MITSUBISHI LANCER 2005 Workshop Manual

Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 251 of 788

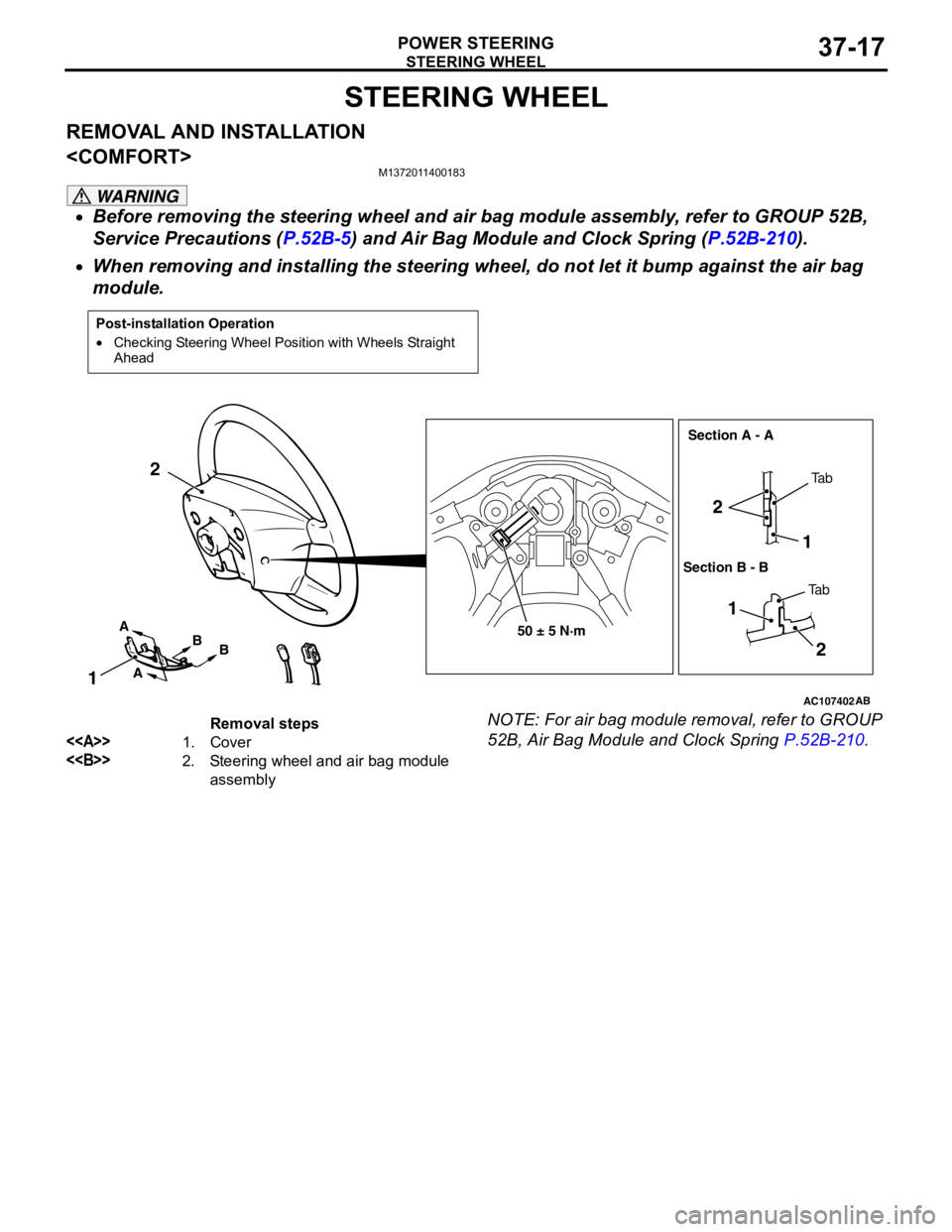

STEERING WHEEL

POWER STEERING37-17

STEERING WHEEL

REMOVAL AND INSTALLATION

M1372011400183

WARNING

•Before removing the steering wheel and air bag module assembly, refer to GROUP 52B,

Service Precautions (P.52B-5) and Air Bag Module and Clock Spring (P.52B-210).

•When removing and installing the steering wheel, do not let it bump against the air bag

module.

NOTE: For air bag module removal, refer to GROUP

52B, Air Bag Module and Clock Spring P.52B-210.

Post-installation Operation

•Checking Steering Wheel Position with Wheels Straight

Ahead

AC107402AB

50 ± 5 N·m

1 2

2

1

12

A

AB

BTa b

Ta b Section A - A

Section B - B

Removal steps

<>1. Cover

<>2. Steering wheel and air bag module

assembly

Page 252 of 788

Page 253 of 788

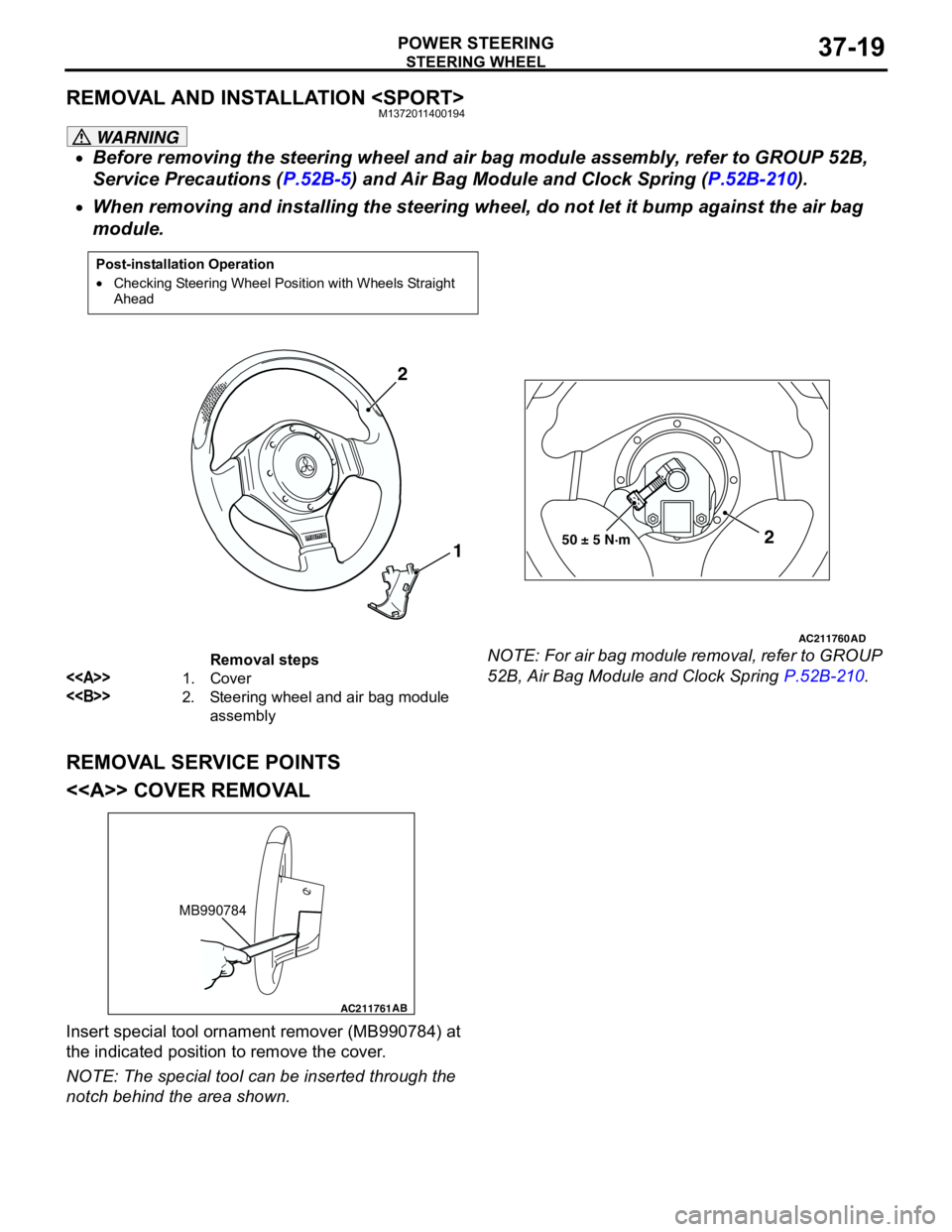

STEERING WHEEL

POWER STEERING37-19

REMOVAL AND INSTALLATION

WARNING

•Before removing the steering wheel and air bag module assembly, refer to GROUP 52B,

Service Precautions (P.52B-5) and Air Bag Module and Clock Spring (P.52B-210).

•When removing and installing the steering wheel, do not let it bump against the air bag

module.

NOTE: For air bag module removal, refer to GROUP

52B, Air Bag Module and Clock Spring P.52B-210.

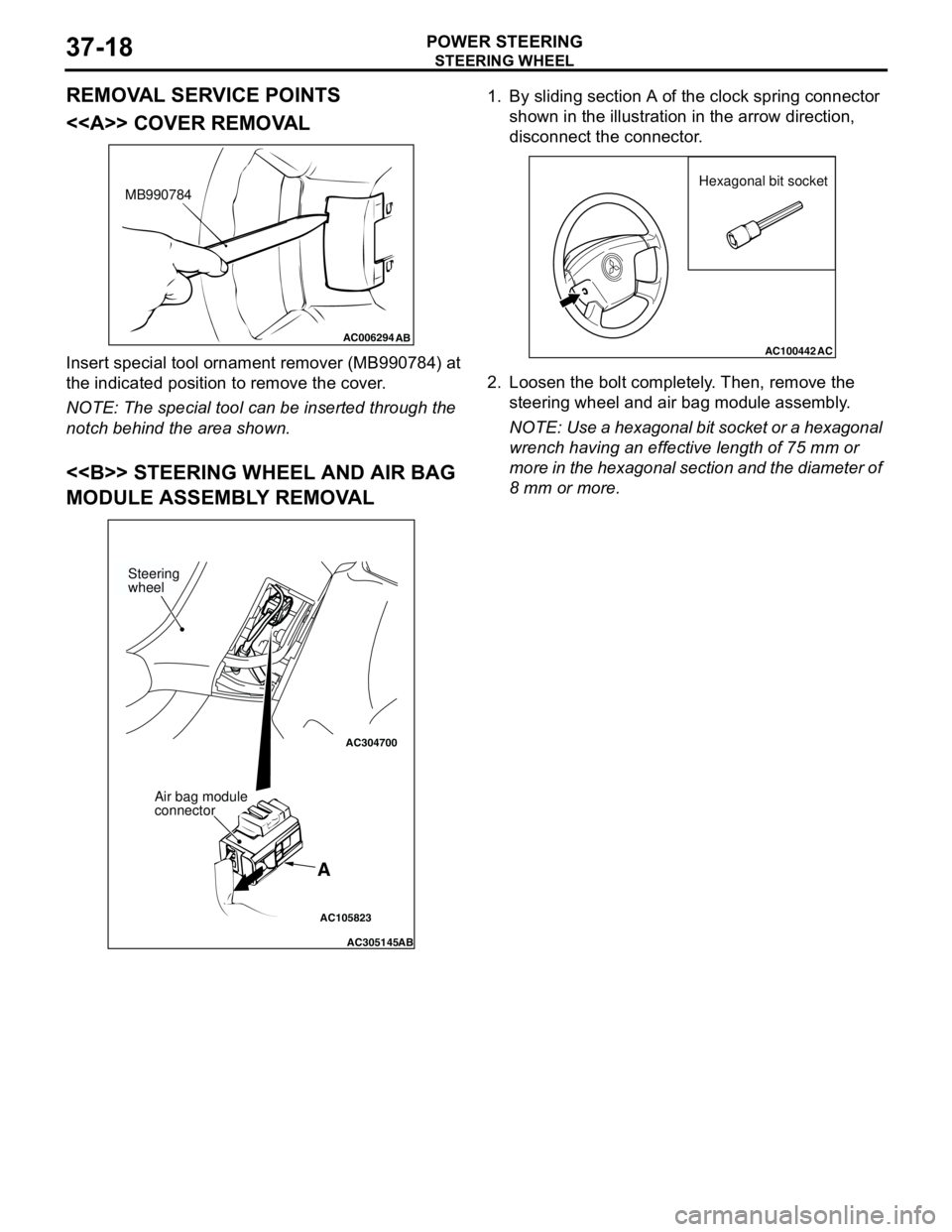

REMOVAL SERVICE POINTS

<> COVER REMOVAL

Insert special tool ornament remover (MB990784) at

the indicated position to remove the cover.

NOTE: The special tool can be inserted through the

notch behind the area shown.

Post-installation Operation

•Checking Steering Wheel Position with Wheels Straight

Ahead

AC211760

AD

50 ± 5 N·m2

1 2

Removal steps

<>1. Cover

<>2. Steering wheel and air bag module

assembly

AC211761AB

MB990784

Page 254 of 788

STEERING WHEEL

POWER STEERING37-20

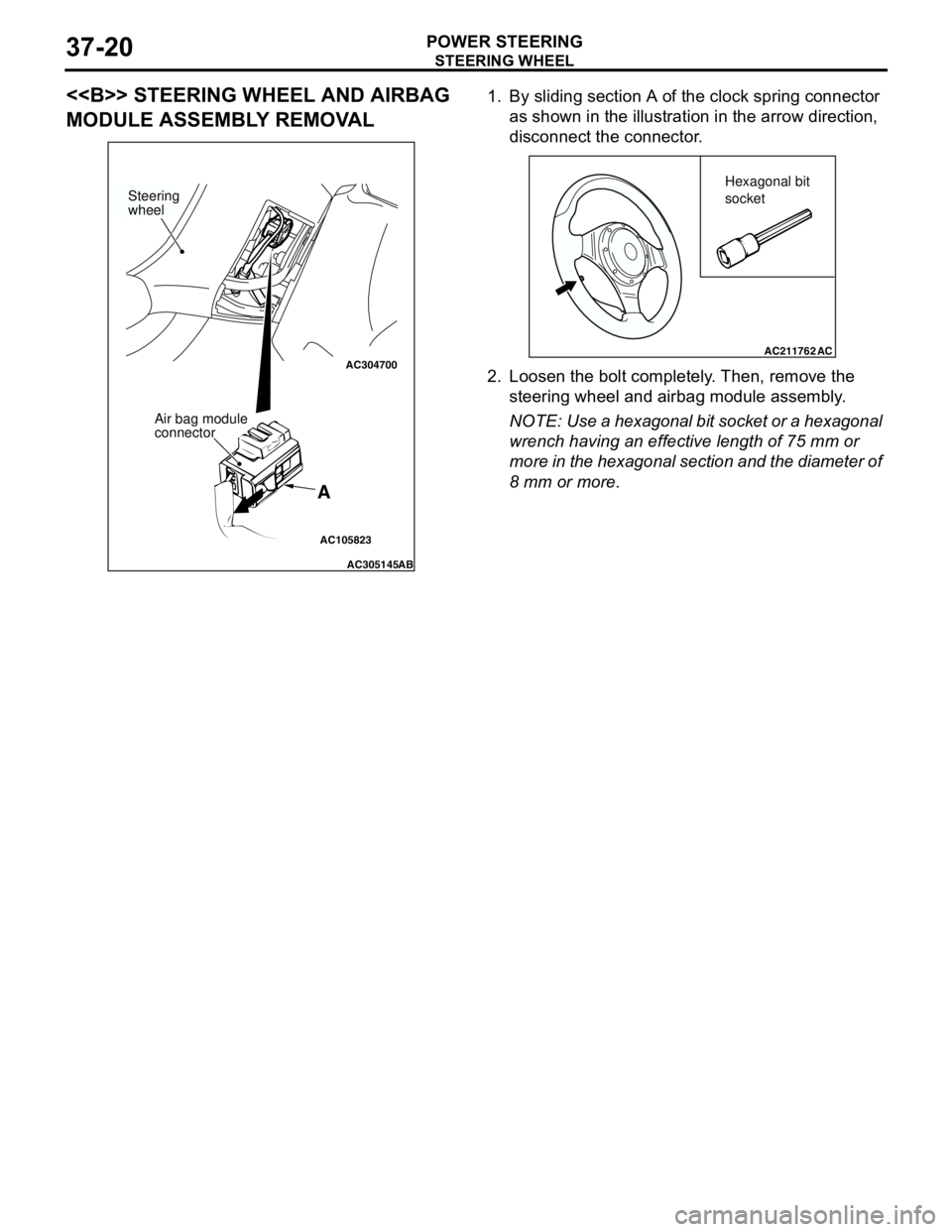

<> STEERING WHEEL AND AIRBAG

MODULE ASSEMBLY REMOVAL1. By sliding section A of the clock spring connector

as shown in the illustration in the arrow direction,

disconnect the connector.

2. Loosen the bolt completely. Then, remove the

steering wheel and airbag module assembly.

NOTE: Use a hexagonal bit socket or a hexagonal

wrench having an effective length of 75 mm or

more in the hexagonal section and the diameter of

8 mm or more.

AC105823

AC304700

AC305145AB

A

Steering

wheel

Air bag module

connector

AC211762AC

Hexagonal bit

socket

Page 255 of 788

STEERING SHAFT

POWER STEERING37-21

STEERING SHAFT

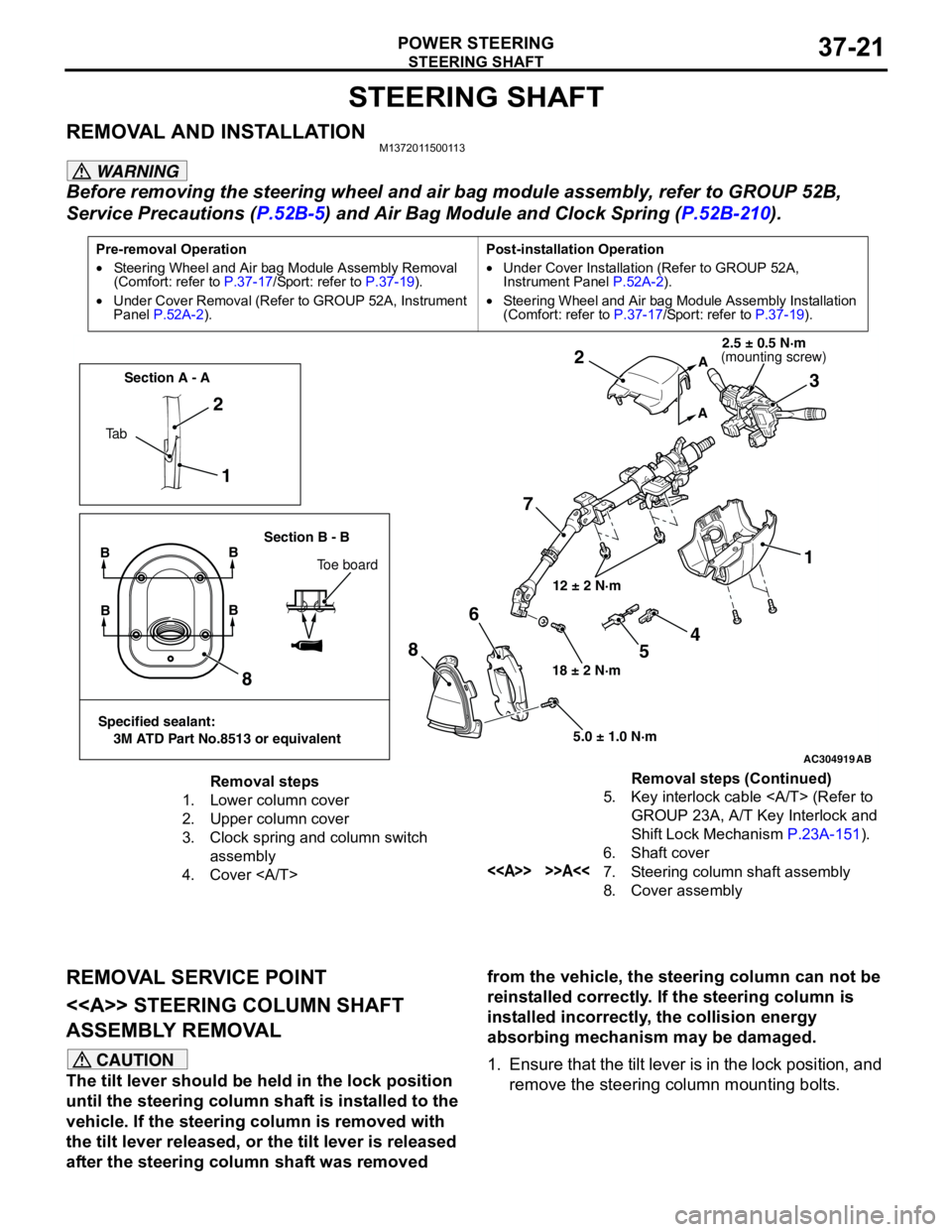

REMOVAL AND INSTALLATIONM1372011500113

WARNING

Before removing the steering wheel and air bag module assembly, refer to GROUP 52B,

Service Precautions (P.52B-5) and Air Bag Module and Clock Spring (P.52B-210).

REMOVAL SERVICE POINT

<> STEERING COLUMN SHAFT

ASSEMBLY REMOVAL

CAUTION

The tilt lever should be held in the lock position

until the steering column shaft is installed to the

vehicle. If the steering column is removed with

the tilt lever released, or the tilt lever is released

after the steering column shaft was removed from the vehicle, the steering column can not be

reinstalled correctly. If the steering column is

installed incorrectly, the collision energy

absorbing mechanism may be damaged.

1. Ensure that the tilt lever is in the lock position, and

remove the steering column mounting bolts.

Pre-removal Operation

•Steering Wheel and Air bag Module Assembly Removal

(Comfort: refer to P.37-17/Sport: refer to P.37-19).

•Under Cover Removal (Refer to GROUP 52A, Instrument

Panel P.52A-2).Post-installation Operation

•Under Cover Installation (Refer to GROUP 52A,

Instrument Panel P.52A-2).

•Steering Wheel and Air bag Module Assembly Installation

(Comfort: refer to P.37-17/Sport: refer to P.37-19).

AC304919AB

12 ± 2 N·m

18 ± 2 N·m

5.0 ± 1.0 N·m

1 2

73 2

1

8

86

A

A

Ta bSection A - A

Section B - B

BB

Toe board

Specified sealant:

3M ATD Part No.8513 or equivalent

BB

4

5

(mounting screw)2.5 ± 0.5 N·m

Removal steps

1. Lower column cover

2. Upper column cover

3. Clock spring and column switch

assembly

4. Cover 5. Key interlock cable (Refer to

GROUP 23A, A/T Key Interlock and

Shift Lock Mechanism P.23A-151).

6. Shaft cover

<> >>A<<7. Steering column shaft assembly

8. Cover assemblyRemoval steps (Continued)

Page 256 of 788

STEERING SHAFT

POWER STEERING37-22

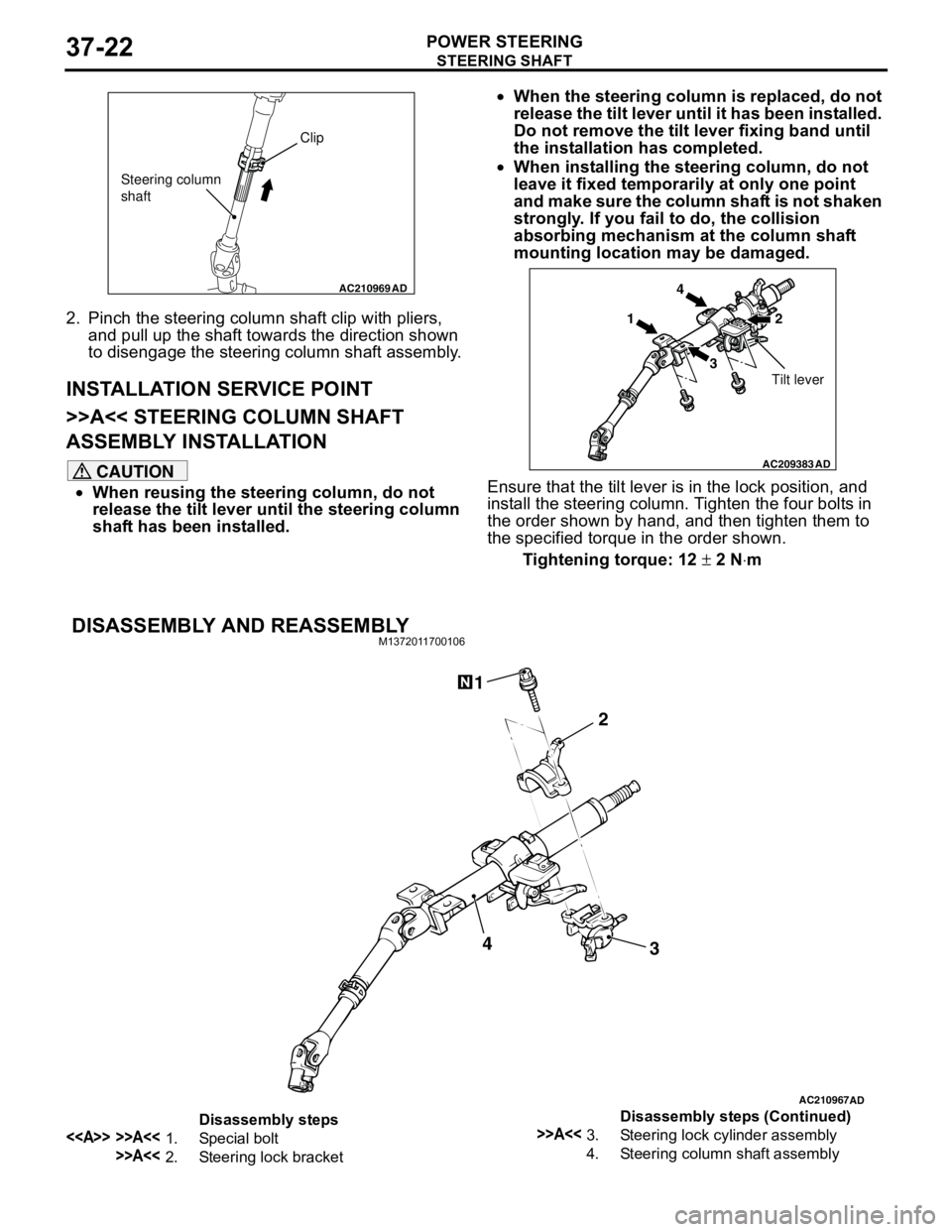

2. Pinch the steering column shaft clip with pliers,

and pull up the shaft towards the direction shown

to disengage the steering column shaft assembly.

INSTALLATION SERVICE POINT

>>A<< STEERING COLUMN SHAFT

ASSEMBLY INSTALLATION

CAUTION

•When reusing the steering column, do not

release the tilt lever until the steering column

shaft has been installed.•When the steering column is replaced, do not

release the tilt lever until it has been installed.

Do not remove the tilt lever fixing band until

the installation has completed.

•When installing the steering column, do not

leave it fixed temporarily at only one point

and make sure the column shaft is not shaken

strongly. If you fail to do, the collision

absorbing mechanism at the column shaft

mounting location may be damaged.

Ensure that the tilt lever is in the lock position, and

install the steering column. Tighten the four bolts in

the order shown by hand, and then tighten them to

the specified torque in the order shown.

Tightening torque: 12 ± 2 N⋅m

DISASSEMBLY AND REASSEMBLYM1372011700106

AC210969AD

Clip

Steering column

shaft

AC209383

AD

14

32

Tilt lever

AC210967AD

3 2 14

Disassembly steps

<> >>A<<1. Special bolt

>>A<<2. Steering lock bracket

>>A<<3. Steering lock cylinder assembly

4. Steering column shaft assemblyDisassembly steps (Continued)

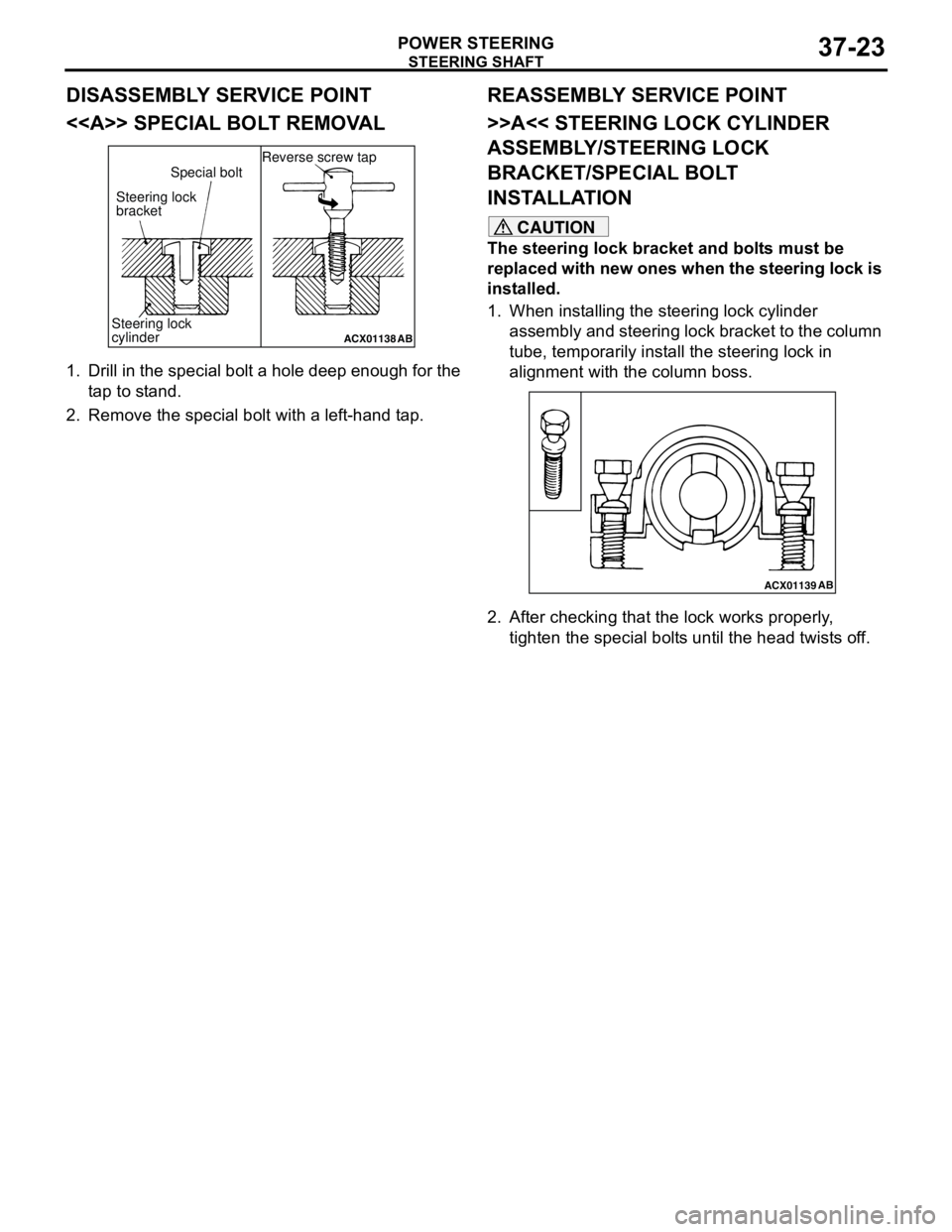

Page 257 of 788

Page 258 of 788

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-24

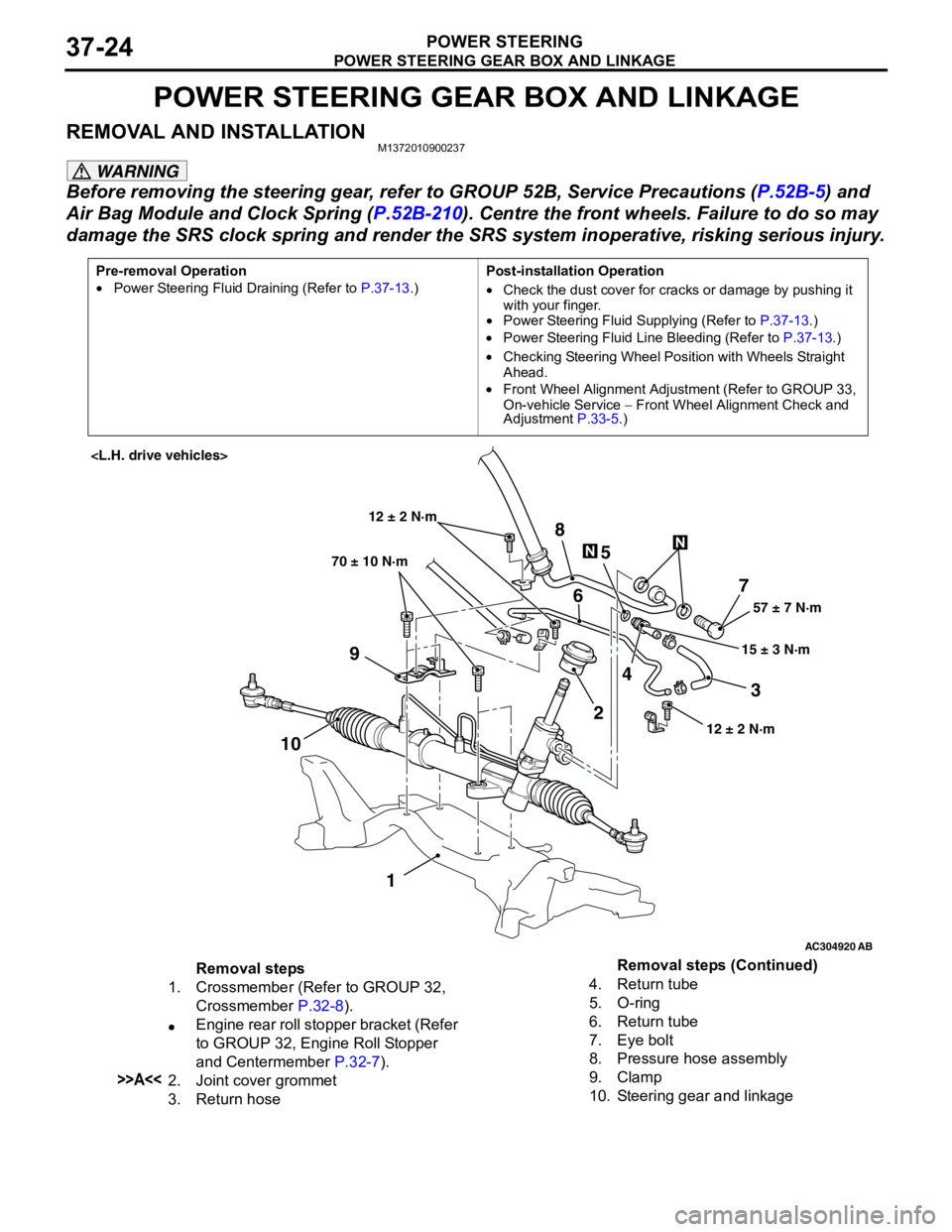

POWER STEERING GEAR BOX AND LINKAGE

REMOVAL AND INSTALLATIONM1372010900237

WARNING

Before removing the steering gear, refer to GROUP 52B, Service Precautions (P.52B-5) and

Air Bag Module and Clock Spring (P.52B-210). Centre the front wheels. Failure to do so may

damage the SRS clock spring and render the SRS system inoperative, risking serious injury.

Pre-removal Operation

•Power Steering Fluid Draining (Refer to P.37-13.)Post-installation Operation

•Check the dust cover for cracks or damage by pushing it

with your finger.

•Power Steering Fluid Supplying (Refer to P.37-13.)

•Power Steering Fluid Line Bleeding (Refer to P.37-13.)

•Checking Steering Wheel Position with Wheels Straight

Ahead.

•Front Wheel Alignment Adjustment (Refer to GROUP 33,

On-vehicle Service − Front Wheel Alignment Check and

Adjustment P.33-5.)

AC304920

AB

57 ± 7 N·m

15 ± 3 N·m 70 ± 10 N·m

7

3 8

5

6

9

1024

1

12 ± 2 N·m

12 ± 2 N·m

Removal steps

1. Crossmember (Refer to GROUP 32,

Crossmember P.32-8).

•Engine rear roll stopper bracket (Refer

to GROUP 32, Engine Roll Stopper

and Centermember P.32-7).

>>A<<2. Joint cover grommet

3. Return hose4. Return tube

5. O-ring

6. Return tube

7. Eye bolt

8. Pressure hose assembly

9. Clamp

10. Steering gear and linkageRemoval steps (Continued)

Page 259 of 788

POWER STEERING GEAR BOX AND LINKAGE

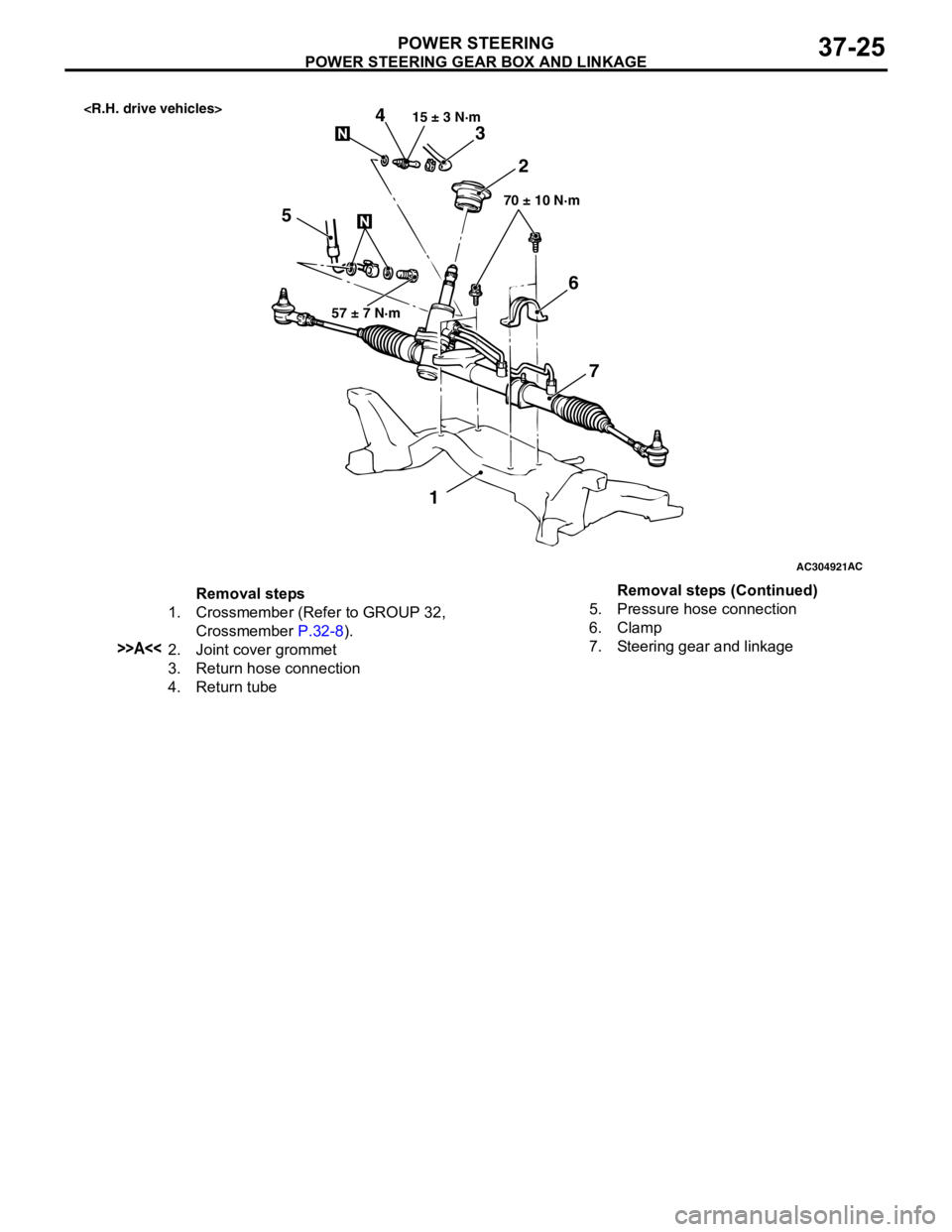

POWER STEERING37-25

AC304921AC

57 ± 7 N·m15 ± 3 N·m

70 ± 10 N·m

3

52 4

1

6

7

Removal steps

1. Crossmember (Refer to GROUP 32,

Crossmember P.32-8).

>>A<<2. Joint cover grommet

3. Return hose connection

4. Return tube5. Pressure hose connection

6. Clamp

7. Steering gear and linkageRemoval steps (Continued)

Page 260 of 788

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-26

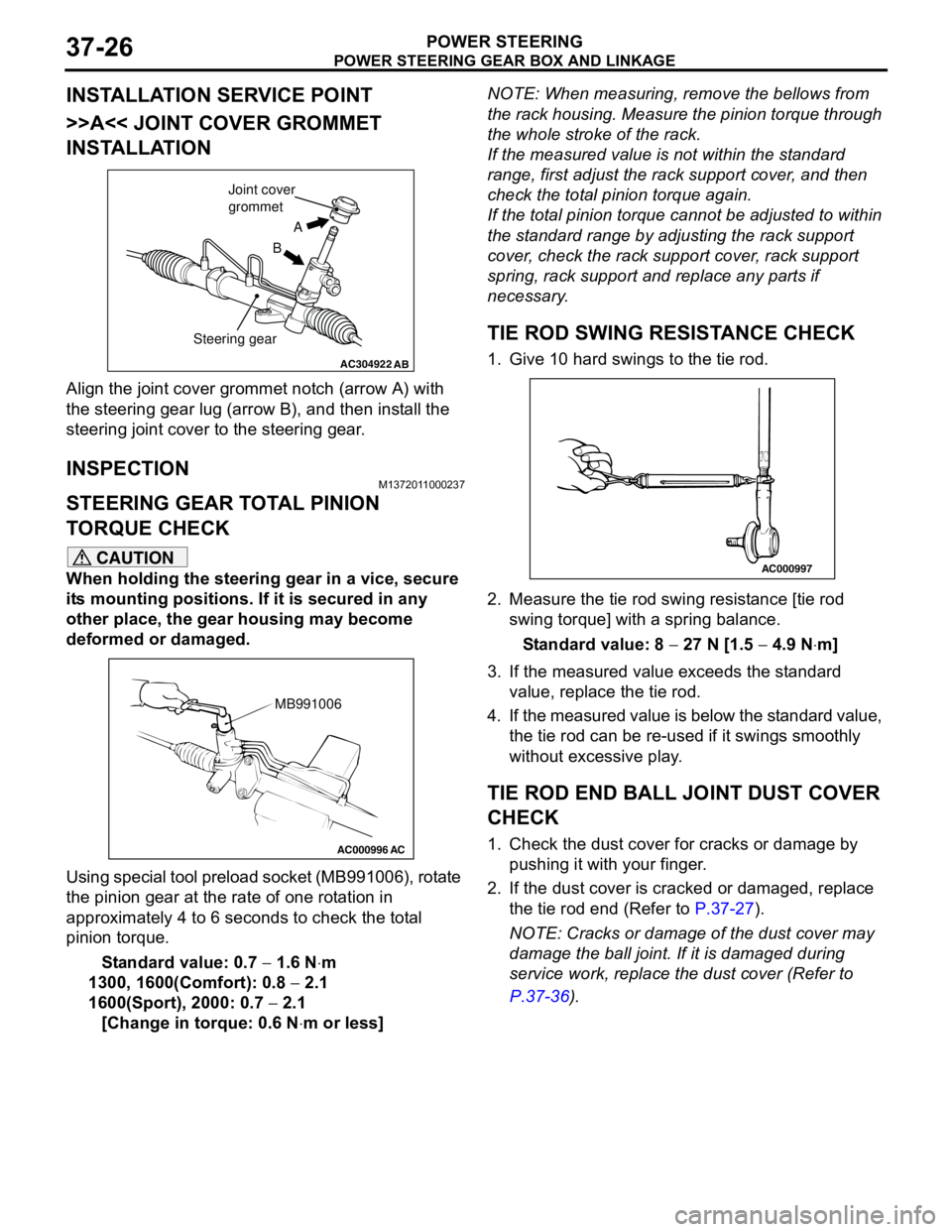

INSTALLATION SERVICE POINT

>>A<< JOINT COVER GROMMET

INSTALLATION

Align the joint cover grommet notch (arrow A) with

the steering gear lug (arrow B), and then install the

steering joint cover to the steering gear.

INSPECTIONM1372011000237

STEERING GEAR TOTAL PINION

TORQUE CHECK

CAUTION

When holding the steering gear in a vice, secure

its mounting positions. If it is secured in any

other place, the gear housing may become

deformed or damaged.

Using special tool preload socket (MB991006), rotate

the pinion gear at the rate of one rotation in

approximately 4 to 6 seconds to check the total

pinion torque.

Standard value: 0.7 − 1.6 N⋅m

1300, 1600(Comfort): 0.8 − 2.1

1600(Sport), 2000: 0.7 − 2.1

[Change in torque: 0.6 N⋅m or less]NOTE: When measuring, remove the bellows from

the rack housing. Measure the pinion torque through

the whole stroke of the rack.

If the measured value is not within the standard

range, first adjust the rack support cover, and then

check the total pinion torque again.

If the total pinion torque cannot be adjusted to within

the standard range by adjusting the rack support

cover, check the rack support cover, rack support

spring, rack support and replace any parts if

necessary.

TIE ROD SWING RESISTANCE CHECK

1. Give 10 hard swings to the tie rod.

2. Measure the tie rod swing resistance [tie rod

swing torque] with a spring balance.

Standard value: 8 − 27 N [1.5 − 4.9 N⋅m]

3. If the measured value exceeds the standard

value, replace the tie rod.

4. If the measured value is below the standard value,

the tie rod can be re-used if it swings smoothly

without excessive play.

TIE ROD END BALL JOINT DUST COVER

CHECK

1. Check the dust cover for cracks or damage by

pushing it with your finger.

2. If the dust cover is cracked or damaged, replace

the tie rod end (Refer to P.37-27).

NOTE: Cracks or damage of the dust cover may

damage the ball joint. If it is damaged during

service work, replace the dust cover (Refer to

P.37-36).

AC304922AB

A

B Joint cover

grommet

Steering gear

AC000996 AC

MB991006

AC000997