MITSUBISHI SPYDER 1990 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1501 of 2103

S H A F T

Plastic

F L A N G E R E M O V A L

Put mating marks on the companion ‘flange and rear,

propeller shaft before removing the companion

SERVICE”

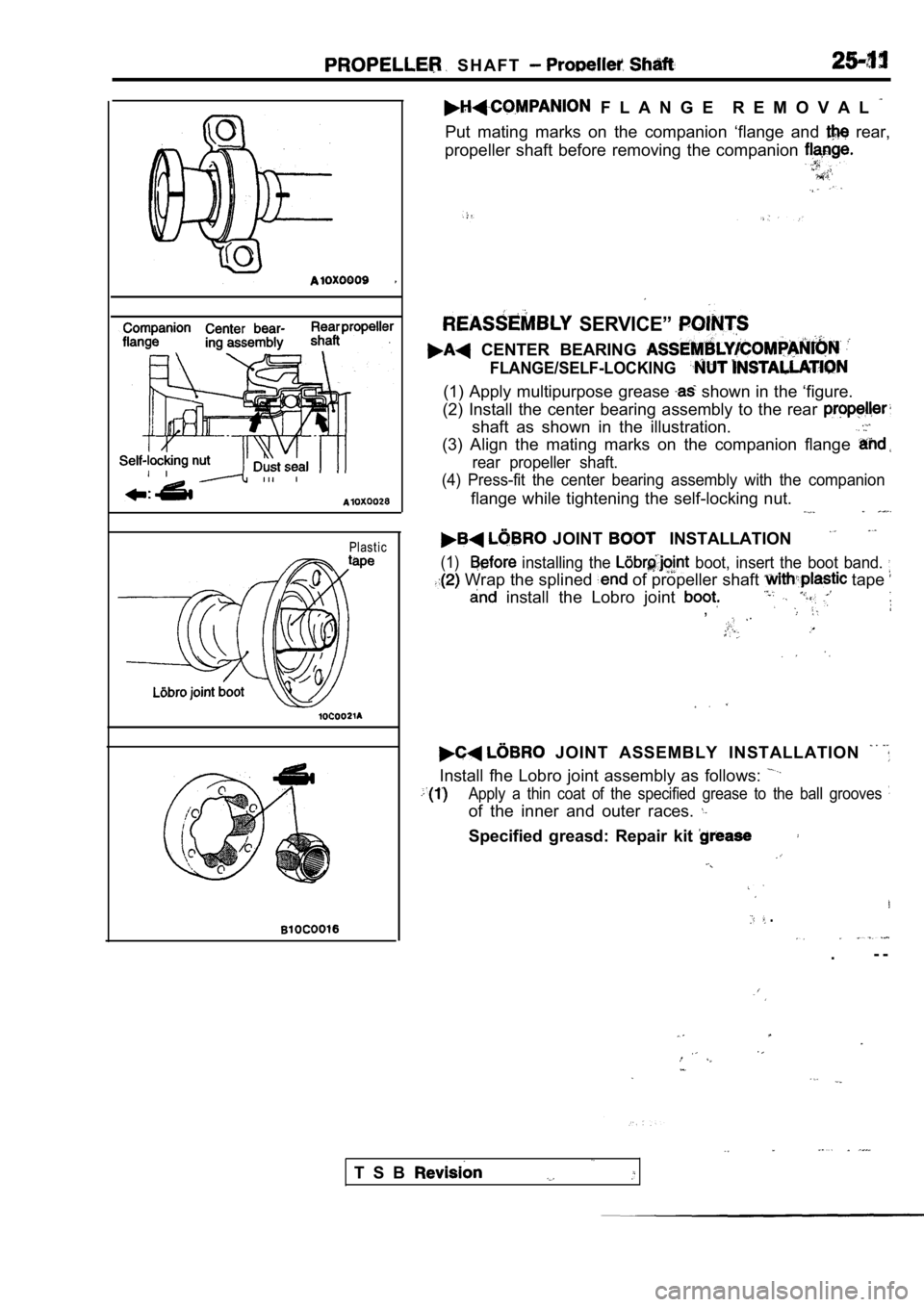

CENTER BEARING

FLANGE/SELF-LOCKING

(1) Apply multipurpose grease shown in the ‘figure.

(2) Install the center bearing assembly to the rear

shaft as shown in the illustration.

(3) Align the mating marks on the companion flange

rear propeller shaft.

(4) Press-fit the center bearing assembly with the companion

flange while tightening the self-locking nut.

JOINT INSTALLATION

(1) installing the boot, insert the boot band.

Wrap the splined of propeller shaft tape

install the Lobro joint ,

JOINT ASSEMBLY INSTALLATION

Install fhe Lobro joint assembly as follows:

Apply a thin coat of the specified grease to the ba ll grooves

of the inner and outer races.

Specified greasd: Repair kit

.

. - -

T S B

Page 1502 of 2103

PROPELLER

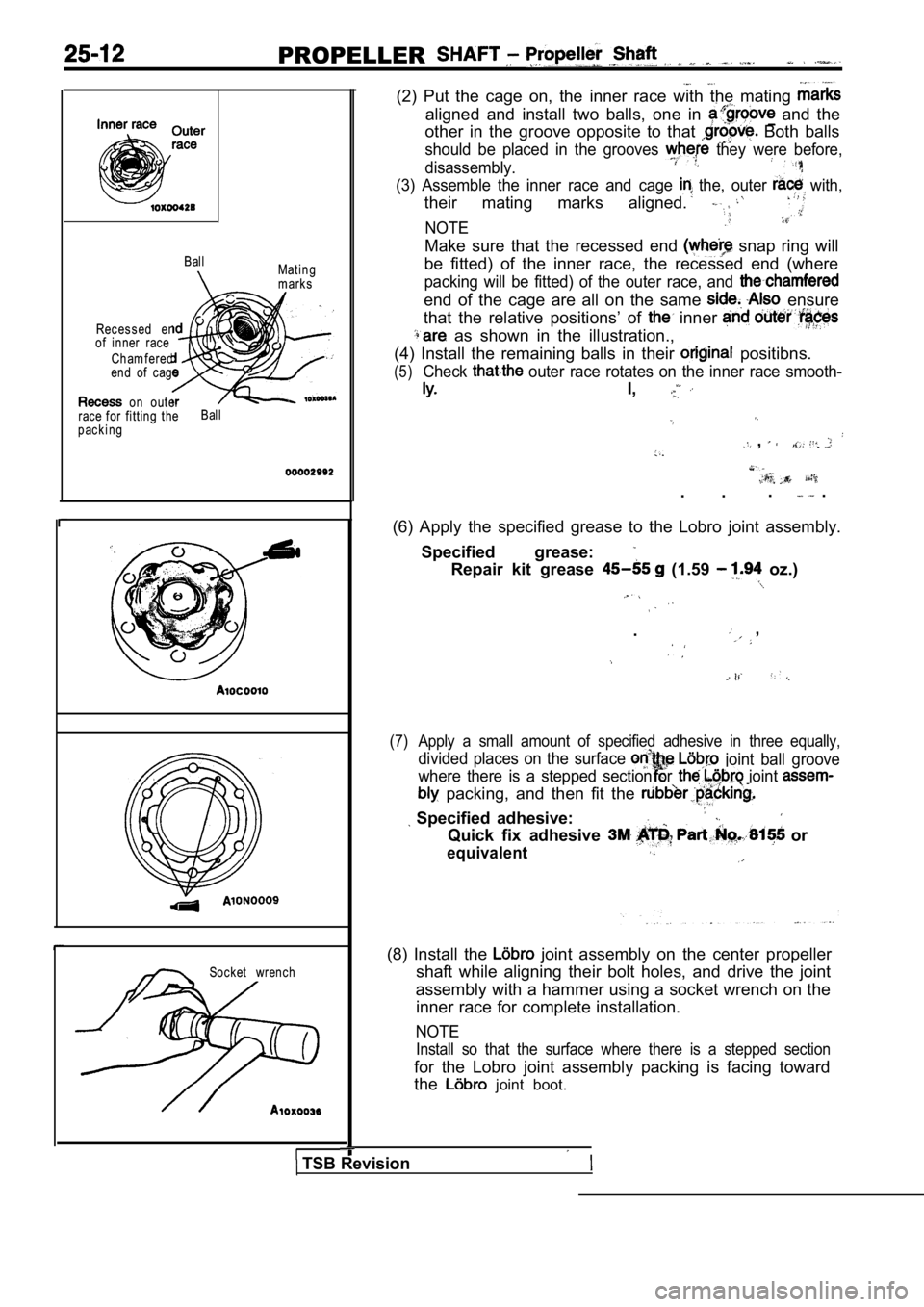

BallMating

marks

Rec es s ed end

of inner race

Chamferedend of cage

on outer

race for fitting the Ball

packing

Socket wrench

(2) Put the cage on, the inner race with the mating

aligned and install two balls, one in and the

other in the groove opposite to that

Both balls

should be placed in the grooves they were before,

disassembly.

(3) Assemble the inner race and cage the, outer with,

their mating marks aligned.

NOTE

Make sure that the recessed end snap ring will

be fitted) of the inner race, the recessed end (whe re

packing will be fitted) of the outer race, and

end of the cage are all on the same ensure

that the relative positions’ of

inner

as shown in the illustration.,

(4) Install the remaining balls in their

positibns.

(5)Check outer race rotates on the inner race smooth-

I,

,

. . . .

(6) Apply the specified grease to the Lobro joint a ssembly.

Specified grease:

Repair kit grease (1.59 oz.)

. ,

(7) Apply a small amount of specified adhesive in th ree equally,

divided places on the surface joint ball groove

where there is a stepped section or

joint

packing, and then fit the

Specified adhesive:

Quick fix adhesive or

equivalent

(8) Install the joint assembly on the center propeller

shaft while aligning their bolt holes, and drive th e joint

assembly with a hammer using a socket wrench on the inner race for complete installation.

NOTE

Install so that the surface where there is a steppe d section

for the Lobro joint assembly packing is facing towa rd

the

joint boot.

TSB Revision

Page 1503 of 2103

P R O P E L L E R S H A F T Propeller Shaft

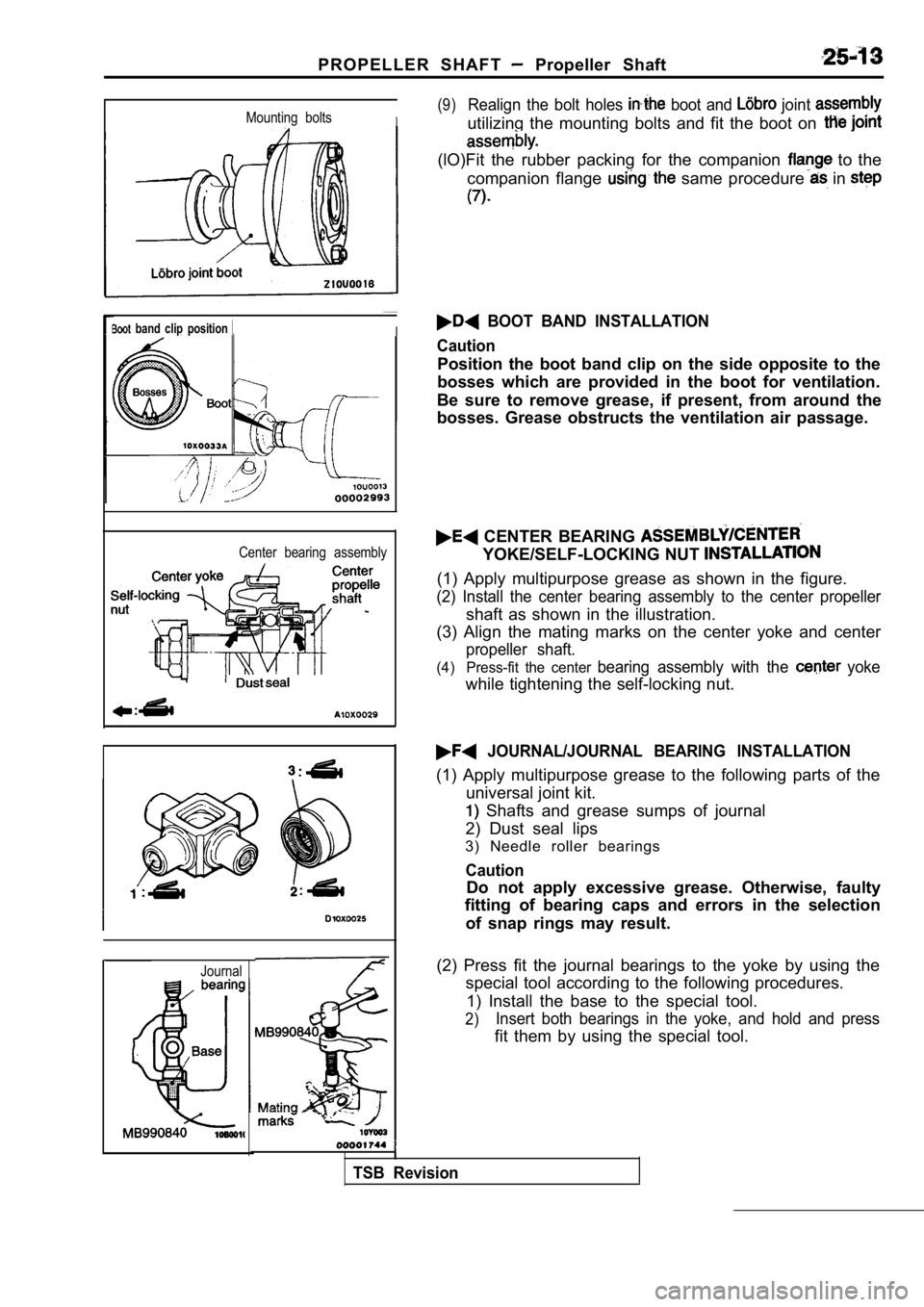

Mounting boltsI

band clip position I

Center bearing assembly

Journal

(9)Realign the bolt holes boot and joint

utilizing the mounting bolts and fit the boot on

(lO)Fit the rubber packing for the companion to the

companion flange

same procedure in

BOOT BAND INSTALLATION

Caution

Position the boot band clip on the side opposite to the

bosses which are provided in the boot for ventilati on.

Be sure to remove grease, if present, from around t he

bosses. Grease obstructs the ventilation air passag e.

CENTER BEARING

YOKE/SELF-LOCKING NUT

(1) Apply multipurpose grease as shown in the figure.

(2) Install the center bearing assembly to the center propeller

shaft as shown in the illustration.

(3) Align the mating marks on the center yoke and c enter

propeller shaft.

(4) Press-fit the center bearing assembly with the yoke

while tightening the self-locking nut.

JOURNAL/JOURNAL BEARING INSTALLATION

(1) Apply multipurpose grease to the following parts of the

universal joint kit.

Shafts and grease sumps of journal

2) Dust seal lips

3) Needle roller bearings

Caution

Do not apply excessive grease. Otherwise, faulty

fitting of bearing caps and errors in the selection

of snap rings may result.

(2) Press fit the journal bearings to the yoke by u sing the

special tool according to the following procedures.

1) Install the base to the special tool.

2)Insert both bearings in the yoke, and hold and pres s

fit them by using the special tool.

TSB Revision

Page 1504 of 2103

PROPELLER SHAFT Propeller Shaft

Balls

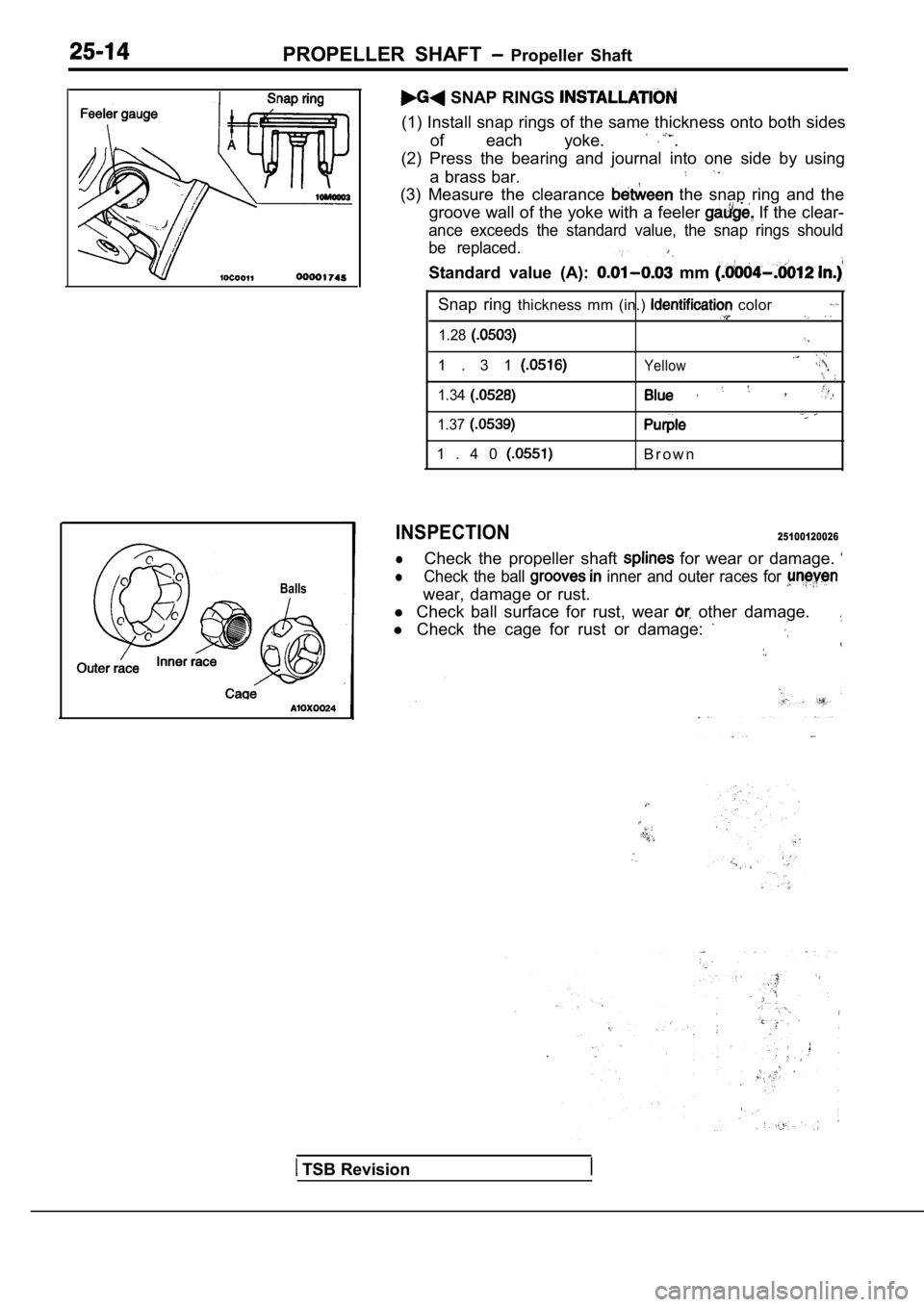

SNAP RINGS

(1) Install snap rings of the same thickness onto both sides

of each yoke. .

(2) Press the bearing and journal into one side by using

a brass bar.

(3) Measure the clearance the snap ring and the

groove wall of the yoke with a feeler

If the clear-

ance exceeds the standard value, the snap rings sho uld

be replaced.

Standard value (A): mm

Snap ring thickness mm (in.) color

1.28

1 . 3 1Yellow

1.34 ,

1.37

1 . 4 0B r o w n

INSPECTION25100120026

l

lCheck the propeller shaft for wear or damage.

Check the ball inner and outer races for

wear, damage or rust.

l Check ball surface for rust, wear

other damage.

l Check the cage for rust or damage:

TSB Revision

Page 1505 of 2103

FRONT AXLE

CONTENTS

DRIVE SHAFT 10ON-VEHICLE SERVICE. . . . . . . . . . . . . . . . . . . . .5. . . . . . . . . . . . . . . . . . . .Hub

Replacement. . . . . . . . . . . . . . . . . . . . . . .5

DRIVE SHAFT . . . . . . . . . . . . . . . . . . . .19Wheel Bearing End Play Check . . . . . . . . . . . . . . .5

FRONT HUB ASSEMBLY. . . . . . . . . . . . . . . . . . .6SERVICE SPECIFICATIONS. . . . . . . . . . . . . . . . .2

GENERAL INFORMATION. . . . . . . . . . . . . . . . . .2SPECIAL TOOLS. . . . . . . . . . . . . . . . . . . . . . . . . . .3

KNUCKLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . .4

LUBRICANTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Page 1506 of 2103

GENERAL INFORMATION

FRONT AXLE General Specification/Lubricants

The front axle consists of a knuckle, front hub,

unit bearing and drive shaft, The unit bearing is has a tripod joint (T.J.) on the transaxle side and

press-fitted to the front hub and bolted to the a

joint

(B.J.) on the wheel side. A center

kunckle. Also, the unit

utilizes a double bearing and an inner been adopted

in some models.

row angular contact ball bearing. The drive shaft

CONSTRUCTION DIAGRAM

Knuckle

inner

Drive shaft

hub

Standard valueLimit

Setting of boot length mm (in.)

Opening dimension of the When the band (small) is 2.9

special tool mm crimped

(in.)When the band (big) is

crimped3.2

Crimped width of the band mm (in.)2.4 2.8

Clearance between the (larger diameter side) 0.1 1.55

and the stepped phase of the B.J. housing mm (in.).

Wheel bearing end play mm (in.)0.05

Wheel bearing breakaway torque Nm 1 (9) or less

SERVICE SPECIFICATIONS

LUBRICANTS

Quantity (oz.) Specified lubricant

Inner

Outer dust sealFWD

Engine (Non-turbo)>105 (3.70)Repair kit grease

FWD

Engine (Turbo) and Engine>120 (4.23)

AWD

. grease

FWD Engine (Non-turbo)>110 (3.88) Repair kit grease

FWD Engine (Turbo) 130 .

AWD95 (3.35)

TSB Revision

Page 1507 of 2103

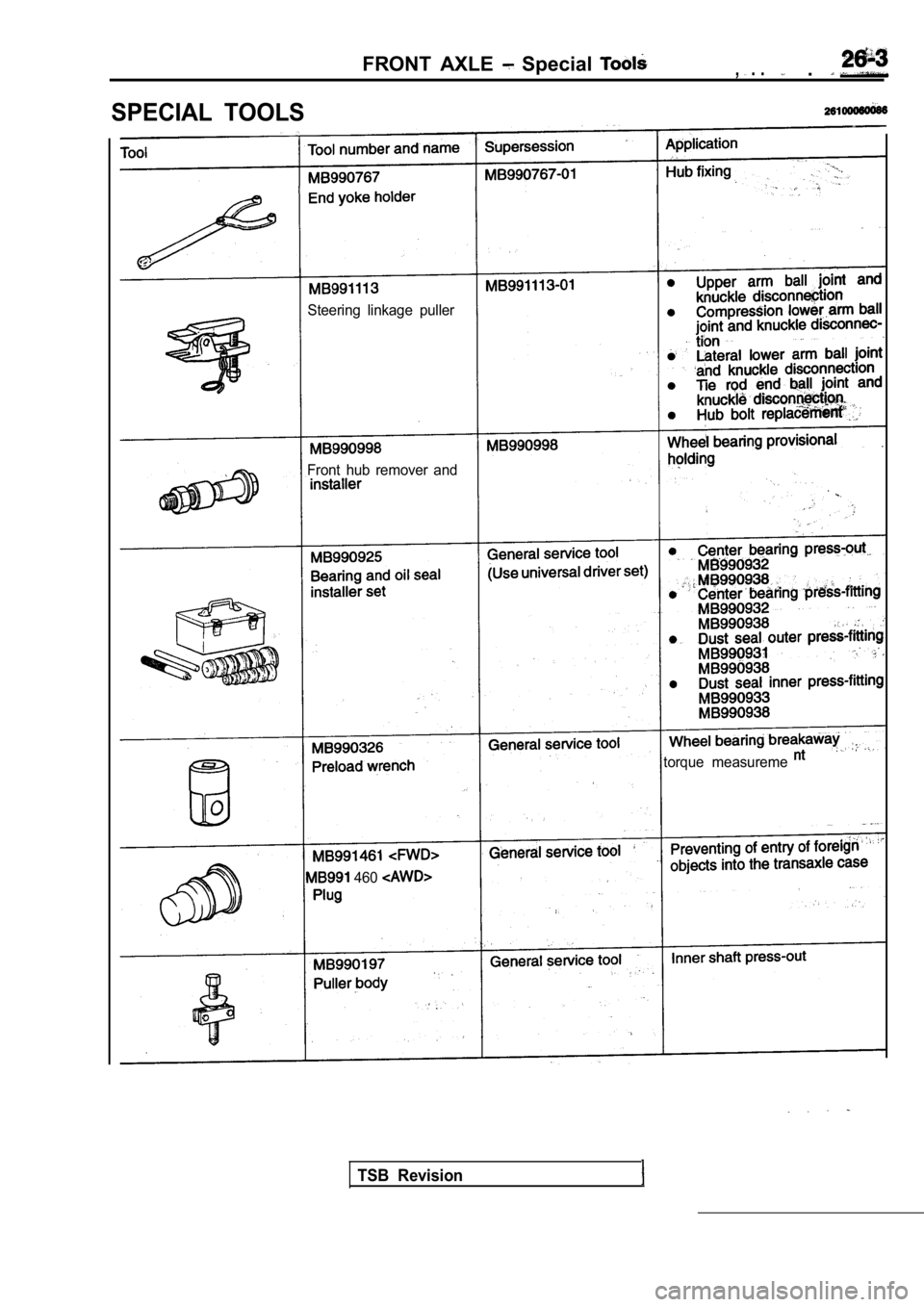

SPECIAL TOOLS

FRONT AXLE Special , . . .

Steering linkage puller

Front hub remover and

torque measureme

460

TSB Revision

Page 1508 of 2103

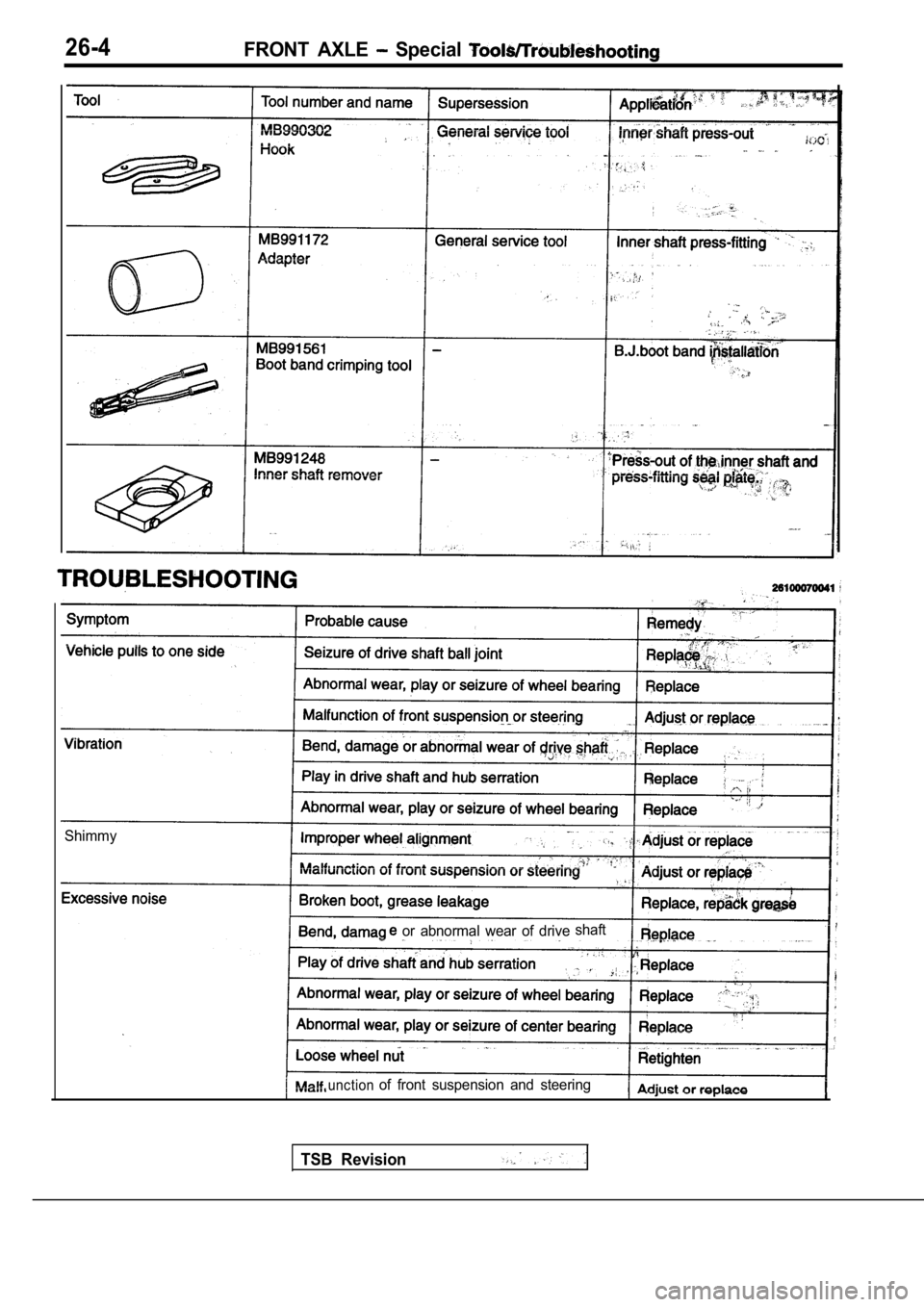

26-4FRONT AXLE Special

Shimmy

or abnormal wear of driveshaft

unctionof front suspension and steering

TSB Revision

Page 1509 of 2103

I

8990767

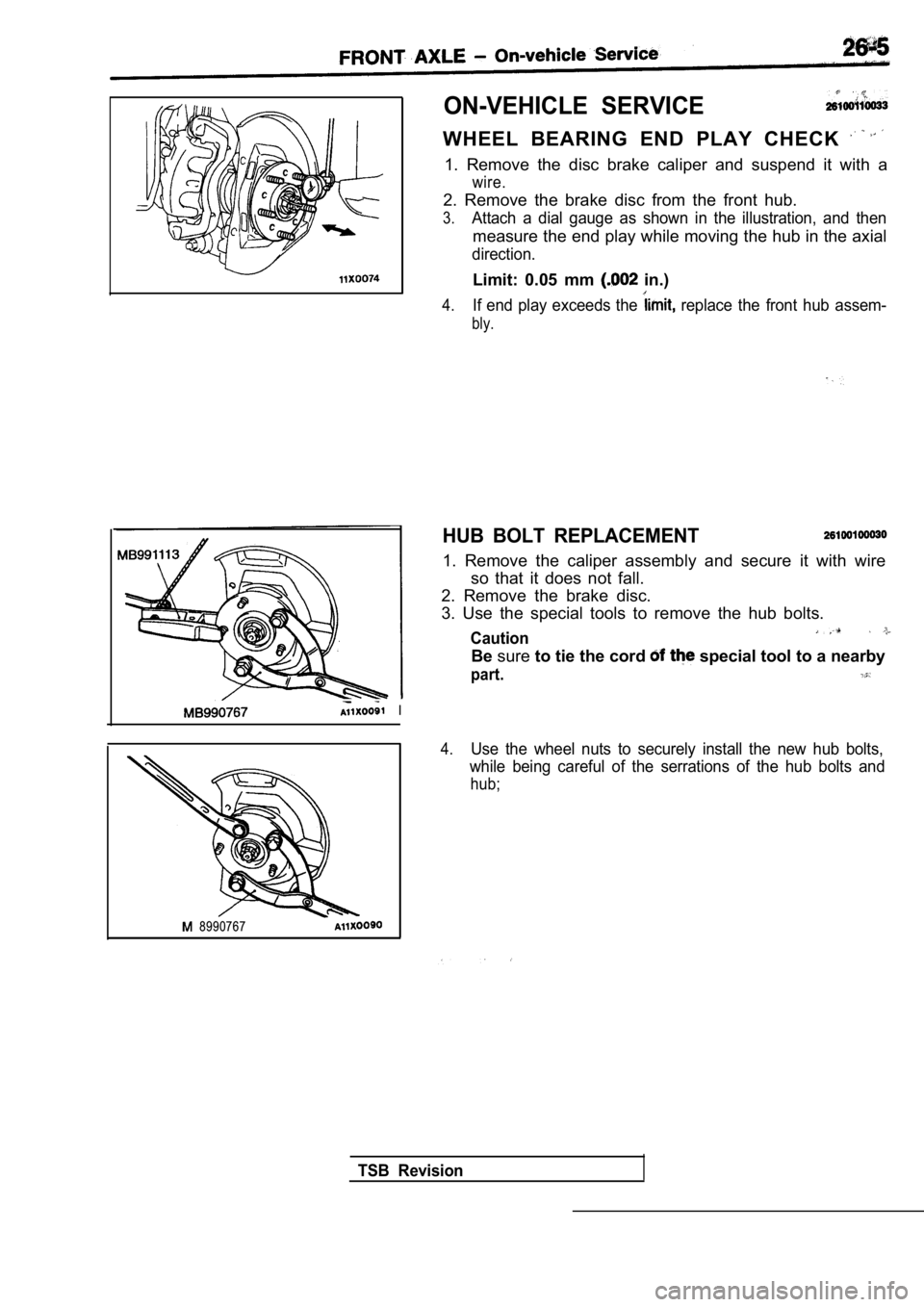

ON-VEHICLE SERVICE

WHEEL BEARING END PLAY CHECK

1. Remove the disc brake caliper and suspend it with a

wire.

2. Remove the brake disc from the front hub.

3.Attach a dial gauge as shown in the illustration, and then

measure the end play while moving the hub in the ax ial

direction.

Limit: 0.05 mm in.)

4.If end play exceeds the replace the front hub assem-

bly.

HUB BOLT REPLACEMENT

1. Remove the caliper assembly and secure it with w ire

so that it does not fall.

2. Remove the brake disc.

3. Use the special tools to remove the hub bolts.

Caution

Be sure to tie the cord special tool to a nearby

part.

4.Use the wheel nuts to securely install the new hub bolts,

while being careful of the serrations of the hub bo lts and

hub;

TSB Revision

Page 1510 of 2103

26-6FRONT AXLE Front

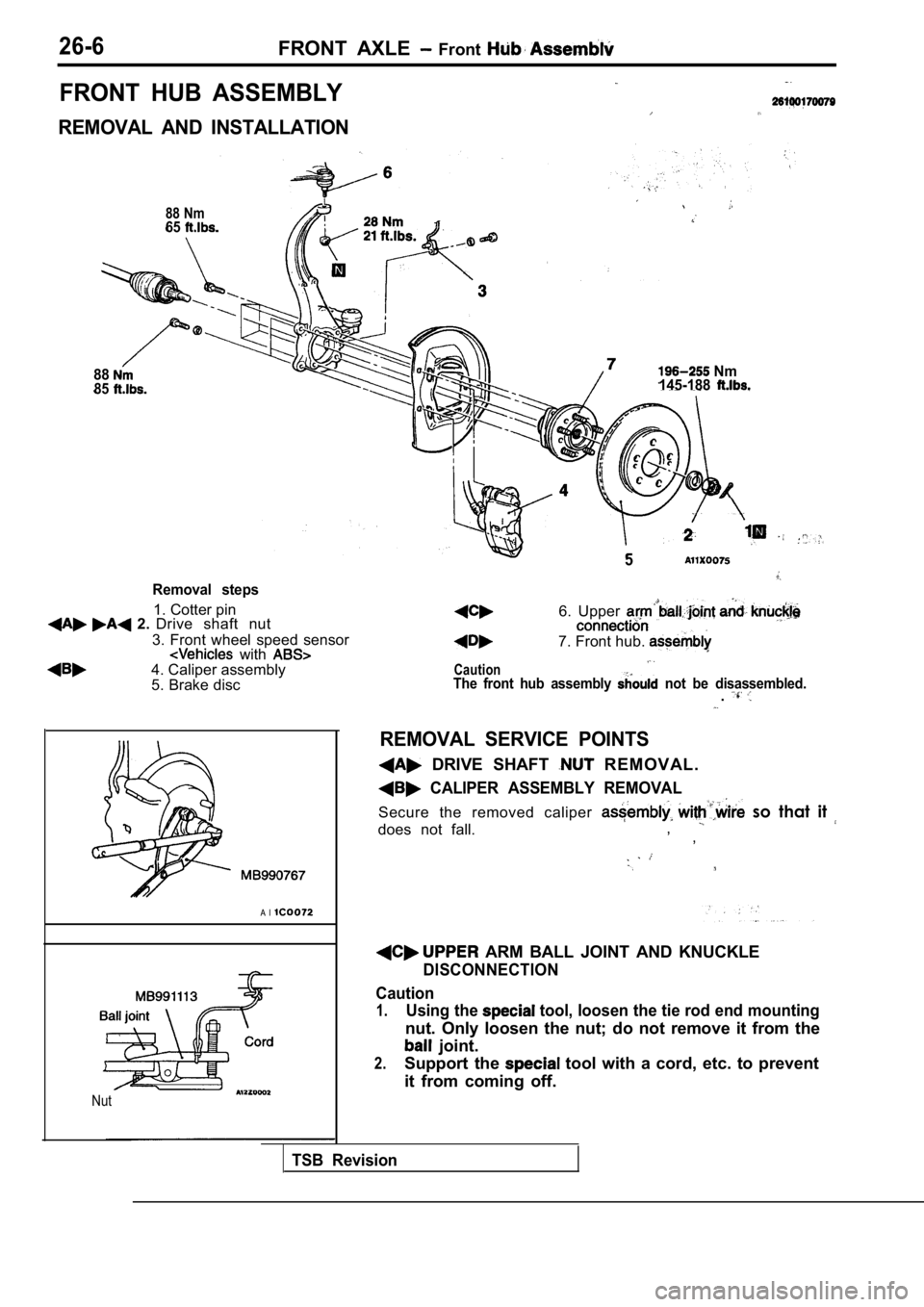

FRONT HUB ASSEMBLY

REMOVAL AND INSTALLATION

88 Nm65

8885

Removal steps

1. Cotter pin 2. Drive shaft nut

3. Front wheel speed sensor

with 4. Caliper assembly

5. Brake disc

A l

Nut

Nm

145-188

5

Caution

6. Upper

7. Front hub.

The front hub assembly not be disassembled..

REMOVAL SERVICE POINTS

DRIVE SHAFT R E M O V A L .

CALIPER ASSEMBLY REMOVAL

Secure the removed caliper so that it

does not fall., ,

ARM BALL JOINT AND KNUCKLE

DISCONNECTION

Caution

1.Using the tool, loosen the tie rod end mounting

nut. Only loosen the nut; do not remove it from the

joint.

2.Support the tool with a cord, etc. to prevent

it from coming off.

TSB Revision