sensor MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 607 of 1449

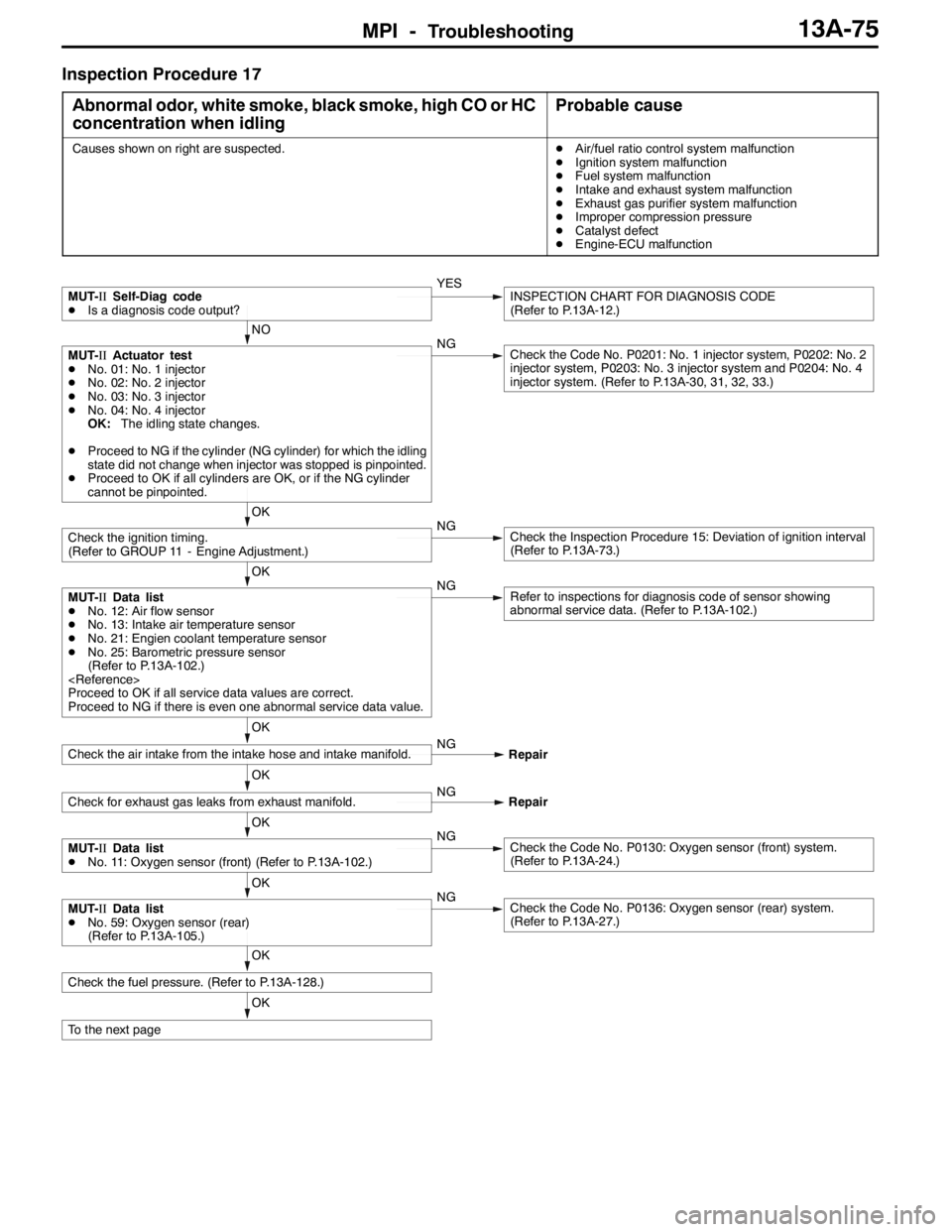

MPI -Troubleshooting13A-75

Inspection Procedure 17

Abnormal odor, white smoke, black smoke, high CO or HC

concentration when idling

Probable cause

Causes shown on right are suspected.DAir/fuel ratio control system malfunction

DIgnition system malfunction

DFuel system malfunction

DIntake and exhaust system malfunction

DExhaust gas purifier system malfunction

DImproper compression pressure

DCatalyst defect

DEngine-ECU malfunction

OK

To the next page

OK

Check the fuel pressure. (Refer to P.13A-128.)

OK

MUT-IIData list

DNo. 59: Oxygen sensor (rear)

(Refer to P.13A-105.)NGCheck the Code No. P0136: Oxygen sensor (rear) system.

(Refer to P.13A-27.)

OK

MUT-IIData list

DNo. 11: Oxygen sensor (front) (Refer to P.13A-102.)NGCheck the Code No. P0130: Oxygen sensor (front) system.

(Refer to P.13A-24.)

OK

Check for exhaust gas leaks from exhaust manifold.NG

Repair

OK

Check the air intake from the intake hose and intake manifold.NG

Repair

OK

MUT-IIData list

DNo. 12: Air flow sensor

DNo. 13: Intake air temperature sensor

DNo. 21: Engien coolant temperature sensor

DNo. 25: Barometric pressure sensor

(Refer to P.13A-102.)

Proceed to OK if all service data values are correct.

Proceed to NG if there is even one abnormal service data value.NGRefer to inspections for diagnosis code of sensor showing

abnormal service data. (Refer to P.13A-102.)

OK

Check the ignition timing.

(Refer to GROUP 11 - Engine Adjustment.)NGCheck the Inspection Procedure 15: Deviation of ignition interval

(Refer to P.13A-73.)

NO

MUT-IIActuator test

DNo. 01: No. 1 injector

DNo. 02: No. 2 injector

DNo. 03: No. 3 injector

DNo. 04: No. 4 injector

OK:The idling state changes.

DProceed to NG if the cylinder (NG cylinder) for which the idling

state did not change when injector was stopped is pinpointed.

DProceed to OK if all cylinders are OK, or if the NG cylinder

cannot be pinpointed.NGCheck the Code No. P0201: No. 1 injector system, P0202: No. 2

injector system, P0203: No. 3 injector system and P0204: No. 4

injector system. (Refer to P.13A-30, 31, 32, 33.)

MUT-IISelf-Diag code

DIs a diagnosis code output?YESINSPECTION CHART FOR DIAGNOSIS CODE

(Refer to P.13A-12.)

Page 611 of 1449

MPI -Troubleshooting13A-79

Inspection Procedure 19

Overheating

Probable cause

Causes shown on right are suspected.DEngine coolant insufficient or deteriorated

DFan controller malfunction

DEngine coolant temperature sensor malfunction

DThermostat malfunction

DWater pump malfunction

DCondenser fan relay malfunction

DRadiator core malfunction

DEngine-ECU malfunction

NO

NG

Replace or replenish the engine coolant.

OK

Replace the radiator core.

OK

Check the water pump. (Refer to GROUP 14 - Water pump.)NGReplace the water pump.

OK

Check the thermostat. (Refer to GROUP 14 - Thermostat.)NGReplace the thermostat.

OK

MUT-IIData list

DNo. 21: Engine coolant temperaure sensor

OK:Approximately the same as the ambient temperature

when cooled.

Between 80 - 120_C when hot.NGCheck the Code No. P0115: Engine coolant temperature

sensor system. (Refer to P.13A-19.)

MUT-IIData list

21 Engine coolant temperature sensor (Refer to P.13A-102.)

OK

MUT-IIActuator Test

DNo. 37: Condenser fan (HI)

DNo. 38: Condenser fan (LOW)

DIgnition switch: ON

OK:Condenser fan rotates (low speed).

OK:Condenser fan rotates (high speed).NGCheck the Inspection Procedure 25: Condenser fan control

relay system. (Refer to P.13A-89.)

MUT-IIActuator Test

DNo. 21: Fan controller

DIgnition switch: ON

OK:Radiator fan rotates.NGCheck the Inspection Procedure 24: Radiator fan control relay

system. (Refer to P.13A-87.)

OK

Check the engine coolant.

(Refer to GROUP 14 - On-vehicle Service.)

If the engine coolant level is low, check whether the engine

coolant has leaked, and repair if required.

MUT-IISelf-Diag Code

Is a diagnosis code output?YESINSPECTION CHART FOR DIAGNOSIS CODE (Refer to

P.13A-12.)

Page 614 of 1449

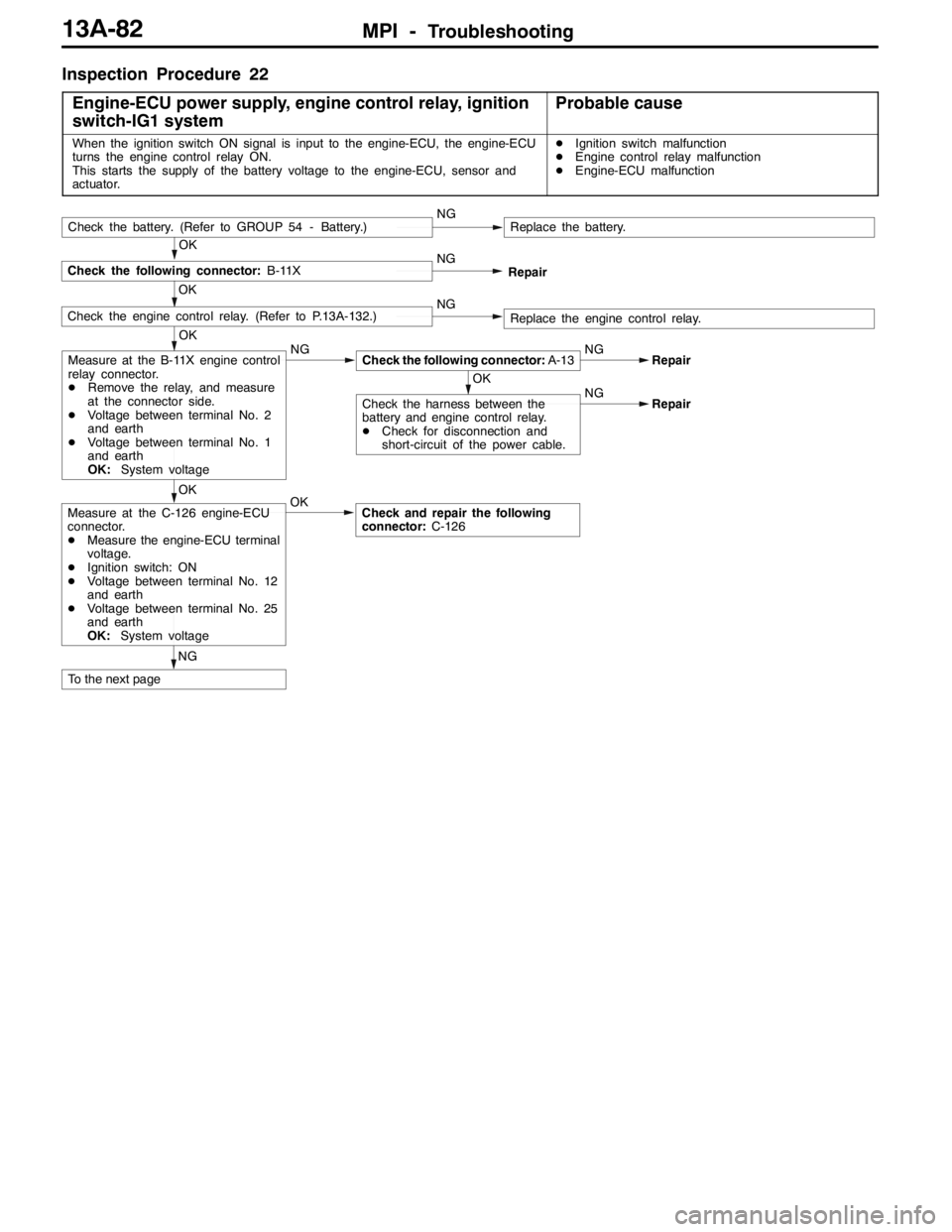

MPI -Troubleshooting13A-82

Inspection Procedure 22

Engine-ECU power supply, engine control relay, ignition

switch-IG1 system

Probable cause

When the ignition switch ON signal is input to the engine-ECU, the engine-ECU

turns the engine control relay ON.

This starts the supply of the battery voltage to the engine-ECU, sensor and

actuator.DIgnition switch malfunction

DEngine control relay malfunction

DEngine-ECU malfunction

OK

Check the engine control relay. (Refer to P.13A-132.)NGReplace the engine control relay.

OK

Check the following connector:B-11XNG

Check the battery. (Refer to GROUP 54 - Battery.)NGReplace the battery.

Repair

OK

OK

Measure at the B-11X engine control

relay connector.

DRemove the relay, and measure

at the connector side.

DVoltage between terminal No. 2

and earth

DVoltage between terminal No. 1

and earth

OK:System voltageNGCheck the following connector:A-13NG

OK

Check the harness between the

battery and engine control relay.

DCheck for disconnection and

short-circuit of the power cable.NGRepair

Repair

NGOK

Check and repair the following

connector:C-126Measure at the C-126 engine-ECU

connector.

DMeasure the engine-ECU terminal

voltage.

DIgnition switch: ON

DVoltage between terminal No. 12

and earth

DVoltage between terminal No. 25

and earth

OK:System voltage

To the next page

Page 627 of 1449

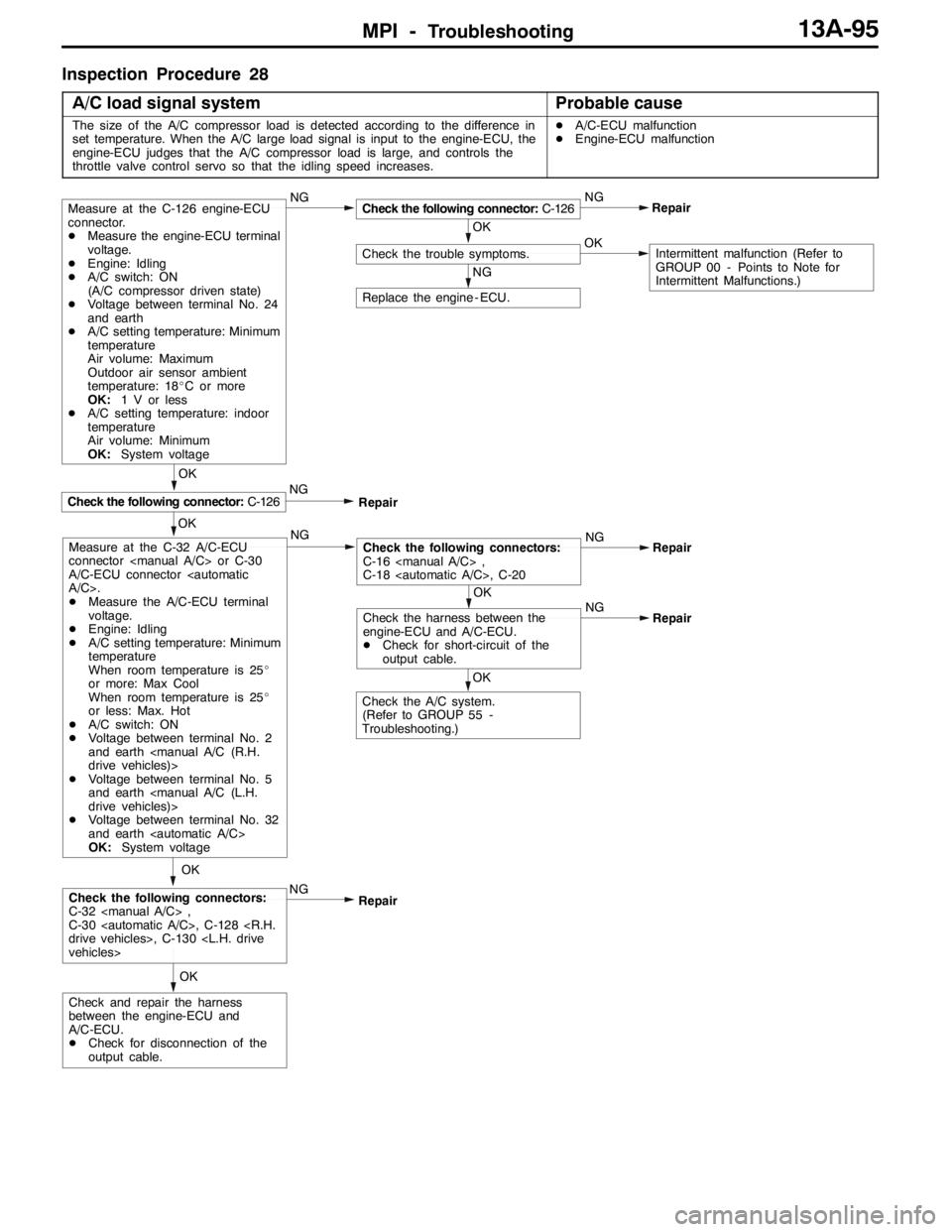

MPI -Troubleshooting13A-95

Inspection Procedure 28

A/C load signal system

Probable cause

The size of the A/C compressor load is detected according to the difference in

set temperature. When the A/C large load signal is input to the engine-ECU, the

engine-ECU judges that the A/C compressor load is large, and controls the

throttle valve control servo so that the idling speed increases.DA/C-ECU malfunction

DEngine-ECU malfunction

OK

NG

OK

NG

Check the trouble symptoms.NG

Check the following connector:C-126Repair

OK

Check the following connector:C-126

Replace the engine - ECU.

Measure at the C-126 engine-ECU

connector.

DMeasure the engine-ECU terminal

voltage.

DEngine: Idling

DA/C switch: ON

(A/C compressor driven state)

DVoltage between terminal No. 24

and earth

DA/C setting temperature: Minimum

temperature

Air volume: Maximum

Outdoor air sensor ambient

temperature: 18_C or more

OK:1 V or less

DA/C setting temperature: indoor

temperature

Air volume: Minimum

OK:System voltage

NG

Repair

NGNG

Repair

OK

OK

Check the harness between the

engine-ECU and A/C-ECU.

DCheck for short-circuit of the

output cable.NG

Repair

Check the A/C system.

(Refer to GROUP 55 -

Troubleshooting.)OK

Intermittent malfunction (Refer to

GROUP 00 - Points to Note for

Intermittent Malfunctions.)

Check the following connectors:

C-16

C-18

NG

Repair OK

OK

Check and repair the harness

between the engine-ECU and

A/C-ECU.

DCheck for disconnection of the

output cable.

Check the following connectors:

C-32

C-30

Measure at the C-32 A/C-ECU

connector

A/C-ECU connector

DMeasure the A/C-ECU terminal

voltage.

DEngine: Idling

DA/C setting temperature: Minimum

temperature

When room temperature is 25_

or more: Max Cool

When room temperature is 25_

or less: Max. Hot

DA/C switch: ON

DVoltage between terminal No. 2

and earth

DVoltage between terminal No. 5

and earth

DVoltage between terminal No. 32

and earth

OK:System voltage

Page 634 of 1449

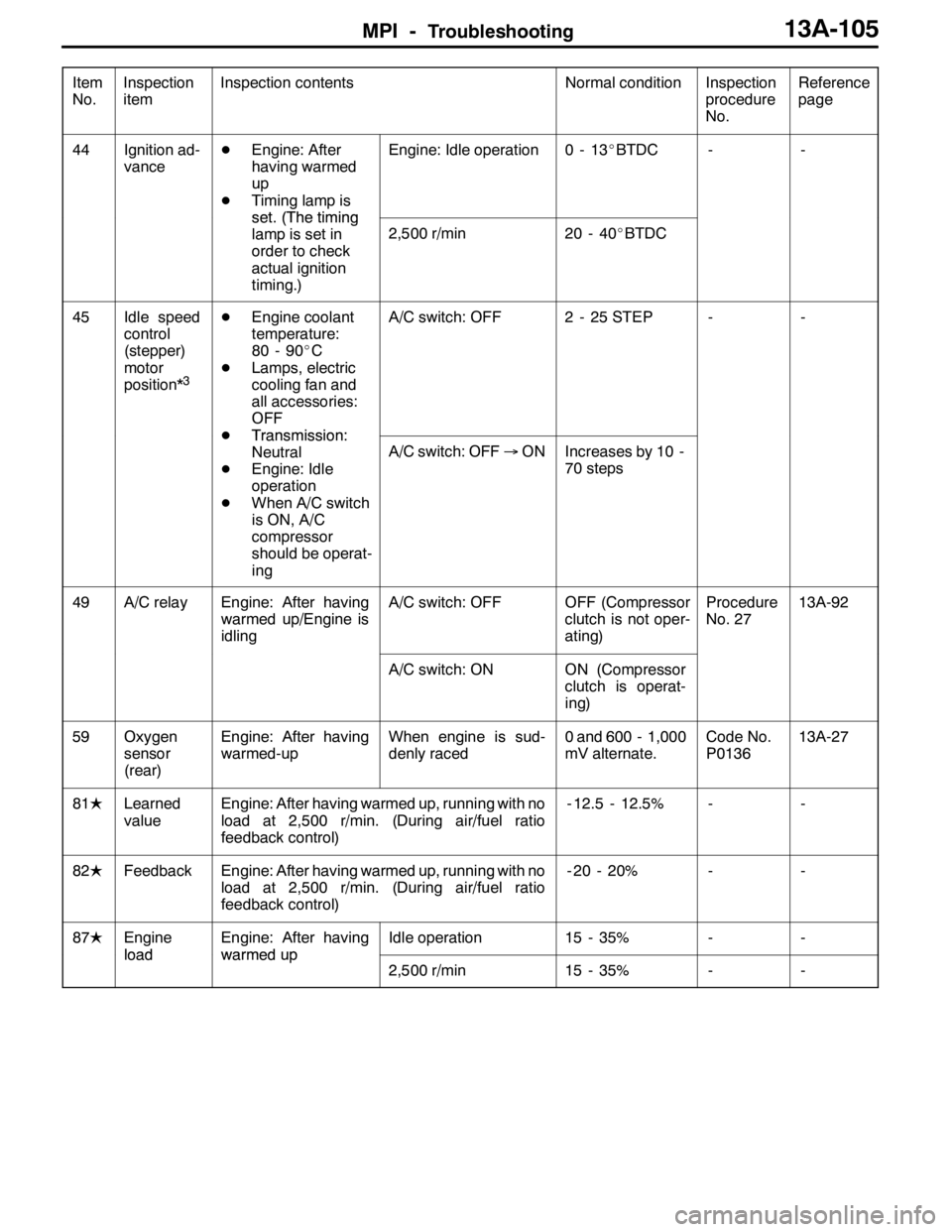

![MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual MPI -Troubleshooting13A-102

DATA LIST REFERENCE TABLE

NOTE

*1. In a new Vehicle [driven approximately 500 km or less], the air flow sensor output frequency time

is sometimes 10% longer than the standa MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual MPI -Troubleshooting13A-102

DATA LIST REFERENCE TABLE

NOTE

*1. In a new Vehicle [driven approximately 500 km or less], the air flow sensor output frequency time

is sometimes 10% longer than the standa](/img/19/57084/w960_57084-633.png)

MPI -Troubleshooting13A-102

DATA LIST REFERENCE TABLE

NOTE

*1. In a new Vehicle [driven approximately 500 km or less], the air flow sensor output frequency time

is sometimes 10% longer than the standard time.

*2. The injector drive time represents the time when the cranking speed is at 250 r/min or below when

the power supply voltage is 11 V.

*3. In a new vehicle [driven approximately 500 km or less], the injector drive time is sometimes 10%

longer than the standard time.

*4. In a new vehicle [driven approximately 500 km or less], the step of the stepper motor is sometimes

30 steps greater than the standard value.

Item

No.Inspection

itemInspection contentsNormal conditionInspection

procedure

No.Reference

page

11Oxygen

sensor

(front)Engine: After having

warmed up

(Air/fuel mixuture is

made leaner whenWhen at 4,000 r/min,

engine is suddenly de-

celerated200 mV or lessCode No.

P013013A-24

madeleanerwhen

decelerating, and is

made richer when rac-

ing.)When engine is sud-

denly raced600 - 1,000 mV

Engine: After having

warmed up

(The oxygen sensor

(front) signal is used

tochecktheair/fuel

Engine is idling400 mV or less↔

600 - 1,000 mV

(Varies)

to check the air/fuel

mixture ratio, and

control condition is

also checked by the

engine-ECU.)2,500 r/min

12Air flow

sensor*1DEngine coolant

temperature:

Idle operation17 - 43 Hz--

sensor*1temperature:

80 - 95_C

DLightningandall

2,500 r/min40 - 100 Hz

DLightning andall

accessories:

OFF

DTransmission:

NeutralAccelerationAccording to ac-

celeration, fre-

quency is ampli-

fied.

13Intake air

temperature

sensor

Ignition switch: “ON”

or engine runningWhen intake air temper-

ature is - 20_C-20_CCode No.

P011013A-13

sensorWhen intake air tem-

perature is 0_C0_C

When intake air tem-

perature is 20_C20_C

When intake air tem-

perature is 40_C40_C

When intake air tem-

perature is 80_C80_C

Page 635 of 1449

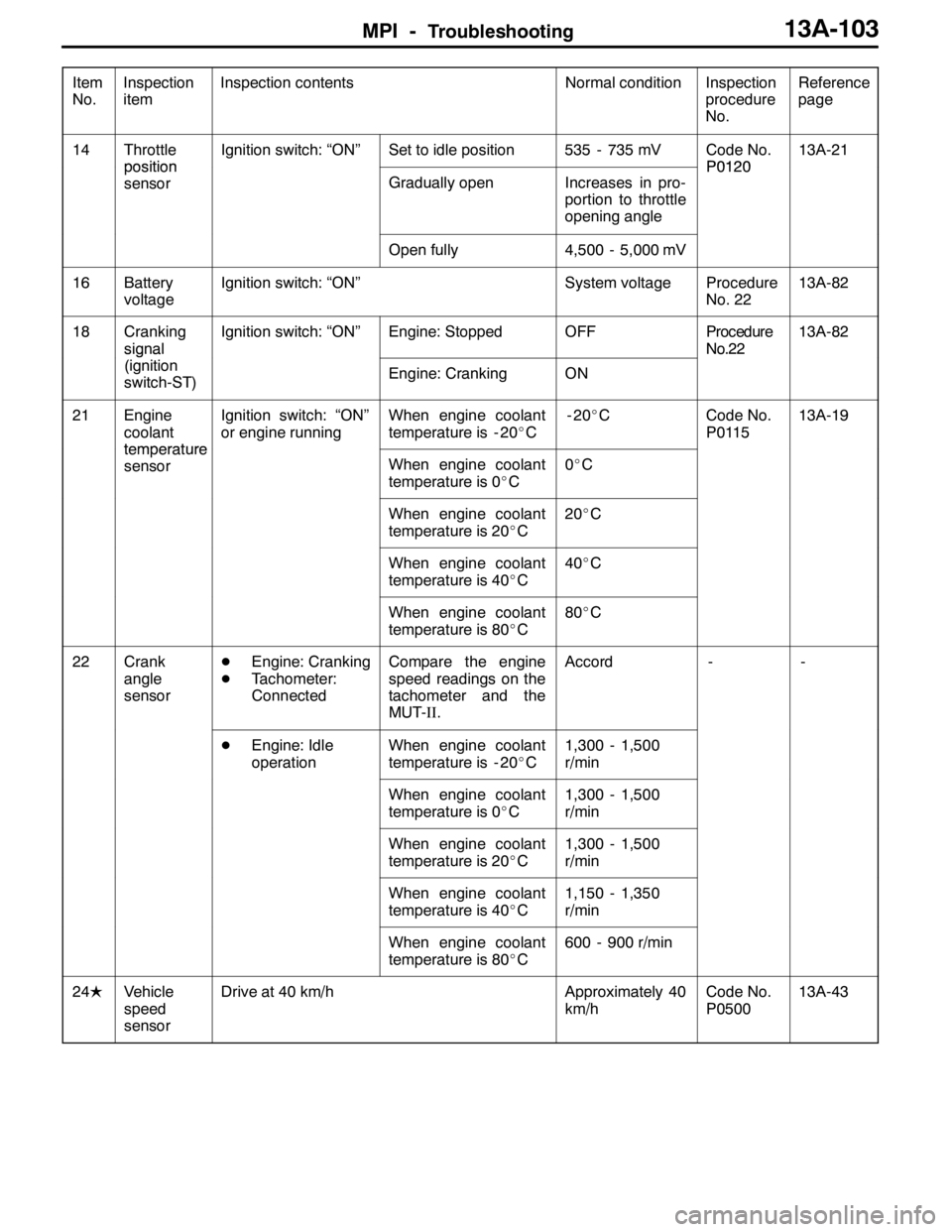

MPI -Troubleshooting13A-103

Item

No.Reference

page Inspection

procedure

No. Normal condition Inspection contents Inspection

item

14Throttle

position

Ignition switch: “ON”Set to idle position535 - 735 mVCode No.

P0120

13A-21

position

sensor

Gradually openIncreases in pro-

portion to throttle

opening angle

P0120

Open fully4,500 - 5,000 mV

16Battery

voltageIgnition switch: “ON”System voltageProcedure

No. 2213A-82

18Cranking

signalIgnition switch: “ON”Engine: StoppedOFFProcedure

No.2213A-82

signal

(ignition

switch-ST)Engine: CrankingON

No.22

21Engine

coolant

temperature

Ignition switch: “ON”

or engine runningWhen engine coolant

temperature is - 20_C-20_CCode No.

P011513A-19

temperature

sensorWhen engine coolant

temperature is 0_C0_C

When engine coolant

temperature is 20_C20_C

When engine coolant

temperature is 40_C40_C

When engine coolant

temperature is 80_C80_C

22Crank

angle

sensorDEngine: Cranking

DTachometer:

ConnectedCompare the engine

speed readings on the

tachometer and the

MUT-II.Accord--

DEngine: Idle

operationWhen engine coolant

temperature is - 20_C1,300 - 1,500

r/min

When engine coolant

temperature is 0_C1,300 - 1,500

r/min

When engine coolant

temperature is 20_C1,300 - 1,500

r/min

When engine coolant

temperature is 40_C1,150 - 1,350

r/min

When engine coolant

temperature is 80_C600 - 900 r/min

24LVehicle

speed

sensorDrive at 40 km/hApproximately 40

km/hCode No.

P050013A-43

Page 636 of 1449

MPI -Troubleshooting13A-104

Item

No.Reference

page Inspection

procedure

No. Normal condition Inspection contents Inspection

item

25Barometric

pressure

Ignition switch: ONAltitude: 0 m101 kPaCode No.

P0105

13A-15

pressure

sensor

Altitude: 0 m95 kPa

P0105

Altitude: 0 m88 kPa

Altitude: 0 m81 kPa

27Power

steering

fluidEngine: Idle operationSteering wheel

stationaryOFFCode No.

P055113A-46

fluid

pressure

switchSteering wheel turningON

28A/C switchEngine: Idle operation

(When A/C switch isA/C switch: OFFOFFProcedure

No. 2613A-92

(WhenA/Cswitchis

ON, A/C compressor

should be operating.)A/C switch: ONON

No.26

34Air flow

sensorEngine: After

warm-upIdle operationONCode No.

P010013A-13

sensor

reset

signal

warm up

3,000 r/minOFF

P0100

37Volumetric

efficiency

DEngine coolant

temperature:

Idle operation15 - 35%--

efficiencytemperature:

85 - 95_C

DLightningand

2,500 r/min15 - 35%

DLightning and

accessories:

OFFExcessive

accellerationAccording to ac-

celeration, volu-

metric efficiency

is increased.

41Injectors*1Engine: CrankingWhen engine coolant

temperature is 0_C

(injection is carried out

for all cylinders simulta-

neously)25 - 37 ms--

When engine coolant

temperature is 20_C15 - 22 ms

When engine coolant

temperature is 80_C4.2 - 6.3 ms

Injectors*2DEngine coolant

temperature:

80–95_C

Engine: Idle operation1.5 - 2.7 ms--

80–95_C

DLamps, electric

cooling fan and

allaccessories:

2,500 r/min1.2 - 2.4 ms

allaccessories:

OFF

DTransmission:

Neutral

When engine is sud-

denly racedIncreases

Page 637 of 1449

MPI -Troubleshooting13A-105

Item

No.Reference

page Inspection

procedure

No. Normal condition Inspection contents Inspection

item

44Ignition ad-

vanceDEngine: After

having warmed

up

DTiming lamp is

set(Thetiming

Engine: Idle operation0-13_BTDC--

set.(Thetiming

lamp is set in

order to check

actual ignition

timing.)

2,500 r/min20 - 40_BTDC

45Idle speed

control

(stepper)

motor

position*

3

DEngine coolant

temperature:

80 - 90_C

DLamps, electric

cooling fan and

all accessories:

OFF

DTransmission:

A/C switch: OFF2 - 25 STEP--

DTransmission:

Neutral

DEngine: Idle

operation

DWhen A/C switch

is ON, A/C

compressor

should be operat-

ing

A/C switch: OFF→ONIncreases by 10 -

70 steps

49A/C relayEngine: After having

warmed up/Engine is

idlingA/C switch: OFFOFF (Compressor

clutch is not oper-

ating)Procedure

No. 2713A-92

A/C switch: ONON (Compressor

clutch is operat-

ing)

59Oxygen

sensor

(rear)Engine: After having

warmed-upWhen engine is sud-

denly raced0 and 600 - 1,000

mV alternate.Code No.

P013613A-27

81LLearned

valueEngine: After having warmed up, running with no

load at 2,500 r/min. (During air/fuel ratio

feedback control)- 12.5 - 12.5%--

82LFeedbackEngine: After having warmed up, running with no

load at 2,500 r/min. (During air/fuel ratio

feedback control)- 20 - 20%--

87LEngine

load

Engine: After having

warmedup

Idle operation15 - 35%--

loadwarmedup

2,500 r/min15 - 35%--

Page 638 of 1449

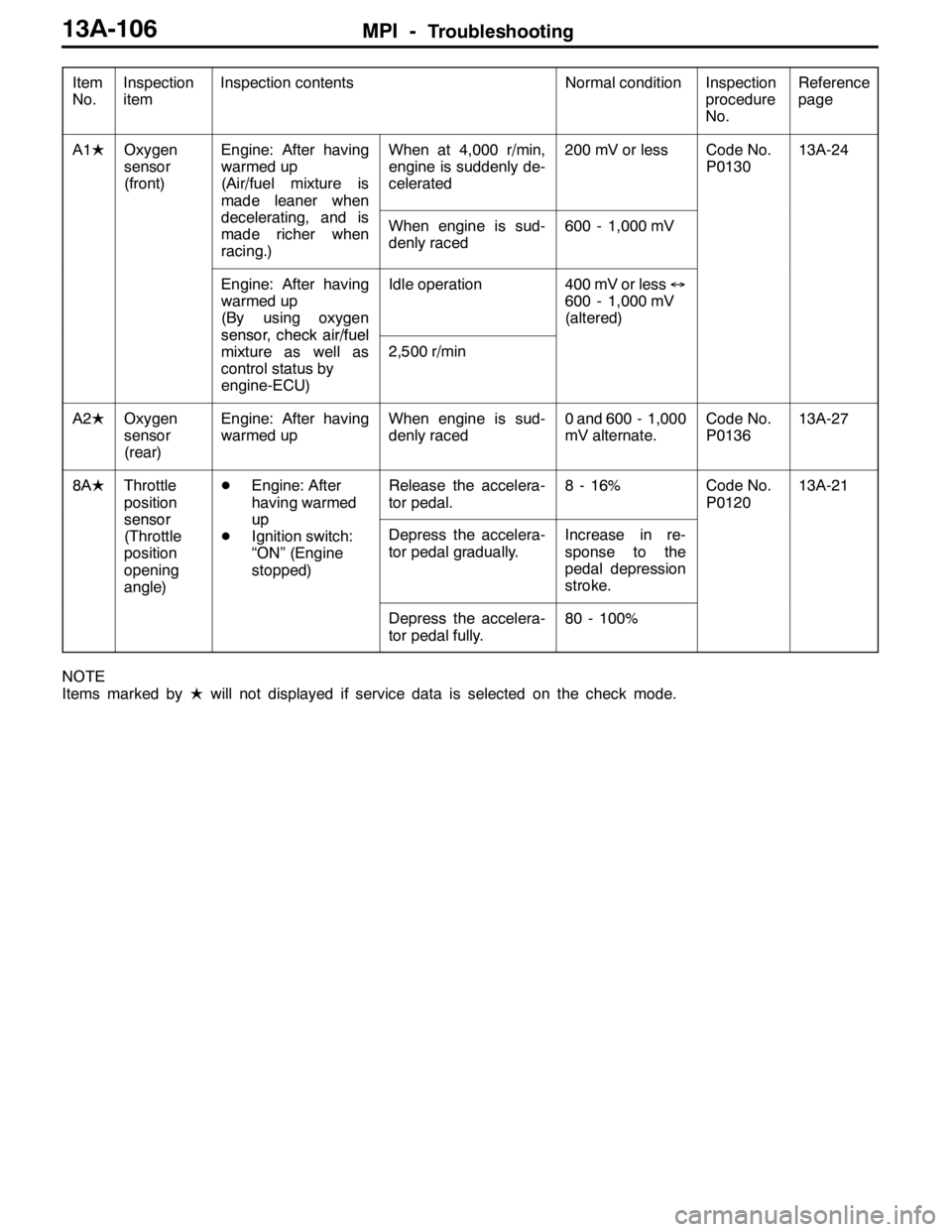

MPI -Troubleshooting13A-106

Item

No.Reference

page Inspection

procedure

No. Normal condition Inspection contents Inspection

item

A1LOxygen

sensor

(front)Engine: After having

warmed up

(Air/fuel mixture is

made leaner whenWhen at 4,000 r/min,

engine is suddenly de-

celerated200 mV or lessCode No.

P013013A-24

madeleanerwhen

decelerating, and is

made richer when

racing.)When engine is sud-

denly raced600 - 1,000 mV

Engine: After having

warmed up

(By using oxygen

sensorcheckair/fuel

Idle operation400 mV or less↔

600 - 1,000 mV

(altered)

sensor, checkair/fuel

mixture as well as

control status by

engine-ECU)2,500 r/min

A2LOxygen

sensor

(rear)Engine: After having

warmed upWhen engine is sud-

denly raced0 and 600 - 1,000

mV alternate.Code No.

P013613A-27

8ALThrottle

position

sensor

DEngine: After

having warmed

up

Release the accelera-

tor pedal.8 - 16%Code No.

P012013A-21

sensor

(Throttle

position

opening

angle)up

DIgnition switch:

“ON” (Engine

stopped)Depress the accelera-

tor pedal gradually.Increase in re-

sponse to the

pedal depression

stroke.

Depress the accelera-

tor pedal fully.80 - 100%

NOTE

Items marked byLwill not displayed if service data is selected on the check mode.

Page 640 of 1449

MPI -Troubleshooting13A-108

Item

No.Reference

page Inspection

procedure

No. Normal condition Inspection contents Drive contents Inspection

item

21Fan

controllerRadiator fan

motor is

driven.Ignition switch: “ON”Fan motor rotates

at high speed.Procedure

No. 2413A-87

36Secondary

air control

solenoid

valveSolenoid valve

turns from

OFF to ON.Ignition switch: “ON”Sound of opera-

tion can be heard

when solenoid

valve is driven.Procedure

No. 2913A-96

37Condenser

fan (HI)Condensor

fan motor is

driven.Ignition switch: “ON”Fan motor rotates

at high speed.Procedure

No. 2513A-89

38Condenser

fan (LOW)Second air

control

solenoid valveIgnition switch: “ON”Fan motor rotates

at low speed.

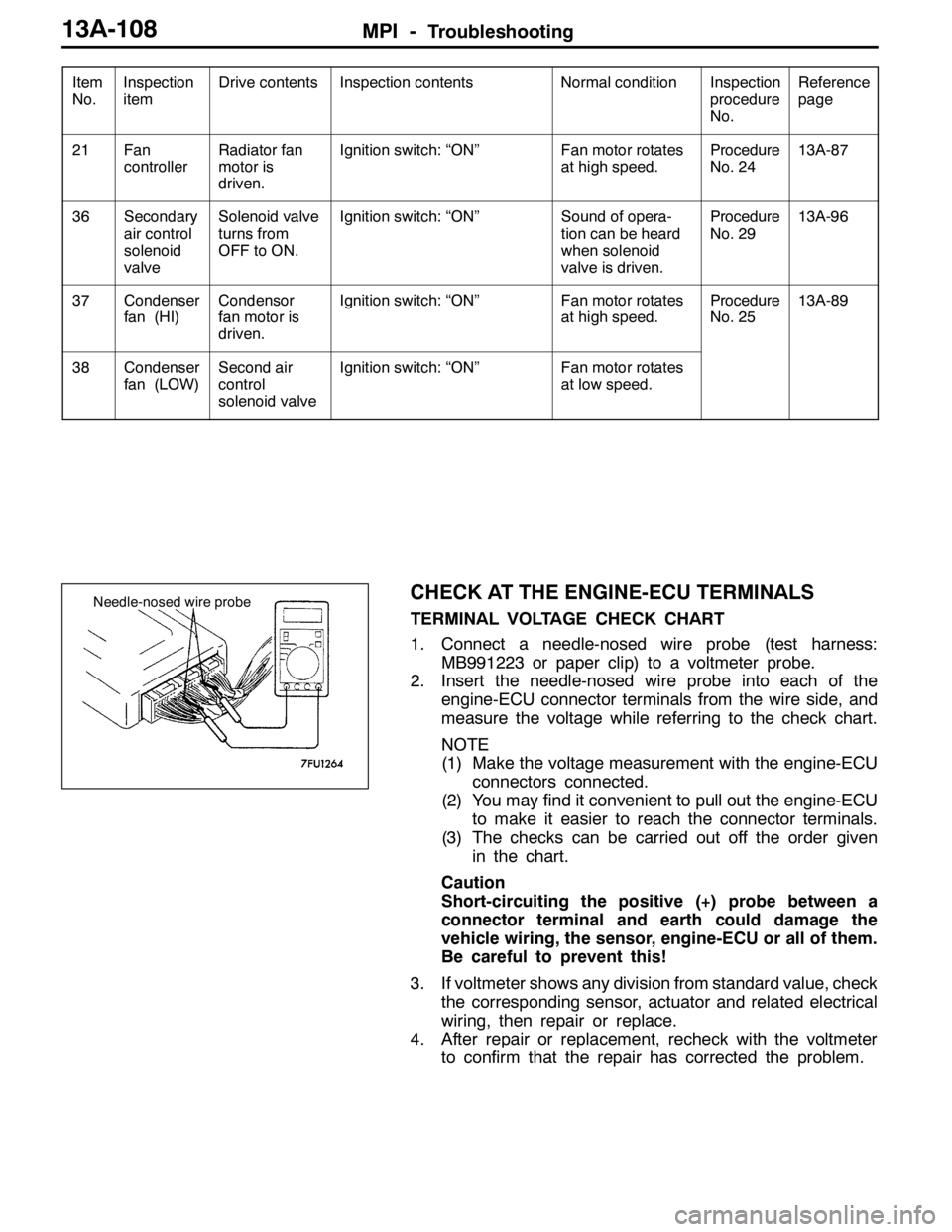

CHECK AT THE ENGINE-ECU TERMINALS

TERMINAL VOLTAGE CHECK CHART

1. Connect a needle-nosed wire probe (test harness:

MB991223 or paper clip) to a voltmeter probe.

2. Insert the needle-nosed wire probe into each of the

engine-ECU connector terminals from the wire side, and

measure the voltage while referring to the check chart.

NOTE

(1) Make the voltage measurement with the engine-ECU

connectors connected.

(2) You may find it convenient to pull out the engine-ECU

to make it easier to reach the connector terminals.

(3) The checks can be carried out off the order given

in the chart.

Caution

Short-circuiting the positive (+) probe between a

connector terminal and earth could damage the

vehicle wiring, the sensor, engine-ECU or all of them.

Be careful to prevent this!

3. If voltmeter shows any division from standard value, check

the corresponding sensor, actuator and related electrical

wiring, then repair or replace.

4. After repair or replacement, recheck with the voltmeter

to confirm that the repair has corrected the problem.

Needle-nosed wire probe