MITSUBISHI SPYDER 1990 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1541 of 2103

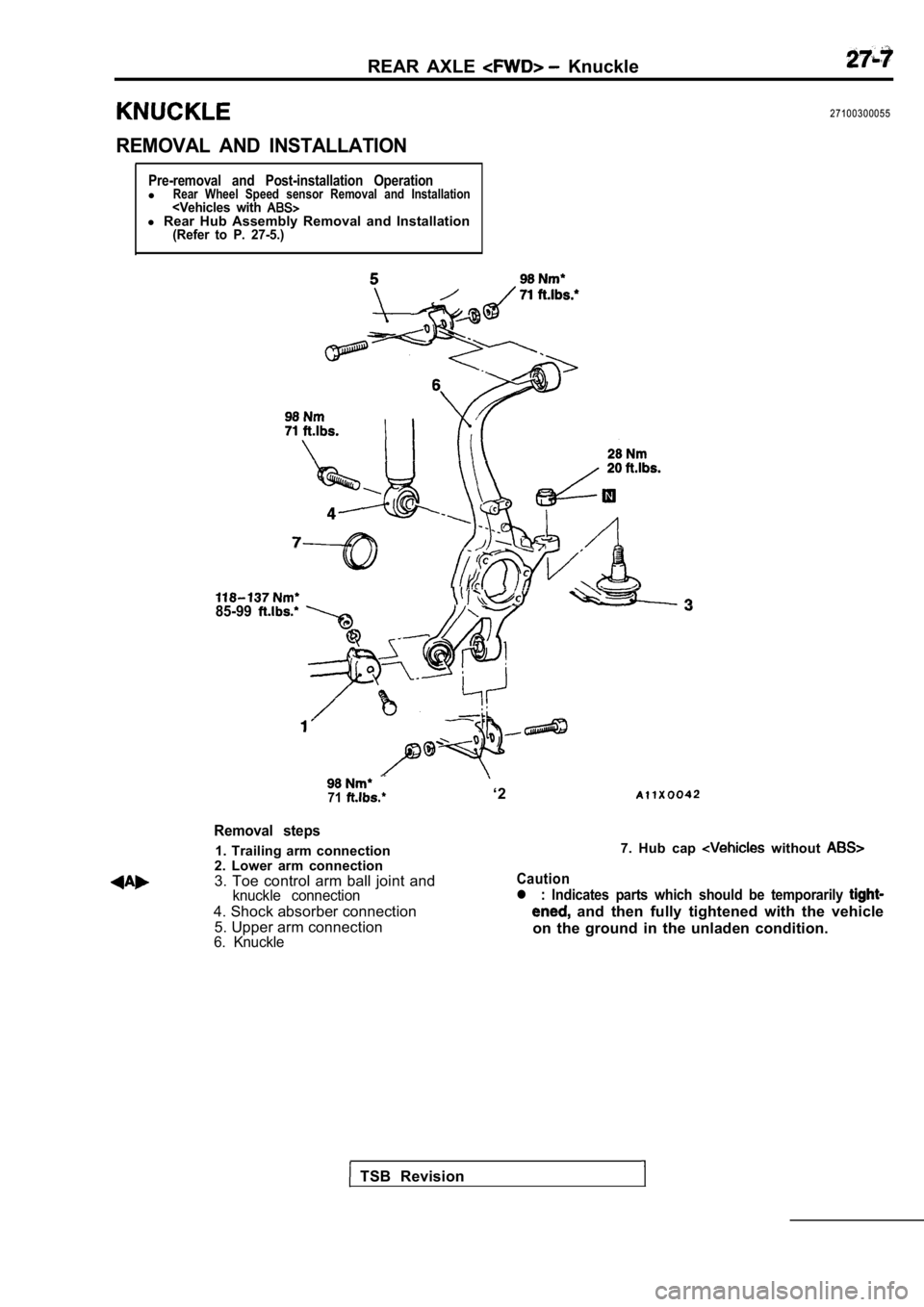

REAR AXLE Knuckle

REMOVAL AND INSTALLATION

27100300055

Pre-removal and Post-installation OperationlRear Wheel Speed sensor Removal and Installation

71‘2

Removal steps

1. Trailing arm connection

2. Lower arm connection

3. Toe control arm ball joint and

knuckle connection

4. Shock absorber connection

5. Upper arm connection

6. Knuckle

Caution

7. Hub cap without

l : Indicates parts which should be temporarily

and then fully tightened with the vehicle

on the ground in the unladen condition.

TSB Revision

Page 1542 of 2103

REAR AXLE Knuckle

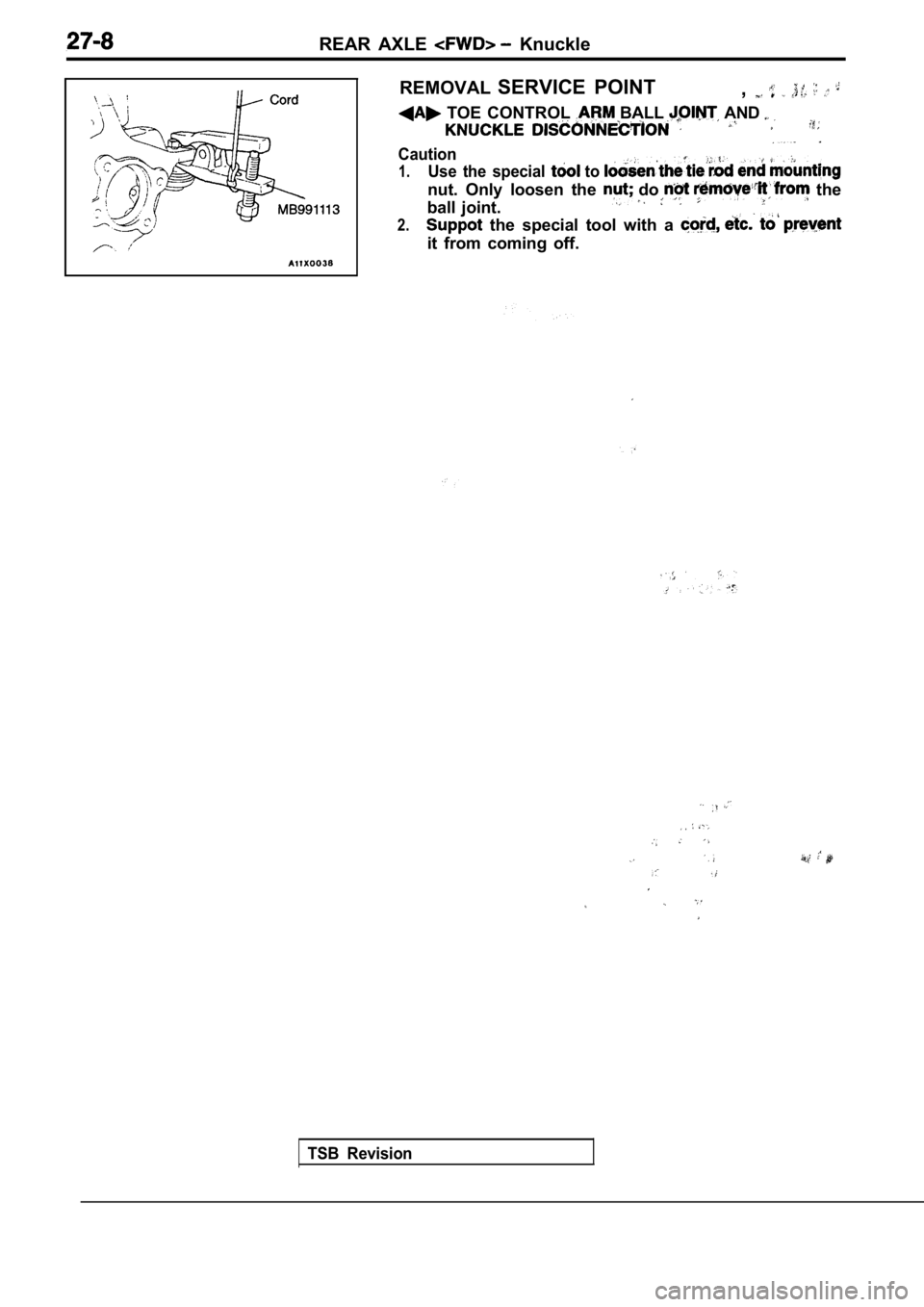

REMOVAL SERVICE POINT

,

TOE CONTROL BALL AND

Caution,1.Use the special to

nut. Only loosen the do the

ball joint.

2. the special tool with a

it from coming off.

TSB Revision

Page 1543 of 2103

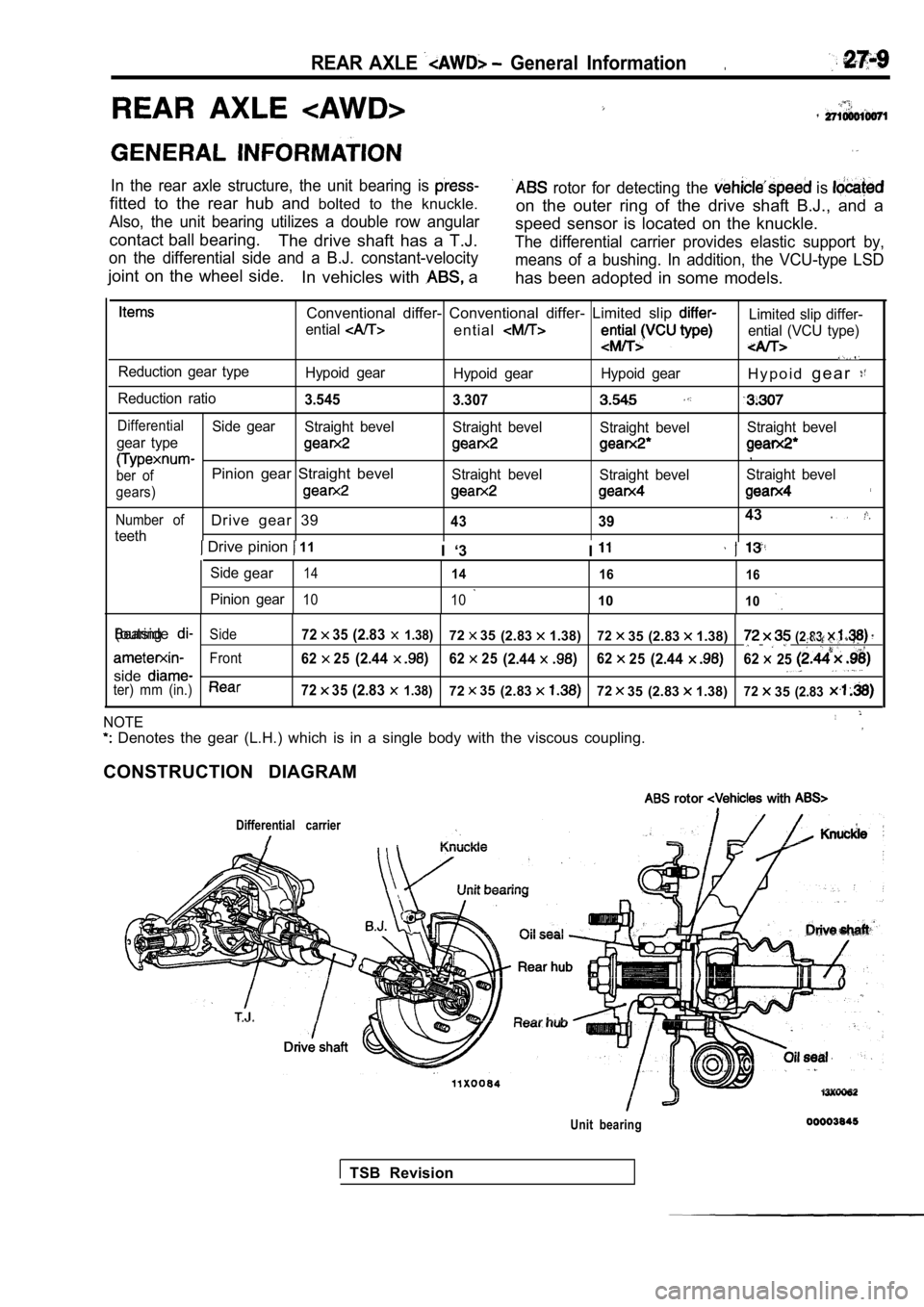

REAR AXLE General Information.

In the rear axle structure, the unit bearing is

fitted to the rear hub and bolted to the knuckle.

Also, the unit bearing utilizes a double row angula r

contact ball bearing.

The drive shaft has a T.J.

on the differential side and a B.J. constant-veloci ty

joint on the wheel side.

In vehicles with a

rotor for detecting the is

on the outer ring of the drive shaft B.J., and a

speed sensor is located on the knuckle.

The differential carrier provides elastic support b y,

means of a bushing. In addition, the VCU-type LSD

has been adopted in some models.

Conventional differ- Conventional differ- Limited s lip Limited slip differ-

ential

entialential (VCU type)

Reduction gear type Hypoid gearHypoid gear Hypoid gearH y p o i dg e a r

Reduction ratio3.545

3.307

DifferentialSide gearStraight bevel Straight bevelStraight bevelStraight bevel

gear type

,

ber ofPinion gear Straight bevelStraight bevel Straight bevelStraight bevel

gears)

Number ofDrive gear 39433943

teeth Drive pinion 11

I ‘3 I

Sidegear1414 1616

Pinion gear10 101010

BearingSide7235(2.83 1.38)7235(2.831.38)7235 (2.83 1.38)(outside(2.83 ,

Front6225(2.446225(2.446225(2.4462 25

sideter) mm (in.)7235(2.83 1.38)7235(2.837235 (2.83 1.38)72 35(2.83

NOTE

Denotes the gear (L.H.) which is in a single body with the viscous coupling.

CONSTRUCTION DIAGRAM

rotor with

Differential carrier

Unit bearing

TSB Revision

Page 1544 of 2103

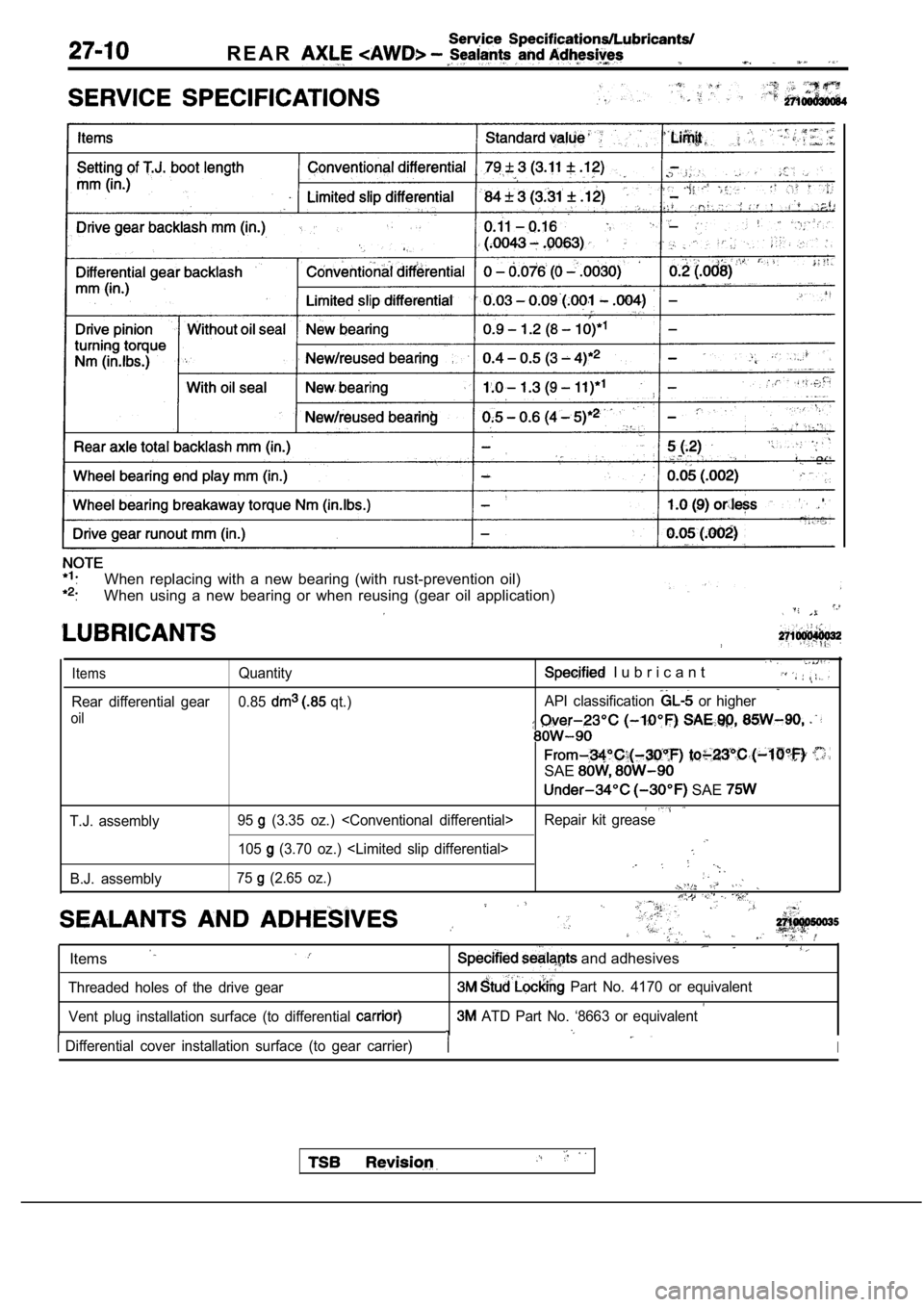

R E A R

.When replacing with a new bearing (with rust-prevention oil)

.When using a new bearing or when reusing (gear oil application)

Items

Rear differential gear

oil

Quantity

0.85

qt.)

l u b r i c a n t

API classification or higher

T.J. assembly

B.J. assembly 95 (3.35 oz.)

105

(3.70 oz.)

75

(2.65 oz.)

SAE

SAE

Repair kit grease

.

Items

Threaded holes of the drive gear

and adhesives

Vent plug installation surface (to differential

Part No. 4170 or equivalent

ATD Part No. ‘8663 or equivalent

Differential cover installation surface (to gear c arrier). .I

Page 1545 of 2103

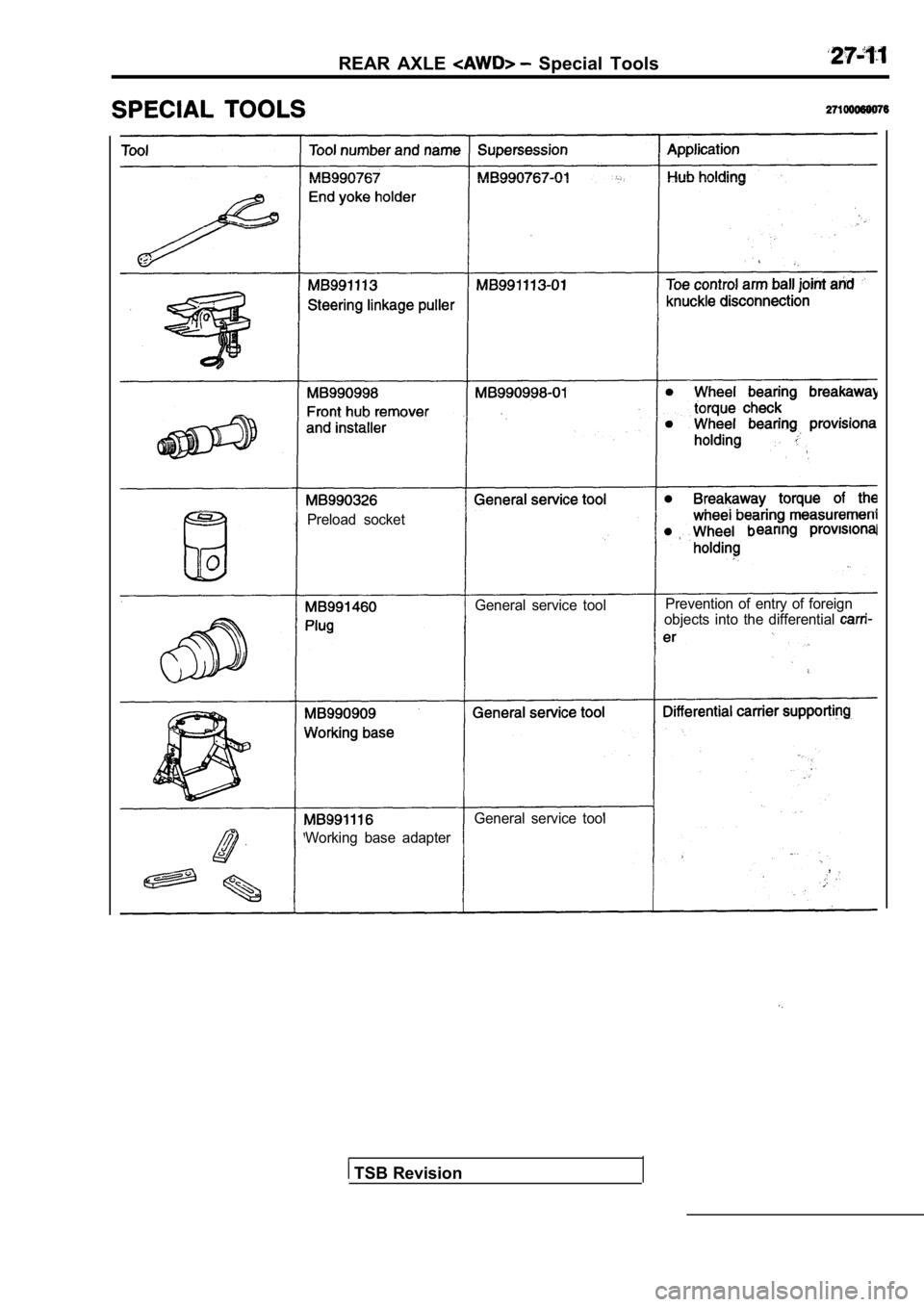

REAR AXLE Special Tools

Preload socket

General service toolPrevention of entry of foreign

objects into the differential

General service tool

Working base adapter

,

TSB Revision

Page 1546 of 2103

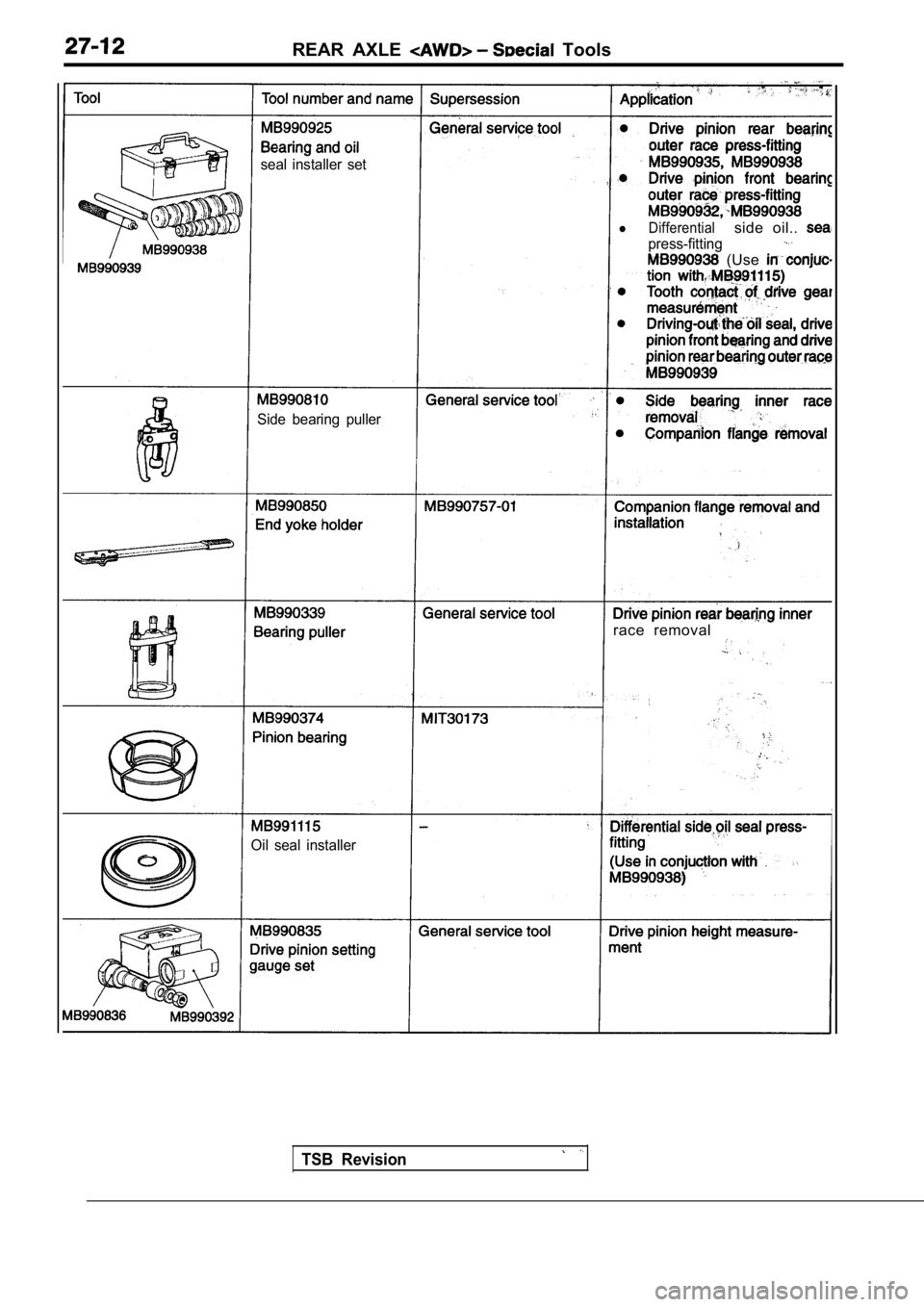

REAR AXLE Tools

seal installer set

lDifferentialside oil..

press-fitting

(Use

Side bearing puller

race removal

Oil seal installer

TSB Revision

Page 1547 of 2103

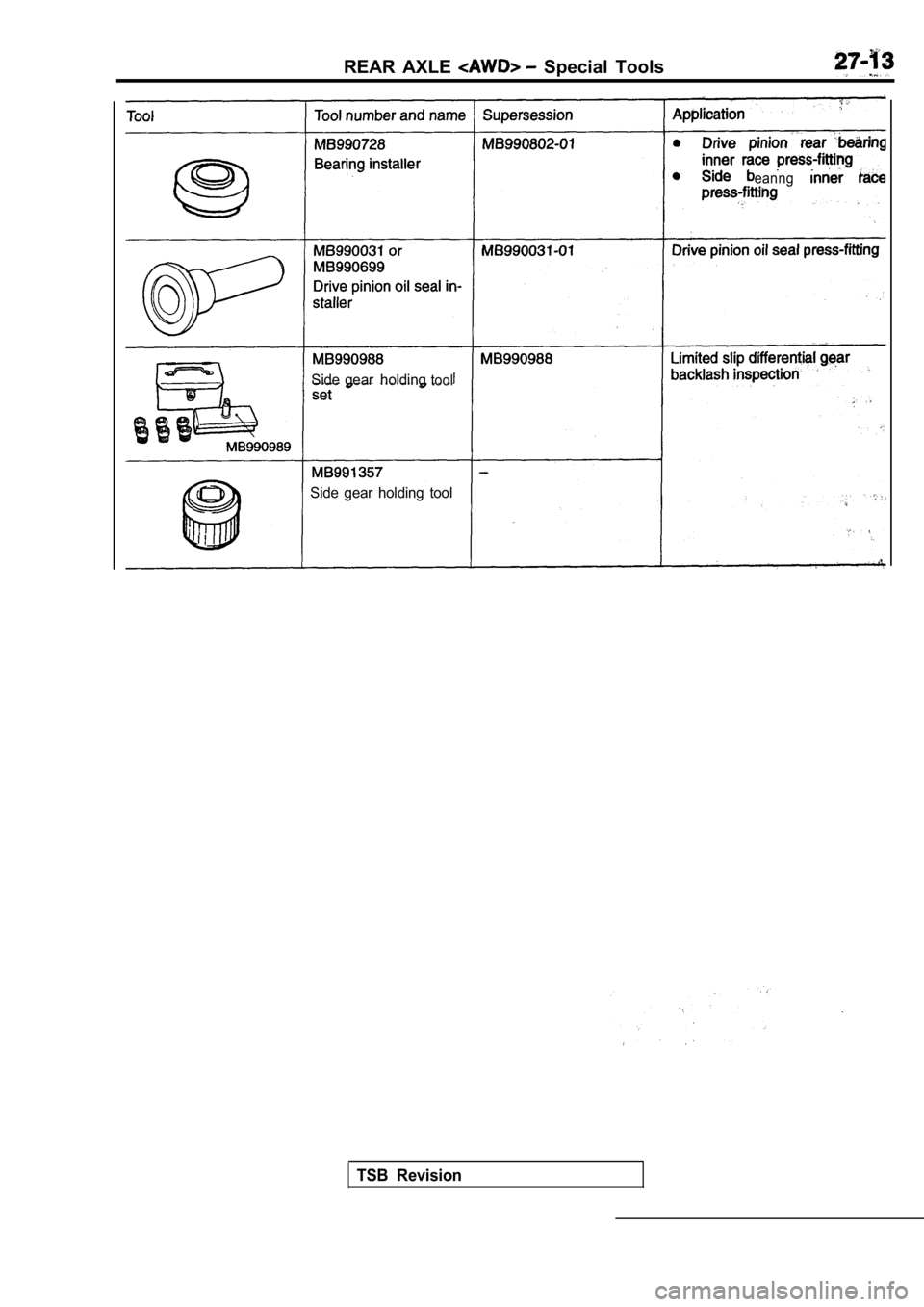

REAR AXLE Special Tools

eanng

Side gear holdingtool

Side gear holding tool

TSB Revision

Page 1548 of 2103

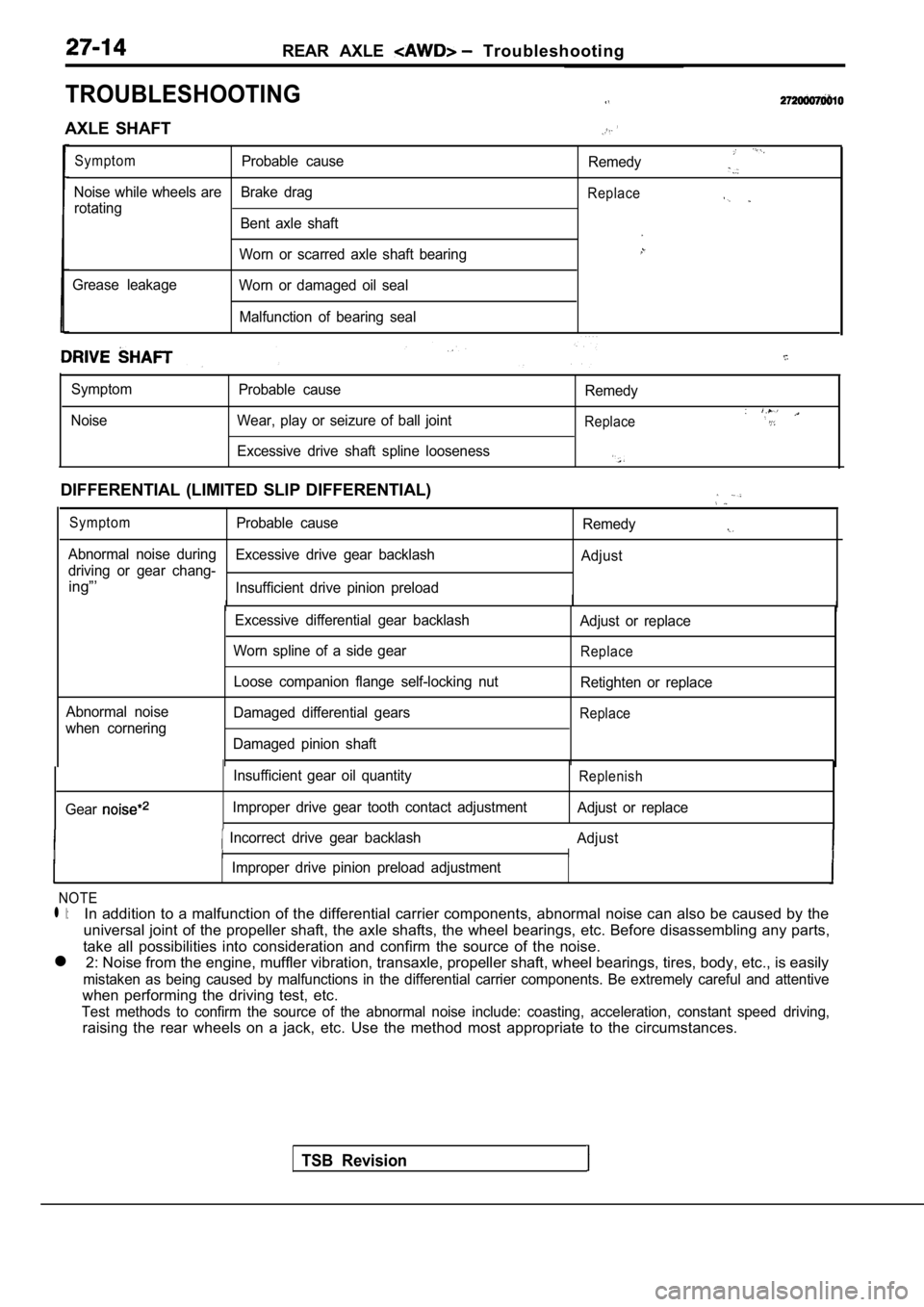

REAR AXLE Troubleshooting

TROUBLESHOOTING

AXLE SHAFT

SymptomProbable causeRemedy

Noise while wheels are Brake drag

rotatingReplace

Bent axle shaft

Worn or scarred axle shaft bearing

Grease leakage Worn or damaged oil seal

Malfunction of bearing seal

Symptom

Noise Probable cause

Wear, play or seizure of ball joint Remedy

Replace

Excessive drive shaft spline looseness

DIFFERENTIAL (LIMITED SLIP DIFFERENTIAL)

SymptomProbable cause

Remedy

Abnormal noise during

driving or gear chang-Excessive drive gear backlash

Adjust

ing”’Insufficient drive pinion preload

II II

Abnormal noise

when cornering Excessive differential gear backlash

Worn spline of a side gear

Loose companion flange self-locking nut

Damaged differential gears

Damaged pinion shaft Adjust or replace

Replace

Retighten or replace

Replace

TSB Revision

Gear

Insufficient gear oil quantity

Improper drive gear tooth contact adjustmentReplenish

Adjust or replace

Incorrect drive gear backlash Adjust

I II

IImproper drive pinion preload adjustment

NOTE

l l:In addition to a malfunction of the differential carrier components, abnormal noise can also be caused by the

universal joint of the propeller shaft, the axle sh afts, the wheel bearings, etc. Before disassembling any parts,

take all possibilities into consideration and confi rm the source of the noise.

l 2: Noise from the engine, muffler vibration, transa xle, propeller shaft, wheel bearings, tires, body, etc., is easily

mistaken as being caused by malfunctions in the dif ferential carrier components. Be extremely careful and attentive

when performing the driving test, etc.

Test methods to confirm the source of the abnormal noise include: coasting, acceleration, constant speed

raising the rear wheels on a jack, etc. Use the met hod most appropriate to the circumstances.

driving,

Page 1549 of 2103

R E A R

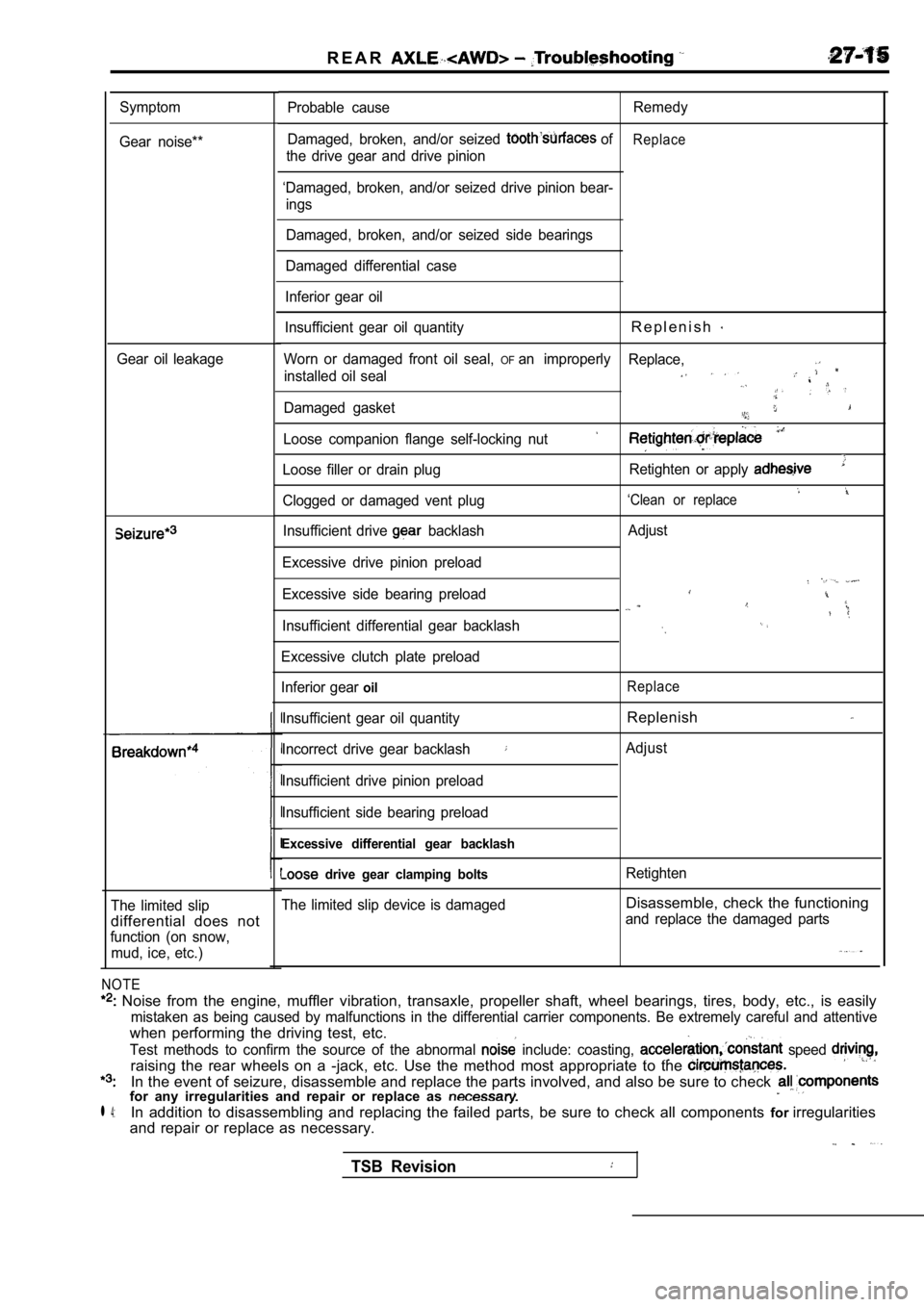

Symptom

Gear noise**

Gear oil leakage

The limited slip

differential does not

function (on snow, mud, ice, etc.)

NOTE

Noise from the engine, muffler vibration, transaxl e, propeller shaft, wheel bearings, tires, body, etc., is easily

mistaken as being caused by malfunctions in the dif ferential carrier components. Be extremely careful and attentive

when performing the driving test, etc.

Test methods to confirm the source of the abnormal include: coasting, speed

raising the rear wheels on a -jack, etc. Use the me thod most appropriate to the

In the event of seizure, disassemble and replace the parts involved, and also be sure to check for any irregularities and repair or replace as

l 4:In addition to disassembling and replacing the failed parts, be sure to check all components forirregularities

and repair or replace as necessary.

Probable cause Remedy

Damaged, broken, and/or seized

ofReplace

the drive gear and drive pinion

‘Damaged, broken, and/or seized drive pinion bear- ings

Damaged, broken, and/or seized side bearings

Damaged differential case

Inferior gear oil

Insufficient gear oil quantity

R e p l e n i s h

Worn or damaged front oil seal, OFan improperly Replace,

installed oil seal

Damaged gasket

Loose companion flange self-locking nut

Loose filler or drain plug Retighten or apply

‘Clean or replaceClogged or damaged vent plug

Insufficient drive

backlash

Excessive drive pinion preload

Excessive side bearing preload

Insufficient differential gear backlash

Excessive clutch plate preload

Inferior gear

oil

Insufficient gear oil quantity

Incorrect drive gear backlash

Insufficient drive pinion preload

Insufficient side bearing preload

Excessive differential gear backlash

drive gear clamping bolts

The limited slip device is damaged Adjust

Replace

Replenish

Adjust

Retighten

Disassemble, check the functioning

and replace the damaged parts

TSB Revision

Page 1550 of 2103

6REAR AXLE Service

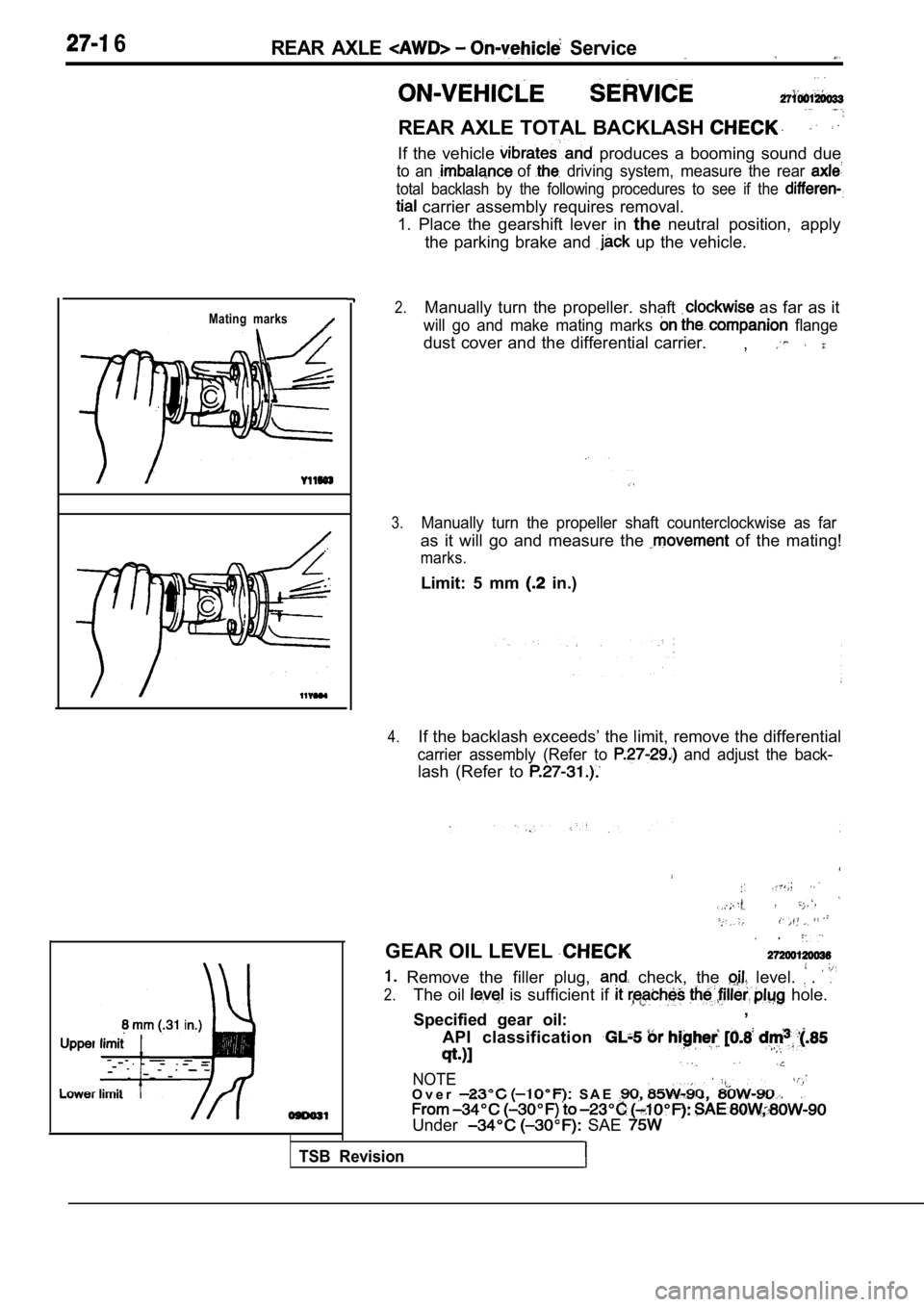

REAR AXLE TOTAL BACKLASH

If the vehicle produces a booming sound due

to an of driving system, measure the rear

total backlash by the following procedures to see if the

carrier assembly requires removal.

1. Place the gearshift lever in theneutral position, apply

the parking brake and

up the vehicle.

Mating marks2.Manually turn the propeller. shaft as far as it

will go and make mating marks flange

dust cover and the differential carrier. ,

3.Manually turn the propeller shaft counterclockwise as far

as it will go and measure the of the mating!

marks.

Limit: 5 mm in.)

4.If the backlash exceeds’ the limit, remove the differential

carrier assembly (Refer to and adjust the back-

lash (Refer to

TSB Revision

GEAR OIL LEVEL

Remove the filler plug, check, the level. .

2.The oil is sufficient if hole.

Specified gear oil: ,

API classification

NOTEO v e r S A E

Under SAE