MITSUBISHI SPYDER 1990 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1551 of 2103

REAR AXLE On-vehicle Service

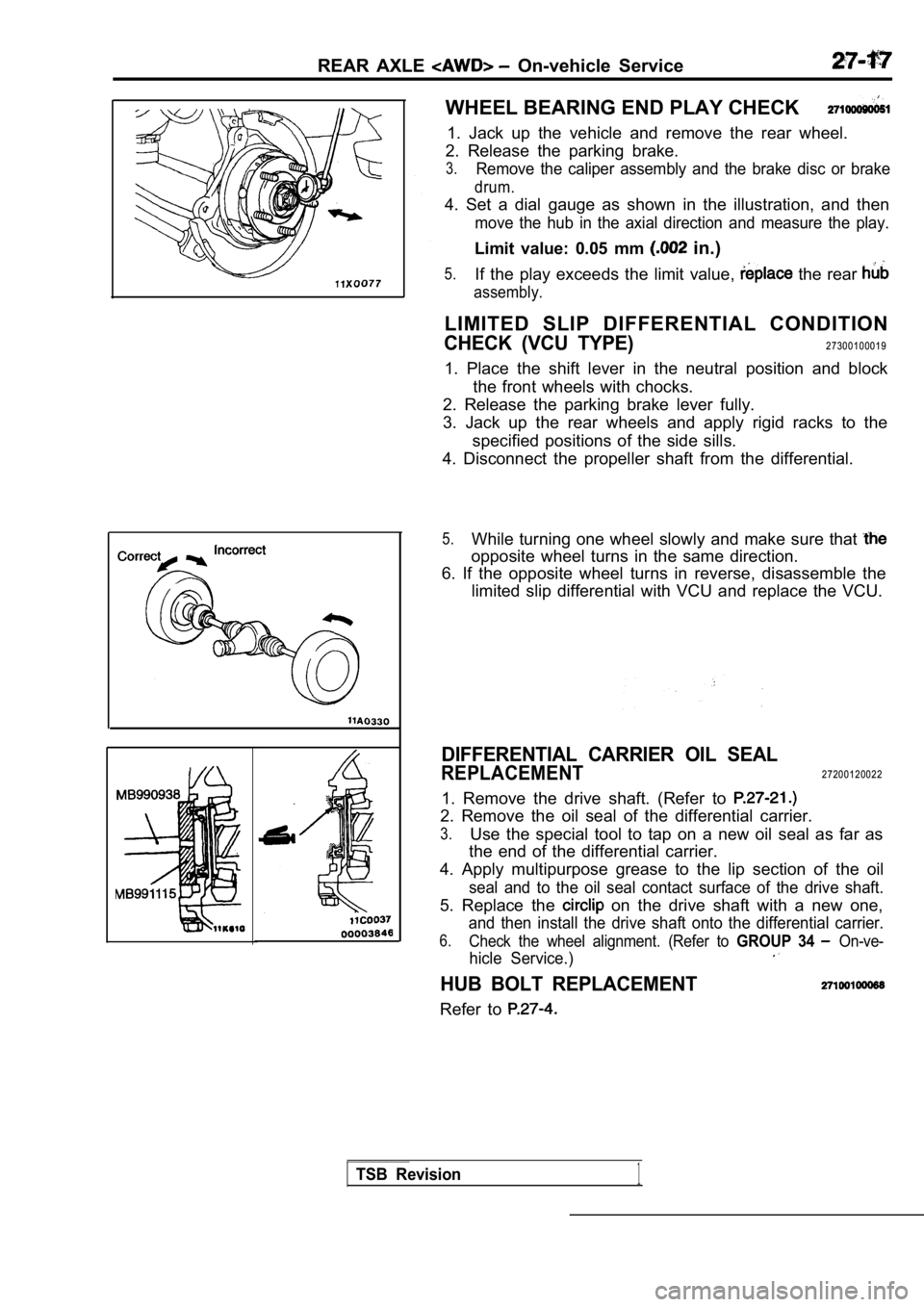

WHEEL BEARING END PLAY CHECK

1. Jack up the vehicle and remove the rear wheel.

2. Release the parking brake.

3.Remove the caliper assembly and the brake disc or b rake

drum.

4. Set a dial gauge as shown in the illustration, and then

move the hub in the axial direction and measure the play.

Limit value: 0.05 mm in.)

5.If the play exceeds the limit value, the rear

assembly.

LIMITED SLIP DIFFERENTIAL CONDITION

CHECK (VCU TYPE)27300100019

1. Place the shift lever in the neutral position an d block

the front wheels with chocks.

2. Release the parking brake lever fully.

3. Jack up the rear wheels and apply rigid racks to the

specified positions of the side sills.

4. Disconnect the propeller shaft from the differen tial.

5.While turning one wheel slowly and make sure that

opposite wheel turns in the same direction.

6. If the opposite wheel turns in reverse, disassem ble the

limited slip differential with VCU and replace the VCU.

DIFFERENTIAL CARRIER OIL SEAL

REPLACEMENT27200120022

1. Remove the drive shaft. (Refer to

2. Remove the oil seal of the differential carrier.

3.Use the special tool to tap on a new oil seal as fa r as

the end of the differential carrier.

4. Apply multipurpose grease to the lip section of the oil

seal and to the oil seal contact surface of the drive shaft.

5. Replace the on the drive shaft with a new one,

and then install the drive shaft onto the differential carrier.

6.Check the wheel alignment. (Refer to GROUP 34 On-ve-

hicle Service.)

HUB BOLT REPLACEMENT

Refer to

TSB Revision1

Page 1552 of 2103

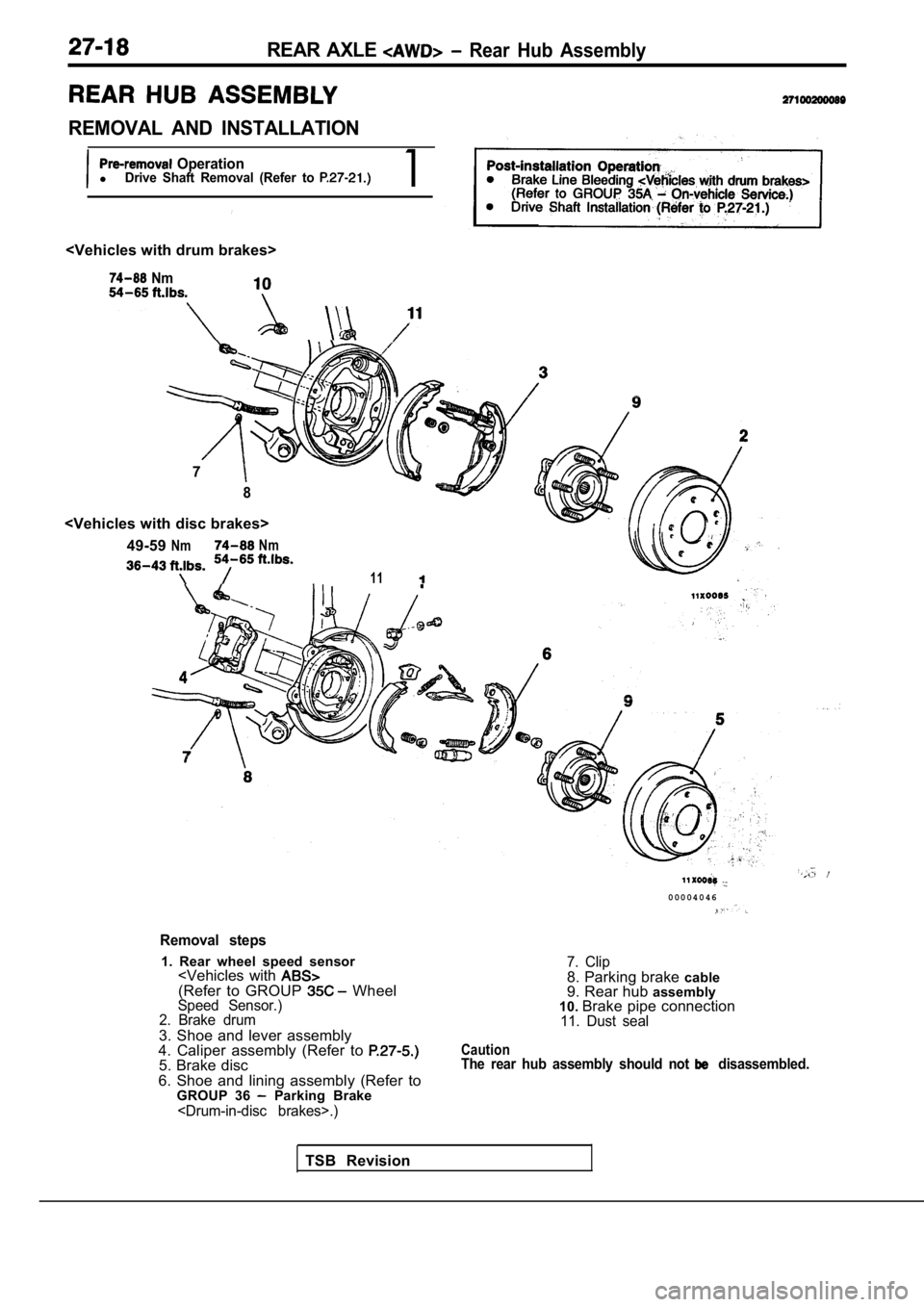

REAR AXLE Rear Hub Assembly

REMOVAL AND INSTALLATION

OperationlDrive Shaft Removal (Refer to 1

Nm

7

8

NmNm

11

Removal steps

1. Rear wheel speed sensor

2. Brake drum

3. Shoe and lever assembly

4. Caliper assembly (Refer to

5. Brake disc

6. Shoe and lining assembly (Refer to GROUP 36

Parking Brake

0 0 0 0 4 0 4 6

7. Clip8. Parking brake cable

9. Rear hub assembly

10. Brake pipe connection

11. Dust seal

CautionThe rear hub assembly should not disassembled.

TSB Revision

Page 1553 of 2103

REAR AXLE Rear Assembly

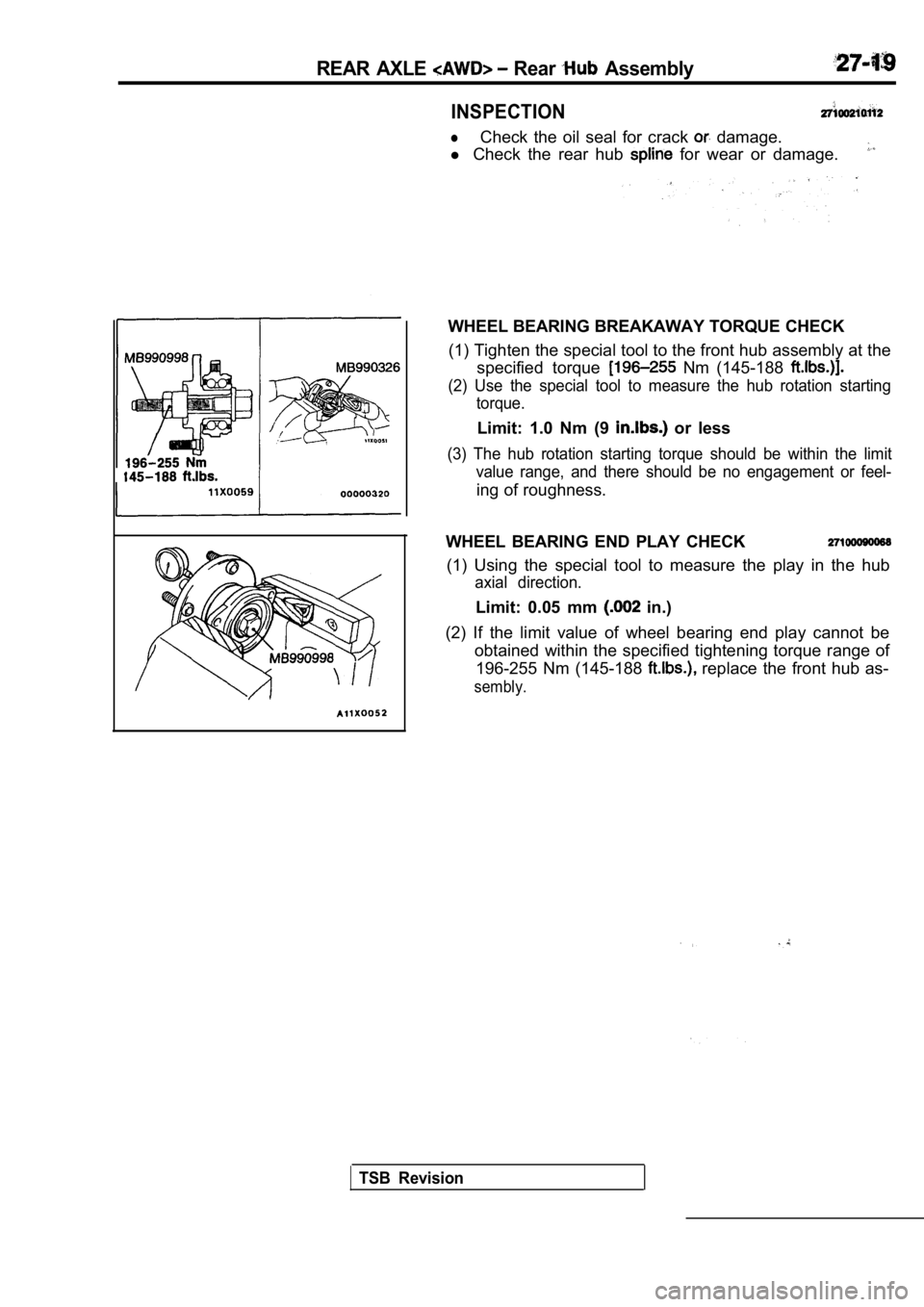

INSPECTION

lCheck the oil seal for crack damage.

l Check the rear hub

for wear or damage.

WHEEL BEARING BREAKAWAY TORQUE CHECK

(1) Tighten the special tool to the front hub assem bly at the

specified torque

Nm (145-188

(2) Use the special tool to measure the hub rotatio n starting

torque.

Limit: 1.0 Nm (9 or less

(3) The hub rotation starting torque should be with in the limit

value range, and there should be no engagement or f eel-

ing of roughness.

WHEEL BEARING END PLAY CHECK

(1) Using the special tool to measure the play in t he hub

axial direction.

Limit: 0.05 mm in.)

(2) If the limit value of wheel bearing end play ca nnot be

obtained within the specified tightening torque ran ge of

196-255 Nm (145-188

replace the front hub as-

sembly.

TSB Revision

Page 1554 of 2103

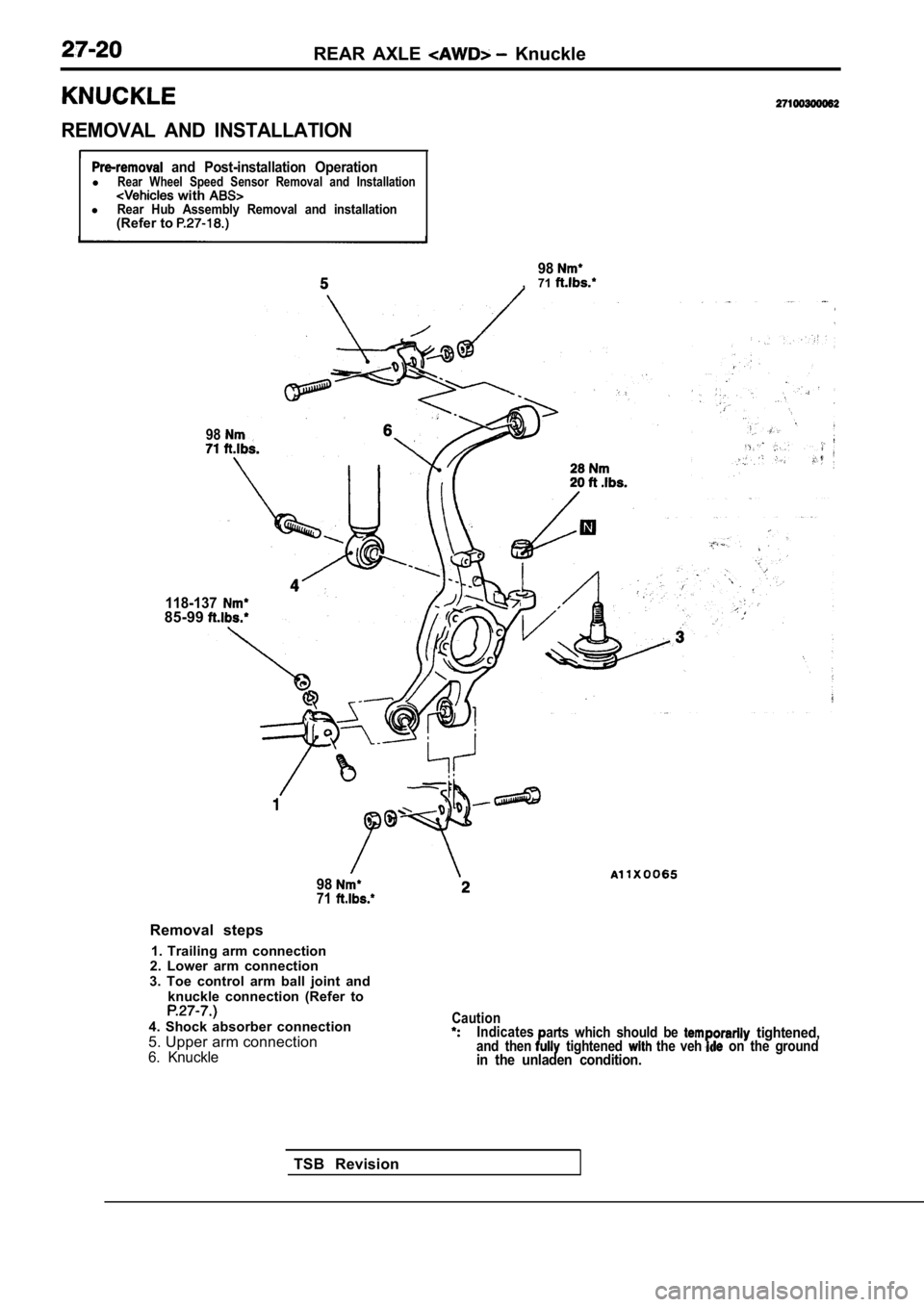

REAR AXLE Knuckle

REMOVAL AND INSTALLATION

II and Post-installation OperationlRear Wheel Speed Sensor Removal and Installation with lRear Hub Assembly Removal and installation(Refer to

98, 71

98

118-13785-99

TSB Revision

9871

Removal steps

1. Trailing arm connection

2. Lower arm connection

3. Toe control arm ball joint and knuckle connection (Refer to

4. Shock absorber connection

5. Upper arm connection

6. Knuckle

CautionIndicates

and thenarts which should be tightened, tightened the veh on the groundin the unladen condition.

Page 1555 of 2103

REAR AXLE Drive

2 7 1 0 0 3 3 0 0 2 3

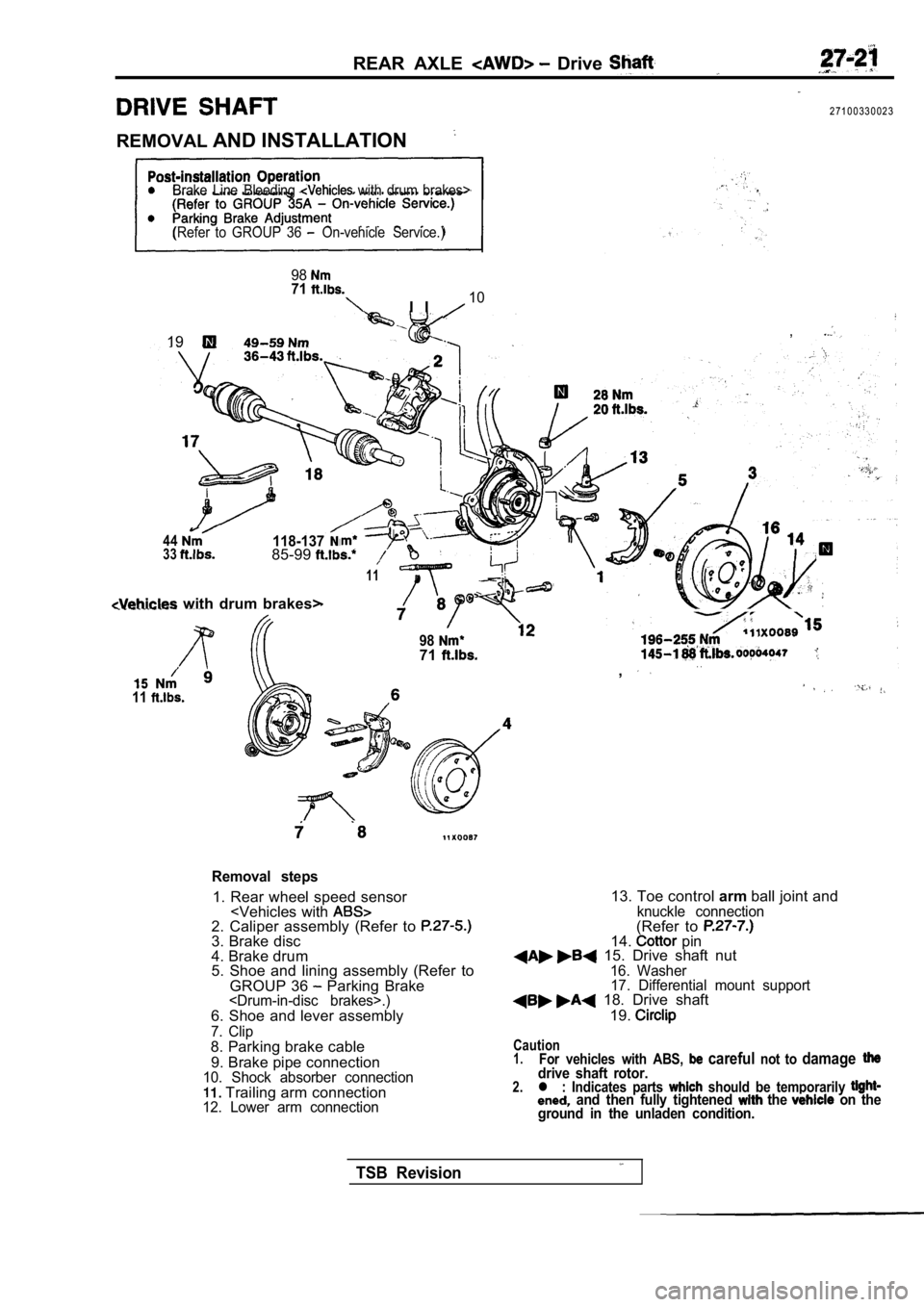

REMOVAL AND INSTALLATION

Brake Line Bleeding with drum brakes>

(Refer to GROUP 36

On-vehicle Service.)

9871

I I10

,19

44118-1373385-99

11

with drum brakes>

11

9871. .,

Removal steps

1. Rear wheel speed sensor

4. Brake drum

5. Shoe and lining assembly (Refer to

GROUP 36

Parking Brake

7. Clip8. Parking brake cable

9. Brake pipe connection

10. Shock absorber connection Trailing arm connection12. Lower arm connection

13. Toe control armball joint andknuckle connection(Refer to 14. pin 15. Drive shaft nut16. Washer

17. Differential mount support

18. Drive shaft

19.

Caution1.For vehicles with ABS, careful not to damagedrive shaft rotor.2.l : Indicates parts should be temporarily and then fully tightened the on the

ground in the unladen condition.

TSB Revision

Page 1556 of 2103

REAR AXLE Shaft

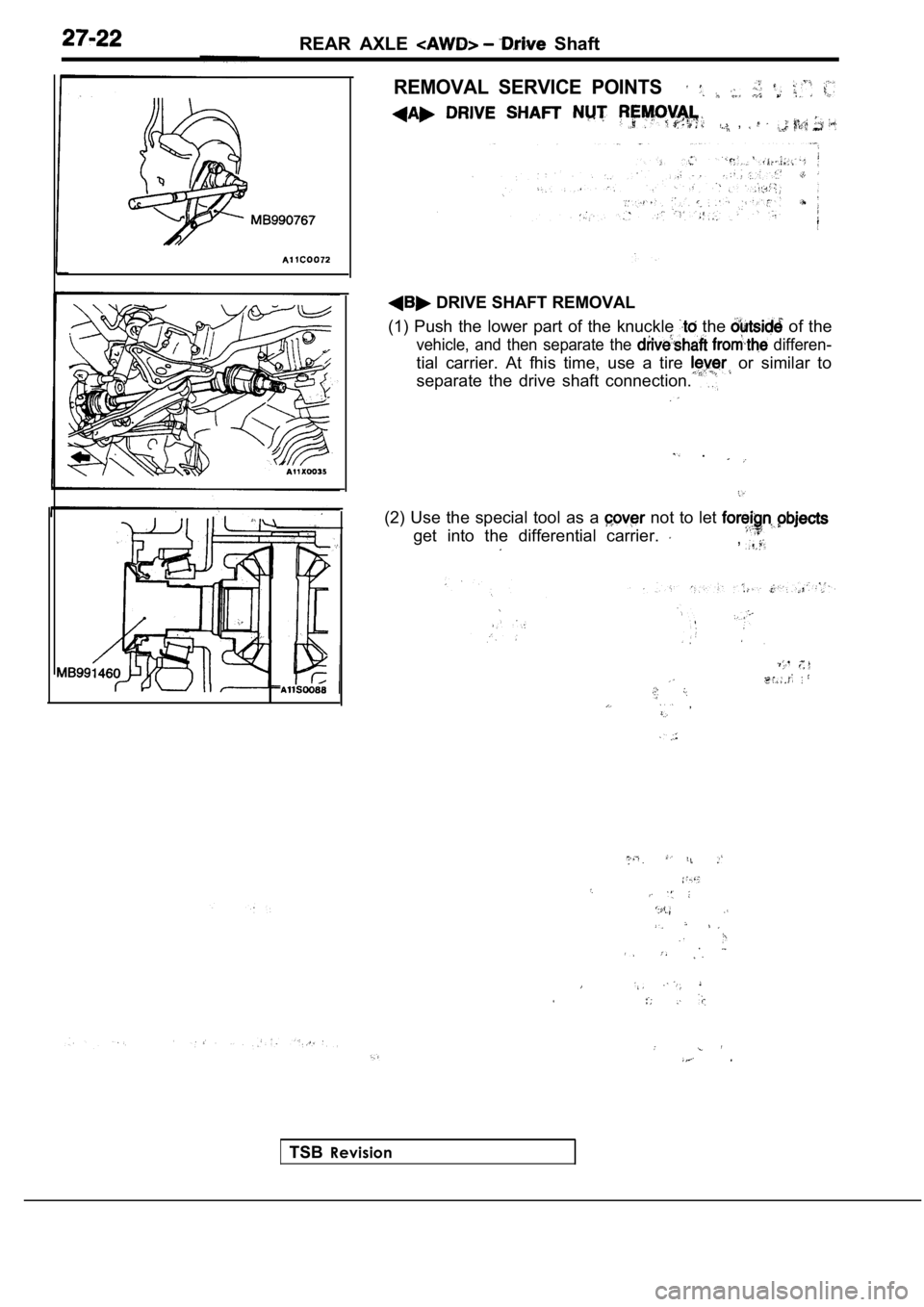

REMOVAL SERVICE POINTS

,

DRIVE SHAFT REMOVAL

(1) Push the lower part of the knuckle

the of the

vehicle, and then separate the differen-

tial carrier. At fhis time, use a tire or similar to

separate the drive shaft connection.

.

(2) Use the special tool as a not to let

get into the differential carrier. ,

,

TSB Revision

Page 1557 of 2103

REAR AXLE Shaft

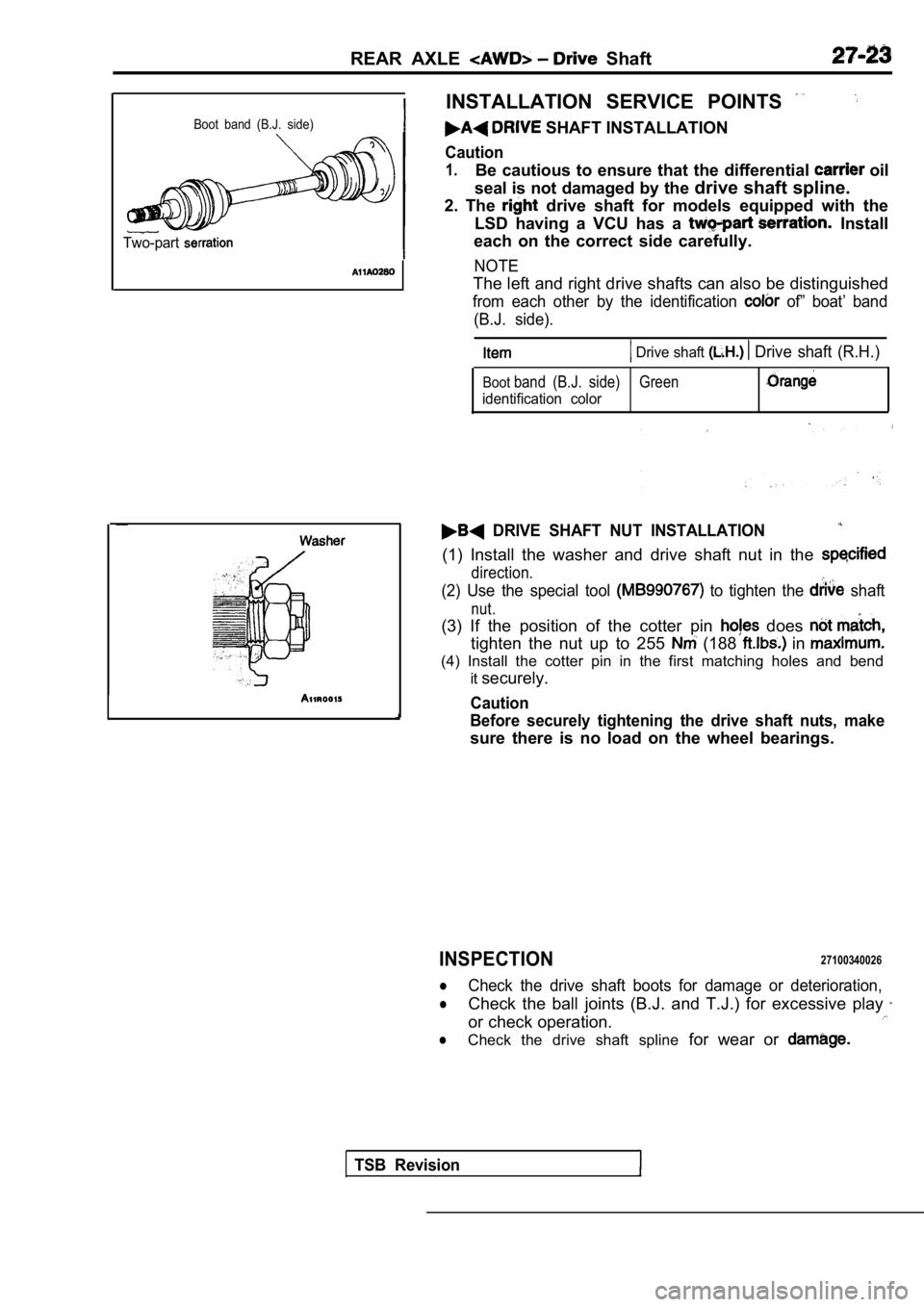

Boot band (B.J. side)

Two-part

INSTALLATION SERVICE POINTS

SHAFT INSTALLATION

Caution

1.Be cautious to ensure that the differential oil

seal is not damaged by the drive shaft spline.

2. The

drive shaft for models equipped with the

LSD having a VCU has a

Install

each on the correct side carefully.

NOTE

The left and right drive shafts can also be disting uished

from each other by the identification of” boat’ band

(B.J. side).

Drive shaft Drive shaft (R.H.)

Bootband (B.J. side) Green

identification color

DRIVE SHAFT NUT INSTALLATION

(1) Install the washer and drive shaft nut in the

direction.

(2) Use the special tool to tighten the shaft

nut.

(3) If the position of the cotter pin does

tighten the nut up to 255 (188 in

(4) Install the cotter pin in the first matching ho les and bend

it securely.

Caution

Before securely tightening the drive shaft nuts, ma ke

sure there is no load on the wheel bearings.

INSPECTION27100340026

lCheck the drive shaft boots for damage or deterioration,

lCheck the ball joints (B.J. and T.J.) for excessive play

or check operation.

lCheck the drive shaft spline for wear or

TSB Revision

Page 1558 of 2103

REAR AXLE Shaft

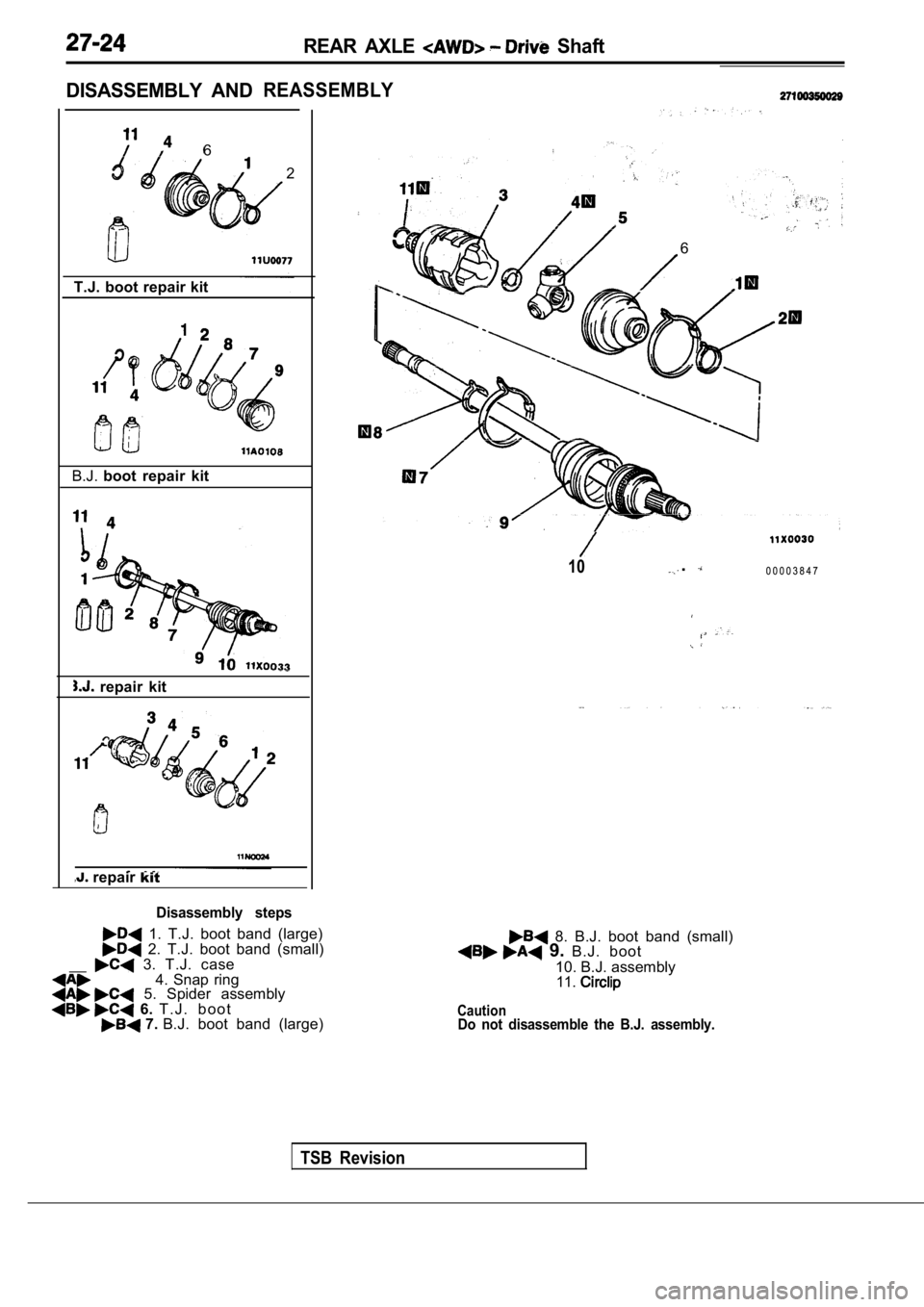

DISASSEMBLY AND

REASSEMBLY

6 2

T.J. boot repair kit

B.J. boot repair kit

repair kit

repair kit

Disassembly steps

1. T.J. boot band (large) 2. T.J. boot band (small)

__ 3. T.J. case4. Snap ring 5. Spider assembly 6. T . J . b o o t 7. B.J. boot band (large)Do not disassemble the B.J. assembly.

6

TSB Revision

10.0 0 0 0 3 8 4 7

8. B.J. boot band (small) 9. B.J. boot

10. B.J. assembly

11.

Caution

Page 1559 of 2103

REAR AXLE Drive Shaft

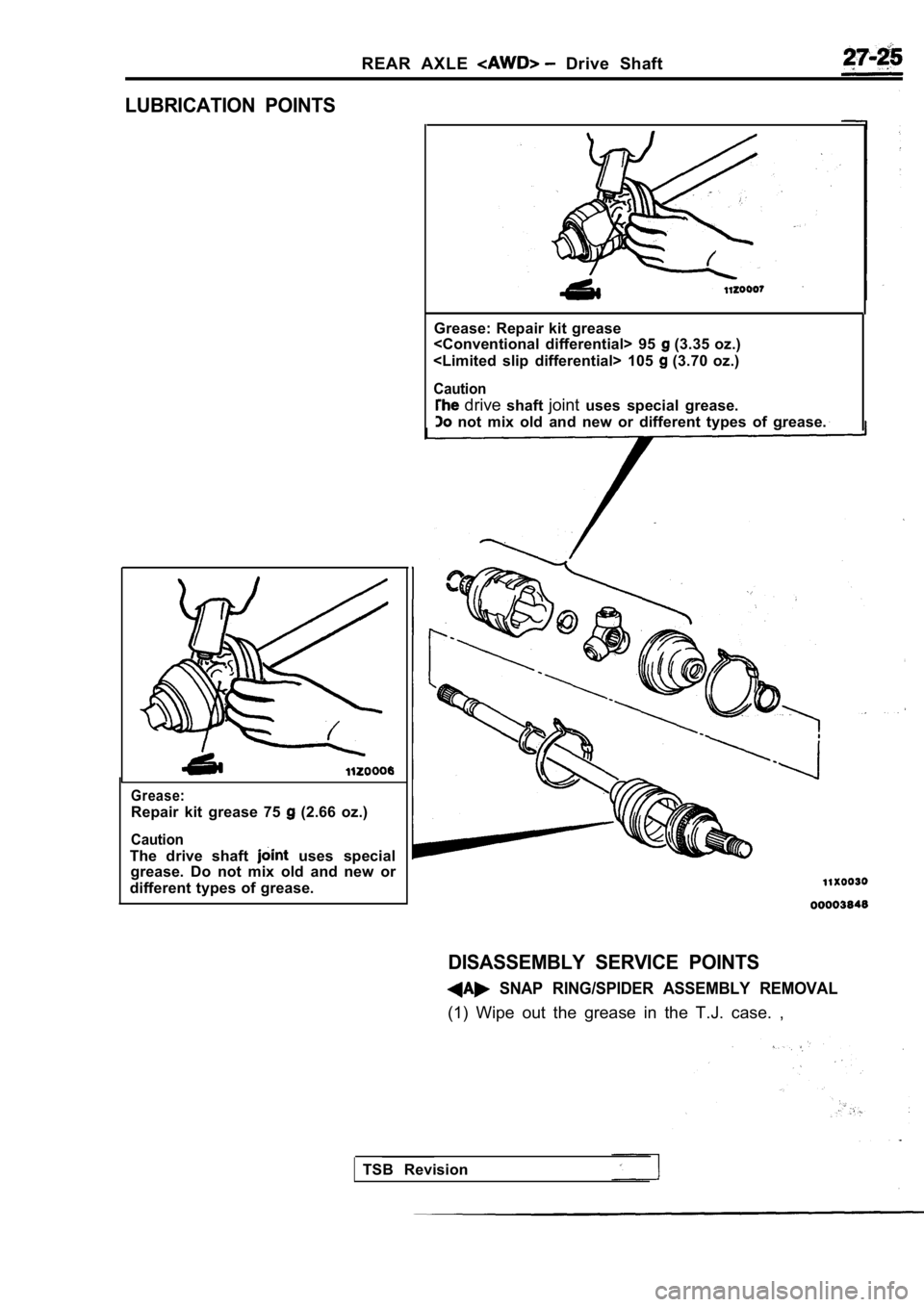

LUBRICATION POINTS

Grease:

Repair kit grease 75 (2.66 oz.)

Caution

The drive shaft uses special

grease. Do not mix old and new or

different types of grease. Grease: Repair kit grease

(3.35 oz.)

(3.70 oz.)

Caution

drive shaftjointuses special grease.

not mix old and new or different types of grease.

DISASSEMBLY SERVICE POINTS

SNAP RING/SPIDER ASSEMBLY REMOVAL

(1) Wipe out the grease in the T.J. case. ,

TSB Revision

Page 1560 of 2103

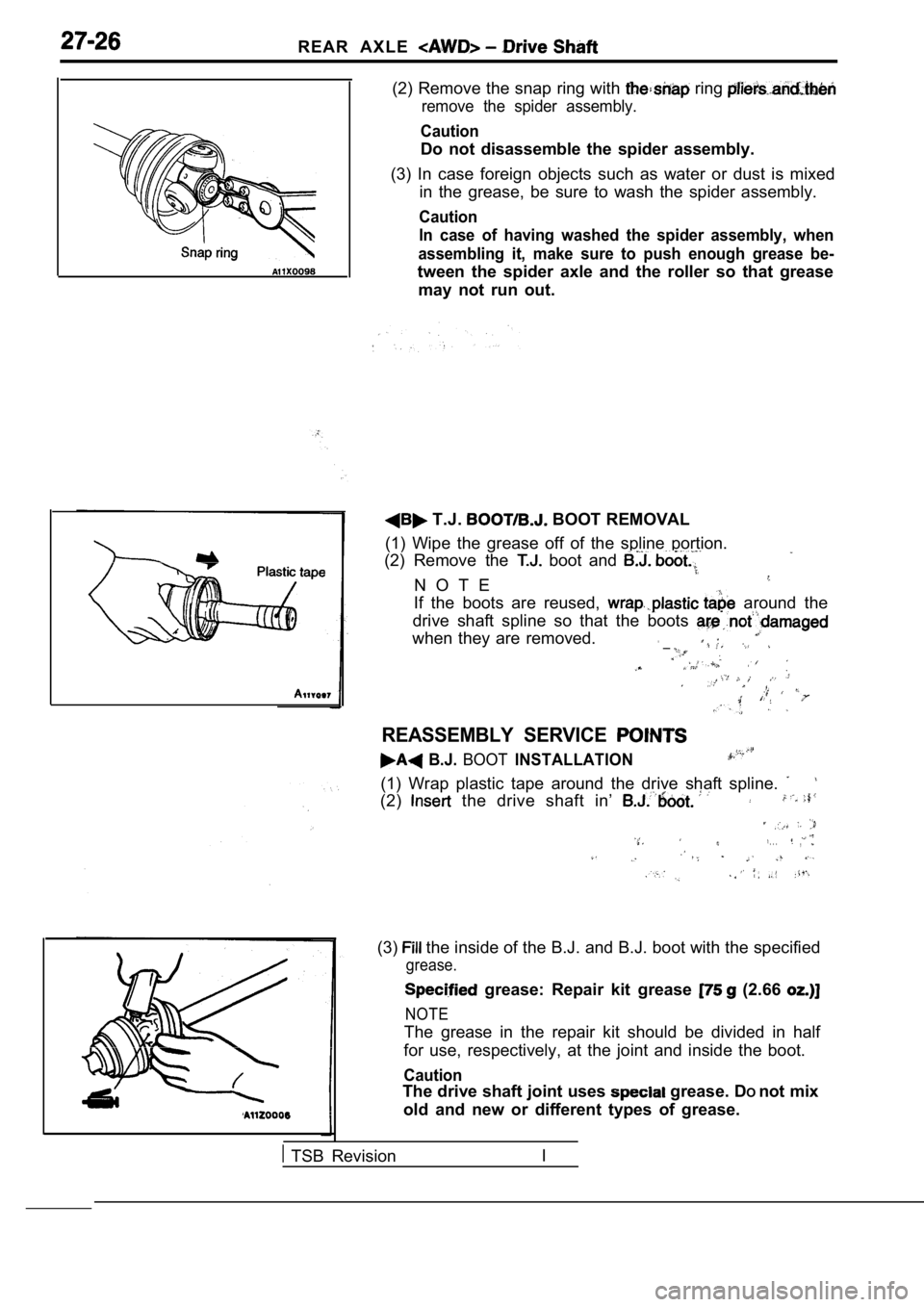

R E A R A X L E

(2) Remove the snap ring with ring

remove the spider assembly.

Caution

Do not disassemble the spider assembly.

(3) In case foreign objects such as water or dust i s mixed

in the grease, be sure to wash the spider assembly.

Caution

In case of having washed the spider assembly, when

assembling it, make sure to push enough grease be-

tween the spider axle and the roller so that grease may not run out.

T.J. BOOT REMOVAL

(1) Wipe the grease off of the spline portion.

(2) Remove the

boot and

N O T E

If the boots are reused, around the

drive shaft spline so that the boots

when they are removed. __

REASSEMBLY SERVICE

B.J. BOOTINSTALLATION

(1) Wrap plastic tape around the drive shaft spline .

(2) the drive shaft in’

. . .,

(3) the inside of the B.J. and B.J. boot with the specified

grease.

grease: Repair kit grease (2.66

NOTE

The grease in the repair kit should be divided in h alf

for use, respectively, at the joint and inside the boot.

Caution

The drive shaft joint uses grease. DOnot mix

old and new or different types of grease.

TSB Revision I