MITSUBISHI SPYDER 1990 Service Repair Manual

SPYDER 1990

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57345/w960_57345-0.png

MITSUBISHI SPYDER 1990 Service Repair Manual

Trending: instrument panel, oil dipstick, light, driver seat adjustment, tow, wiring, ignition

Page 1491 of 2103

PROPELLER

SHAFT

CONTENTS

ADHESIVE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2SERVICE . . . . . . . . . . . 2

GENERAL INFORMATION2SPECIAL. . . . . . . . . . . . . . . . . . . . . . . . . . .3,

LUBRICANTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2TROUBLESHOOTING . . . . . . . . . . . . . . . . . .

. . . . . 3’

Page 1492 of 2103

General Information/Service Specifications/

PROPELLER SHAFT Lubricants/Adhesive

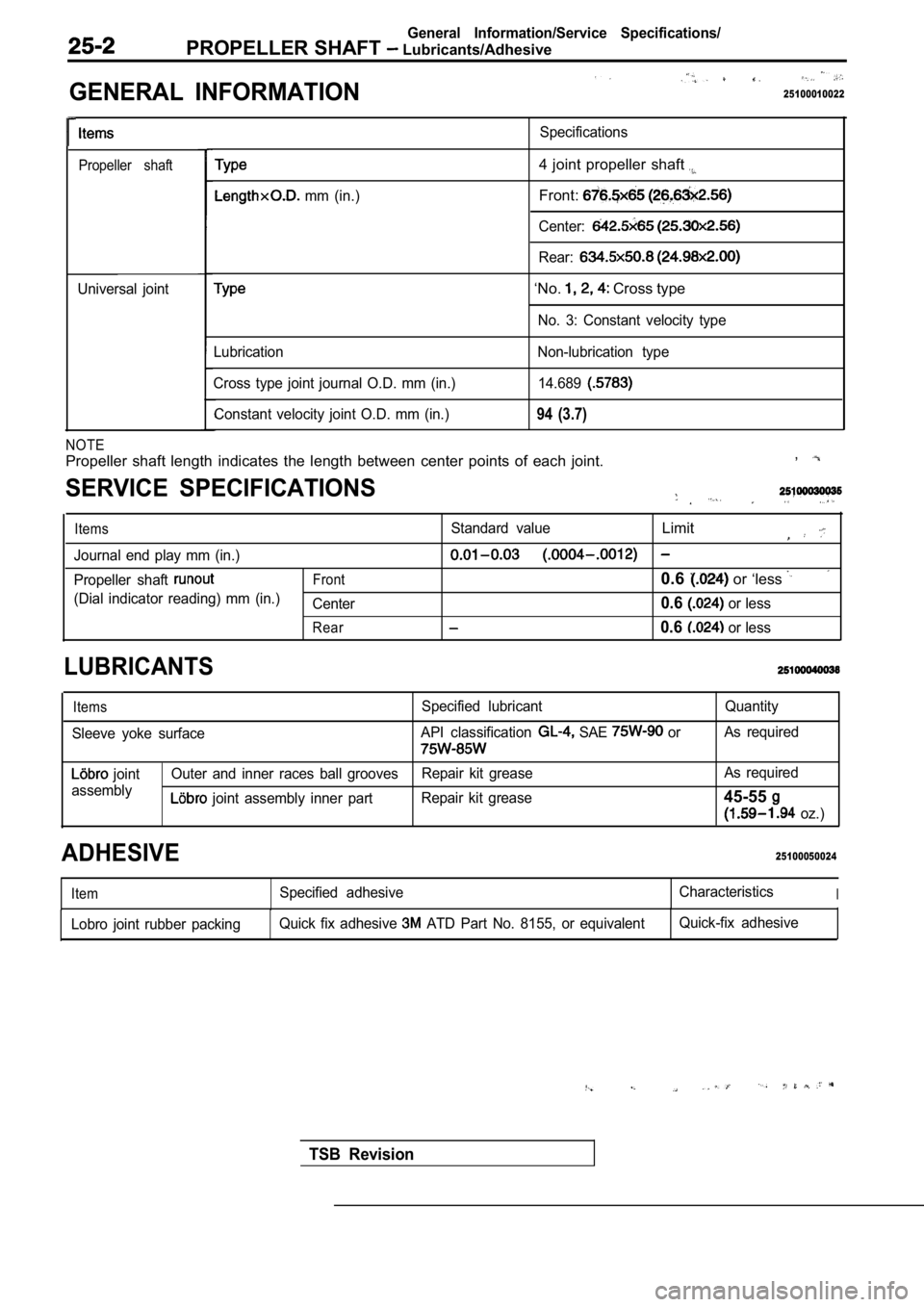

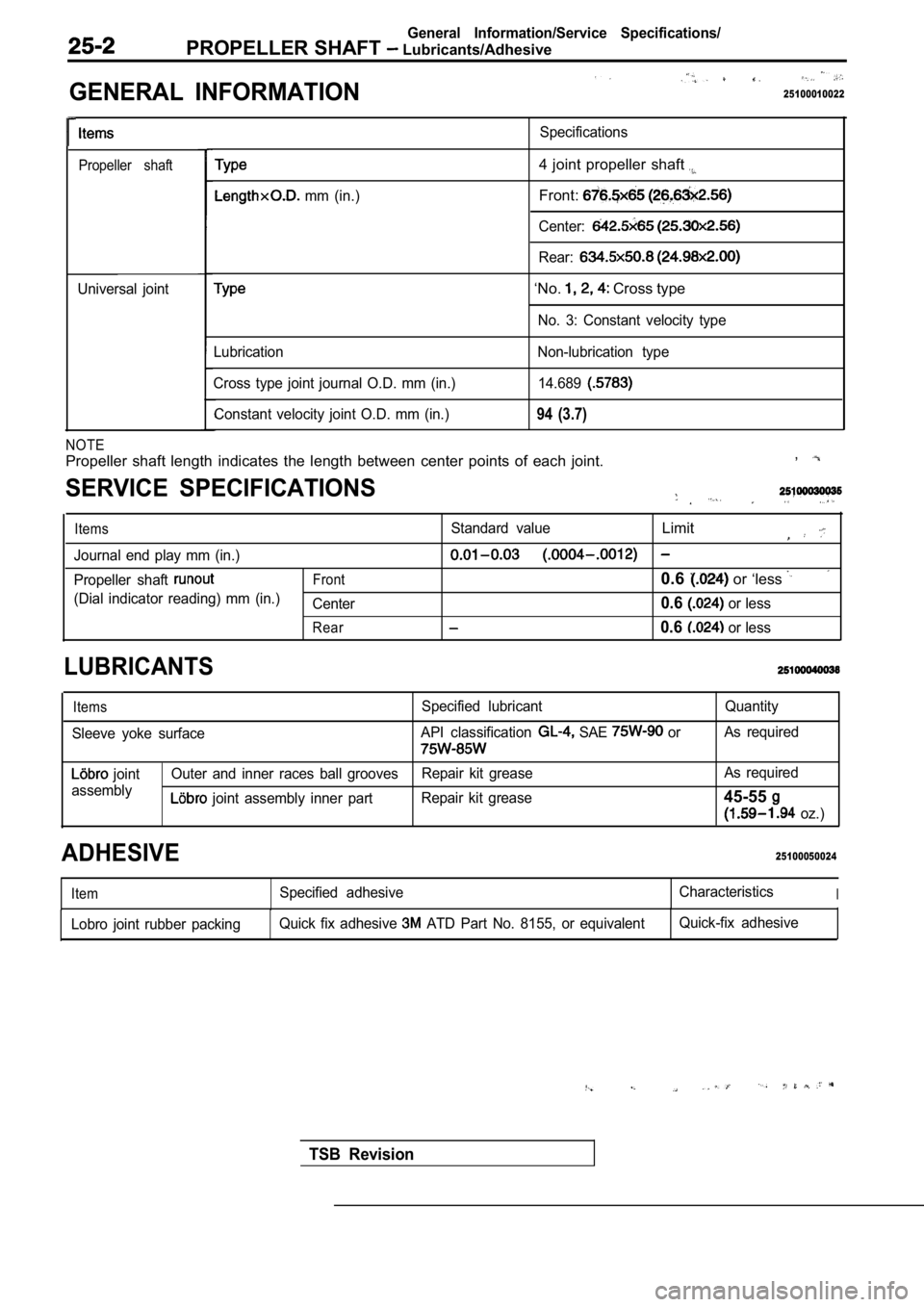

GENERAL INFORMATION

. .

25100010022

Propeller shaft

Universal jointSpecifications

mm (in.)

4 joint propeller shaft

Front:

Center:

Rear:

‘No. Cross type

No. 3: Constant velocity type

Lubrication

Cross type joint journal O.D. mm (in.) Constant velocity joint O.D. mm (in.) Non-lubrication type

14.689

94 (3.7)

NOTE

Propeller shaft length indicates the length between center points of each joint. ,

SERVICE SPECIFICATIONS

ItemsStandard valueLimit

Journal end play mm (in.)

Propeller shaft Front0.6 or ‘less

(Dial indicator reading) mm (in.)

Center0.6 or less

Rear0.6 or less

LUBRICANTS

Items

Sleeve yoke surface Specified lubricant

API classification SAE or

Quantity

As required

joint

assembly Outer and inner races ball grooves

Repair kit grease As required

joint assembly inner part

Repair kit grease45-55

oz.)

25100050024ADHESIVE

ItemSpecified adhesive CharacteristicsI

Lobro joint rubber packingQuick fix adhesive ATD Part No. 8155, or equivalent Quick-fix adhesive

TSB Revision

Page 1493 of 2103

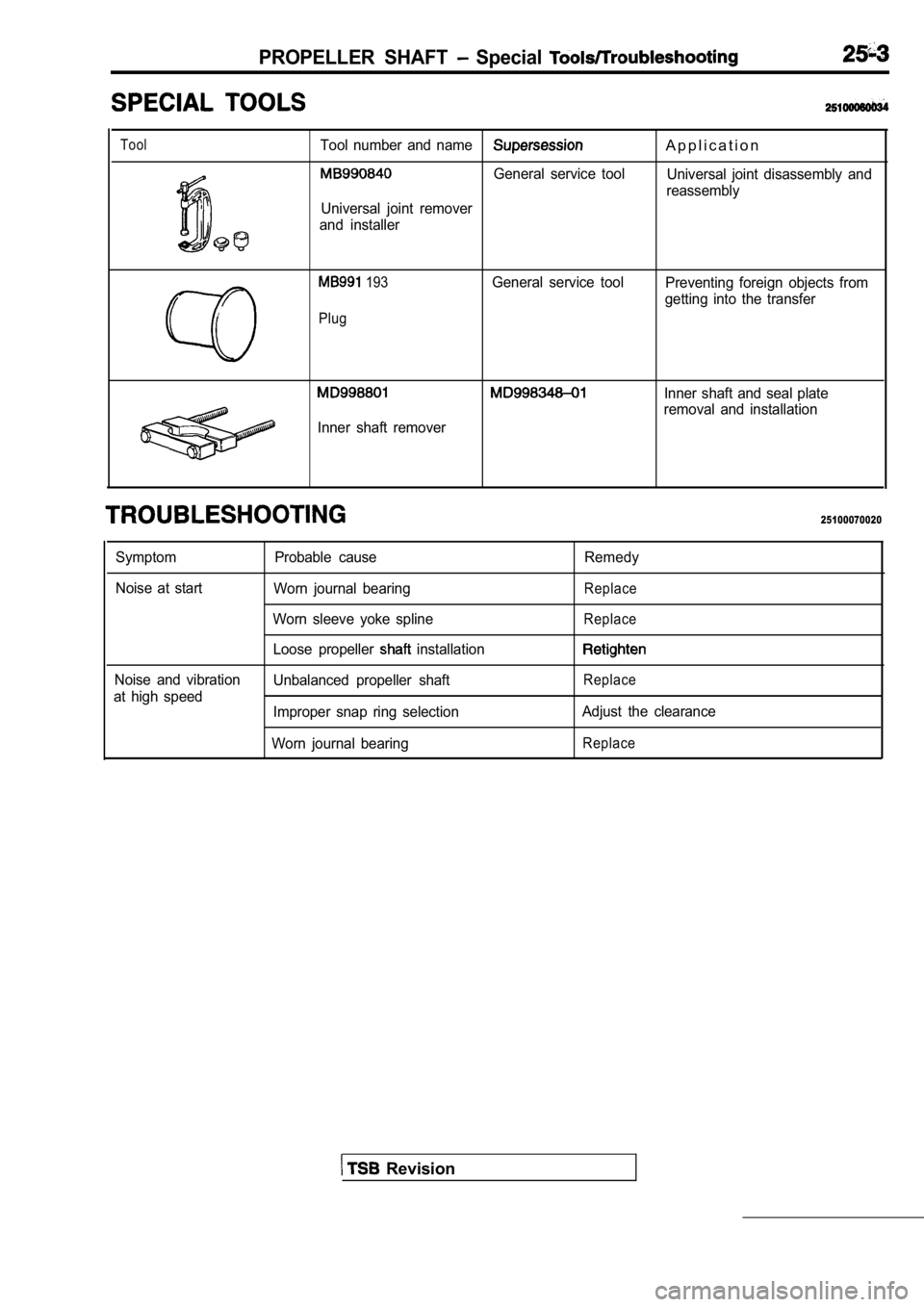

PROPELLER SHAFT Special

ToolTool number and nameA p p l i c a t i o n

General service toolUniversal joint disassembly and

reassembly

Universal joint remover

and installer

193

PlugGeneral service tool Preventing foreign objects from

getting into the transfer

Inner shaft remover

Inner shaft and seal plate

removal and installation

25100070020

Symptom

Noise at start

Noise and vibration

at high speed Probable cause Remedy

Worn journal bearing

Replace

Worn sleeve yoke splineReplace

Loose propeller installation

Unbalanced propeller shaftReplace

Improper snap ring selection Adjust the clearance

Worn journal bearing

Replace

Revision

Page 1494 of 2103

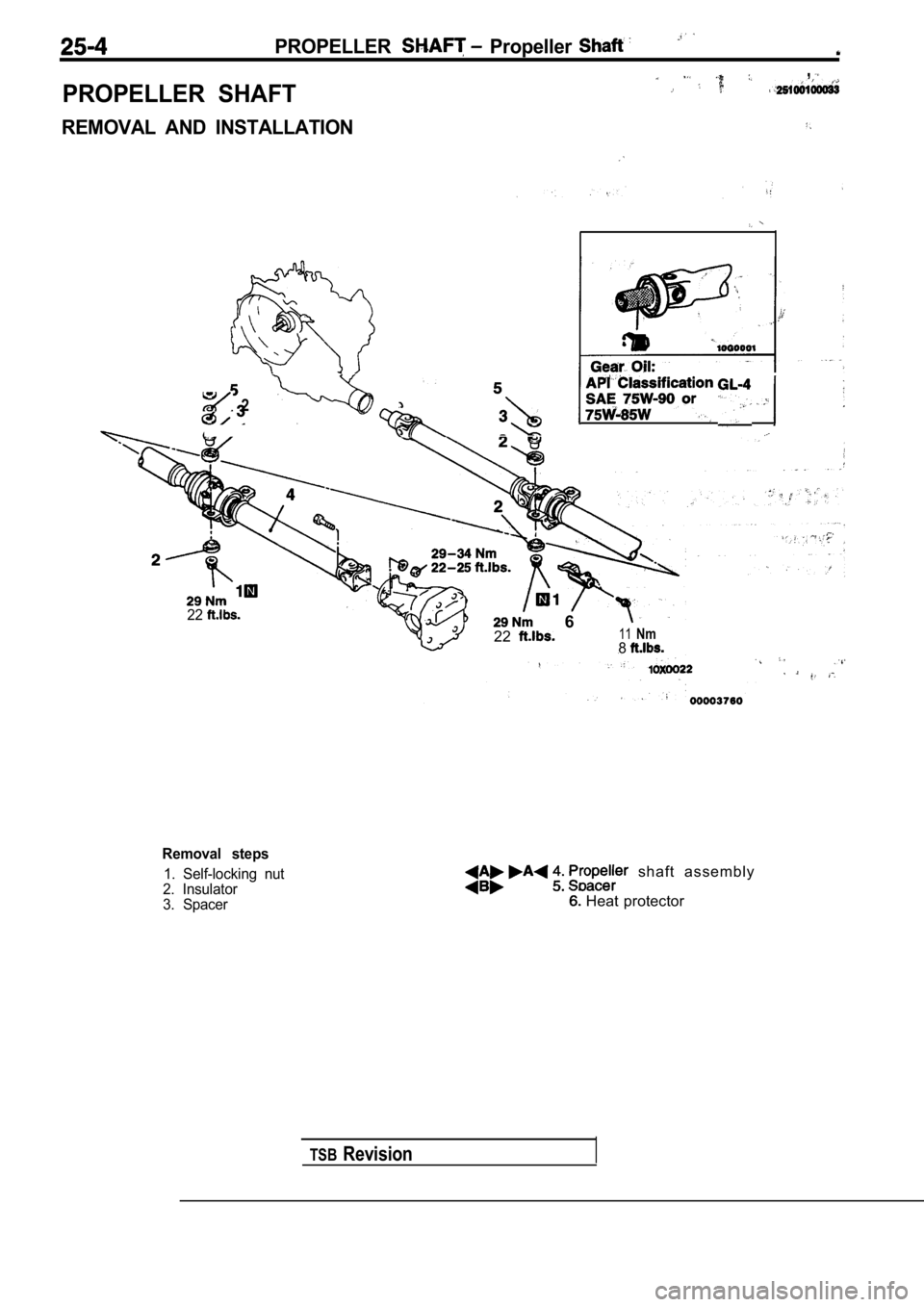

PROPELLER Propeller

PROPELLER SHAFT

,

REMOVAL AND INSTALLATION

2

22 6

2211Nm8

TSBRevision

Removal steps

1. Self-locking nut

2. Insulator

3. Spacer shaft assembly

Heat protector

Page 1495 of 2103

SHAFT Propeller

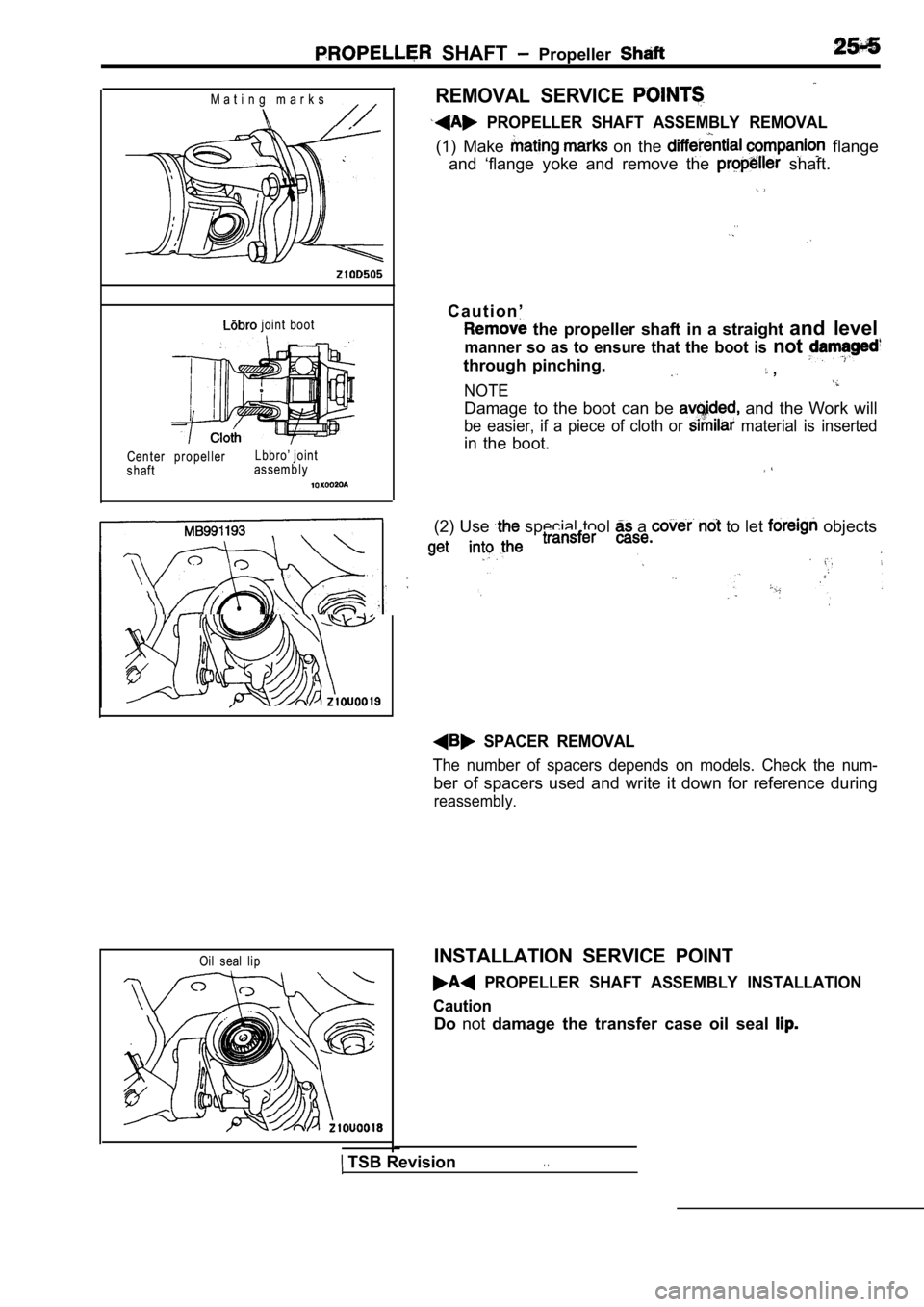

M a t i n g m a r k s

joint boot

Center propeller

shaft Lbbro’ joint

assembly

REMOVAL SERVICE

PROPELLER SHAFT ASSEMBLY REMOVAL

(1) Make on the flange

and ‘flange yoke and remove the

shaft.

. .

C a u t i o n ’

the propeller shaft in a straight and level

manner so as to ensure that the boot is not

through pinching. ,

NOTE

Damage to the boot can be and the Work will

be easier, if a piece of cloth or material is inserted

in the boot.

(2) Use special tool a to let objects

SPACER REMOVAL

The number of spacers depends on models. Check the num-

ber of spacers used and write it down for reference during

reassembly.

Oil seal lipINSTALLATION SERVICE POINT

PROPELLER SHAFT ASSEMBLY INSTALLATION

Caution

Do not damage the transfer case oil seal

TSB Revision. .

Page 1496 of 2103

. . ,

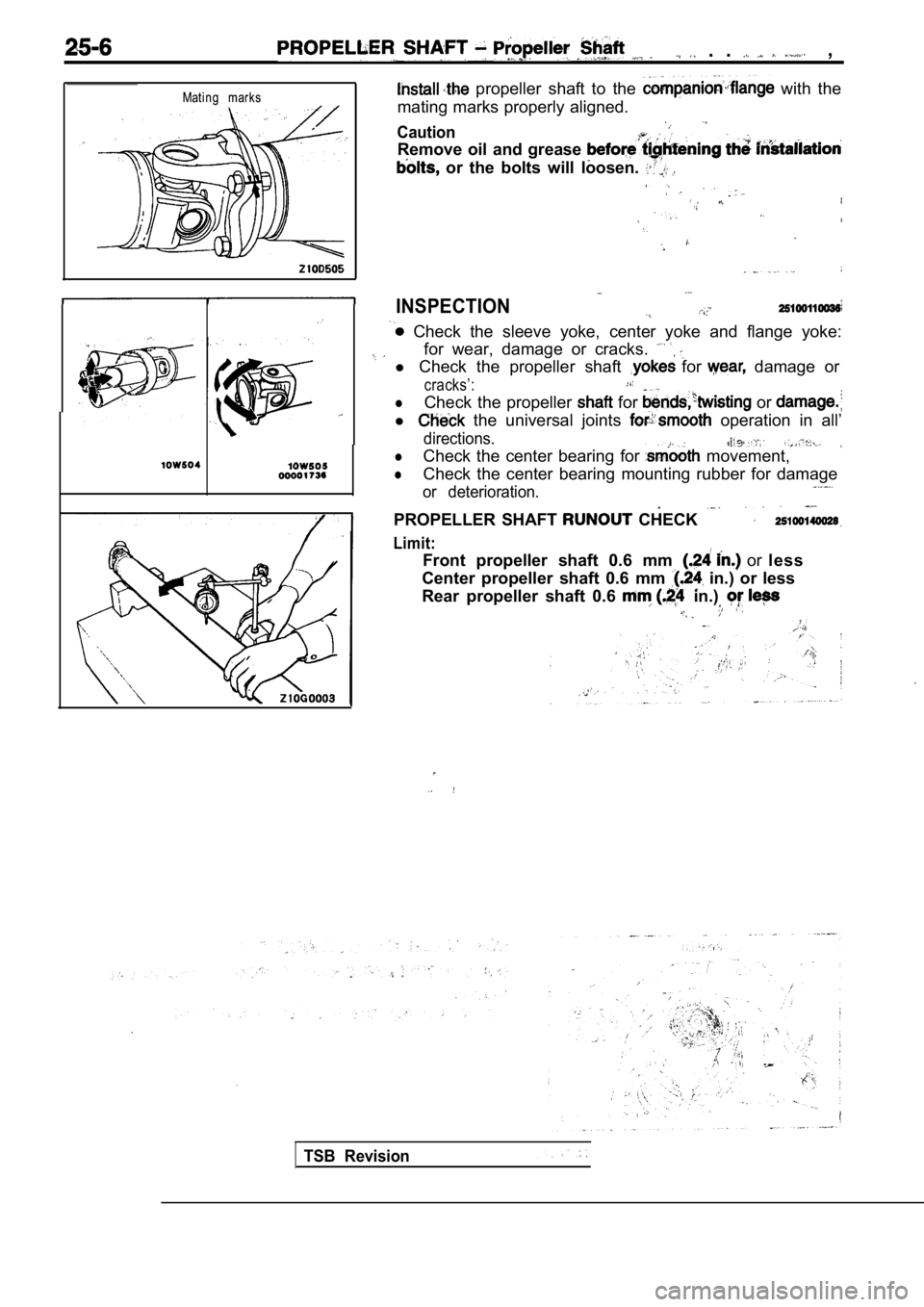

Mating marks

propeller shaft to the with the

mating marks properly aligned.

Caution

Remove oil and grease

or the bolts will loosen.

INSPECTION

Check the sleeve yoke, center yoke and flange yoke :

for wear, damage or cracks.

l Check the propeller shaft for damage or

cracks’:

lCheck the propeller for or

l the universal joints operation in all’

directions.

lCheck the center bearing for movement,

lCheck the center bearing mounting rubber for damage

or deterioration..

PROPELLER SHAFT CHECK

Limit:

Front propeller shaft 0.6 mm or less

Center propeller shaft 0.6 mm

in.) or less

Rear propeller shaft 0.6

in.)

TSB Revision

Page 1497 of 2103

PROPELLER SHAFT Propeller Shaft

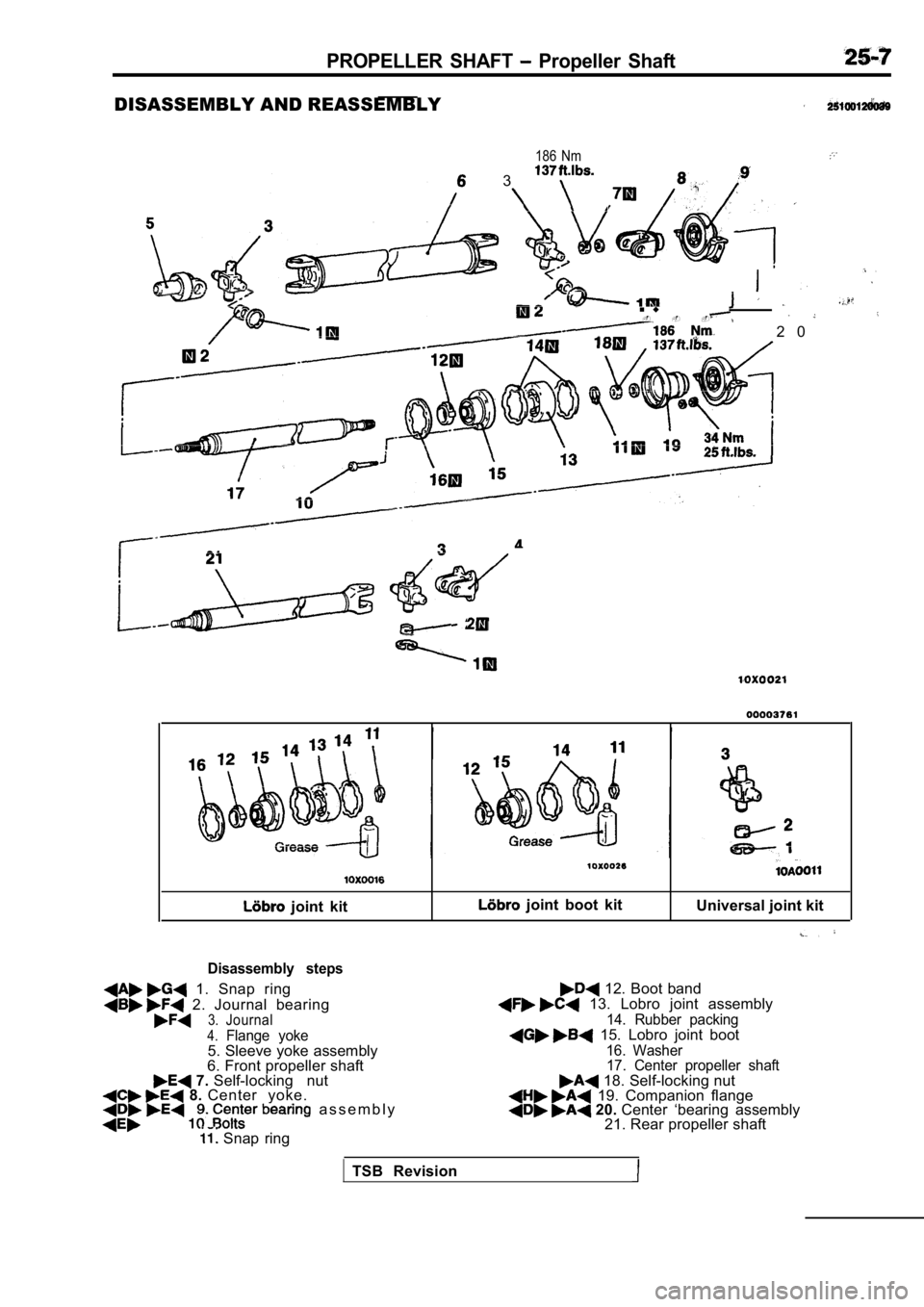

DISASSEMBLY AND REASSEMBLY

186 Nm

3

n u- - -

2 0

21

joint kit joint boot kitUniversal joint kit

Disassembly steps

1. Snap ring

2. Journal bearing3.Journal

4.Flange yoke5. Sleeve yoke assembly

6. Front propeller shaft

7. Self-locking nut 8. Center yoke. a s s e m b l y

Snap ring

12. Boot band 13. Lobro joint assembly

14. Rubber packing 15. Lobro joint boot

16. Washer

17. Center propeller shaft

18. Self-locking nut 19. Companion flange 20. Center ‘bearing assembly

21. Rear propeller shaft

TSB Revision

Page 1498 of 2103

25-8PROPELLER SHAFT ‘Propeller

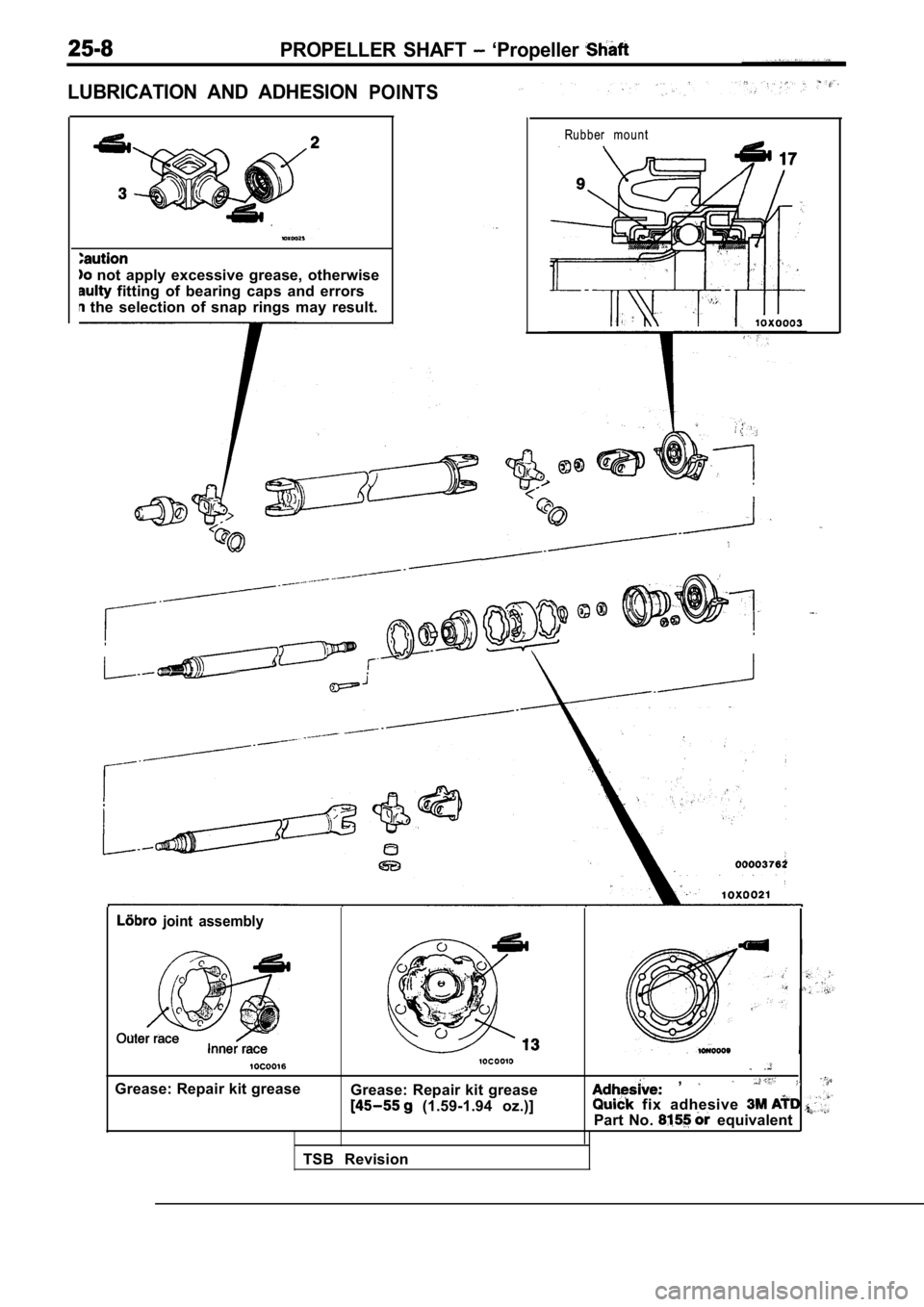

LUBRICATION AND ADHESIONPOINTS

not apply excessive grease, otherwise

fitting of bearing caps and errors

the selection of snap rings may result.

Rubber mount

joint assembly

Grease: Repair kit greaseGrease: Repair kit grease

(1.59-1.94 oz.)]

,

fix adhesive

Part No. equivalent

TSB Revision

Page 1499 of 2103

PROPELLER SHAFT Propeller, Shaft

J o u r n a l

I

Mating

Cen t er

\I

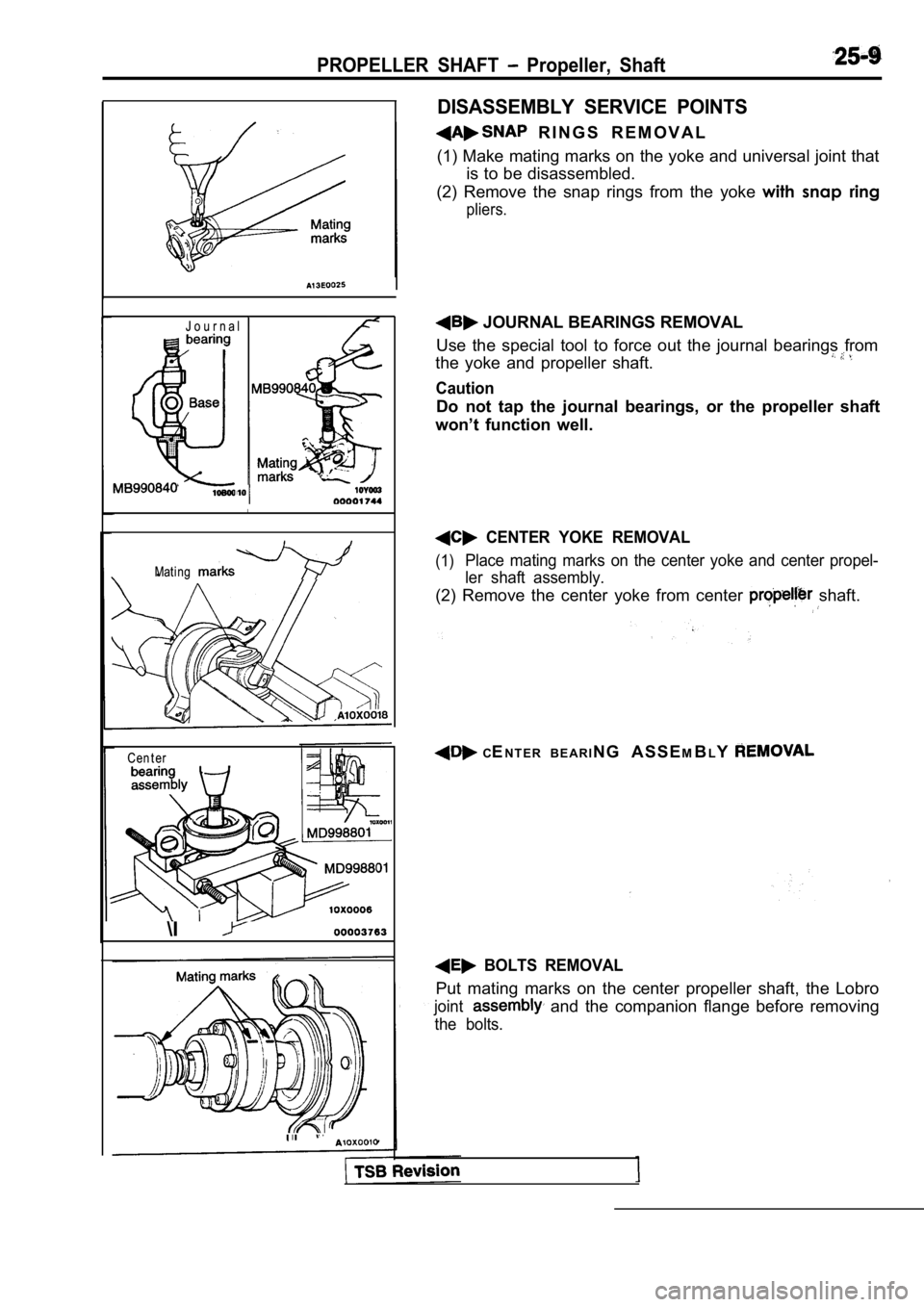

DISASSEMBLY SERVICE POINTS

R I N G S R E M O V A L

(1) Make mating marks on the yoke and universal joi nt that

is to be disassembled.

(2) Remove the snap rings from the yoke with snap ring

pliers.

JOURNAL BEARINGS REMOVAL

Use the special tool to force out the journal beari ngs from

the yoke and propeller shaft.

Caution

Do not tap the journal bearings, or the propeller s haft

won’t function well.

CENTER YOKE REMOVAL

(1)Place mating marks on the center yoke and center pr opel-

ler shaft assembly.

(2) Remove the center yoke from center shaft.

C EN T E R B E A R I N G A S S E MB LY

BOLTS REMOVAL

Put mating marks on the center propeller shaft, the Lobro

joint and the companion flange before removing

the bolts.

Page 1500 of 2103

PROPELLER SHAFT Shaft

Mat i n g m ar k s

Inner race

Cag e

Cag e

Lbbro ioint

Plastic

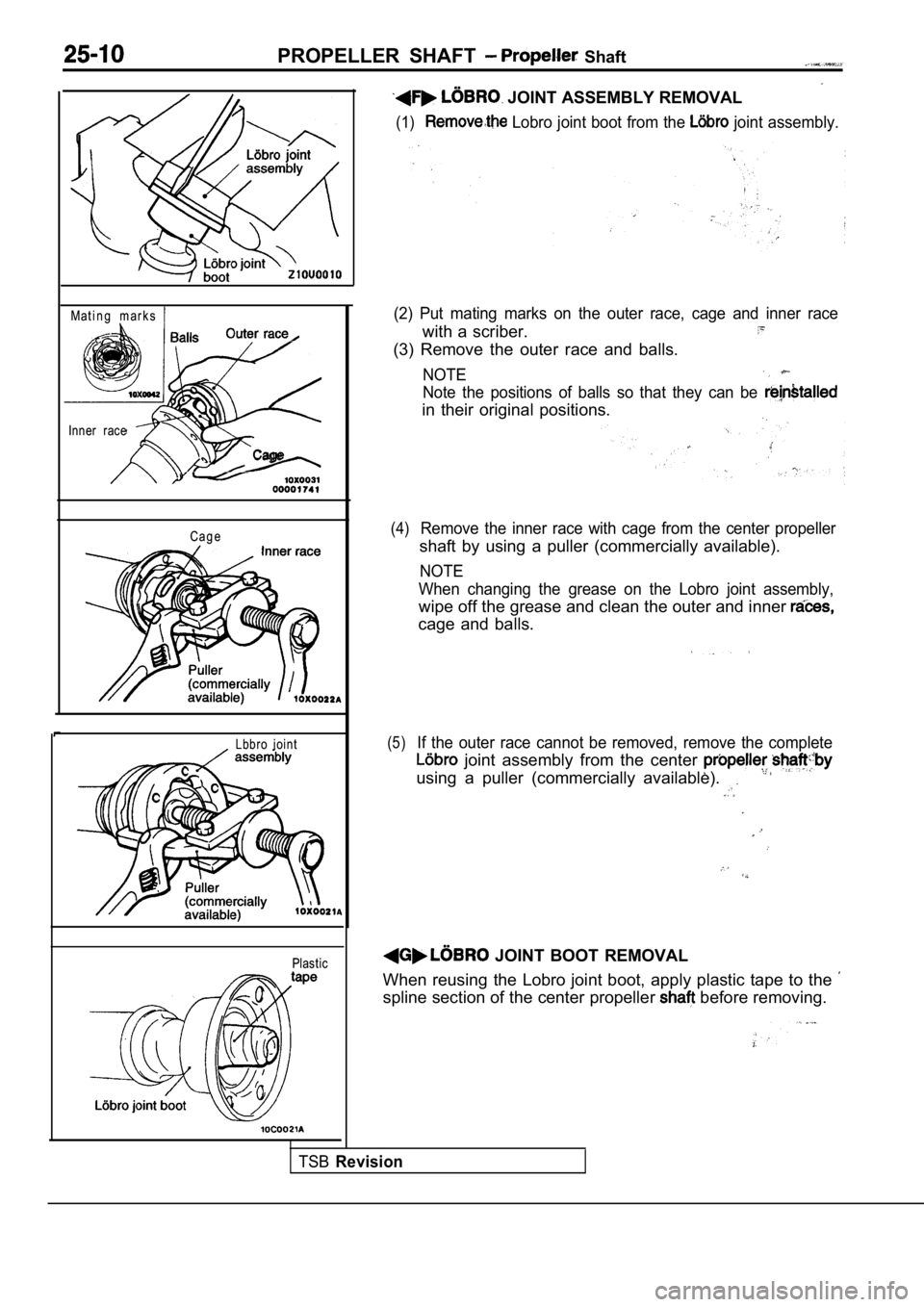

JOINT ASSEMBLY REMOVAL

(1) Lobro joint boot from the joint assembly.

(2) Put mating marks on the outer race, cage and in ner race

with a scriber.

(3) Remove the outer race and balls.

NOTE

Note the positions of balls so that they can be

in their original positions.

(4)Remove the inner race with cage from the center propeller

shaft by using a puller (commercially available).

NOTE

When changing the grease on the Lobro joint assembl y,

wipe off the grease and clean the outer and inner

cage and balls.

(5)If the outer race cannot be removed, remove the complete

joint assembly from the center

using a puller (commercially available).

JOINT BOOT REMOVAL

When reusing the Lobro joint boot, apply plastic ta pe to the

spline section of the center propeller before removing.

TSBRevision

Trending: check transmission fluid, fuel, battery replacement, tires, steering, height, low beam