ron MITSUBISHI LANCER 2006 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 204 of 800

ON-VEHICLE SERVICE

REAR SUSPENSION34-6

ON-VEHICLE SERVICE

REAR WHEEL ALIGNMENT CHECK AND

ADJUSTMENT

M1341011000372

Measure wheel alignment with an alignment equip-

ment on level earth.

The rear suspension, wheels, and tyres should be

serviced to the normal condition prior to wheel align

-

ment measurement.

CAMBER

Standard value: −0°40' ± 0°30' (Left/right devi-

ation within 30')

CAUTION

Never subject the wheel bearings to the vehicle

load when the rear wheel hub nuts (self-locking

nuts) or special tool wheel alignment gauge

attachment (MB991014) are loosened.

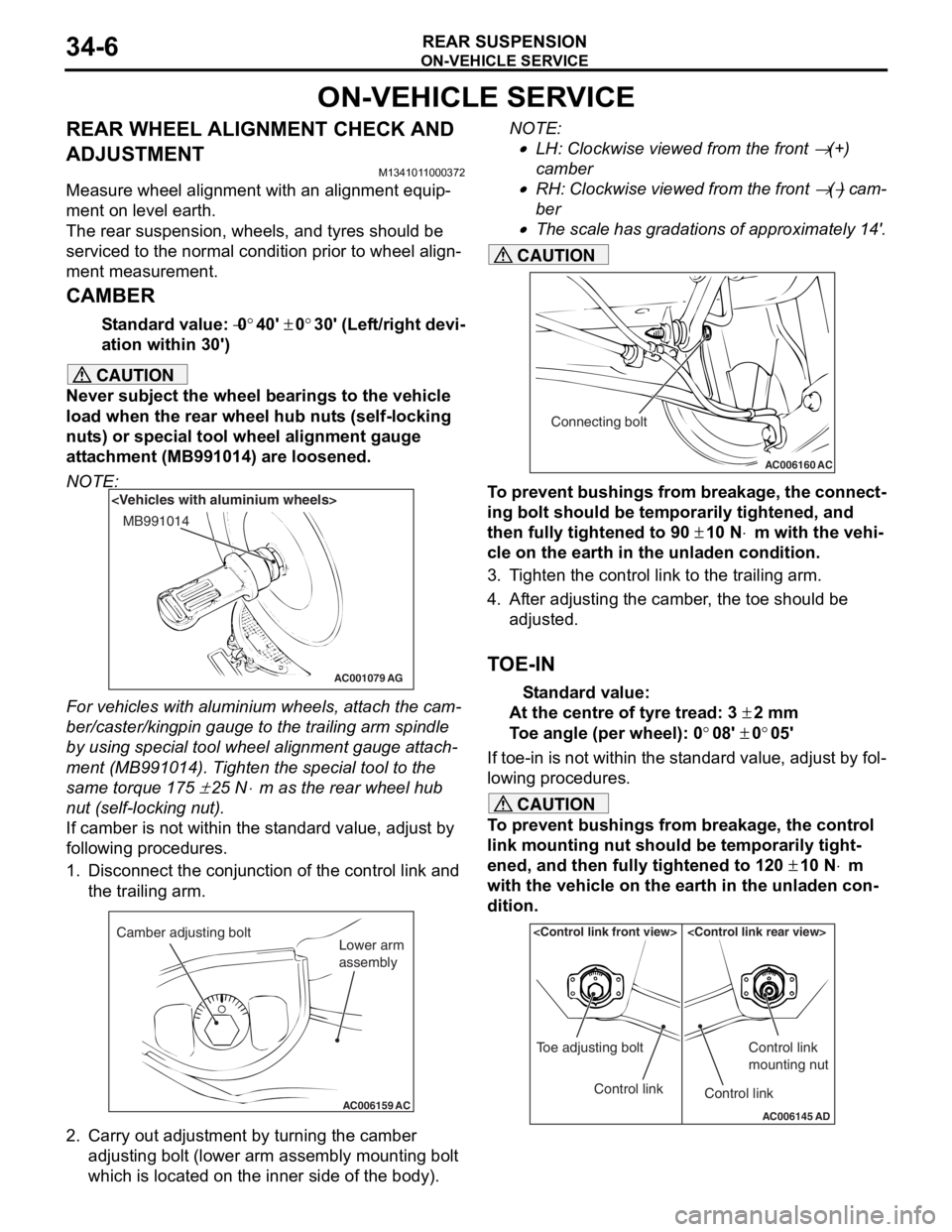

NOTE:

AC001079

MB991014

AG

For vehicles with aluminium wheels, attach the cam-

ber/caster/kingpin gauge to the trailing arm spindle

by using special tool wheel alignment gauge attach

-

ment (MB991014). Tighten the special tool to the

same torque 175

± 25 N⋅m as the rear wheel hub

nut (self-locking nut).

If camber is not within the standard value, adjust by

following procedures.

1. Disconnect the conjunction of the control link and the trailing arm.

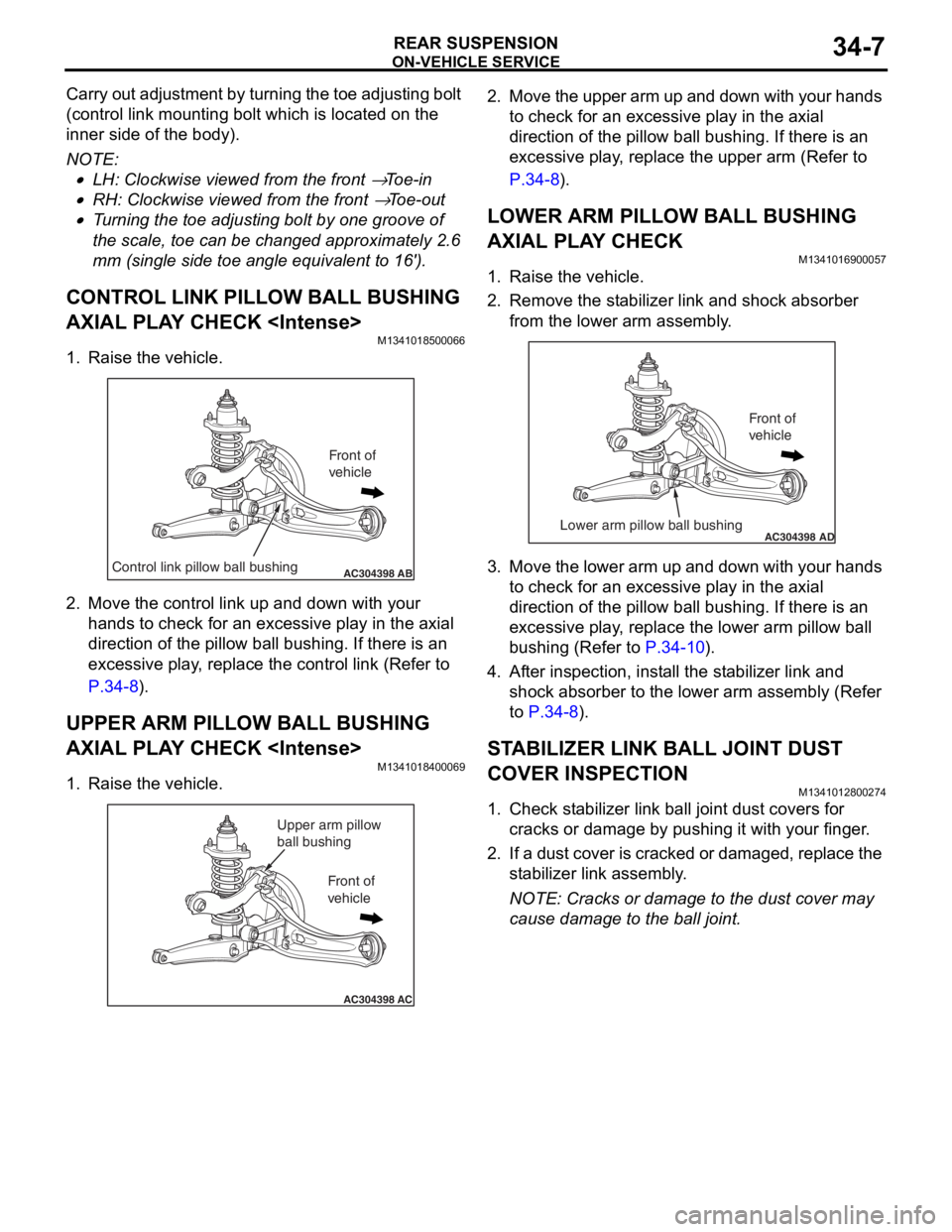

AC006159 AC

Camber adjusting bolt

Lower arm

assembly

2. Carry out adjustment by turning the camber

adjusting bolt (lower arm assembly mounting bolt

which is located on the inner side of the body).

NOTE: .

•LH: Clockwise viewed from the front → (+)

camber

•RH: Clockwise viewed from the front → (−) cam-

ber

•

AC006160 AC

Connecting bolt

The scale has gradations of approximately 14'.

CAUTION

To prevent bushings from breakage, the connect-

ing bolt should be temporarily tightened, and

then fully tightened to 90

± 10 N⋅m with the vehi-

cle on the earth in the unladen condition.

3. Tighten the control link to the trailing arm.

4. After adjusting the camber, the toe should be

adjusted.

TOE-IN

Standard value:

At the centre of tyre tread: 3 ± 2 mm

Toe angle (per wheel): 0°08' ± 0°05'

If toe-in is not within the standard value, adjust by fol-

lowing procedures.

CAUTION

To prevent bushings from breakage, the control

link mounting nut should be temporarily tight

-

ened, and then fully tightened to 120 ± 10 N⋅m

with the vehicle on the earth in the unladen con

-

dition.

AC006145 AD

Control link

Toe adjusting boltControl link

Control link

mounting nut

Page 205 of 800

ON-VEHICLE SERVICE

REAR SUSPENSION34-7

Carry out adjustment by turning the toe adjusting bolt

(control link mounting bolt which is located on the

inner side of the body).

NOTE: .

•LH: Clockwise viewed from the front → To e - i n

•RH: Clockwise viewed from the front → Toe-out

•Turning the toe adjusting bolt by one groove of

the scale, toe can be changed approximately 2.6

mm (single side toe angle equivalent to 16').

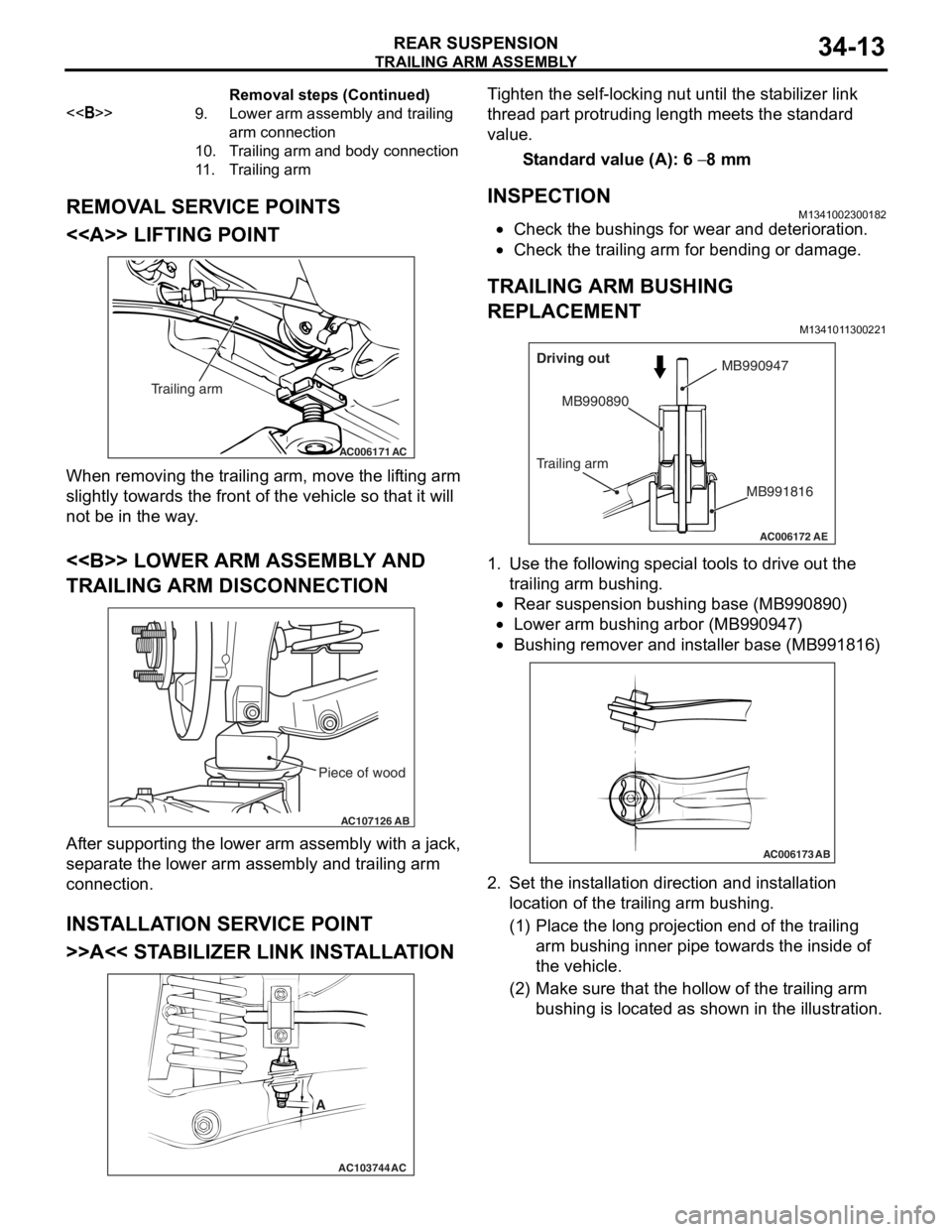

CONTROL LINK PILLOW BALL BUSHING

AXIAL PLAY CHECK

M1341018500066

1. Raise the vehicle.

AC304398ABControl link pillow ball bushing

Front of

vehicle

2.Move the control link up and d o wn with your

ha nds to ch eck for an excessive pla y in the a x ia l

direct ion o f the p illow ball bushing . If the r e is an

exce ssive play , re place the cont rol link (Re f er to

P.34-8).

UPPER ARM PILLOW BALL BUSHING

AXIAL PLAY CHECK

M13410184 0006 9

1.Raise th e ve hicle.

AC304398AC

Upper arm pillow

ball bushing

Front of

vehicle

2. Move the up per arm up and down with you r hand s

to che ck for an e xce ssive play in the axial

d i rection o f the p illow ball bushing . If the r e is an

e xce ssive play , re place the upper arm (Refe r to

P.34-8).

LOWER ARM PILLOW BALL BUSHING

AXIAL PLAY CHECK

M13410169 0005 7

1.Raise th e ve hicle.

2.Remove the st a b ilizer link and shock a b sorb er

f r om t h e l o we r arm a s s e mb l y .

AC304398ADLower arm pillow ball bushing

Front of

vehicle

3.Move the lower a r m u p and down with your h ands

to che ck for an e xce ssive play in the axial

d i rection o f the p illow ball bushing . If the r e is an

e xce ssive play , re place the lower a r m pillo w b a ll

b u shing (Refer to

P.34-10).

4.Af ter inspe c tio n , in st all the st a b ilizer link and

shock a b sorb er to the lower arm assembly (Refer

to

P.34-8).

STABILIZER LINK BALL JOINT DUST

COVER INSPECTION

M1341 0128 0027 4

1.Check st abilize r lin k ba ll joint dust covers f o r

cracks o r damage by pushing it wit h you r fing er .

2. If a du st cove r is crack ed or da mag ed, rep l ace t he

st a b ili zer link assembly .

NOTE: Cracks or dama ge to t he dust co ver may

cause damage to the b a ll join t.

Page 211 of 800

Page 228 of 800

Page 229 of 800

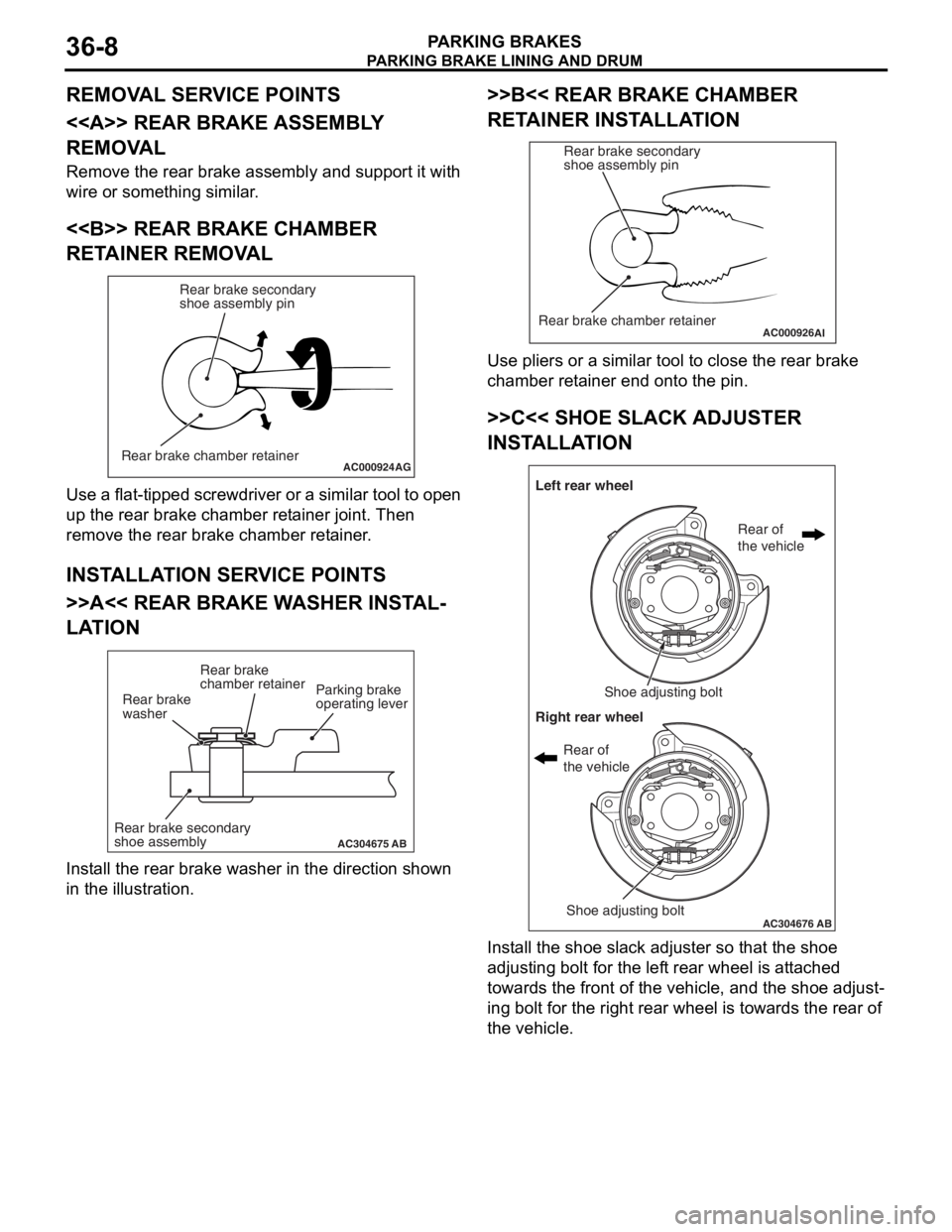

PARKING BRAKE LINING AND DRUM

PARKING BRAKES36-9

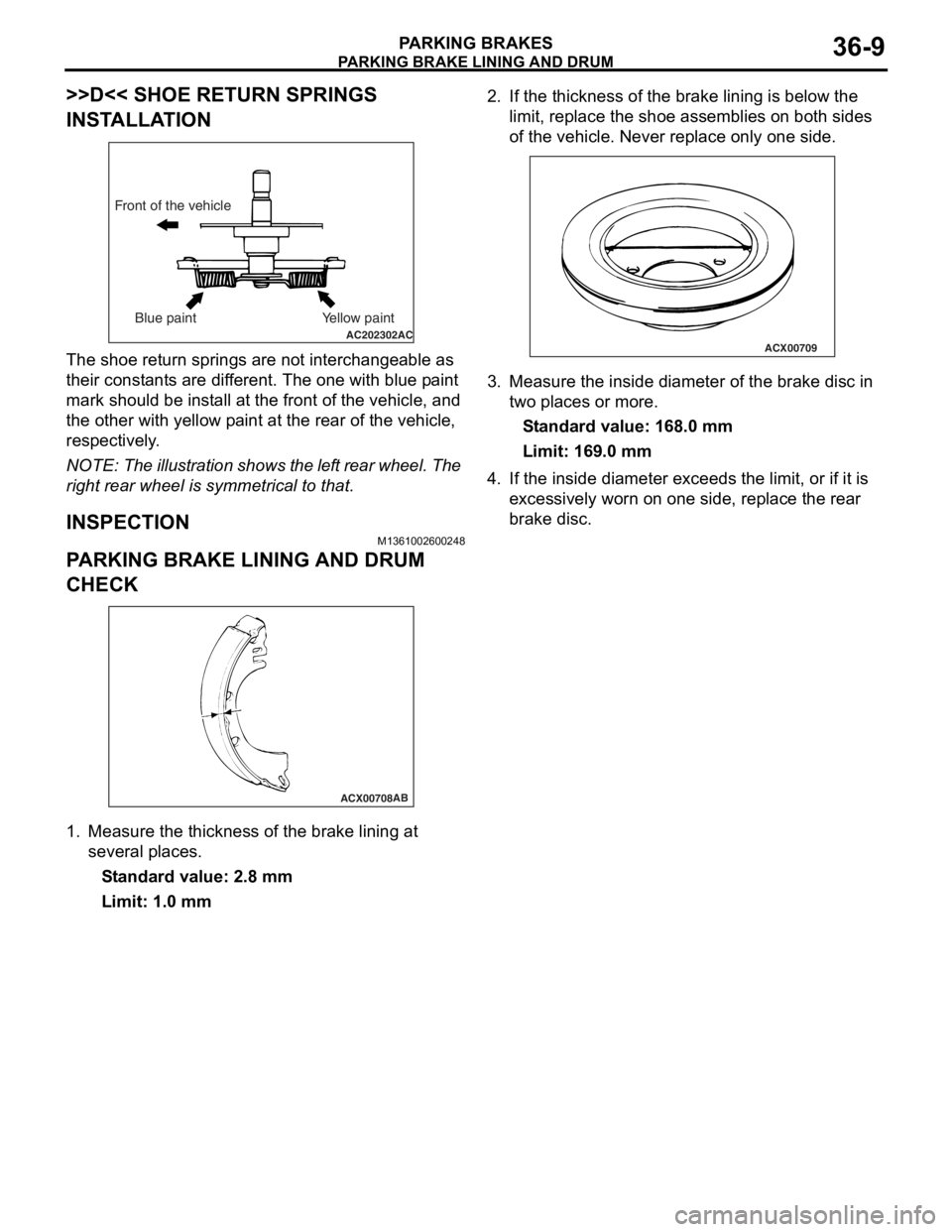

>>D<< SHOE RETURN SPRINGS

INSTALLATION

AC202302AC

Front of the vehicleBlue paint Yellow paint

The shoe ret u rn sp rings are n o t in tercha ngeab le as

their const

a nt s are d i f f e r ent. Th e one with blue p a in t

mark

should be inst a ll at t he fron t o f th e vehicle, and

the oth

e r with yellow p a int a t the re ar of th e ve hicle,

respectively

.

NOTE: The ill ustratio n sh ows th e lef t rear whee l. T he

right re

ar wheel is symme trical to that.

INSPECTION

M13610026 0024 8

PARKING BRAKE LI NING AND DRUM

CHECK

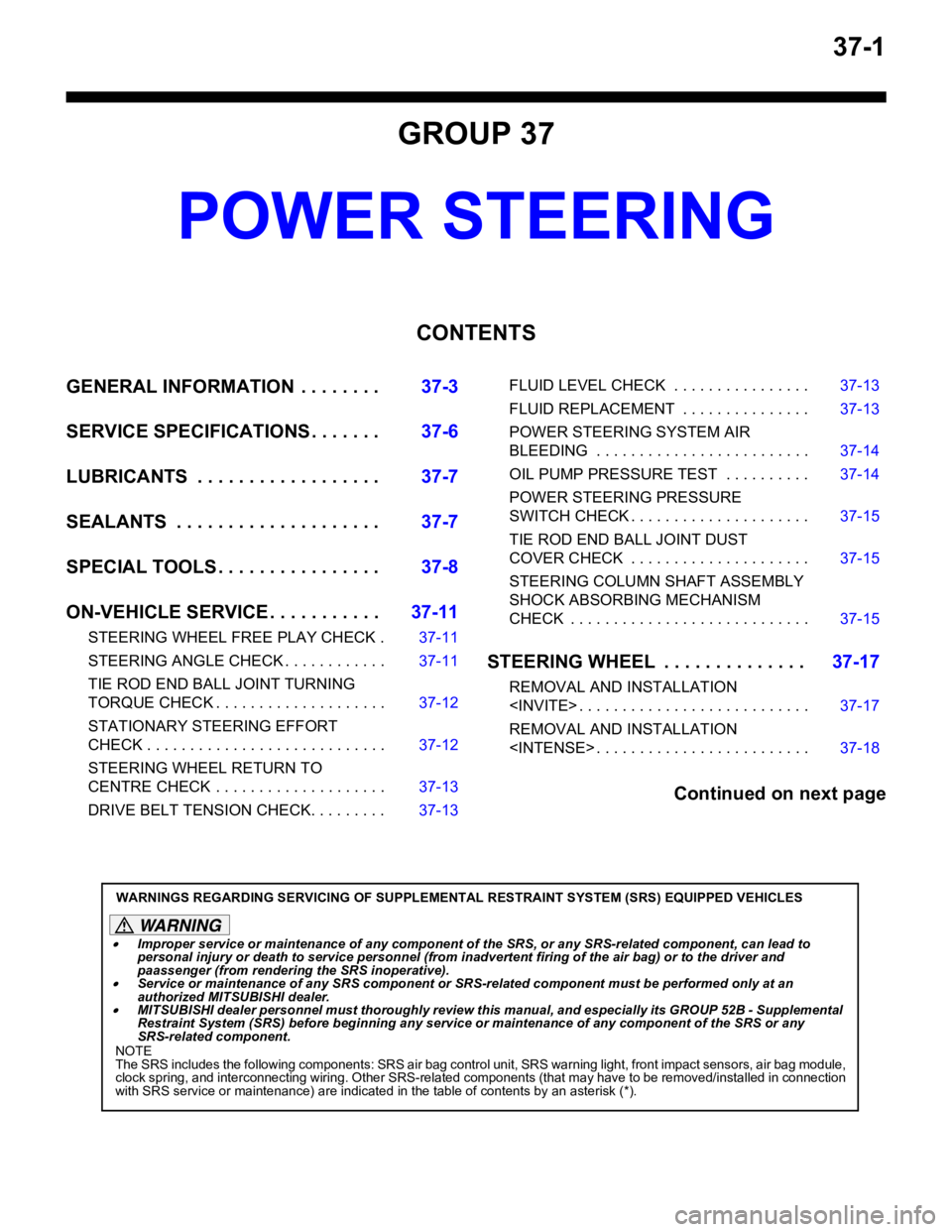

ACX00708AB

1.

Measure the thickne ss of the b r ake lining at

seve ral place s .

St andard va lue: 2.8 mm

Limit: 1.0 mm

2.If the thickness of t he brake linin g is belo w the

limit, rep l ace the shoe a s semblies on bo th sides

o f the vehicle. Ne ver re place only on e side.

ACX00709

3.Measure the inside d i ameter of the bra k e d i sc in

two p l aces o r more .

St andard va lue: 16 8.0 mm

Limit: 169.0 mm

4.If the inside diamete r exceeds the limit, or if it is

e xce ssively worn on one side, rep l ace the re ar

b r ake d i sc.

Page 231 of 800

37-1

GROUP 37

POWER STEERING

CONTENTS

GENERAL INFORMATION . . . . . . . .37-3

SERVICE SPECIFICATIONS . . . . . . .37-6

LUBRICANTS . . . . . . . . . . . . . . . . . .37-7

SEALANTS . . . . . . . . . . . . . . . . . . . .37-7

SPECIAL TOOLS . . . . . . . . . . . . . . . .37-8

ON-VEHICLE SERVICE . . . . . . . . . . .37-11

STEERING WHEEL FREE PLAY CHECK . 37-11

STEERING ANGLE CHECK . . . . . . . . . . . . 37-11

TIE ROD END BALL JOINT TURNING

TORQUE CHECK . . . . . . . . . . . . . . . . . . . . 37-12

STATIONARY STEERING EFFORT

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-12

STEERING WHEEL RETURN TO

CENTRE CHECK . . . . . . . . . . . . . . . . . . . . 37-13

DRIVE BELT TENSION CHECK. . . . . . . . . 37-13

FLUID LEVEL CHECK . . . . . . . . . . . . . . . . 37-13

FLUID REPLACEMENT . . . . . . . . . . . . . . . 37-13

POWER STEERING SYSTEM AIR

BLEEDING . . . . . . . . . . . . . . . . . . . . . . . . . 37-14

OIL PUMP PRESSURE TEST . . . . . . . . . . 37-14

POWER STEERING PRESSURE

SWITCH CHECK . . . . . . . . . . . . . . . . . . . . . 37-15

TIE ROD END BALL JOINT DUST

COVER CHECK . . . . . . . . . . . . . . . . . . . . . 37-15

STEERING COLUMN SHAFT ASSEMBLY

SHOCK ABSORBING MECHANISM

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-15

STEERING WHEEL . . . . . . . . . . . . . .37-17

REMOVAL AND INSTALLATION

REMOVAL AND INSTALLATION

Continued on next page

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING

•Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inad vertent firing of the air bag) or to the driver and

paassenger (from renderin g the SRS inoperative).

•Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.

•MITSUBISHI dealer personnel must thoroughly review th is manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before begi nning any service or maintenance of any component of the SRS or any

SRS-related component.

NOTE

The SRS includes the following components: SRS air bag control unit, SRS warning light, front impact sensors, air bag module,

clock spring, and interconnecting wiring. Other SRS-related components (that may have to be removed/installed in connection

with SRS service or maintenance) are indicated in the table of contents by an asterisk (*).

Page 237 of 800

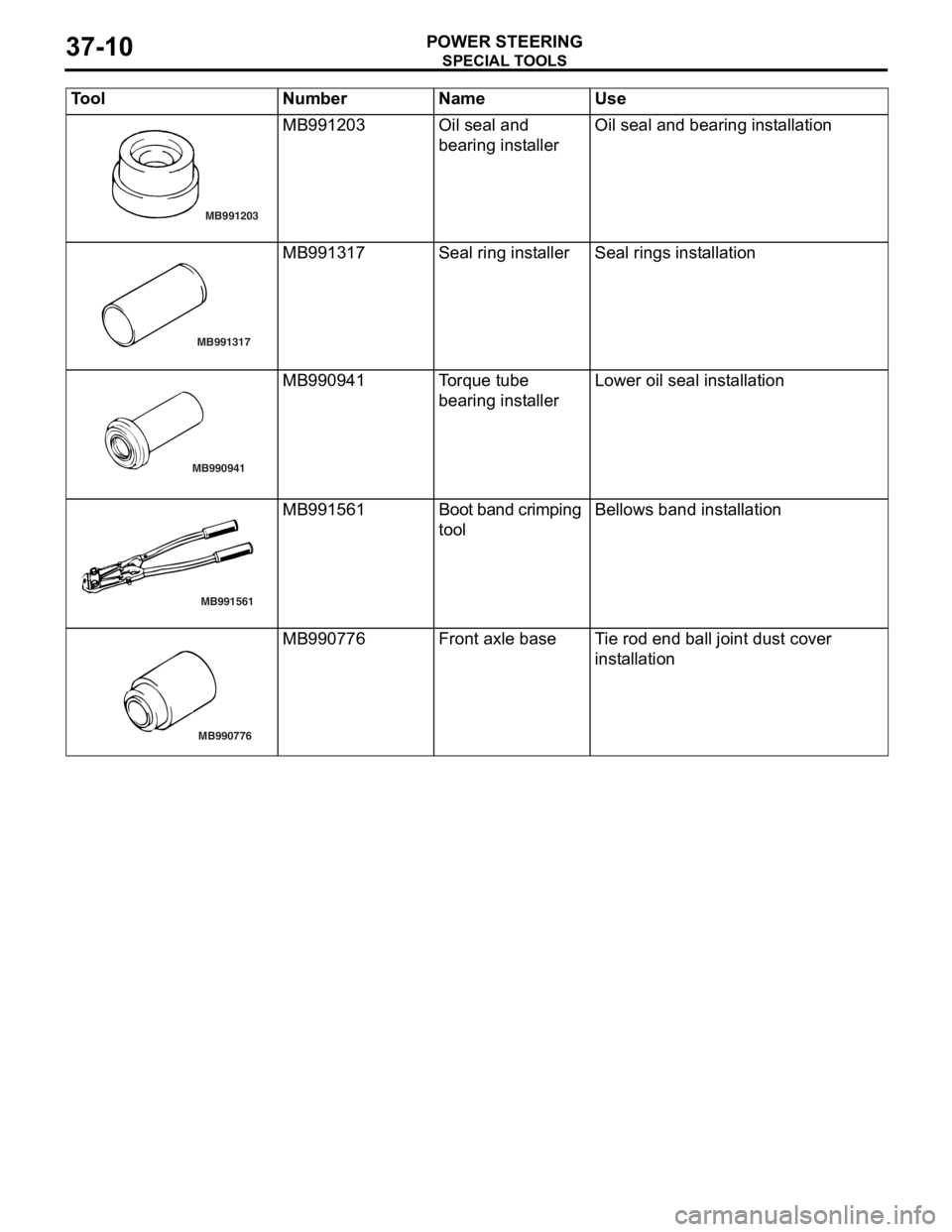

LUBRICANTS

POWER STEERING37-7

LUBRICANTS

M1372000400350

ItemSpecified lubricantQuantity

Power steering fluidATF DEXRON III or DEXRON IIApproximately 1.0 L

Steering gearBearingATF DEXRON III or DEXRON IIAs required

O-ring and seal ring

Oil seal

Special tool (MB991212,

MB991213)

Pinion and valve assembly

seal ring part

BellowsSilicon greaseAs required

Tie rod end ball jointMultipurpose grease SAE J310,

NLGI No.2 or equivalentAs required

Oil pumpFriction surface of rotor vane,

cam ring and pump coverATF DEXRON III or DEXRON IIAs required

O-ring

SEALANTS

M1372000500357

ItemSpecified sealant

Steering shaft cover assembly bolt hole on the toeboard3M ATD Part No.8513 or equivalent

Steering gearEnd plug3M ATD Part No.8661 or equivalent

Rack support cover

Page 240 of 800

MB991203

SPECIA L T O OLS

POWER ST E E RING37-10

MB991203Oil seal an d

bearing in

st allerOil seal and bea ring inst allation

MB991317

MB991317Seal ring in st allerSeal rings inst a llat i on

MB990941

MB990941To rqu e tube

bearing in

st allerLower oil seal inst allation

MB991561

MB991561Boot ba nd crimp i n g

toolBellows ban d inst a lla tion

MB990776

MB990776Front ax le baseTi e rod end b a ll join t dust co ver

inst

a llat i on

Tool Num ber Na me Use

Page 241 of 800

ON-VEHICLE SERVICE

POWER STEERING37-11

ON-VEHICLE SERVICE

STEERING WHEEL FREE PLAY CHECKM1372001000311

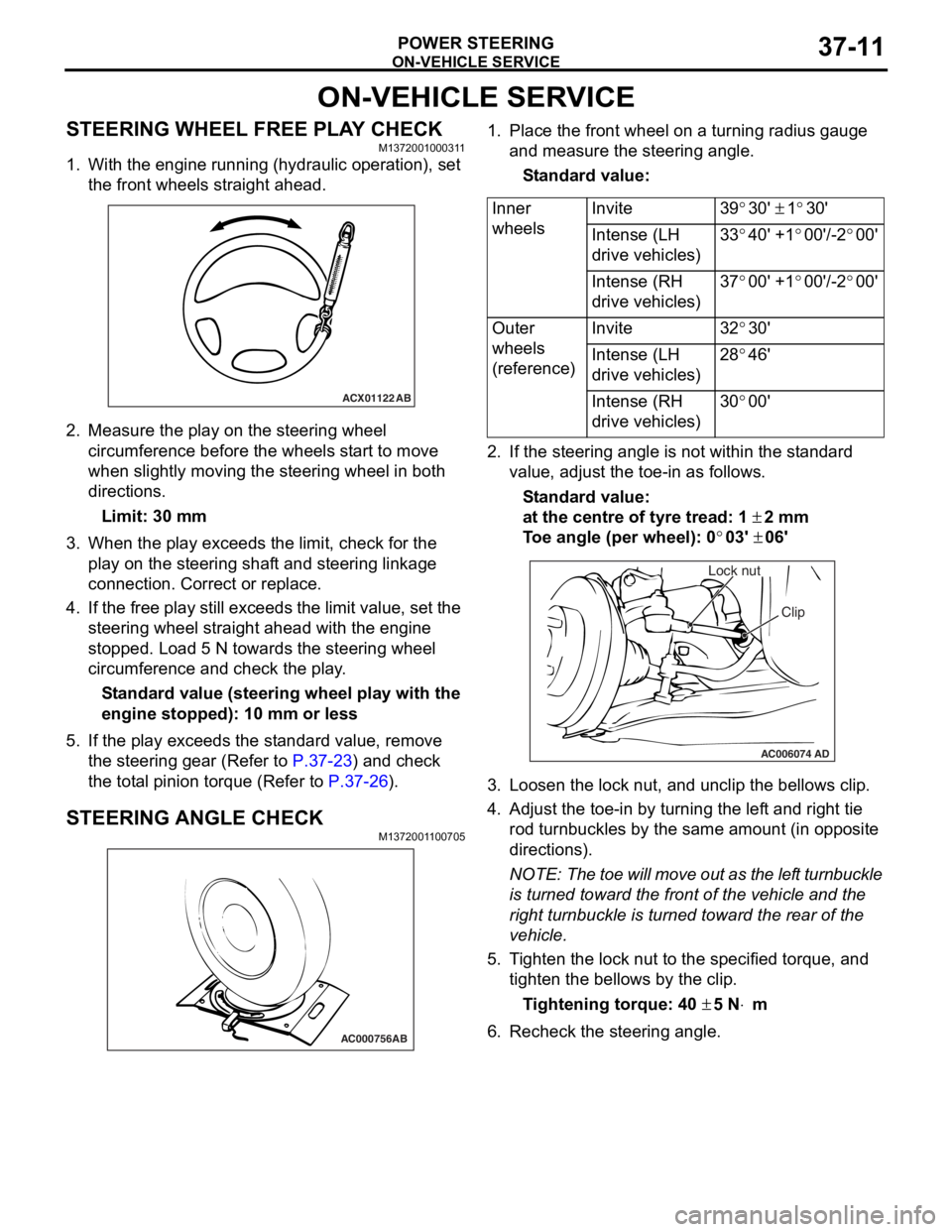

1. With the engine running (hydraulic operation), set the front wheels straight ahead.

ACX01122 AB

2.Measure the play on th e ste e ring wh eel

circumfer ence before the whee ls st a r t to move

when slightly moving the stee ring whe e l in both

direct ions.

Limit: 30 mm

3.Wh en the play exceed s the limit, check fo r the

play on the stee ring shaf t and stee ring linkage

connectio n . Correct or replace .

4.If th e free play still exceeds the limit valu e, set t he

steering wheel stra ight ahead with the engine

stoppe d. Loa d 5 N towards the steer ing whee l

circumfer ence and check the play .

St andard value (steering whee l pla y with the

engine s

t opped): 1 0 mm o r l ess

5.If the play e xce eds the st an dard value , remove

th e ste e ring gear (Refe r to

P.37-23) and check

the tot a l p i nion torqu e (Refer to P.37-26).

STEERING ANGLE CHECKM137200 1 1 0070 5

AC000756AB

1.Place t he fron t wh eel on a tu rning radiu s gau ge

a nd me asure the steering ang le.

St andard va lue:

Inner

wheelsInvite39°30' ± 1°30'

Intense (LH

drive vehicles)33°40' +1°00'/-2°00'

Intense (RH

drive vehicles)37°00' +1°00'/-2°00'

Outer

wheels

(reference)Invite32°30'

Intense (LH

drive vehicles)28°46'

Intense (RH

drive vehicles)30°00'

2.If the steerin g ang le is not within the st a ndard

value , adjust t he toe-in as follows.

St andard va lue:

at the centre of tyre trea d: 1 ± 2 mm

To e angle (p er whee l): 0°03' ± 06'

AC006074 AD

Lock nut

Clip

3.L oose n the lock nut, and un clip the bellows clip .

4.Adjust the toe - in by turning th e lef t an d righ t tie

ro d turnb u ckles by th e sa me a m oun t (in o pposite

directions).

NOTE: The to e will move out as th e lef t turnbuckle

is tur

ned toward the fro n t of th e ve hicle an d the

right tu

rnbuckle is turned toward the rear of the

vehicle.

5. T i ghten the lo ck nut to the specified torque , and

tighten the be llo ws by the clip .

Ti ghte n ing torque: 40 ± 5 N⋅m

6.Recheck the stee ring a ngle .

Page 242 of 800

ON-VEHICLE SERVICE

POWER STEERING37-12

TIE ROD END BALL JOINT TURNING

TORQUE CHECK

M1372001500554

CAUTION

•Do not remove the tie rod end nut from the

ball joint. Loosen it and use special tool to

avoid possible damage to the ball joint

threads.

•

AC208247AJ

CordBoltMB991897

or

MB992011

Nut

Ball joint

Hang special tool with cord to prevent it from

falling.

1. Install special tool ball joint remover (MB991897 or MB992011) as shown in the figure.

AC106821

Knob

Parallel

Bolt

Correct Wrong

AD

2. Turn the bolt and knob as necessary to make the jaws of special tool parallel, tighten the bolt by

hand and confirm that the jaws are still parallel.

NOTE: When adjusting the jaws in parallel, make

sure the knob is in the position shown in the fig

-

ure.

3. Tighten the bolt with a wrench to disconnect the tie rod end.

ACX01129 AB

MB990326

4. Move the ball joint stud several times and install

the nut on the stud. Using special tool preload

socket (MB990326), measure the ball joint turning

torque.

Standard value: 0.5 − 2.5 N⋅m

5. If the turning torque exceeds the standard value, replace the tie rod end.

6. If the turning torque is under the standard value, check the ball joint for axial play or ratcheting. If

no axial play or ratcheting, the ball joint can be

re-used.

CAUTION

Always use a new ball joint nut as it is a self-lock-

ing nut.

7. Install the tie rod end to the knuckle, then tighten a new self-locking nut to the specified torque.

Tightening torque: 25 ± 5 N⋅m

STATIONARY STEERING EFFORT CHECKM1372001700332

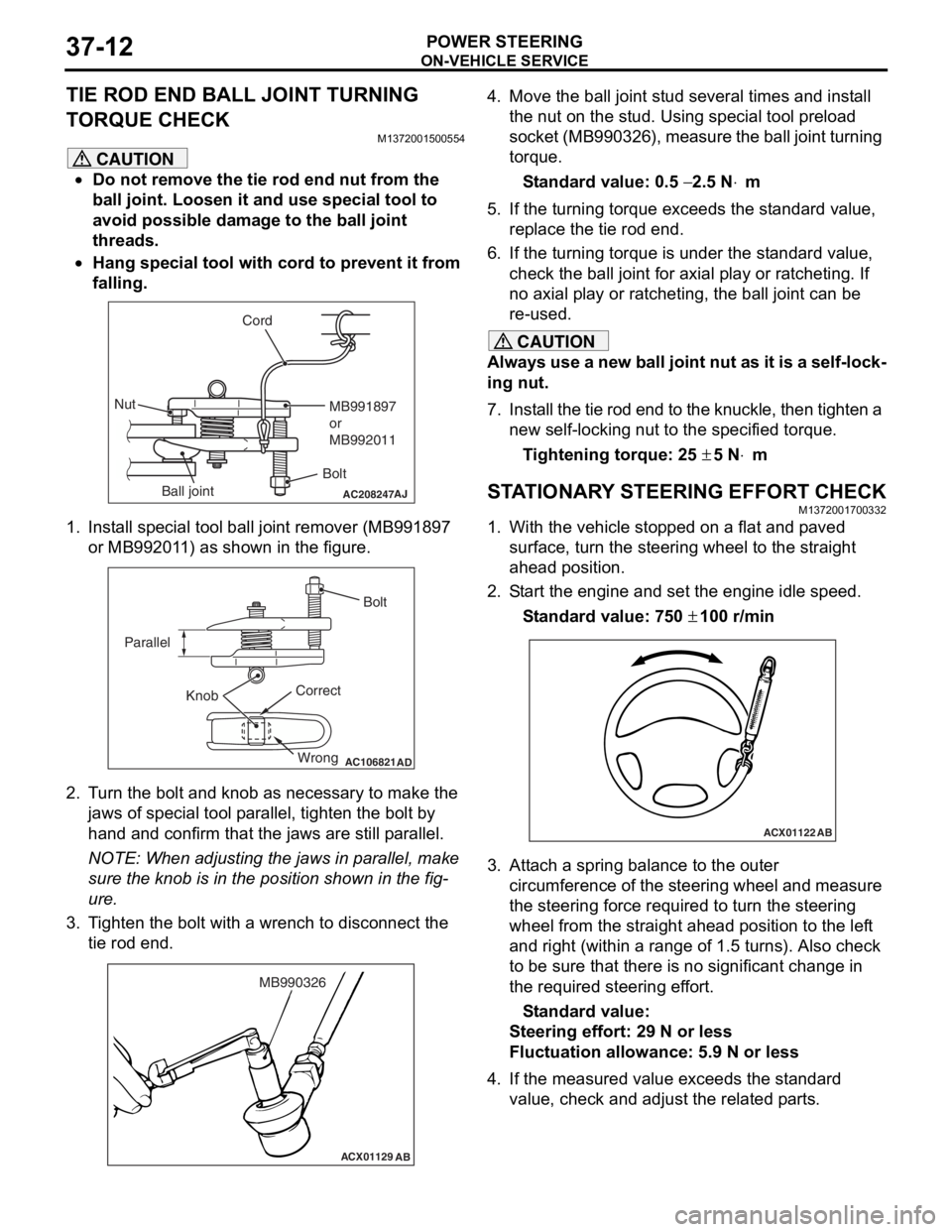

1. With the vehicle stopped on a flat and paved

surface, turn the steering wheel to the straight

ahead position.

2. Start the engine and set the engine idle speed.

Standard value: 750 ± 100 r/min

ACX01122 AB

3. Attach a spring balance to the outer

circumference of the steering wheel and measure

the steering force required to turn the steering

wheel from the straight ahead position to the left

and right (within a range of 1.5 turns). Also check

to be sure that there is no significant change in

the required steering effort.

Standard value:

Steering effort: 29 N or less

Fluctuation allowance: 5.9 N or less

4. If the measured value exceeds the standard value, check and adjust the related parts.