MITSUBISHI LANCER EVOLUTION X 2008 Service Manual

LANCER EVOLUTION X 2008

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57326/w960_57326-0.png

MITSUBISHI LANCER EVOLUTION X 2008 Service Manual

Trending: navigation system, park, oil dipstick, rims, steering wheel adjustment, power steering fluid, lock

Page 41 of 241

A/C COMPRESSOR

HEATER, AIR CONDITIONING AND VENTILATION55-9

A/C COMPRESSORM2551001100268

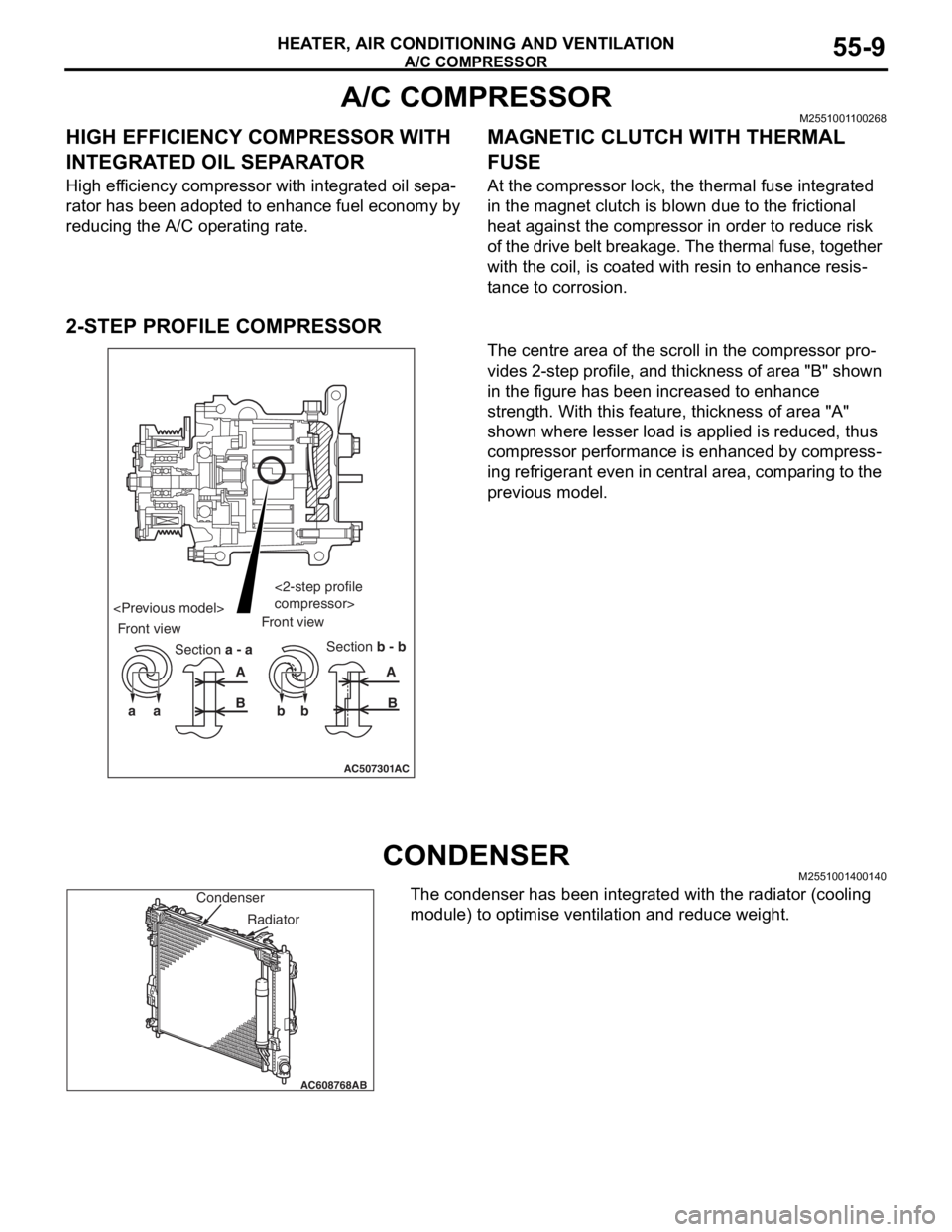

HIGH EFFICIENCY COMPRESSOR WITH

INTEGRATED OIL SEPARATOR

High efficiency compressor with integrated oil sepa-

rator has been adopted to enhance fuel economy by

reducing the A/C operating rate.

MAGNETIC CLUTCH WITH THERMAL

FUSE

At the compressor lock, the thermal fuse integrated

in the magnet clutch is blown due to the frictional

heat against the compressor in order to reduce risk

of the drive belt breakage. The thermal fuse, together

with the coil, is coated with resin to enhance resis

-

tance to corrosion.

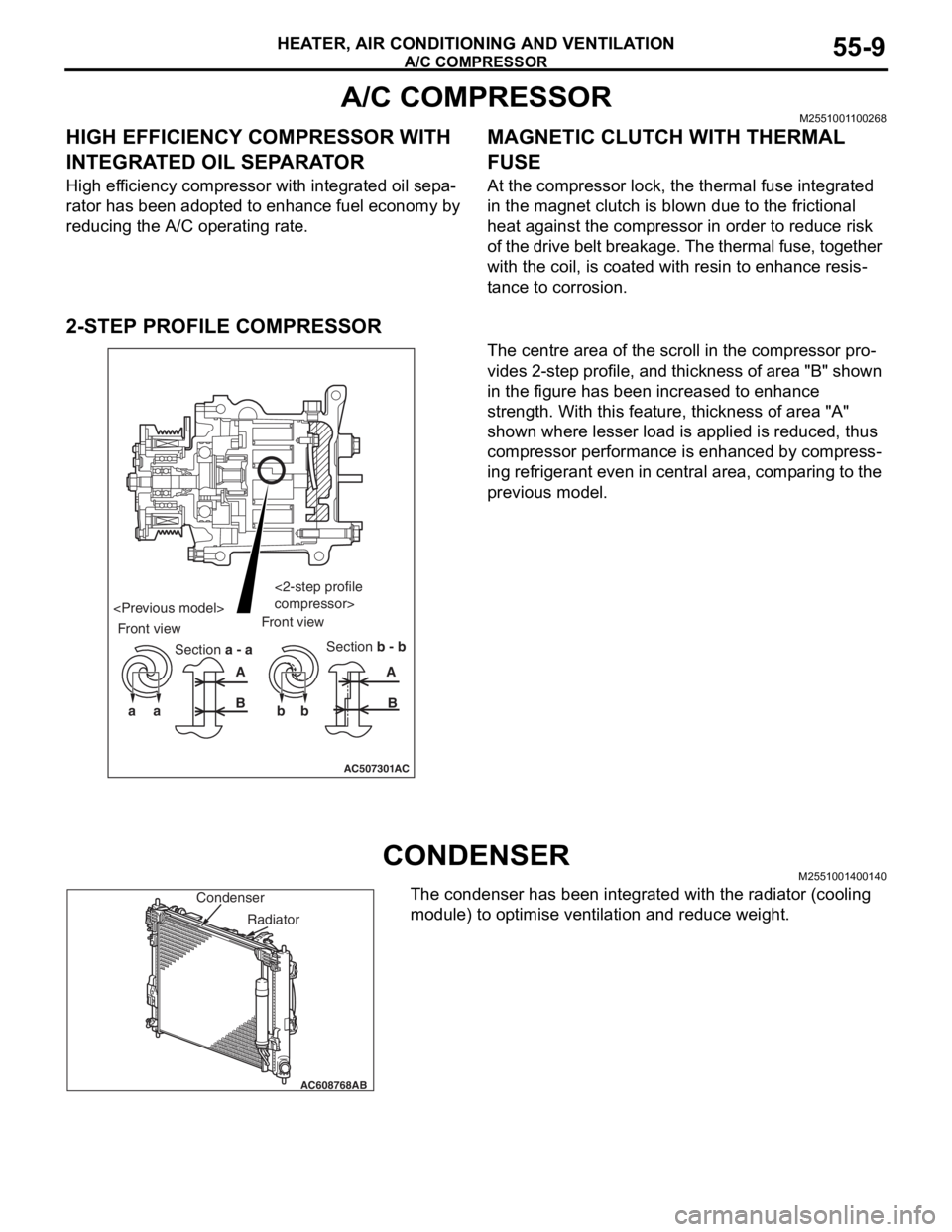

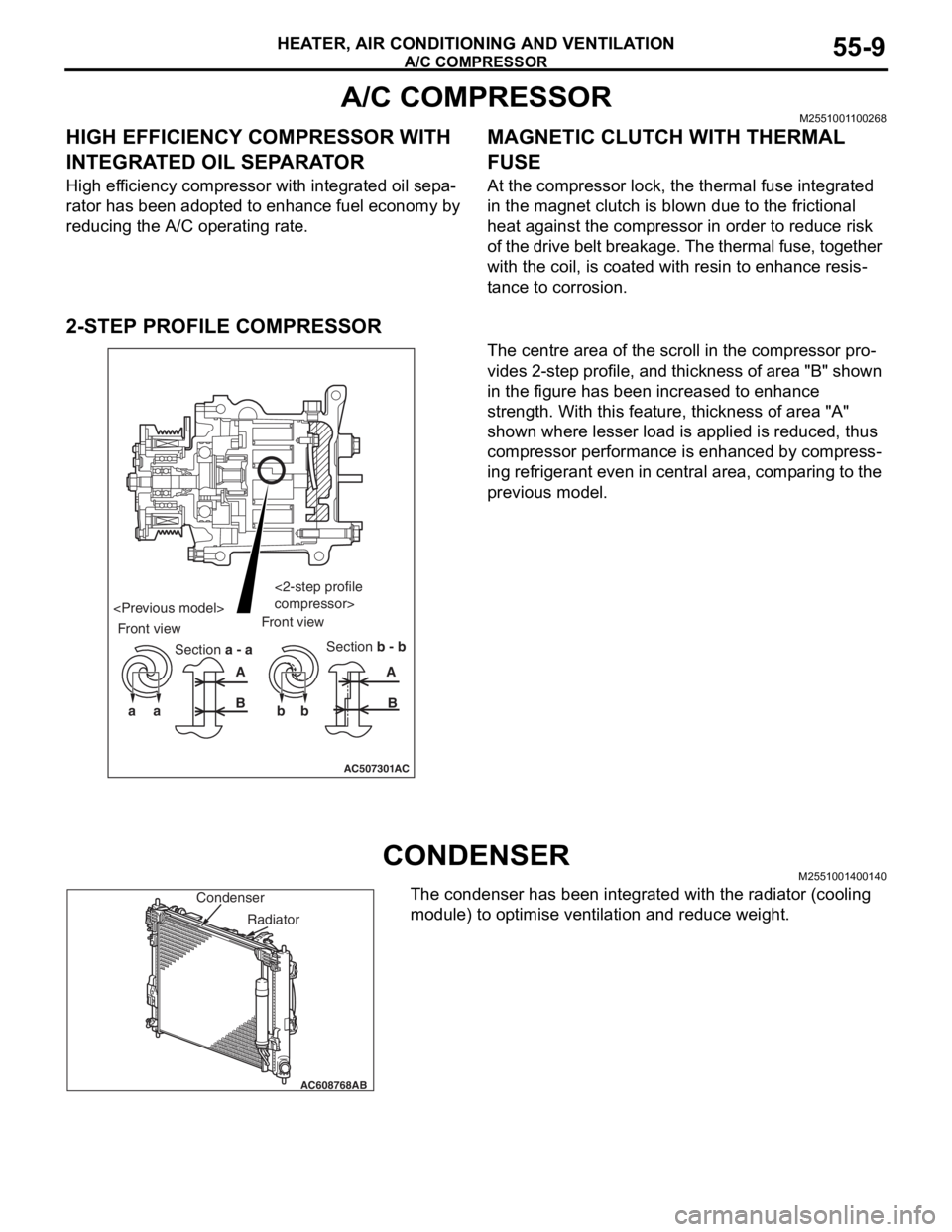

2-STEP PROFILE COMPRESSOR

The centre area of the scroll in the compressor pro-

vides 2-step profile, and thickness of area "B" shown

in the figure has been increased to enhance

strength. With this feature, thickness of area "A"

shown where lesser load is applied is reduced, thus

compressor performance is enhanced by compress

-

ing refrigerant even in central area, comparing to the

previous model.

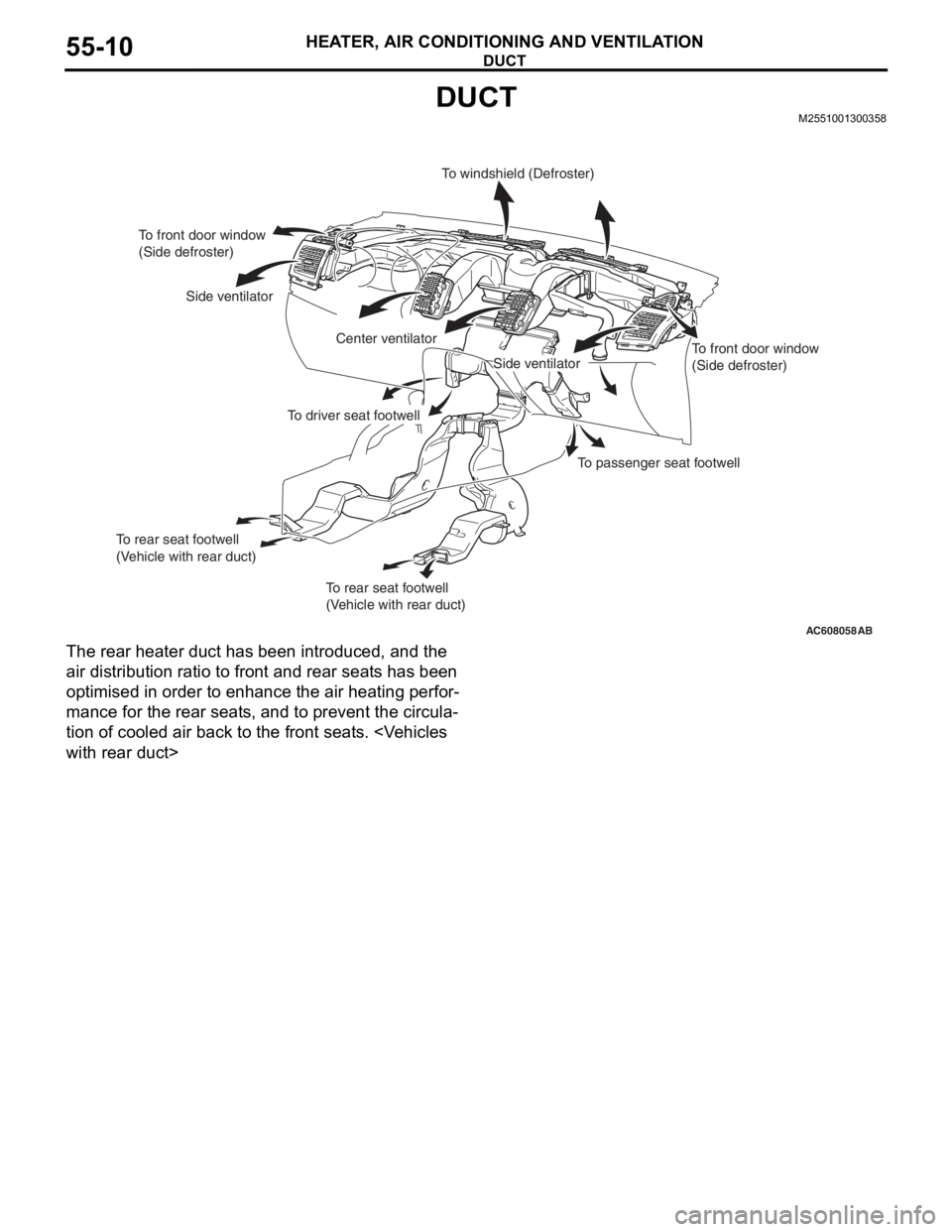

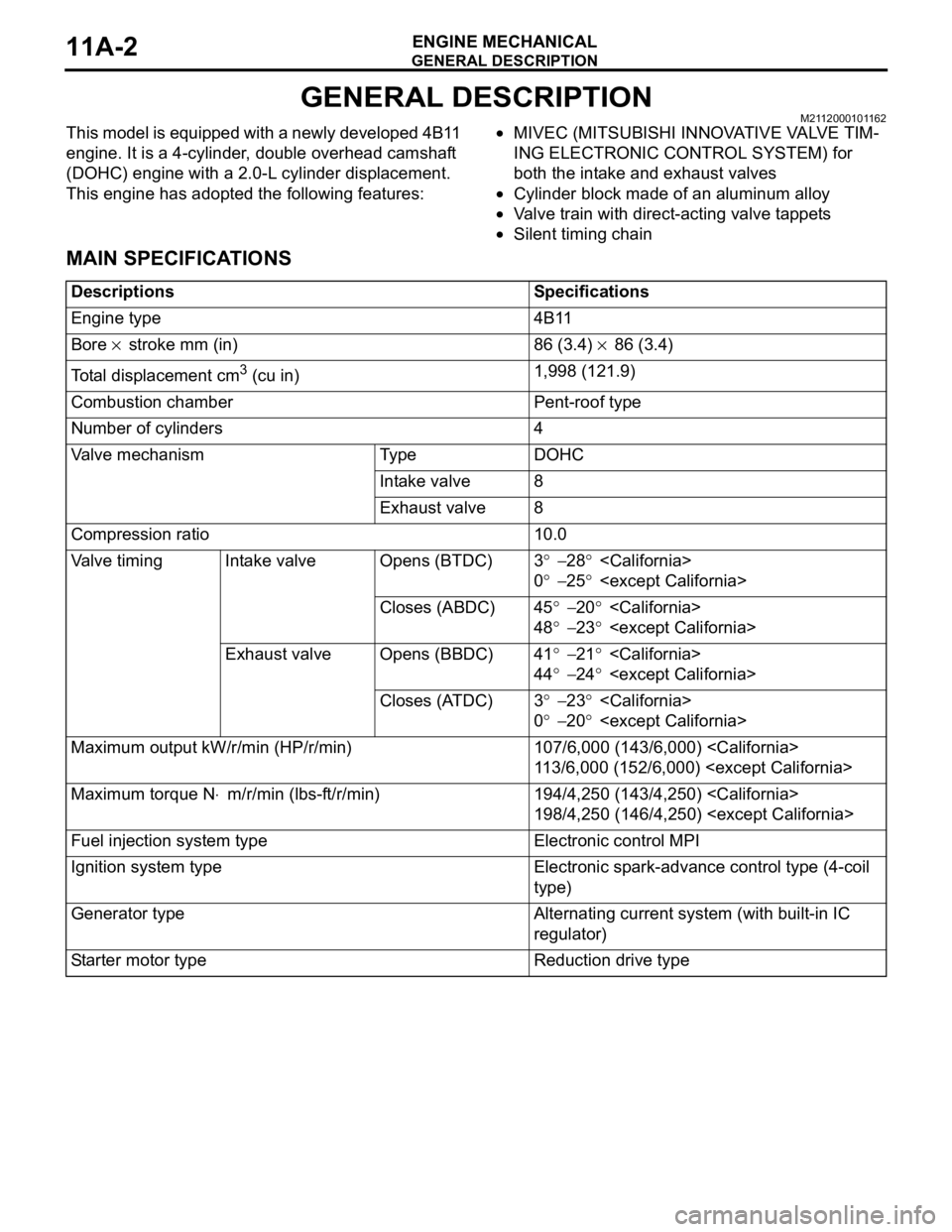

CONDENSERM2551001400140

The condenser has been integrated with the radiator (cooling

module) to optimise ventilation and reduce weight.

AC507301

aa bbAA

BB

AC

Section a - aSection b - b Front viewFront view <2-step profile

compressor>

AC608768

Condenser

AB

Radiator

Page 42 of 241

DUCT

HEATER, AIR CONDITIONING AND VENTILATION55-10

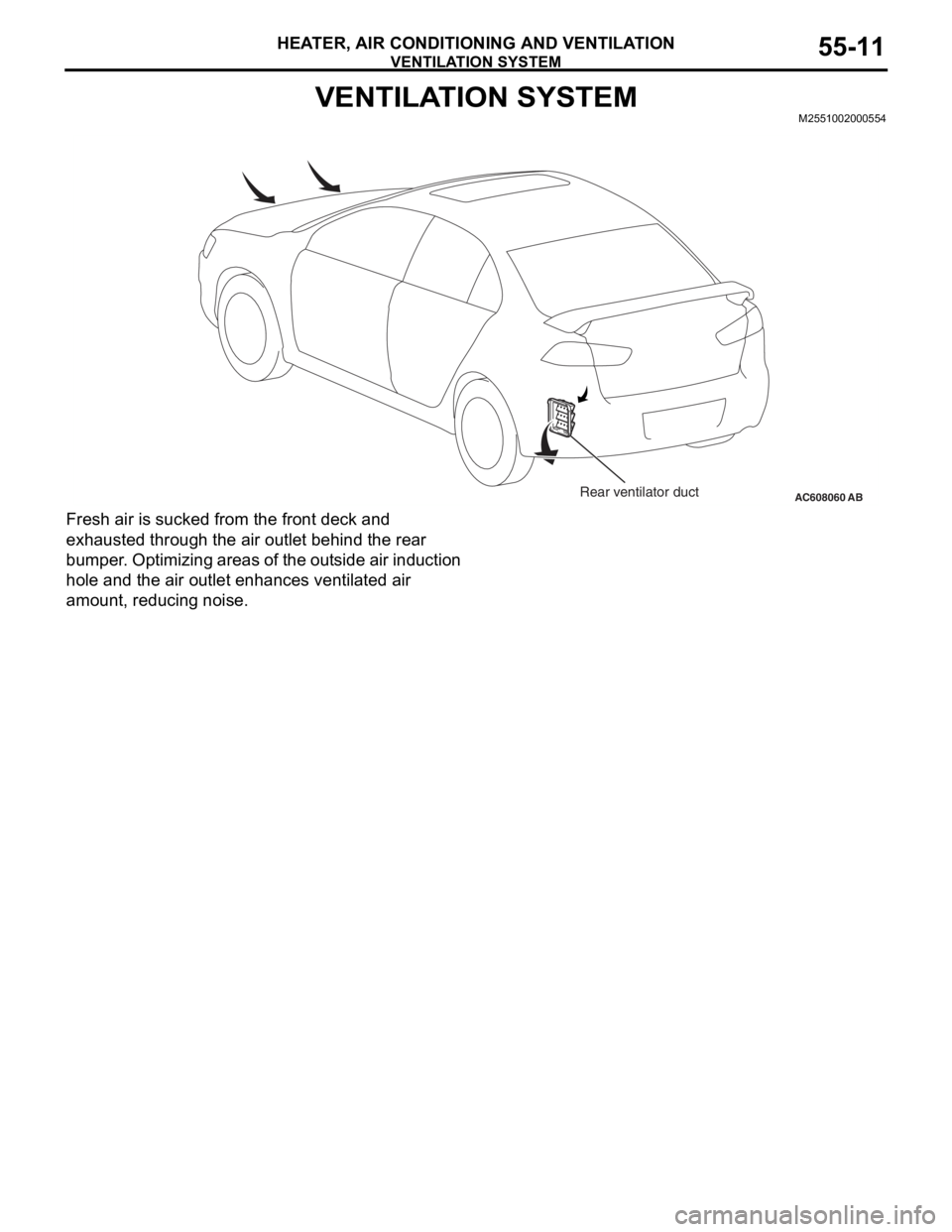

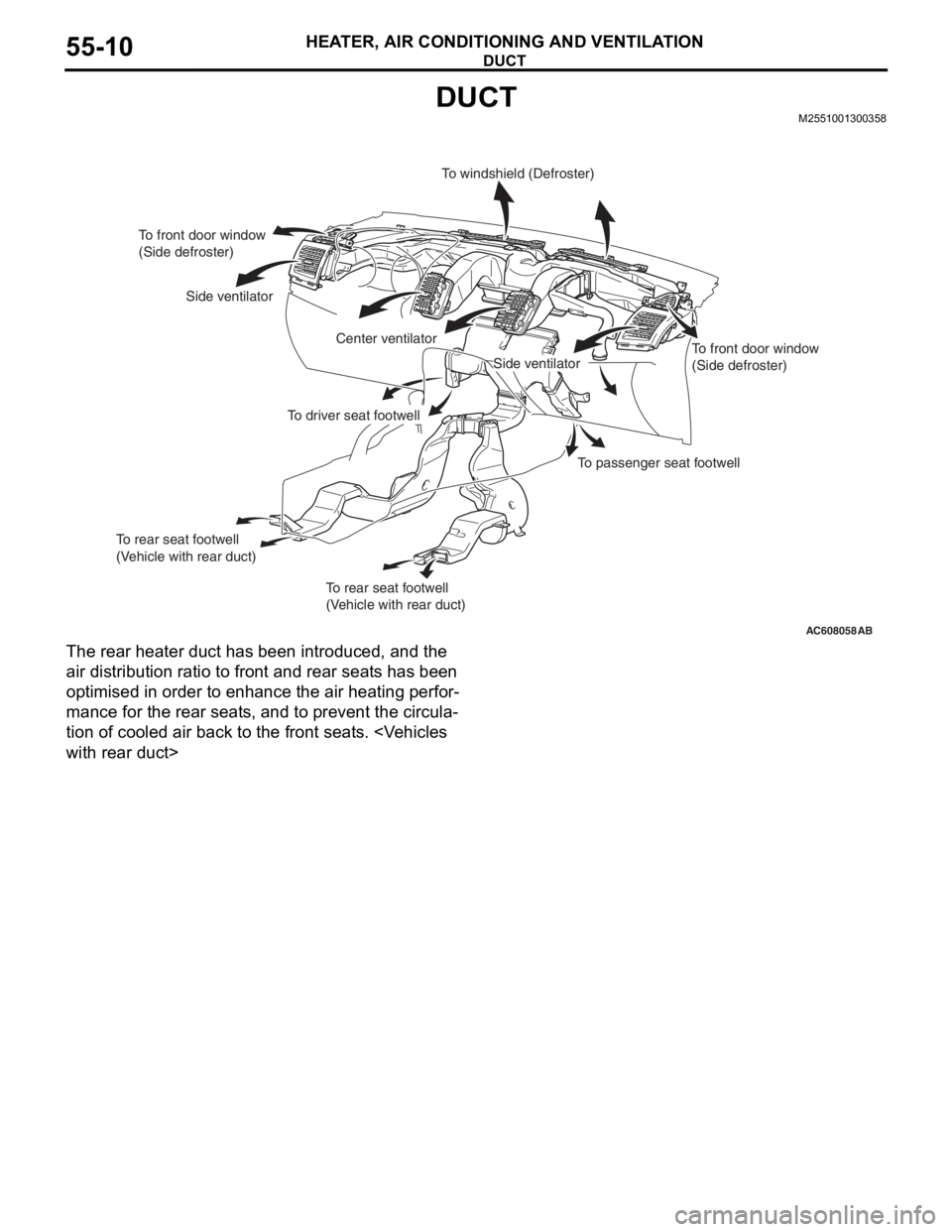

DUCTM2551001300358

The rear heater duct has been introduced, and the

air distribution ratio to front and rear seats has been

optimised in order to enhance the air heating perfor

-

mance for the rear seats, and to prevent the circula-

tion of cooled air back to the front seats.

with rear duct>

AC608058

To front door window

(Side defroster)

Side ventilator

Center ventilatorTo windshield (Defroster)

To front door window

(Side defroster)

To passenger seat footwell

To driver seat footwell

To rear seat footwell

(Vehicle with rear duct)

To rear seat footwell

(Vehicle with rear duct)

Side ventilator

AB

Page 43 of 241

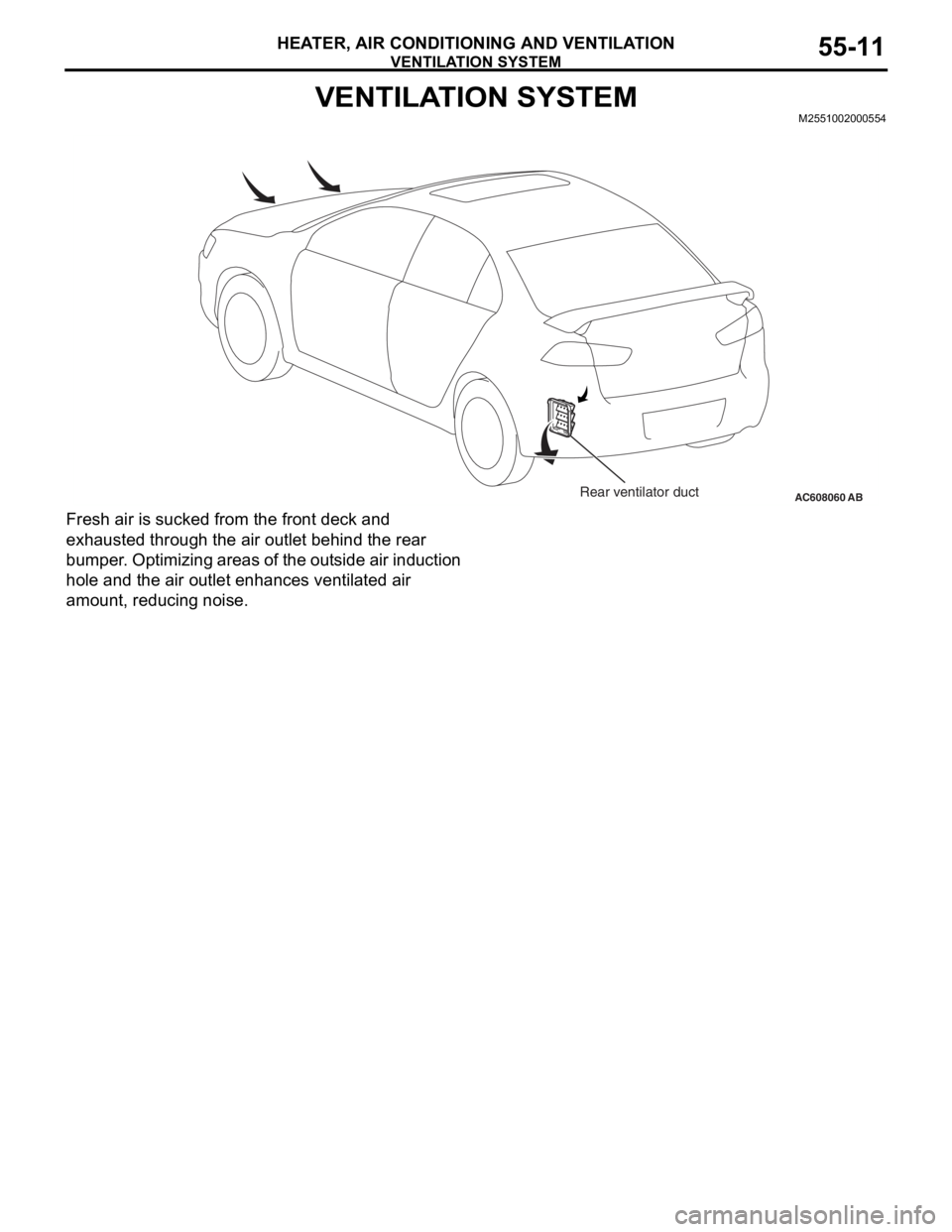

VENTILATION SYSTEM

HEATER, AIR CONDITIONING AND VENTILATION55-11

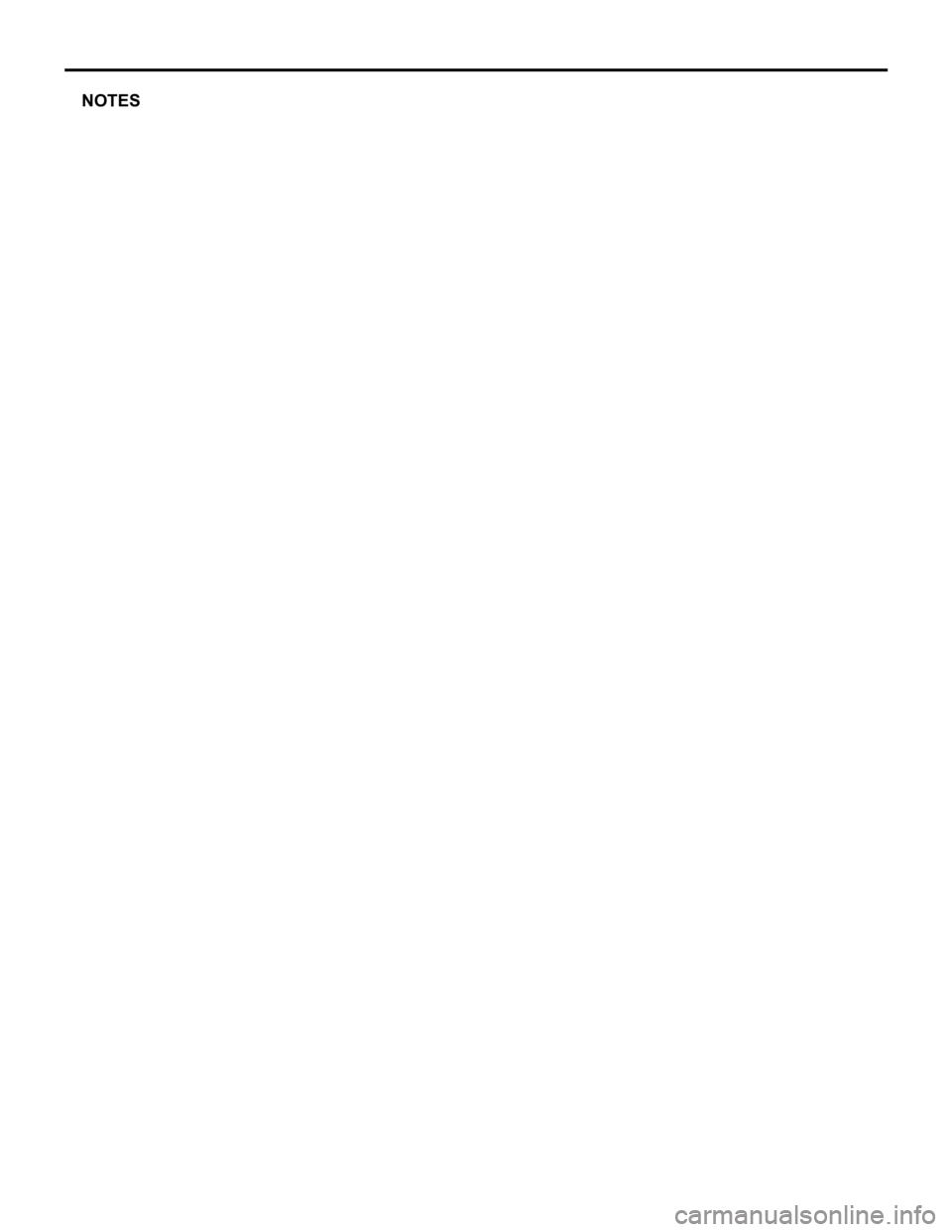

VENTILATION SYSTEMM2551002000554

Fresh air is sucked from the front deck and

exhausted through the air outlet behind the rear

bumper. Optimizing areas of the outside air induction

hole and the air outlet enhances ventilated air

amount, reducing noise.

AC608060Rear ventilator ductAB

Page 44 of 241

Page 45 of 241

11A-1

GROUP 11A

ENGINE

MECHANICAL

CONTENTS

GENERAL DESCRIPTION. . . . . . . . .11A-2BASE ENGINE . . . . . . . . . . . . . . . . . .11A-3

Page 46 of 241

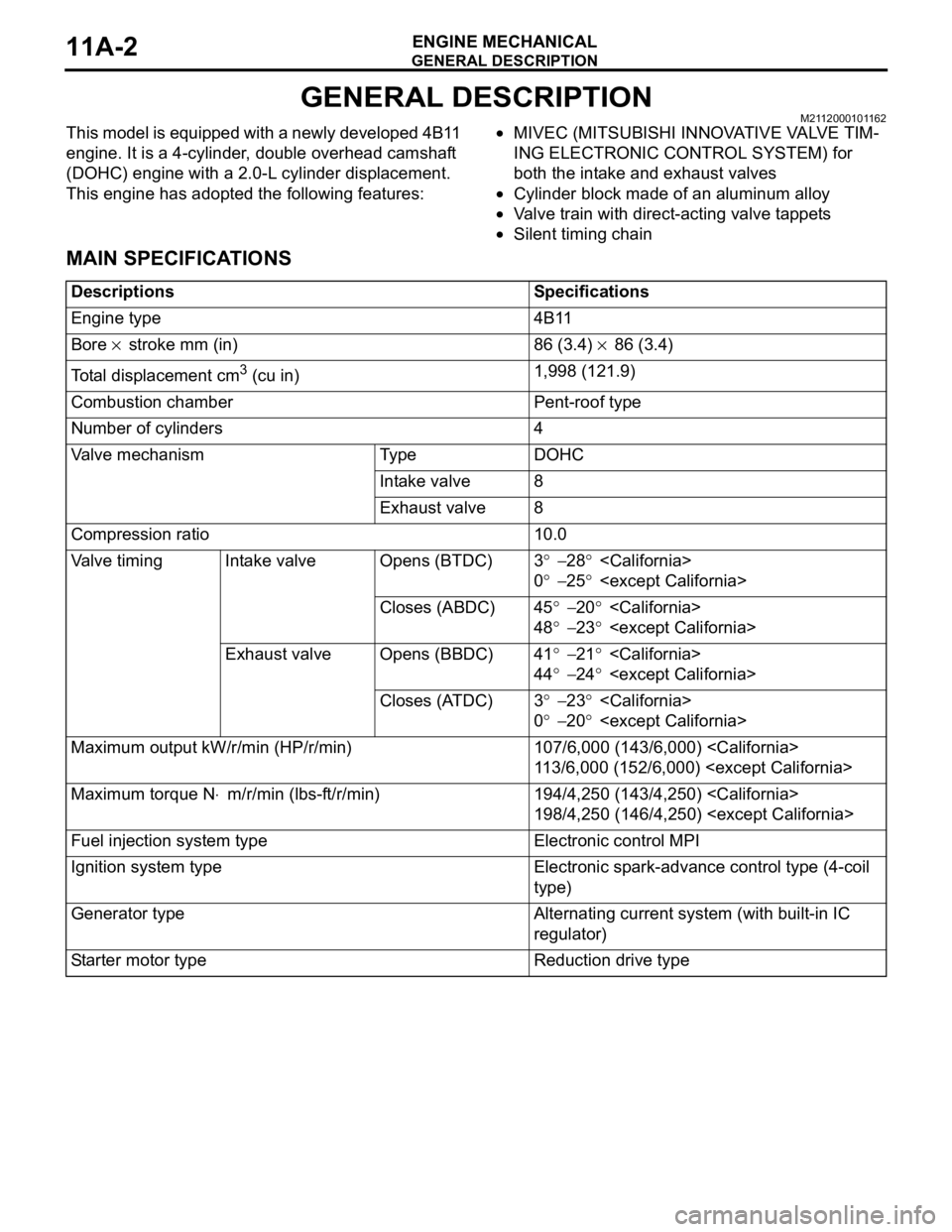

GENERAL DESCRIPTION

ENGINE MECHANICAL11A-2

GENERAL DESCRIPTIONM2112000101162

This model is equipped with a newly developed 4B11

engine. It is a 4-cylinder, double overhead camshaft

(DOHC) engine with a 2.0-L cylinder displacement.

This engine has adopted the following features:

•MIVEC (MITSUBISHI INNOVATIVE VALVE TIM-

ING ELECTRONIC CONTROL SYSTEM) for

both the intake and exhaust valves

•Cylinder block made of an aluminum alloy

•Valve train with direct-acting valve tappets

•Silent timing chain

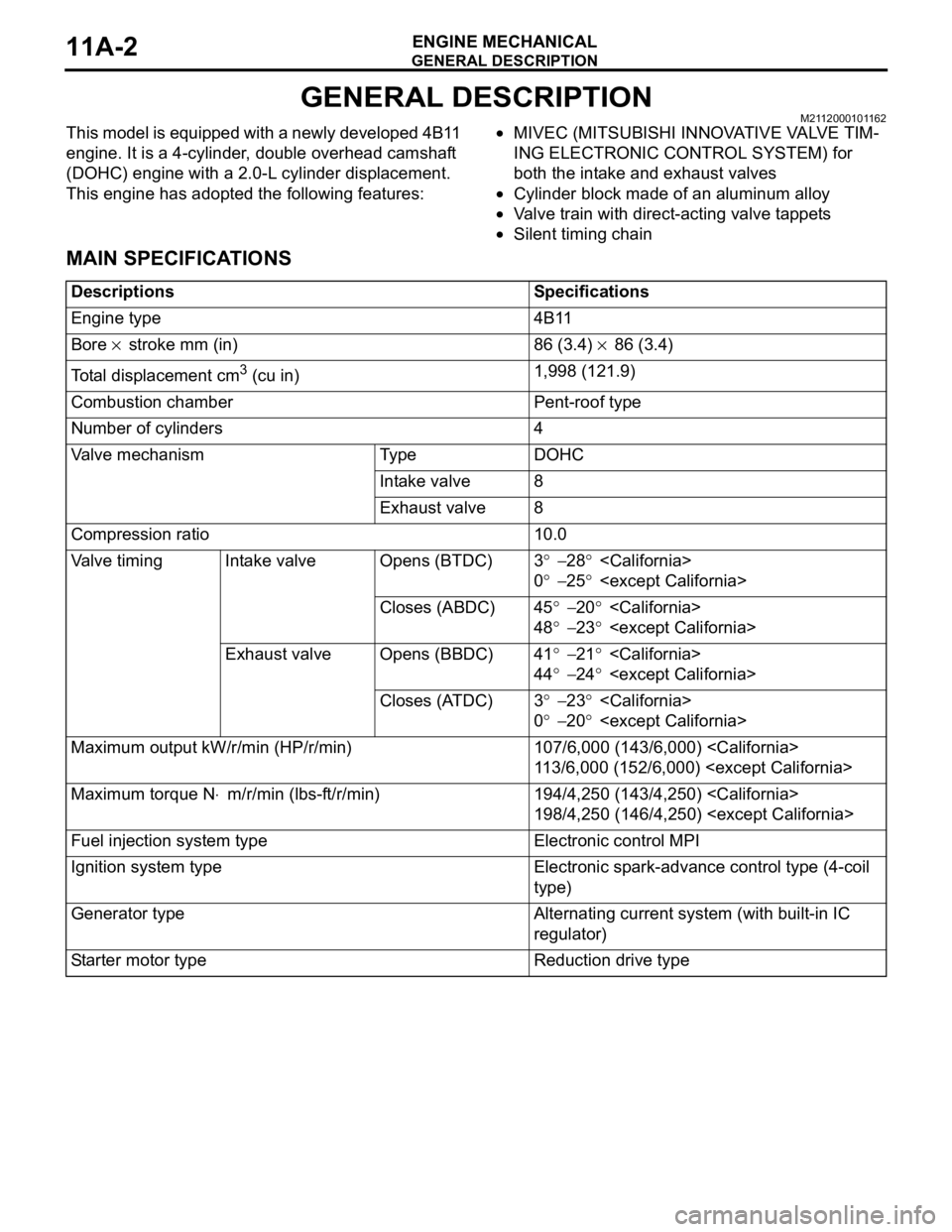

MAIN SPECIFICATIONS

DescriptionsSpecifications

Engine type4B11

Bore × stroke mm (in)86 (3.4) × 86 (3.4)

Total displacement cm3 (cu in)1,998 (121.9)

Combustion chamberPent-roof type

Number of cylinders4

Valve mechanismTy p eDOHC

Intake valve8

Exhaust valve8

Compression ratio10.0

Va l v e t i m i n gIntake valveOpens (BTDC)3° − 28°

0° − 25°

Closes (ABDC)45° − 20°

48° − 23°

Exhaust valveOpens (BBDC)41° − 21°

44° − 24°

Closes (ATDC)3° − 23°

0° − 20°

Maximum output kW/r/min (HP/r/min)107/6,000 (143/6,000)

113/6,000 (152/6,000)

Maximum torque N⋅m/r/min (lbs-ft/r/min)194/4,250 (143/4,250)

198/4,250 (146/4,250)

Fuel injection system typeElectronic control MPI

Ignition system typeElectronic spark-advance control type (4-coil

type)

Generator typeAlternating current system (with built-in IC

regulator)

Starter motor typeReduction drive type

Page 47 of 241

BASE ENGINE

ENGINE MECHANICAL11A-3

BASE ENGINEM2112001001050

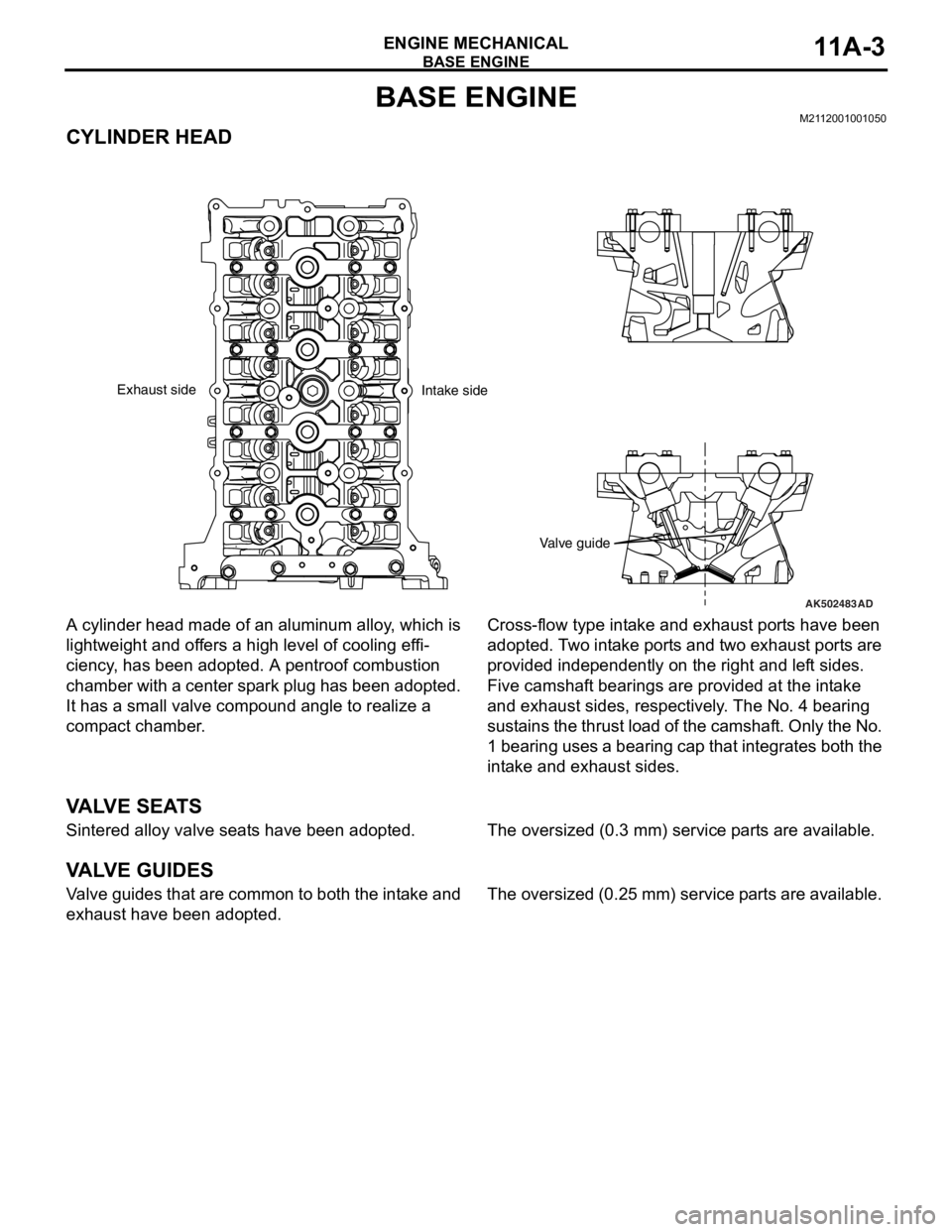

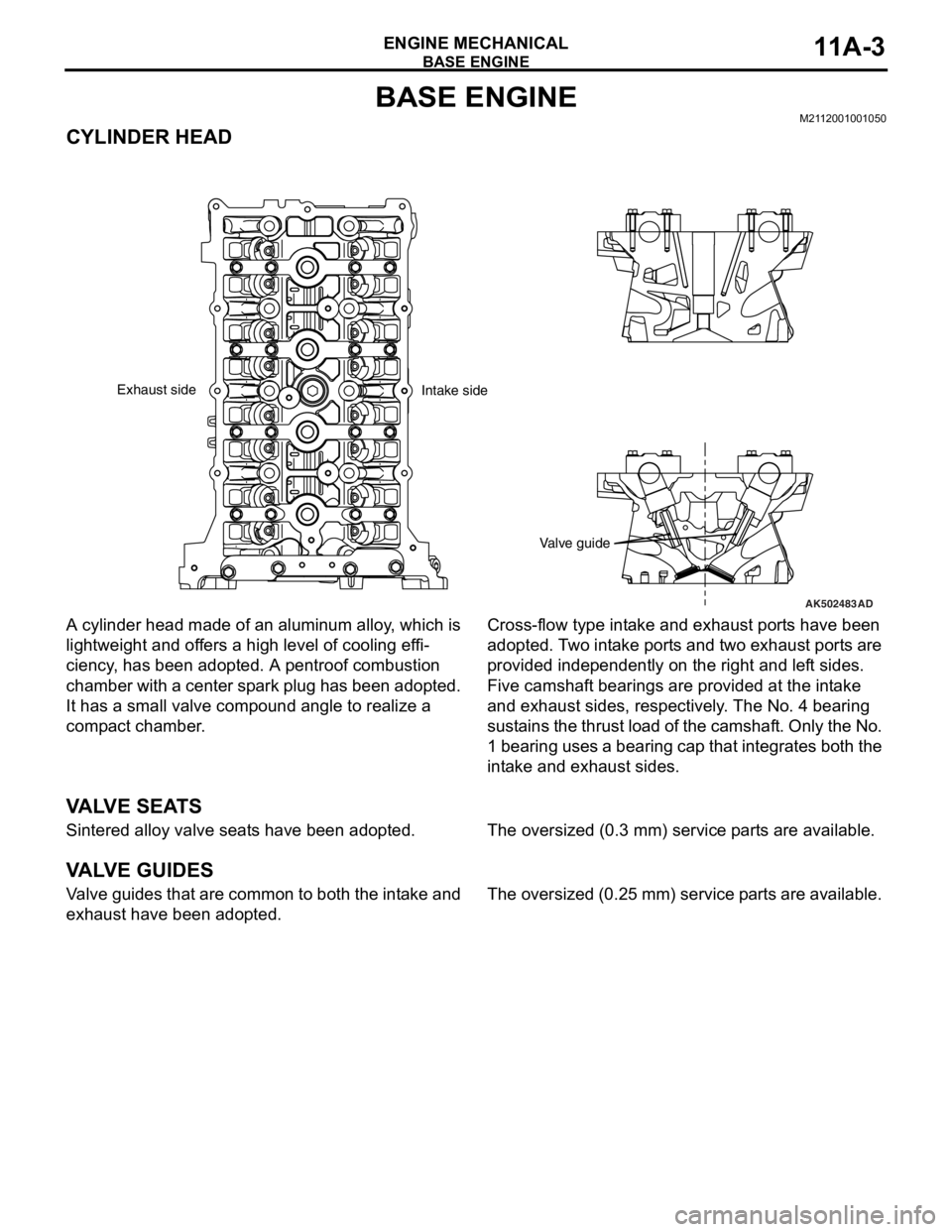

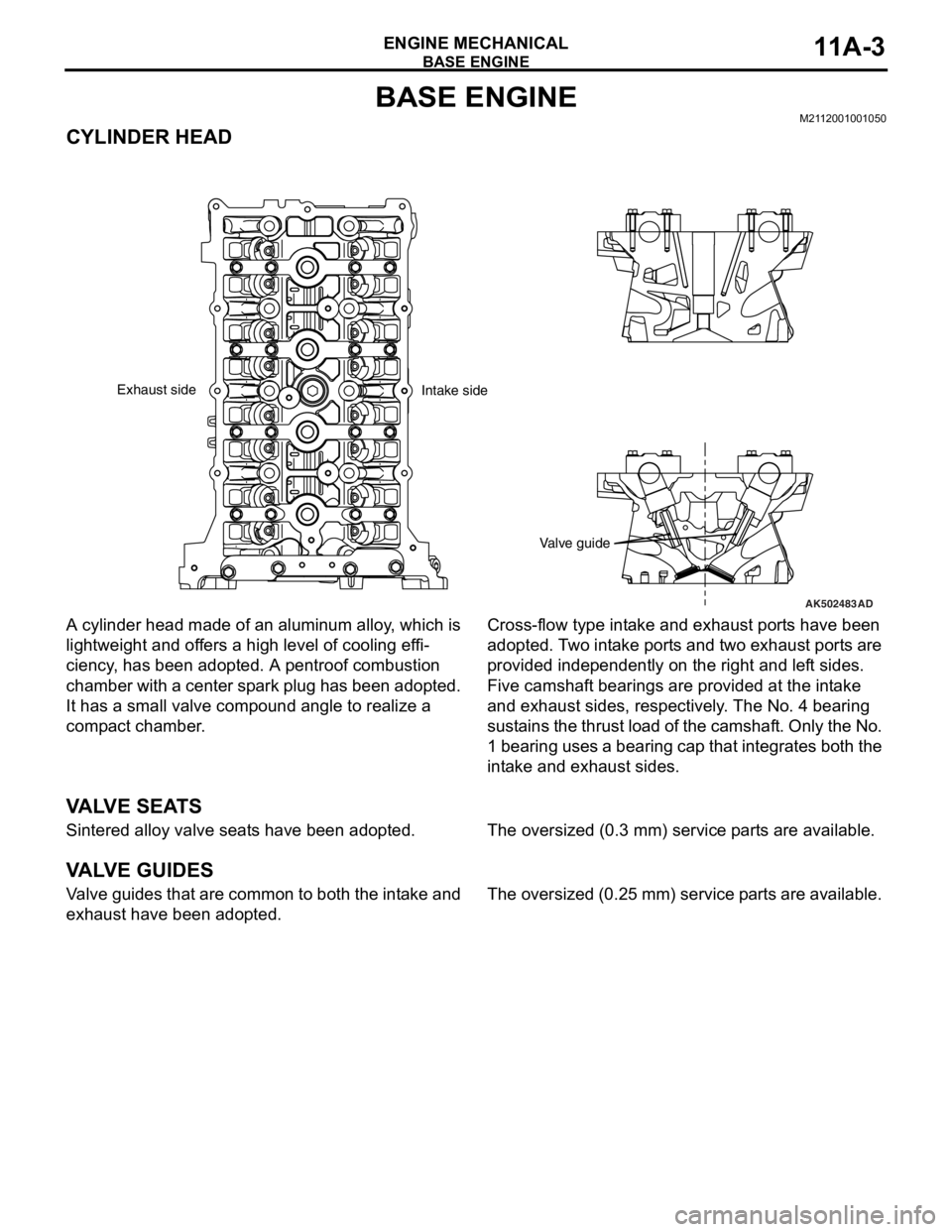

CYLINDER HEAD

A cylinder head made of an aluminum alloy, which is

lightweight and offers a high level of cooling effi

-

ciency, has been adopted. A pentroof combustion

chamber with a center spark plug has been adopted.

It has a small valve compound angle to realize a

compact chamber.

Cross-flow type intake and exhaust ports have been

adopted. Two intake ports and two exhaust ports are

provided independently on the right and left sides.

Five camshaft bearings are provided at the intake

and exhaust sides, respectively. The No. 4 bearing

sustains the thrust load of the camshaft. Only the No.

1 bearing uses a bearing cap that integrates both the

intake and exhaust sides.

VA LV E S E AT S

Sintered alloy valve seats have been adopted.The oversized (0.3 mm) service parts are available.

VA LV E G U I D E S

Valve guides that are common to both the intake and

exhaust have been adopted.The oversized (0.25 mm) service parts are available.

AK502483

Valve guide

AD

Exhaust side

Intake side

Page 48 of 241

BASE ENGINE

ENGINE MECHANICAL11A-4

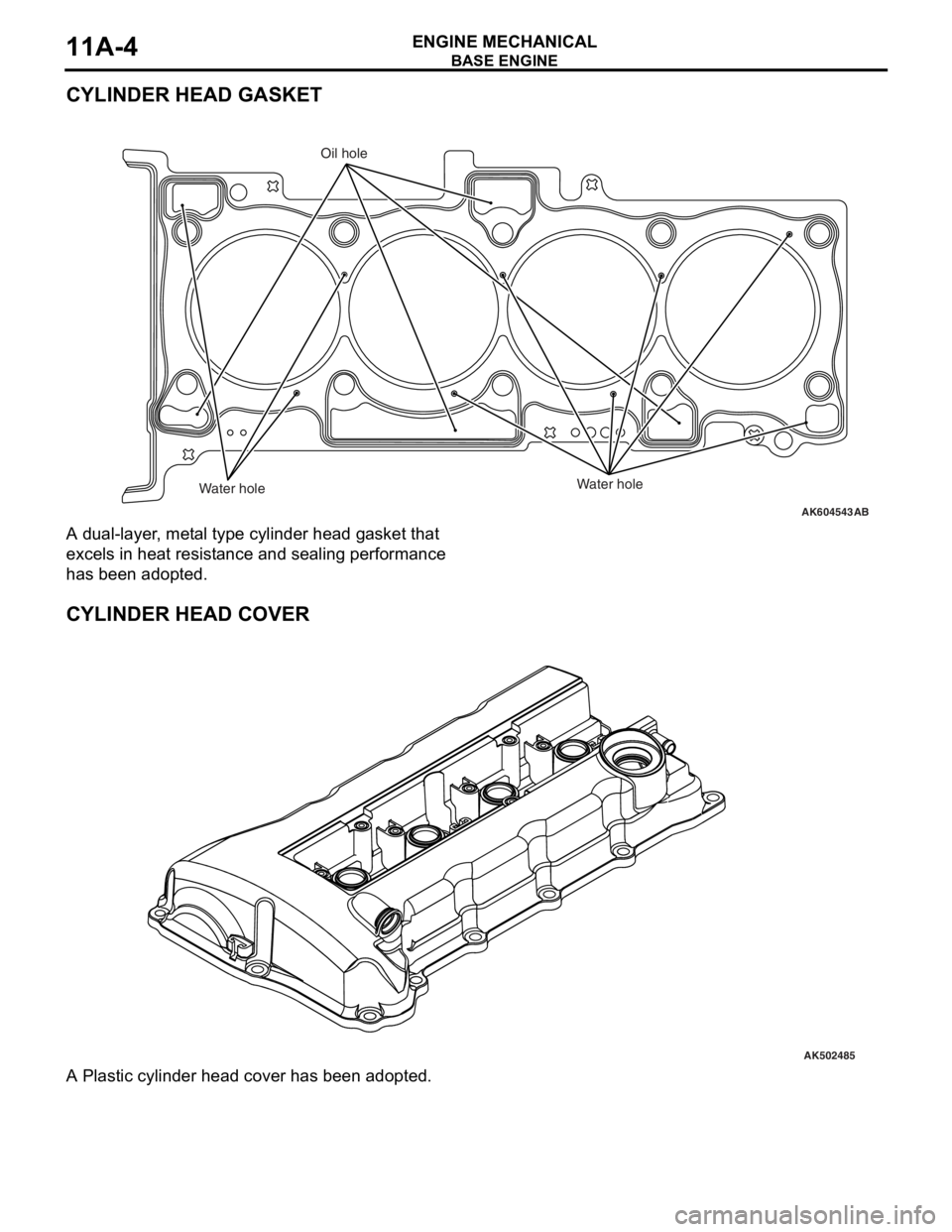

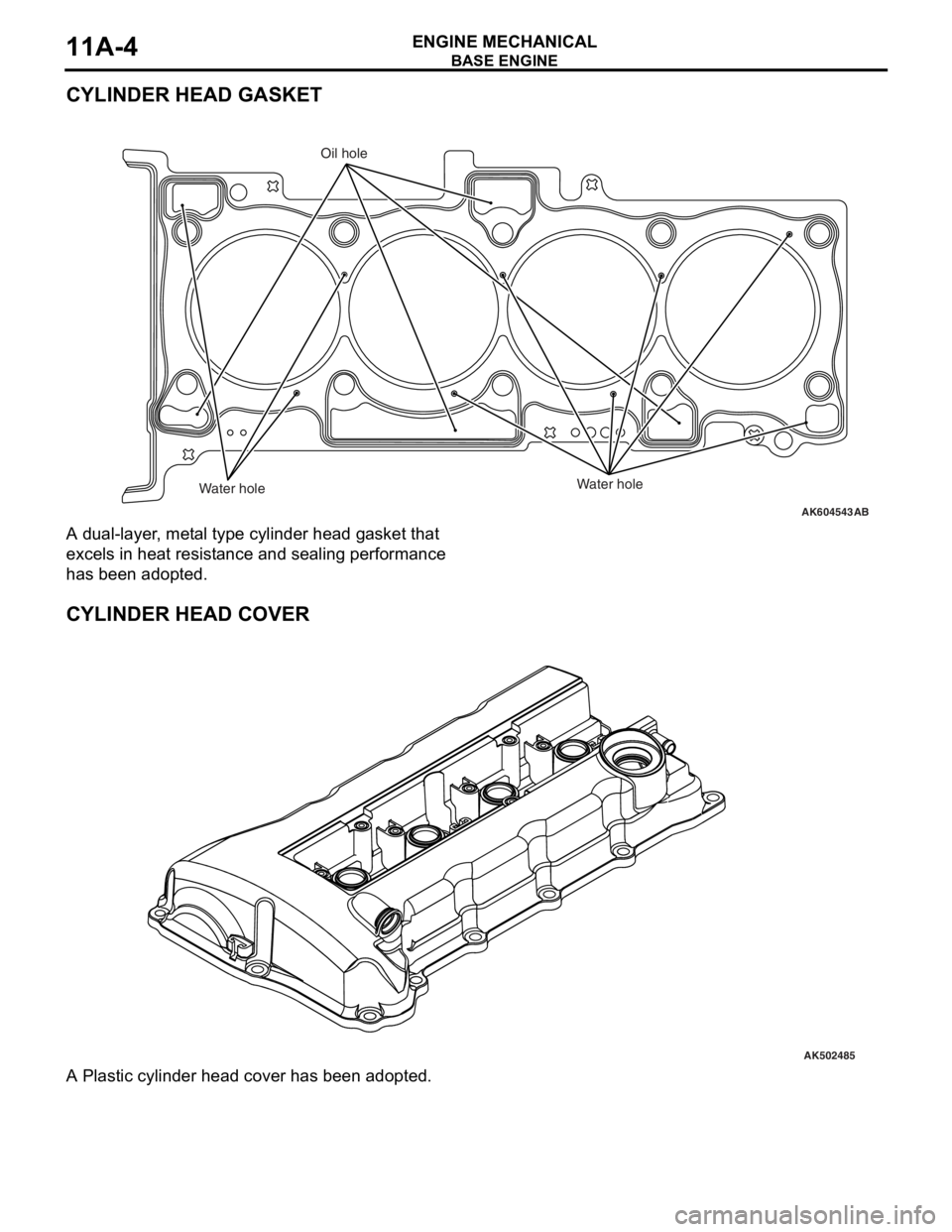

CYLINDER HEAD GASKET

A dual-layer, metal type cylinder head gasket that

excels in heat resistance and sealing performance

has been adopted.

CYLINDER HEAD COVER

A Plastic cylinder head cover has been adopted.

AK604543

Oil hole

Water hole

Water hole

AB

AK502485

Page 49 of 241

BASE ENGINE

ENGINE MECHANICAL11A-5

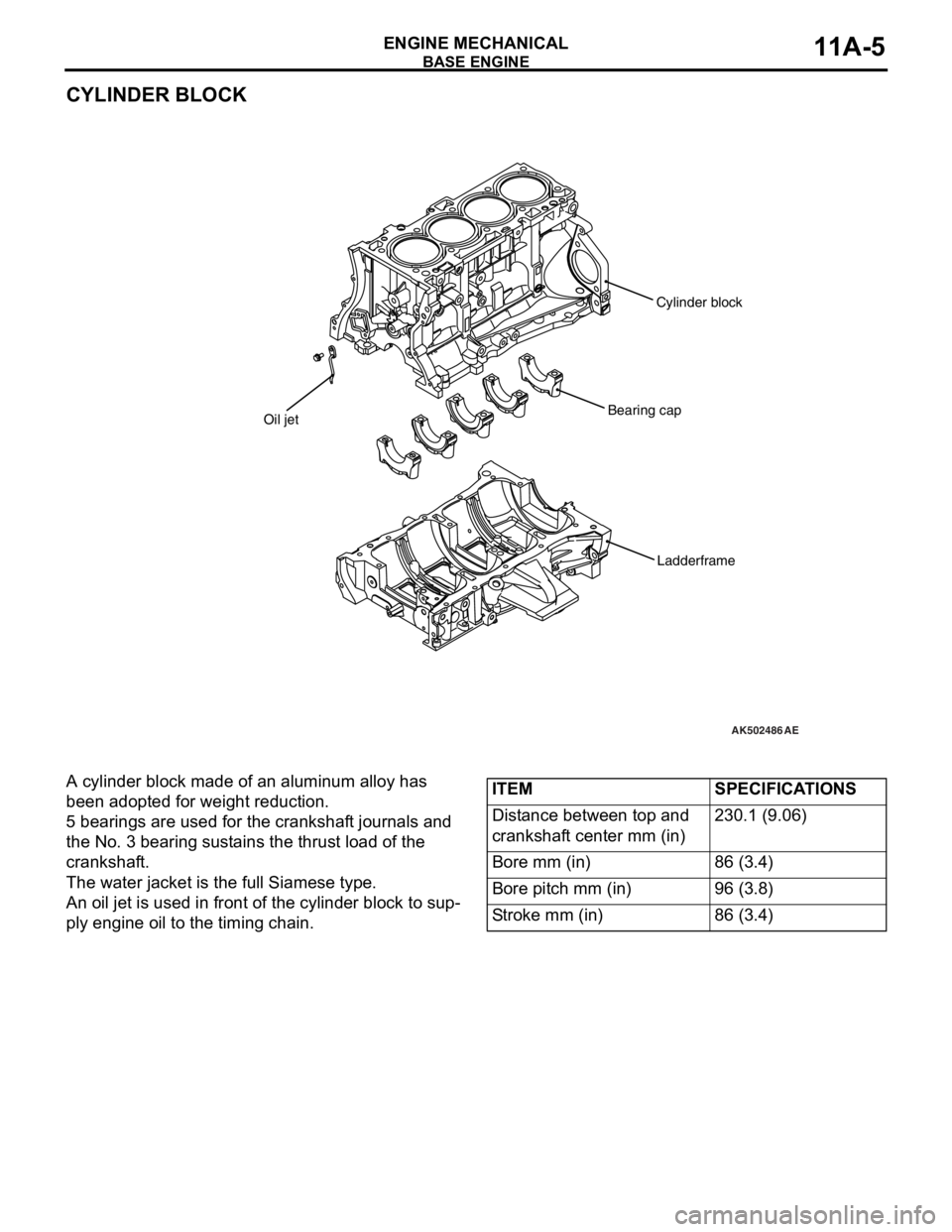

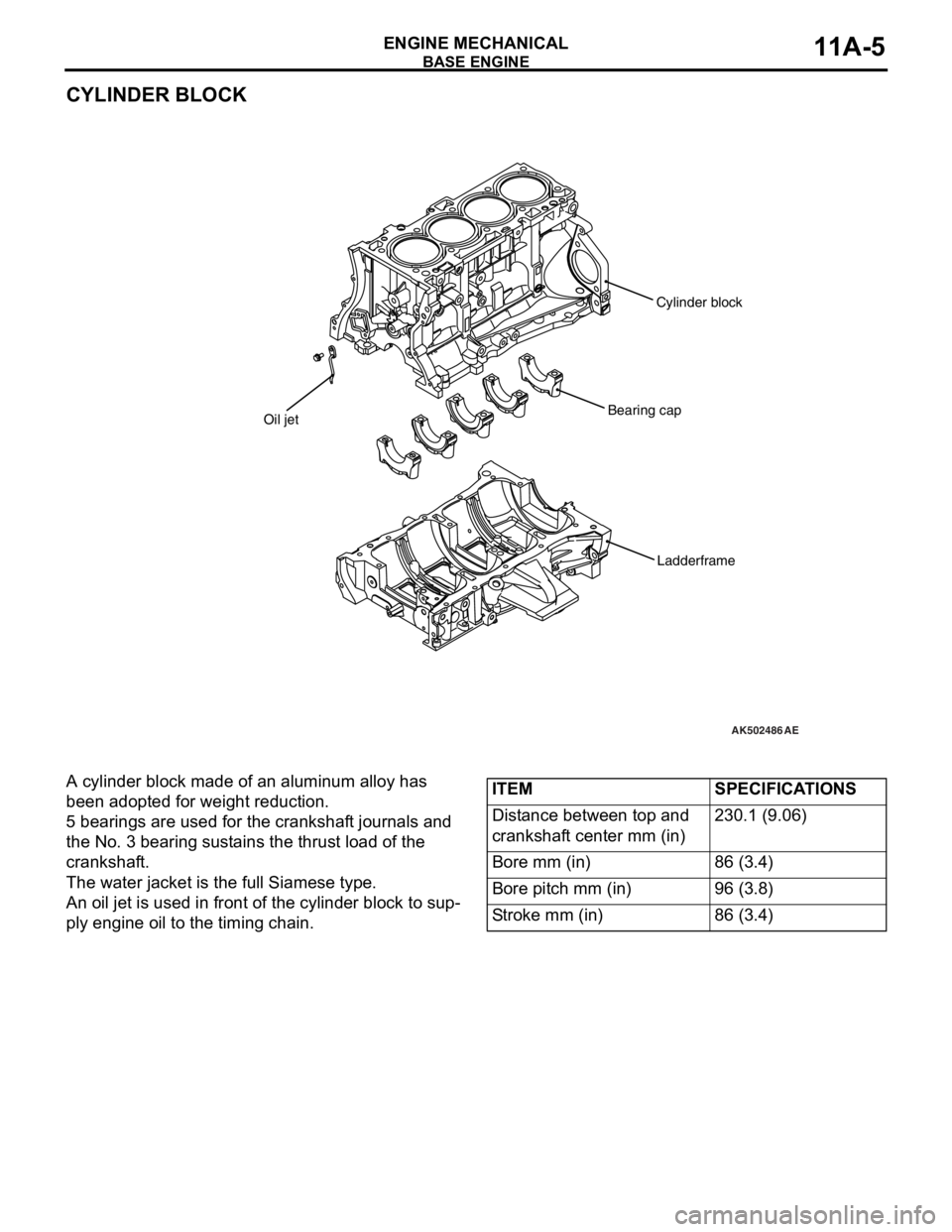

CYLINDER BLOCK

A cylinder block made of an aluminum alloy has

been adopted for weight reduction.

5 bearings are used for the crankshaft journals and

the No. 3 bearing sustains the thrust load of the

crankshaft.

The water jacket is the full Siamese type.

An oil jet is used in front of the cylinder block to sup-

ply engine oil to the timing chain.

AK502486

Oil jetCylinder blockBearing cap

AE

Ladderframe

ITEMSPECIFICATIONS

Distance between top and

crankshaft center mm (in)230.1 (9.06)

Bore mm (in)86 (3.4)

Bore pitch mm (in)96 (3.8)

Stroke mm (in)86 (3.4)

Page 50 of 241

BASE ENGINE

ENGINE MECHANICAL11A-6

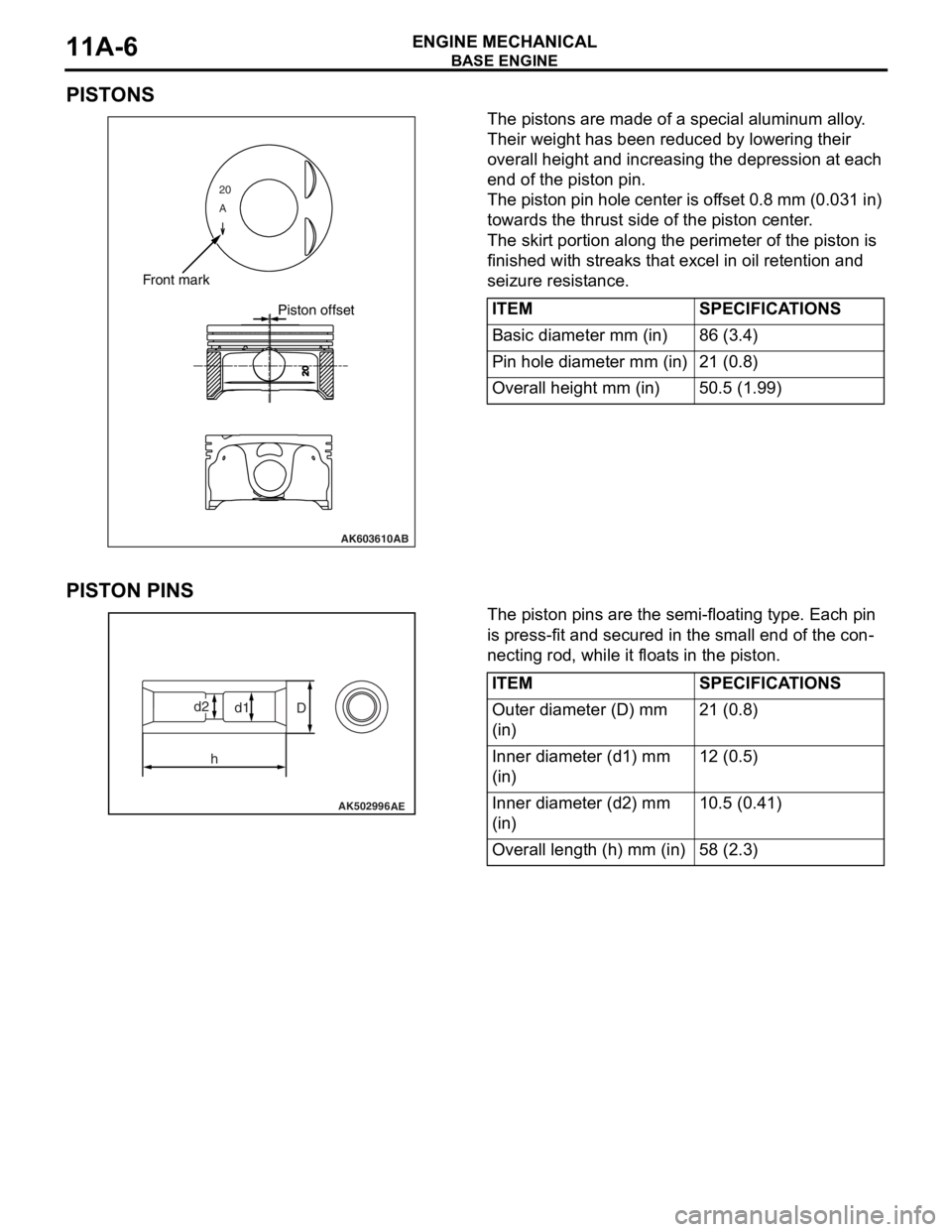

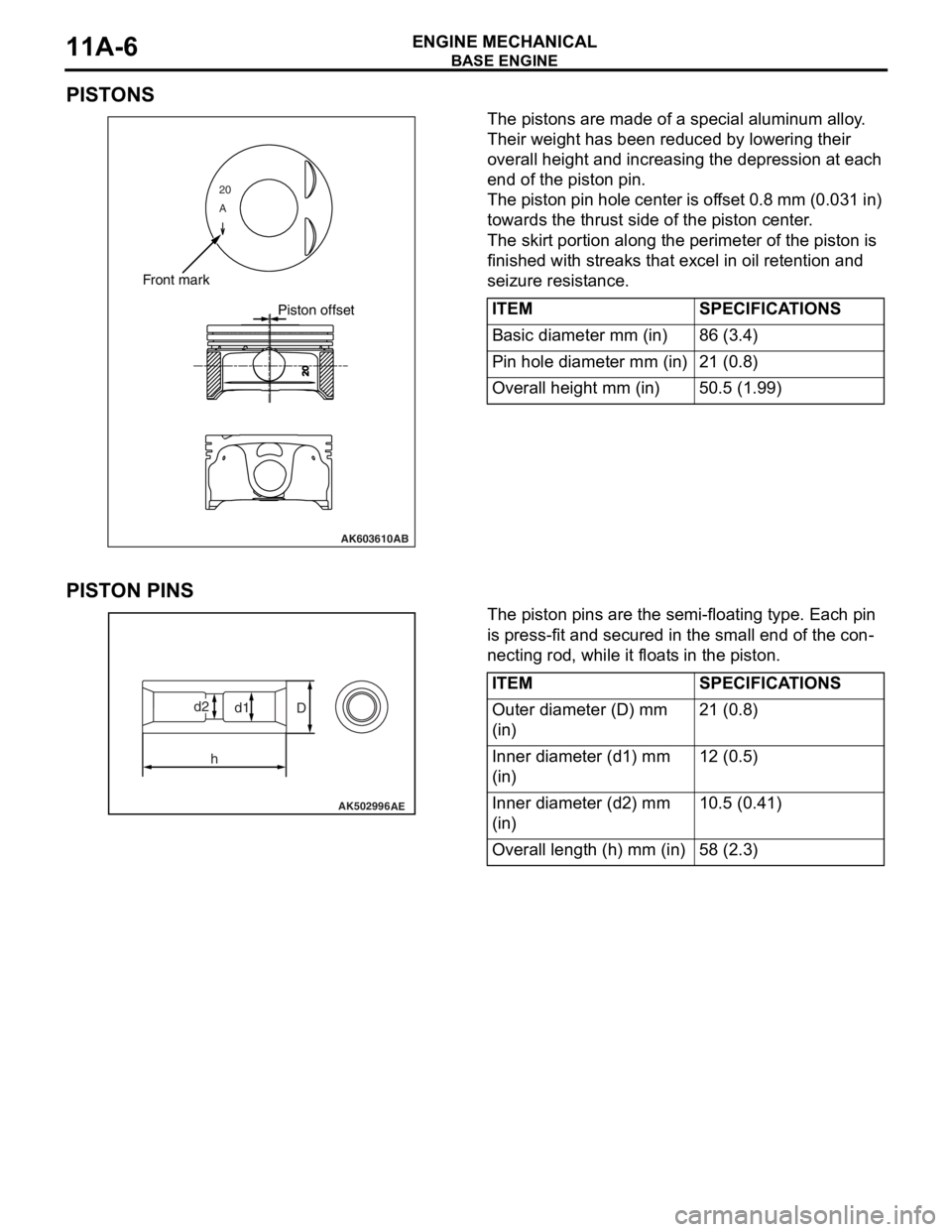

PISTONS

The pistons are made of a special aluminum alloy.

Their weight has been reduced by lowering their

overall height and increasing the depression at each

end of the piston pin.

The piston pin hole center is offset 0.8 mm (0.031 in)

towards the thrust side of the piston center.

The skirt portion along the perimeter of the piston is

finished with streaks that excel in oil retention and

seizure resistance.

PISTON PINS

The piston pins are the semi-floating type. Each pin

is press-fit and secured in the small end of the con

-

necting rod, while it floats in the piston.

20

A

AK603610

Front mark

Piston offset

AB

ITEMSPECIFICATIONS

Basic diameter mm (in)86 (3.4)

Pin hole diameter mm (in)21 (0.8)

Overall height mm (in)50.5 (1.99)

AK502996AE

D

hd1d2

ITEMSPECIFICATIONS

Outer diameter (D) mm

(in)21 (0.8)

Inner diameter (d1) mm

(in)12 (0.5)

Inner diameter (d2) mm

(in)10.5 (0.41)

Overall length (h) mm (in)58 (2.3)

Trending: fuel cap, break, ECU, alternator, radio, steering, radio antenna