sensor MITSUBISHI LANCER EVOLUTION 2007 Service Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 541 of 1449

MPI -Troubleshooting13A-9

TROUBLESHOOTING

DIAGNOSIS TROUBLESHOOTING FLOW

Refer to GROUP 00 - How to Use Troubleshooting/Inspection

Service Point.

NOTE

If the engine-ECU is replaced, the immobilizer-ECU and

ignition key should be replaced together with it.

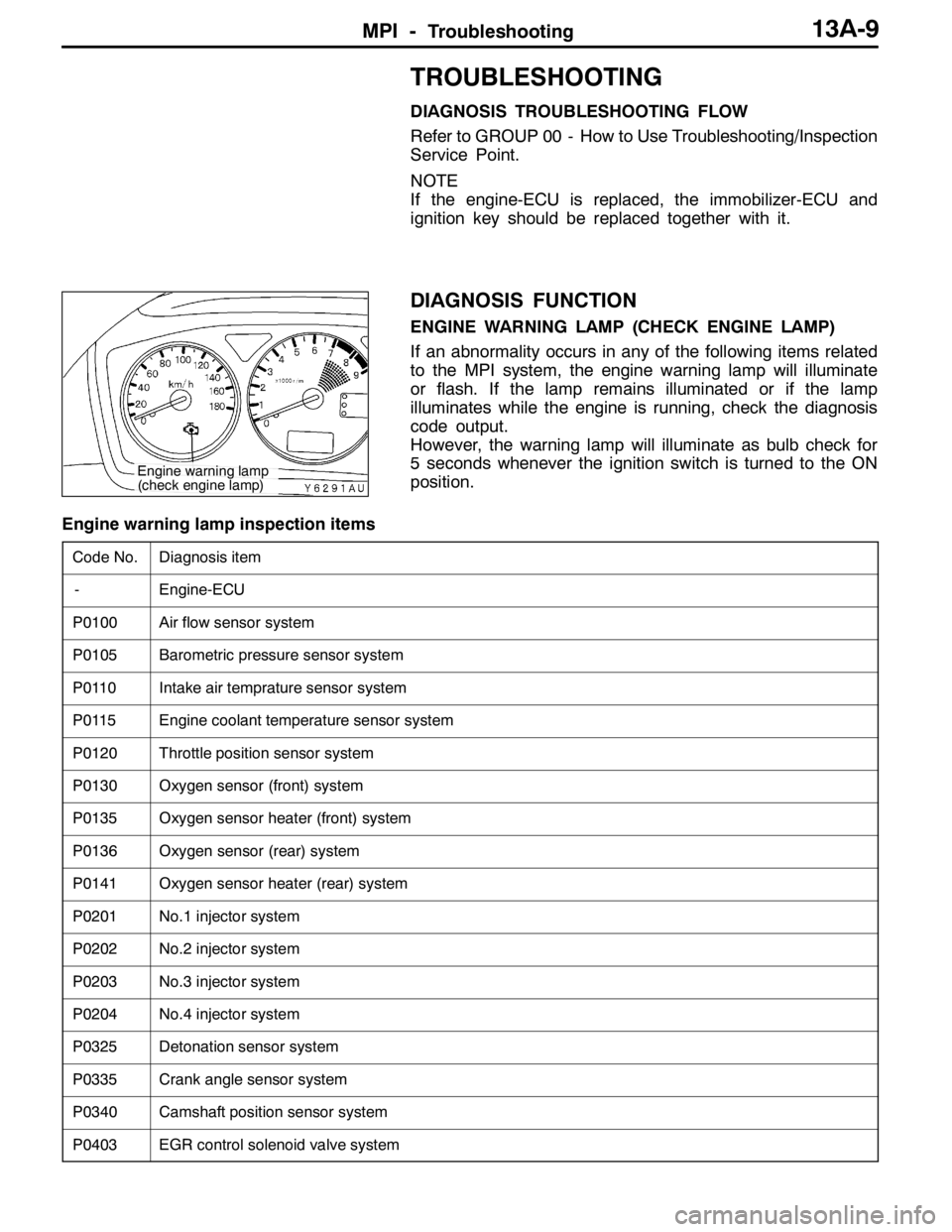

DIAGNOSIS FUNCTION

ENGINE WARNING LAMP (CHECK ENGINE LAMP)

If an abnormality occurs in any of the following items related

to the MPI system, the engine warning lamp will illuminate

or flash. If the lamp remains illuminated or if the lamp

illuminates while the engine is running, check the diagnosis

code output.

However, the warning lamp will illuminate as bulb check for

5 seconds whenever the ignition switch is turned to the ON

position.

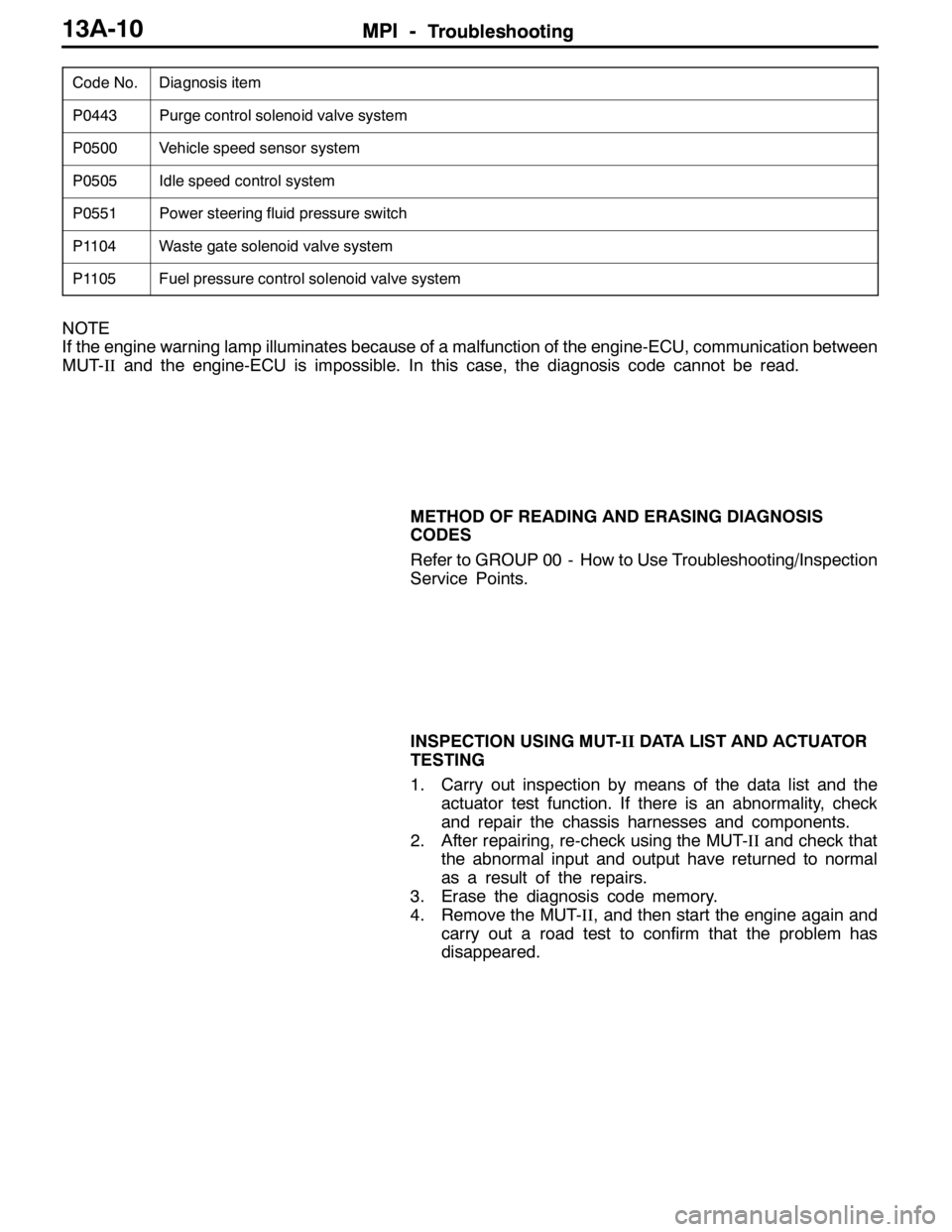

Engine warning lamp inspection items

Code No.Diagnosis item

-Engine-ECU

P0100Air flow sensor system

P0105Barometric pressure sensor system

P0110Intake air temprature sensor system

P0115Engine coolant temperature sensor system

P0120Throttle position sensor system

P0130Oxygen sensor (front) system

P0135Oxygen sensor heater (front) system

P0136Oxygen sensor (rear) system

P0141Oxygen sensor heater (rear) system

P0201No.1 injector system

P0202No.2 injector system

P0203No.3 injector system

P0204No.4 injector system

P0325Detonation sensor system

P0335Crank angle sensor system

P0340Camshaft position sensor system

P0403EGR control solenoid valve system

Engine warning lamp

(check engine lamp)

Page 542 of 1449

MPI -TroubleshootingMPI -Troubleshooting13A-10

Code No. Diagnosis item

P0443Purge control solenoid valve system

P0500Vehicle speed sensor system

P0505Idle speed control system

P0551Power steering fluid pressure switch

P1104Waste gate solenoid valve system

P1105Fuel pressure control solenoid valve system

NOTE

If the engine warning lamp illuminates because of a malfunction of the engine-ECU, communication between

MUT-IIand the engine-ECU is impossible. In this case, the diagnosis code cannot be read.

METHOD OF READING AND ERASING DIAGNOSIS

CODES

Refer to GROUP 00 - How to Use Troubleshooting/Inspection

Service Points.

INSPECTION USING MUT-IIDATA LIST AND ACTUATOR

TESTING

1. Carry out inspection by means of the data list and the

actuator test function. If there is an abnormality, check

and repair the chassis harnesses and components.

2. After repairing, re-check using the MUT-IIand check that

the abnormal input and output have returned to normal

as a result of the repairs.

3. Erase the diagnosis code memory.

4. Remove the MUT-II, and then start the engine again and

carry out a road test to confirm that the problem has

disappeared.

Page 543 of 1449

MPI -TroubleshootingMPI -Troubleshooting13A-11

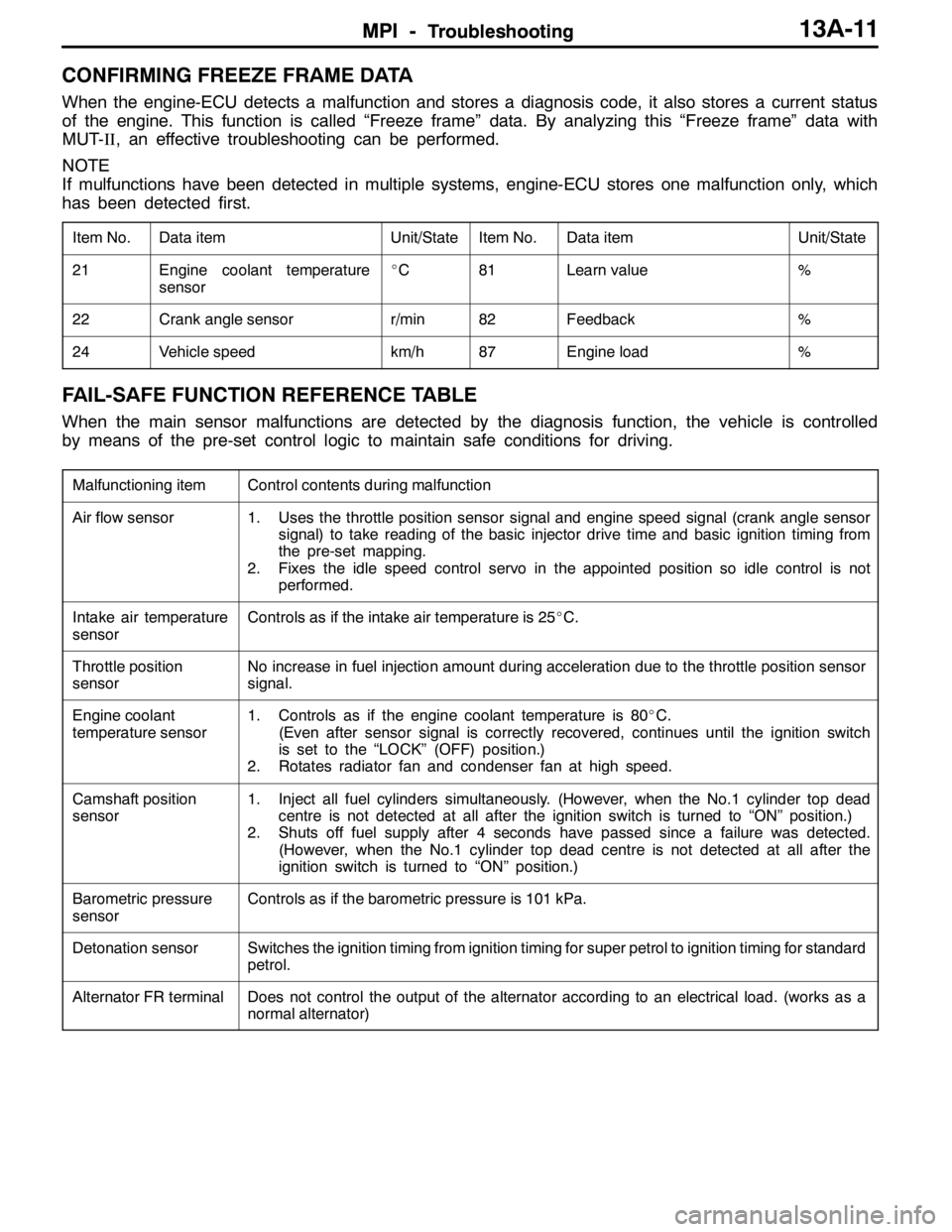

CONFIRMING FREEZE FRAME DATA

When the engine-ECU detects a malfunction and stores a diagnosis code, it also stores a current status

of the engine. This function is called “Freeze frame” data. By analyzing this “Freeze frame” data with

MUT-II, an effective troubleshooting can be performed.

NOTE

If mulfunctions have been detected in multiple systems, engine-ECU stores one malfunction only, which

has been detected first.

Item No.Data itemUnit/StateItem No.Data itemUnit/State

21Engine coolant temperature

sensor_C81Learn value%

22Crank angle sensorr/min82Feedback%

24Vehicle speedkm/h87Engine load%

FAIL-SAFE FUNCTION REFERENCE TABLE

When the main sensor malfunctions are detected by the diagnosis function, the vehicle is controlled

by means of the pre-set control logic to maintain safe conditions for driving.

Malfunctioning itemControl contents during malfunction

Air flow sensor1. Uses the throttle position sensor signal and engine speed signal (crank angle sensor

signal) to take reading of the basic injector drive time and basic ignition timing from

the pre-set mapping.

2. Fixes the idle speed control servo in the appointed position so idle control is not

performed.

Intake air temperature

sensorControls as if the intake air temperature is 25_C.

Throttle position

sensorNo increase in fuel injection amount during acceleration due to the throttle position sensor

signal.

Engine coolant

temperature sensor1. Controls as if the engine coolant temperature is 80_C.

(Even after sensor signal is correctly recovered, continues until the ignition switch

is set to the “LOCK” (OFF) position.)

2. Rotates radiator fan and condenser fan at high speed.

Camshaft position

sensor1. Inject all fuel cylinders simultaneously. (However, when the No.1 cylinder top dead

centre is not detected at all after the ignition switch is turned to “ON” position.)

2. Shuts off fuel supply after 4 seconds have passed since a failure was detected.

(However, when the No.1 cylinder top dead centre is not detected at all after the

ignition switch is turned to “ON” position.)

Barometric pressure

sensorControls as if the barometric pressure is 101 kPa.

Detonation sensorSwitches the ignition timing from ignition timing for super petrol to ignition timing for standard

petrol.

Alternator FR terminalDoes not control the output of the alternator according to an electrical load. (works as a

normal alternator)

Page 544 of 1449

MPI -Troubleshooting13A-12

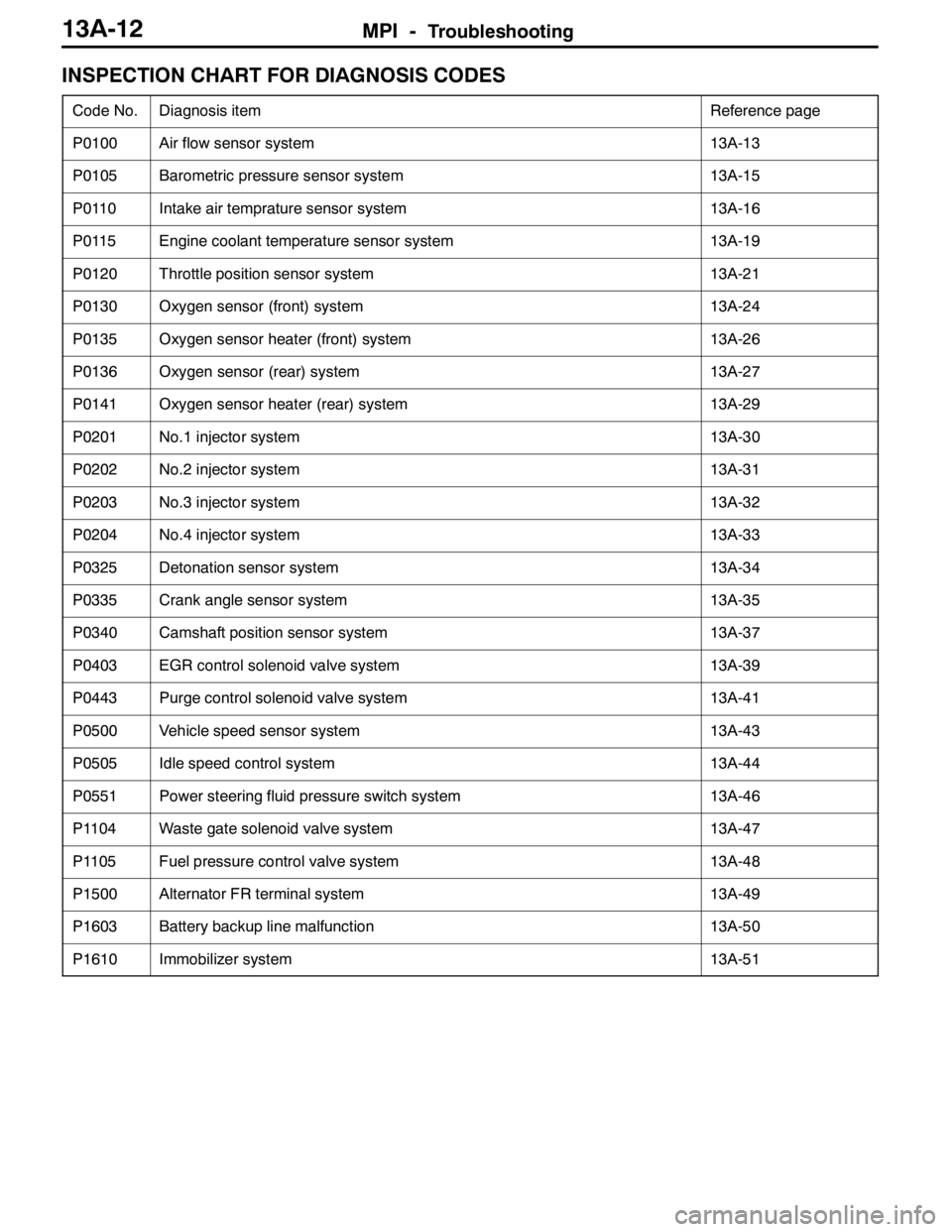

INSPECTION CHART FOR DIAGNOSIS CODES

Code No.Diagnosis itemReference page

P0100Air flow sensor system13A-13

P0105Barometric pressure sensor system13A-15

P0110Intake air temprature sensor system13A-16

P0115Engine coolant temperature sensor system13A-19

P0120Throttle position sensor system13A-21

P0130Oxygen sensor (front) system13A-24

P0135Oxygen sensor heater (front) system13A-26

P0136Oxygen sensor (rear) system13A-27

P0141Oxygen sensor heater (rear) system13A-29

P0201No.1 injector system13A-30

P0202No.2 injector system13A-31

P0203No.3 injector system13A-32

P0204No.4 injector system13A-33

P0325Detonation sensor system13A-34

P0335Crank angle sensor system13A-35

P0340Camshaft position sensor system13A-37

P0403EGR control solenoid valve system13A-39

P0443Purge control solenoid valve system13A-41

P0500Vehicle speed sensor system13A-43

P0505Idle speed control system13A-44

P0551Power steering fluid pressure switch system13A-46

P1104Waste gate solenoid valve system13A-47

P1105Fuel pressure control valve system13A-48

P1500Alternator FR terminal system13A-49

P1603Battery backup line malfunction13A-50

P1610Immobilizer system13A-51

Page 545 of 1449

MPI -Troubleshooting13A-13

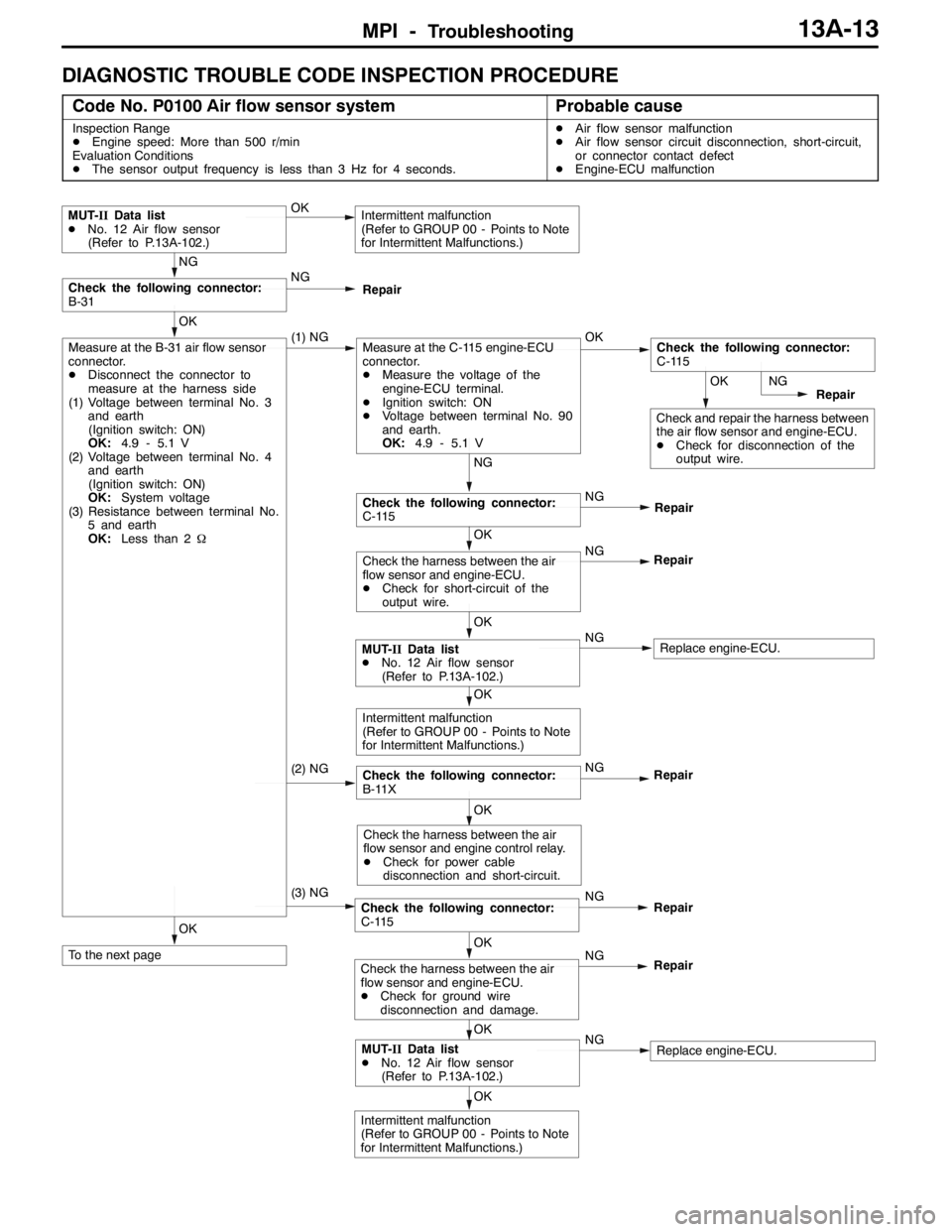

DIAGNOSTIC TROUBLE CODE INSPECTION PROCEDURE

Code No. P0100 Air flow sensor systemProbable cause

Inspection Range

DEngine speed: More than 500 r/min

Evaluation Conditions

DThe sensor output frequency is less than 3 Hz for 4 seconds.DAir flow sensor malfunction

DAir flow sensor circuit disconnection, short-circuit,

or connector contact defect

DEngine-ECU malfunction

OK

Intermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

OK

MUT-IIData list

DNo. 12 Air flow sensor

(Refer to P.13A-102.)NGReplace engine-ECU.

OK

To the next pageOK

Check the harness between the air

flow sensor and engine-ECU.

DCheck for ground wire

disconnection and damage.NG

Repair

(3) NGCheck the following connector:

C-115NG

Repair

OK

Check the harness between the air

flow sensor and engine control relay.

DCheck for power cable

disconnection and short-circuit.

(2) NGCheck the following connector:

B-11XNG

OK

Intermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

OK

MUT-IIData list

DNo. 12 Air flow sensor

(Refer to P.13A-102.)NGReplace engine-ECU.

OK

Check the harness between the air

flow sensor and engine-ECU.

DCheck for short-circuit of the

output wire.NG

Repair

NG

Check the following connector:

C-115NG

Repair

OK

Check and repair the harness between

the air flow sensor and engine-ECU.

DCheck for disconnection of the

output wire.NG

Repair

OK

Measure at the B-31 air flow sensor

connector.

DDisconnect the connector to

measure at the harness side

(1) Voltage between terminal No. 3

and earth

(Ignition switch: ON)

OK:4.9 - 5.1 V

(2) Voltage between terminal No. 4

and earth

(Ignition switch: ON)

OK:System voltage

(3) Resistance between terminal No.

5 and earth

OK:Less than 2Ω(1) NGMeasure at the C-115 engine-ECU

connector.

DMeasure the voltage of the

engine-ECU terminal.

DIgnition switch: ON

DVoltage between terminal No. 90

and earth.

OK:4.9 - 5.1 VOKCheck the following connector:

C-115

NG

Check the following connector:

B-31NG

Repair

MUT-IIData list

DNo. 12 Air flow sensor

(Refer to P.13A-102.)OKIntermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

Repair

Page 546 of 1449

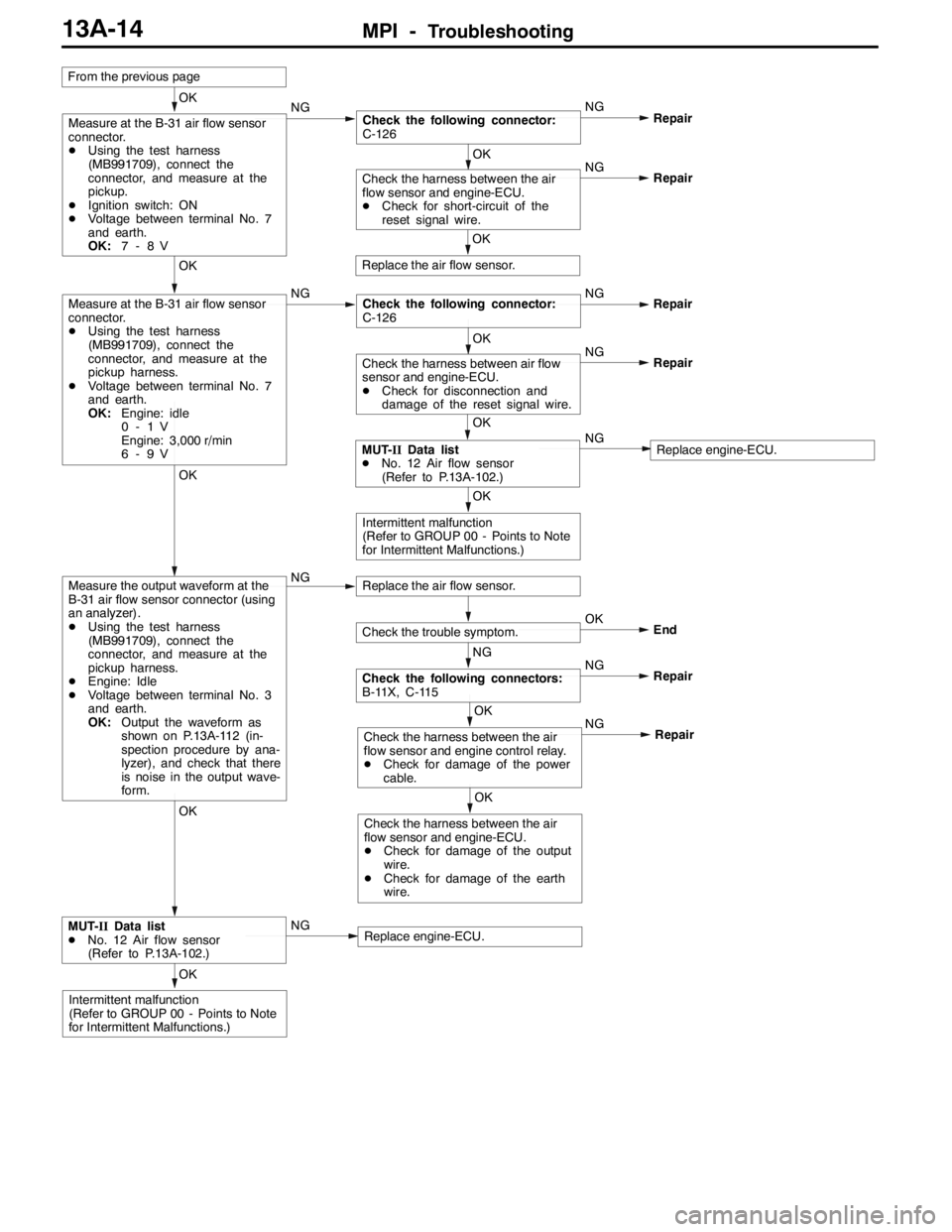

MPI -Troubleshooting13A-14

OK

Check the harness between the air

flow sensor and engine-ECU.

DCheck for damage of the output

wire.

DCheck for damage of the earth

wire.NG

OK

Check the harness between the air

flow sensor and engine control relay.

DCheck for damage of the power

cable.Repair NG

NG

Check the following connectors:

B-11X, C-115Repair OK

Check the trouble symptom.End

OK

Intermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

OK

MUT-IIData list

DNo. 12 Air flow sensor

(Refer to P.13A-102.)NGReplace engine-ECU.

Replace the air flow sensor.

OK

Intermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

OK

Measure the output waveform at the

B-31 air flow sensor connector (using

an analyzer).

DUsing the test harness

(MB991709), connect the

connector, and measure at the

pickup harness.

DEngine: Idle

DVoltage between terminal No. 3

and earth.

OK:Output the waveform as

shown on P.13A-112 (in-

spection procedure by ana-

lyzer), and check that there

is noise in the output wave-

form.NG

OK

MUT-IIData list

DNo. 12 Air flow sensor

(Refer to P.13A-102.)NGReplace engine-ECU.

OK

Check the harness between air flow

sensor and engine-ECU.

DCheck for disconnection and

damage of the reset signal wire.NG

Repair

OK

Measure at the B-31 air flow sensor

connector.

DUsing the test harness

(MB991709), connect the

connector, and measure at the

pickup harness.

DVoltage between terminal No. 7

and earth.

OK:Engine: idle

0-1V

Engine: 3,000 r/min

6-9VNGCheck the following connector:

C-126NGRepair

OK

Replace the air flow sensor.

OK

Check the harness between the air

flow sensor and engine-ECU.

DCheck for short-circuit of the

reset signal wire.NG

Repair

OK

Measure at the B-31 air flow sensor

connector.

DUsing the test harness

(MB991709), connect the

connector, and measure at the

pickup.

DIgnition switch: ON

DVoltage between terminal No. 7

and earth.

OK:7-8VNGCheck the following connector:

C-126NGRepair

From the previous page

Page 547 of 1449

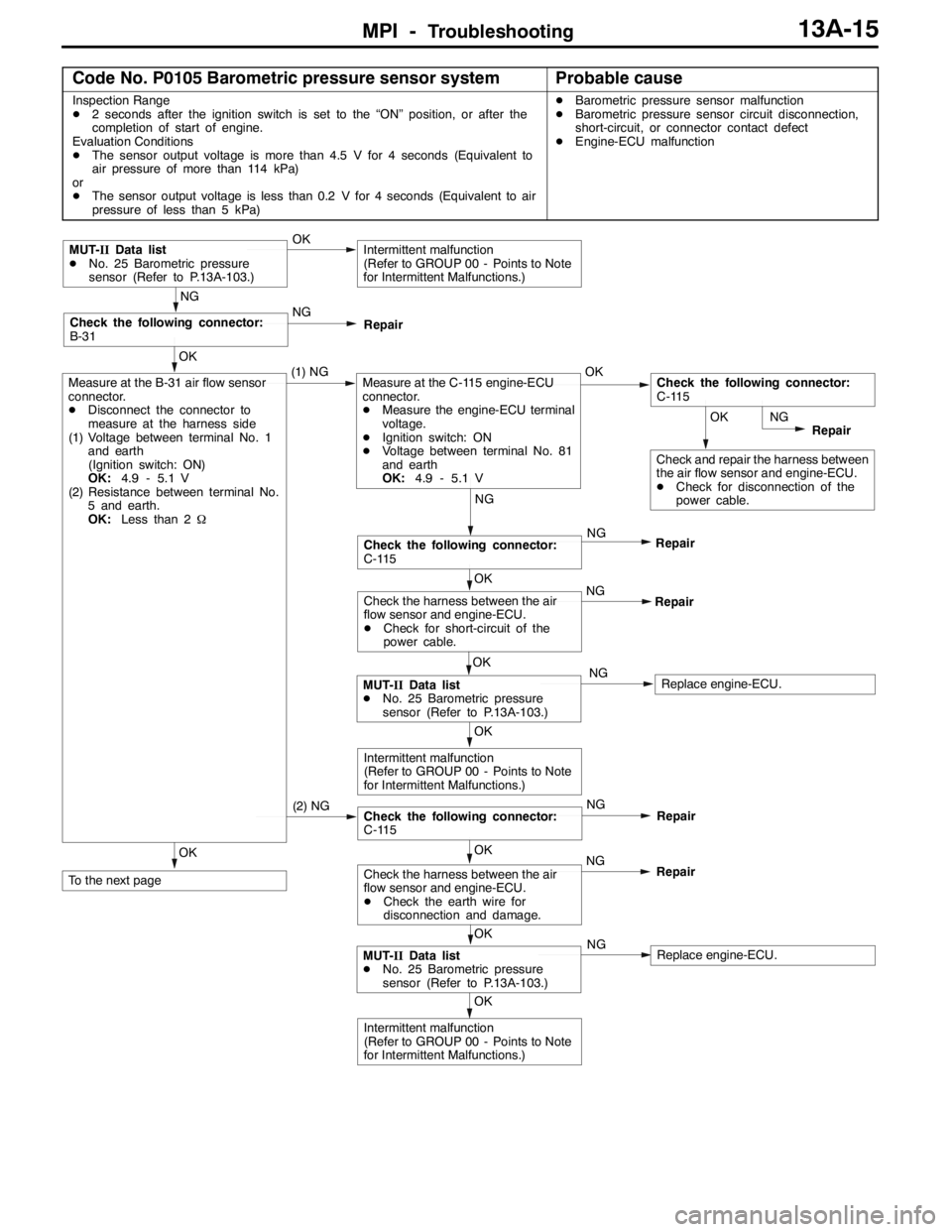

MPI -Troubleshooting13A-15

Code No. P0105 Barometric pressure sensor systemProbable cause

Inspection Range

D2 seconds after the ignition switch is set to the “ON” position, or after the

completion of start of engine.

Evaluation Conditions

DThe sensor output voltage is more than 4.5 V for 4 seconds (Equivalent to

air pressure of more than 114 kPa)

or

DThe sensor output voltage is less than 0.2 V for 4 seconds (Equivalent to air

pressure of less than 5 kPa)DBarometric pressure sensor malfunction

DBarometric pressure sensor circuit disconnection,

short-circuit, or connector contact defect

DEngine-ECU malfunction

OK

To the next page

OK

Intermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

OK

MUT-IIData list

DNo. 25 Barometric pressure

sensor (Refer to P.13A-103.)NGReplace engine-ECU.

OK

Check the harness between the air

flow sensor and engine-ECU.

DCheck the earth wire for

disconnection and damage.NG

Repair

(2) NGCheck the following connector:

C-115NG

Repair

OK

Intermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

OK

MUT-IIData list

DNo. 25 Barometric pressure

sensor (Refer to P.13A-103.)NGReplace engine-ECU.

OK

Check the harness between the air

flow sensor and engine-ECU.

DCheck for short-circuit of the

power cable.NG

Repair

NG

Check the following connector:

C-115NG

Repair

OK

Check and repair the harness between

the air flow sensor and engine-ECU.

DCheck for disconnection of the

power cable.NG

Repair

OK

Measure at the B-31 air flow sensor

connector.

DDisconnect the connector to

measure at the harness side

(1) Voltage between terminal No. 1

and earth

(Ignition switch: ON)

OK:4.9 - 5.1 V

(2) Resistance between terminal No.

5 and earth.

OK:Less than 2Ω(1) NGMeasure at the C-115 engine-ECU

connector.

DMeasure the engine-ECU terminal

voltage.

DIgnition switch: ON

DVoltage between terminal No. 81

and earth

OK:4.9 - 5.1 VOKCheck the following connector:

C-115

NG

Check the following connector:

B-31NG

Repair

MUT-IIData list

DNo. 25 Barometric pressure

sensor (Refer to P.13A-103.)OKIntermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

Page 548 of 1449

MPI -Troubleshooting13A-16

OK

Intermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

OK

MUT-IIData list

DNo. 25 Barometric pressure

sensor (Refer to P.13A-103.)NGReplace engine-ECU.

OK

Check the following connector:

C-115NG

Repair

OK

Check and repair the harness between

the air flow sensor and engine-ECU.

DCheck for disconnection and

damage of the output wire.

OK

Measure at the C-115 engine-ECU

connector.

DMeasure the engine-ECU terminal

voltage.

DIgnition switch: ON

DVoltage between terminal No. 85

and earth.

OK:High 0 m 3.8 - 4.2 V

High 600 m 3.5 - 3.9 V

High 1,200 m 3.3 - 3.7 V

High 1,800 m 3.0 - 3.4 VNGCheck the following connector:

C-115NGRepair

OK

Replace the air flow sensor.

OK

Check the harness between the air

flow sensor and engine-ECU.

DCheck for short-circuit and

damage of the output wire.NG

Repair

(3) NGCheck the following connector:

C-115NG

Repair

OK

Check and repair the harness between

the air flow sensor and engine-ECU.

DCheck for damage of the power

cable.

DCheck for damage of the earth

wire.

OK

Measure at the B-31 air flow sensor

connector.

DUsing the test harness

(MB991709), connect only

connector terminals No. 1, No. 2,

and No. 5, and measure at the

pickup harness.

DIgnition switch: ON

(1) Voltage between terminal No. 1

and earth

OK:4.9 - 5.1 V

(2) Voltage between terminal No. 5

and earth

OK:Less than 0.5 V

(3) Voltage from No. 2 to earth

OK:High 0 m 3.8 - 4.2 V

High 600 m 3.5 - 3.9 V

High 1,200 m 3.3 - 3.7 V

High 1,800 m 3.0 - 3.4 V(1), (2) NGCheck the following connectors:

C-115NGRepair

From the previous page

Code No. P0110 Intake air temperature sensor systemProbable cause

Inspection Range

DAfter setting the ignition switch to the “ON” position, or after 2 seconds from

completion of start.

Evaluation Conditions

DThe sensor output voltage is more than 4.6 V for 4 seconds (Equivalent to intake

air temperature less than - 40_C)

or

DThe sensor output voltage is less than 0.2 V for 4 seconds (Equivalent to intake

air temperature of more than 120_C)DIntake air temperature sensor malfunction

DIntake air temperature sensor circuit disconnection,

short-circuit, or connector contact defect

DEngine-ECU malfunction

Page 549 of 1449

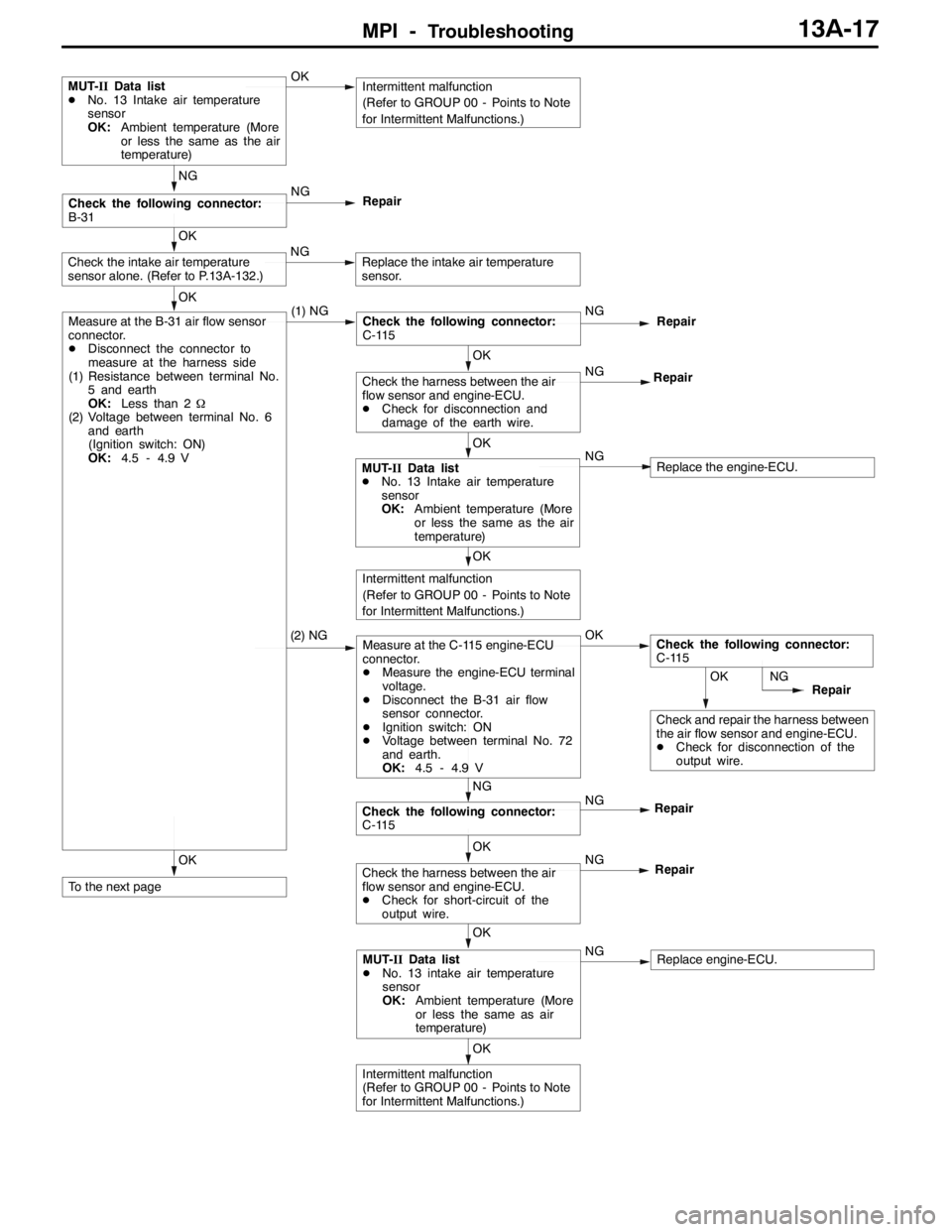

MPI -Troubleshooting13A-17

OK

Check the intake air temperature

sensor alone. (Refer to P.13A-132.)NGReplace the intake air temperature

sensor.

OK

Intermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

OK

To the next page

OK

Intermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

OK

MUT-IIData list

DNo. 13 intake air temperature

sensor

OK:Ambient temperature (More

or less the same as air

temperature)NGReplace engine-ECU.

OK

Check the harness between the air

flow sensor and engine-ECU.

DCheck for short-circuit of the

output wire.NG

Repair

OK

Check and repair the harness between

the air flow sensor and engine-ECU.

DCheck for disconnection of the

output wire.NG

Repair

NG

Check the following connector:

C-115NG

Repair

(2) NGMeasure at the C-115 engine-ECU

connector.

DMeasure the engine-ECU terminal

voltage.

DDisconnect the B-31 air flow

sensor connector.

DIgnition switch: ON

DVoltage between terminal No. 72

and earth.

OK:4.5 - 4.9 VOKCheck the following connector:

C-115

OK

MUT-IIData list

DNo. 13 Intake air temperature

sensor

OK:Ambient temperature (More

or less the same as the air

temperature)NGReplace the engine-ECU.

OK

Check the harness between the air

flow sensor and engine-ECU.

DCheck for disconnection and

damage of the earth wire.NG

Repair

OK

Measure at the B-31 air flow sensor

connector.

DDisconnect the connector to

measure at the harness side

(1) Resistance between terminal No.

5 and earth

OK:Less than 2Ω

(2) Voltage between terminal No. 6

and earth

(Ignition switch: ON)

OK:4.5 - 4.9 V(1) NGCheck the following connector:

C-115NGRepair

NG

Check the following connector:

B-31NG

Repair

MUT-IIData list

DNo. 13 Intake air temperature

sensor

OK:Ambient temperature (More

or less the same as the air

temperature)OKIntermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

Page 550 of 1449

MPI -Troubleshooting13A-18

OK

Intermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

OK

MUT-IIData list

DNo. 13 intake air temperature

sensor

OK:Ambient temperature (More

or less the same as the air

temperature)NGReplace engine-ECU.

OK

Check and repair the harness between

the air flow sensor and engine-ECU.

DCheck for damage of the output

wire.

DCheck for damage of the earth

wire.

OK

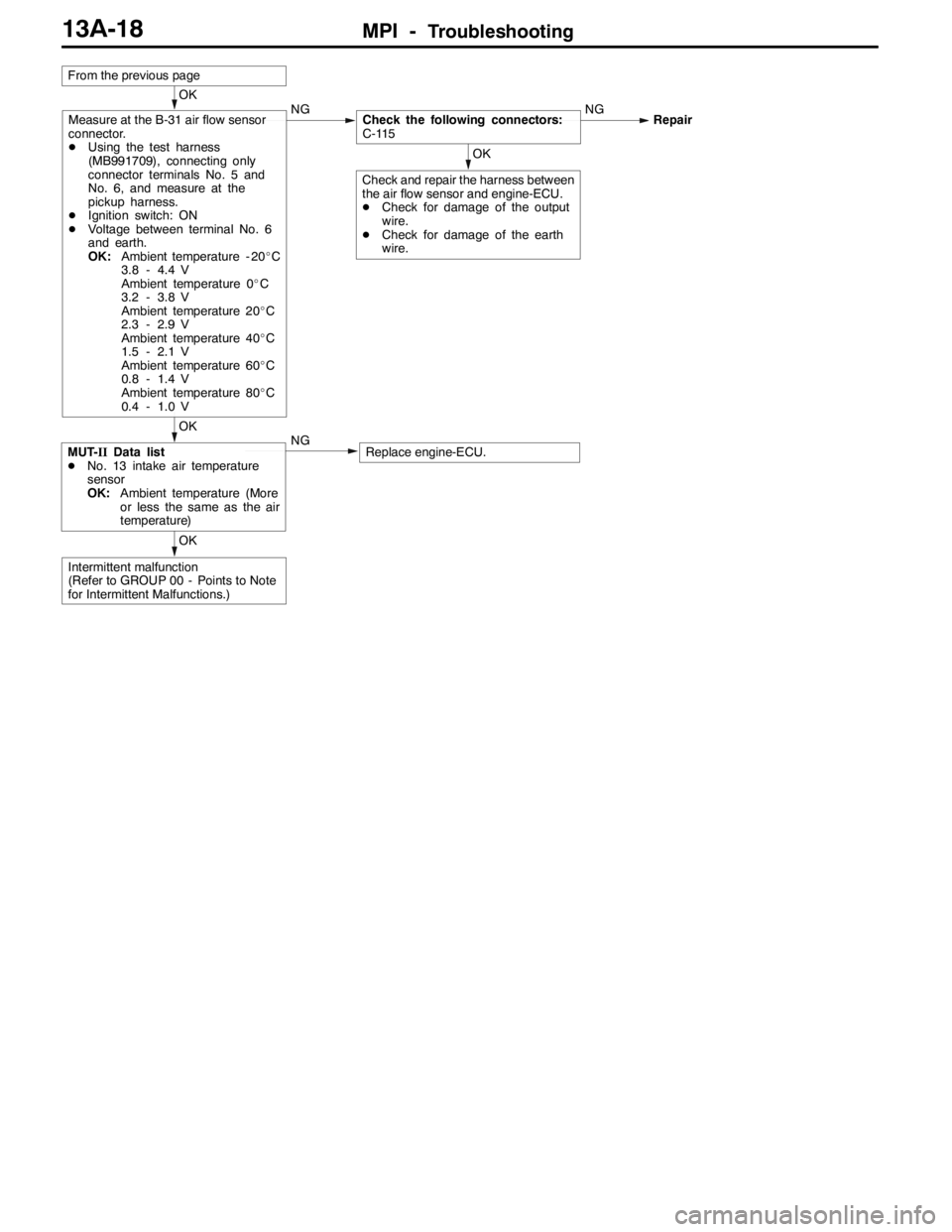

Measure at the B-31 air flow sensor

connector.

DUsing the test harness

(MB991709), connecting only

connector terminals No. 5 and

No. 6, and measure at the

pickup harness.

DIgnition switch: ON

DVoltage between terminal No. 6

and earth.

OK:Ambient temperature - 20_C

3.8 - 4.4 V

Ambient temperature 0_C

3.2 - 3.8 V

Ambient temperature 20_C

2.3 - 2.9 V

Ambient temperature 40_C

1.5 - 2.1 V

Ambient temperature 60_C

0.8 - 1.4 V

Ambient temperature 80_C

0.4 - 1.0 VNGCheck the following connectors:

C-115NGRepair

From the previous page