MITSUBISHI LANCER EVOLUTION X 2008 Workshop Manual

Manufacturer: MITSUBISHI, Model Year: 2008, Model line: LANCER EVOLUTION X, Model: MITSUBISHI LANCER EVOLUTION X 2008Pages: 241, PDF Size: 8.26 MB

Page 101 of 241

SENSOR

MULTIPORT FUEL SYSTEM (MFI)13A-8

SENSORM2132001000565.

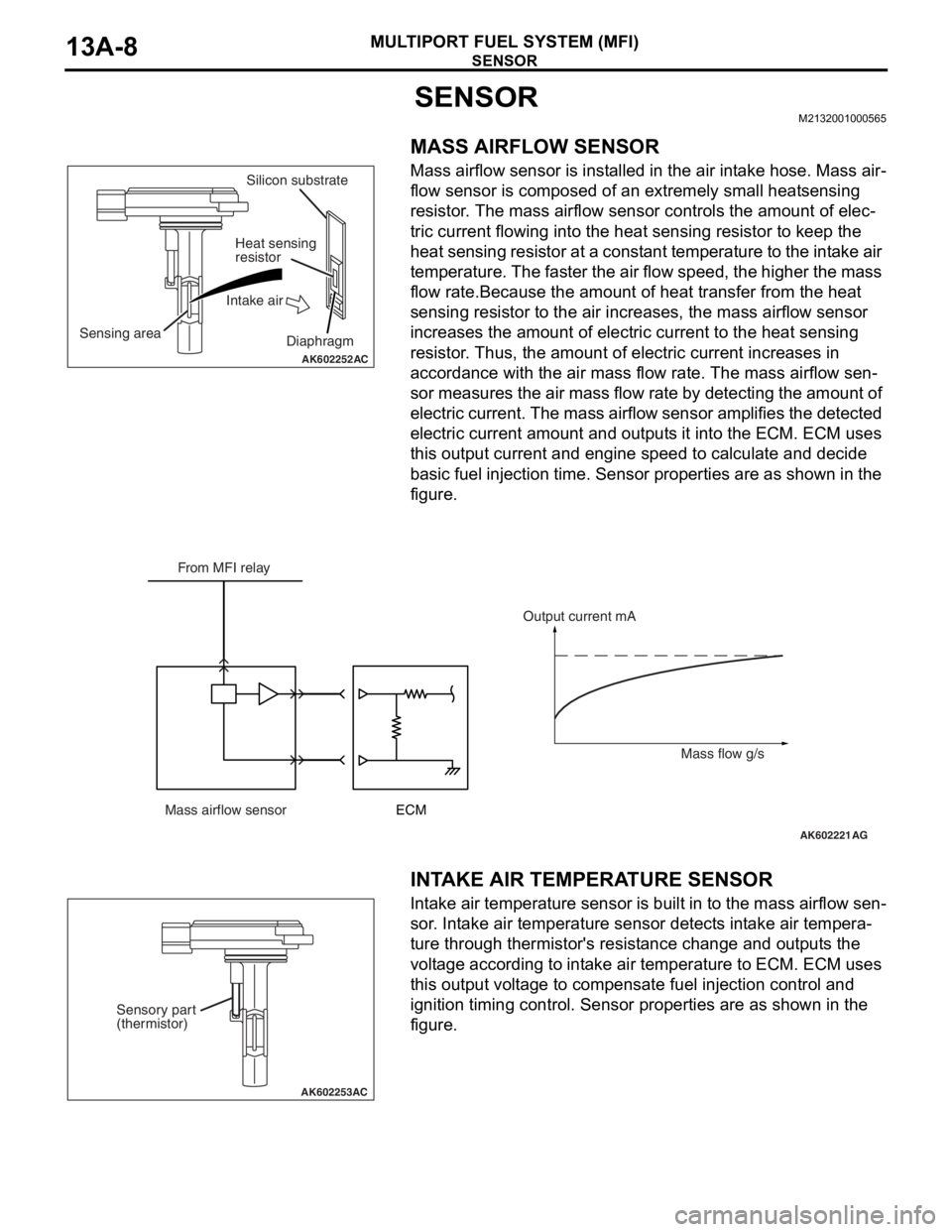

MASS AIRFLOW SENSOR

Mass airflow sensor is installed in the air intake hose. Mass air-

flow sensor is composed of an extremely small heatsensing

resistor. The mass airflow sensor controls the amount of elec

-

tric current flowing into the heat sensing resistor to keep the

heat sensing resistor at a constant temperature to the intake air

temperature. The faster the air flow speed, the higher the mass

flow rate.Because the amount of heat transfer from the heat

sensing resistor to the air increases, the mass airflow sensor

increases the amount of electric current to the heat sensing

resistor. Thus, the amount of electric current increases in

accordance with the air mass flow rate. The mass airflow sen

-

sor measures the air mass flow rate by detecting the amount of

electric current. The mass airflow sensor amplifies the detected

electric current amount and outputs it into the ECM. ECM uses

this output current and engine speed to calculate and decide

basic fuel injection time. Sensor properties are as shown in the

figure.

.

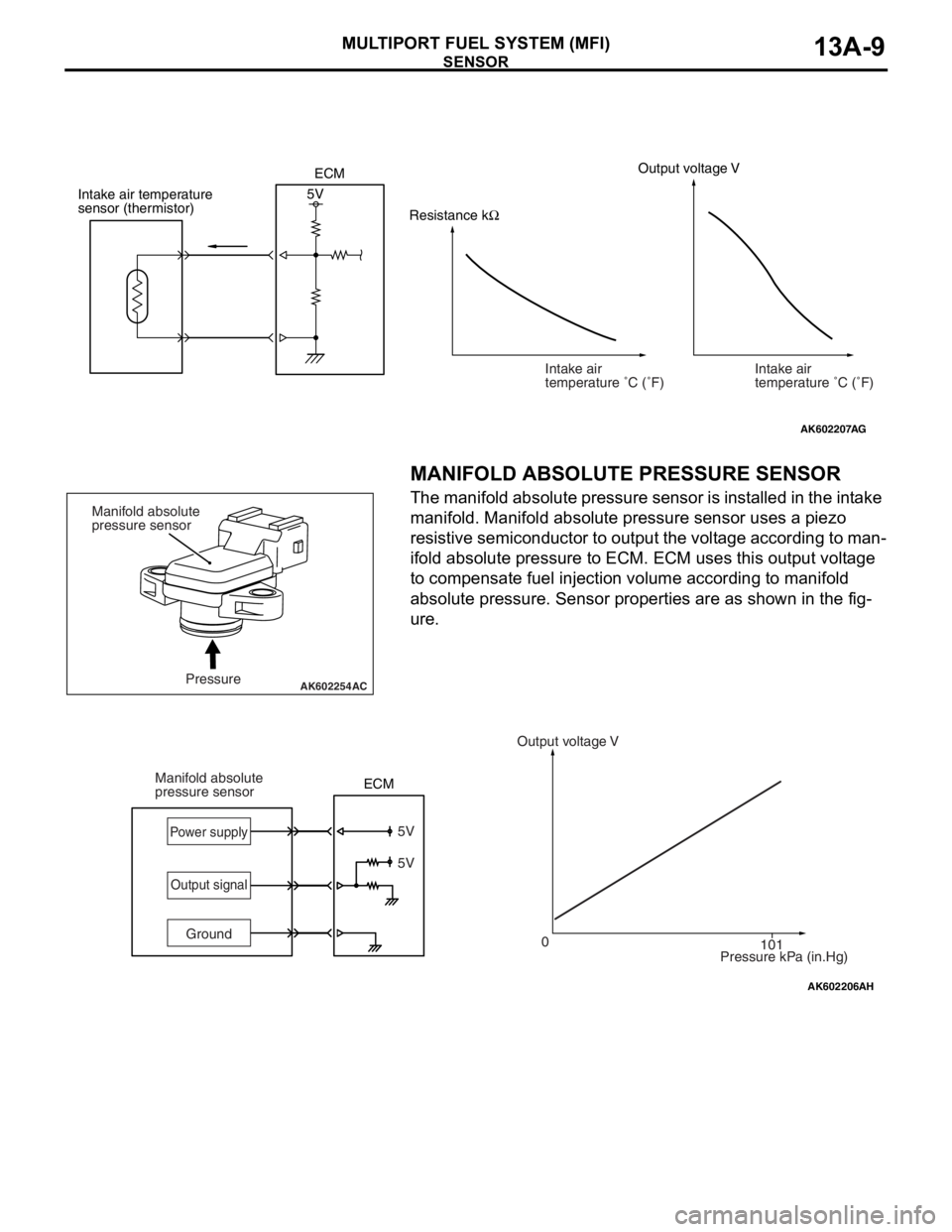

INTAKE AIR TEMPERATURE SENSOR

Intake air temperature sensor is built in to the mass airflow sen-

sor. Intake air temperature sensor detects intake air tempera-

ture through thermistor's resistance change and outputs the

voltage according to intake air temperature to ECM. ECM uses

this output voltage to compensate fuel injection control and

ignition timing control. Sensor properties are as shown in the

figure.

AK602252AC

Sensing areaSilicon substrate

Heat sensing

resistor

Intake air

Diaphragm

AK602221AG

From MFI relay

Mass airflow sensorECMOutput current mA

Mass flow g/s

AK602253AC

Sensory part

(thermistor)

Page 102 of 241

SENSOR

MULTIPORT FUEL SYSTEM (MFI)13A-9

.

MANIFOLD ABSOLUTE PRESSURE SENSOR

The manifold absolute pressure sensor is installed in the intake

manifold. Manifold absolute pressure sensor uses a piezo

resistive semiconductor to output the voltage according to man

-

ifold absolute pressure to ECM. ECM uses this output voltage

to compensate fuel injection volume according to manifold

absolute pressure. Sensor properties are as shown in the fig

-

ure.

.

AK602207

Intake air

temperature �C (�F)

AG

Resistance kΩOutput voltage V

Intake air temperature

sensor (thermistor)5V

Intake air

temperature �C (�F) ECM

AK602254 ACPressure Manifold absolute

pressure sensor

AK602206AH

5V

0

101 5V

GroundOutput voltage V

Pressure kPa (in.Hg) Manifold absolute

pressure sensorPower supply

Output signal

ECM

Page 103 of 241

SENSOR

MULTIPORT FUEL SYSTEM (MFI)13A-10

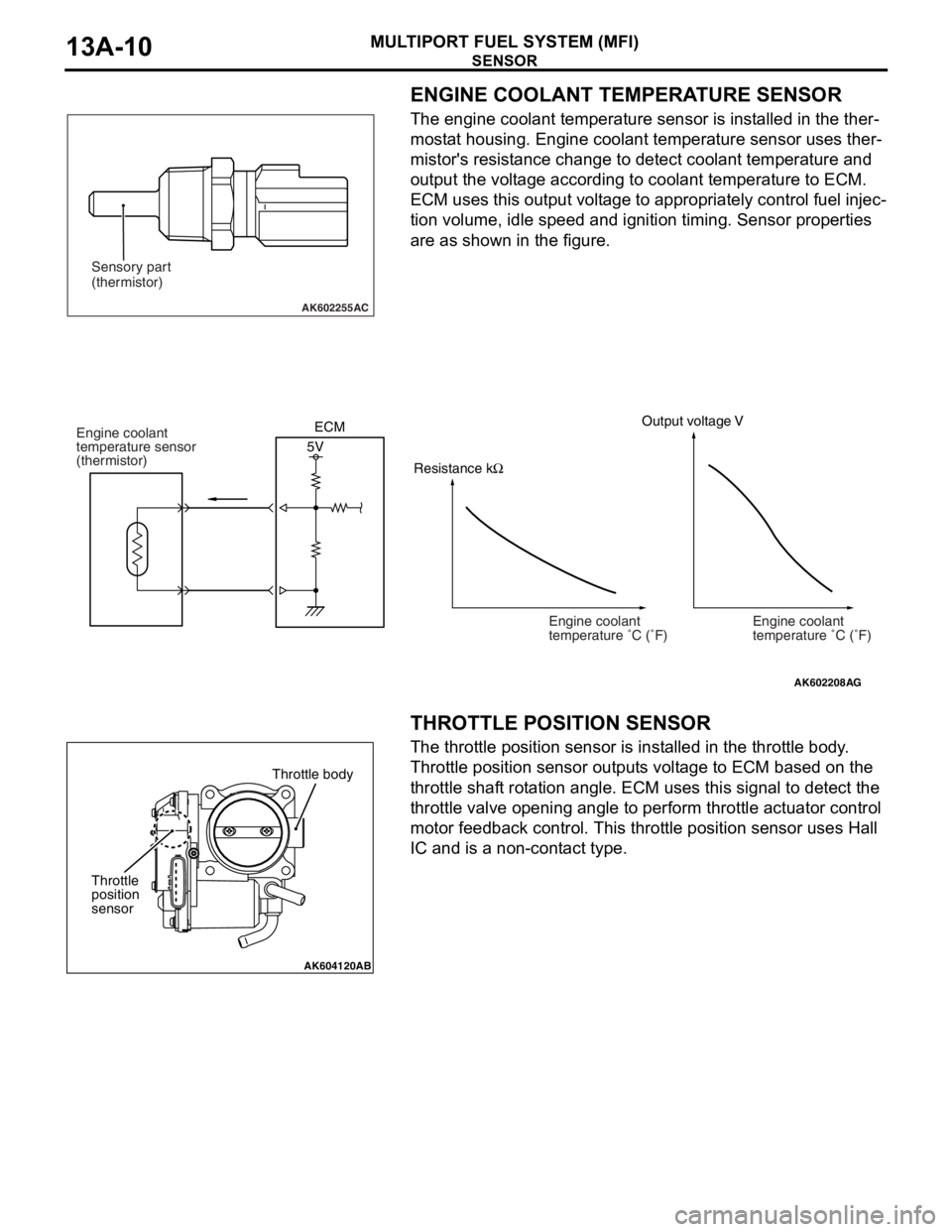

ENGINE COOLANT TEMPERATURE SENSOR

The engine coolant temperature sensor is installed in the ther-

mostat housing. Engine coolant temperature sensor uses ther-

mistor's resistance change to detect coolant temperature and

output the voltage according to coolant temperature to ECM.

ECM uses this output voltage to appropriately control fuel injec

-

tion volume, idle speed and ignition timing. Sensor properties

are as shown in the figure.

.

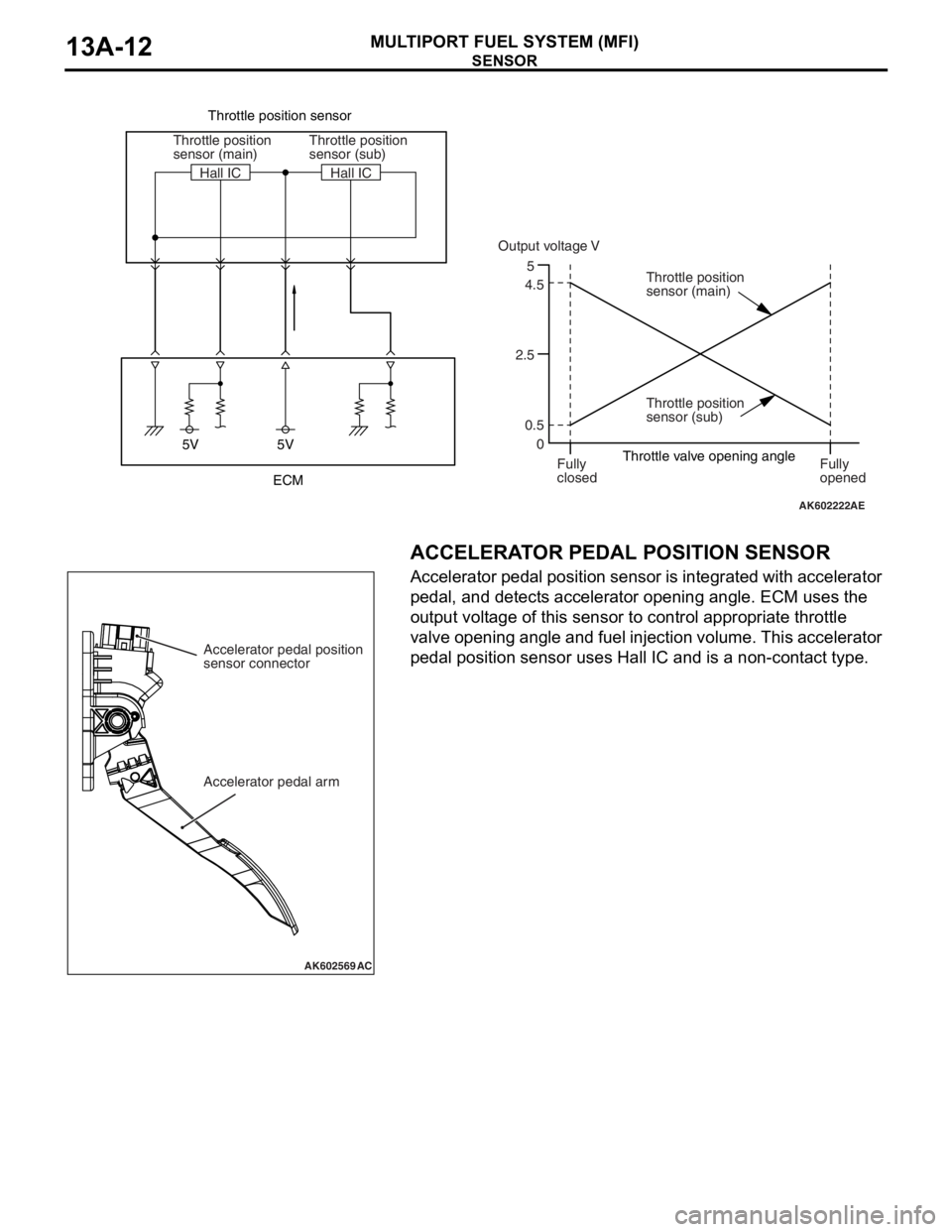

THROTTLE POSITION SENSOR

The throttle position sensor is installed in the throttle body.

Throttle position sensor outputs voltage to ECM based on the

throttle shaft rotation angle. ECM uses this signal to detect the

throttle valve opening angle to perform throttle actuator control

motor feedback control. This throttle position sensor uses Hall

IC and is a non-contact type.

.

AK602255AC

Sensory part

(thermistor)

AK602208

Engine coolant

temperature �C (�F)

AG

Output voltage V

5V Engine coolant

temperature sensor

(thermistor)

Engine coolant

temperature �C (�F) ECM

Resistance kΩ

AK604120AB

Throttle body

Throttle

position

sensor

Page 104 of 241

SENSOR

MULTIPORT FUEL SYSTEM (MFI)13A-11

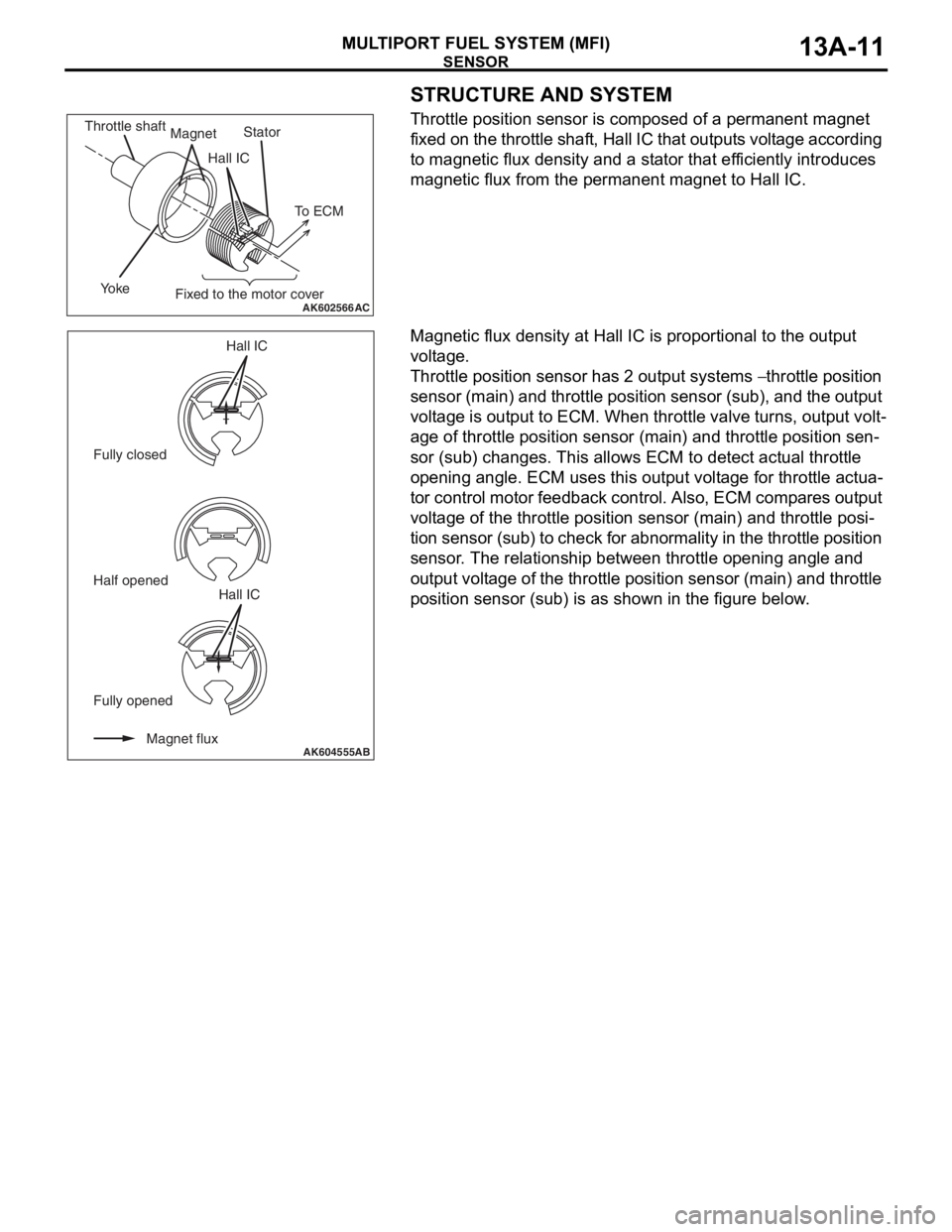

STRUCTURE AND SYSTEM

Throttle position sensor is composed of a permanent magnet

fixed on the throttle shaft, Hall IC that outputs voltage according

to magnetic flux density and a stator that efficiently introduces

magnetic flux from the permanent magnet to Hall IC.

Magnetic flux density at Hall IC is proportional to the output

voltage.

Throttle position sensor has 2 output systems − throttle position

sensor (main) and throttle position sensor (sub), and the output

voltage is output to ECM. When throttle valve turns, output volt

-

age of throttle position sensor (main) and throttle position sen-

sor (sub) changes. This allows ECM to detect actual throttle

opening angle. ECM uses this output voltage for throttle actua

-

tor control motor feedback control. Also, ECM compares output

voltage of the throttle position sensor (main) and throttle posi

-

tion sensor (sub) to check for abnormality in the throttle position

sensor. The relationship between throttle opening angle and

output voltage of the throttle position sensor (main) and throttle

position sensor (sub) is as shown in the figure below.

AK602566AC

Hall ICStator

Yo k e

Fixed to the motor cover Magnet Throttle shaft

To ECM

AK604555Magnet flux Fully opened Fully closedHall IC

Half opened

Hall ICAB

Page 105 of 241

SENSOR

MULTIPORT FUEL SYSTEM (MFI)13A-12

.

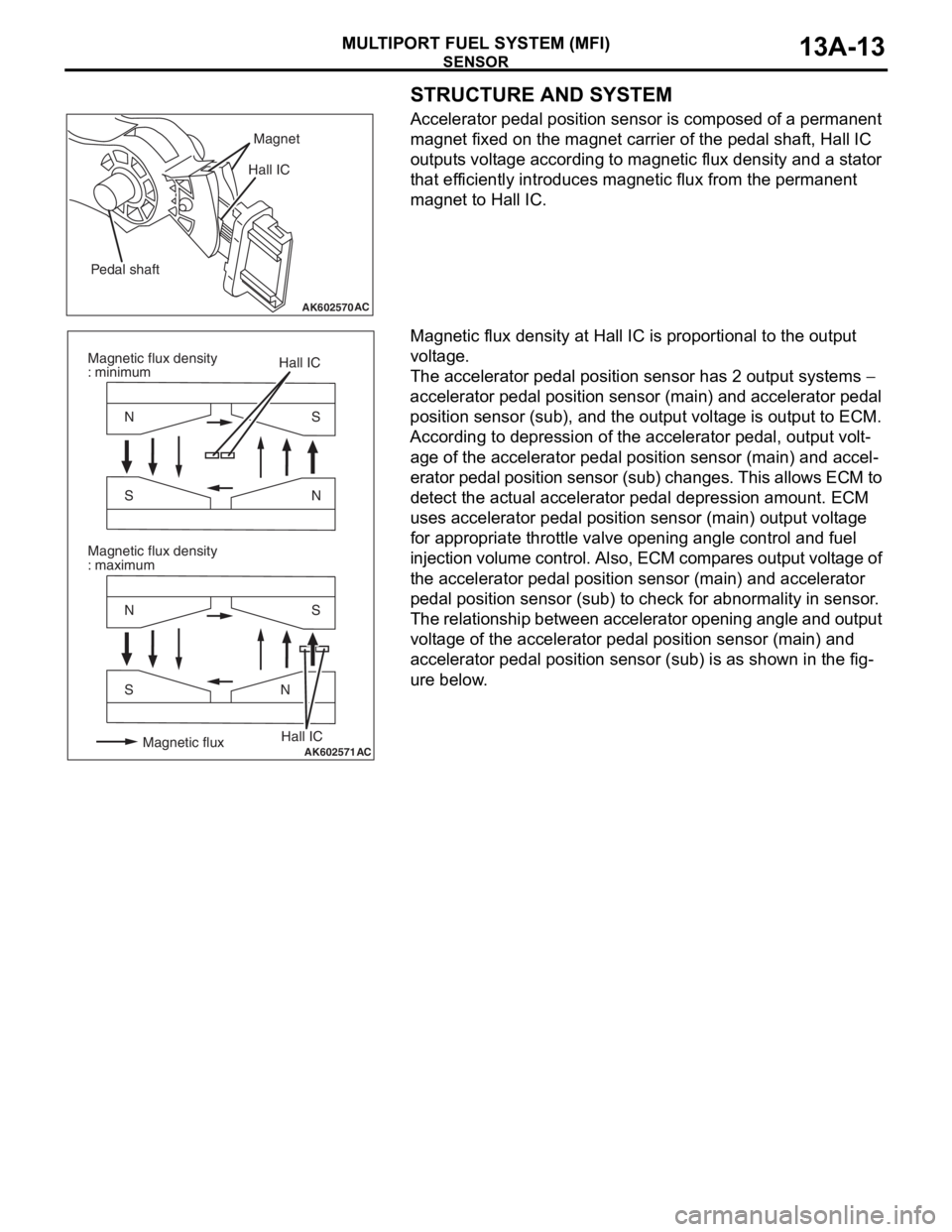

ACCELERATOR PEDAL POSITION SENSOR

Accelerator pedal position sensor is integrated with accelerator

pedal, and detects accelerator opening angle. ECM uses the

output voltage of this sensor to control appropriate throttle

valve opening angle and fuel injection volume. This accelerator

pedal position sensor uses Hall IC and is a non-contact type.

.

AK602222AE

5V 5VThrottle position sensor

Throttle valve opening angle

5

2.54.5

0.5

0 Throttle position

sensor (main)

Throttle position

sensor (sub) Throttle position

sensor (sub)

Throttle position

sensor (main) Hall IC

Fully

closedFully

opened Hall IC

Output voltage V

ECM

AK602569AC

Accelerator pedal position

sensor connector

Accelerator pedal arm

Page 106 of 241

SENSOR

MULTIPORT FUEL SYSTEM (MFI)13A-13

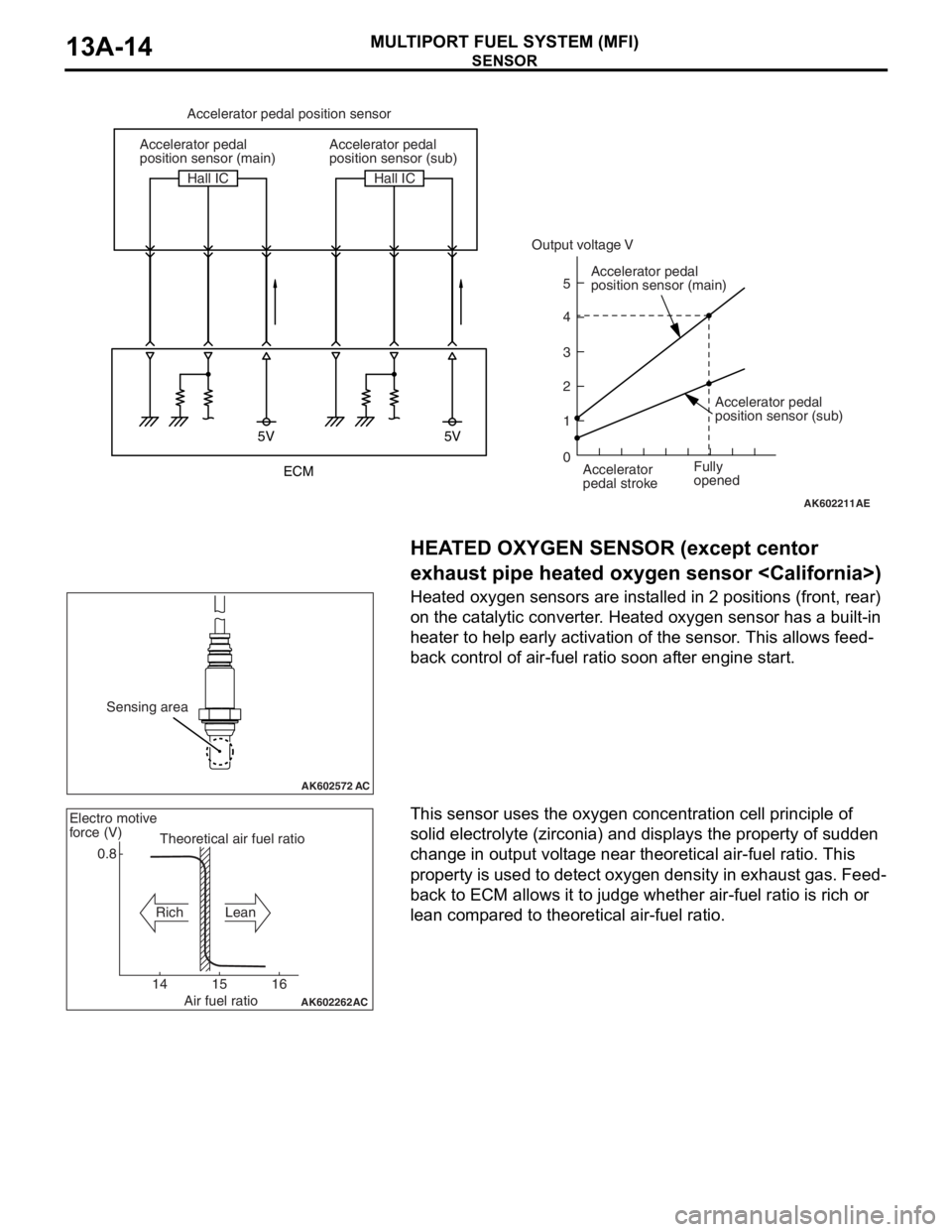

STRUCTURE AND SYSTEM

Accelerator pedal position sensor is composed of a permanent

magnet fixed on the magnet carrier of the pedal shaft, Hall IC

outputs voltage according to magnetic flux density and a stator

that efficiently introduces magnetic flux from the permanent

magnet to Hall IC.

Magnetic flux density at Hall IC is proportional to the output

voltage.

The accelerator pedal position sensor has 2 output systems −

accelerator pedal position sensor (main) and accelerator pedal

position sensor (sub), and the output voltage is output to ECM.

According to depression of the accelerator pedal, output volt

-

age of the accelerator pedal position sensor (main) and accel-

erator pedal position sensor (sub) changes. This allows ECM to

detect the actual accelerator pedal depression amount. ECM

uses accelerator pedal position sensor (main) output voltage

for appropriate throttle valve opening angle control and fuel

injection volume control. Also, ECM compares output voltage of

the accelerator pedal position sensor (main) and accelerator

pedal position sensor (sub) to check for abnormality in sensor.

The relationship between accelerator opening angle and output

voltage of the accelerator pedal position sensor (main) and

accelerator pedal position sensor (sub) is as shown in the fig

-

ure below.

AK602570AC

Magnet

Pedal shaftHall IC

AK602571

S N

S N N S

N S

AC

Hall IC

Hall IC Magnetic flux density

: minimum

Magnetic flux density

: maximum

Magnetic flux

Page 107 of 241

SENSOR

MULTIPORT FUEL SYSTEM (MFI)13A-14

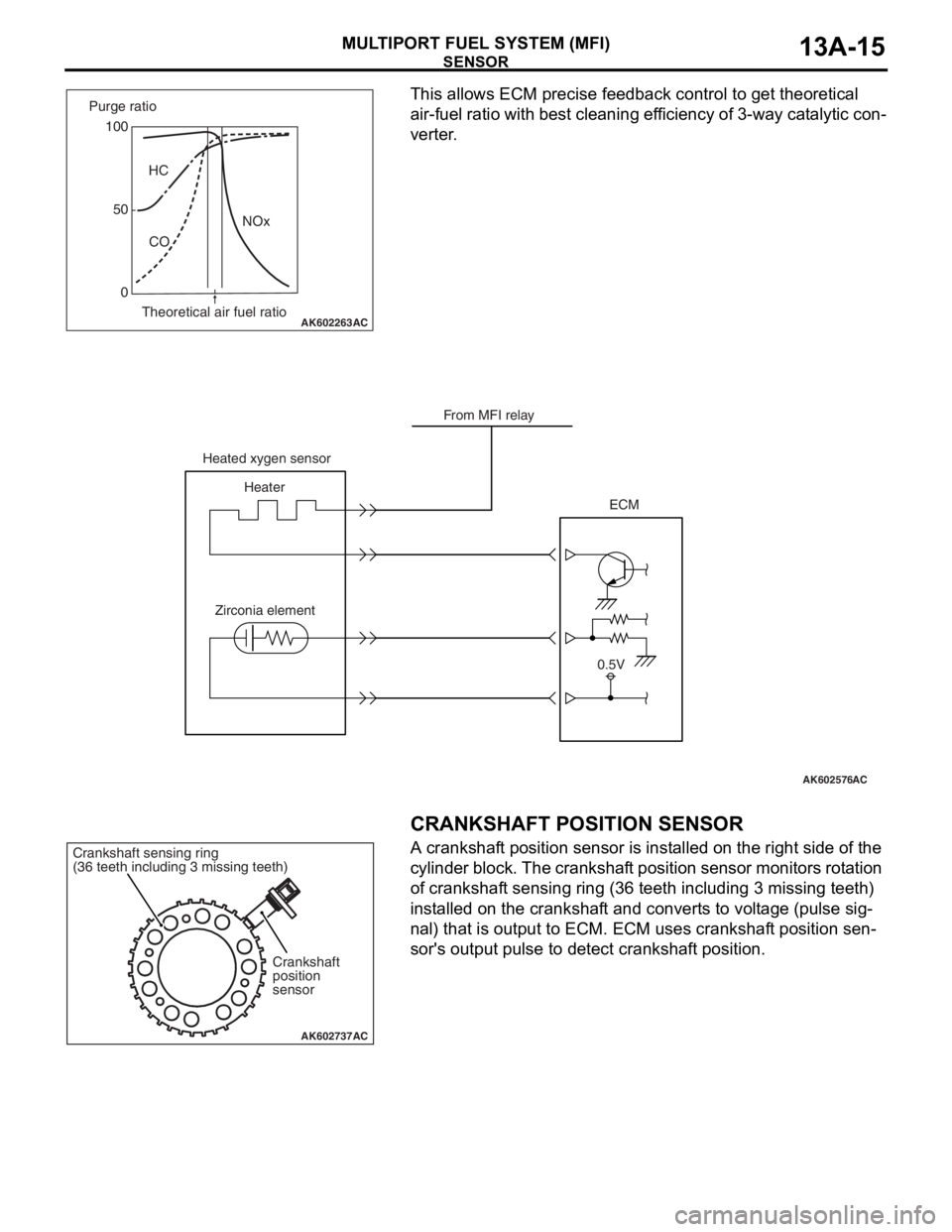

.

HEATED OXYGEN SENSOR (except centor

exhaust pipe heated oxygen sensor

Heated oxygen sensors are installed in 2 positions (front, rear)

on the catalytic converter. Heated oxygen sensor has a built-in

heater to help early activation of the sensor. This allows feed

-

back control of air-fuel ratio soon after engine start.

.

This sensor uses the oxygen concentration cell principle of

solid electrolyte (zirconia) and displays the property of sudden

change in output voltage near theoretical air-fuel ratio. This

property is used to detect oxygen density in exhaust gas. Feed

-

back to ECM allows it to judge whether air-fuel ratio is rich or

lean compared to theoretical air-fuel ratio.

AK602211

5V 5V

5

4

3

2

1

0

AE

Accelerator pedal position sensor

Accelerator pedal

position sensor (main)

Accelerator pedal

position sensor (main)

Accelerator

pedal stroke Accelerator pedal

position sensor (sub)

Accelerator pedal

position sensor (sub) Hall IC Hall IC

Fully

opened

Output voltage V

ECM

AK602572 AC

Sensing area

AK602262

AC

0.8

14 15 16Theoretical air fuel ratio Electro motive

force (V)

Rich Lean

Air fuel ratio

Page 108 of 241

SENSOR

MULTIPORT FUEL SYSTEM (MFI)13A-15

This allows ECM precise feedback control to get theoretical

air-fuel ratio with best cleaning efficiency of 3-way catalytic con

-

verter.

.

CRANKSHAFT POSITION SENSOR

A crankshaft position sensor is installed on the right side of the

cylinder block. The crankshaft position sensor monitors rotation

of crankshaft sensing ring (36 teeth including 3 missing teeth)

installed on the crankshaft and converts to voltage (pulse sig

-

nal) that is output to ECM. ECM uses crankshaft position sen-

sor's output pulse to detect crankshaft position.

.

AK602263AC

100

0HC

CONOx 50 Purge ratio

Theoretical air fuel ratio

AK602576AC

From MFI relay

Heated xygen sensor

Heater

Zirconia elementECM

0.5V

AK602737AC

Crankshaft

position

sensor Crankshaft sensing ring

(36 teeth including 3 missing teeth)

Page 109 of 241

SENSOR

MULTIPORT FUEL SYSTEM (MFI)13A-16

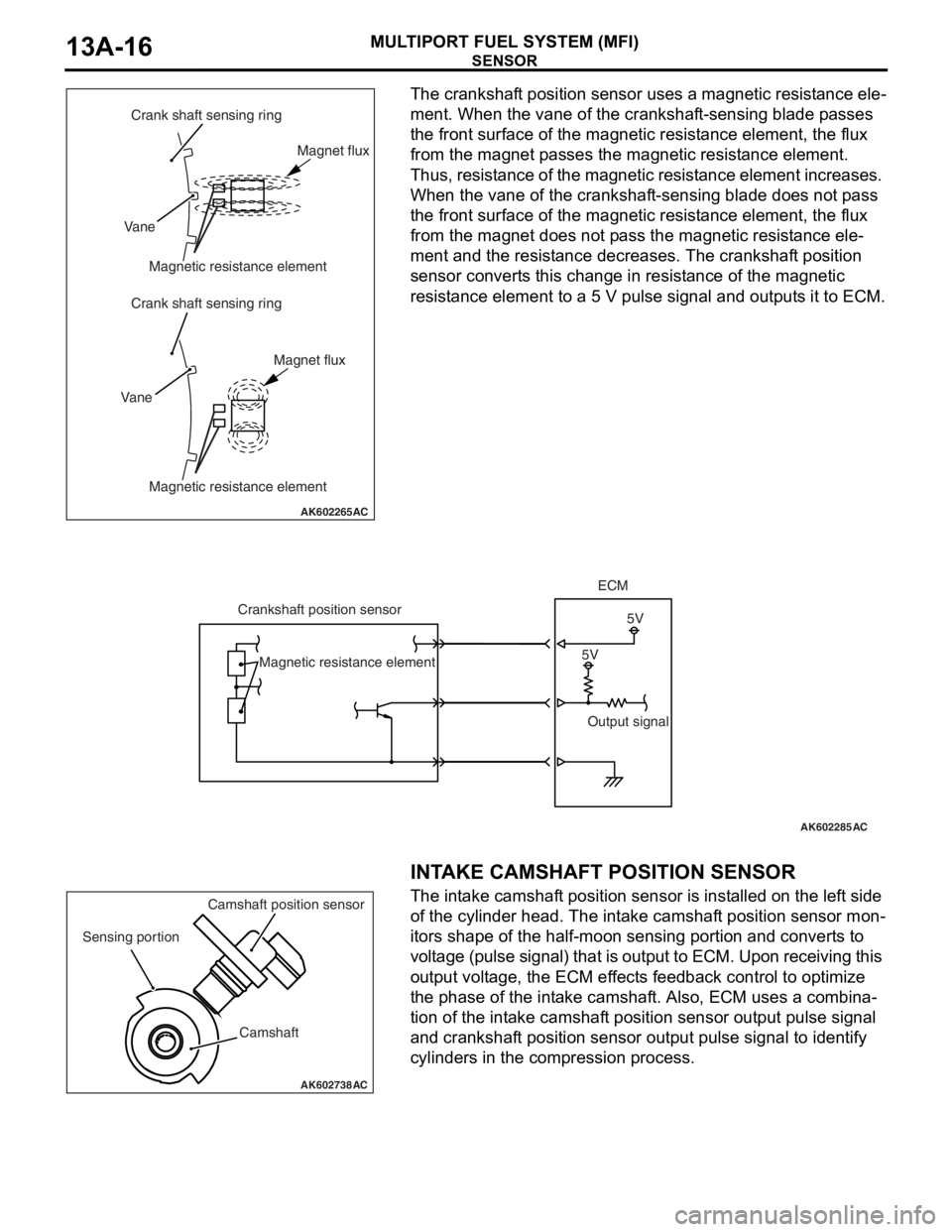

The crankshaft position sensor uses a magnetic resistance ele-

ment. When the vane of the crankshaft-sensing blade passes

the front surface of the magnetic resistance element, the flux

from the magnet passes the magnetic resistance element.

Thus, resistance of the magnetic resistance element increases.

When the vane of the crankshaft-sensing blade does not pass

the front surface of the magnetic resistance element, the flux

from the magnet does not pass the magnetic resistance ele

-

ment and the resistance decreases. The crankshaft position

sensor converts this change in resistance of the magnetic

resistance element to a 5 V pulse signal and outputs it to ECM.

.

INTAKE CAMSHAFT POSITION SENSOR

The intake camshaft position sensor is installed on the left side

of the cylinder head. The intake camshaft position sensor mon

-

itors shape of the half-moon sensing portion and converts to

voltage (pulse signal) that is output to ECM. Upon receiving this

output voltage, the ECM effects feedback control to optimize

the phase of the intake camshaft. Also, ECM uses a combina

-

tion of the intake camshaft position sensor output pulse signal

and crankshaft position sensor output pulse signal to identify

cylinders in the compression process.

AK602265AC

Crank shaft sensing ring

Crank shaft sensing ring Vane

VaneMagnetic resistance element

Magnetic resistance elementMagnet flux

Magnet flux

AK602285AC

5V5V Crankshaft position sensorECM

Output signal Magnetic resistance element

AK602738AC

Camshaft Sensing portionCamshaft position sensor

Page 110 of 241

SENSOR

MULTIPORT FUEL SYSTEM (MFI)13A-17

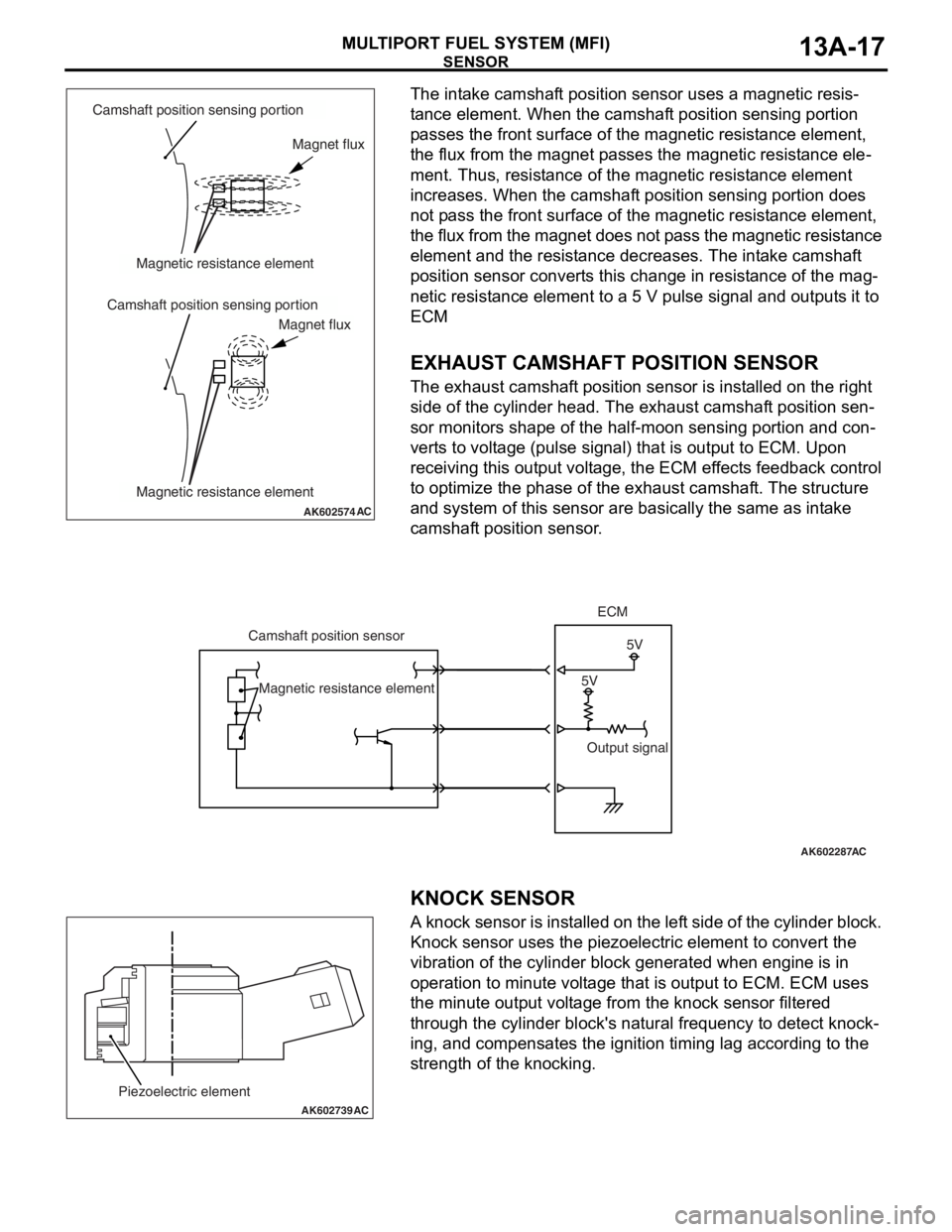

The intake camshaft position sensor uses a magnetic resis-

tance element. When the camshaft position sensing portion

passes the front surface of the magnetic resistance element,

the flux from the magnet passes the magnetic resistance ele

-

ment. Thus, resistance of the magnetic resistance element

increases. When the camshaft position sensing portion does

not pass the front surface of the magnetic resistance element,

the flux from the magnet does not pass the magnetic resistance

element and the resistance decreases. The intake camshaft

position sensor converts this change in resistance of the mag

-

netic resistance element to a 5 V pulse signal and outputs it to

ECM

.

EXHAUST CAMSHAFT POSITION SENSOR

The exhaust camshaft position sensor is installed on the right

side of the cylinder head. The exhaust camshaft position sen

-

sor monitors shape of the half-moon sensing portion and con-

verts to voltage (pulse signal) that is output to ECM. Upon

receiving this output voltage, the ECM effects feedback control

to optimize the phase of the exhaust camshaft. The structure

and system of this sensor are basically the same as intake

camshaft position sensor.

.

.

KNOCK SENSOR

A knock sensor is installed on the left side of the cylinder block.

Knock sensor uses the piezoelectric element to convert the

vibration of the cylinder block generated when engine is in

operation to minute voltage that is output to ECM. ECM uses

the minute output voltage from the knock sensor filtered

through the cylinder block's natural frequency to detect knock

-

ing, and compensates the ignition timing lag according to the

strength of the knocking.

AK602574AC

Camshaft position sensing portion

Camshaft position sensing portionMagnetic resistance element

Magnetic resistance elementMagnet flux

Magnet flux

AK602287

5V5V Camshaft position sensorECM

Output signal Magnetic resistance element

AC

AK602739

Piezoelectric element

AC