MITSUBISHI MONTERO 2000 Service User Guide

Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 11 of 1839

GENERAL -How to Use Troubleshooting/Inspection Service Points00-10

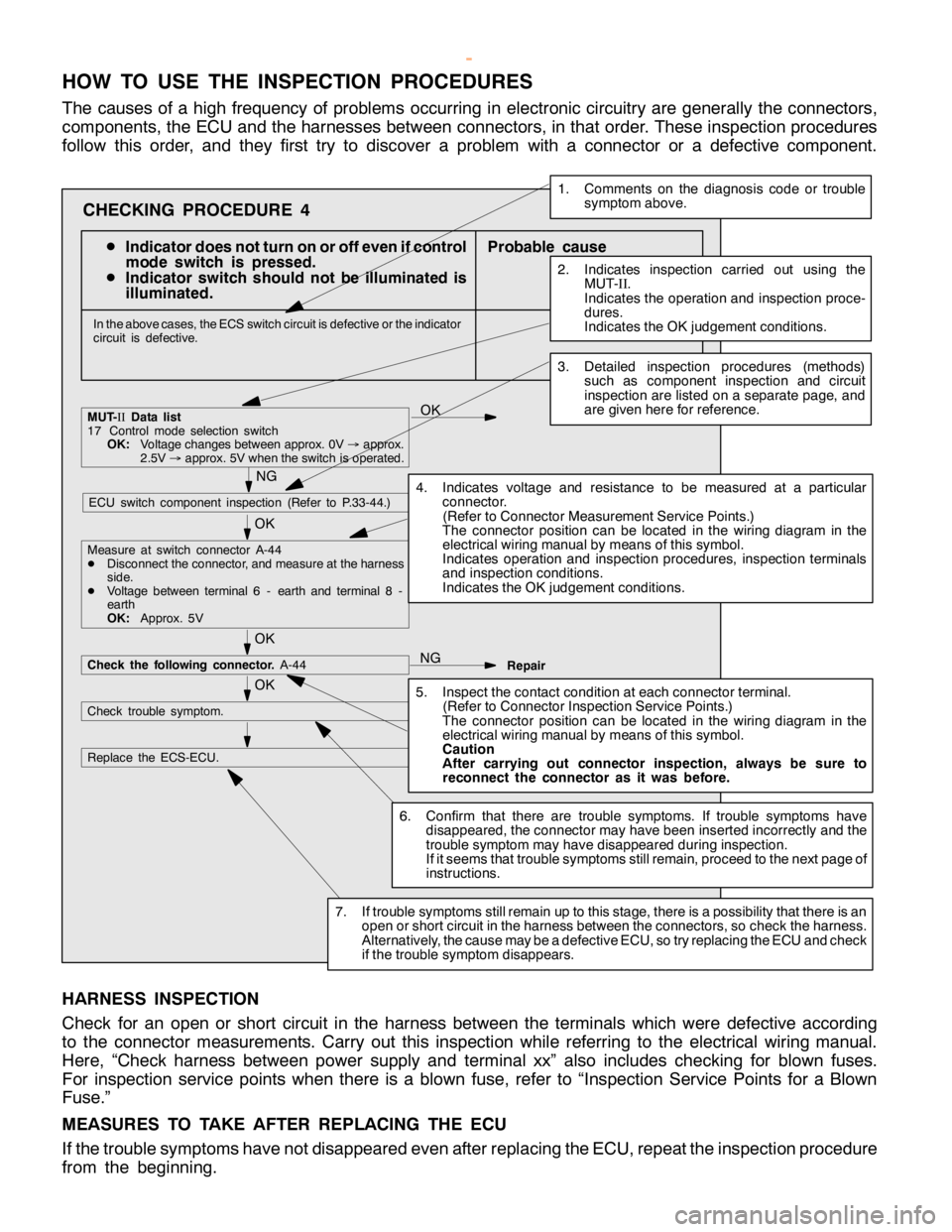

HOW TO USE THE INSPECTION PROCEDURES

The causes of a high frequency of problems occurring in electronic circuitry are generally the connectors,

components, the ECU and the harnesses between connectors, in that order. These inspection procedures

follow this order, and they first try to discover a problem with a connector or a defective component.

D

Indicator does not turn on or off even if control

mode switch is pressed.

D

Indicator switch should not be illuminated is

illuminated.Probable cause

OK

OK

OK

Measure at switch connector A-44

DDisconnect the connector, and measure at the harness

side.

DVoltage between terminal 6 - earth and terminal 8 -

earth

OK:Approx. 5V

OK

NG

Check the following connector.A-44

Repair

OK

Check trouble symptom.

Replace the ECS-ECU.

In the above cases, the ECS switch circuit is defective or the indicator

circuit is defective.

CHECKING PROCEDURE 4

2. Indicates inspection carried out using the

MUT-

II.

Indicates the operation and inspection proce-

dures.

Indicates the OK judgement conditions.

3. Detailed inspection procedures (methods)

such as component inspection andcircuit

inspection are listed on a separate page, and

are given here for reference.

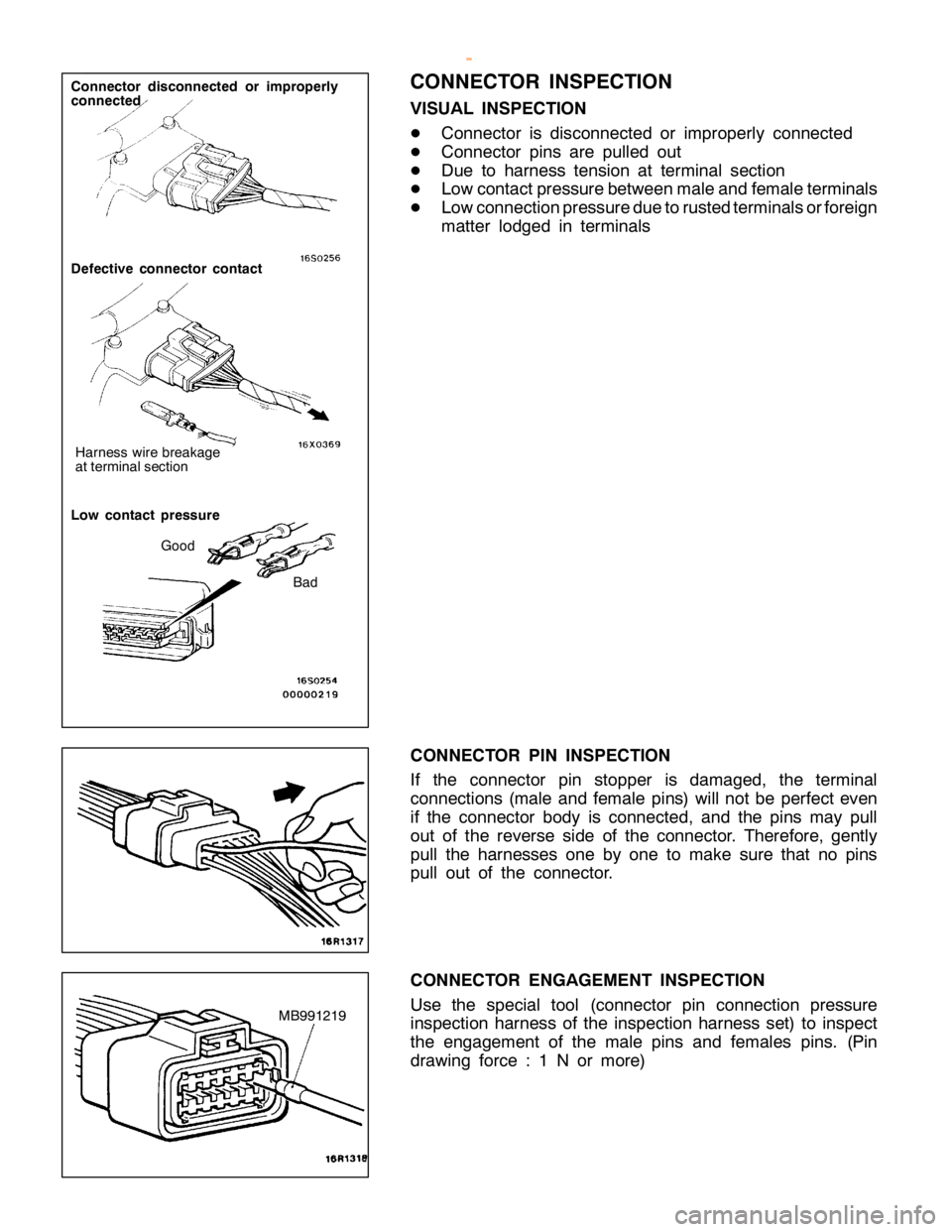

5. Inspect the contact condition at each connectorterminal.

(Refer to Connector Inspection Service Points.)

The connector position can be located in the wiring diagram in the

electrical wiring manual bymeans ofthis symbol.

Caution

After carrying out connector inspection, always be sure to

reconnect the connector as it was before.

6. Confirm that there are trouble symptoms. If trouble symptomshave

disappeared, the connector may have been inserted incorrectly and the

trouble symptom mayhave disappeared during inspection.

If it seemsthat trouble symptoms still remain, proceed to the nextpage of

instructions.

7. If trouble symptoms still remain up to this stage, there is a possibility that there is an

open orshort circuit in the harness between the connectors, socheck the harness.

Alternatively, the cause may be a defectiveECU, so try replacing the ECU andcheck

if the trouble symptom disappears.

NGECU switch component inspection (Refer to P.33-44.)

NG

1. Comments on the diagnosis code ortrouble

symptom above.

MUT-II

Data list

17 Control mode selectionswitch

OK:Voltage changes between approx. 0V

®approx.

2.5V

®approx. 5V when the switch is operated.

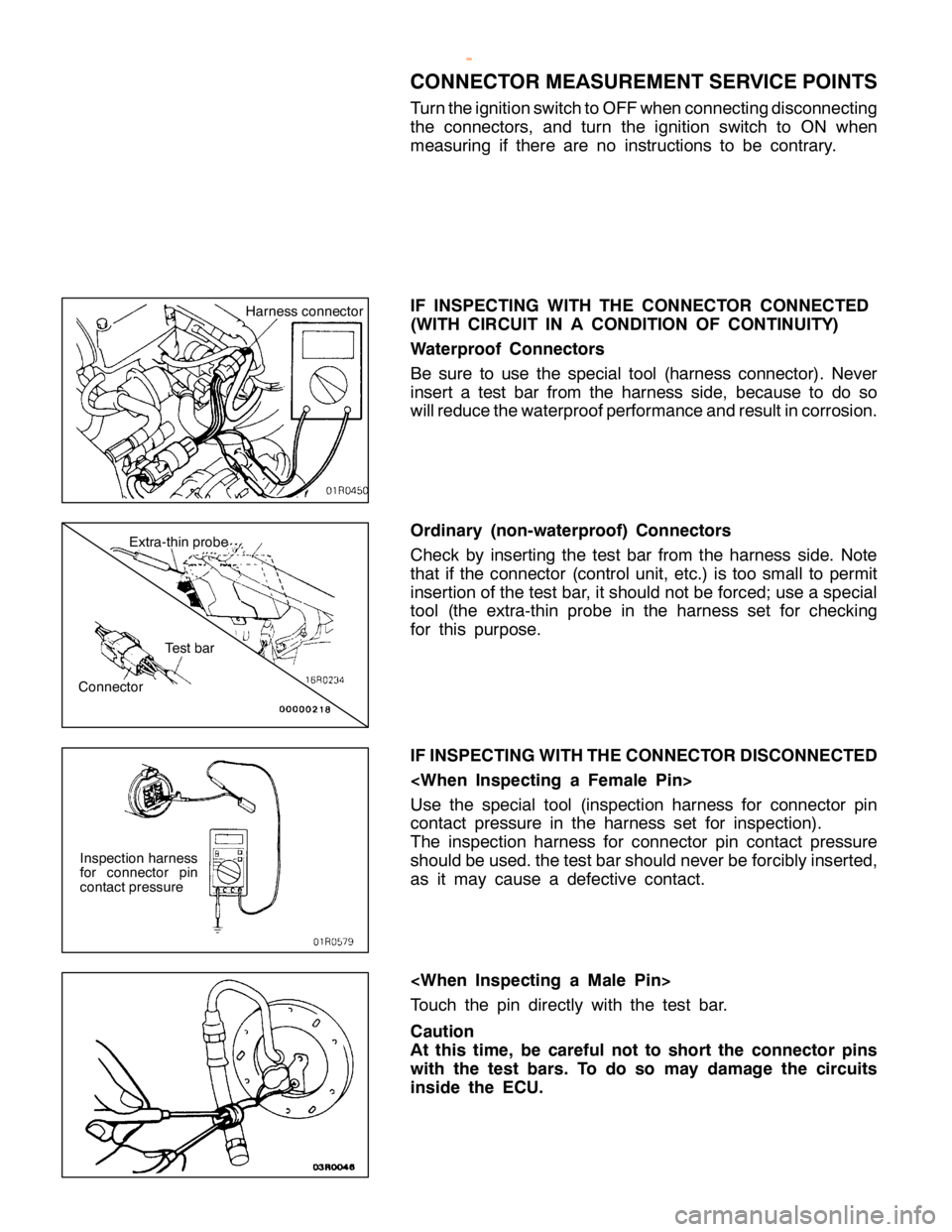

4. Indicates voltage and resistance to be measured at a particular

connector.

(Refer to Connector Measurement Service Points.)

The connector position can be located in the wiring diagram in the

electrical wiring manual bymeans ofthis symbol.

Indicates operation and inspection procedures, inspection terminals

and inspection conditions.

Indicates the OK judgement conditions.

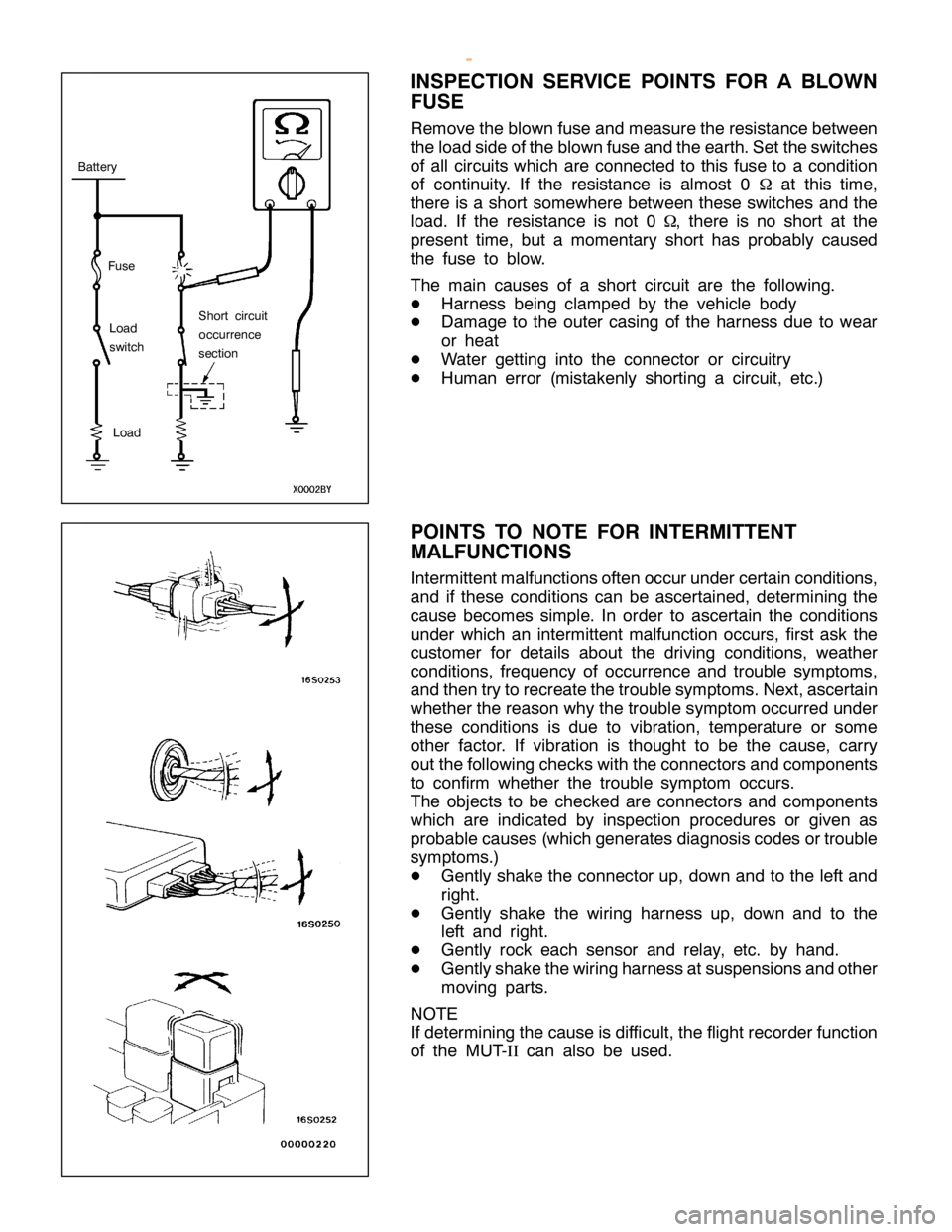

HARNESS INSPECTION

Check for an open or short circuit in the harness between the terminals which were defective according

to the connector measurements. Carry out this inspection while referring to the electrical wiring manual.

Here, “Check harness between power supply and terminal xx” also includes checking for blown fuses.

For inspection service points when there is a blown fuse, refer to “Inspection Service Points for a Blown

Fuse.”

MEASURES TO TAKE AFTER REPLACING THE ECU

If the trouble symptoms have not disappeared even after replacing the ECU, repeat the inspection procedure

from the beginning.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 12 of 1839

E

xtr a -th in pro be

T e st bar

C onnecto r I

n sp ectio n harn ess

f o r co nnecto r pin

c o nta ct p re ssu re

Page 13 of 1839

M

B991219

Page 14 of 1839

B

atte ry

L o ad

s w it c h L

o ad S

ho rt cir c u it

o ccu rre n ce

s e ctio n

Page 15 of 1839

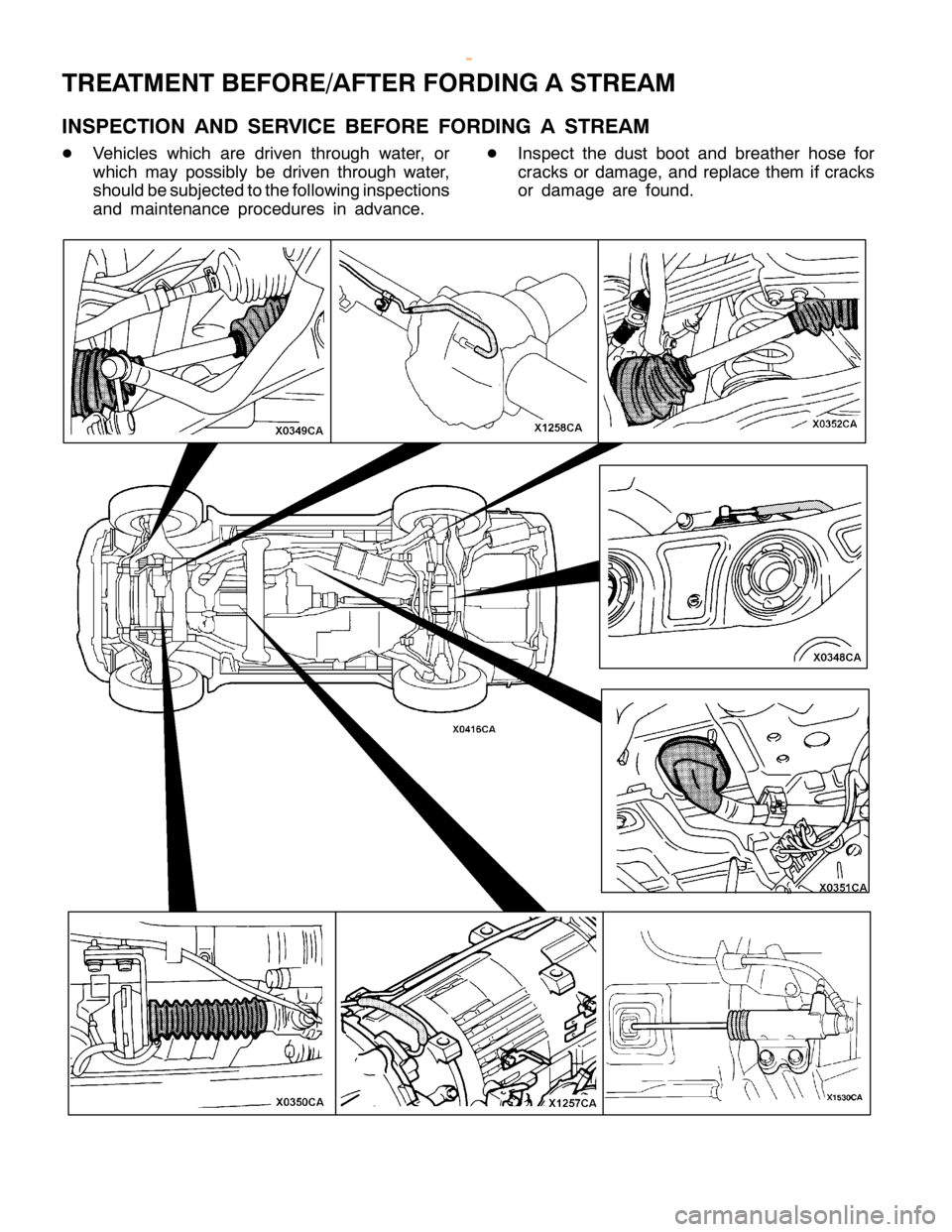

T

R EATM EN T BEFO RE/A FTE R FO RDIN G ASTR EA M

I N SPEC TIO N AND SER VIC E BEFO RE FO RDIN G ASTR EA M

D Vehic le s whic h are driv e n th ro ugh wate r, or

w hic h may possib ly be driv e n th ro ugh wate r,

s h ould be su bje cte d to th e fo llo w in g in sp ectio ns

a nd main te nance pro ce dure s in adva nce . D

In sp ect th e dust boot and bre ath er hose fo r

c ra cks or dam age, and re pla ce th em if cra cks

o r dam age are fo und.

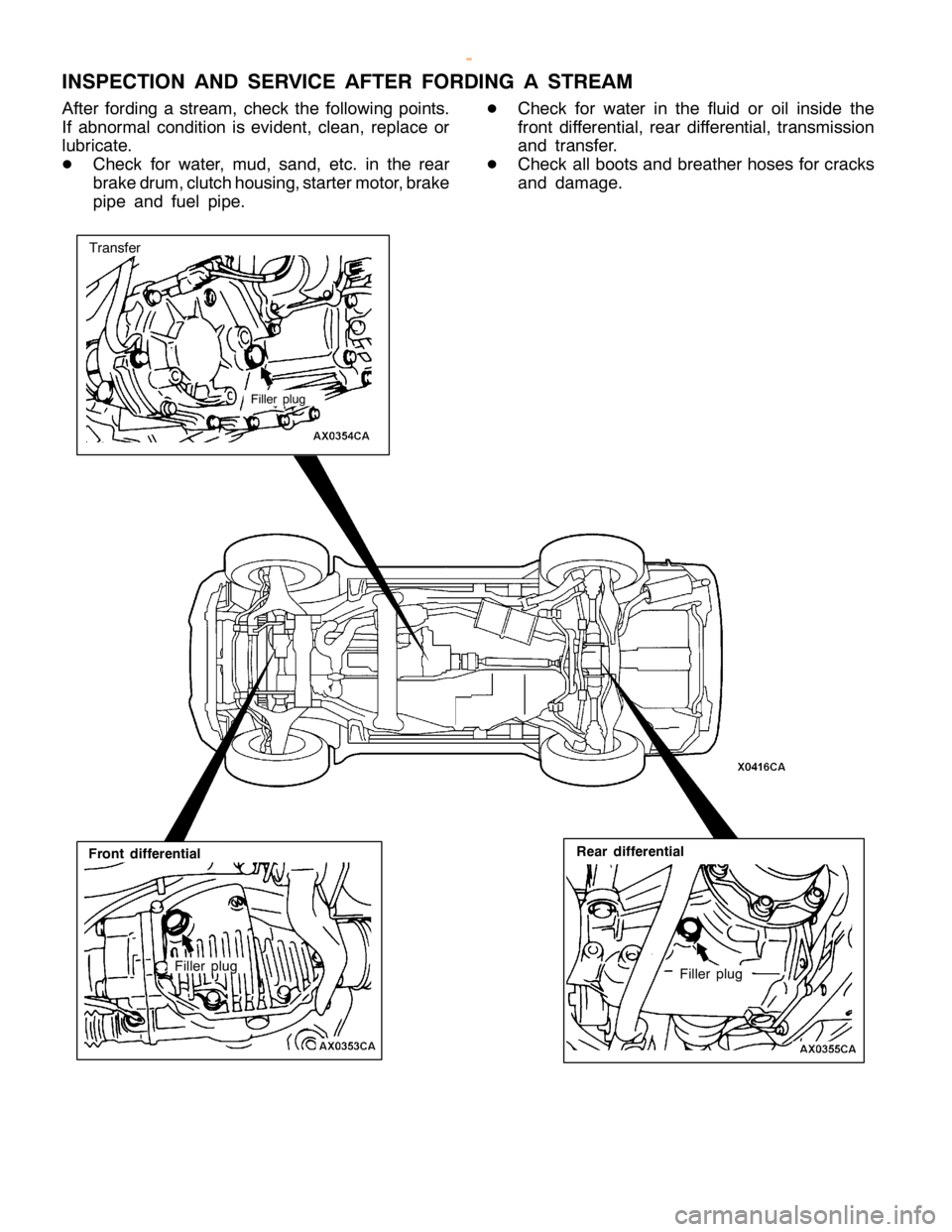

Page 16 of 1839

Page 17 of 1839

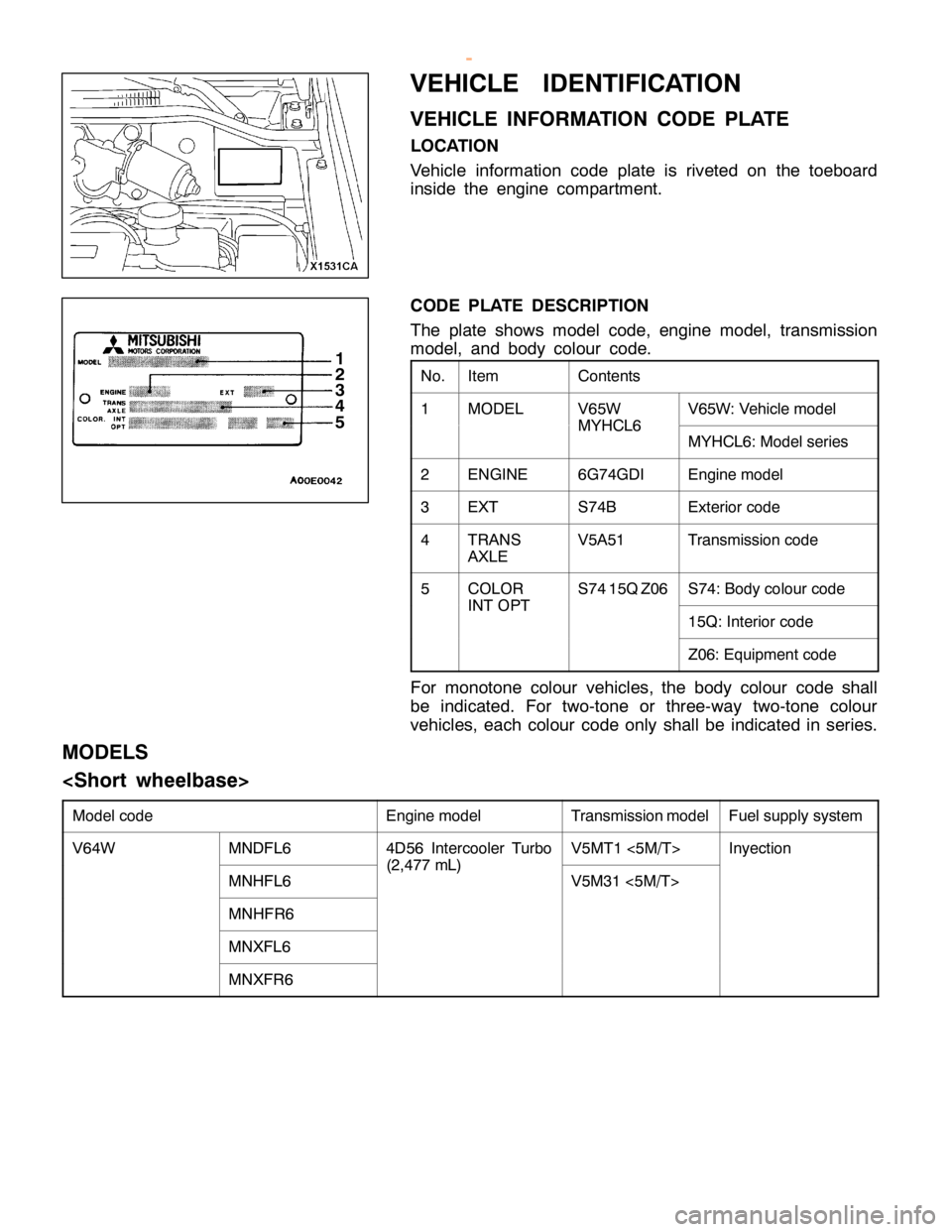

V

EH IC LE ID EN TIF IC ATIO N

V EH IC LE IN FO RM ATIO N CO DE PLA TE

L O CATIO N

V ehic le in fo rm atio n co de pla te is riv e te d on th e to eboard

i n sid e th e engin e co m partm ent.

C O DE PLA TE DESC RIP TIO N

T he pla te sh ow s model co de, engin e model, tr a nsm is sio n

m odel, and body co lo ur co de.

N o. I

te m C

onte nts 1 M

ODEL V

65W V

65W :V ehic le model M

YH CL6 M

YH CL6: M odelse rie s 2 E

N G IN E 6

G 74G DI E

ngin e model 3 E

XT S

74B E

xte rio r co de 4 T

R AN S

A XLE V

5A 51 T

ra nsm is sio n co de 5 C

O LO R S

74 15Q Z06 S

74: B ody co lo ur co de I

N T OPT 1

5Q :In te rio r co de Z

06: E quip m ent co de E

ngin e model T

ra nsm is sio n m odel F

uels u pply syste m V

64W M

NDFL6 4

D 56 In te rc o ole r Turb o V

5M T1 <5M /T > I

n ye ctio n M

NHFL6 (

2 ,4 77 mL) V

5M 31 <5M /T > M

NHFR 6 M

NXFL6 M

NXFR 6

Page 18 of 1839

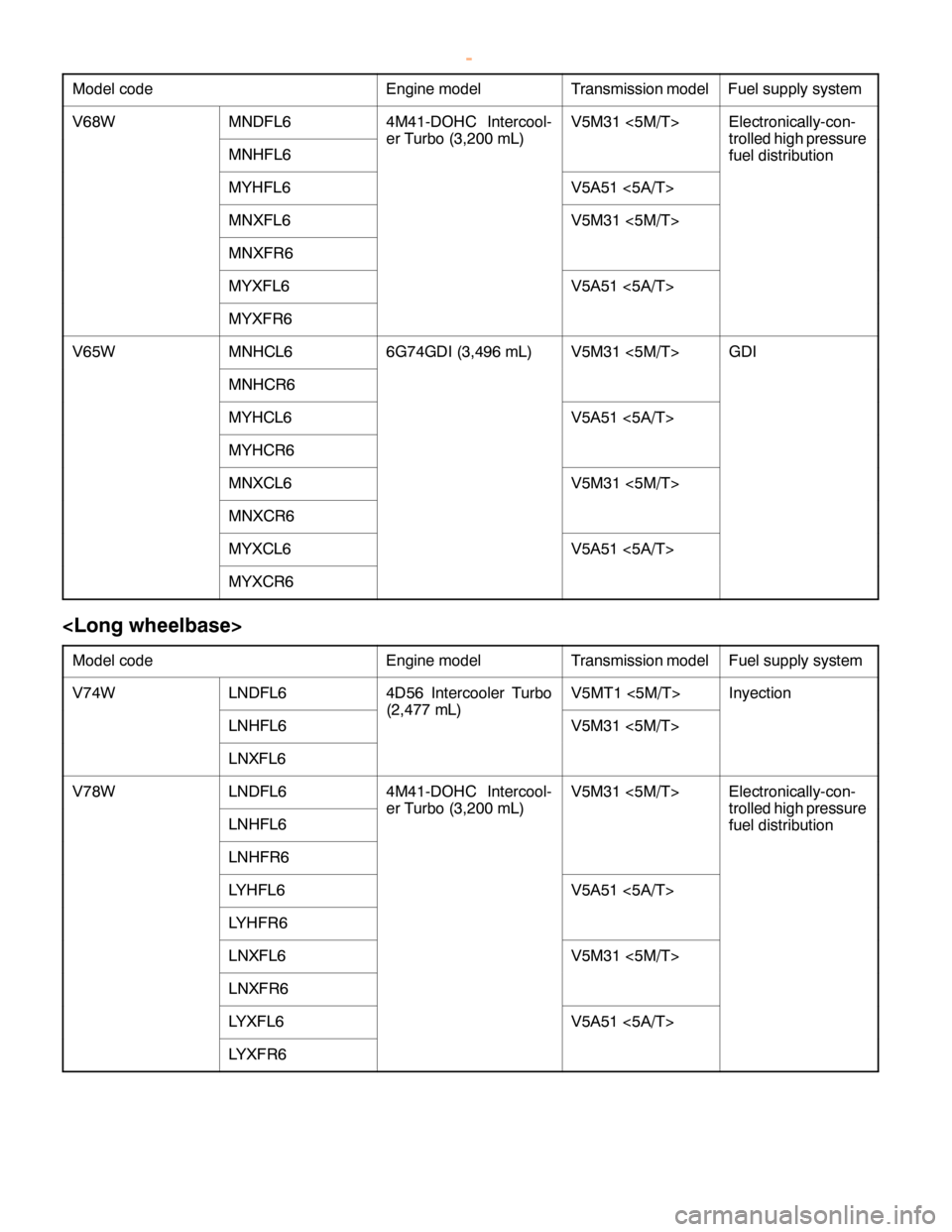

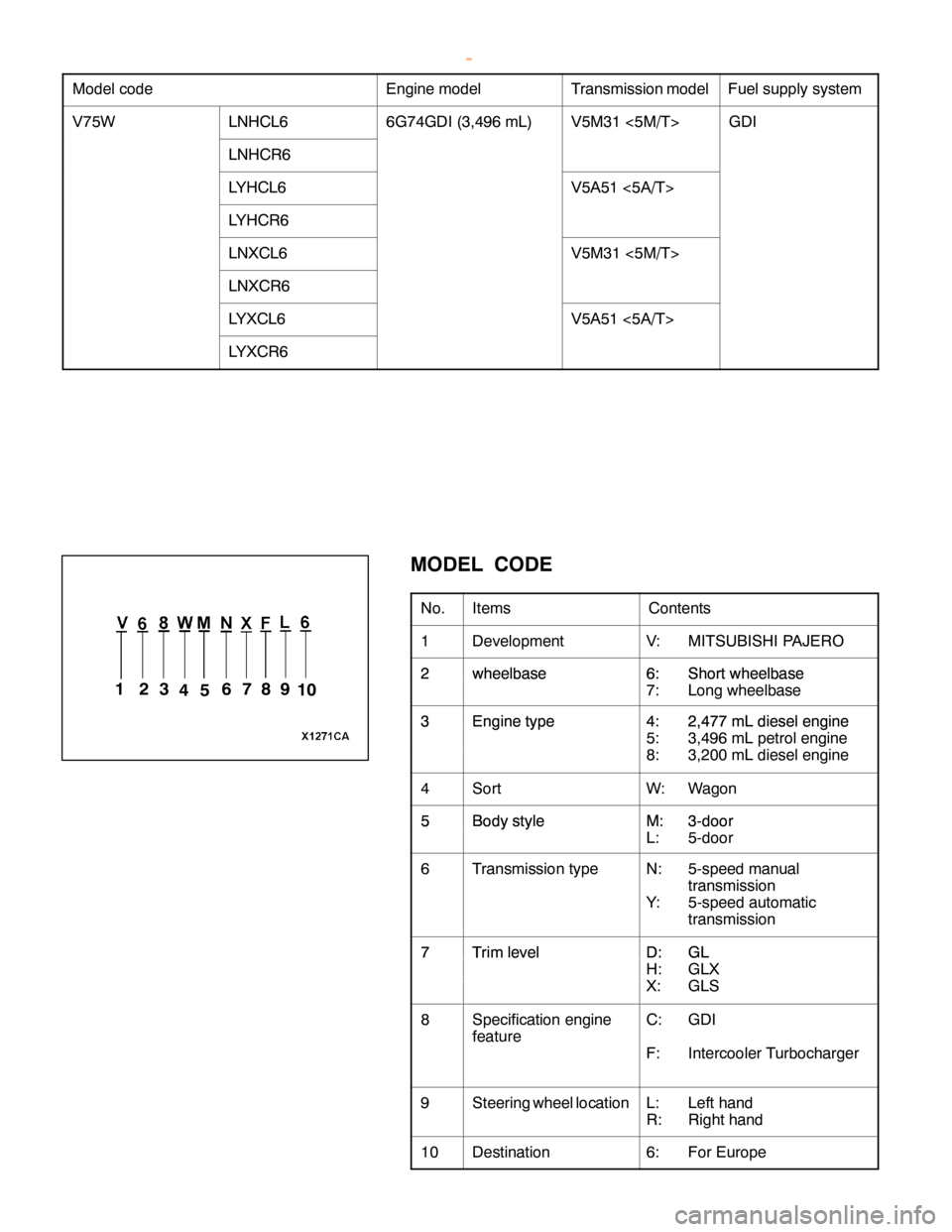

GENERAL -Vehicle Identification00-17

Model codeFuel supply system Transmission model Engine model

V68WMNDFL64M41-DOHC Intercool-V5M31<5M/T>Electronically-con-

MNHFL6

er Turbo (3,200 mL)trolled high pressure

fuel distribution

MYHFL6V5A51 <5A/T>

MNXFL6V5M31<5M/T>

MNXFR6

MYXFL6V5A51 <5A/T>

MYXFR6

V65WMNHCL66G74GDI (3,496 mL)V5M31<5M/T>GDI

MNHCR6

MYHCL6V5A51 <5A/T>

MYHCR6

MNXCL6V5M31<5M/T>

MNXCR6

MYXCL6V5A51 <5A/T>

MYXCR6

Model codeEngine modelTransmission modelFuel supply system

V74WLNDFL64D56 Intercooler TurboV5MT1 <5M/T>Inyection

LNHFL6

(2,477 mL)

V5M31<5M/T>

LNXFL6

V78WLNDFL64M41-DOHC Intercool-V5M31<5M/T>Electronically-con-

LNHFL6

er Turbo (3,200 mL)trolled high pressure

fuel distribution

LNHFR6

LYHFL6V5A51 <5A/T>

LYHFR6

LNXFL6V5M31<5M/T>

LNXFR6

LYXFL6V5A51 <5A/T>

LYXFR6

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 19 of 1839

V

75W L

N HCL6 6

G 74G DI(3 ,4 96 mL) V

5M 31 <5M /T > G

DI L

N HCR6 L

Y H CL6 V

5A 51 <5A /T > L

Y H CR6 L

N XC L6 V

5M 31 <5M /T > L

N XC R6 L

Y XC L6 V

5A 51 <5A /T > L

Y XC R6 I

te m s C

onte nts 1 D

eve lo pm ent V

: MIT S U BIS H IP A JE R O 2 w

heelb ase 6

: Short w heelb ase 2 w

heelb ase 6

: Short w heelb ase

7 : Long wheelb ase 3 E

ngin e ty p e 4

: 2,4 77 mL die se le ngin e 3 E

ngin e ty p e 4

: 2,4 77 mL die se le ngin e

5 : 3,4 96 mL petr o le ngin e 8

: 3,2 00 mL die se le ngin e 4 S

ort W

: Wagon 5 B

ody sty le M

: 3-d oor 5 B

ody sty le M

: 3-d oor

L : 5-d oor 6 T

ra nsm is sio n ty p e N

: 5-s p eed manual

t r a nsm is sio n

Y : 5-s p eed auto m atic

t r a nsm is sio n 7 T

rim le ve l D

: GL 7 T

rim le ve l D

: GL

H : GLX X

: GLS 8 S

pecif ic a tio n engin e

f e atu re C

: GDI

F : In te rc o ole r Turb och arg er 9 S

te erin g wheello ca tio n L

: Left hand

R : Rig ht hand 1

0 D

estin atio n 6

: For E uro pe

Page 20 of 1839

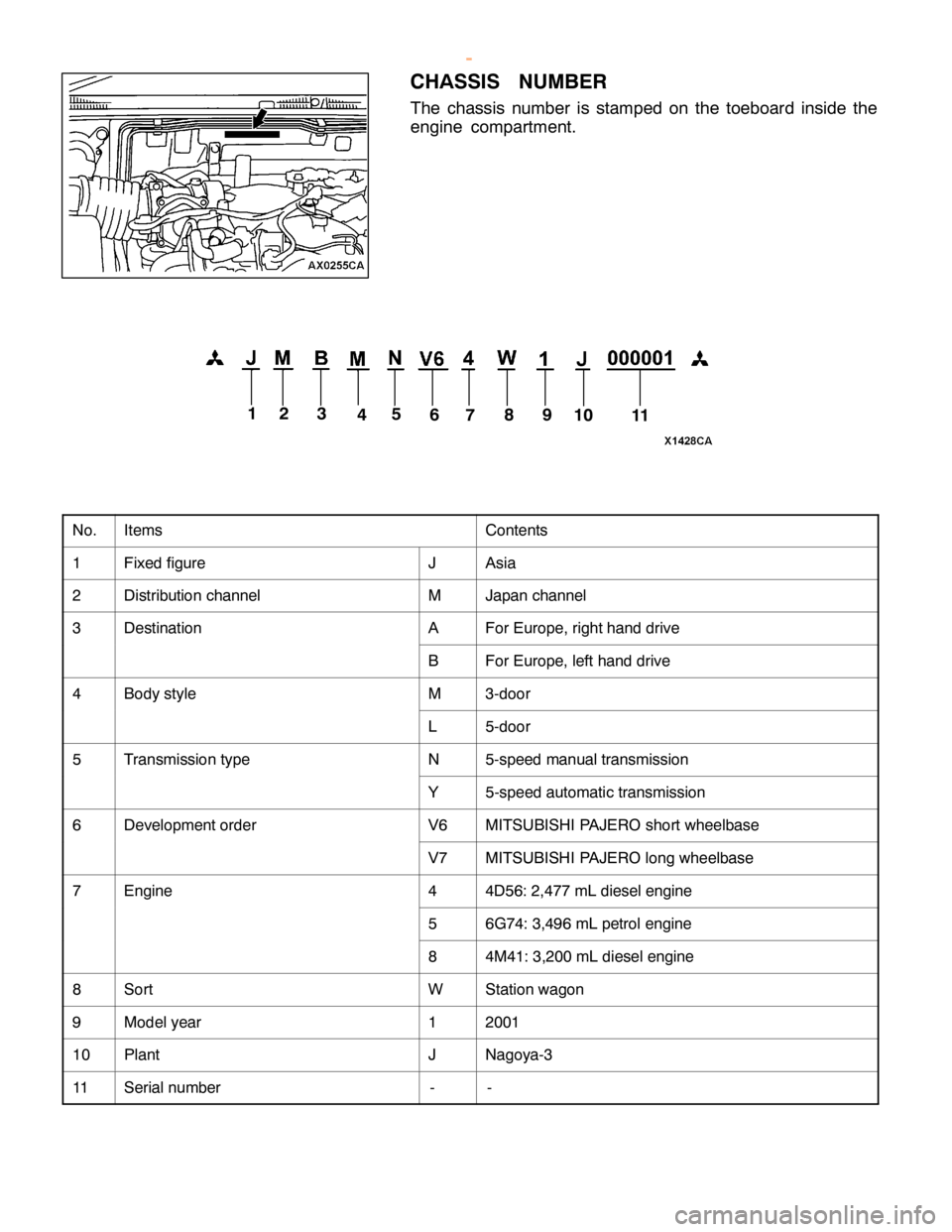

I

te m s C

onte nts 1 F

ix e d fig ure J A

sia 2 D

is tr ib utio n ch annel M J

a pan ch annel 3 D

estin atio n A F

or E uro pe, rig hth and driv e B F

or E uro pe, le ft hand driv e 4 B

ody sty le M 3

-d oor L 5

-d oor 5 T

ra nsm is sio n ty p e N 5

-s p eed manualtr a nsm is sio n Y 5

-s p eed auto m atic tr a nsm is sio n 6 D

eve lo pm ent ord er V

6 M

IT S U BIS H IP A JE R O sh ort w heelb ase V

7 M

IT S U BIS H IP A JE R O lo ng wheelb ase 7 E

ngin e 4 4

D 56: 2,4 77 mL die se le ngin e 5 6

G 74: 3,4 96 mL petr o le ngin e 8 4

M 41:3 ,2 00 mL die se le ngin e 8 S

ort W S

ta tio n wagon 9 M

odelye ar 1 2

001 1

0 P

la nt J N

agoya -3 1

1 S

eria ln um ber - -