MITSUBISHI LANCER EVOLUTION X 2008 Workshop Manual

Manufacturer: MITSUBISHI, Model Year: 2008, Model line: LANCER EVOLUTION X, Model: MITSUBISHI LANCER EVOLUTION X 2008Pages: 241, PDF Size: 8.26 MB

Page 131 of 241

THROTTLE VALVE OPENING ANGLE CONTROL AND IDLE SPEED CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-38

THROTTLE VALVE OPENING ANGLE CONTROL AND IDLE

SPEED CONTROL

M2132003500328

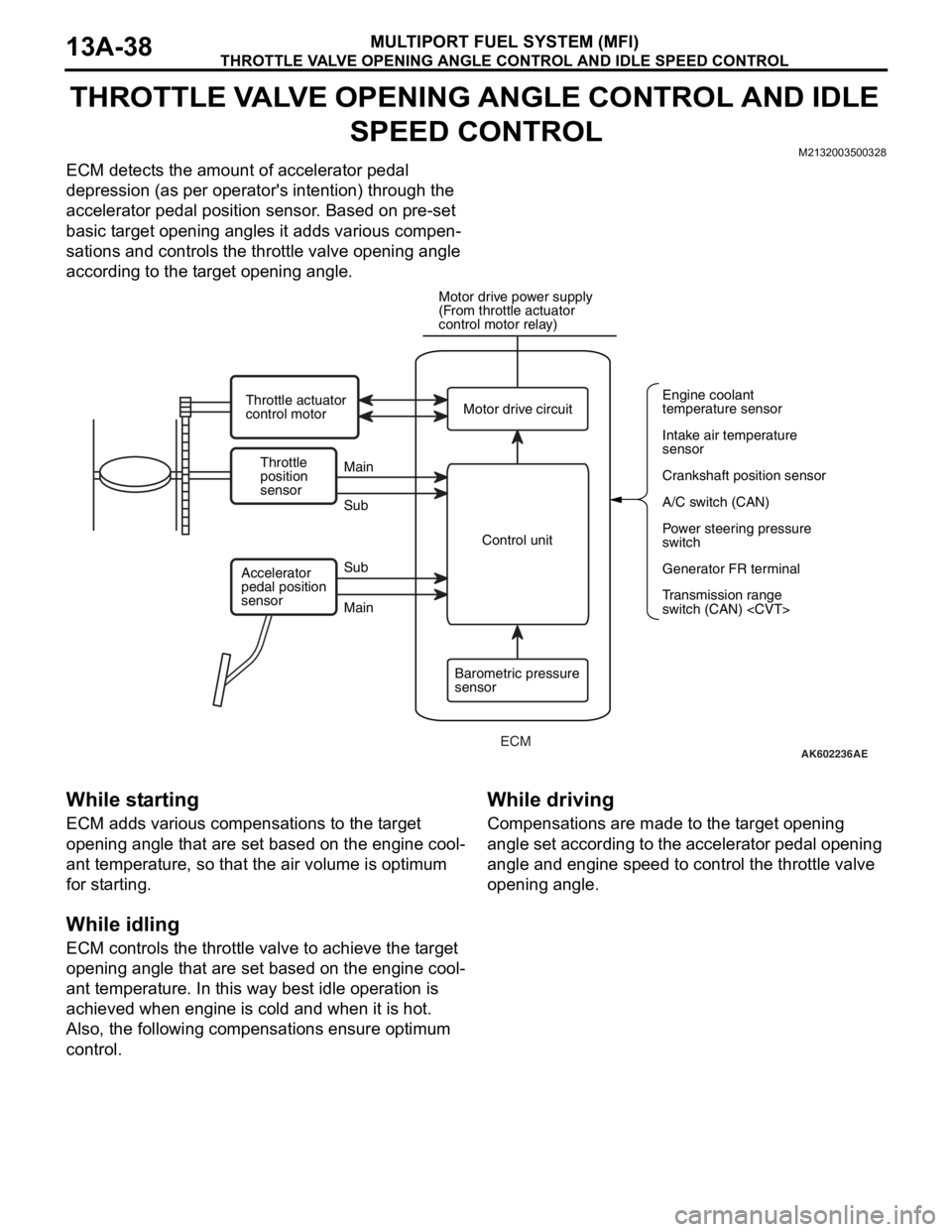

ECM detects the amount of accelerator pedal

depression (as per operator's intention) through the

accelerator pedal position sensor. Based on pre-set

basic target opening angles it adds various compen

-

sations and controls the throttle valve opening angle

according to the target opening angle.

While starting

ECM adds various compensations to the target

opening angle that are set based on the engine cool

-

ant temperature, so that the air volume is optimum

for starting.

While idling

ECM controls the throttle valve to achieve the target

opening angle that are set based on the engine cool

-

ant temperature. In this way best idle operation is

achieved when engine is cold and when it is hot.

Also, the following compensations ensure optimum

control.

While driving

Compensations are made to the target opening

angle set according to the accelerator pedal opening

angle and engine speed to control the throttle valve

opening angle.

AK602236AE

Throttle

position

sensorMain

Main Sub

SubMotor drive circuit

A/C switch (CAN) Engine coolant

temperature sensor

Intake air temperature

sensor

Crankshaft position sensor

Power steering pressure

switch

Generator FR terminal

Transmission range

switch (CAN)

(From throttle actuator

control motor relay)

Throttle actuator

control motor

Control unit

Barometric pressure

sensor Accelerator

pedal position

sensor

ECM

Page 132 of 241

THROTTLE VALVE OPENING ANGLE CONTROL AND IDLE SPEED CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-39

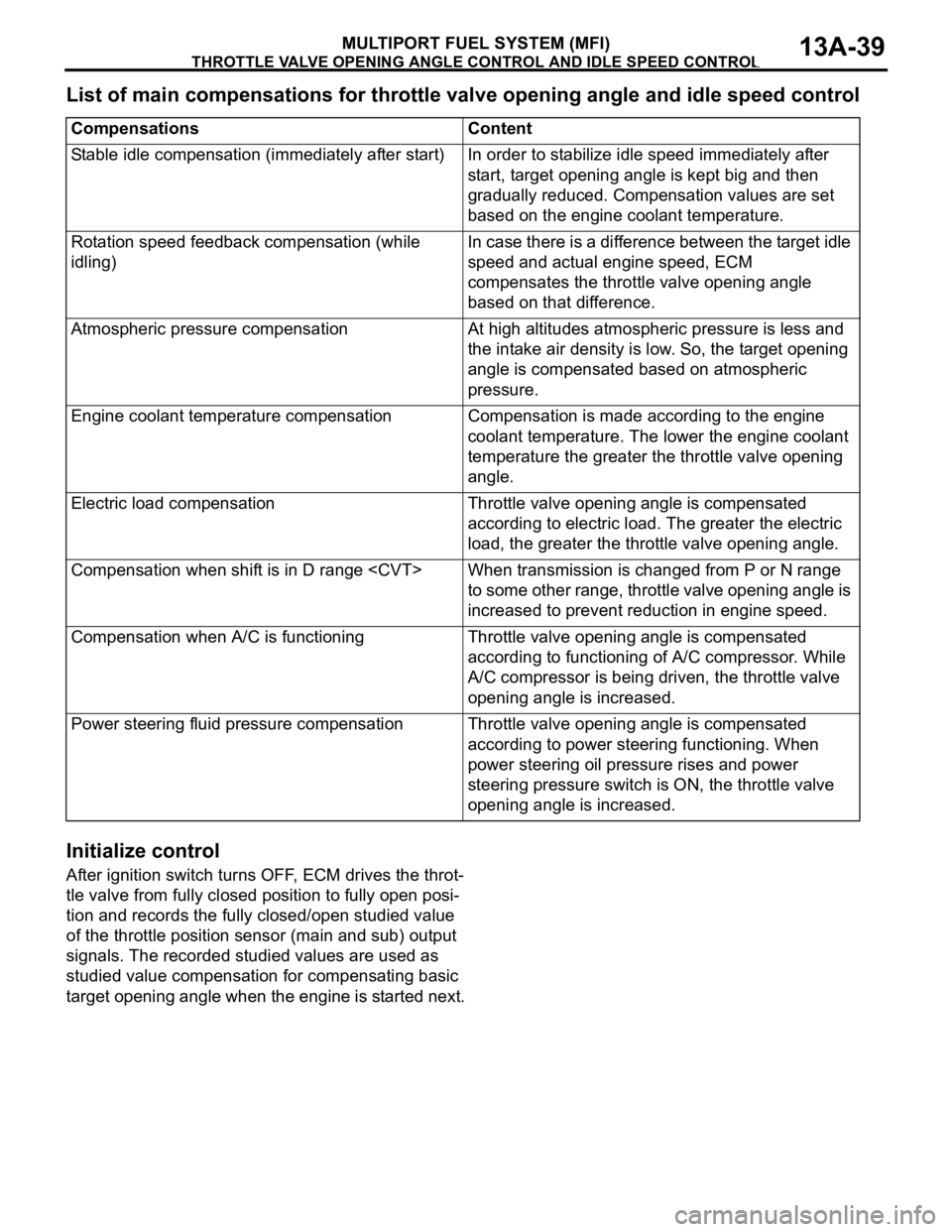

List of main compensations for throttle valve opening angle and idle speed control

Initialize control

After ignition switch turns OFF, ECM drives the throt-

tle valve from fully closed position to fully open posi-

tion and records the fully closed/open studied value

of the throttle position sensor (main and sub) output

signals. The recorded studied values are used as

studied value compensation for compensating basic

target opening angle when the engine is started next.

CompensationsContent

Stable idle compensation (immediately after start)In order to stabilize idle speed immediately after

start, target opening angle is kept big and then

gradually reduced. Compensation values are set

based on the engine coolant temperature.

Rotation speed feedback compensation (while

idling)In case there is a difference between the target idle

speed and actual engine speed, ECM

compensates the throttle valve opening angle

based on that difference.

Atmospheric pressure compensationAt high altitudes atmospheric pressure is less and

the intake air density is low. So, the target opening

angle is compensated based on atmospheric

pressure.

Engine coolant temperature compensationCompensation is made according to the engine

coolant temperature. The lower the engine coolant

temperature the greater the throttle valve opening

angle.

Electric load compensationThrottle valve opening angle is compensated

according to electric load. The greater the electric

load, the greater the throttle valve opening angle.

Compensation when shift is in D range

to some other range, throttle valve opening angle is

increased to prevent reduction in engine speed.

Compensation when A/C is functioningThrottle valve opening angle is compensated

according to functioning of A/C compressor. While

A/C compressor is being driven, the throttle valve

opening angle is increased.

Power steering fluid pressure compensationThrottle valve opening angle is compensated

according to power steering functioning. When

power steering oil pressure rises and power

steering pressure switch is ON, the throttle valve

opening angle is increased.

Page 133 of 241

MIVEC (Mitsubishi Innovative Valve Timing Electronic Control System)

MULTIPORT FUEL SYSTEM (MFI)13A-40

MIVEC (Mitsubishi Innovative Valve Timing Electronic

Control System)

M2132023500212

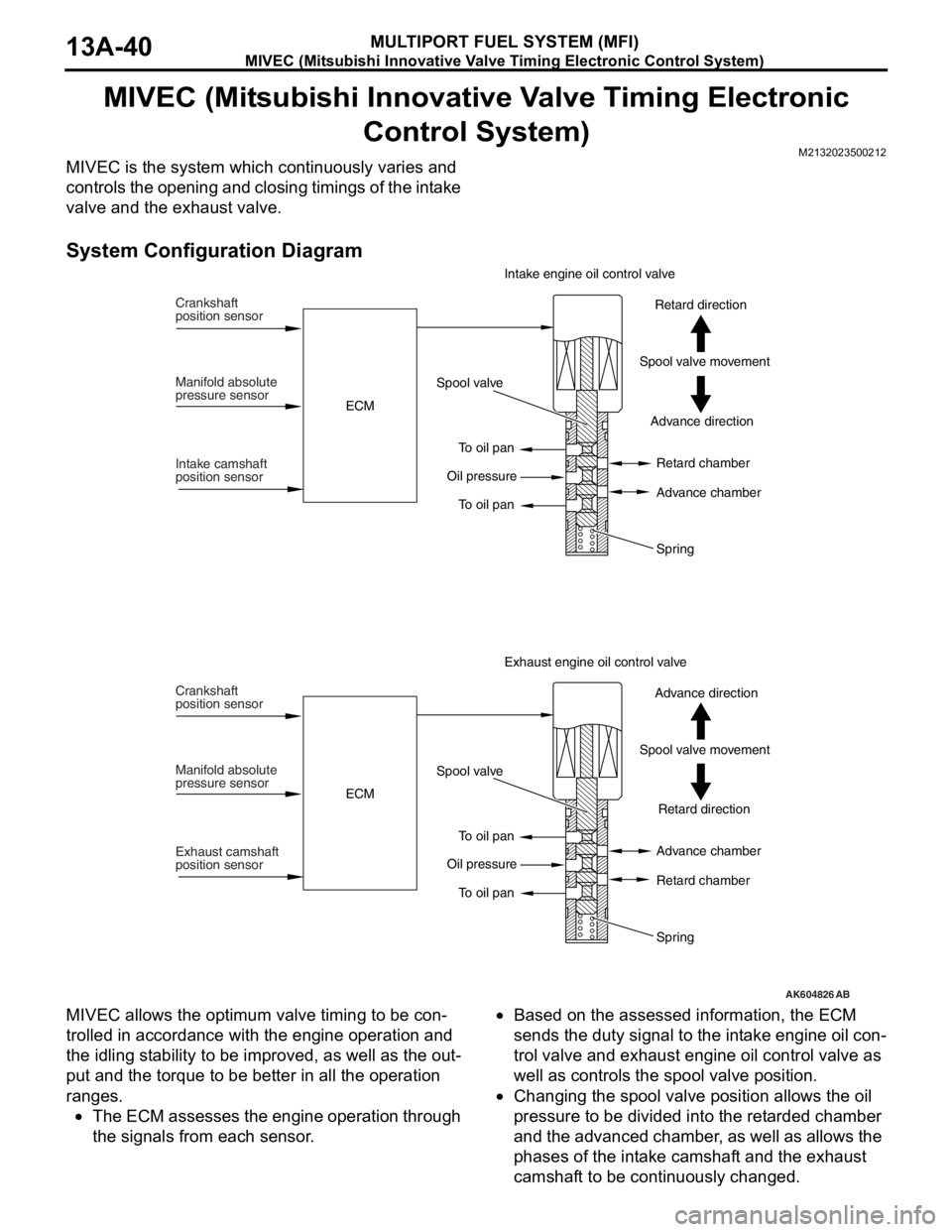

MIVEC is the system which continuously varies and

controls the opening and closing timings of the intake

valve and the exhaust valve.

System Configuration Diagram

MIVEC allows the optimum valve timing to be con-

trolled in accordance with the engine operation and

the idling stability to be improved, as well as the out

-

put and the torque to be better in all the operation

ranges.

•The ECM assesses the engine operation through

the signals from each sensor.

•Based on the assessed information, the ECM

sends the duty signal to the intake engine oil con

-

trol valve and exhaust engine oil control valve as

well as controls the spool valve position.

•Changing the spool valve position allows the oil

pressure to be divided into the retarded chamber

and the advanced chamber, as well as allows the

phases of the intake camshaft and the exhaust

camshaft to be continuously changed.

AK604826AB

Crankshaft

position sensor

Manifold absolute

pressure sensor

Intake camshaft

position sensorECMSpool valve

To oil pan

To oil pan Oil pressureAdvance direction Spool valve movementRetard direction Intake engine oil control valve

Retard chamber

Advance chamber

Spring

Crankshaft

position sensor

Manifold absolute

pressure sensor

Exhaust camshaft

position sensorECMSpool valve

To oil pan

To oil pan Oil pressureRetard direction Spool valve movementAdvance direction Exhaust engine oil control valve

Advance chamber

Retard chamber

Spring

Page 134 of 241

MIVEC (Mitsubishi Innovative Valve Timing Electronic Control System)

MULTIPORT FUEL SYSTEM (MFI)13A-41

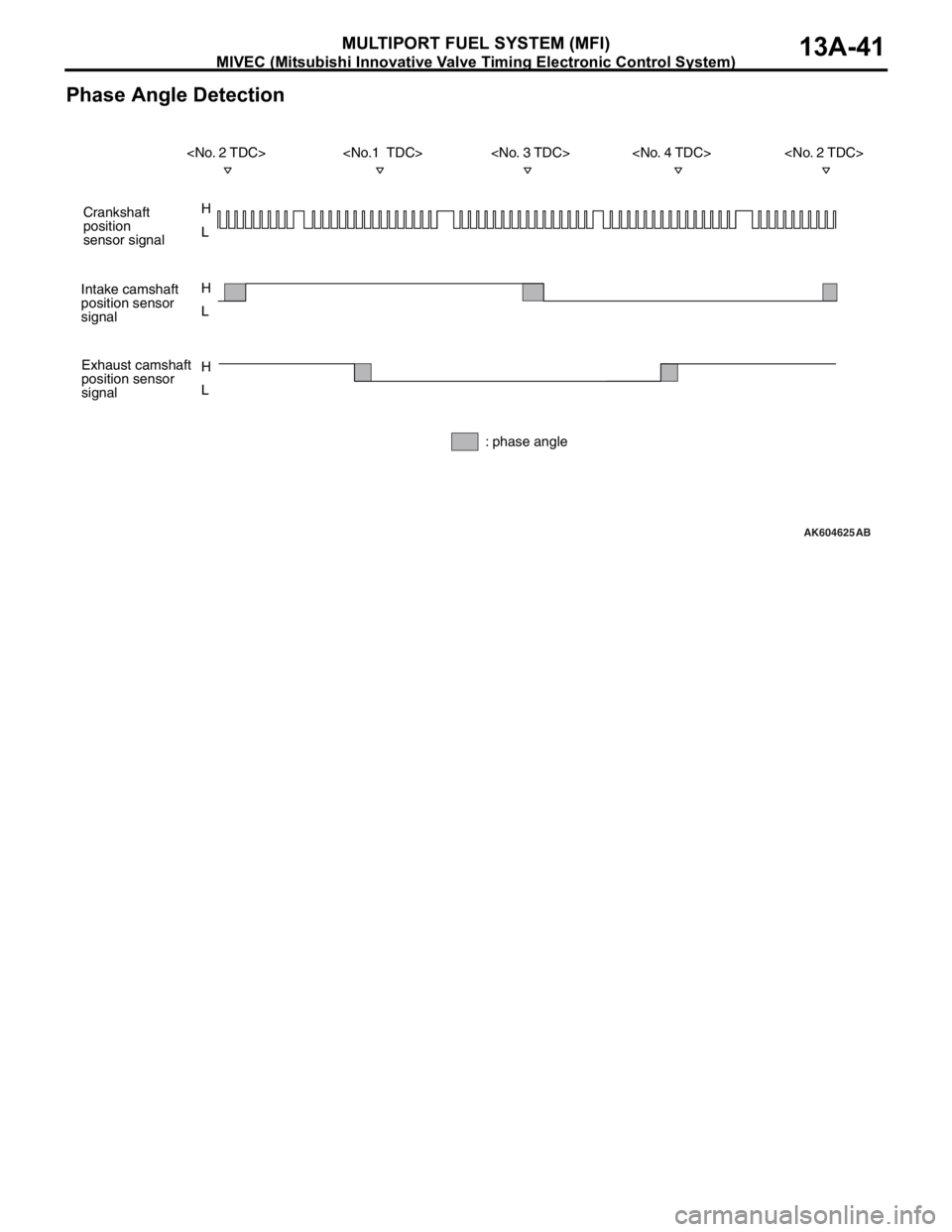

Phase Angle Detection

AK604625

H

L H

L

H

L

AB

Crankshaft

position

sensor signal

Intake camshaft

position sensor

signal

Exhaust camshaft

position sensor

signal

: phase angle

Page 135 of 241

MIVEC (Mitsubishi Innovative Valve Timing Electronic Control System)

MULTIPORT FUEL SYSTEM (MFI)13A-42

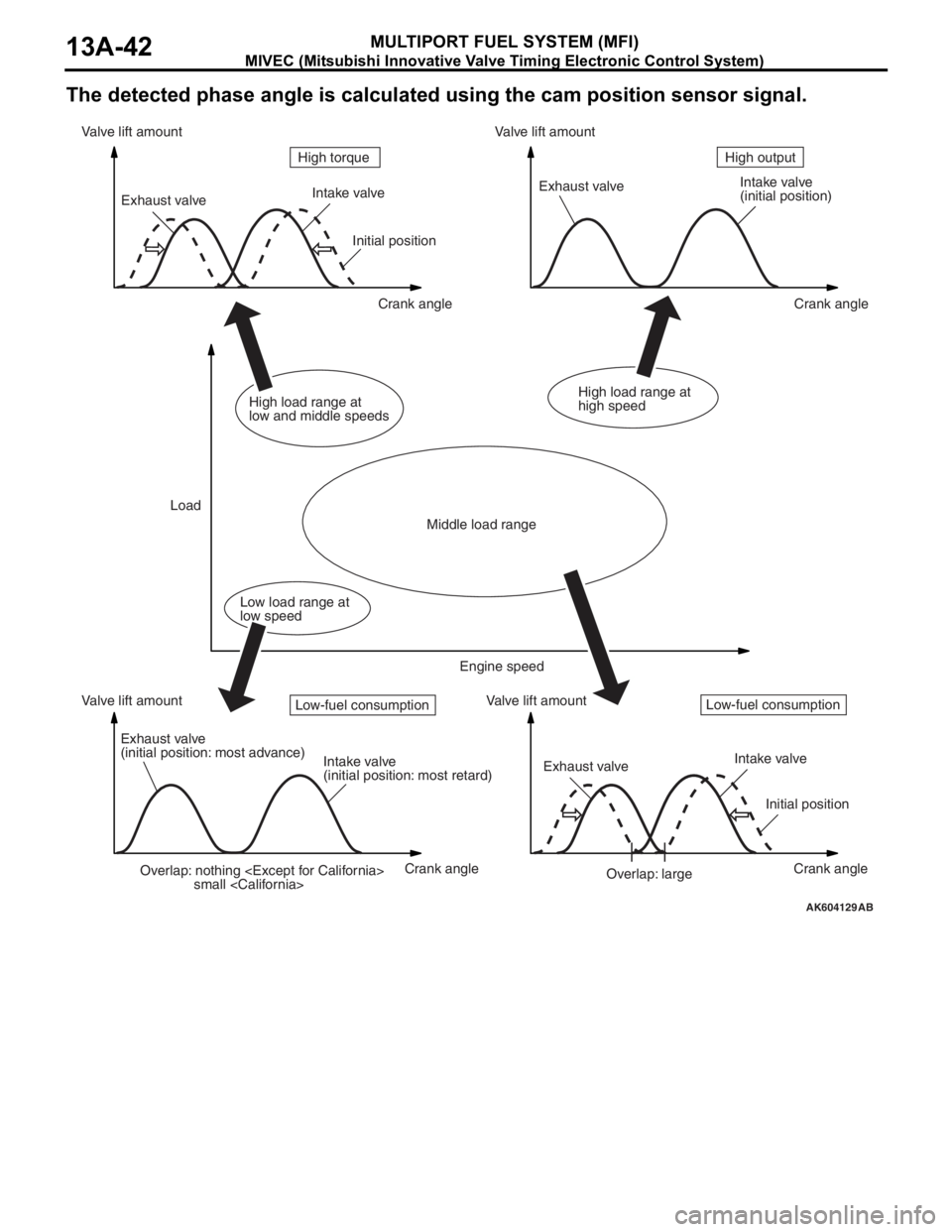

The detected phase angle is calculated using the cam position sensor signal.

AK604129AB

Overlap: nothing

small

(initial position)

Exhaust valve

(initial position: most advance)

Intake valve

(initial position: most retard)Exhaust valveIntake valve

Initial position

Overlap: large Initial position

Crank angle Crank angle

Crank angle Crank angle Valve lift amount Valve lift amountValve lift amount Valve lift amount

LoadHigh output High torque

Middle load range

Low load range at

low speedHigh load range at

low and middle speedsHigh load range at

high speed

Engine speed

Low-fuel consumptionLow-fuel consumption

Page 136 of 241

MIVEC (Mitsubishi Innovative Valve Timing Electronic Control System)

MULTIPORT FUEL SYSTEM (MFI)13A-43

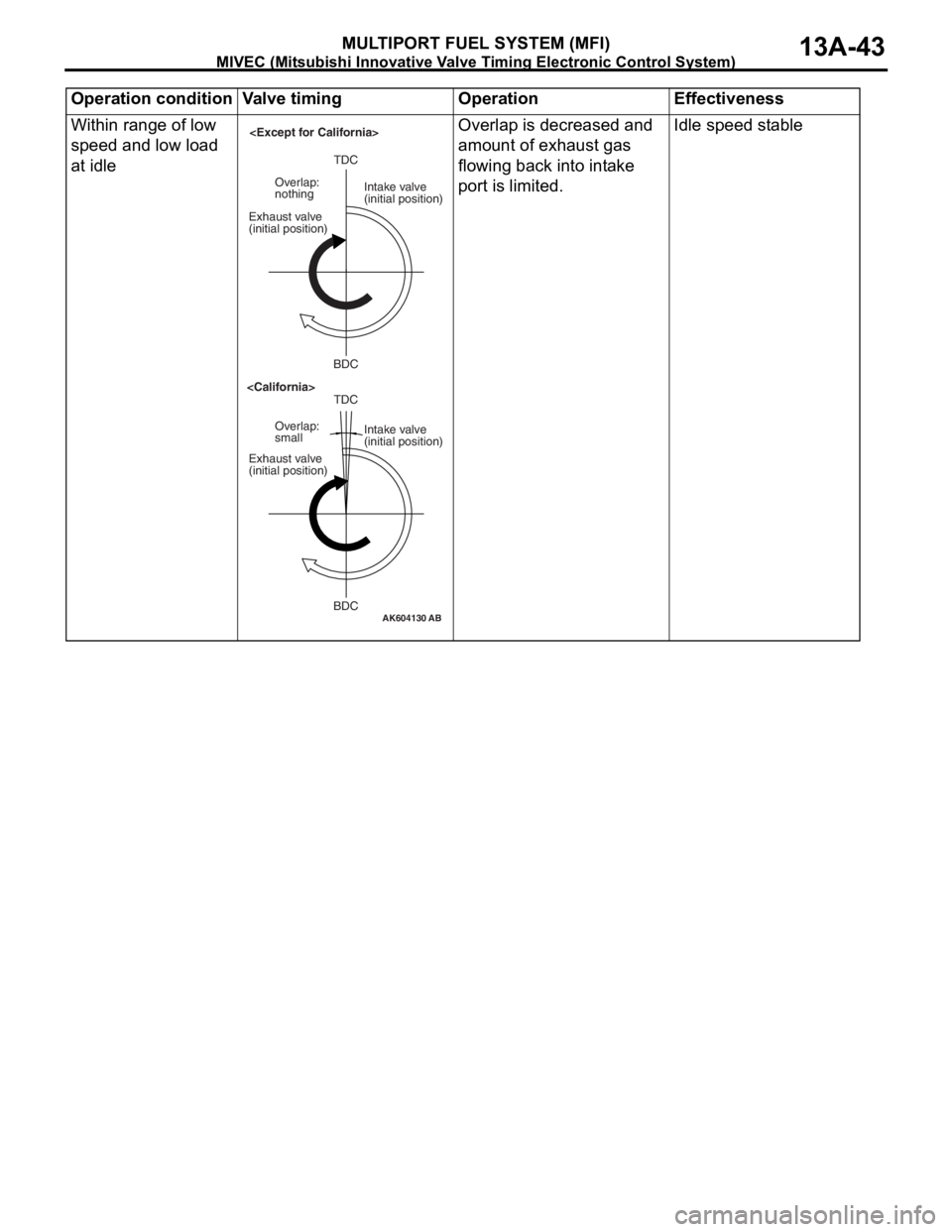

Operation conditionValve timingOperationEffectiveness

Within range of low

speed and low load

at idleOverlap is decreased and

amount of exhaust gas

flowing back into intake

port is limited.Idle speed stable

AK604130AB

TDC

BDC Exhaust valve

(initial position)Intake valve

(initial position) Overlap:

smallTDC

BDC Exhaust valve

(initial position)Intake valve

(initial position) Overlap:

nothing

Page 137 of 241

MIVEC (Mitsubishi Innovative Valve Timing Electronic Control System)

MULTIPORT FUEL SYSTEM (MFI)13A-44

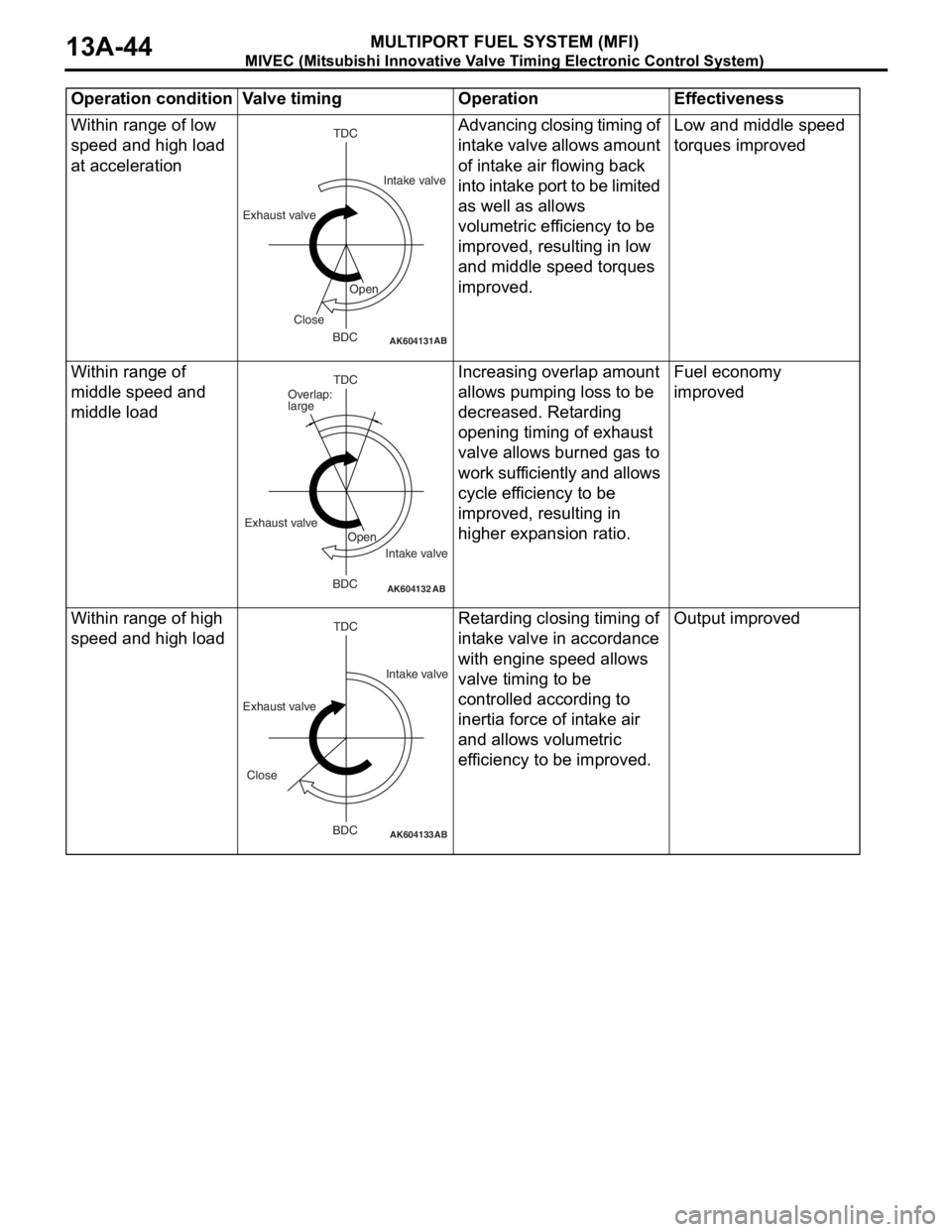

Within range of low

speed and high load

at accelerationAdvancing closing timing of

intake valve allows amount

of intake air flowing back

into intake port to be limited

as well as allows

volumetric efficiency to be

improved, resulting in low

and middle speed torques

improved.Low and middle speed

torques improved

Within range of

middle speed and

middle loadIncreasing overlap amount

allows pumping loss to be

decreased. Retarding

opening timing of exhaust

valve allows burned gas to

work sufficiently and allows

cycle efficiency to be

improved, resulting in

higher expansion ratio.Fuel economy

improved

Within range of high

speed and high loadRetarding closing timing of

intake valve in accordance

with engine speed allows

valve timing to be

controlled according to

inertia force of intake air

and allows volumetric

efficiency to be improved.Output improved

Operation condition Valve timing Operation Effectiveness

AK604131AB

TDC

BDC Exhaust valveIntake valve

Open

Close

AK604132AB

TDC

BDC Exhaust valve

Intake valve Overlap:

large

Open

AK604133

TDC

BDC

AB

Exhaust valveIntake valve

Close

Page 138 of 241

MULTIPORT FUEL INJECTION (MFI) RELAY CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-45

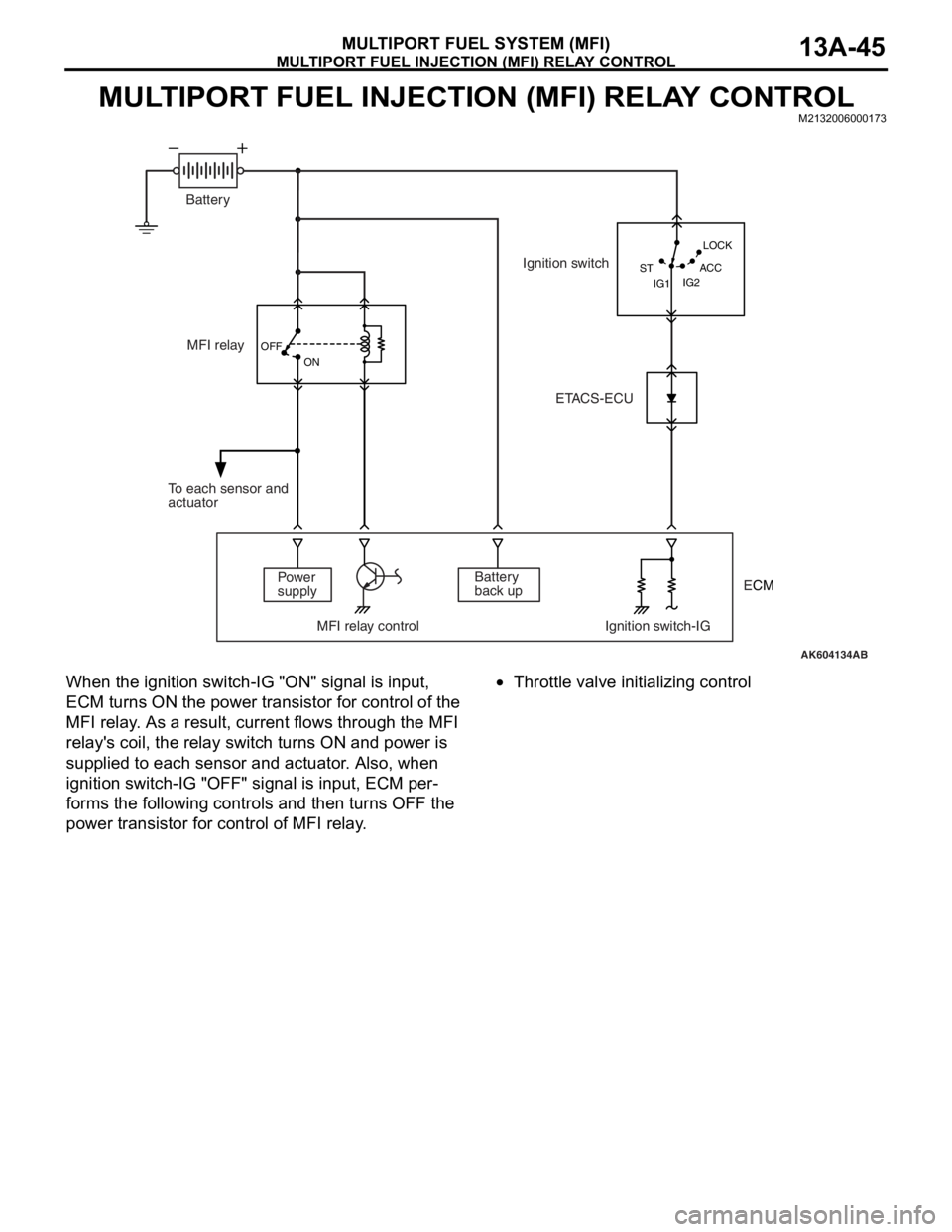

MULTIPORT FUEL INJECTION (MFI) RELAY CONTROLM2132006000173

When the ignition switch-IG "ON" signal is input,

ECM turns ON the power transistor for control of the

MFI relay. As a result, current flows through the MFI

relay's coil, the relay switch turns ON and power is

supplied to each sensor and actuator. Also, when

ignition switch-IG "OFF" signal is input, ECM per

-

forms the following controls and then turns OFF the

power transistor for control of MFI relay.

•Throttle valve initializing control

AK604134AB OFF

ON

IG2 STLOCK

ACC

IG1

MFI relay

Power

supply

MFI relay control Ignition switch-IGBattery

back up To each sensor and

actuatorIgnition switch

ETACS-ECU Battery

ECM

Page 139 of 241

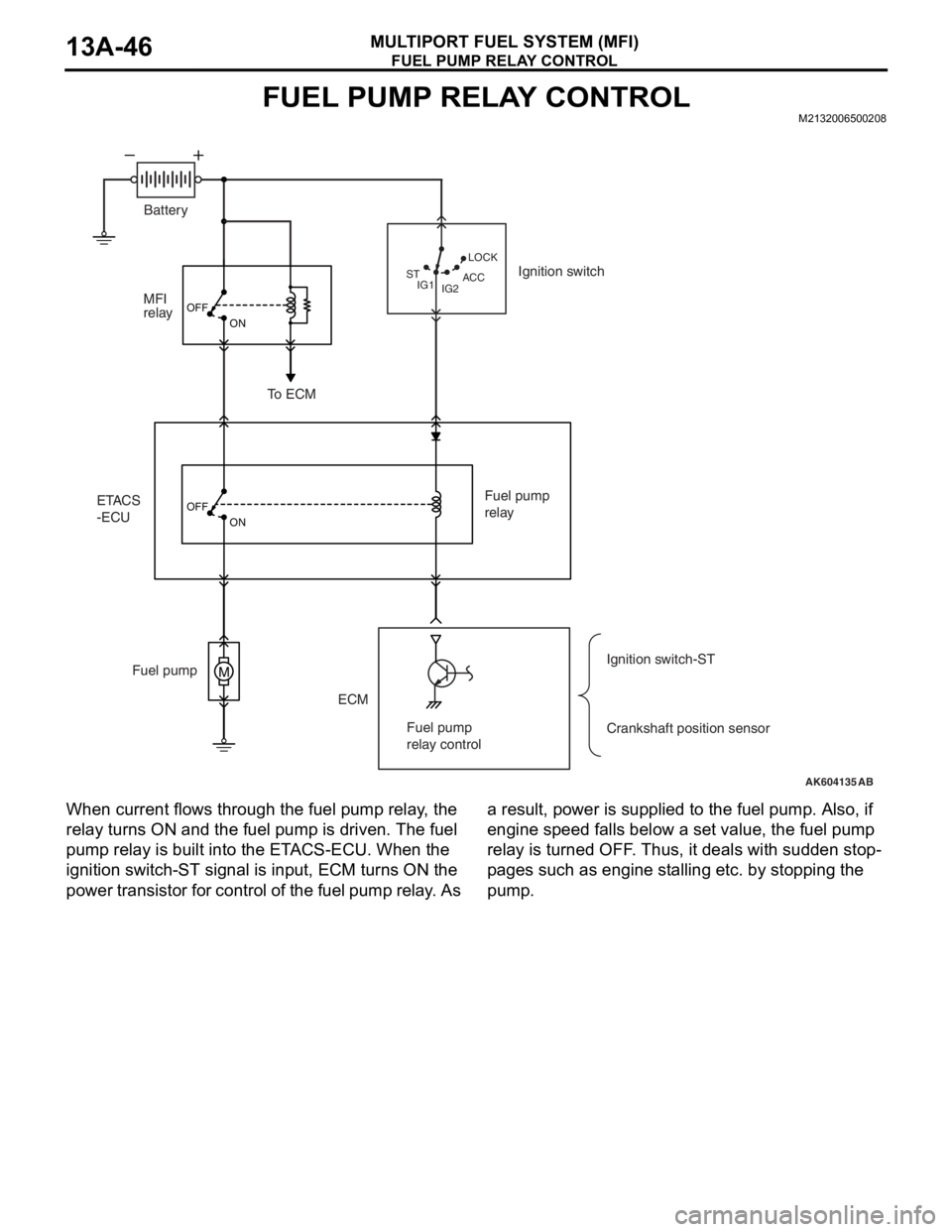

FUEL PUMP RELAY CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-46

FUEL PUMP RELAY CONTROLM2132006500208

When current flows through the fuel pump relay, the

relay turns ON and the fuel pump is driven. The fuel

pump relay is built into the ETACS-ECU. When the

ignition switch-ST signal is input, ECM turns ON the

power transistor for control of the fuel pump relay. As a result, power is supplied to the fuel pump. Also, if

engine speed falls below a set value, the fuel pump

relay is turned OFF. Thus, it deals with sudden stop

-

pages such as engine stalling etc. by stopping the

pump.

AK604135

M

OFF

ON

OFF

ON

AB IG2 STLOCK

ACC

IG1

ETACS

-ECUMFI

relay

ECM Fuel pumpFuel pump

relay

Crankshaft position sensor Ignition switch

To ECM

Ignition switch-ST Battery

Fuel pump

relay control

Page 140 of 241

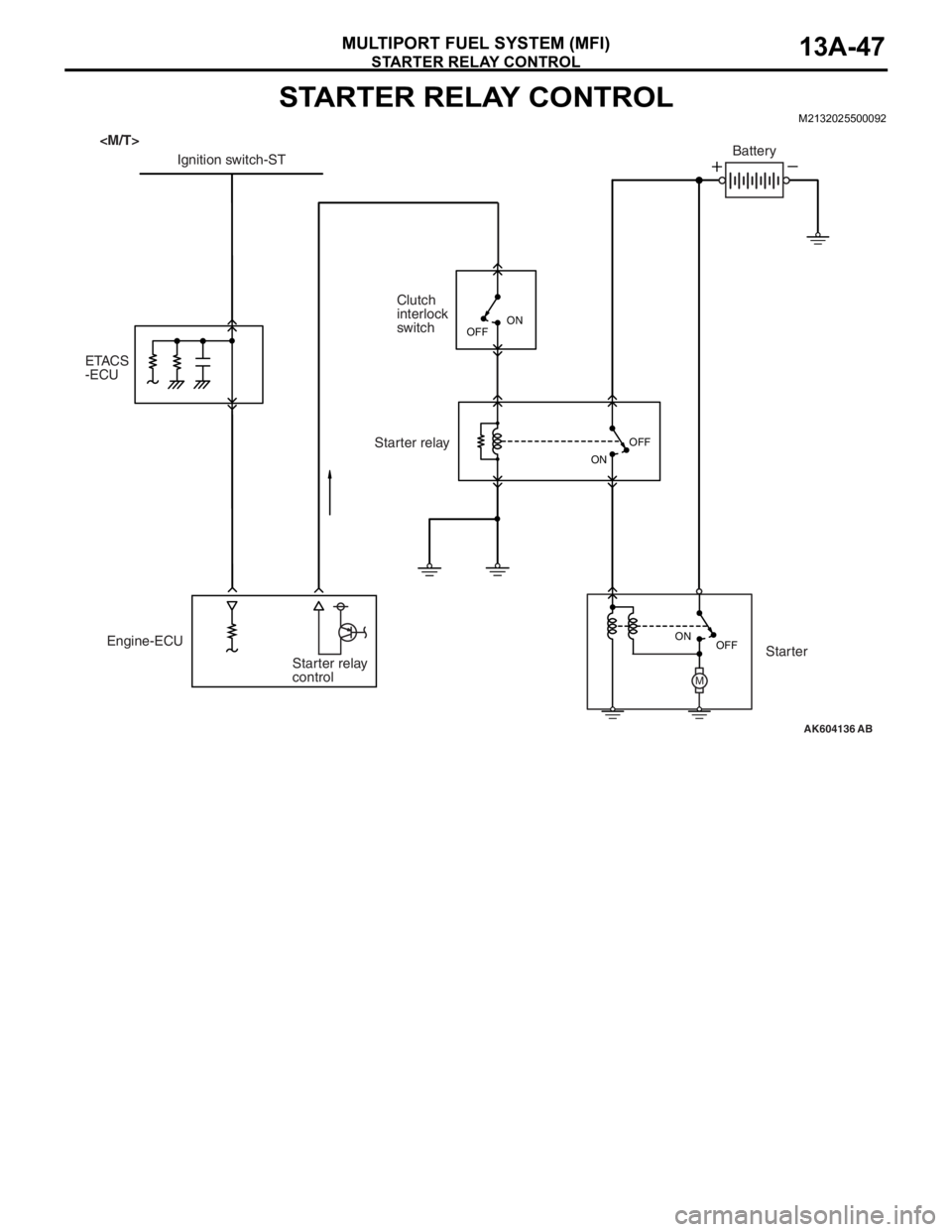

STARTER RELAY CONTROL

MULTIPORT FUEL SYSTEM (MFI)13A-47

STARTER RELAY CONTROLM2132025500092

AK604136

M

AB OFF ON OFF

ON

Engine-ECU

Starter relay

controlClutch

interlock

switch

ETACS

-ECUIgnition switch-STBattery

Starter relay

Starter

OFFON