sensor MITSUBISHI LANCER EVOLUTION 2007 Service Owners Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 561 of 1449

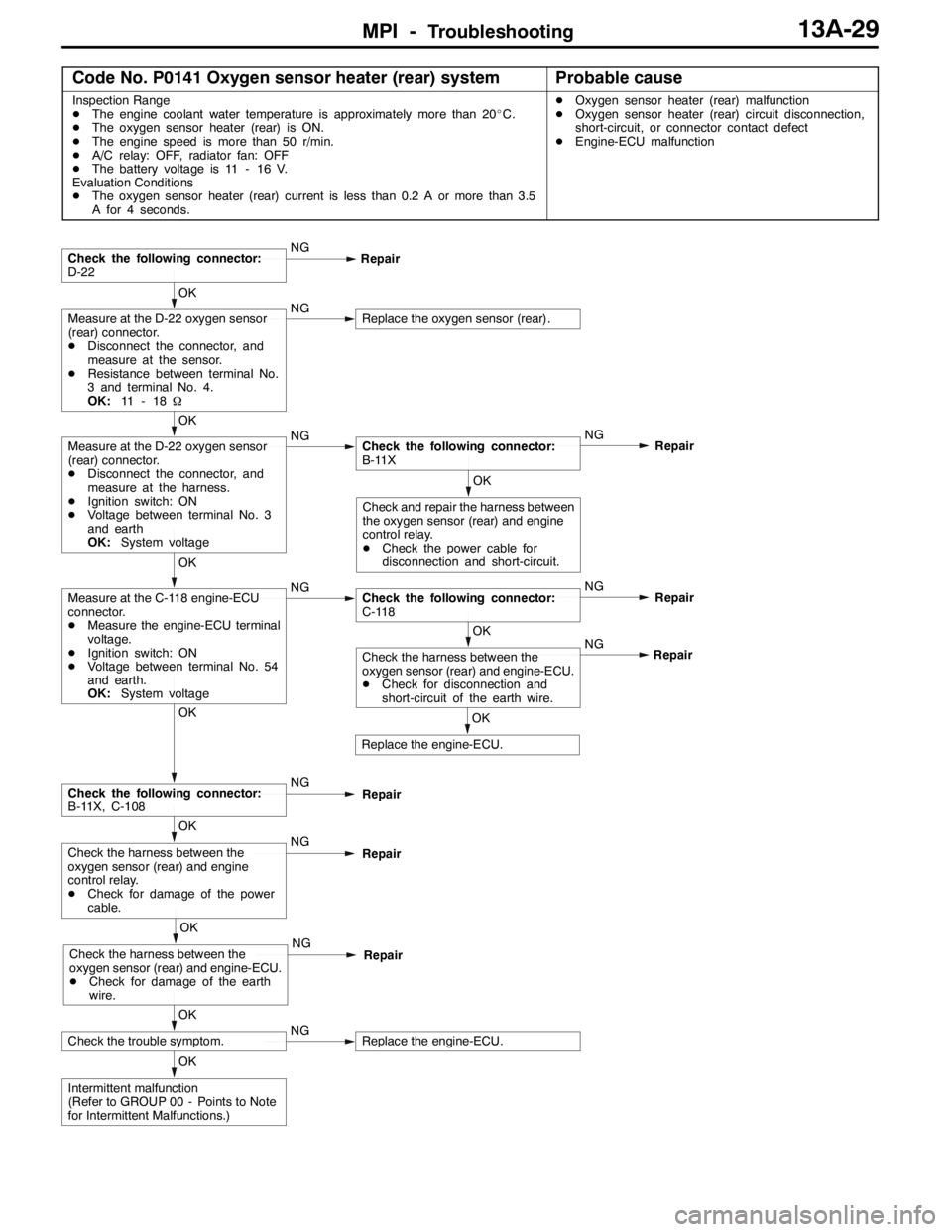

MPI -Troubleshooting13A-29

Code No. P0141 Oxygen sensor heater (rear) systemProbable cause

Inspection Range

DThe engine coolant water temperature is approximately more than 20_C.

DThe oxygen sensor heater (rear) is ON.

DThe engine speed is more than 50 r/min.

DA/C relay: OFF, radiator fan: OFF

DThe battery voltage is 11 - 16 V.

Evaluation Conditions

DThe oxygen sensor heater (rear) current is less than 0.2 A or more than 3.5

A for 4 seconds.DOxygen sensor heater (rear) malfunction

DOxygen sensor heater (rear) circuit disconnection,

short-circuit, or connector contact defect

DEngine-ECU malfunction

OK

Intermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

OK

Check the trouble symptom.NGReplace the engine-ECU.

OK

Check the harness between the

oxygen sensor (rear) and engine-ECU.

DCheck for damage of the earth

wire.NG

Repair

OK

Check the harness between the

oxygen sensor (rear) and engine

control relay.

DCheck for damage of the power

cable.NG

Repair

OK

Check the following connector:

B-11X, C-108NG

Repair

OK

Replace the engine-ECU.NG

OK

Check the harness between the

oxygen sensor (rear) and engine-ECU.

DCheck for disconnection and

short-circuit of the earth wire.Repair

OK

Measure at the C-118 engine-ECU

connector.

DMeasure the engine-ECU terminal

voltage.

DIgnition switch: ON

DVoltage between terminal No. 54

and earth.

OK:System voltageNGCheck the following connector:

C-118NG

Repair

OK

Check and repair the harness between

the oxygen sensor (rear) and engine

control relay.

DCheck the power cable for

disconnection and short-circuit.

OK

Measure at the D-22 oxygen sensor

(rear) connector.

DDisconnect the connector, and

measure at the harness.

DIgnition switch: ON

DVoltage between terminal No. 3

and earth

OK:System voltageNGCheck the following connector:

B-11XNG

Repair

OK

Measure at the D-22 oxygen sensor

(rear) connector.

DDisconnect the connector, and

measure at the sensor.

DResistance between terminal No.

3 and terminal No. 4.

OK:11 - 1 8ΩNGReplace the oxygen sensor (rear).

Check the following connector:

D-22NG

Repair

Page 562 of 1449

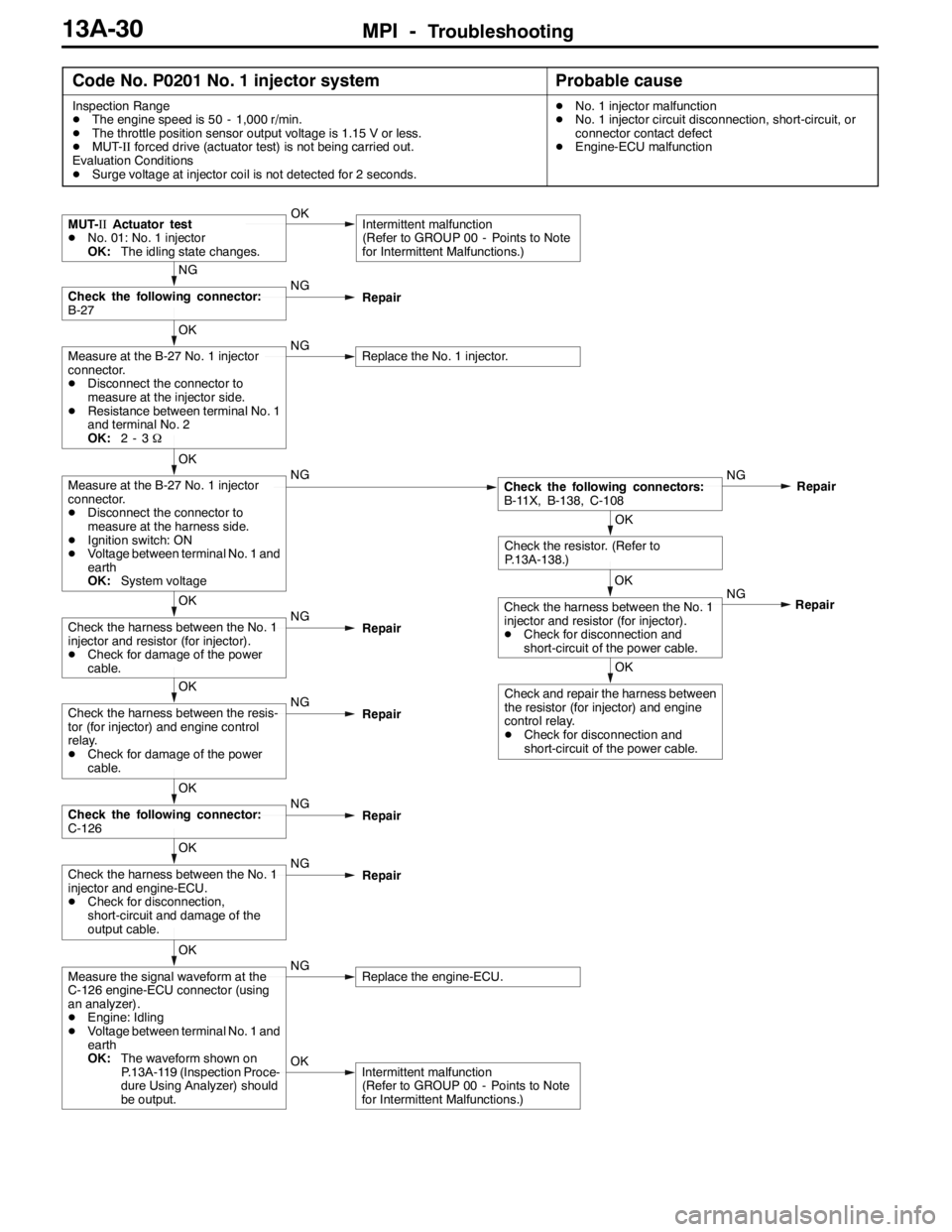

MPI -Troubleshooting13A-30

Code No. P0201 No. 1 injector systemProbable cause

Inspection Range

DThe engine speed is 50 - 1,000 r/min.

DThe throttle position sensor output voltage is 1.15 V or less.

DMUT-IIforced drive (actuator test) is not being carried out.

Evaluation Conditions

DSurge voltage at injector coil is not detected for 2 seconds.DNo. 1 injector malfunction

DNo. 1 injector circuit disconnection, short-circuit, or

connector contact defect

DEngine-ECU malfunction

OKIntermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

OK

Measure the signal waveform at the

C-126 engine-ECU connector (using

an analyzer).

DEngine: Idling

DVoltage between terminal No. 1 and

earth

OK:The waveform shown on

P.13A-119 (Inspection Proce-

dure Using Analyzer) should

be output.NGReplace the engine-ECU.

OK

Check the harness between the No. 1

injector and engine-ECU.

DCheck for disconnection,

short-circuit and damage of the

output cable.NG

Repair

OK

Check the following connector:

C-126NG

Repair

OK

Check the harness between the resis-

tor (for injector) and engine control

relay.

DCheck for damage of the power

cable.NG

Repair

OK

Check the harness between the No. 1

injector and resistor (for injector).

DCheck for damage of the power

cable.NG

Repair

OK

Check and repair the harness between

the resistor (for injector) and engine

control relay.

DCheck for disconnection and

short-circuit of the power cable.NG

OK

Check the harness between the No. 1

injector and resistor (for injector).

DCheck for disconnection and

short-circuit of the power cable.Repair

OK

Check the resistor. (Refer to

P.13A-138.)

OK

Measure at the B-27 No. 1 injector

connector.

DDisconnect the connector to

measure at the harness side.

DIgnition switch: ON

DVoltage between terminal No. 1 and

earth

OK:System voltageNGCheck the following connectors:

B-11X, B-138, C-108NG

Repair

OK

Measure at the B-27 No. 1 injector

connector.

DDisconnect the connector to

measure at the injector side.

DResistance between terminal No. 1

and terminal No. 2

OK:2-3ΩNGReplace the No. 1 injector.

NG

Check the following connector:

B-27NG

Repair

MUT-IIActuator test

DNo. 01: No. 1 injector

OK:The idling state changes.OKIntermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

Page 563 of 1449

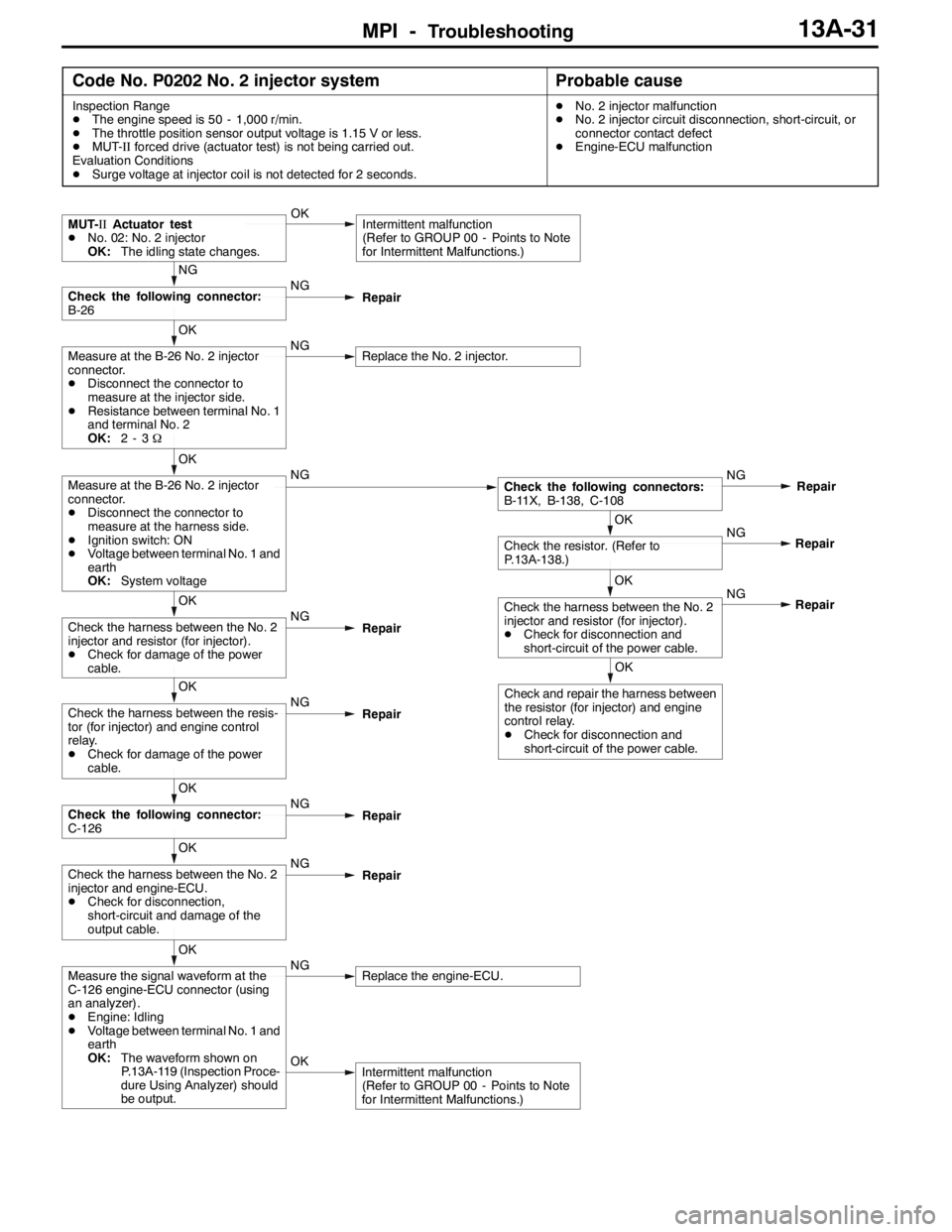

MPI -Troubleshooting13A-31

Code No. P0202 No. 2 injector systemProbable cause

Inspection Range

DThe engine speed is 50 - 1,000 r/min.

DThe throttle position sensor output voltage is 1.15 V or less.

DMUT-IIforced drive (actuator test) is not being carried out.

Evaluation Conditions

DSurge voltage at injector coil is not detected for 2 seconds.DNo. 2 injector malfunction

DNo. 2 injector circuit disconnection, short-circuit, or

connector contact defect

DEngine-ECU malfunction

OKIntermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

OK

Measure the signal waveform at the

C-126 engine-ECU connector (using

an analyzer).

DEngine: Idling

DVoltage between terminal No. 1 and

earth

OK:The waveform shown on

P.13A-119 (Inspection Proce-

dure Using Analyzer) should

be output.NGReplace the engine-ECU.

OK

Check the harness between the No. 2

injector and engine-ECU.

DCheck for disconnection,

short-circuit and damage of the

output cable.NG

Repair

OK

Check the following connector:

C-126NG

Repair

OK

Check the harness between the resis-

tor (for injector) and engine control

relay.

DCheck for damage of the power

cable.NG

Repair

OK

Check and repair the harness between

the resistor (for injector) and engine

control relay.

DCheck for disconnection and

short-circuit of the power cable.NG

OK

Check the harness between the No. 2

injector and resistor (for injector).

DCheck for disconnection and

short-circuit of the power cable.Repair NG

OK

Check the resistor. (Refer to

P.13A-138.)Repair

OK

Check the harness between the No. 2

injector and resistor (for injector).

DCheck for damage of the power

cable.NG

Repair

OK

Measure at the B-26 No. 2 injector

connector.

DDisconnect the connector to

measure at the harness side.

DIgnition switch: ON

DVoltage between terminal No. 1 and

earth

OK:System voltageNGCheck the following connectors:

B-11X, B-138, C-108NG

Repair

OK

Measure at the B-26 No. 2 injector

connector.

DDisconnect the connector to

measure at the injector side.

DResistance between terminal No. 1

and terminal No. 2

OK:2-3ΩNGReplace the No. 2 injector.

NG

Check the following connector:

B-26NG

Repair

MUT-IIActuator test

DNo. 02: No. 2 injector

OK:The idling state changes.OKIntermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

Page 564 of 1449

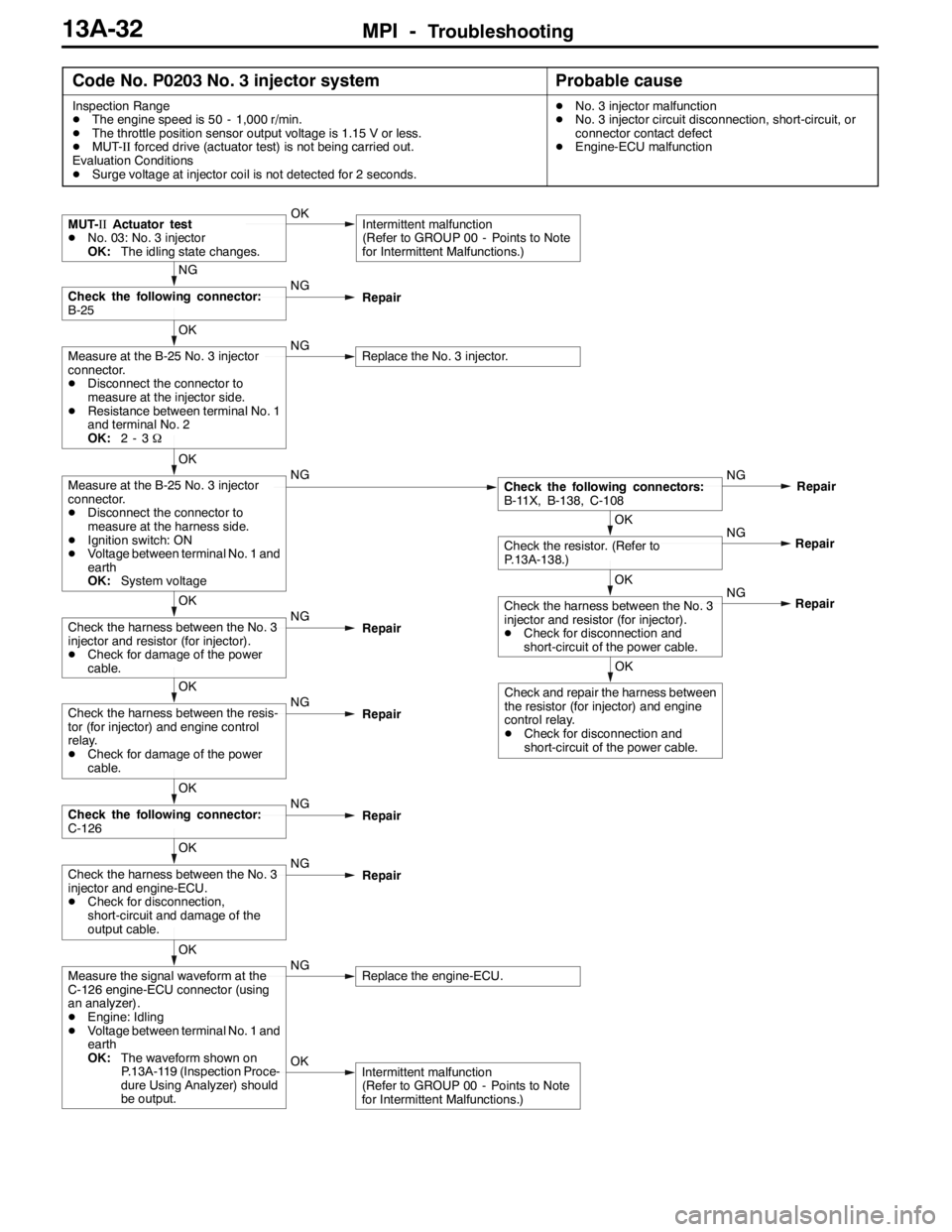

MPI -Troubleshooting13A-32

Code No. P0203 No. 3 injector systemProbable cause

Inspection Range

DThe engine speed is 50 - 1,000 r/min.

DThe throttle position sensor output voltage is 1.15 V or less.

DMUT-IIforced drive (actuator test) is not being carried out.

Evaluation Conditions

DSurge voltage at injector coil is not detected for 2 seconds.DNo. 3 injector malfunction

DNo. 3 injector circuit disconnection, short-circuit, or

connector contact defect

DEngine-ECU malfunction

OKIntermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

OK

Measure the signal waveform at the

C-126 engine-ECU connector (using

an analyzer).

DEngine: Idling

DVoltage between terminal No. 1 and

earth

OK:The waveform shown on

P.13A-119 (Inspection Proce-

dure Using Analyzer) should

be output.NGReplace the engine-ECU.

OK

Check the harness between the No. 3

injector and engine-ECU.

DCheck for disconnection,

short-circuit and damage of the

output cable.NG

Repair

OK

Check the following connector:

C-126NG

Repair

OK

Check the harness between the resis-

tor (for injector) and engine control

relay.

DCheck for damage of the power

cable.NG

Repair

OK

Check and repair the harness between

the resistor (for injector) and engine

control relay.

DCheck for disconnection and

short-circuit of the power cable.NG

OK

Check the harness between the No. 3

injector and resistor (for injector).

DCheck for disconnection and

short-circuit of the power cable.Repair NG

OK

Check the resistor. (Refer to

P.13A-138.)Repair

OK

Check the harness between the No. 3

injector and resistor (for injector).

DCheck for damage of the power

cable.NG

Repair

OK

Measure at the B-25 No. 3 injector

connector.

DDisconnect the connector to

measure at the harness side.

DIgnition switch: ON

DVoltage between terminal No. 1 and

earth

OK:System voltageNGCheck the following connectors:

B-11X, B-138, C-108NG

Repair

OK

Measure at the B-25 No. 3 injector

connector.

DDisconnect the connector to

measure at the injector side.

DResistance between terminal No. 1

and terminal No. 2

OK:2-3ΩNGReplace the No. 3 injector.

NG

Check the following connector:

B-25NG

Repair

MUT-IIActuator test

DNo. 03: No. 3 injector

OK:The idling state changes.OKIntermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

Page 565 of 1449

MPI -Troubleshooting13A-33

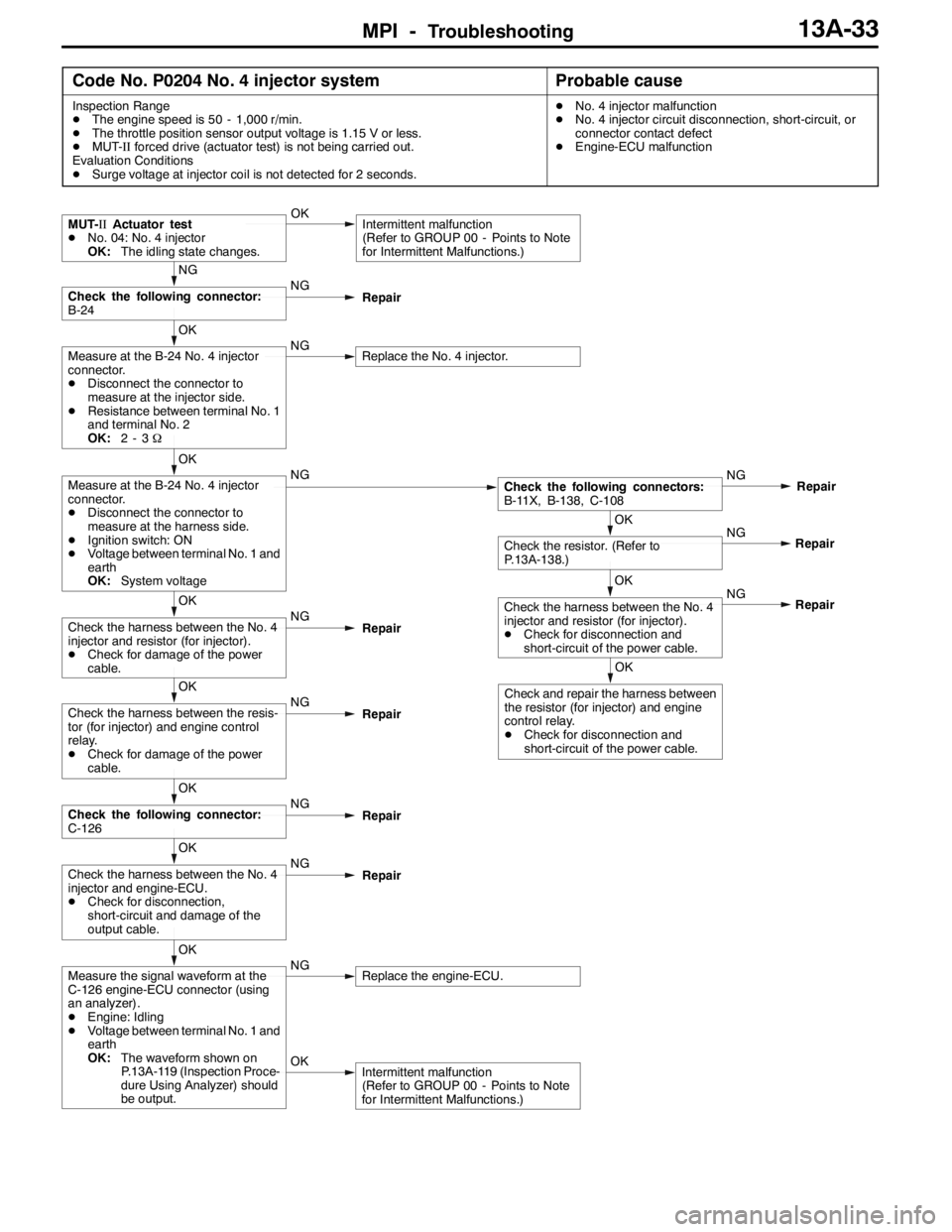

Code No. P0204 No. 4 injector systemProbable cause

Inspection Range

DThe engine speed is 50 - 1,000 r/min.

DThe throttle position sensor output voltage is 1.15 V or less.

DMUT-IIforced drive (actuator test) is not being carried out.

Evaluation Conditions

DSurge voltage at injector coil is not detected for 2 seconds.DNo. 4 injector malfunction

DNo. 4 injector circuit disconnection, short-circuit, or

connector contact defect

DEngine-ECU malfunction

OKIntermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

OK

Measure the signal waveform at the

C-126 engine-ECU connector (using

an analyzer).

DEngine: Idling

DVoltage between terminal No. 1 and

earth

OK:The waveform shown on

P.13A-119 (Inspection Proce-

dure Using Analyzer) should

be output.NGReplace the engine-ECU.

OK

Check the harness between the No. 4

injector and engine-ECU.

DCheck for disconnection,

short-circuit and damage of the

output cable.NG

Repair

OK

Check the following connector:

C-126NG

Repair

OK

Check the harness between the resis-

tor (for injector) and engine control

relay.

DCheck for damage of the power

cable.NG

Repair

OK

Check and repair the harness between

the resistor (for injector) and engine

control relay.

DCheck for disconnection and

short-circuit of the power cable.NG

OK

Check the harness between the No. 4

injector and resistor (for injector).

DCheck for disconnection and

short-circuit of the power cable.Repair NG

OK

Check the resistor. (Refer to

P.13A-138.)Repair

OK

Check the harness between the No. 4

injector and resistor (for injector).

DCheck for damage of the power

cable.NG

Repair

OK

Measure at the B-24 No. 4 injector

connector.

DDisconnect the connector to

measure at the harness side.

DIgnition switch: ON

DVoltage between terminal No. 1 and

earth

OK:System voltageNGCheck the following connectors:

B-11X, B-138, C-108NG

Repair

OK

Measure at the B-24 No. 4 injector

connector.

DDisconnect the connector to

measure at the injector side.

DResistance between terminal No. 1

and terminal No. 2

OK:2-3ΩNGReplace the No. 4 injector.

NG

Check the following connector:

B-24NG

Repair

MUT-IIActuator test

DNo. 04: No. 4 injector

OK:The idling state changes.OKIntermittent malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunctions.)

Page 566 of 1449

MPI -Troubleshooting13A-34

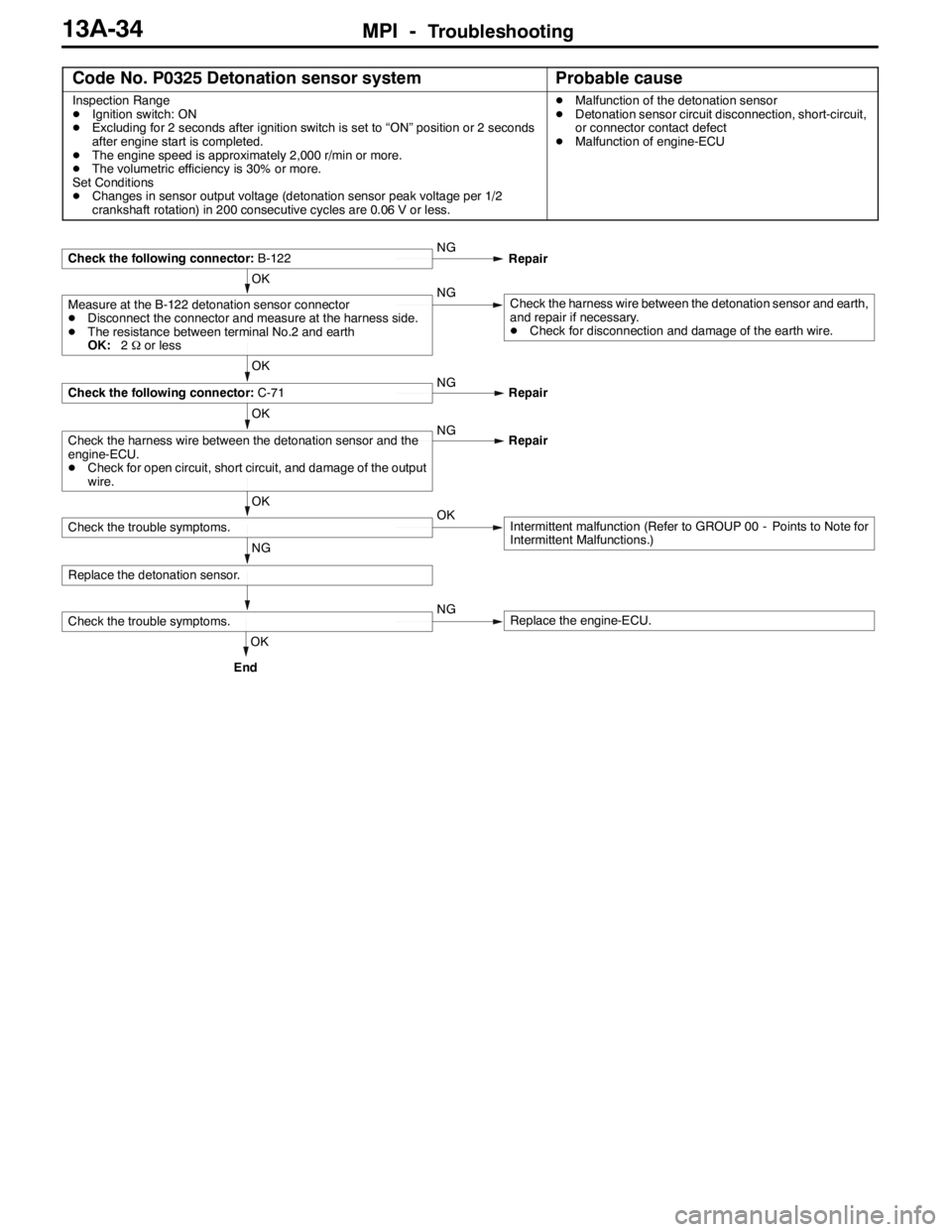

Code No. P0325 Detonation sensor systemProbable cause

Inspection Range

DIgnition switch: ON

DExcluding for 2 seconds after ignition switch is set to “ON” position or 2 seconds

after engine start is completed.

DThe engine speed is approximately 2,000 r/min or more.

DThe volumetric efficiency is 30% or more.

Set Conditions

DChanges in sensor output voltage (detonation sensor peak voltage per 1/2

crankshaft rotation) in 200 consecutive cycles are 0.06 V or less.DMalfunction of the detonation sensor

DDetonation sensor circuit disconnection, short-circuit,

or connector contact defect

DMalfunction of engine-ECU

OK

Check the trouble symptoms.NGReplace the engine-ECU.

NG

Replace the detonation sensor.

OK

Check the trouble symptoms.OKIntermittent malfunction (Refer to GROUP 00 - Points to Note for

Intermittent Malfunctions.)

OK

Check the harness wire between the detonation sensor and the

engine-ECU.

DCheck for open circuit, short circuit, and damage of the output

wire.NG

Repair

OK

Check the following connector:C-71NG

Repair

OK

Measure at the B-122 detonation sensor connector

DDisconnect the connector and measure at the harness side.

DThe resistance between terminal No.2 and earth

OK:2Ωor lessNGCheck the harness wire between the detonation sensor and earth,

and repair if necessary.

DCheck for disconnection and damage of the earth wire.

Check the following connector:B-122NG

Repair

End

Page 567 of 1449

MPI -Troubleshooting13A-35

Code No. P0335 Crank angle sensor systemProbable cause

Inspection Range

DEngine: During cranking

Evaluation Conditions

DThe sensor output voltage does not change for 2 seconds (no pulse signal output)DMalfunction of crank angle sensor

DOpen or short circuit in the crank angle sensor circuit

or loose connector contact

DMalfunction of engine-ECU

OK

To the next page

(3) NGCheck the harness between the crank

angle sensor and body earth, and

repair if necessary.

DCheck for open circuit and damage

of the earth wire.

OK

Check the harness between the crank

angle sensor and engine control relay,

repair if necessary.

DCheck for open circuit and short

circuit of the power cable.

(2) NGCheck the following connector:

B-11XNG

Repair

OK

Intermittent Malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunction.)

OK

MUT-IIData list

DNo. 22 Crank angle sensor

(Refer to P.13A-103.)NGReplace the engine-ECU. NG

OK

Check the harness between the crank

angle sensor and engine-ECU.

DCheck for short circuit of the output

wire.Repair

OK

Check the harness between the crank

angle sensor and engine-ECU, and

repair if necessary.

DCheck for open circuit of the output

wire.NG

Repair

NG

NG

Check the following connector:

C-115Repair

OK

Measure at the B-121 crank angle

sensor connector.

DDisconnect the connector to

measure at the harness side

(1) Voltage between terminal No. 2 and

earth.

(Ignition switch: ON)

OK:4.9 - 5.1 V

(2) Voltage between terminal No. 3 and

earth.

(Ignition switch: ON)

OK:System voltage

(3) Resistance between terminal No. 1

and earth.

OK:Less than 2Ω(1) NGMeasure at the C-115 engine-ECU

connector.

DMeasure the engine-ECU terminal

voltage.

DDisconnect the crank angle sensor

connector B-121.

DIgnition switch: ON

DVoltage between terminal No. 89

and earth.

OK:4.9 - 5.1 VOKCheck the following connector:

C-115

NG

Check the following connector:

B-121NG

Repair

MUT-IIData list

DNo. 22 Crank angle sensor

(Refer to P.13A-103.)OKIntermittent Malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunction.)

Page 568 of 1449

MPI -Troubleshooting13A-36

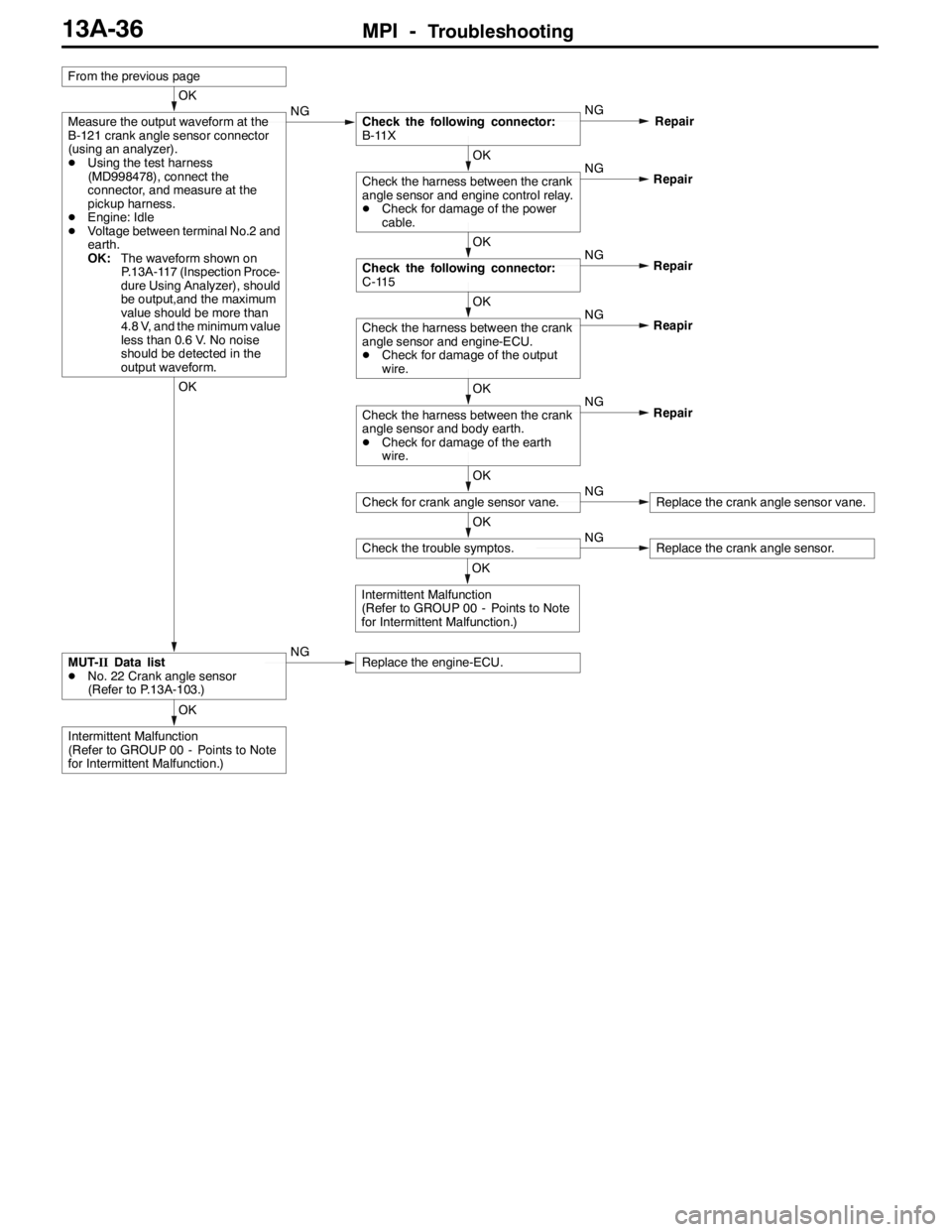

OK

Intermittent Malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunction.)

OK

MUT-IIData list

DNo. 22 Crank angle sensor

(Refer to P.13A-103.)NGReplace the engine-ECU.

OK

Intermittent Malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunction.)

OK

Check the trouble symptos.NGReplace the crank angle sensor.

OK

Check for crank angle sensor vane.NGReplace the crank angle sensor vane. NG

OK

Check the harness between the crank

angle sensor and body earth.

DCheck for damage of the earth

wire.Repair NG

OK

Check the harness between the crank

angle sensor and engine-ECU.

DCheck for damage of the output

wire.Reapir NG

OK

Check the following connector:

C-115Repair NG

OK

Check the harness between the crank

angle sensor and engine control relay.

DCheck for damage of the power

cable.Repair

OK

Measure the output waveform at the

B-121 crank angle sensor connector

(using an analyzer).

DUsing the test harness

(MD998478), connect the

connector, and measure at the

pickup harness.

DEngine: Idle

DVoltage between terminal No.2 and

earth.

OK:The waveform shown on

P.13A-117 (Inspection Proce-

dure Using Analyzer), should

be output,and the maximum

value should be more than

4.8 V, and the minimum value

less than 0.6 V. No noise

should be detected in the

output waveform.NGCheck the following connector:

B-11XNG

Repair

From the previous page

Page 569 of 1449

MPI -Troubleshooting13A-37

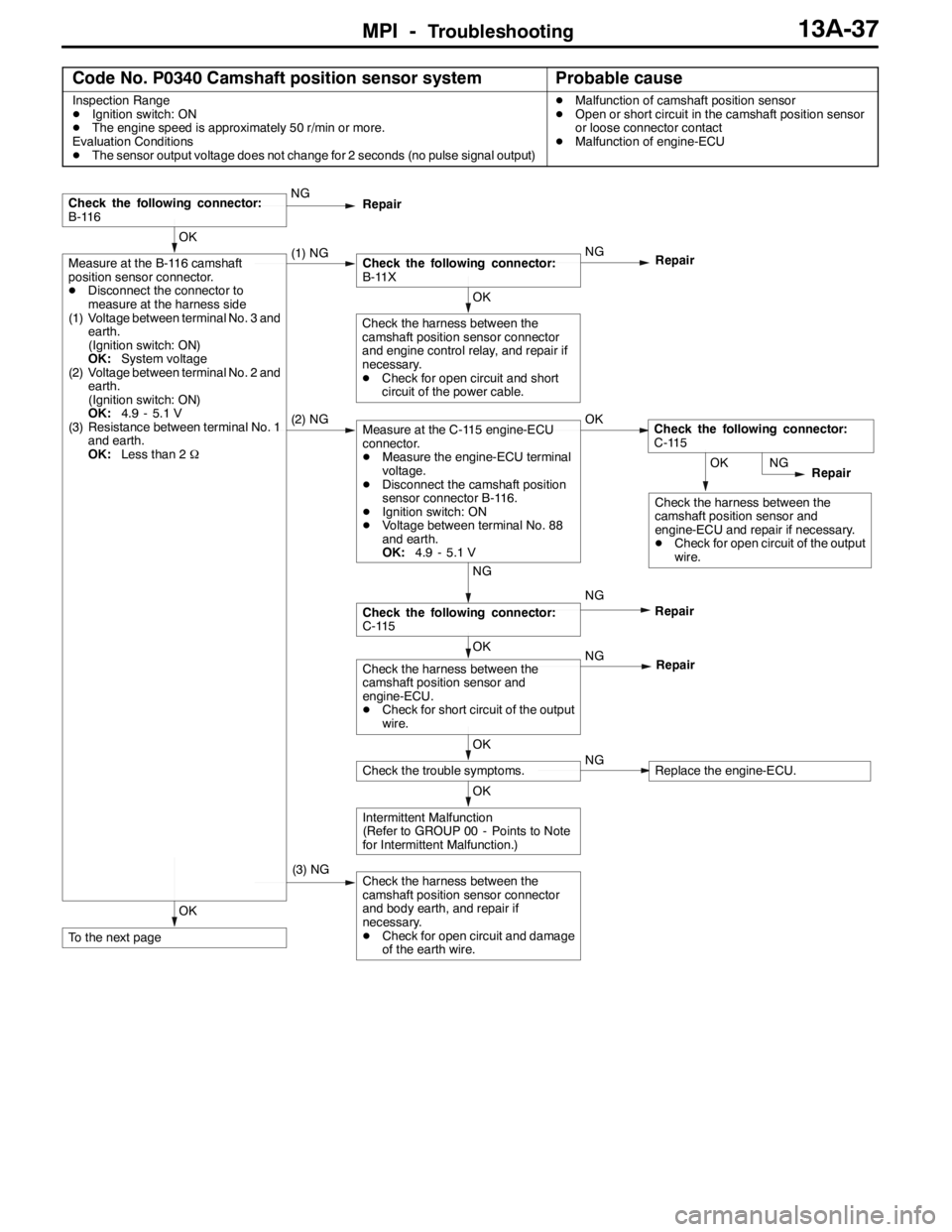

Code No. P0340 Camshaft position sensor systemProbable cause

Inspection Range

DIgnition switch: ON

DThe engine speed is approximately 50 r/min or more.

Evaluation Conditions

DThe sensor output voltage does not change for 2 seconds (no pulse signal output)DMalfunction of camshaft position sensor

DOpen or short circuit in the camshaft position sensor

or loose connector contact

DMalfunction of engine-ECU

OK

To the next page

(3) NGCheck the harness between the

camshaft position sensor connector

and body earth, and repair if

necessary.

DCheck for open circuit and damage

of the earth wire.

OK

Intermittent Malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunction.)

OK

Check the trouble symptoms.NGReplace the engine-ECU.

OK

Check the harness between the

camshaft position sensor and

engine-ECU.

DCheck for short circuit of the output

wire.NG

Repair

NG

Check the following connector:

C-115NG

Repair

OK

Check the harness between the

camshaft position sensor and

engine-ECU and repair if necessary.

DCheck for open circuit of the output

wire.NG

Repair

(2) NGMeasure at the C-115 engine-ECU

connector.

DMeasure the engine-ECU terminal

voltage.

DDisconnect the camshaft position

sensor connector B-116.

DIgnition switch: ON

DVoltage between terminal No. 88

and earth.

OK:4.9 - 5.1 VOKCheck the following connector:

C-115

OK

Check the harness between the

camshaft position sensor connector

and engine control relay, and repair if

necessary.

DCheck for open circuit and short

circuit of the power cable.

OK

Measure at the B-116 camshaft

position sensor connector.

DDisconnect the connector to

measure at the harness side

(1) Voltage between terminal No. 3 and

earth.

(Ignition switch: ON)

OK:System voltage

(2) Voltage between terminal No. 2 and

earth.

(Ignition switch: ON)

OK:4.9 - 5.1 V

(3) Resistance between terminal No. 1

and earth.

OK:Less than 2Ω(1) NGCheck the following connector:

B-11XNG

Repair

Check the following connector:

B-116NG

Repair

Page 570 of 1449

MPI -Troubleshooting13A-38

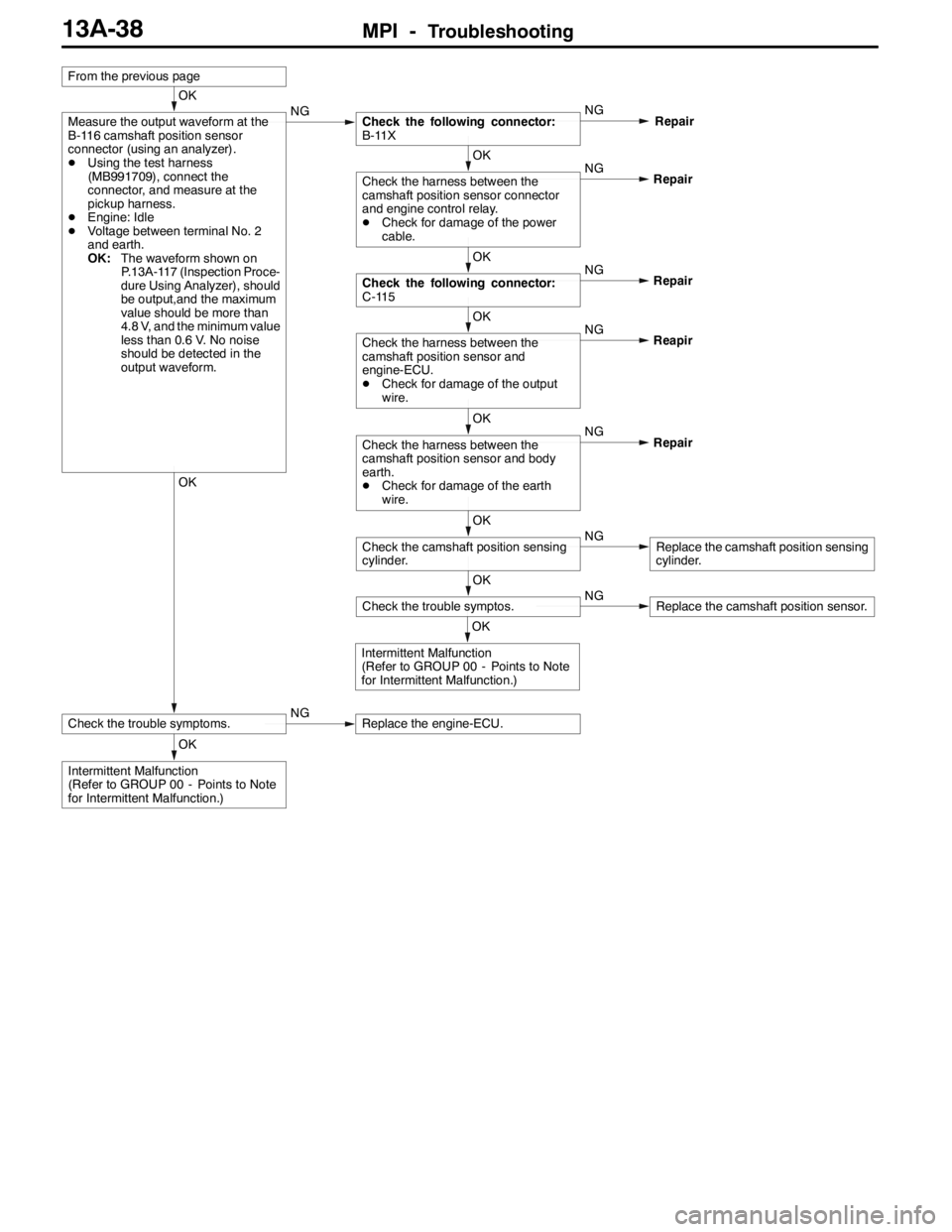

OK

Intermittent Malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunction.)

OK

Check the trouble symptoms.NGReplace the engine-ECU.

OK

Intermittent Malfunction

(Refer to GROUP 00 - Points to Note

for Intermittent Malfunction.)

OK

Check the trouble symptos.NGReplace the camshaft position sensor.

OK

Check the camshaft position sensing

cylinder.NGReplace the camshaft position sensing

cylinder. NG

OK

Check the harness between the

camshaft position sensor and body

earth.

DCheck for damage of the earth

wire.Repair NG

OK

Check the harness between the

camshaft position sensor and

engine-ECU.

DCheck for damage of the output

wire.Reapir NG

OK

Check the following connector:

C-115Repair NG

OK

Check the harness between the

camshaft position sensor connector

and engine control relay.

DCheck for damage of the power

cable.Repair

OK

Measure the output waveform at the

B-116 camshaft position sensor

connector (using an analyzer).

DUsing the test harness

(MB991709), connect the

connector, and measure at the

pickup harness.

DEngine: Idle

DVoltage between terminal No. 2

and earth.

OK:The waveform shown on

P.13A-117 (Inspection Proce-

dure Using Analyzer), should

be output,and the maximum

value should be more than

4.8 V, and the minimum value

less than 0.6 V. No noise

should be detected in the

output waveform.NGCheck the following connector:

B-11XNG

Repair

From the previous page