value: 0.15 mm

(406 in.) or less

Limit: 0.3 mm (.012

in.)

05AOO28

SERVICE POINTS OF INSTALLATIONMlSMDAL

16.lNSTALLATlON OF FUEL RAIL, FUEL INJECTOR

AND PRESSURE REGULATOR

CautionBe careful not to drop the injector when the fuel rail

is installed.

Page 610 of 1273

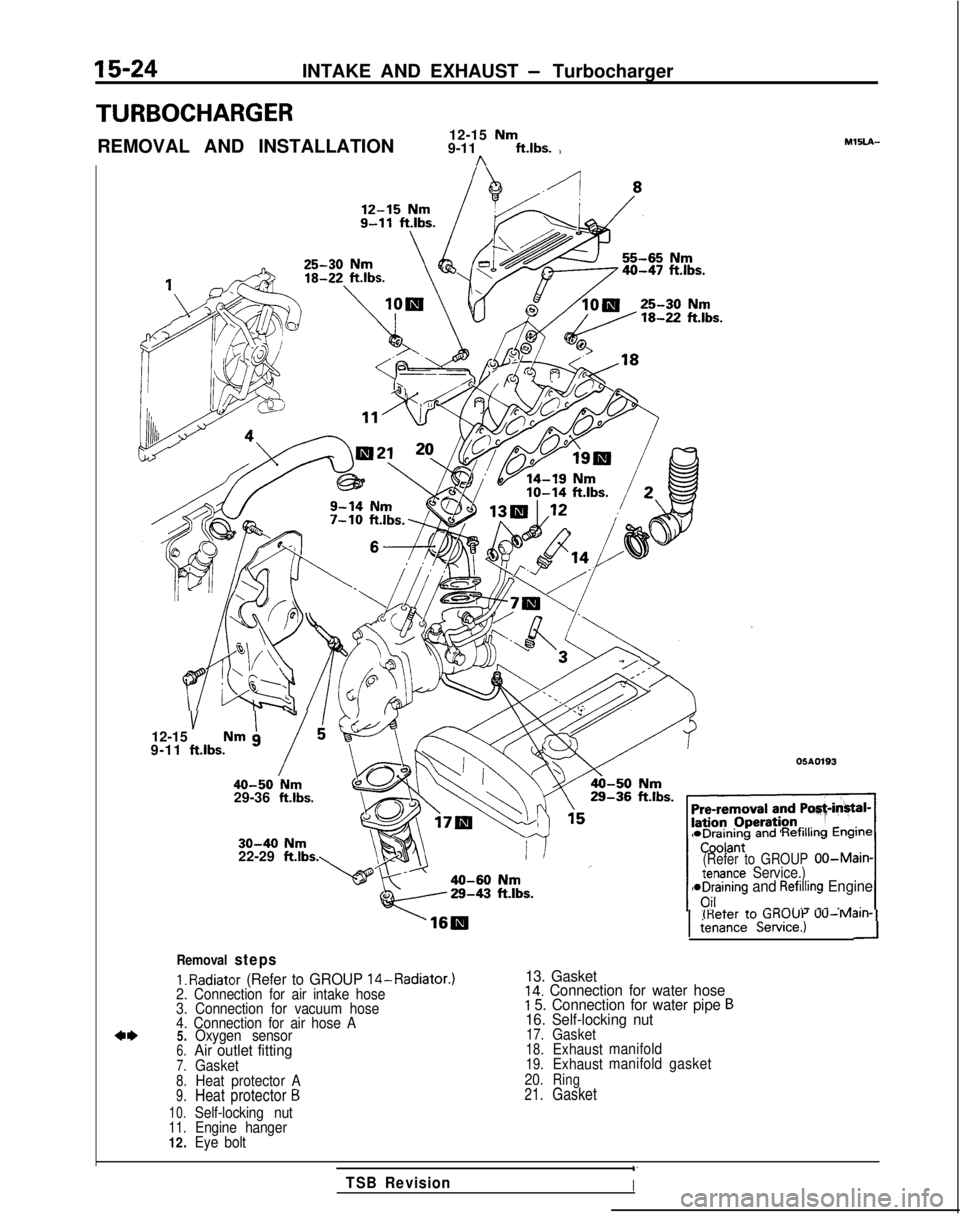

15-24INTAKE AND EXHAUST - Turbocharger

TURBOCHARGER

REMOVAL AND INSTALLATION12-15 Nm9-11 ft.lbs. )n

MlSLA-

40-47 ftlbs.

v I”12-15 Nm g

9-11 ftlbs.

i40-50 Nm29-36 ft.lbs.

05A0193

30-40 Nm22-29 ftlbs. *Draining

andRefilling Engine

(Refer to GROUPOO-Main-tenance Service.)aDraining and Refilling Engine

---. .- _^ . ._;_I(Refer to CiKUUi-’

UU-M~III-11

tenance Service.)-I

Removal steps

1.

Radiator (Refer to GROUP 14-Radiator.)

13. Gasket2. Connection for air intake hose14. Connection for water hose

3. Connection for vacuum hoseI 5. Connection for water pipe B

4. Connection for air hose A16. Self-locking nut

4*5.Oxygen sensor17.Gasket

6.Air outlet fitting18.Exhaust

manifold

7.Gasket19.Exhaustmanifold

gasket

8.Heat protector A 20.Ring

9.Heat protector B21.Gasket

10.Self-locking nut11.Engine hanger

12. Eye bolt

1‘

TSB RevisionI