speed sensor MITSUBISHI MONTERO 2000 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 125 of 1839

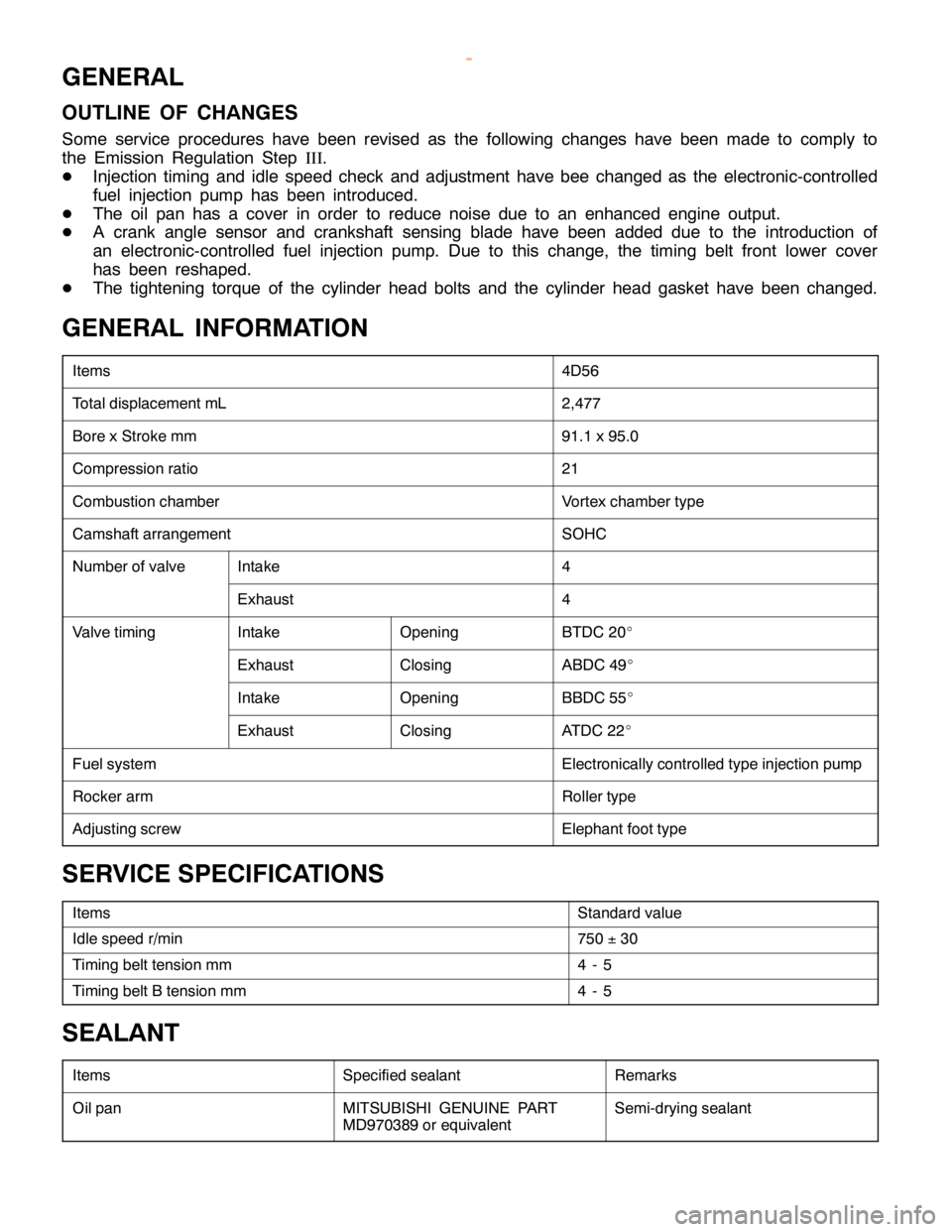

ENGINE <4D5> -General/General Information/Service Specifications/Sealant11B-2

GENERAL

OUTLINE OF CHANGES

Some service procedures have been revised as the following changes have been made to comply to

the Emission Regulation StepIII.

DInjection timing and idle speed check and adjustment have bee changed as the electronic-controlled

fuel injection pump has been introduced.

DThe oil pan has a cover in order to reduce noise due to an enhanced engine output.

DA crank angle sensor and crankshaft sensing blade have been added due to the introduction of

an electronic-controlled fuel injection pump. Due to this change, the timing belt front lower cover

has been reshaped.

DThe tightening torque of the cylinder head bolts and the cylinder head gasket have been changed.

GENERAL INFORMATION

Items4D56

Total displacement mL2,477

Bore x Stroke mm91.1 x 95.0

Compression ratio21

Combustion chamberVortex chamber type

Camshaft arrangementSOHC

Number of valveIntake4

Exhaust4

Valve timingIntakeOpeningBTDC 20_

ExhaustClosingABDC 49_

IntakeOpeningBBDC 55_

ExhaustClosingATDC 22_

Fuel systemElectronically controlled type injection pump

Rocker armRoller type

Adjusting screwElephant foot type

SERVICE SPECIFICATIONS

ItemsStandard value

Idle speed r/min750±30

Timing belt tension mm4-5

Timing belt B tension mm4-5

SEALANT

ItemsSpecified sealantRemarks

Oil panMITSUBISHI GENUINE PART

MD970389 or equivalentSemi-drying sealant

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 217 of 1839

GDI -General Information13A-3

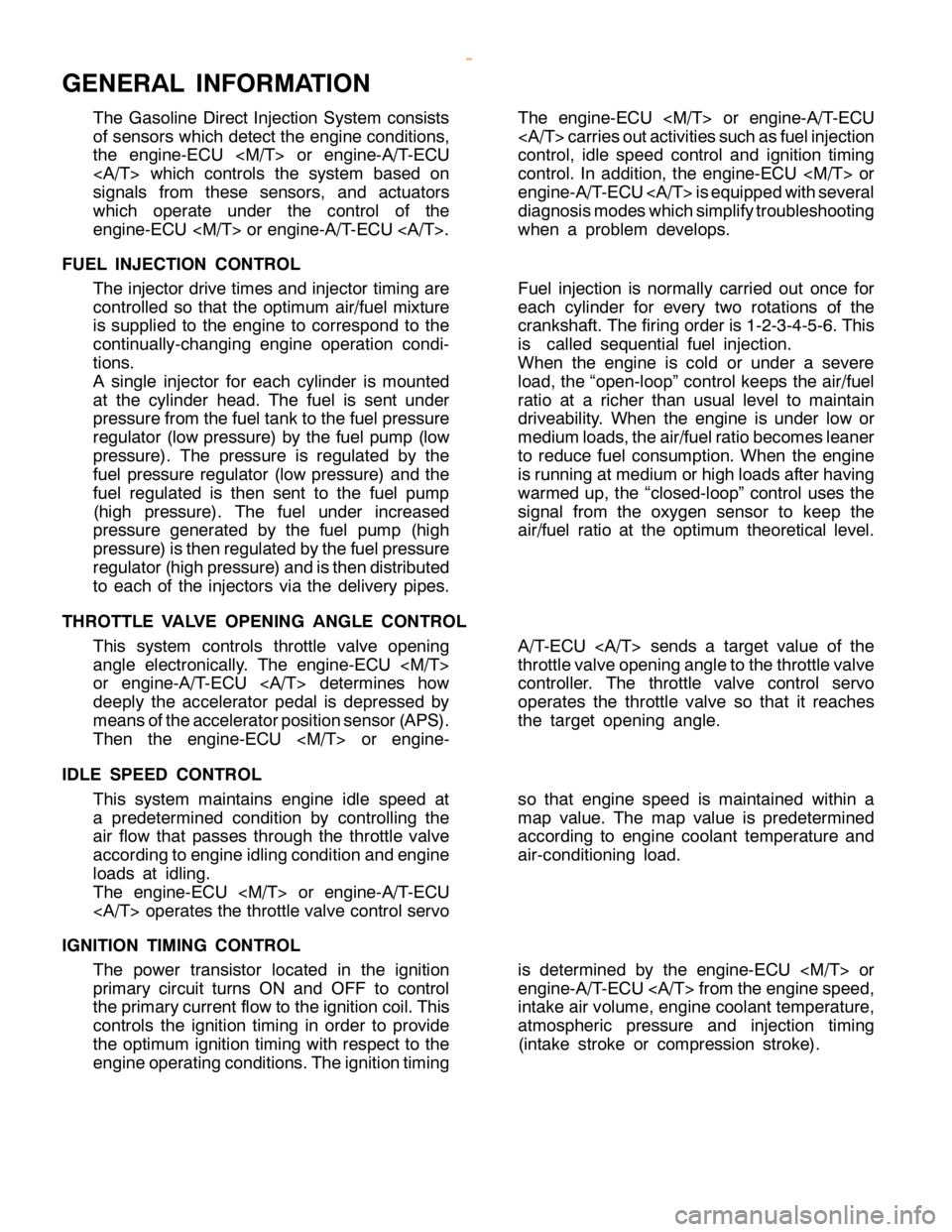

GENERAL INFORMATION

The Gasoline Direct Injection System consists

of sensors which detect the engine conditions,

the engine-ECU

which controls the system based on

signals from these sensors, and actuators

which operate under the control of the

engine-ECU

carries out activities such as fuel injection

control, idle speed control and ignition timing

control. In addition, the engine-ECU

engine-A/T-ECU is equipped with several

diagnosis modes which simplify troubleshooting

when a problem develops.

FUEL INJECTION CONTROL

The injector drive times and injector timing are

controlled so that the optimum air/fuel mixture

is supplied to the engine to correspond to the

continually-changing engine operation condi-

tions.

A single injector for each cylinder is mounted

at the cylinder head. The fuel is sent under

pressure from the fuel tank to the fuel pressure

regulator (low pressure) by the fuel pump (low

pressure). The pressure is regulated by the

fuel pressure regulator (low pressure) and the

fuel regulated is then sent to the fuel pump

(high pressure). The fuel under increased

pressure generated by the fuel pump (high

pressure) is then regulated by the fuel pressure

regulator (high pressure) and is then distributed

to each of the injectors via the delivery pipes.Fuel injection is normally carried out once for

each cylinder for every two rotations of the

crankshaft. The firing order is 1-2-3-4-5-6. This

is called sequential fuel injection.

When the engine is cold or under a severe

load, the “open-loop” control keeps the air/fuel

ratio at a richer than usual level to maintain

driveability. When the engine is under low or

medium loads, the air/fuel ratio becomes leaner

to reduce fuel consumption. When the engine

is running at medium or high loads after having

warmed up, the “closed-loop” control uses the

signal from the oxygen sensor to keep the

air/fuel ratio at the optimum theoretical level.

THROTTLE VALVE OPENING ANGLE CONTROL

This system controls throttle valve opening

angle electronically. The engine-ECU

or engine-A/T-ECU determines how

deeply the accelerator pedal is depressed by

means of the accelerator position sensor (APS).

Then the engine-ECU

throttle valve opening angle to the throttle valve

controller. The throttle valve control servo

operates the throttle valve so that it reaches

the target opening angle.

IDLE SPEED CONTROL

This system maintains engine idle speed at

a predetermined condition by controlling the

air flow that passes through the throttle valve

according to engine idling condition and engine

loads at idling.

The engine-ECU

operates the throttle valve control servoso that engine speed is maintained within a

map value. The map value is predetermined

according to engine coolant temperature and

air-conditioning load.

IGNITION TIMING CONTROL

The power transistor located in the ignition

primary circuit turns ON and OFF to control

the primary current flow to the ignition coil. This

controls the ignition timing in order to provide

the optimum ignition timing with respect to the

engine operating conditions. The ignition timingis determined by the engine-ECU

engine-A/T-ECU from the engine speed,

intake air volume, engine coolant temperature,

atmospheric pressure and injection timing

(intake stroke or compression stroke).

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 219 of 1839

GDI -General Information13A-5

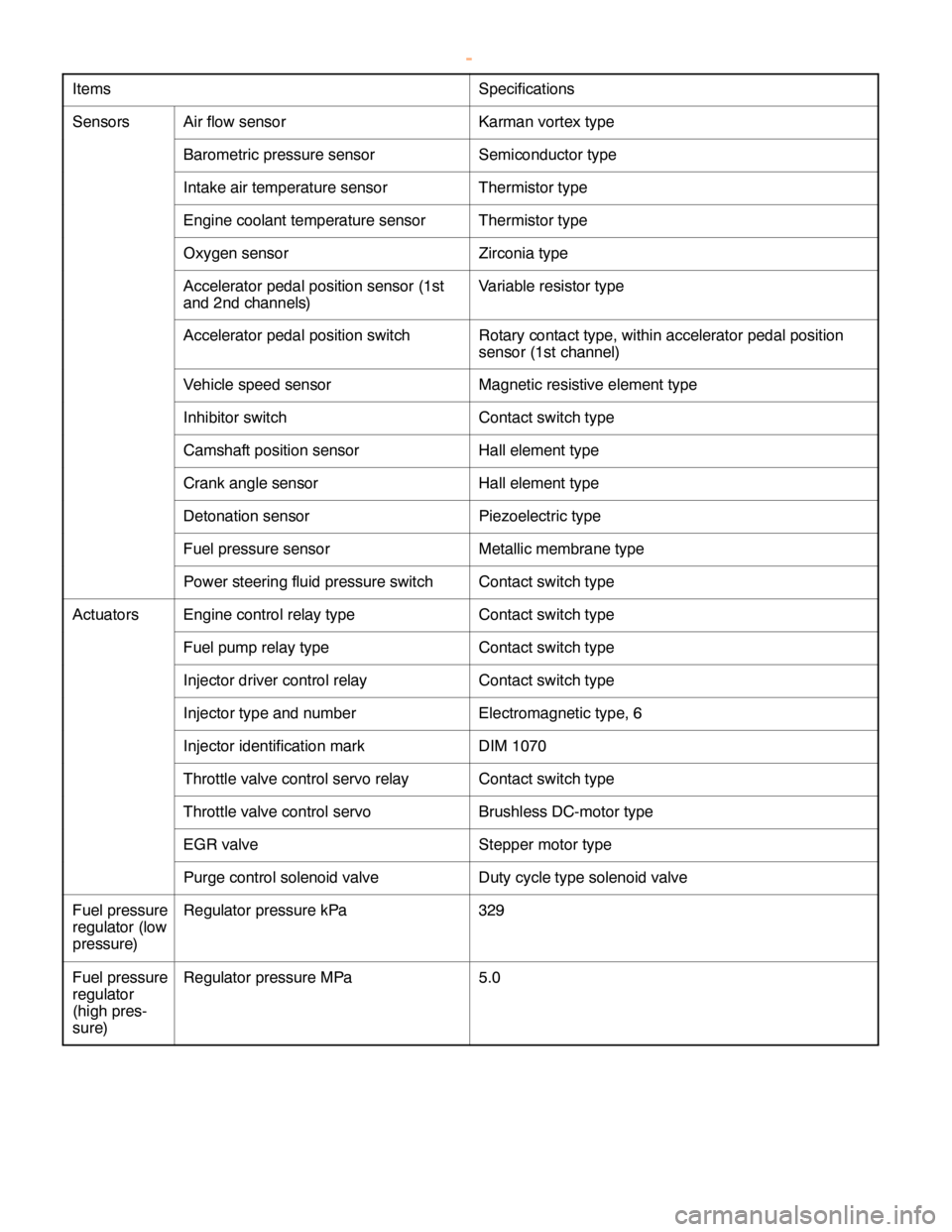

Items Specifications

SensorsAir flow sensorKarman vortex type

Barometric pressure sensorSemiconductor type

Intake air temperature sensorThermistor type

Engine coolant temperature sensorThermistor type

Oxygen sensorZirconia type

Accelerator pedal position sensor (1st

and 2nd channels)Variable resistor type

Accelerator pedal position switchRotary contact type, within accelerator pedal position

sensor (1st channel)

Vehicle speed sensorMagnetic resistive element type

Inhibitor switchContact switch type

Camshaft position sensorHall element type

Crank angle sensorHall element type

Detonation sensorPiezoelectric type

Fuel pressure sensorMetallic membrane type

Power steering fluid pressure switchContact switch type

ActuatorsEngine control relay typeContact switch type

Fuel pump relay typeContact switch type

Injector driver control relayContact switch type

Injector type and numberElectromagnetic type, 6

Injector identification markDIM 1070

Throttle valve control servo relayContact switch type

Throttle valve control servoBrushless DC-motor type

EGR valveStepper motor type

Purge control solenoid valveDuty cycle type solenoid valve

Fuel pressure

regulator (low

pressure)Regulator pressure kPa329

Fuel pressure

regulator

(high pres-

sure)Regulator pressure MPa5.0

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 224 of 1839

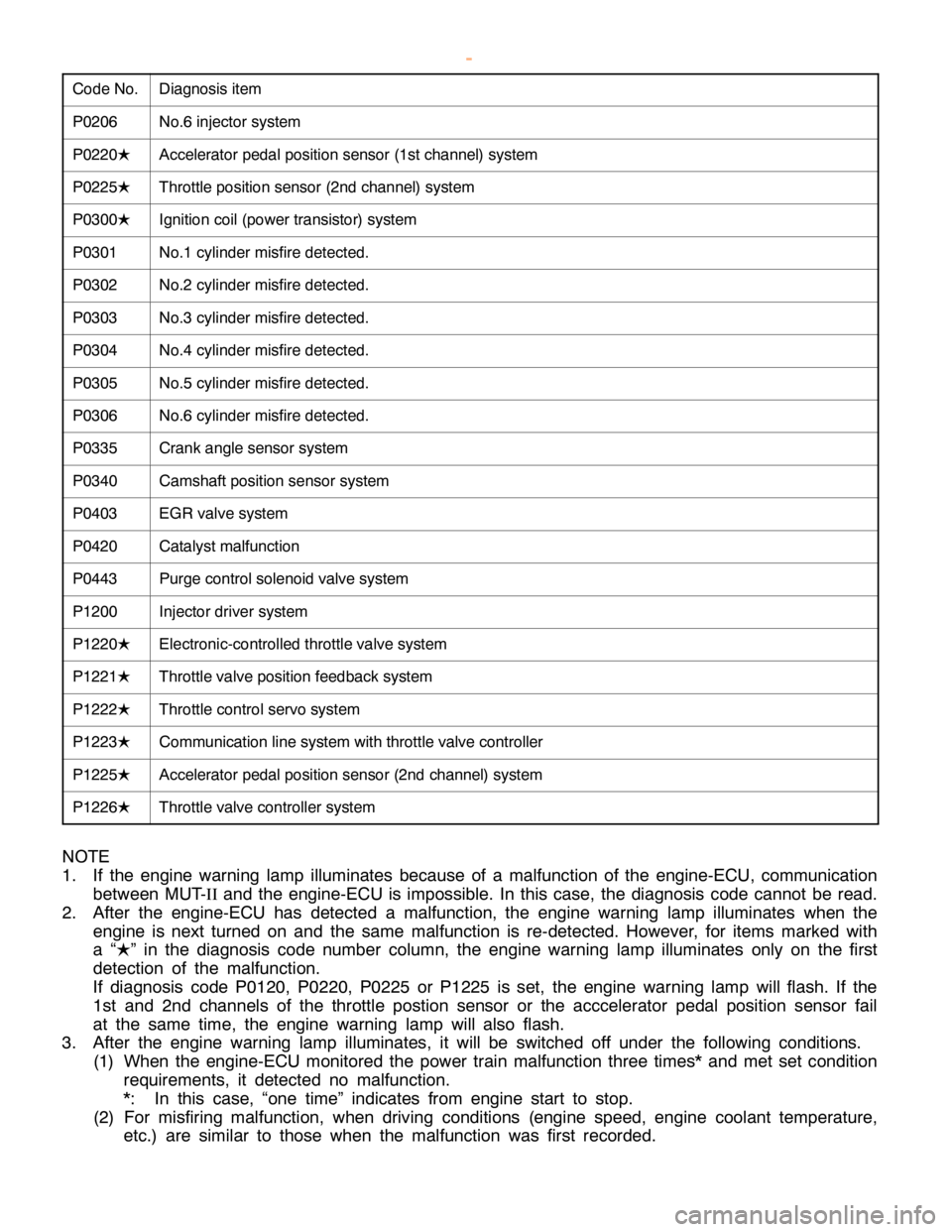

GDI -Troubleshooting

Code No. Diagnosis item

P0206No.6 injector system

P0220LAccelerator pedal position sensor (1st channel) system

P0225LThrottle position sensor (2nd channel) system

P0300LIgnition coil (power transistor) system

P0301No.1 cylinder misfire detected.

P0302No.2 cylinder misfire detected.

P0303No.3 cylinder misfire detected.

P0304No.4 cylinder misfire detected.

P0305No.5 cylinder misfire detected.

P0306No.6 cylinder misfire detected.

P0335Crank angle sensor system

P0340Camshaft position sensor system

P0403EGR valve system

P0420Catalyst malfunction

P0443Purge control solenoid valve system

P1200Injector driver system

P1220LElectronic-controlled throttle valve system

P1221LThrottle valve position feedback system

P1222LThrottle control servo system

P1223LCommunication line system with throttle valve controller

P1225LAccelerator pedal position sensor (2nd channel) system

P1226LThrottle valve controller system

NOTE

1. If the engine warning lamp illuminates because of a malfunction of the engine-ECU, communication

between MUT-

IIand the engine-ECU is impossible. In this case, the diagnosis code cannot be read.

2. After the engine-ECU has detected a malfunction, the engine warning lamp illuminates when the

engine is next turned on and the same malfunction is re-detected. However, for items marked with

a“

L” in the diagnosis code number column, the engine warning lamp illuminates only on the first

detection of the malfunction.

If diagnosis code P0120, P0220, P0225 or P1225 is set, the engine warning lamp will flash. If the

1st and 2nd channels of the throttle postion sensor or the acccelerator pedal position sensor fail

at the same time, the engine warning lamp will also flash.

3. After the engine warning lamp illuminates, it will be switched off under the following conditions.

(1) When the engine-ECU monitored the power train malfunction three times* and met set condition

requirements, it detected no malfunction.

*: In this case, “one time” indicates from engine start to stop.

(2) For misfiring malfunction, when driving conditions (engine speed, engine coolant temperature,

etc.) are similar to those when the malfunction was first recorded.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 226 of 1839

GDI -Troubleshooting

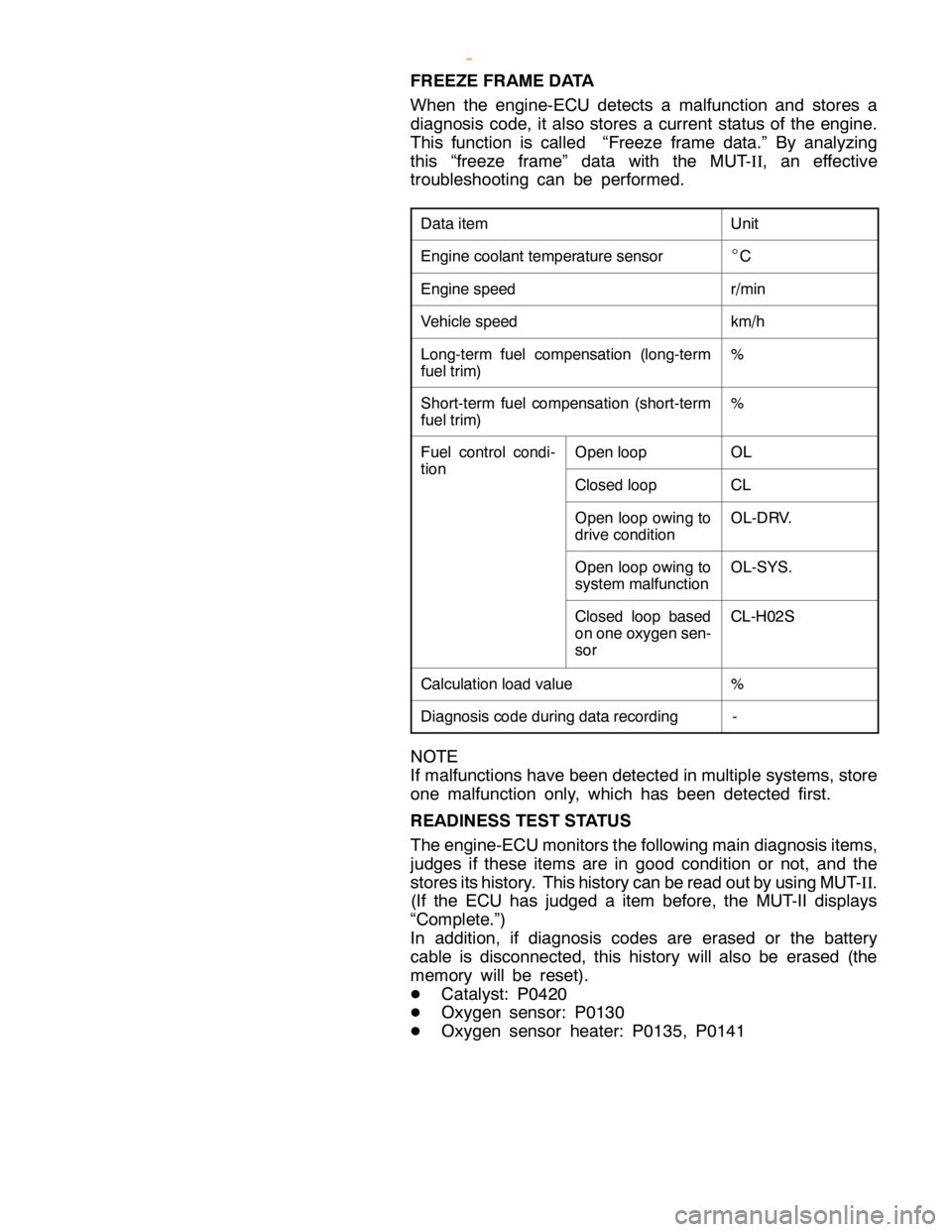

FREEZE FRAME DATA

When the engine-ECU detects a malfunction and stores a

diagnosis code, it also stores a current status of the engine.

This function is called “Freeze frame data.” By analyzing

this “freeze frame” data with the MUT-II, an effective

troubleshooting can be performed.

Data itemUnit

Engine coolant temperature sensor_C

Engine speedr/min

Vehicle speedkm/h

Long-term fuel compensation (long-term

fuel trim)%

Short-term fuel compensation (short-term

fuel trim)%

Fuel control condi-Open loopOL

tion

Closed loopCL

Open loop owing to

drive conditionOL-DRV.

Open loop owing to

system malfunctionOL-SYS.

Closed loop based

on one oxygen sen-

sorCL-H02S

Calculation load value%

Diagnosis code during data recording-

NOTE

If malfunctions have been detected in multiple systems, store

one malfunction only, which has been detected first.

READINESS TEST STATUS

The engine-ECU monitors the following main diagnosis items,

judges if these items are in good condition or not, and the

stores its history. This history can be read out by using MUT-II.

(If the ECU has judged a item before, the MUT-II displays

“Complete.”)

In addition, if diagnosis codes are erased or the battery

cable is disconnected, this history will also be erased (the

memory will be reset).

DCatalyst: P0420

DOxygen sensor: P0130

DOxygen sensor heater: P0135, P0141

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 227 of 1839

GDI -Troubleshooting

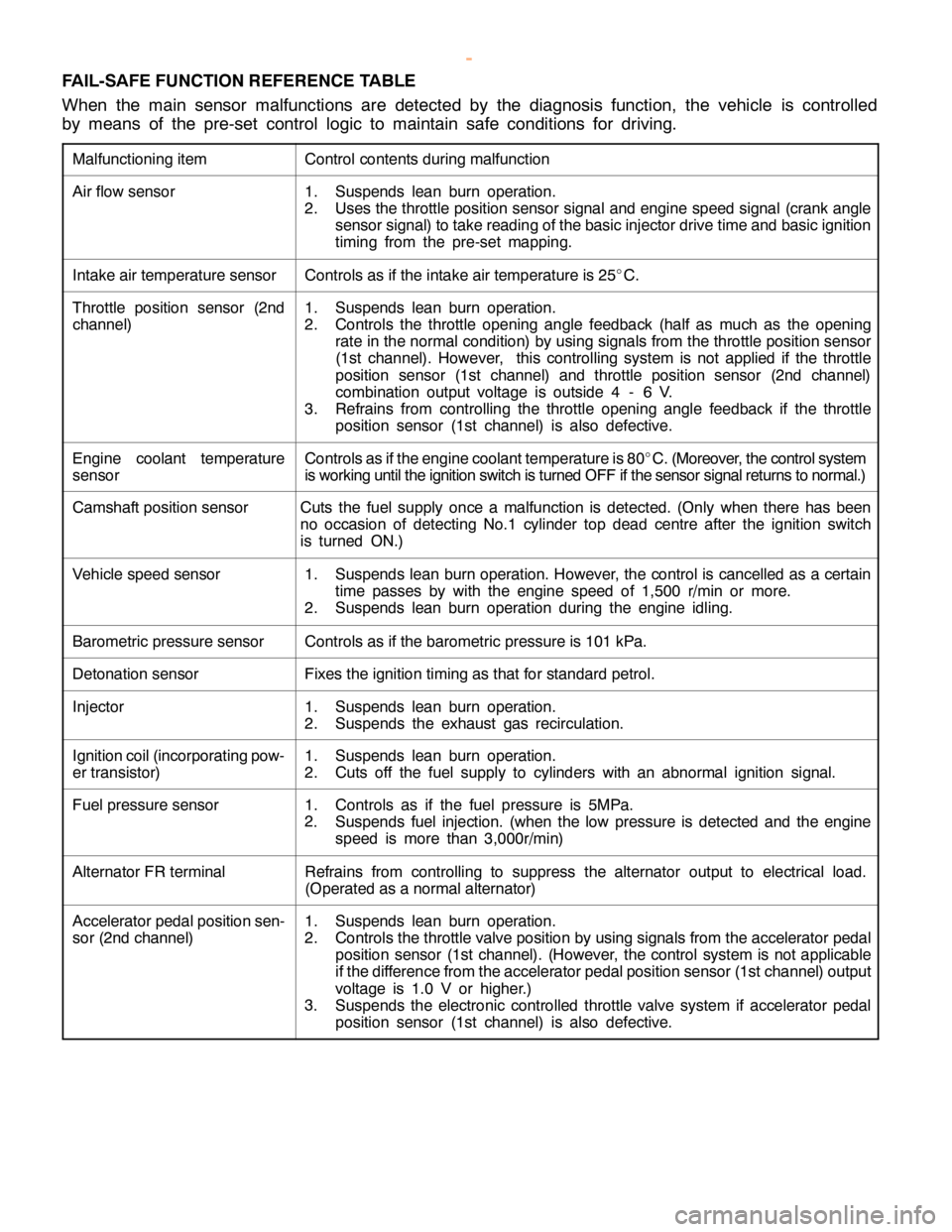

FAIL-SAFE FUNCTION REFERENCE TABLE

When the main sensor malfunctions are detected by the diagnosis function, the vehicle is controlled

by means of the pre-set control logic to maintain safe conditions for driving.

Malfunctioning itemControl contents during malfunction

Air flow sensor1. Suspends lean burn operation.

2. Uses the throttle position sensor signal and engine speed signal (crank angle

sensor signal) to take reading of the basic injector drive time and basic ignition

timing from the pre-set mapping.

Intake air temperature sensorControls as if the intake air temperature is 25_

C.

Throttle position sensor (2nd

channel)1. Suspends lean burn operation.

2. Controls the throttle opening angle feedback (half as much as the opening

rate in the normal condition) by using signals from the throttle position sensor

(1st channel). However, this controlling system is not applied if the throttle

position sensor (1st channel) and throttle position sensor (2nd channel)

combination output voltage is outside 4 - 6 V.

3. Refrains from controlling the throttle opening angle feedback if the throttle

position sensor (1st channel) is also defective.

Engine coolant temperature

sensorControls as if the engine coolant temperature is 80_

C. (Moreover, the control system

is working until the ignition switch is turned OFF if the sensor signal returns to normal.)

Camshaft position sensorCuts the fuel supply once a malfunction is detected. (Only when there has been

no occasion of detecting No.1 cylinder top dead centre after the ignition switch

is turned ON.)

Vehicle speed sensor1. Suspends lean burn operation. However, the control is cancelled as a certain

time passes by with the engine speed of 1,500 r/min or more.

2. Suspends lean burn operation during the engine idling.

Barometric pressure sensorControls as if the barometric pressure is 101 kPa.

Detonation sensorFixes the ignition timing as that for standard petrol.

Injector1. Suspends lean burn operation.

2. Suspends the exhaust gas recirculation.

Ignition coil (incorporating pow-

er transistor)1. Suspends lean burn operation.

2. Cuts off the fuel supply to cylinders with an abnormal ignition signal.

Fuel pressure sensor1. Controls as if the fuel pressure is 5MPa.

2

. Suspends fuel injection. (when the low pressure is detected and the engine

speed is more than 3,000r/min)

Alternator FR terminalRefrains from controlling to suppress the alternator output to electrical load.

(Operated as a normal alternator)

Accelerator pedal position sen-

sor (2nd channel)1. Suspends lean burn operation.

2. Controls the throttle valve position by using signals from the accelerator pedal

position sensor (1st channel). (However, the control system is not applicable

if the difference from the accelerator pedal position sensor (1st channel) output

voltage is 1.0 V or higher.)

3

. Suspends the electronic controlled throttle valve system if accelerator pedal

position sensor (1st channel) is also defective.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 228 of 1839

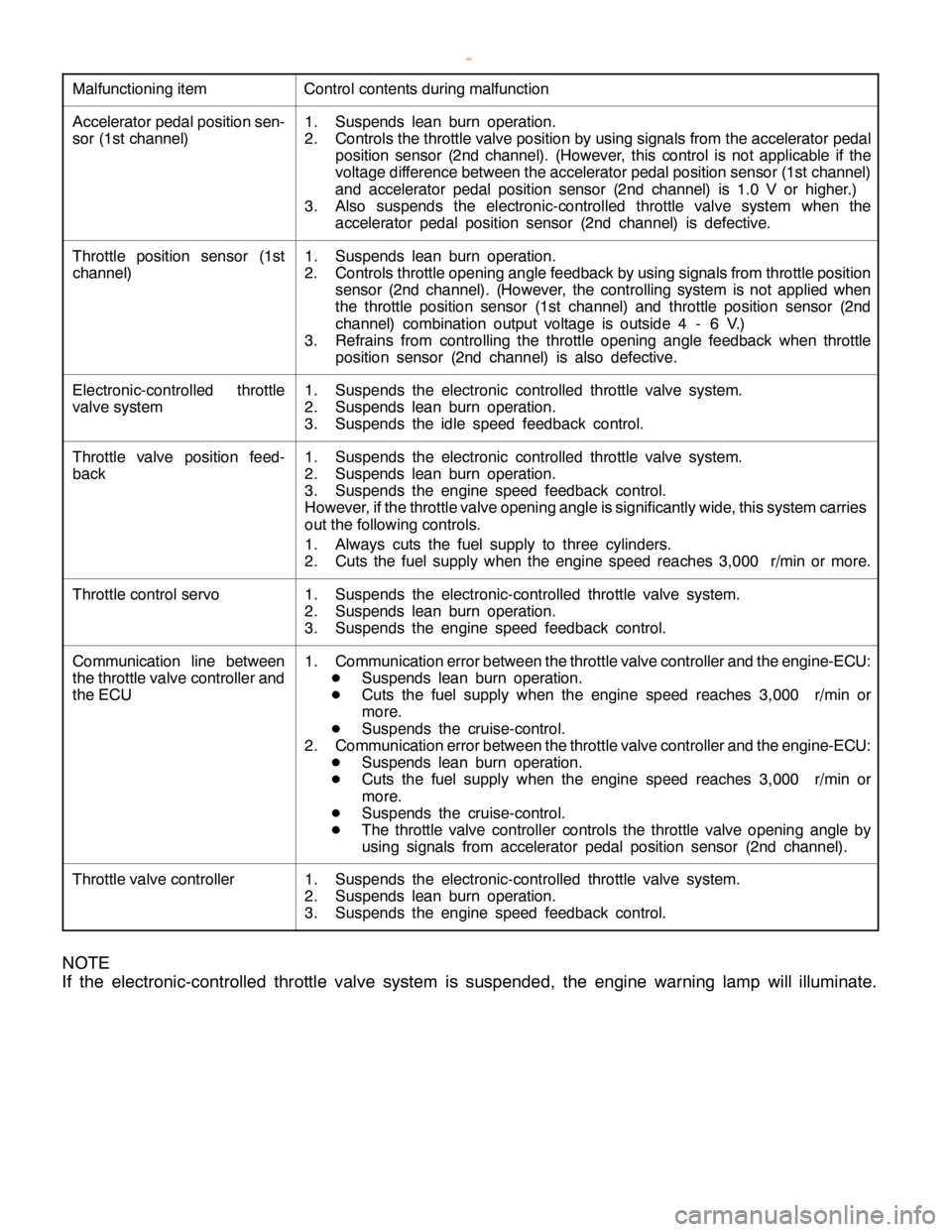

GDI -Troubleshooting

Malfunctioning item Control contents during malfunction

Accelerator pedal position sen-

sor (1st channel)1. Suspends lean burn operation.

2. Controls the throttle valve position by using signals from the accelerator pedal

position sensor (2nd channel). (However, this control is not applicable if the

voltage difference between the accelerator pedal position sensor (1st channel)

and accelerator pedal position sensor (2nd channel) is 1.0 V or higher.)

3. Also suspends the electronic-controlled throttle valve system when the

accelerator pedal position sensor (2nd channel) is defective.

Throttle position sensor (1st

channel)1. Suspends lean burn operation.

2.Controls throttle opening angle feedback by using signals from throttle position

sensor (2nd channel). (However, the controlling system is not applied when

the throttle position sensor (1st channel) and throttle position sensor (2nd

channel) combination output voltage is outside 4 - 6 V.)

3.Refrains from controlling the throttle opening angle feedback when throttle

position sensor (2nd channel) is also defective.

Electronic-controlled throttle

valve system1. Suspends the electronic controlled throttle valve system.

2. Suspends lean burn operation.

3. Suspends the idle speed feedback control.

Throttle valve position feed-

back1. Suspends the electronic controlled throttle valve system.

2. Suspends lean burn operation.

3. Suspends the engine speed feedback control.

However, if the throttle valve opening angle is significantly wide, this system carries

out the following controls.

1. Always cuts the fuel supply to three cylinders.

2. Cuts the fuel supply when the engine speed reaches 3,000 r/min or more.

Throttle control servo1. Suspends the electronic-controlled throttle valve system.

2. Suspends lean burn operation.

3. Suspends the engine speed feedback control.

Communication line between

the throttle valve controller and

the ECU1. Communication error between the throttle valve controller and the engine-ECU:

DSuspends lean burn operation.

DCuts the fuel supply when the engine speed reaches 3,000 r/min or

more.

DSuspends the cruise-control.

2. Communication error between the throttle valve controller and the engine-ECU:

DSuspends lean burn operation.

DCuts the fuel supply when the engine speed reaches 3,000 r/min or

more.

DSuspends the cruise-control.

DThe throttle valve controller controls the throttle valve opening angle by

using signals from accelerator pedal position sensor (2nd channel).

Throttle valve controller1. Suspends the electronic-controlled throttle valve system.

2. Suspends lean burn operation.

3. Suspends the engine speed feedback control.

NOTE

If the electronic-controlled throttle valve system is suspended, the engine warning lamp will illuminate.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 230 of 1839

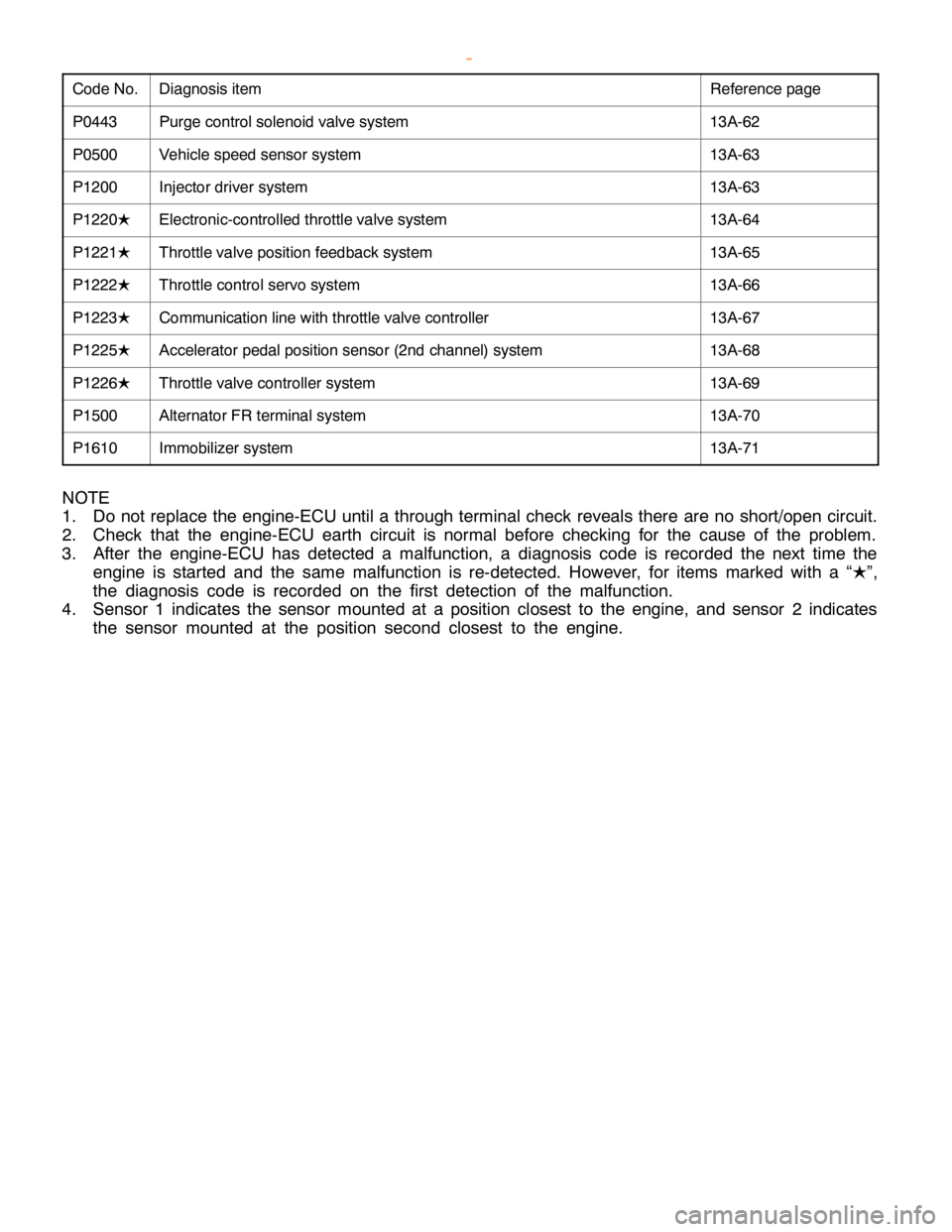

GDI -Troubleshooting

Code No.Reference page Diagnosis item

P0443Purge control solenoid valve system13A-62

P0500Vehicle speed sensor system13A-63

P1200Injector driver system13A-63

P1220LElectronic-controlled throttle valve system13A-64

P1221LThrottle valve position feedback system13A-65

P1222LThrottle control servo system13A-66

P1223LCommunication line with throttle valve controller13A-67

P1225LAccelerator pedal position sensor (2nd channel) system13A-68

P1226LThrottle valve controller system13A-69

P1500Alternator FR terminal system13A-70

P1610Immobilizer system13A-71

NOTE

1. Do not replace the engine-ECU until a through terminal check reveals there are no short/open circuit.

2. Check that the engine-ECU earth circuit is normal before checking for the cause of the problem.

3. After the engine-ECU has detected a malfunction, a diagnosis code is recorded the next time the

engine is started and the same malfunction is re-detected. However, for items marked with a “

L”,

the diagnosis code is recorded on the first detection of the malfunction.

4. Sensor 1 indicates the sensor mounted at a position closest to the engine, and sensor 2 indicates

the sensor mounted at the position second closest to the engine.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 231 of 1839

GDI -Troubleshooting

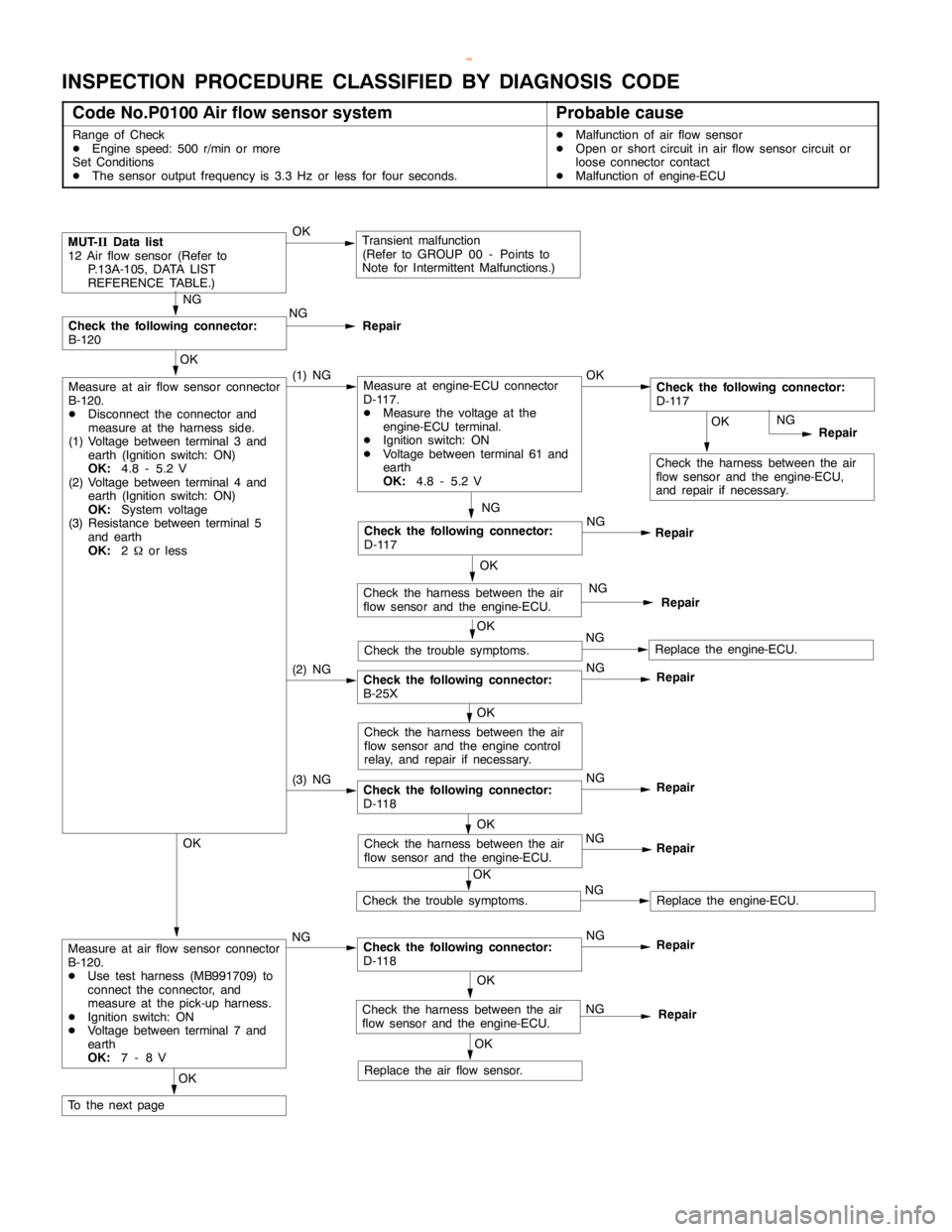

INSPECTION PROCEDURE CLASSIFIED BY DIAGNOSIS CODE

Code No.P0100 Air flow sensor systemProbable cause

Range of Check

DEngine speed: 500 r/min or more

Set Conditions

DThe sensor output frequency is 3.3 Hz or less for four seconds.DMalfunction of air flow sensor

DOpen or short circuit in air flow sensor circuit or

loose connector contact

DMalfunction of engine-ECU

(3) NGCheck the following connector:

D-118NG

Repair

(2) NGCheck the following connector:

B-25XNG

Repair

OK

Check the harness between the air

flow sensor and the engine-ECU,

and repair if necessary.

MUT-

IIData list

12 Air flow sensor (Refer to

P.13A-105, DATA LIST

REFERENCE TABLE.)OKTransient malfunction

(Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions.)

NG

Check the following connector:

B-120NG

Repair

OK

Measure at air flow sensor connector

B-120.

DDisconnect the connector and

measure at the harness side.

(1) Voltage between terminal 3 and

earth (Ignition switch: ON)

OK:

4.8 - 5.2 V

(2) Voltage between terminal 4 and

earth (Ignition switch: ON)

OK:

System voltage

(3) Resistance between terminal 5

and earth

OK:

2Wor less(1) NGMeasure at engine-ECU connector

D-117.

DMeasure the voltage at the

engine-ECU terminal.

DIgnition switch: ON

DVoltage between terminal 61 and

earth

OK:

4.8 - 5.2 VOKCheck the following connector:

D-117

NG

Repair

OK

Replace the air flow sensor.

NG

Check the following connector:

D-117NG

Repair

OK

Check the harness between the air

flow sensor and the engine-ECU.NG

Repair

OK

Check the trouble symptoms.NGReplace the engine-ECU.

OK

Check the harness between the air

flow sensor and theengine control

relay, and repair if necessary.

OK

Check the harness between the air

flow sensor and the engine-ECU.NG

Repair

OK

Check the trouble symptoms.NGReplace the engine-ECU.

OK

Measure at air flow sensor connector

B-120.

DUse test harness (MB991709) to

connect the connector, and

measure at the pick-up harness.

DIgnition switch: ON

DVoltage between terminal 7 and

earth

OK:

7-8VNGCheck the following connector:

D-118NG

Repair

OK

Check the harness between the air

flow sensor and the engine-ECU.NG

Repair

OK

To the nextpage

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 232 of 1839

GDI -Troubleshooting

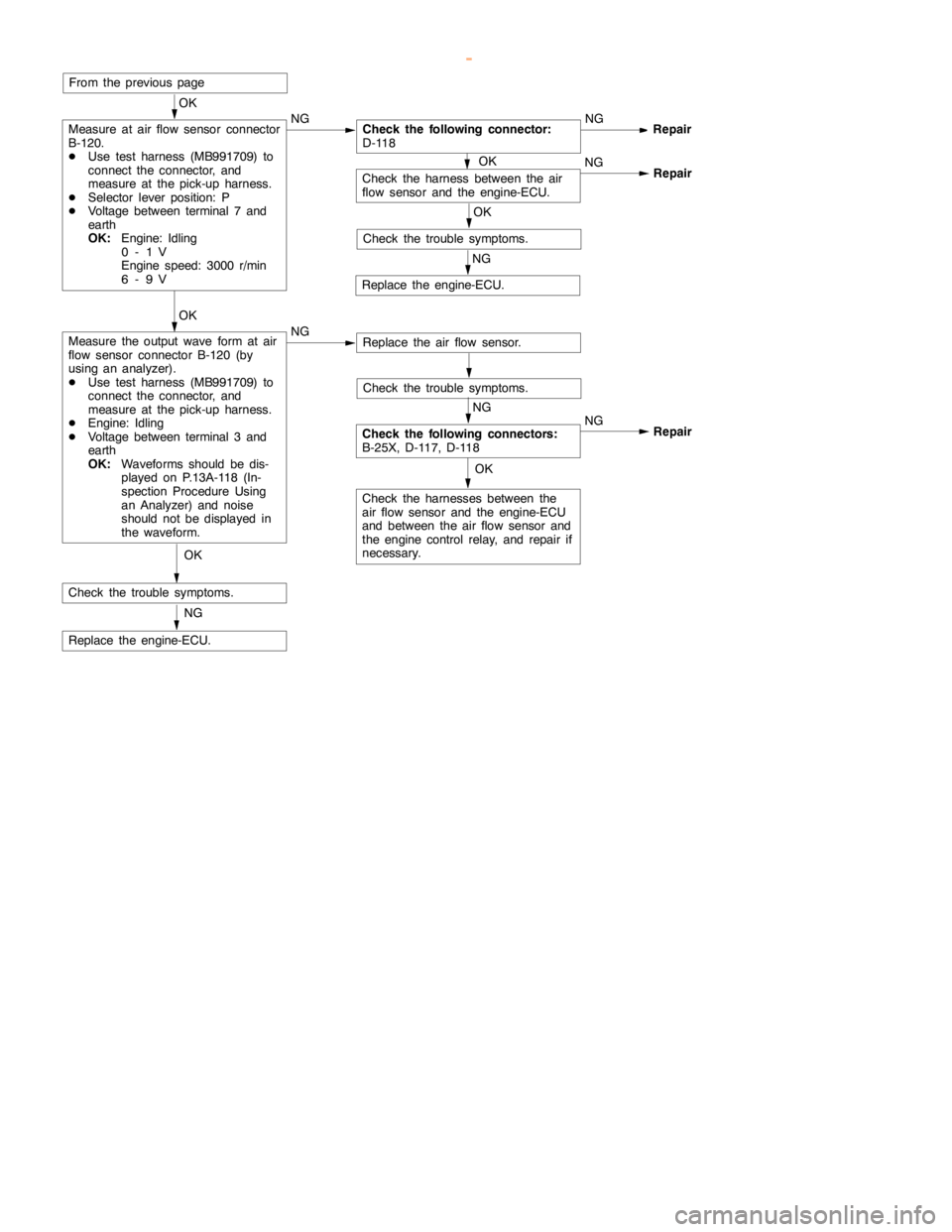

OK

Check the harness between the air

flow sensor and the engine-ECU.NG

Repair

OK

Check the harnesses between the

air flow sensor and the engine-ECU

and between the air flow sensor and

the engine controlrelay, and repair if

necessary.

From the previouspage

OK

Measure at air flow sensor connector

B-120.

DUse test harness (MB991709) to

connect the connector, and

measure at the pick-up harness.

DSelector lever position: P

DVoltage between terminal 7 and

earth

OK:

Engine: Idling

0-1V

Engine speed: 3000 r/min

6-9VNGCheck the following connector:

D-118NGRepair

OK

Check the trouble symptoms.

NG

Replace the engine-ECU.

Check the trouble symptoms.

NG

Check the following connectors:

B-25X, D-117, D-118NG

Repair

OK

Measure the output wave form at air

flow sensor connector B-120 (by

using an analyzer).

DUse test harness (MB991709) to

connect the connector, and

measure at the pick-up harness.

DEngine: Idling

DVoltage between terminal 3 and

earth

OK:

Waveforms should be dis-

played on P.13A-118 (In-

spection Procedure Using

an Analyzer) and noise

should not be displayed in

the waveform.NGReplace the air flow sensor.

OK

Check the trouble symptoms.

NG

Replace the engine-ECU.OK

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk