MITSUBISHI LANCER EVOLUTION X 2008 Workshop Manual

LANCER EVOLUTION X 2008

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57326/w960_57326-0.png

MITSUBISHI LANCER EVOLUTION X 2008 Workshop Manual

Trending: spare wheel, spare tire, timing belt, air inlet, heating, automatic transmission, headlights

Page 141 of 241

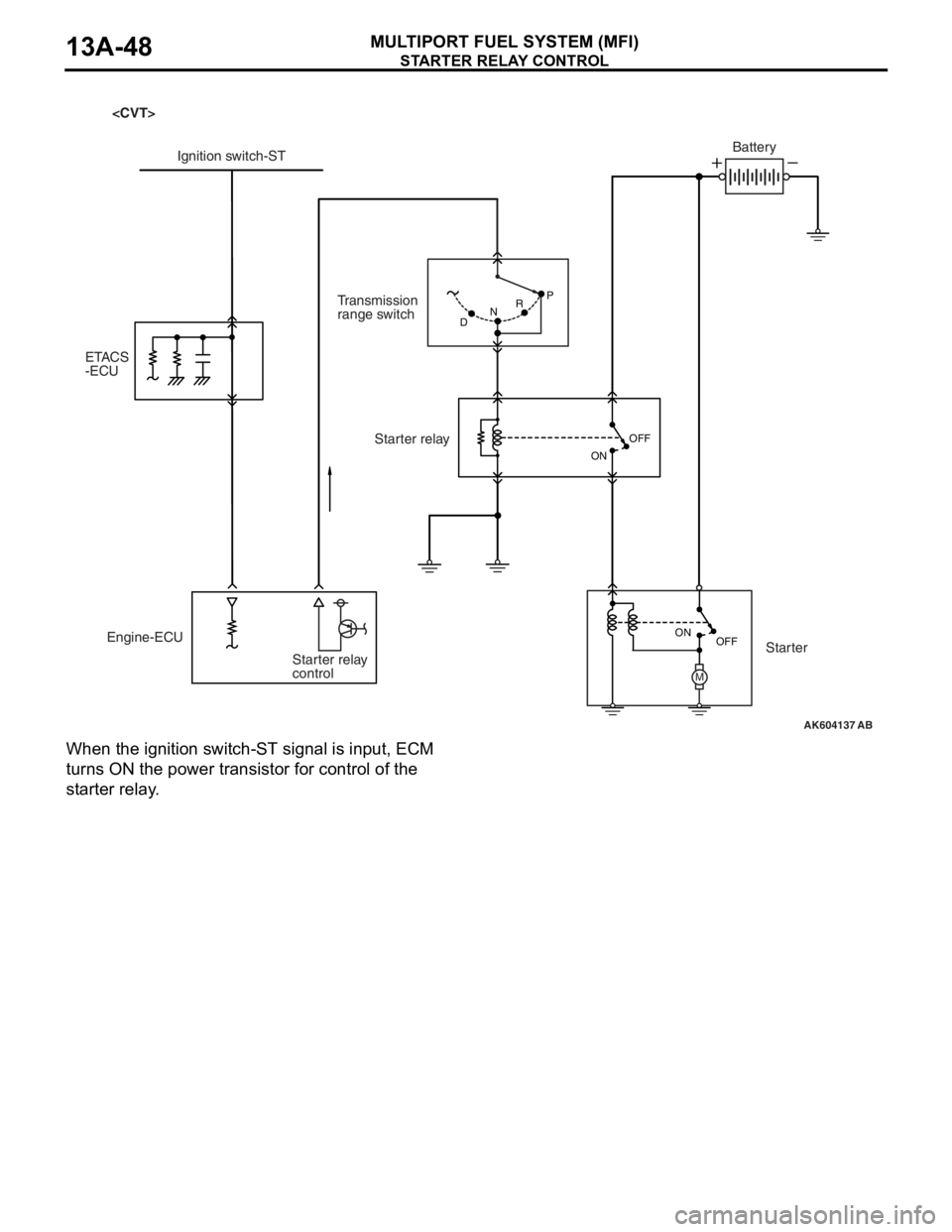

STARTER RELAY CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-48

When the ignition switch-ST signal is input, ECM

turns ON the power transistor for control of the

starter relay.

AK604137

M

AB P

DNR

OFF ON OFF

ON

Engine-ECU

Starter relay

controlTransmission

range switch Ignition switch-STBattery

Starter relay

Starter ETACS

-ECU

Page 142 of 241

HEATED OXYGEN SENSOR HEATER CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-49

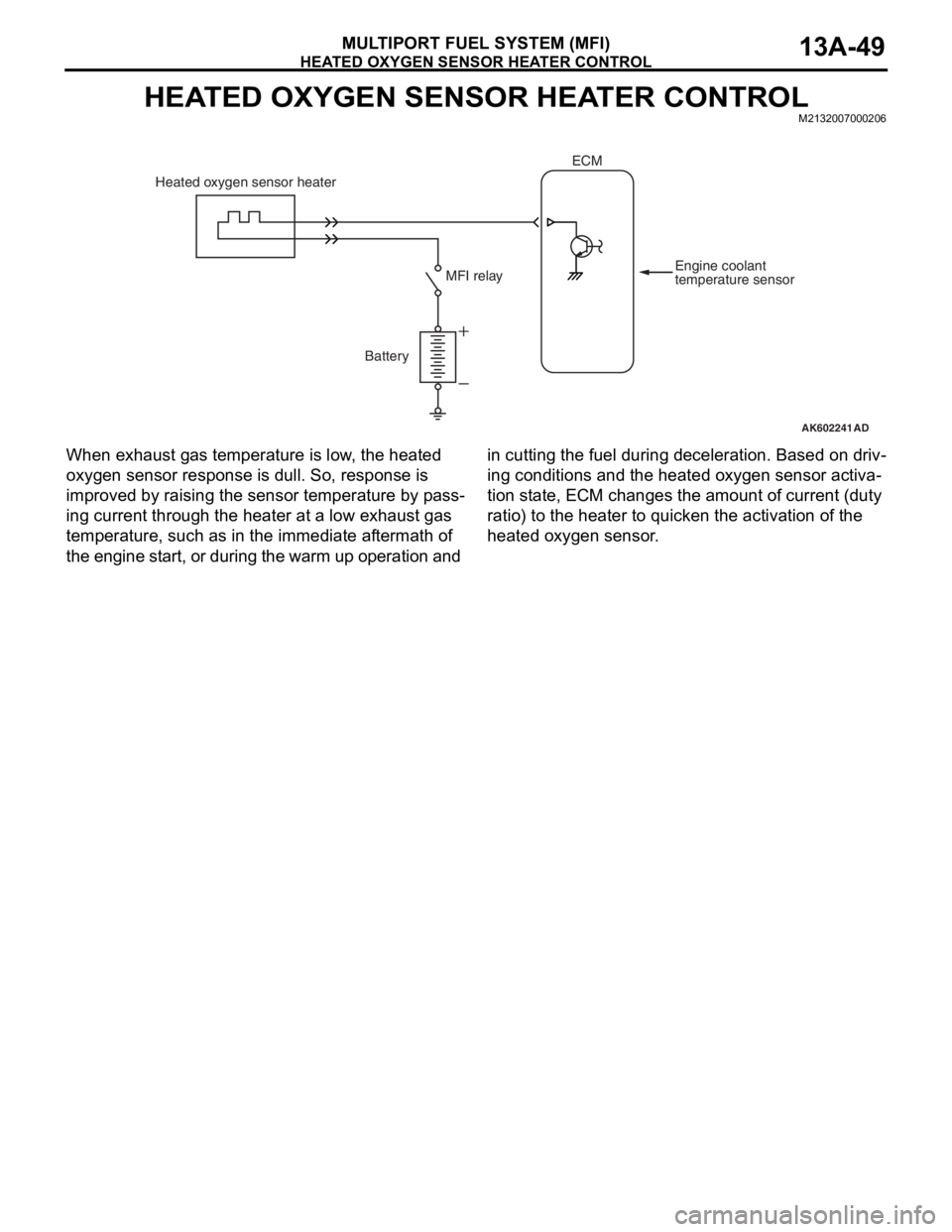

HEATED OXYGEN SENSOR HEATER CONTROLM2132007000206

When exhaust gas temperature is low, the heated

oxygen sensor response is dull. So, response is

improved by raising the sensor temperature by pass

-

ing current through the heater at a low exhaust gas

temperature, such as in the immediate aftermath of

the engine start, or during the warm up operation and in cutting the fuel during deceleration. Based on driv

-

ing conditions and the heated oxygen sensor activa-

tion state, ECM changes the amount of current (duty

ratio) to the heater to quicken the activation of the

heated oxygen sensor.

AK602241AD

Battery Heated oxygen sensor heater

Engine coolant

temperature sensor MFI relay

ECM

Page 143 of 241

A/C COMPRESSOR RELAY CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-50

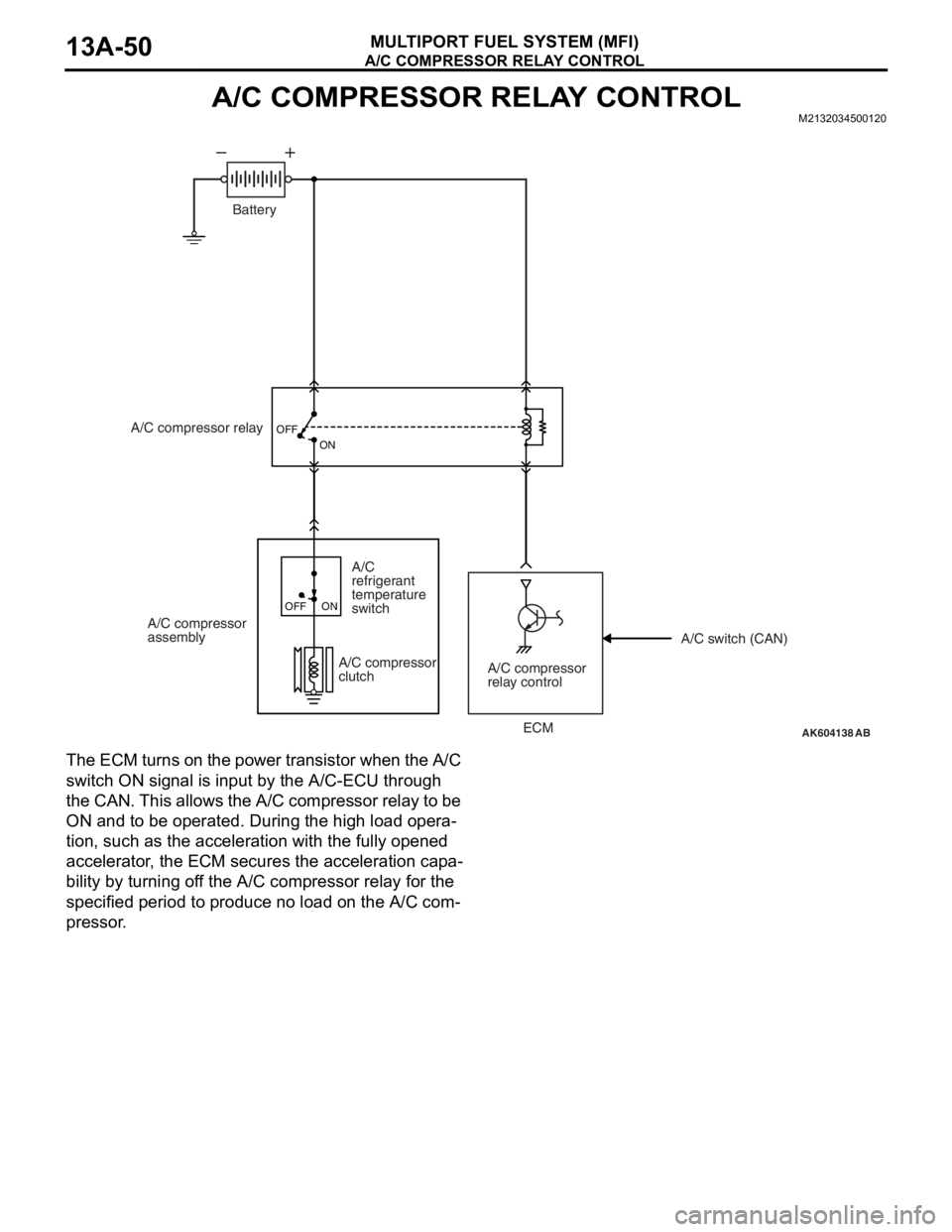

A/C COMPRESSOR RELAY CONTROLM2132034500120

The ECM turns on the power transistor when the A/C

switch ON signal is input by the A/C-ECU through

the CAN. This allows the A/C compressor relay to be

ON and to be operated. During the high load opera

-

tion, such as the acceleration with the fully opened

accelerator, the ECM secures the acceleration capa

-

bility by turning off the A/C compressor relay for the

specified period to produce no load on the A/C com

-

pressor.

AK604138

OFF

ON

AB

Battery

A/C compressor relay

A/C compressor

assembly

A/C compressor

relay control A/C compressor

clutch

A/C

refrigerant

temperature

switch

OFF ON

A/C switch (CAN)

ECM

Page 144 of 241

GENERATOR CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-51

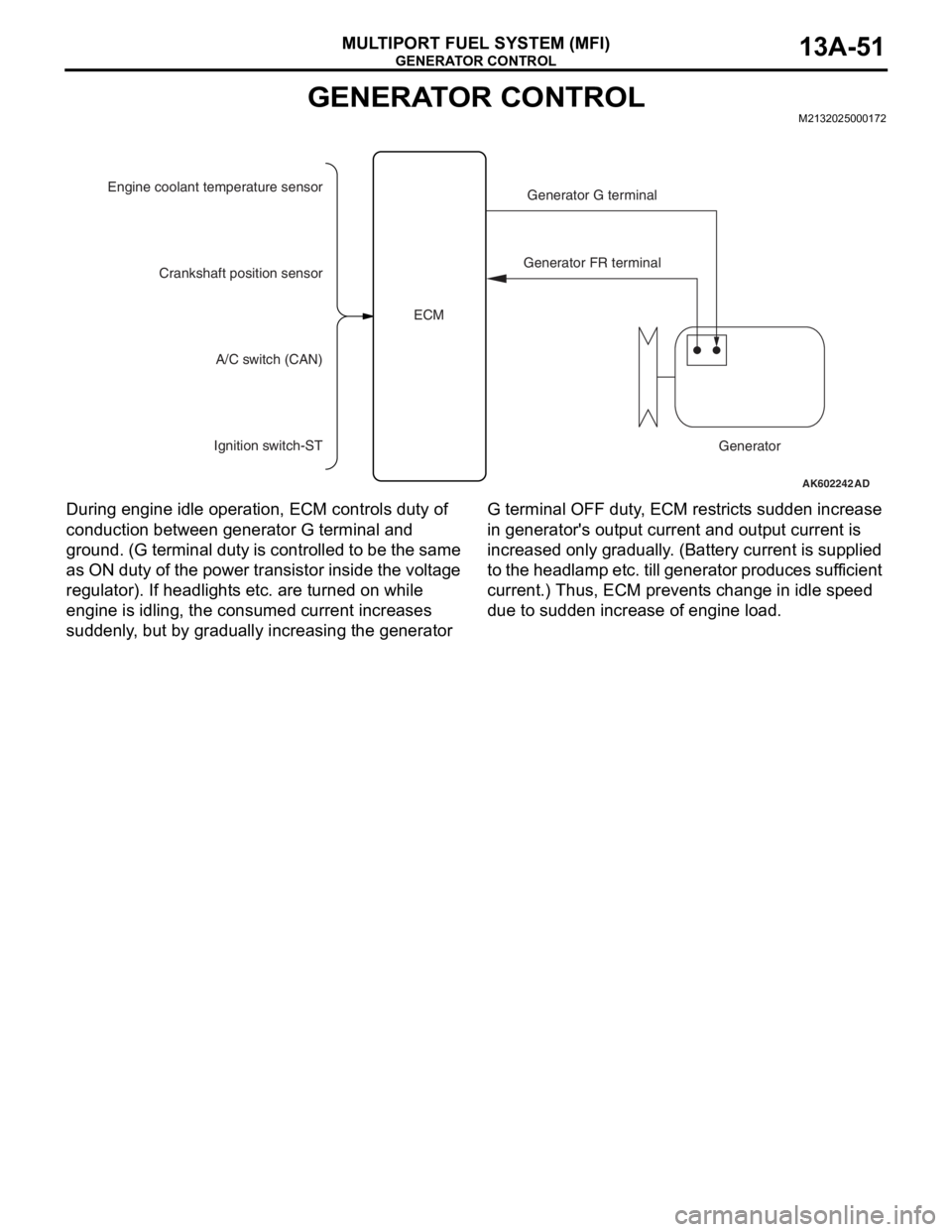

GENERATOR CONTROLM2132025000172

During engine idle operation, ECM controls duty of

conduction between generator G terminal and

ground. (G terminal duty is controlled to be the same

as ON duty of the power transistor inside the voltage

regulator). If headlights etc. are turned on while

engine is idling, the consumed current increases

suddenly, but by gradually increasing the generator G terminal OFF duty, ECM restricts sudden increase

in generator's output current and output current is

increased only gradually. (Battery current is supplied

to the headlamp etc. till generator produces sufficient

current.) Thus, ECM prevents change in idle speed

due to sudden increase of engine load.

AK602242 AD

Engine coolant temperature sensor

Generator G terminal

Generator FR terminal

Generator Crankshaft position sensor

A/C switch (CAN)

Ignition switch-STECM

Page 145 of 241

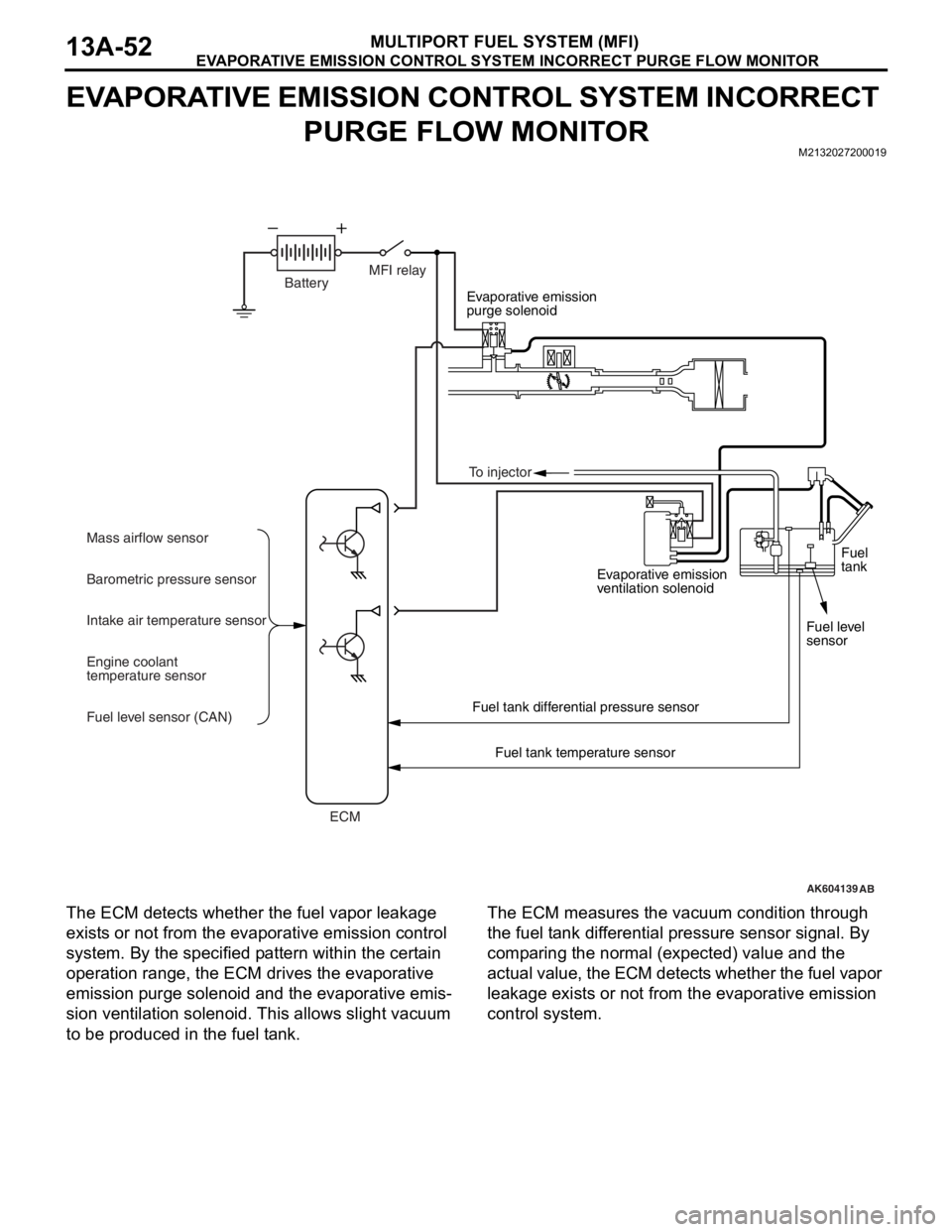

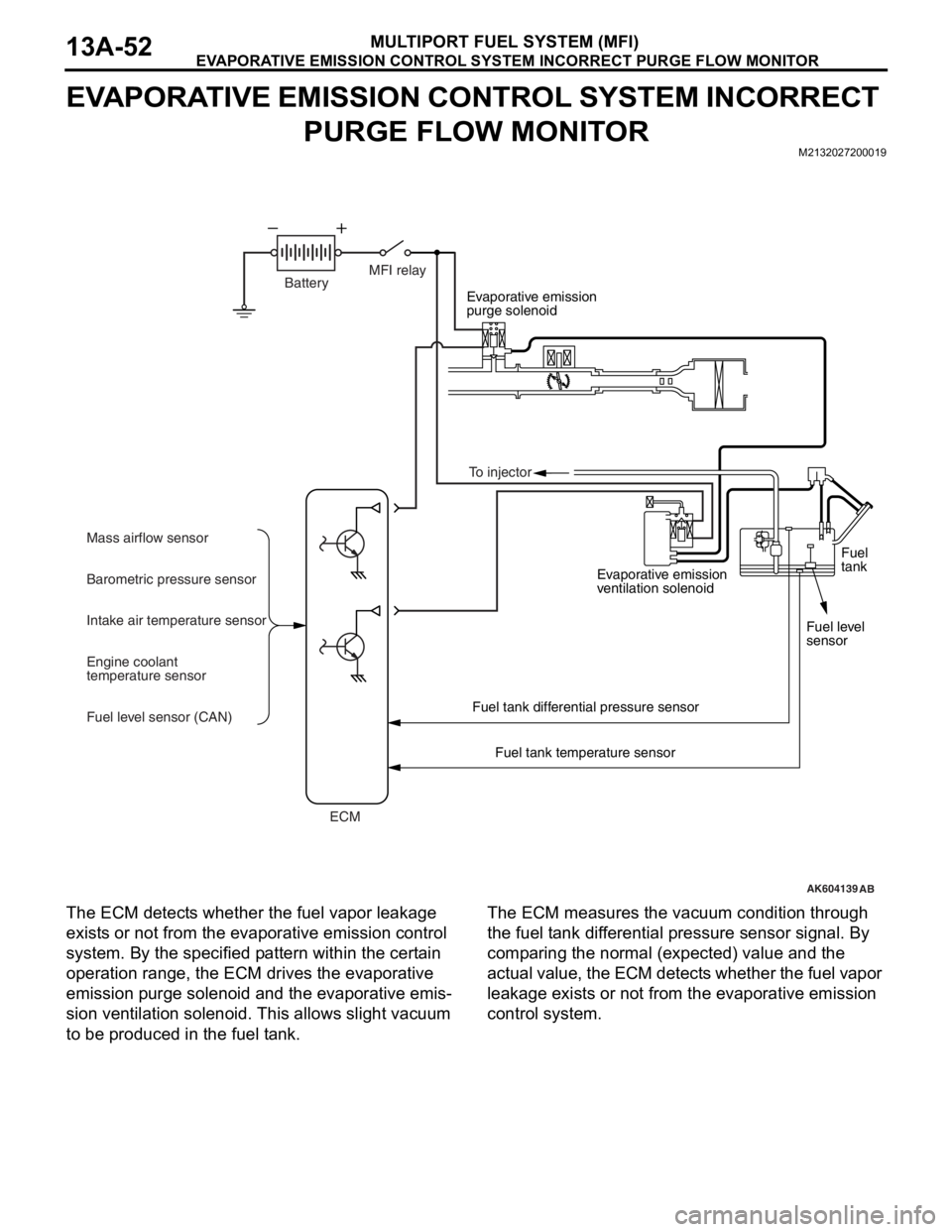

EVAPORATIVE EMISSION CONTROL SYSTEM INCORRECT PURGE FLOW MONITOR

MULTIPORT FUEL SYSTEM (MFI)13A-52

EVAPORATIVE EMISSION CONTROL SYSTEM INCORRECT

PURGE FLOW MONITOR

M2132027200019

The ECM detects whether the fuel vapor leakage

exists or not from the evaporative emission control

system. By the specified pattern within the certain

operation range, the ECM drives the evaporative

emission purge solenoid and the evaporative emis

-

sion ventilation solenoid. This allows slight vacuum

to be produced in the fuel tank.

The ECM measures the vacuum condition through

the fuel tank differential pressure sensor signal. By

comparing the normal (expected) value and the

actual value, the ECM detects whether the fuel vapor

leakage exists or not from the evaporative emission

control system.

AK604139

Evaporative emission

purge solenoid

Evaporative emission

ventilation solenoid

Fuel tank differential pressure sensor

Fuel tank temperature sensor

AB

BatteryMFI relay

ECM Mass airflow sensor

Barometric pressure sensor

Intake air temperature sensor

Engine coolant

temperature sensor

Fuel level sensor (CAN)Fuel

tank

Fuel level

sensor To injector

Page 146 of 241

12-1

GROUP 12

ENGINE

LUBRICATION

CONTENTS

GENERAL DESCRIPTION. . . . . . . . .12-2

OIL PASSAGE . . . . . . . . . . . . . . . . . .12-2

OIL FILTER . . . . . . . . . . . . . . . . . . . .12-3

OIL PAN . . . . . . . . . . . . . . . . . . . . . . .12-3

OIL DIPSTICK, OIL FILLER CAP,

OIL DRAIN PLUG . . . . . . . . . . . . . . . .12-4

OIL PUMP . . . . . . . . . . . . . . . . . . . . . .12-4

Page 147 of 241

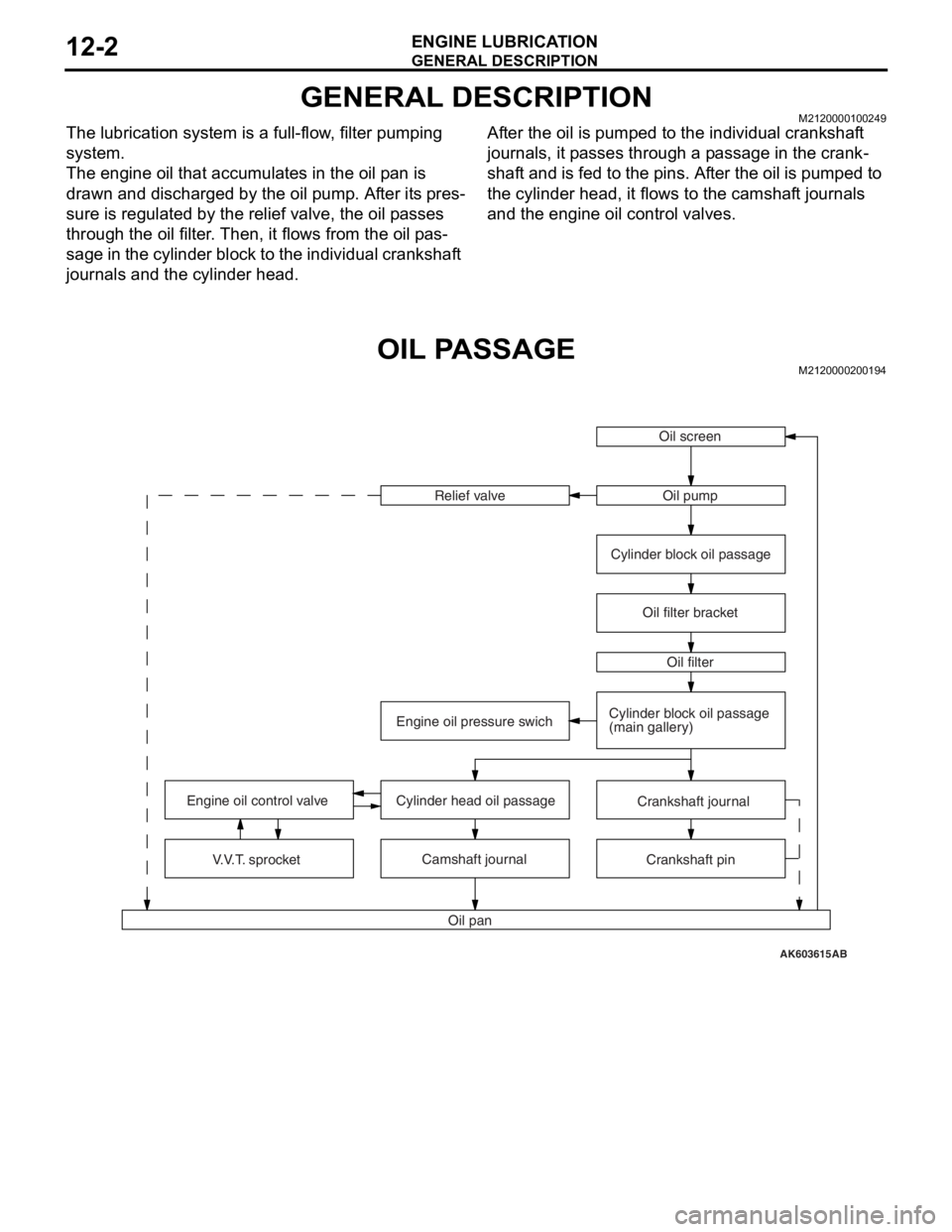

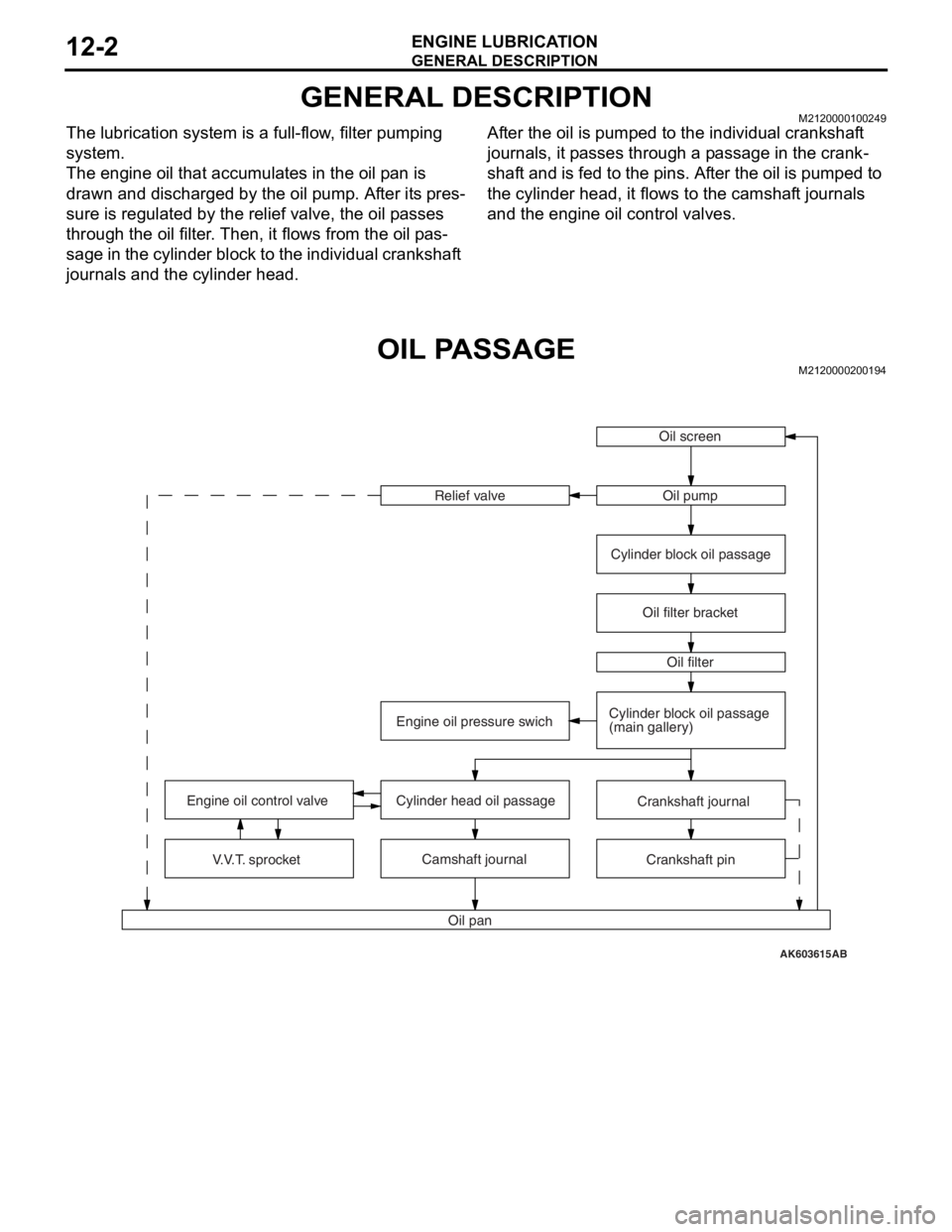

GENERAL DESCRIPTION

ENGINE LUBRICATION12-2

GENERAL DESCRIPTIONM2120000100249

The lubrication system is a full-flow, filter pumping

system.

The engine oil that accumulates in the oil pan is

drawn and discharged by the oil pump. After its pres

-

sure is regulated by the relief valve, the oil passes

through the oil filter. Then, it flows from the oil pas

-

sage in the cylinder block to the individual crankshaft

journals and the cylinder head.

After the oil is pumped to the individual crankshaft

journals, it passes through a passage in the crank

-

shaft and is fed to the pins. After the oil is pumped to

the cylinder head, it flows to the camshaft journals

and the engine oil control valves.

OIL PASSAGEM2120000200194

AK603615

Oil screen

Oil pan Relief valve

V.V.T. sprocket Engine oil control valveOil pump

Oil filter

Engine oil pressure swichOil filter bracket Cylinder block oil passage

Crankshaft journal

Camshaft journal

Crankshaft pin Cylinder block oil passage

(main gallery)

Cylinder head oil passage

AB

Page 148 of 241

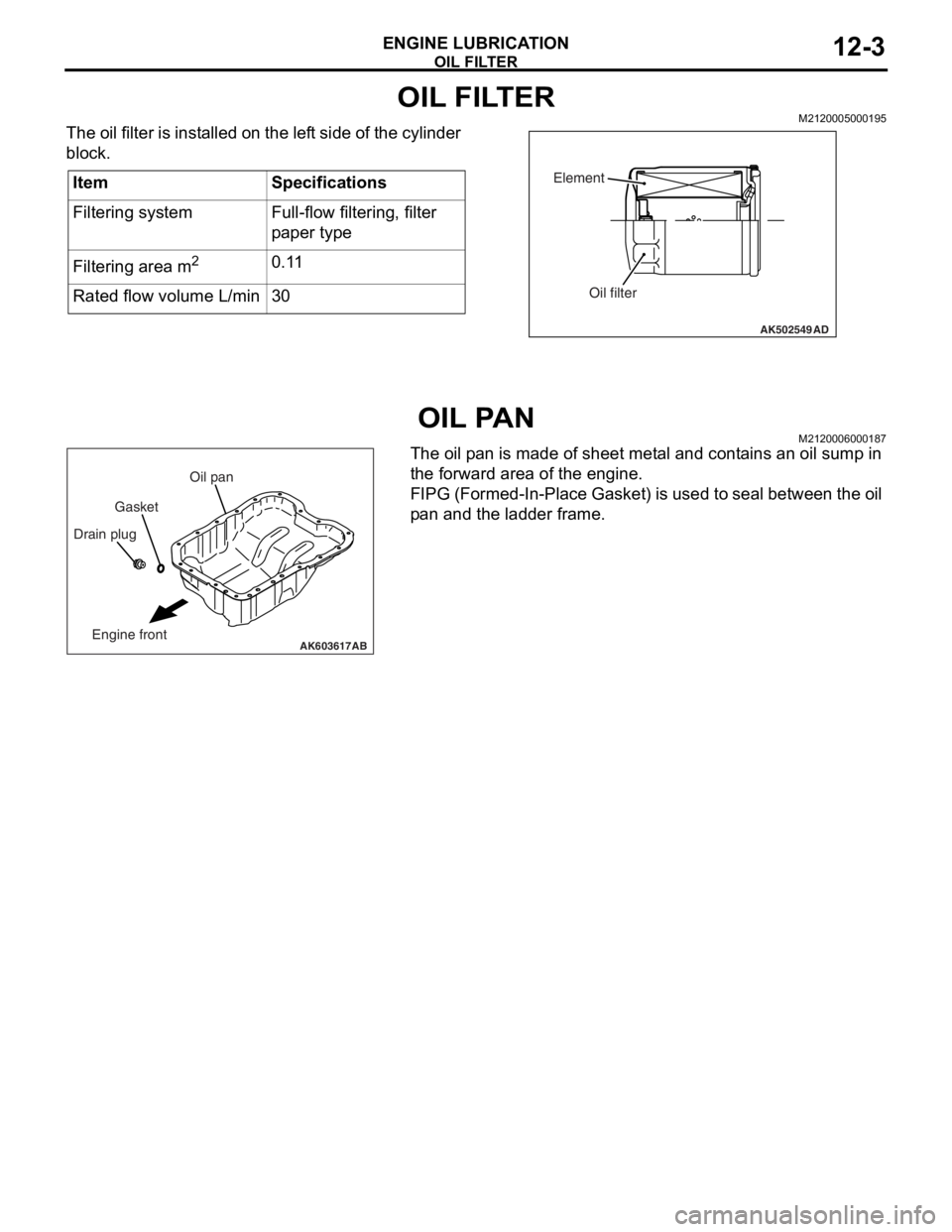

OIL FILTER

ENGINE LUBRICATION12-3

OIL FILTERM2120005000195

The oil filter is installed on the left side of the cylinder

block.

OIL PANM2120006000187

The oil pan is made of sheet metal and contains an oil sump in

the forward area of the engine.

FIPG (Formed-In-Place Gasket) is used to seal between the oil

pan and the ladder frame.

ItemSpecifications

Filtering systemFull-flow filtering, filter

paper type

Filtering area m20.11

Rated flow volume L/min30

AK502549

Element

Oil filter

AD

AK603617

Drain plugGasketOil pan

Engine frontAB

Page 149 of 241

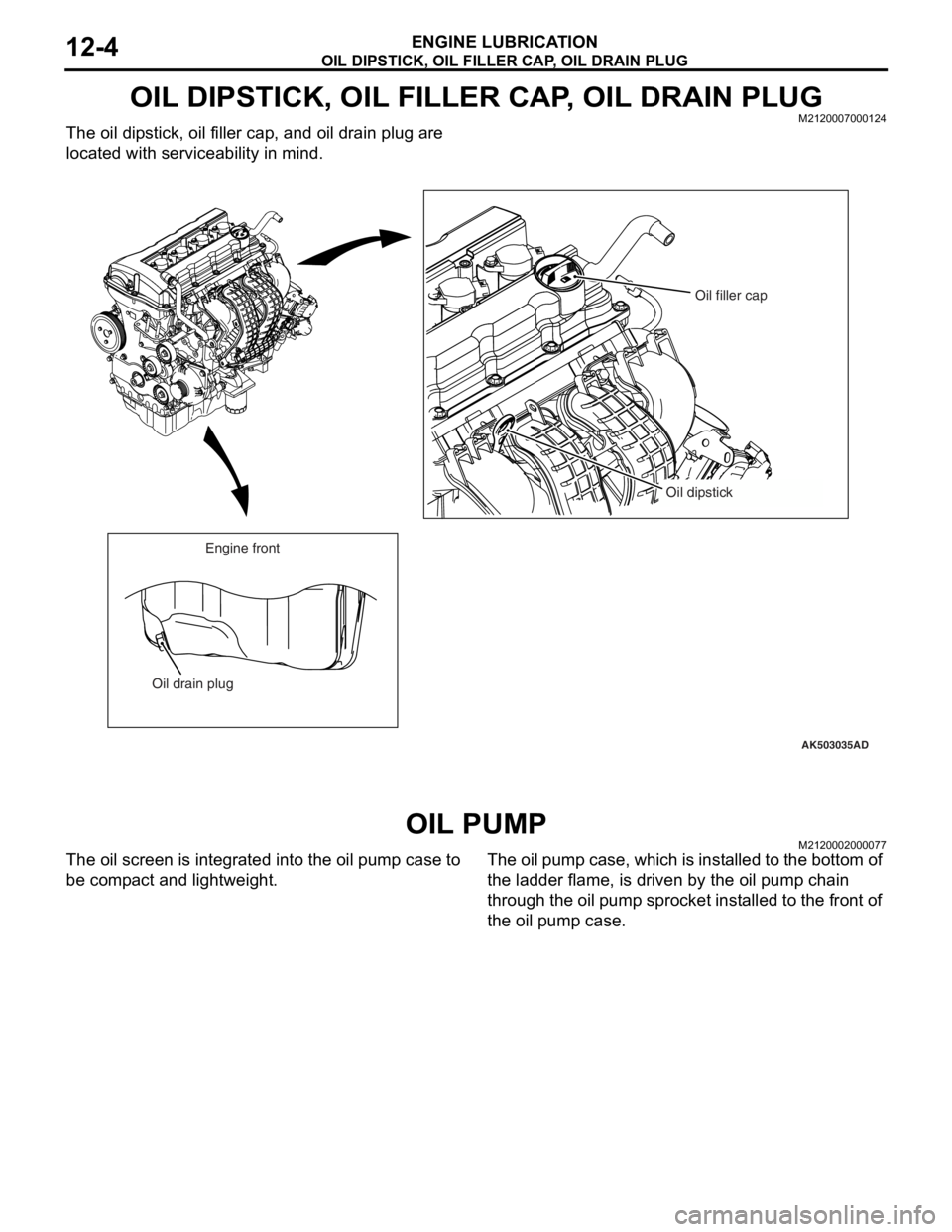

OIL DIPSTICK, OIL FILLER CAP, OIL DRAIN PLUG

ENGINE LUBRICATION12-4

OIL DIPSTICK, OIL FILLER CAP, OIL DRAIN PLUGM2120007000124

The oil dipstick, oil filler cap, and oil drain plug are

located with serviceability in mind.

OIL PUMPM2120002000077

The oil screen is integrated into the oil pump case to

be compact and lightweight.The oil pump case, which is installed to the bottom of

the ladder flame, is driven by the oil pump chain

through the oil pump sprocket installed to the front of

the oil pump case.

AK503035

Oil drain plug

Engine front

Oil dipstickOil filler cap

AD

Page 150 of 241

52A-1

GROUP 52A

INTERIOR

CONTENTS

GENERAL INFORMATION . . . . . . . .52A-2

INSTRUMENT PANEL AND FLOOR

CONSOLE . . . . . . . . . . . . . . . . . . . . .52A-3

SEAT . . . . . . . . . . . . . . . . . . . . . . . . .52A-5

FRONT SEAT . . . . . . . . . . . . . . . . . . . . . . . 52A-5

REAR SEAT . . . . . . . . . . . . . . . . . . . . . . . . 52A-7

SEAT BELT. . . . . . . . . . . . . . . . . . . . .52A-8

TRIMS . . . . . . . . . . . . . . . . . . . . . . . . .52A-10

INTERIOR TRIMS . . . . . . . . . . . . . . . . . . . . 52A-10

DOOR TRIM . . . . . . . . . . . . . . . . . . . . . . . . 52A-11

HEADLINING . . . . . . . . . . . . . . . . . . .52A-12

Trending: wheel alignment, ECU, Motor, fuel pump, child restraint, service indicator, brake fluid