ron MITSUBISHI LANCER 2006 Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 243 of 800

ON-VEHICLE SERVICE

POWER STEERING37-13

STEERING WHEEL RETURN TO CENTRE

CHECK

M1372001800317

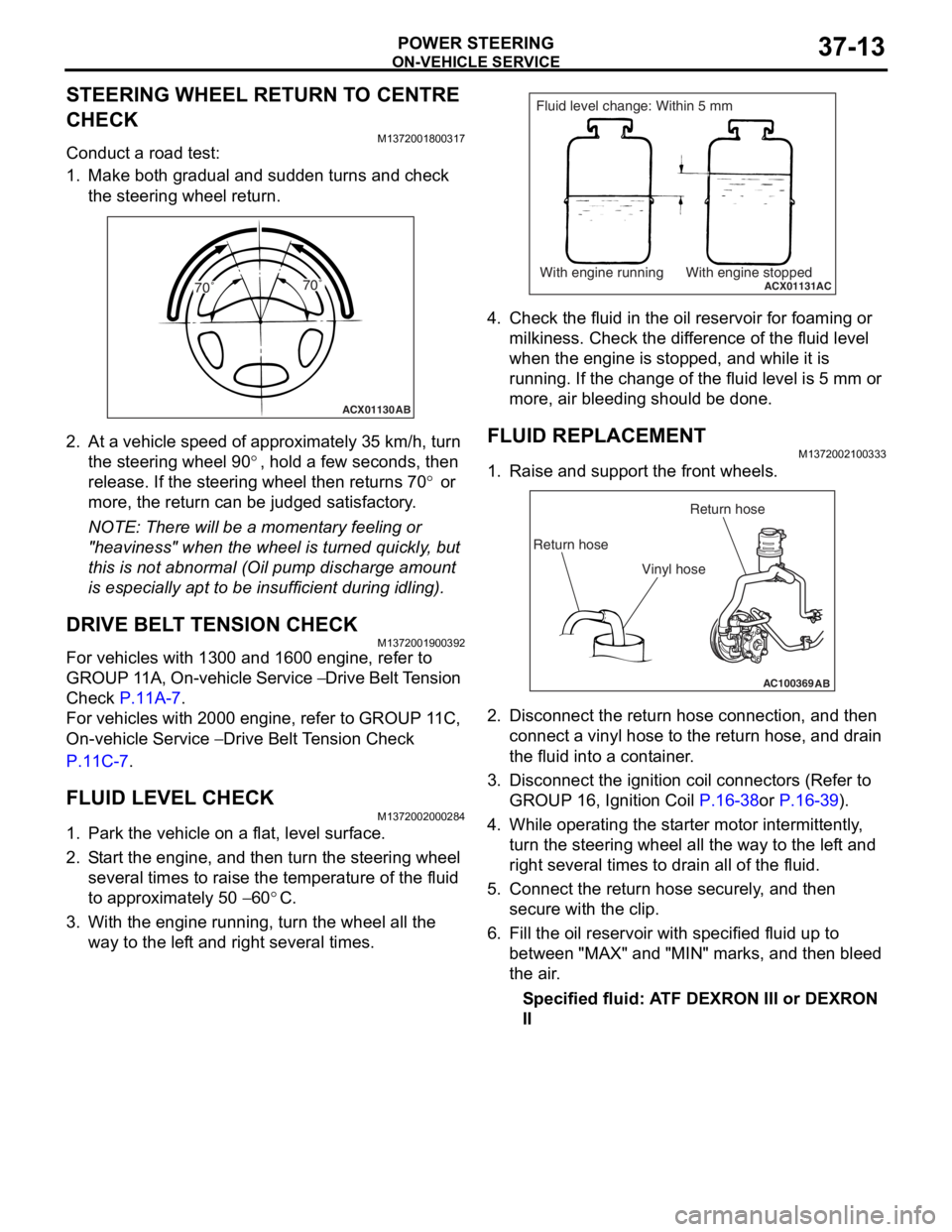

Conduct a road test:

1. Make both gradual and sudden turns and check the steering wheel return.

ACX01130 AB

70˚ 70˚

2.

At a vehicle sp eed of a pproxima t ely 35 km/h, turn

th e ste e ring wh eel 9 0

°, ho ld a few se cond s, the n

release. If th

e ste

e

ring

wh eel t hen ret u rns 7 0

° or

more, th

e return

can

be ju

dged satisfactory

.

NOTE: There will be a mome nt a r y fee lin g or

"he

a

viness" when t he wheel is turned quickly , but

th

is is n o t abno rmal (Oil pu mp discharge amou nt

is especially a p t to b e insufficie n t during id lin g).

DRIVE BELT TENSION CHECK

M13720019 0039 2

For vehicles with 13 00 and 1600 engin e , refer to

GROUP 1

1 A, On-vehicle Service

− Drive Belt T ension

Che

c

k

P.11A-7.

For veh i cles wit h 2000 e ngin e , refer to GROUP 1 1 C,

On-vehicle Se

rvice

− Drive Belt Te nsion Check

P.1 1 C - 7.

FLUID LEVEL CHECK

M13720020 0028 4

1.Park the vehicle on a f l at, leve l su rface .

2.S t art the engine, and t hen tu rn the ste e ring wheel

seve ral times to raise the temperat ure of th e flu i d

to approximately 50

− 60°C.

3.With the engine run n ing, turn the wheel all the

way to the lef t an d righ t several times.

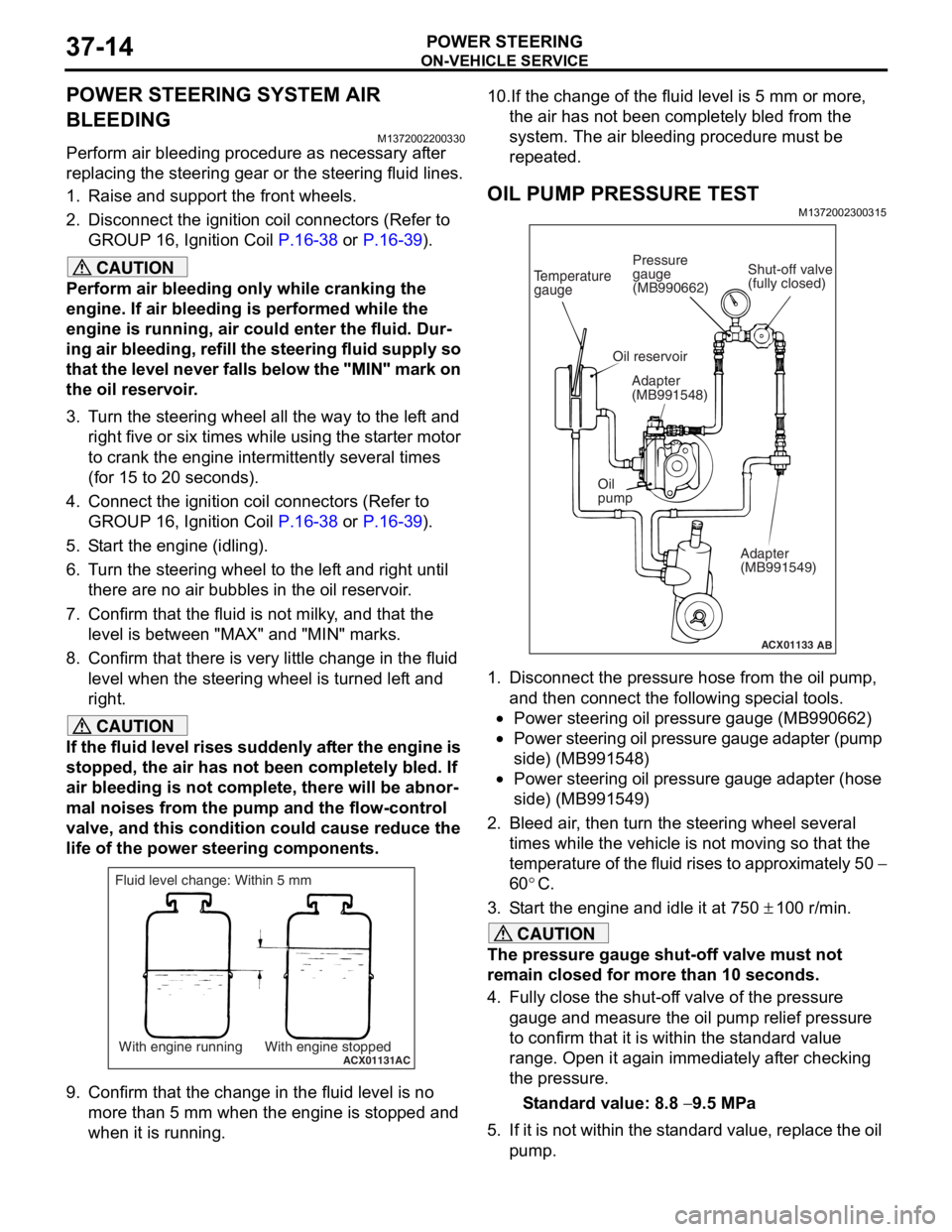

ACX01131With engine running With engine stoppedAC

Fluid level change: Within 5 mm

4.Check t he flu i d in the oil r e servoir f o r foaming or

milkine s s. Check the d i f f e r ence of the fluid le vel

when the e ngine is stop ped, an d while it is

ru nning . If the chan ge of th e fluid le vel is 5 mm or

more, a i r bleedin g sh ould be don e.

FLUID REPLACEMENT

M13720021 0033 3

1.Raise a nd su pport t he fron t wheels.

AC100369AB

Return hoseReturn hose

Vinyl hose

2. Disco nnect the re turn hose connection , and then

conne ct a vinyl hose to the re turn h o se, and drain

th e flu i d into a cont ain e r .

3.Disco nnect the ignition coil con necto rs (Refe r to

GROUP 16, Ignition Coil

P.16-38or P.16-39).

4.Wh ile operat ing th e st arter moto r inter m itt ently ,

tu rn the steering whee l all the wa y to t he le f t a nd

right seve ral times to dra i n all of the fluid.

5.Conn ect the retu rn hose se curely , and then

secu re with t he clip.

6.Fill the oil reservo i r with specified fluid u p to

b e tween "MAX" and "MIN" marks, and then bleed

th e air .

Specified fluid: A TF DEXRON III or DEXRON

II

Page 244 of 800

ON-VEHICLE SERVICE

POWER STEERING37-14

POWER STEERING SYSTEM AIR

BLEEDING

M1372002200330

Perform air bleeding procedure as necessary after

replacing the steering gear or the steering fluid lines.

1. Raise and support the front wheels.

2. Disconnect the ignition coil connectors (Refer to GROUP 16, Ignition Coil

P.16-38 or P.16-39).

CAUTION

Perform air bleeding only while cranking the

engine. If air bleeding is performed while the

engine is running, air could enter the fluid. Dur

-

ing air bleeding, refill the steering fluid supply so

that the level never falls below the "MIN" mark on

the oil reservoir.

3. Turn the steering wheel all the way to the left and

right five or six times wh ile using the starter motor

to crank the engine intermittently several times

(for 15 to 20 seconds).

4. Connect the ignition coil connectors (Refer to GROUP 16, Ignition Coil

P.16-38 or P.16-39).

5. Start the engine (idling).

6. Turn the steering wheel to the left and right until there are no air bubbles in the oil reservoir.

7. Confirm that the fluid is not milky, and that the level is between "MAX" and "MIN" marks.

8. Confirm that there is very little change in the fluid

level when the steering wheel is turned left and

right.

CAUTION

If the fluid level rises suddenly after the engine is

stopped, the air has not been completely bled. If

air bleeding is not complete, there will be abnor

-

mal noises from the pump and the flow-control

valve, and this condition could cause reduce the

life of the power steering components.

ACX01131With engine running With engine stoppedAC

Fluid level change: Within 5 mm

9. Confirm that the change in the fluid level is no more than 5 mm when the engine is stopped and

when it is running.

10.If the change of the fluid level is 5 mm or more,

the air has not been completely bled from the

system. The air bleeding procedure must be

repeated.

OIL PUMP PRESSURE TEST

M1372002300315

ACX01133

Temperature

gauge

Oil reservoir

Adapter

(MB991548)

Oil

pump Adapter

(MB991549)

AB

Shut-off valve

(fully closed)

Pressure

gauge

(MB990662)

1. Disconnect the pressure hose from the oil pump,

and then connect the following special tools.

•Power steering oil pressure gauge (MB990662)

•Power steering oil pressure gauge adapter (pump

side) (MB991548)

•Power steering oil pressure gauge adapter (hose

side) (MB991549)

2. Bleed air, then turn the steering wheel several times while the vehicle is not moving so that the

temperature of the fluid rises to approximately 50

−

60

°C.

3. Start the engine and idle it at 750 ± 100 r/min.

CAUTION

The pressure gauge shut-off valve must not

remain closed for more than 10 seconds.

4. Fully close the shut-off valve of the pressure gauge and measure the oil pump relief pressure

to confirm that it is within the standard value

range. Open it again immediately after checking

the pressure.

Standard value: 8.8 − 9.5 MPa

5. If it is not within the standard value, replace the oil pump.

Page 251 of 800

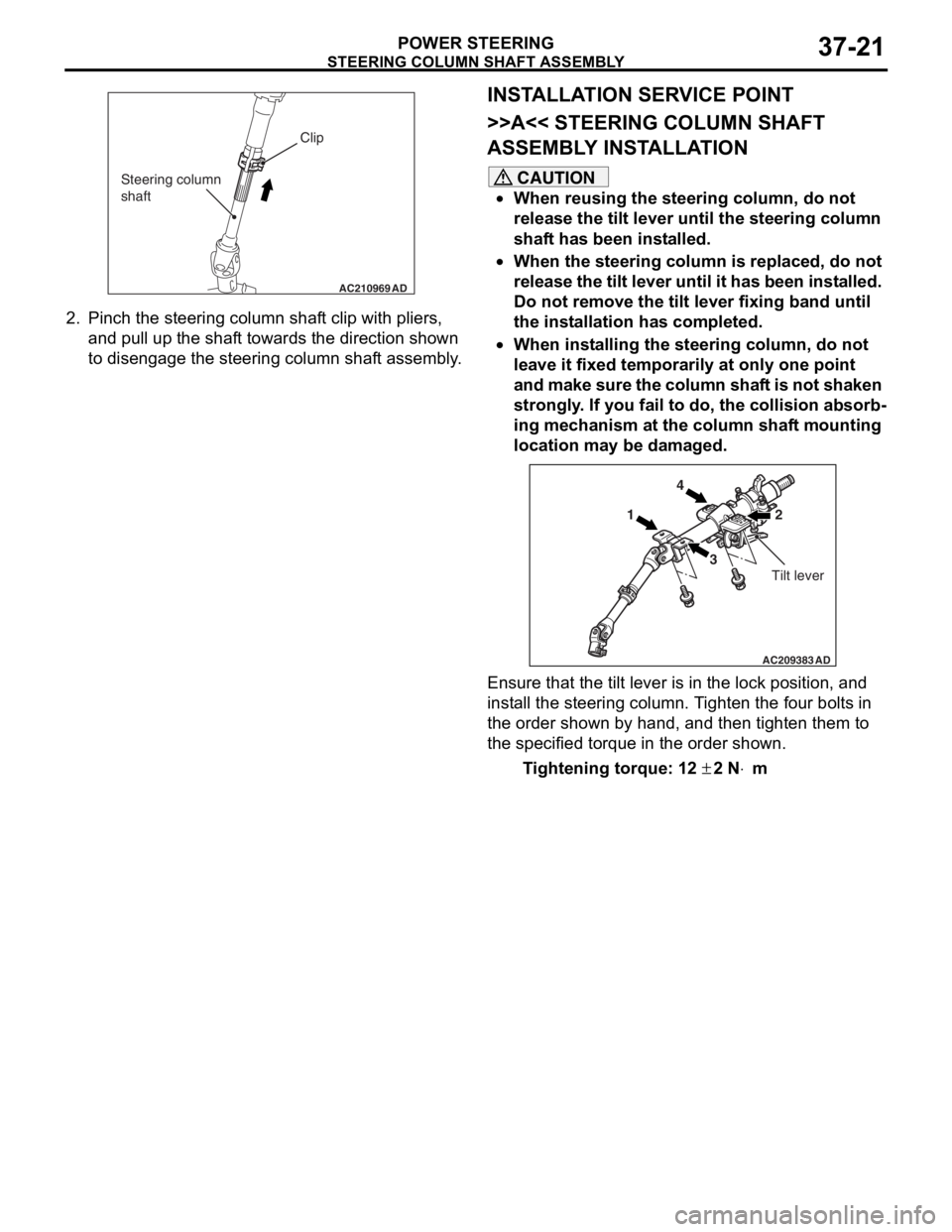

AC210969AD

Clip

Steering column

shaft

STE E RING C O LUMN SHAFT AS SEMBL Y

POWER STEERING37-21

2.Pin c h t he st eering column shaf t clip with pliers,

an d pull up the shaf t towards the d i rection shown

to disengag e the steering column shaf t assembly .

INSTALLA T ION SER VICE POINT

>>A<< STEERING COLUMN SHAFT

ASSEMBL

Y INST ALLA TION

CAUTION

•When reusing the steering column, do not

release the tilt lever until the steering column

shaft has been installed.

•When the steering column is replaced, do not

release the tilt lever until it has been installed.

Do not remove the tilt lever fixing band until

the installation has completed.

•When installing the steering column, do not

leave it fixed temporarily at only one point

and make sure the column shaft is not shaken

strongly. If you fail to do, the collision absorb

-

ing mechanism at the column shaft mounting

location may be damaged.

AC209383AD

14

3 2

Tilt lever

Ensure that the tilt lever is in the lock position, and

install the steering column. Tighten the four bolts in

the order shown by hand, and then tighten them to

the specified torque in the order shown.

Tightening torque: 12 ± 2 N⋅m

Page 253 of 800

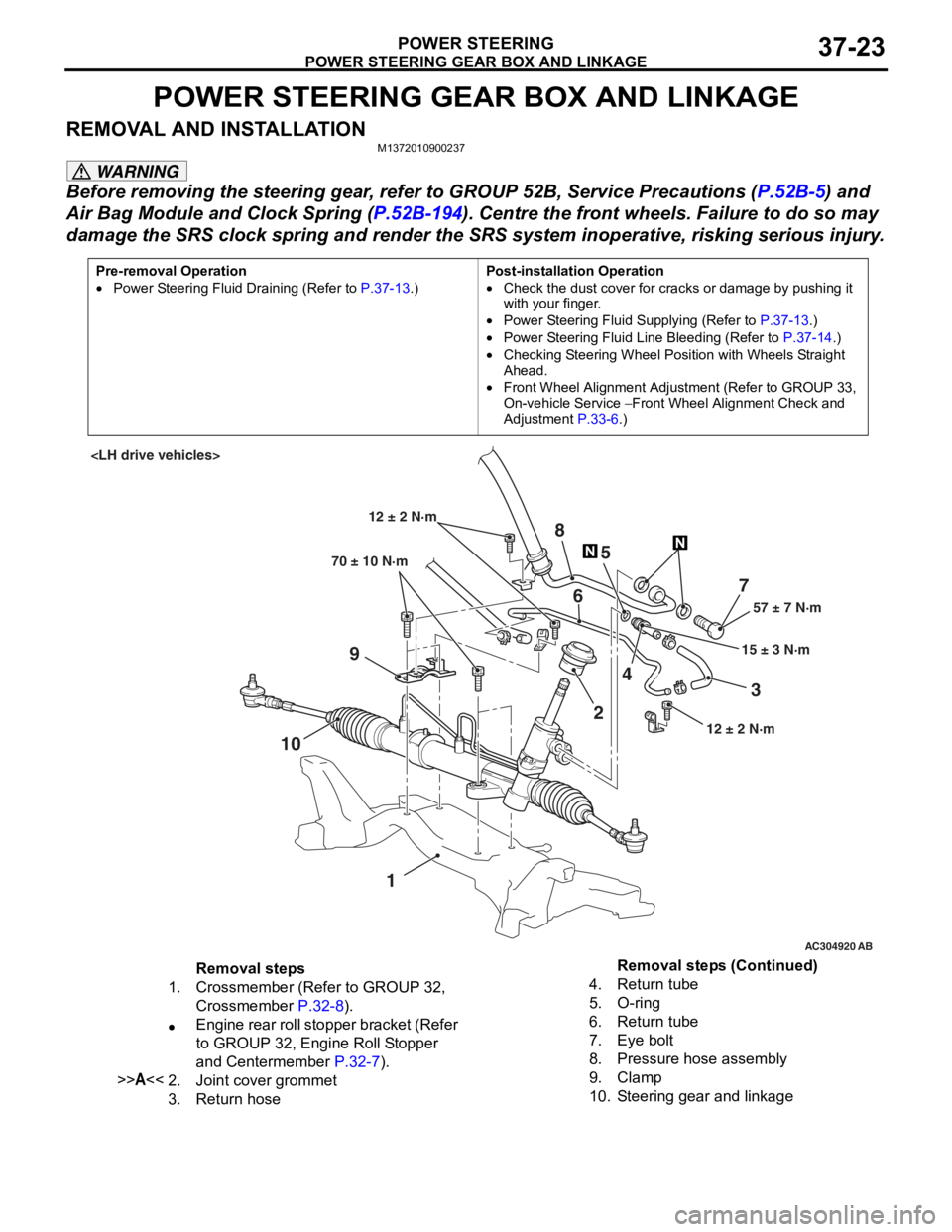

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-23

POWER STEERING GEAR BOX AND LINKAGE

REMOVAL AND INSTALLATIONM1372010900237

WARNING

Before removing the steering gear, refer to GROUP 52B, Service Precautions (P.52B-5) and

Air Bag Module and Clock Spring (P.52B-194). Centre the front wheels. Failure to do so may

damage the SRS clock spring and render the SRS system inoperative, risking serious injury.

Pre-removal Operation

•Power Steering Fluid Draining (Refer to P.37-13.)

Post-installation Operation

•Check the dust cover for cracks or damage by pushing it

with your finger.

•Power Steering Fluid Supplying (Refer to P.37-13.)

•Power Steering Fluid Line Bleeding (Refer to P.37-14.)

•Checking Steering Wheel Position with Wheels Straight

Ahead.

•Front Wheel Alignment Adjustment (Refer to GROUP 33,

On-vehicle Service

− Front Wheel Alignment Check and

Adjustment

P.33-6.)

AC304920 AB

57 ± 7 N·m

15 ± 3 N·m

70 ± 10 N·m

7

3

8

5

6

9

10 24

1

12 ± 2 N·m

12 ± 2 N·m

Removal steps

1.Crossmember (Refer to GROUP 32,

Crossmember

P.32-8).

•Engine rear roll stopper bracket (Refer

to GROUP 32, Engine Roll Stopper

and Centermember

P.32-7).

>>A<<2.Joint cover grommet

3.Return hose

4.Return tube

5.O-ring

6.Return tube

7.Eye bolt

8.Pressure hose assembly

9.Clamp

10.Steering gear and linkage

Removal steps (Continued)

Page 258 of 800

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-28

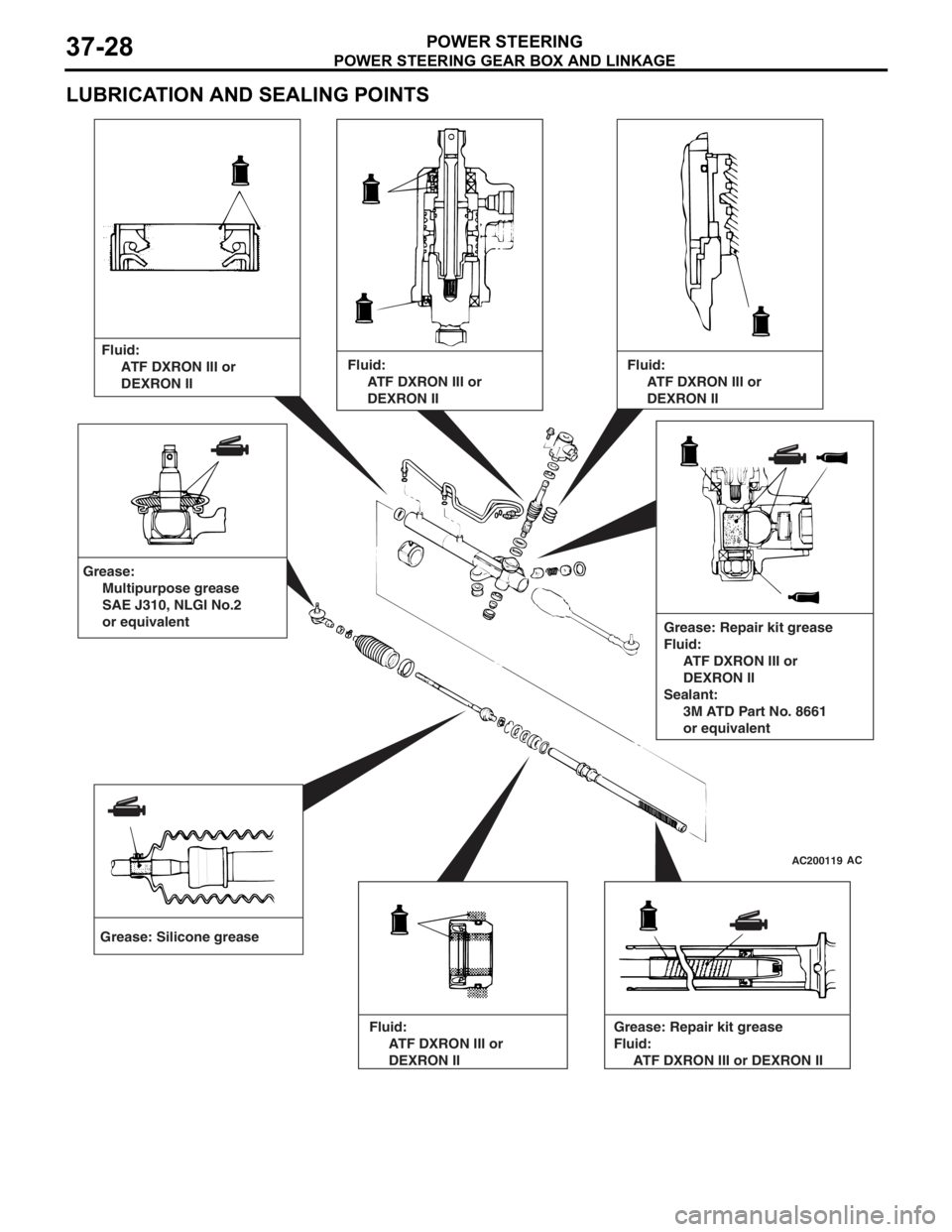

LUBRICATION AND SEALING POINTS

AC200119AC

Grease: Silicone greaseFluid:

ATF DXRON III or

DEXRON II

Grease: Repair kit grease

Fluid:

ATF DXRON III or

DEXRON II

Sealant:

3M ATD Part No. 8661

or equivalent

Grease:

Multipurpose grease

SAE J310, NLGI No.2

or equivalent

Fluid:

ATF DXRON III or

DEXRON II

Fluid:

ATF DXRON III or

DEXRON II

Fluid:

ATF DXRON III or

DEXRON II Grease: Repair kit grease

Fluid:

ATF DXRON III or DEXRON II

Page 260 of 800

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-30

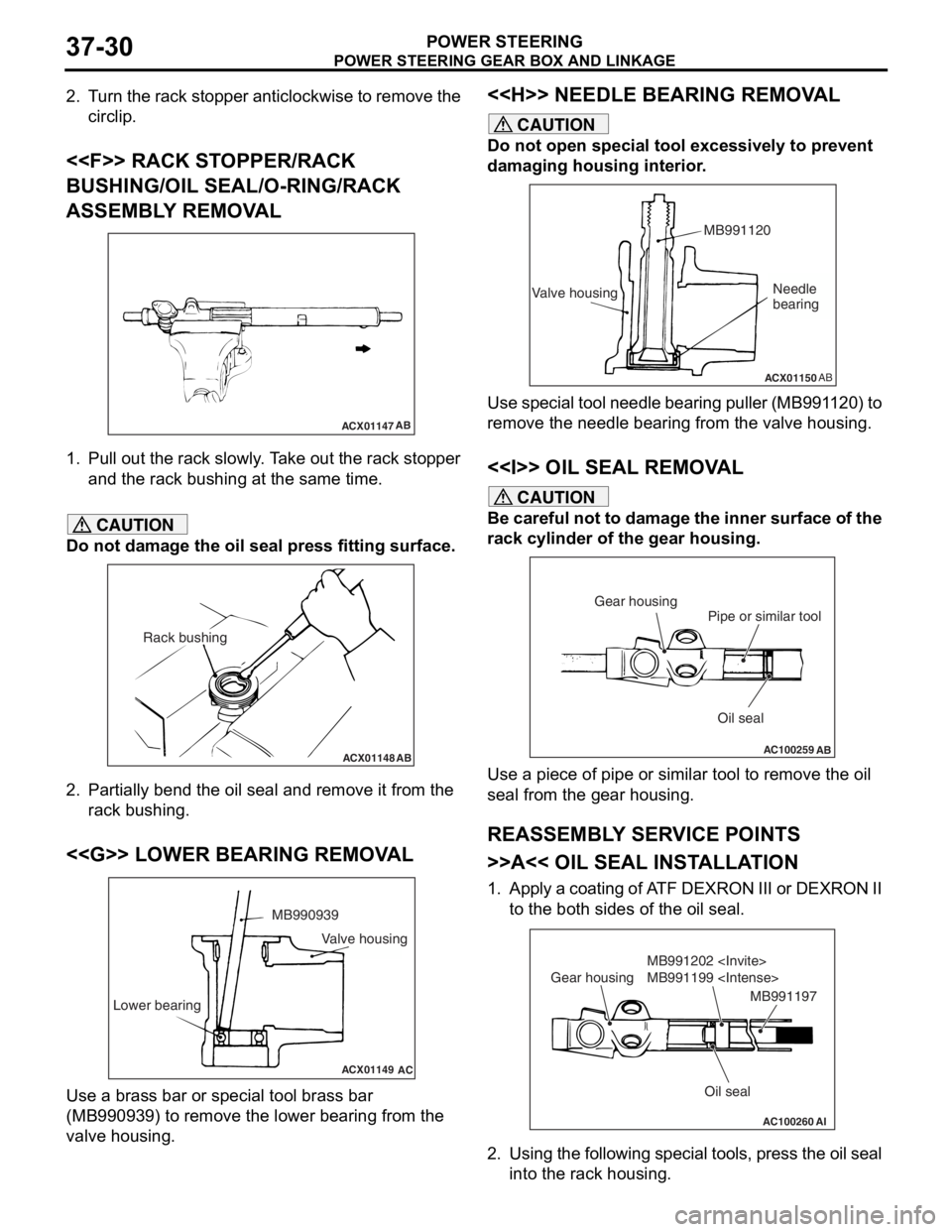

2. Turn the rack stopper anticlockwise to remove the circlip.

<

BUSHING/OIL SEAL/O-RING/RACK

ASSEMBLY REMOVAL

ACX01147 AB

1.

Pull out th e rack slo w ly . T a ke out th e rack stop per

an d the rack bushing at the same time.

CAUTION

Do not damage the oil seal press fitting surface.

ACX01148AB

Rack bushing

2. Partially bend the oil seal and remove it from the

rack bushing.

<

ACX01149

MB990939

Lower bearing

AC

Valve housing

Use a brass bar or special tool brass bar

(MB990939) to remove the lower bearing from the

valve housing.

<

CAUTION

Do not open special tool excessively to prevent

damaging housing interior.

ACX01150 AB

Valve housing MB991120Needle

bearing

Use special tool needle bearing puller (MB991120) to

remove the needle bearing from the valve housing.

<> OIL SEAL REMOVAL

CAUTION

Be careful not to damage the inner surface of the

rack cylinder of the gear housing.

AC100259

Oil seal

Pipe or similar tool

Gear housing

AB

Use a piece of pipe or simila

r tool to remove the oil

seal from the gear housing.

REASSEMBLY SERVICE POINTS

>>A<< OIL SEAL INSTALLATION

1. Apply a coating of ATF DEXRON III or DEXRON II to the both sides of the oil seal.

AC100260AI

Oil seal

MB991202

MB991199

Gear housing

MB991197

2. Using the following special tools, press the oil seal

into the rack housing.

Page 261 of 800

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-31

•Bar (long type) (MB991197)

•Oil seal installer (MB991199)

•Oil seal and bearing installer (MB991202)

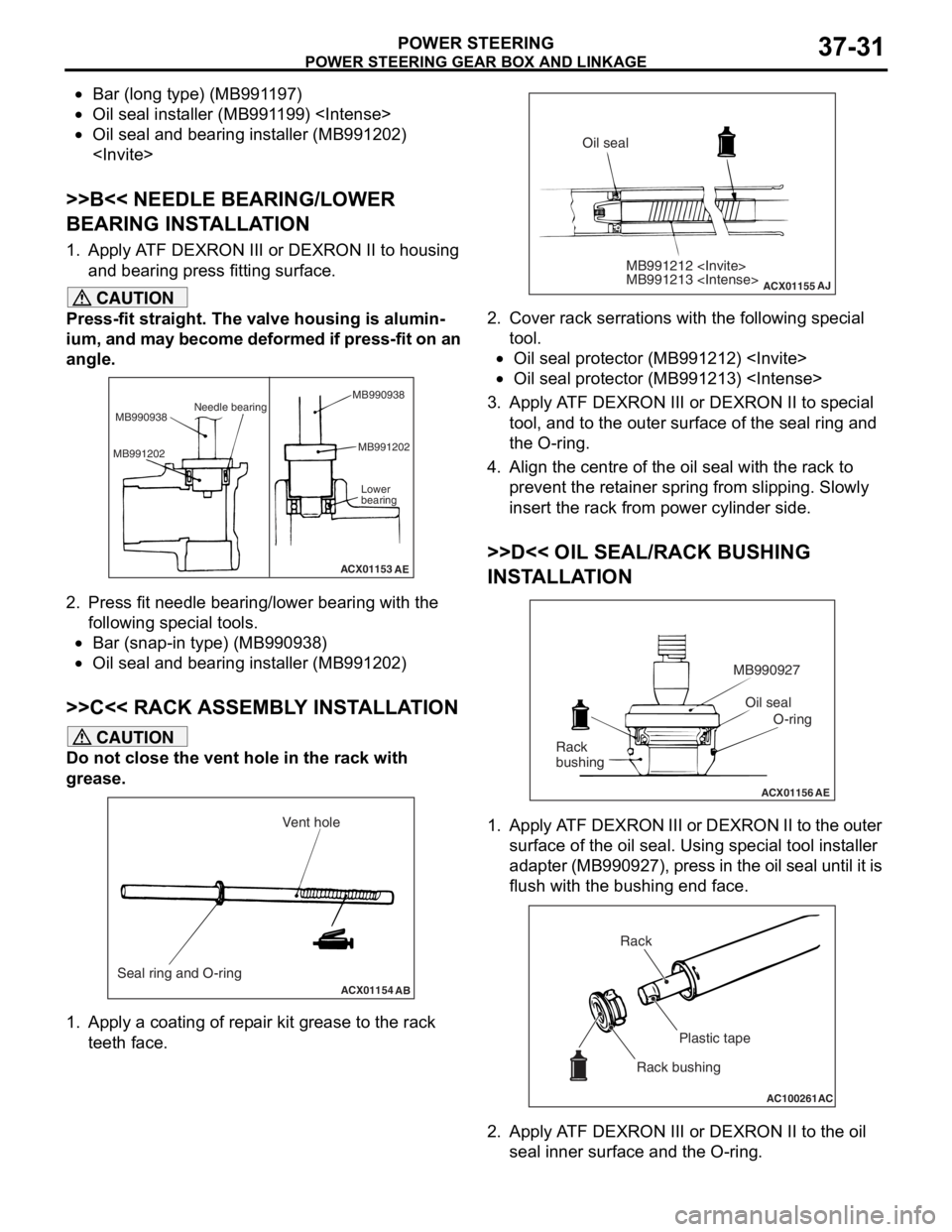

>>B<< NEEDLE BEARING/LOWER

BEARING INSTALLATION

1. Apply ATF DEXRON III or DEXRON II to housing and bearing press fitting surface.

CAUTION

Press-fit straight. The valve housing is alumin-

ium, and may become deformed if press-fit on an

angle.

ACX01153

Needle bearing

MB990938

MB991202 MB991202

Lower

bearing

AE

MB990938

2. Press fit needle bearing/lower bearing with the

following special tools.

•Bar (snap-in type) (MB990938)

•Oil seal and bearing installer (MB991202)

>>C<< RACK ASSEMBLY INSTALLATION

CAUTION

Do not close the vent hole in the rack with

grease.

ACX01154 AB

Seal ring and O-ring Vent hole

1. Apply a coating of repair kit grease to the rack

teeth face.

ACX01155

MB991212

MB991213

AJ

Oil seal

2. Cover rack serrations with the following special tool.

•Oil seal protector (MB991212)

•Oil seal protector (MB991213)

3. Apply ATF DEXRON III or DEXRON II to special

tool, and to the outer surface of the seal ring and

the O-ring.

4. Align the centre of the oil seal with the rack to prevent the retainer spring from slipping. Slowly

insert the rack from power cylinder side.

>>D<< OIL SEAL/RACK BUSHING

INSTALLATION

ACX01156 AE

Oil seal

O-ring

MB990927

Rack

bushing

1. Apply ATF DEXRON III or DEXRON II to the outer surface of the oil seal. Using special tool installer

adapter (MB990927), press in the oil seal until it is

flush with the bushing end face.

AC100261 AC

Rack

Plastic tape

Rack bushing

2. Apply ATF DEXRON III or DEXRON II to the oil seal inner surface and the O-ring.

Page 262 of 800

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-32

3. Wrap the rack end with plastic tape, and push the rack bushing onto the rack.

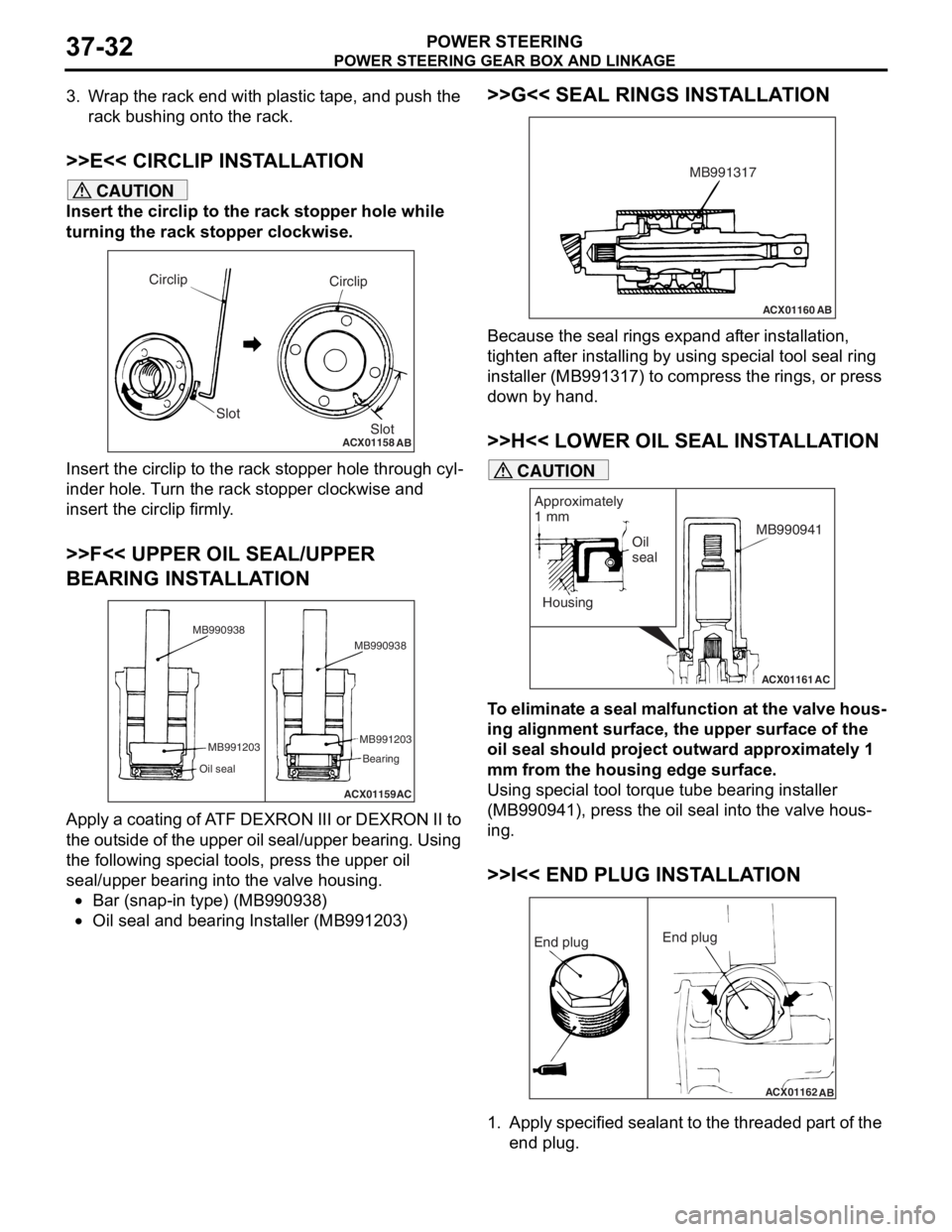

>>E<< CIRCLIP INSTALLATION

CAUTION

Insert the circlip to the rack stopper hole while

turning the rack stopper clockwise.

ACX01158

Circlip

Slot

AB

Circlip

Slot

Insert the circlip to the rack stopper hole through cyl-

inder hole. Turn the rack stopper clockwise and

insert the circlip firmly.

>>F<< UPPER OIL SEAL/UPPER

BEARING INSTALLATION

ACX01159AC

MB990938

MB991203

Oil seal

MB991203 Bearing

MB990938

Apply a coating of ATF DEXRON III or DEXRON II to

the outside of the upper oil seal/upper bearing. Using

the following special tools, press the upper oil

seal/upper bearing into the valve housing.

•Bar (snap-in type) (MB990938)

•Oil seal and bearing Installer (MB991203)

>>G<< SEAL RINGS INSTALLATION

ACX01160

AB

MB991317

Because the seal rings expand after installation,

tighten after installing by using special tool seal ring

installer (MB991317) to compress the rings, or press

down by hand.

>>H<< LOWER OIL SEAL INSTALLATION

ACX01161

Housing

AC

Oil

seal

Approximately

1 mm

MB990941

CAUTION

To eliminate a seal malfunction at the valve hous-

ing alignment surface, the upper surface of the

oil seal should project outward approximately 1

mm from the housing edge surface.

Using special tool torque tube bearing installer

(MB990941), press the oil seal into the valve hous

-

ing.

>>I<< END PLUG INSTALLATION

ACX01162

AB

End plug End plug

1. Apply specified sealant to the threaded part of the

end plug.

Page 267 of 800

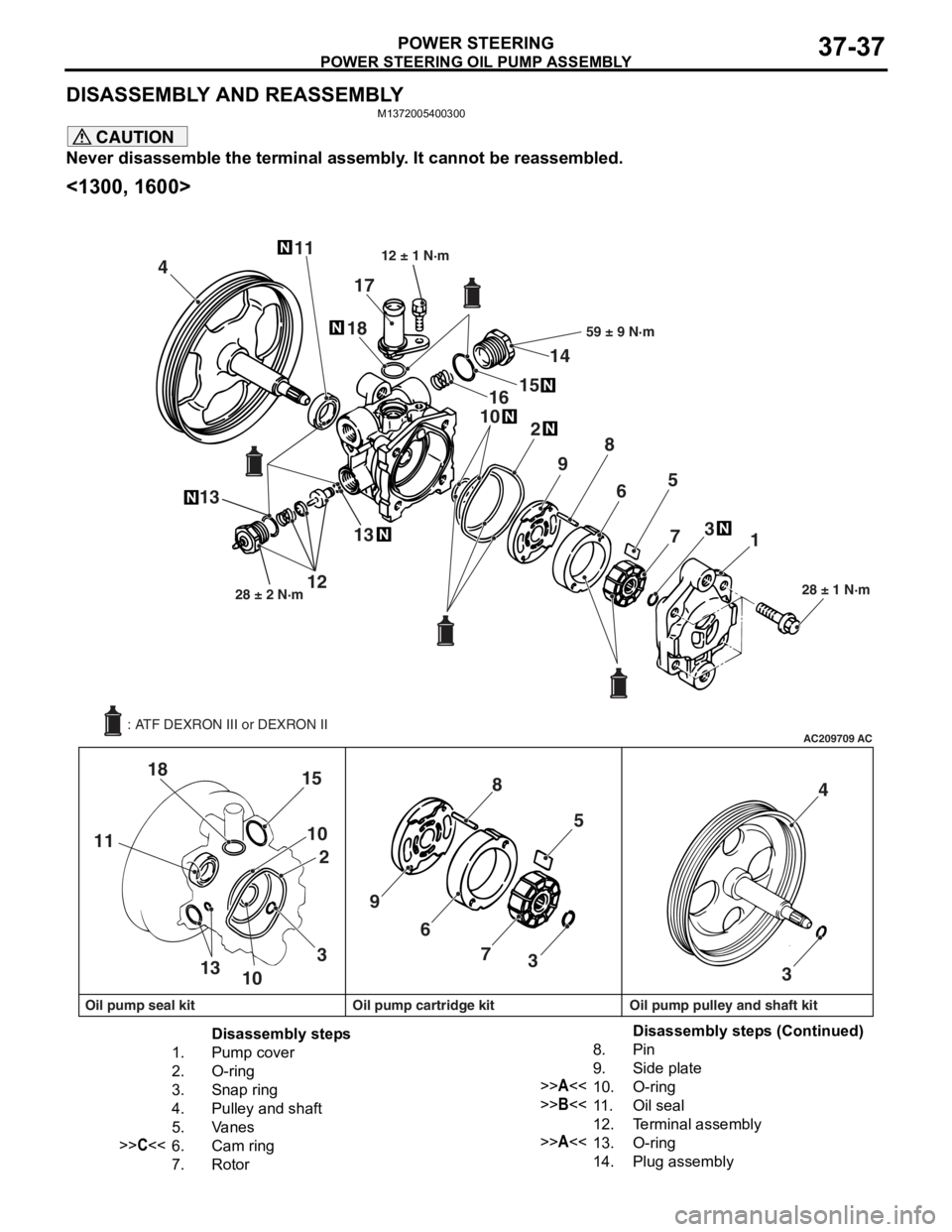

POWER STEERING OIL PUMP ASSEMBLY

POWER STEERING37-37

DISASSEMBLY AND REASSEMBLY

M1372005400300

CAUTION

Never disassemble the terminal assembly. It cannot be reassembled.

<1300, 1600>

AC209709AC

411

13 18

102

9 8

6 5

7 3

1

18 15

10 2

11

1310 39 8

6 5

7 3 4

3

28 ± 1 N·m

16 1514

59 ± 9 N·m

1228 ± 2 N·m

17

12 ± 1 N·m

13

Oil pump seal kit Oil pump cartridge kit Oil pump pulley and shaft kit : ATF DEXRON III or DEXRON II

Disassembly steps

1.Pump cover

2.O-ring

3.Snap ring

4.Pulley and shaft

5.Va n e s

>>C<<6.Cam ring

7.Rotor

8.Pin

9.Side plate

>>A<<10.O-ring

>>B<<11 .Oil seal

12.Terminal assembly

>>A<<13.O-ring

14.Plug assembly

Disassembly steps (Continued)

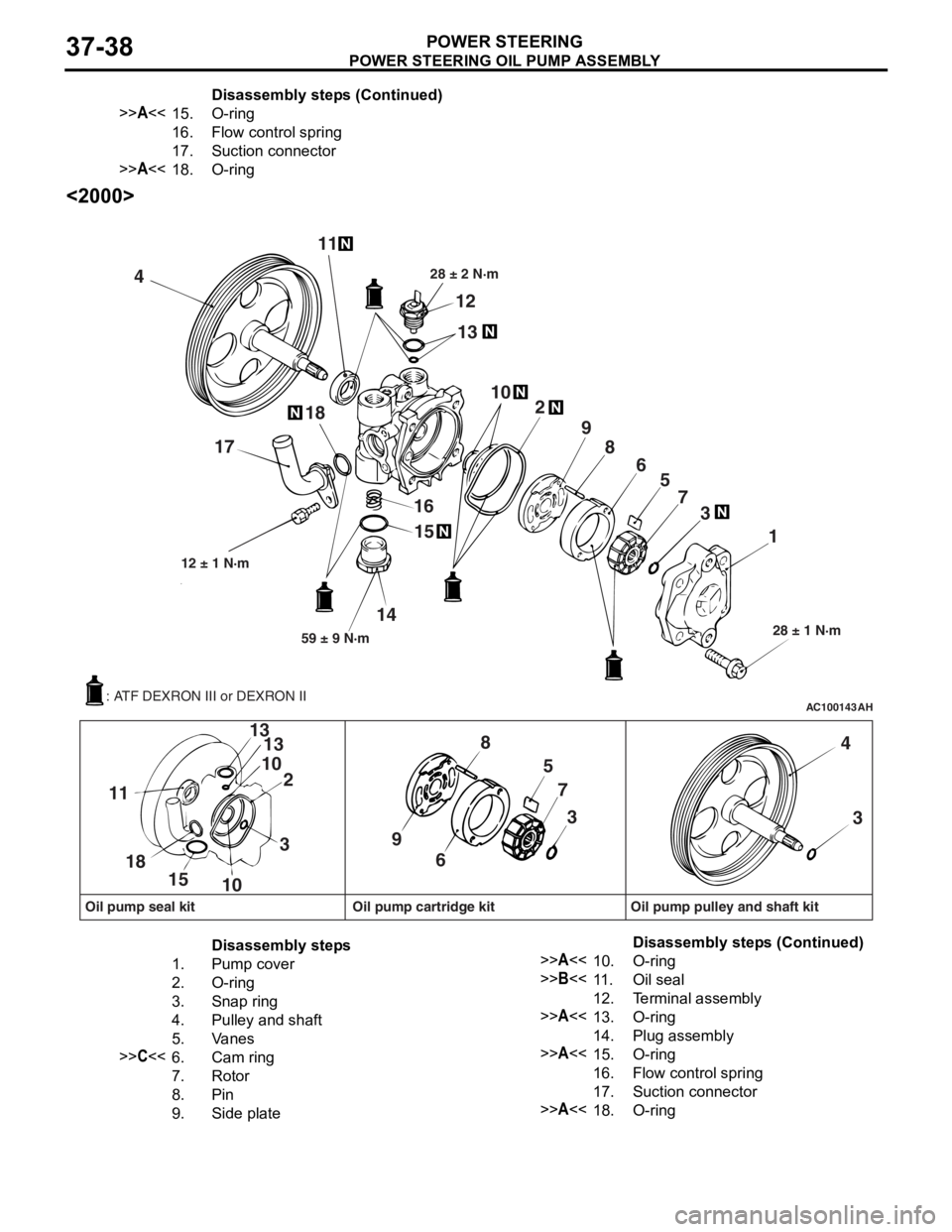

Page 268 of 800

POWER STEERING OIL PUMP ASSEMBLY

POWER STEERING37-38

<2000>

AC100143AH

4 11

12

13

28 ± 2 N·m

102

9 8 65

7 3

1

28 ± 1 N·m

15

16

14

59 ± 9 N·m

12 ± 1 N·m

18

17

57

3

9 8

6

3

13

10 2

13

10

15

18

11

4

3

Oil pump seal kit Oil pump cartridge kit Oil pump pulley and shaft kit

: ATF DEXRON III or DEXRON II

Disassembly steps

1.Pump cover

2.O-ring

3.Snap ring

4.Pulley and shaft

5.Va n e s

>>C<<6.Cam ring

7.Rotor

8.Pin

9.Side plate

>>A<<10.O-ring

>>B<<11 .Oil seal

12.Terminal assembly

>>A<<13.O-ring

14.Plug assembly

>>A<<15.O-ring

16.Flow control spring

17.Suction connector

>>A<<18.O-ring

>>A<<15.O- rin g

16.Fl ow co n t ro l s p r i ng

17.Suction connector

>>A<<18.O-rin g

Disass embly st ep s ( C ont inu e d)

Disassembly steps (Continued)