MITSUBISHI LANCER 2005 Workshop Manual

Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 291 of 788

WINDOW GLASS

BODY42-13

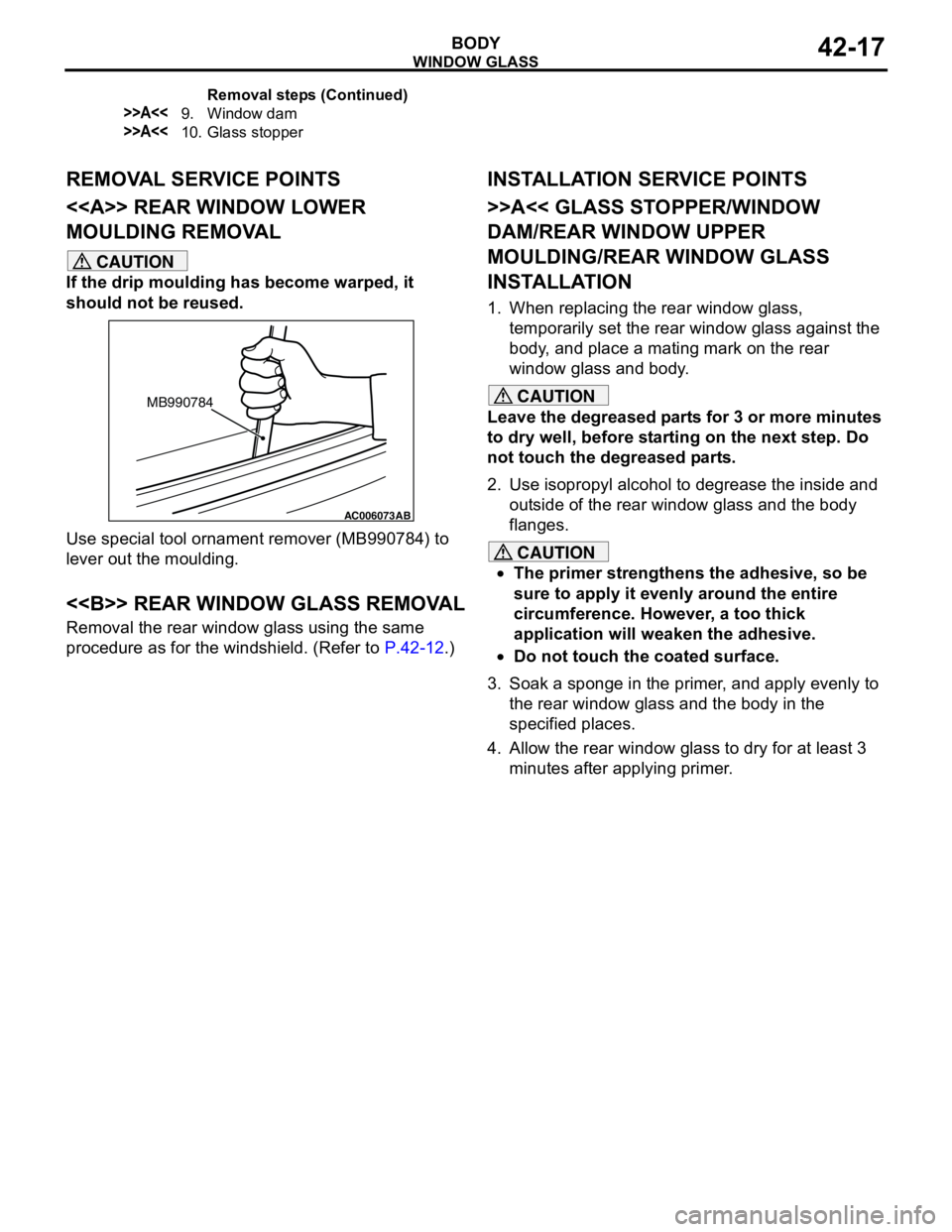

REMOVAL SERVICE POINT

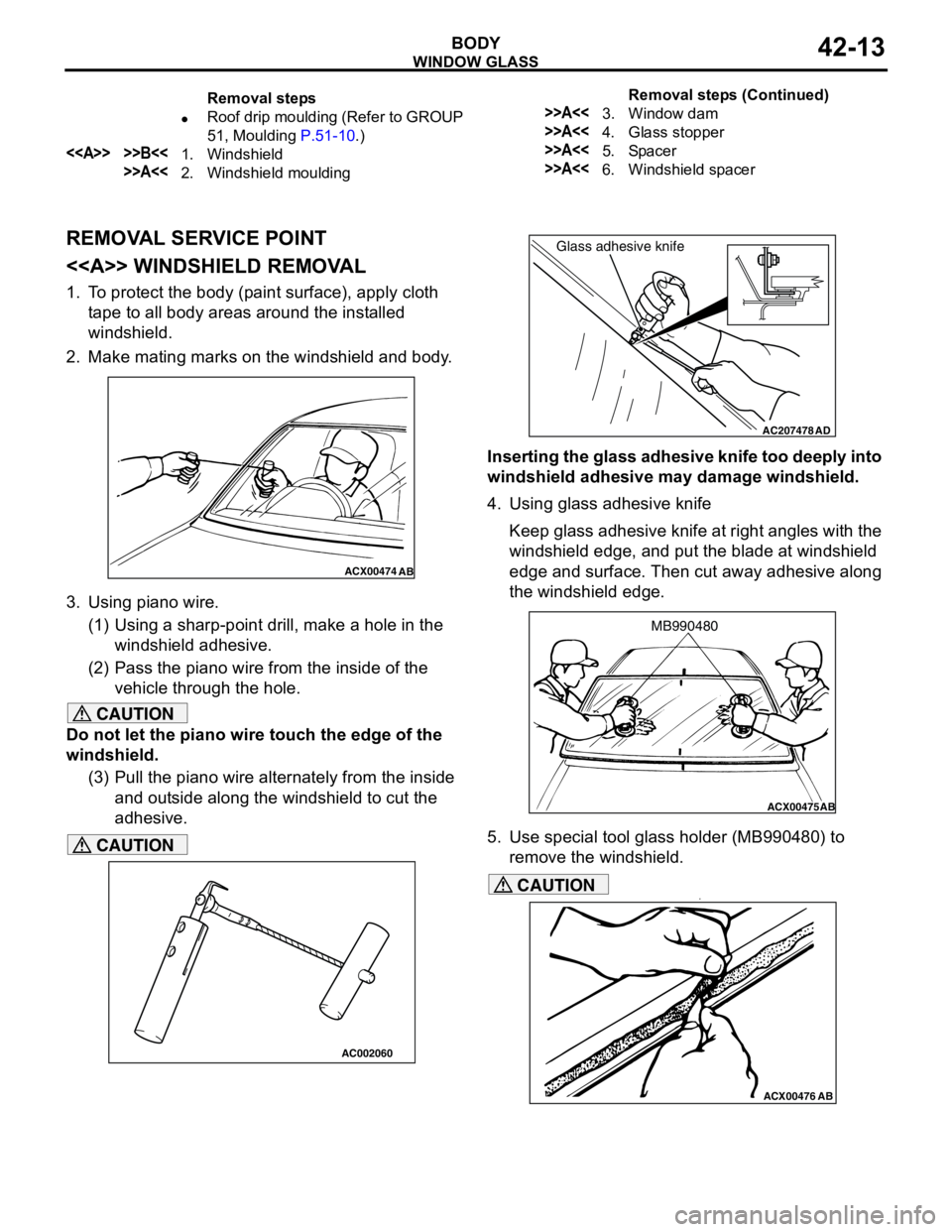

<> WINDSHIELD REMOVAL

1. To protect the body (paint surface), apply cloth

tape to all body areas around the installed

windshield.

2. Make mating marks on the windshield and body.

3. Using piano wire.

(1) Using a sharp-point drill, make a hole in the

windshield adhesive.

(2) Pass the piano wire from the inside of the

vehicle through the hole.

CAUTION

Do not let the piano wire touch the edge of the

windshield.

(3) Pull the piano wire alternately from the inside

and outside along the windshield to cut the

adhesive.

CAUTION

Inserting the glass adhesive knife too deeply into

windshield adhesive may damage windshield.

4. Using glass adhesive knife

Keep glass adhesive knife at right angles with the

windshield edge, and put the blade at windshield

edge and surface. Then cut away adhesive along

the windshield edge.

5. Use special tool glass holder (MB990480) to

remove the windshield.

CAUTION•

Removal steps

•Roof drip moulding (Refer to GROUP

51, Moulding P.51-10.)

<> >>B<<1. Windshield

>>A<<2. Windshield moulding

>>A<<3. Window dam

>>A<<4. Glass stopper

>>A<<5. Spacer

>>A<<6. Windshield spacerRemoval steps (Continued)

ACX00474

AB

AC002060

AC207478

Glass adhesive knife

AD

ACX00475

AB

MB990480

ACX00476

AB

Page 292 of 788

WINDOW GLASS

BODY42-14

Be careful not to remove more adhesive than is

necessary.

•Be careful also not to damage the paintwork

on the body surface with the knife. If the

paintwork is damaged, repair the damaged

area with repair paint or anti-rust agent.

6. Use a knife to cut away the remaining adhesive so

that the thickness is within 2 mm around the entire

circumference of the body flange.

7. Finish the flange surfaces so that they are

smooth.

CAUTION

Allow the cleaned area to dry for at least three

minutes. Do not touch any surface that has been

cleaned.8. When reusing the windshield, remove the

adhesive still adhering to the windshield, and

clean with isopropyl alcohol.

9. Clean the body side in the same way.

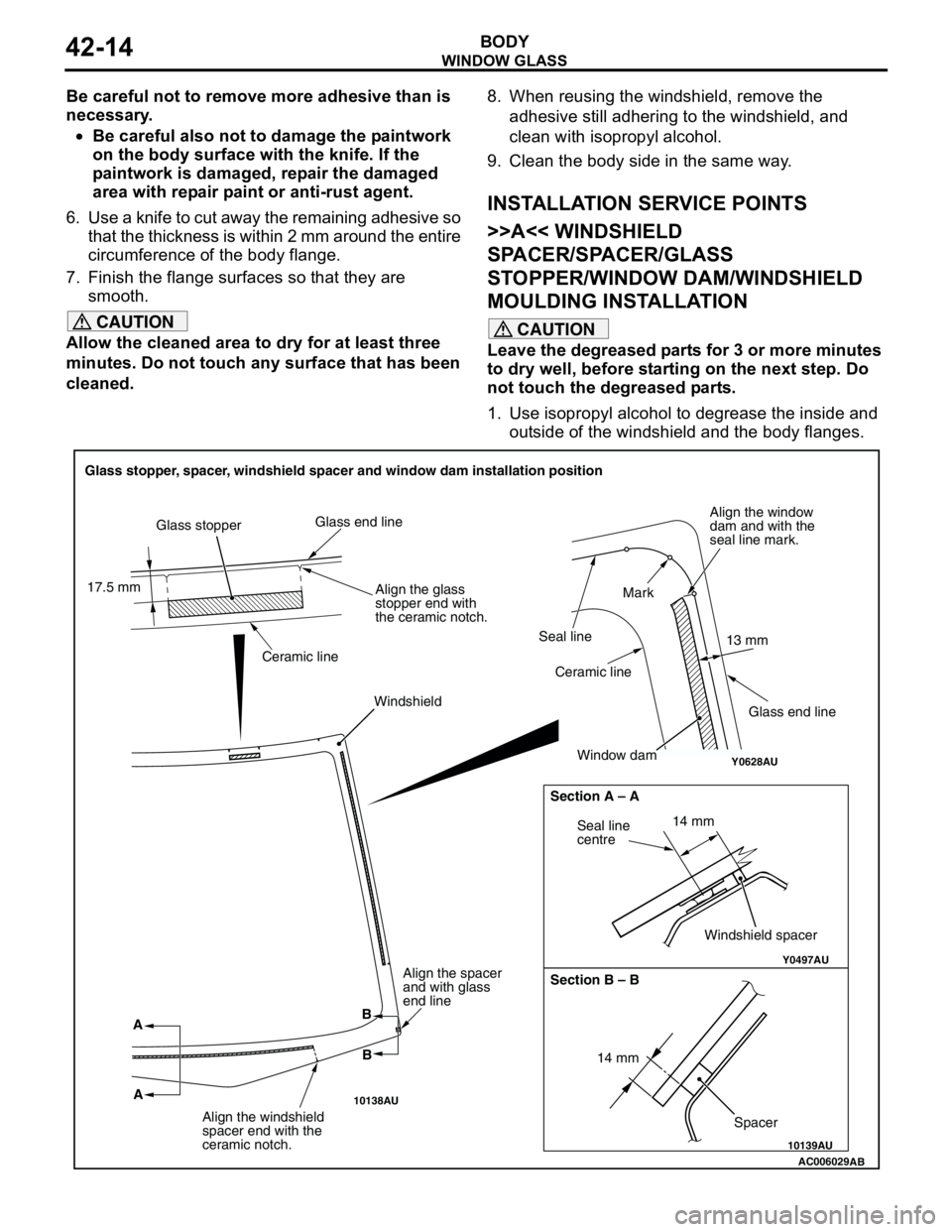

INSTALLATION SERVICE POINTS

>>A<< WINDSHIELD

SPACER/SPACER/GLASS

STOPPER/WINDOW DAM/WINDSHIELD

MOULDING INSTALLATION

CAUTION

Leave the degreased parts for 3 or more minutes

to dry well, before starting on the next step. Do

not touch the degreased parts.

1. Use isopropyl alcohol to degrease the inside and

outside of the windshield and the body flanges.

Y0628AU

AC006029

10138AU

10139AU

Y0497AU

Glass stopper, spacer, windshield spacer and window dam installation position

17.5 mmGlass stopper

Glass end line

Ceramic line

Align the glass

stopper end with

the ceramic notch.

Align the window

dam and with the

seal line mark.

13 mm

Glass end line

Mark

Seal line

Ceramic line

Window dam

AB

A

AWindshield

Seal line

centre14 mm

Windshield spacer Section A – A

Section B – B

B

B

14 mm

Spacer

Align the spacer

and with glass

end line

Align the windshield

spacer end with the

ceramic notch.

Page 293 of 788

WINDOW GLASS

BODY42-15

2. The inner side of the windshield is curved,

therefore, make a point to assemble the glass

stopper and windshield spacer without any lifting

and assemble in the position shown in the Figure

of the instructions.

3. Install the windshield moulding.

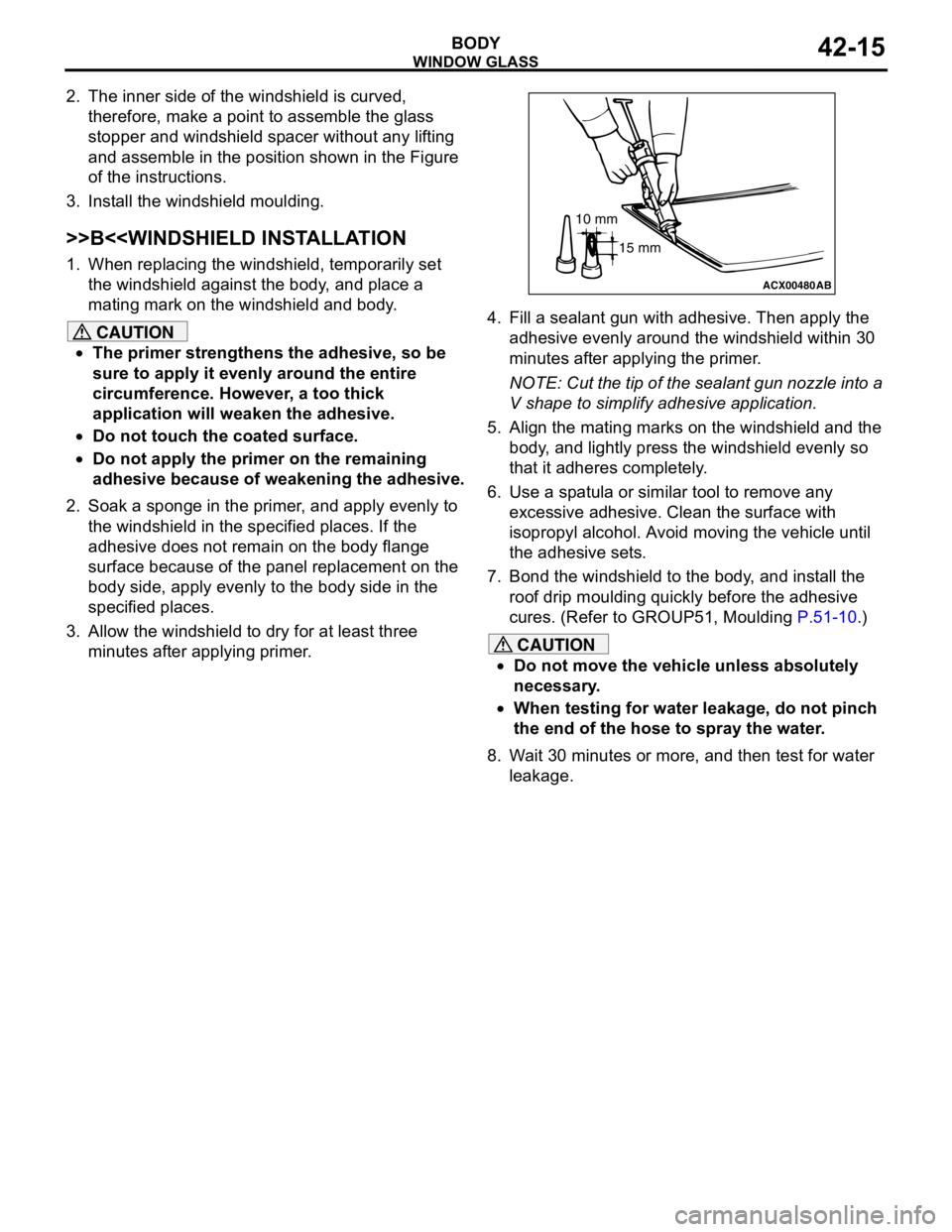

>>B<

the windshield against the body, and place a

mating mark on the windshield and body.

CAUTION

•The primer strengthens the adhesive, so be

sure to apply it evenly around the entire

circumference. However, a too thick

application will weaken the adhesive.

•Do not touch the coated surface.

•Do not apply the primer on the remaining

adhesive because of weakening the adhesive.

2. Soak a sponge in the primer, and apply evenly to

the windshield in the specified places. If the

adhesive does not remain on the body flange

surface because of the panel replacement on the

body side, apply evenly to the body side in the

specified places.

3. Allow the windshield to dry for at least three

minutes after applying primer.4. Fill a sealant gun with adhesive. Then apply the

adhesive evenly around the windshield within 30

minutes after applying the primer.

NOTE: Cut the tip of the sealant gun nozzle into a

V shape to simplify adhesive application.

5. Align the mating marks on the windshield and the

body, and lightly press the windshield evenly so

that it adheres completely.

6. Use a spatula or similar tool to remove any

excessive adhesive. Clean the surface with

isopropyl alcohol. Avoid moving the vehicle until

the adhesive sets.

7. Bond the windshield to the body, and install the

roof drip moulding quickly before the adhesive

cures. (Refer to GROUP51, Moulding P.51-10.)

CAUTION

•Do not move the vehicle unless absolutely

necessary.

•When testing for water leakage, do not pinch

the end of the hose to spray the water.

8. Wait 30 minutes or more, and then test for water

leakage.

ACX00480

10 mm

15 mm

AB

Page 294 of 788

WINDOW GLASS

BODY42-16

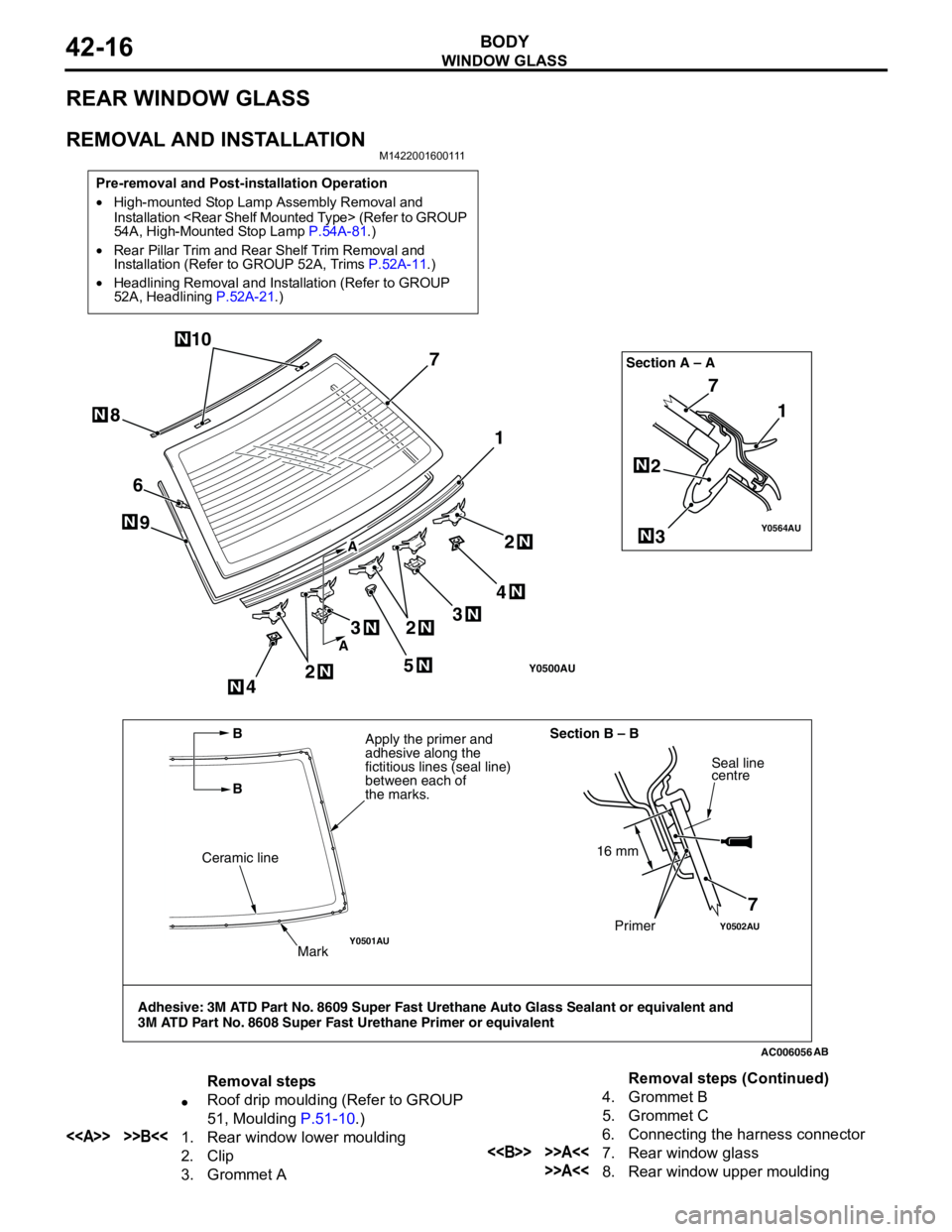

REAR WINDOW GLASS

REMOVAL AND INSTALLATIONM1422001600111

Pre-removal and Post-installation Operation

•High-mounted Stop Lamp Assembly Removal and

Installation

54A, High-Mounted Stop Lamp P.54A-81.)

•Rear Pillar Trim and Rear Shelf Trim Removal and

Installation (Refer to GROUP 52A, Trims P.52A-11.)

•Headlining Removal and Installation (Refer to GROUP

52A, Headlining P.52A-21.)

Y0500AU

Y0502AUY0501AU

Y0564AU

AC006056

11 7

7

AB

6

25

4 9

7 3

N

2N

2N

N

4N

N

3N3N

NN

2N

Ceramic line

Mark

Apply the primer and

adhesive along the

fictitious lines (seal line)

between each of

the marks.Section A – A

Section B – B

Seal line

centre

Primer

8N

10N

Adhesive: 3M ATD Part No. 8609 Super Fast Urethane Auto Glass Sealant or equivalent and

3M ATD Part No. 8608 Super Fast Urethane Primer or equivalent

16 mm

A

A

B

B

Removal steps

•Roof drip moulding (Refer to GROUP

51, Moulding P.51-10.)

<> >>B<<1. Rear window lower moulding

2. Clip

3. Grommet A4. Grommet B

5. Grommet C

6. Connecting the harness connector<> >>A<<7. Rear window glass

>>A<<8. Rear window upper mouldingRemoval steps (Continued)

Page 295 of 788

Page 296 of 788

WINDOW GLASS

BODY42-18

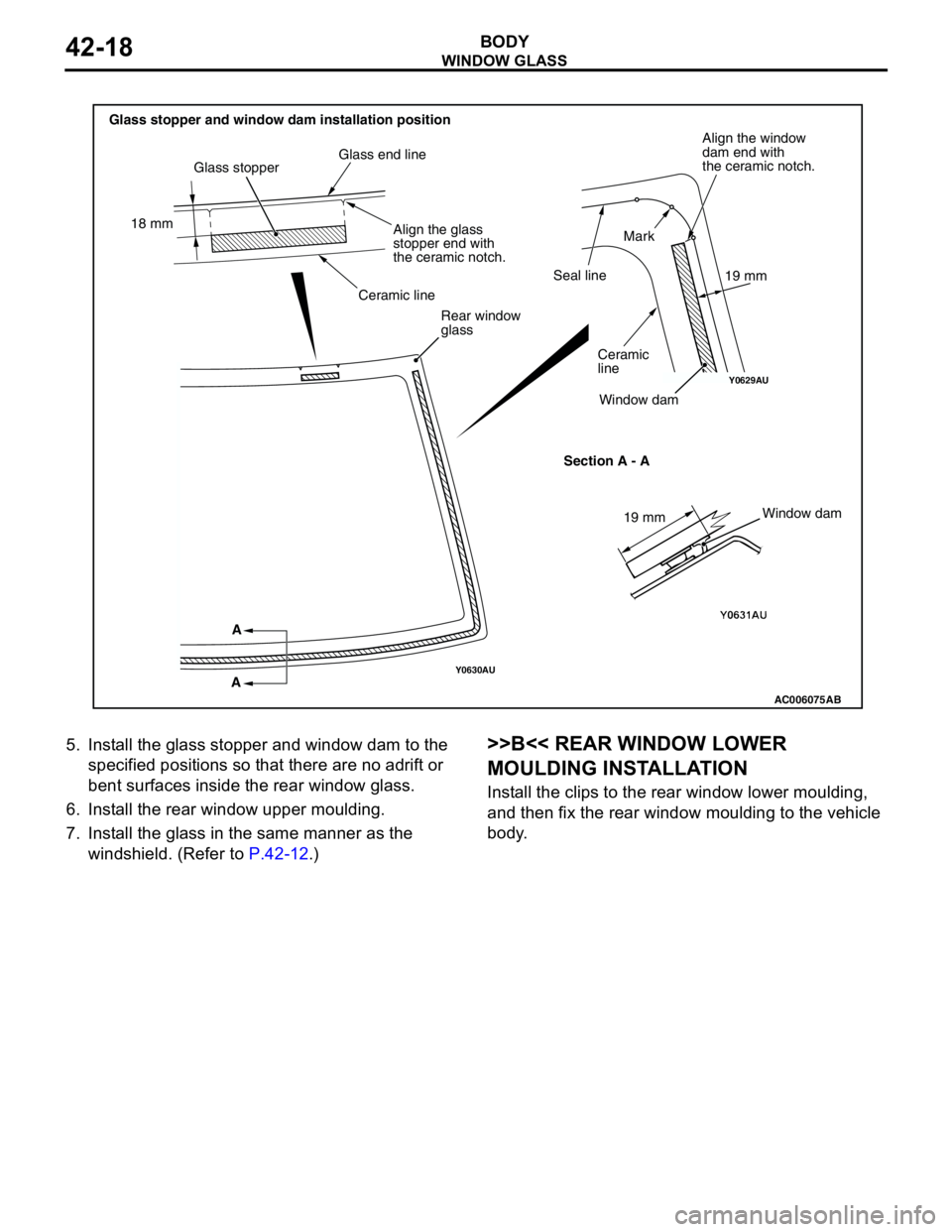

5. Install the glass stopper and window dam to the

specified positions so that there are no adrift or

bent surfaces inside the rear window glass.

6. Install the rear window upper moulding.

7. Install the glass in the same manner as the

windshield. (Refer to P.42-12.)>>B<< REAR WINDOW LOWER

MOULDING INSTALLATION

Install the clips to the rear window lower moulding,

and then fix the rear window moulding to the vehicle

body.

Y0630AU

Y0629AU

AC006075

Glass stopper and window dam installation position

Glass stopper

18 mm

Glass end line

Align the glass

stopper end with

the ceramic notch.

Ceramic line

Rear window

glass

A

ASection A - A

19 mmWindow dam Align the window

dam end with

the ceramic notch.

Mark

Seal line

Ceramic

line

Window dam

19 mm

AB

Page 297 of 788

WINDOW GLASS

BODY42-19

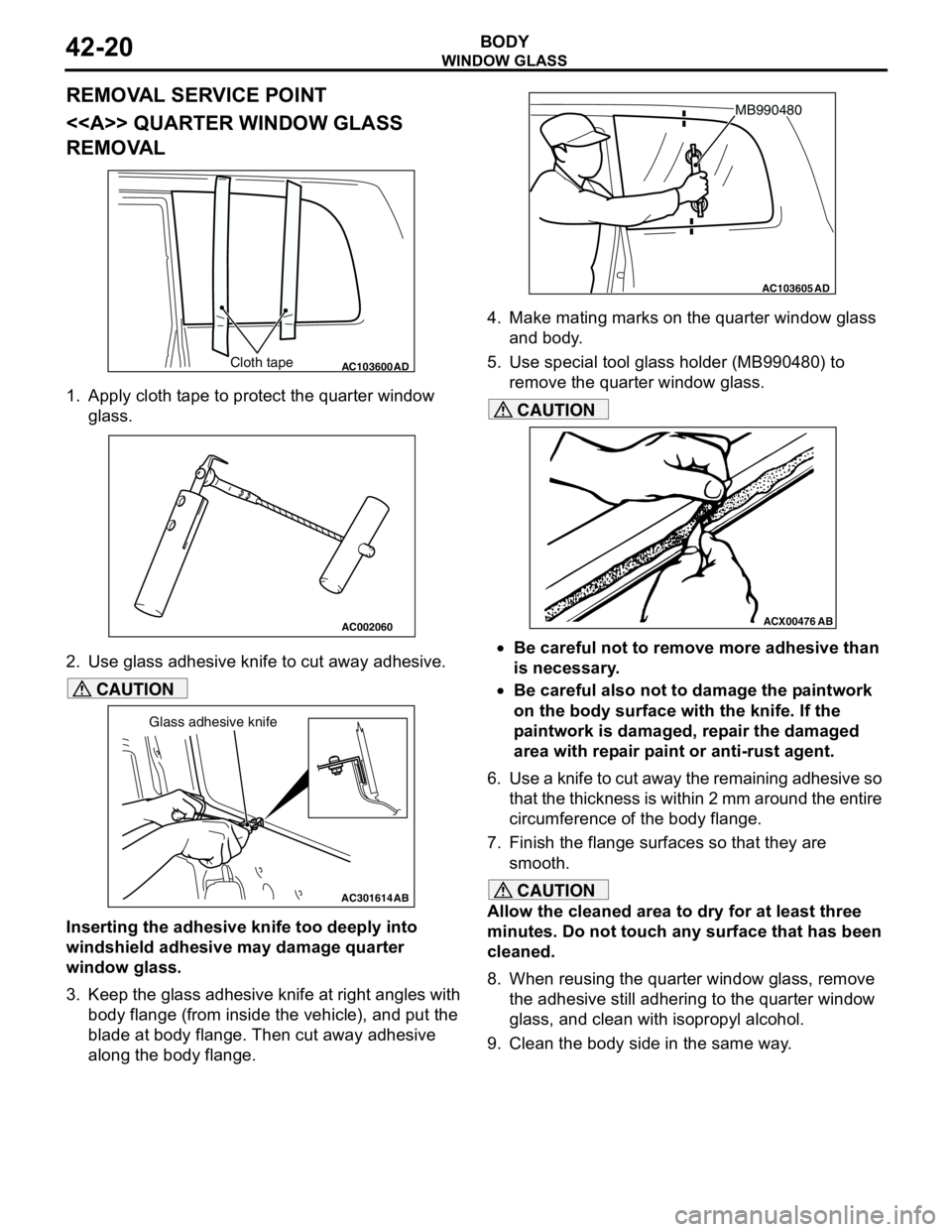

QUARTER WINDOW GLASS

REMOVAL AND INSTALLATIONM1422002500247

Pre-removal and Post-installation Operation

•Quarter Trim Upper Removal and Installation (Refer to

GROUP 52A, Trims P.52A-11).

AC304783

N

N

N

12

3

N3 4

AB

Y1509AU

Y1508AU

Y1507AU

Y1485AU

Y1535AU

AC304784

AAB B

DD

C

C

Mark

Apply the primer and adhesive

along the fictitious lines (seal line)

between each of the marks.

Adhesive: 3M ATD Part No. 8609 Super Fast Urethane Auto Glass Sealant or equivalent and

3M ATD Part No. 8608 Super Fast Urethane Primer or equivalent

1 11

Seal line centrePrimer Section A – A Section B – BSeal line

centre

Primer

Section C – C Section D – D

Seal line

centrePrimer

1Seal line

centre

Units: mm

Primer

16

161616

Ceramic line

AB

Removal steps

<> >>B<<1. Quarter window glass assembly

>>A<<2. Dual lock fastener

>>A<<3. Clip

>>A<<4. GasketRemoval steps (Continued)

Page 298 of 788

Page 299 of 788

WINDOW GLASS

BODY42-21

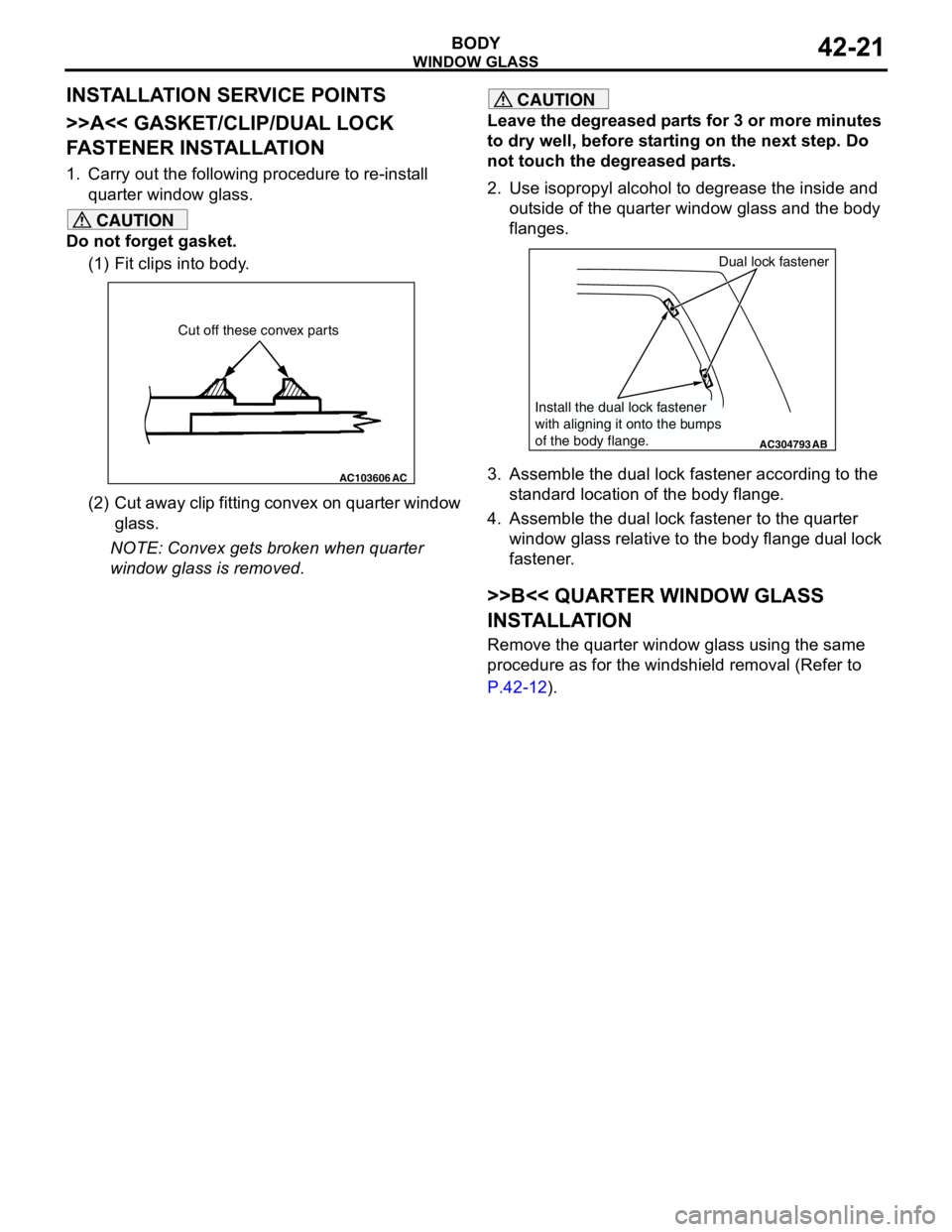

INSTALLATION SERVICE POINTS

>>A<< GASKET/CLIP/DUAL LOCK

FASTENER INSTALLATION

1. Carry out the following procedure to re-install

quarter window glass.

CAUTION

Do not forget gasket.

(1) Fit clips into body.

(2) Cut away clip fitting convex on quarter window

glass.

NOTE: Convex gets broken when quarter

window glass is removed.

CAUTION

Leave the degreased parts for 3 or more minutes

to dry well, before starting on the next step. Do

not touch the degreased parts.

2. Use isopropyl alcohol to degrease the inside and

outside of the quarter window glass and the body

flanges.

3. Assemble the dual lock fastener according to the

standard location of the body flange.

4. Assemble the dual lock fastener to the quarter

window glass relative to the body flange dual lock

fastener.

>>B<< QUARTER WINDOW GLASS

INSTALLATION

Remove the quarter window glass using the same

procedure as for the windshield removal (Refer to

P.42-12).

AC103606

AC

Cut off these convex parts

AC304793AB

Dual lock fastener

Install the dual lock fastener

with aligning it onto the bumps

of the body flange.

Page 300 of 788

WINDOW GLASS

BODY42-22

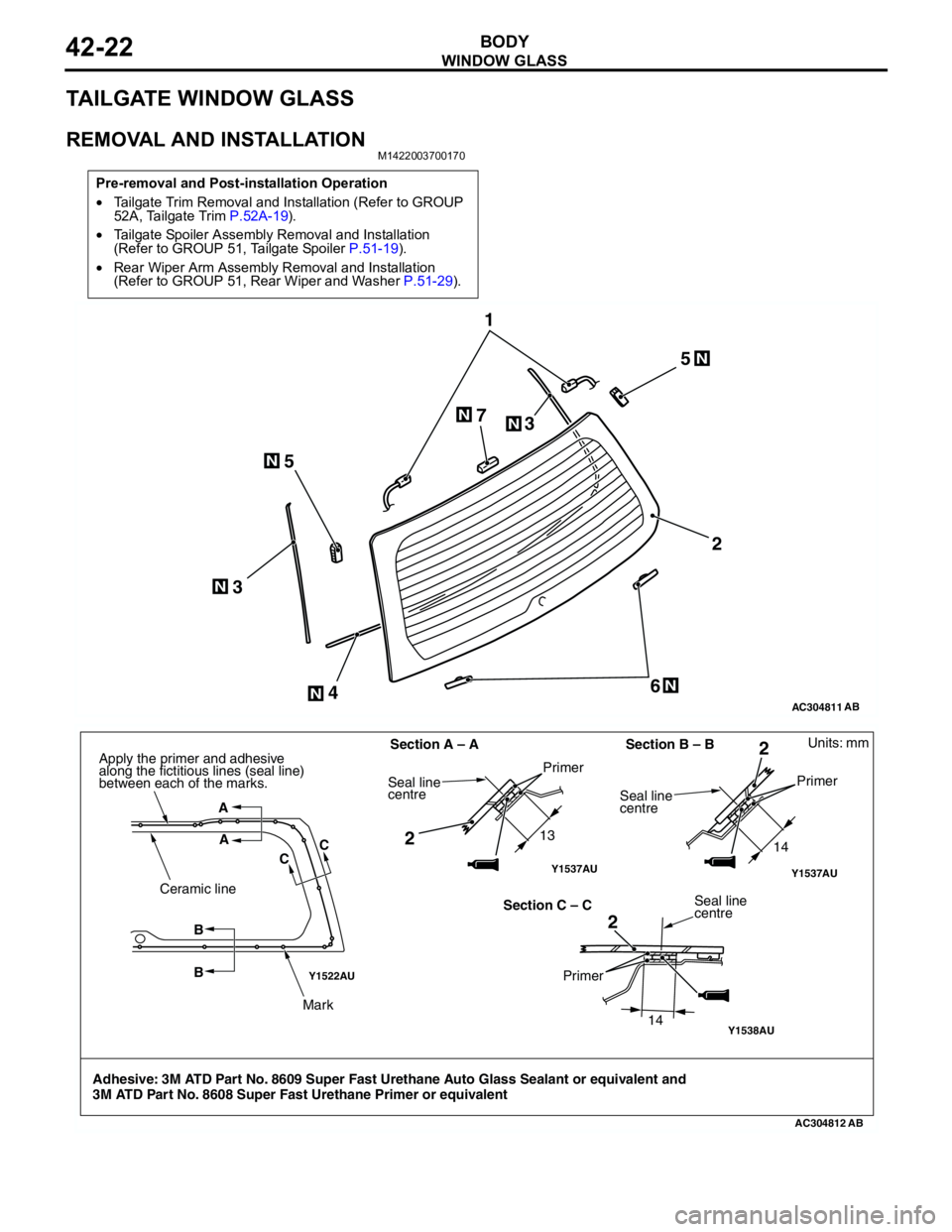

TAILGATE WINDOW GLASS

REMOVAL AND INSTALLATIONM1422003700170

Pre-removal and Post-installation Operation

•Tailgate Trim Removal and Installation (Refer to GROUP

52A, Tailgate Trim P.52A-19).

•Tailgate Spoiler Assembly Removal and Installation

(Refer to GROUP 51, Tailgate Spoiler P.51-19).

•Rear Wiper Arm Assembly Removal and Installation

(Refer to GROUP 51, Rear Wiper and Washer P.51-29).

AC304811

1

2

6 55

4 33 7

AB

N

NN

N

N

N

N

Y1522AU

Y1538AU

AC304812

Y1537AUY1537AU

AB

Units: mm

Adhesive: 3M ATD Part No. 8609 Super Fast Urethane Auto Glass Sealant or equivalent and

3M ATD Part No. 8608 Super Fast Urethane Primer or equivalentSection A – A

13

14

14 Section B – B

Section C – C A

A

CC

B

B Ceramic line

Mark Apply the primer and adhesive

along the fictitious lines (seal line)

between each of the marks.

Seal line

centrePrimer

Seal line

centrePrimer

Seal line

centre

Primer

22

2