MITSUBISHI SPYDER 1990 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1681 of 2103

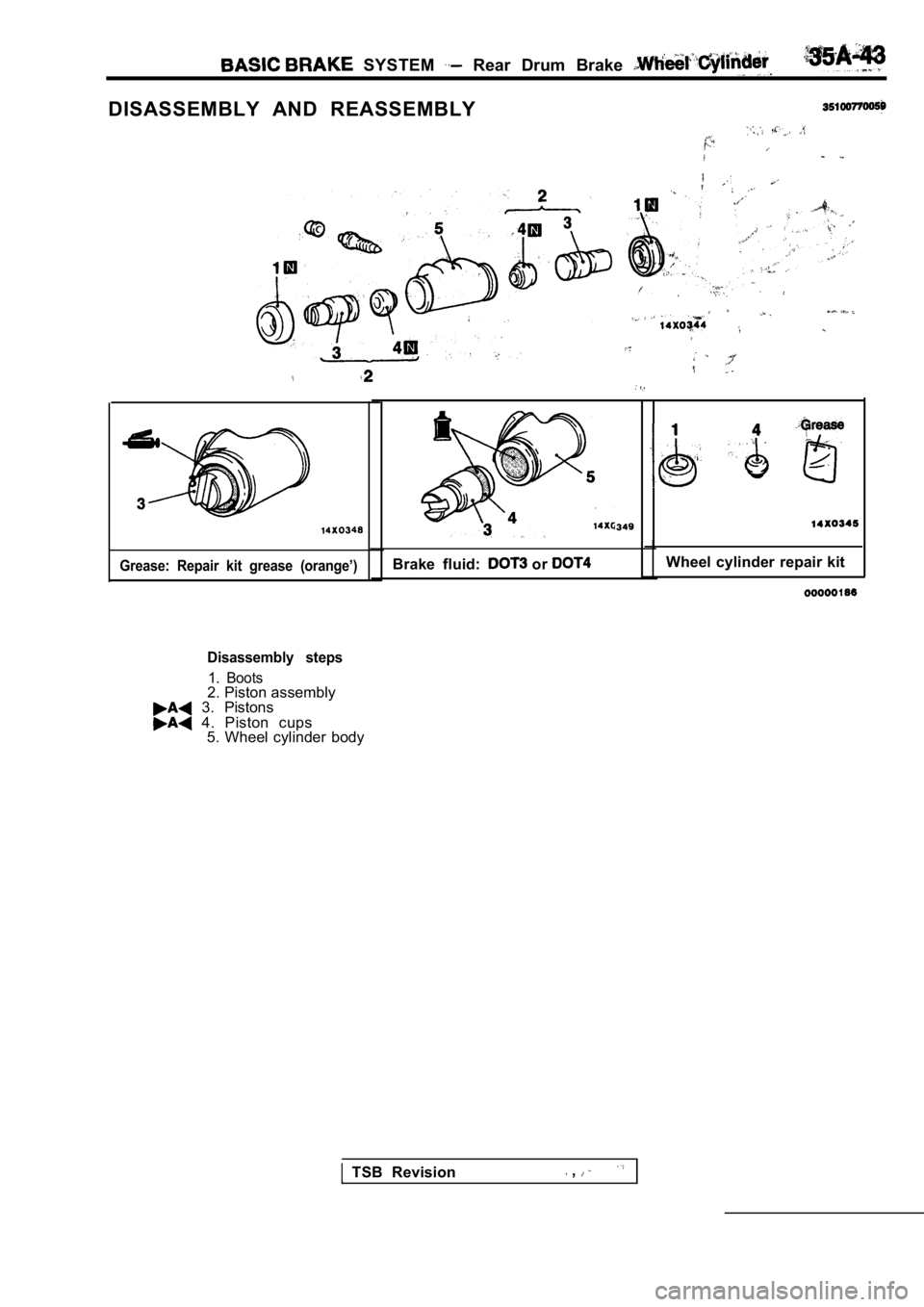

SYSTEM Rear Drum Brake

DISASSEMBLY AND REASSEMBLY

Grease: Repair kit grease (orange’)Brake fluid: or

Disassembly steps

1. Boots2. Piston assembly 3. Pistons 4. Piston cups5. Wheel cylinder body

Wheel cylinder repair kit

TSB Revision ,

Page 1682 of 2103

BASIC BRAKE SYSTEM Rear Drum Brake

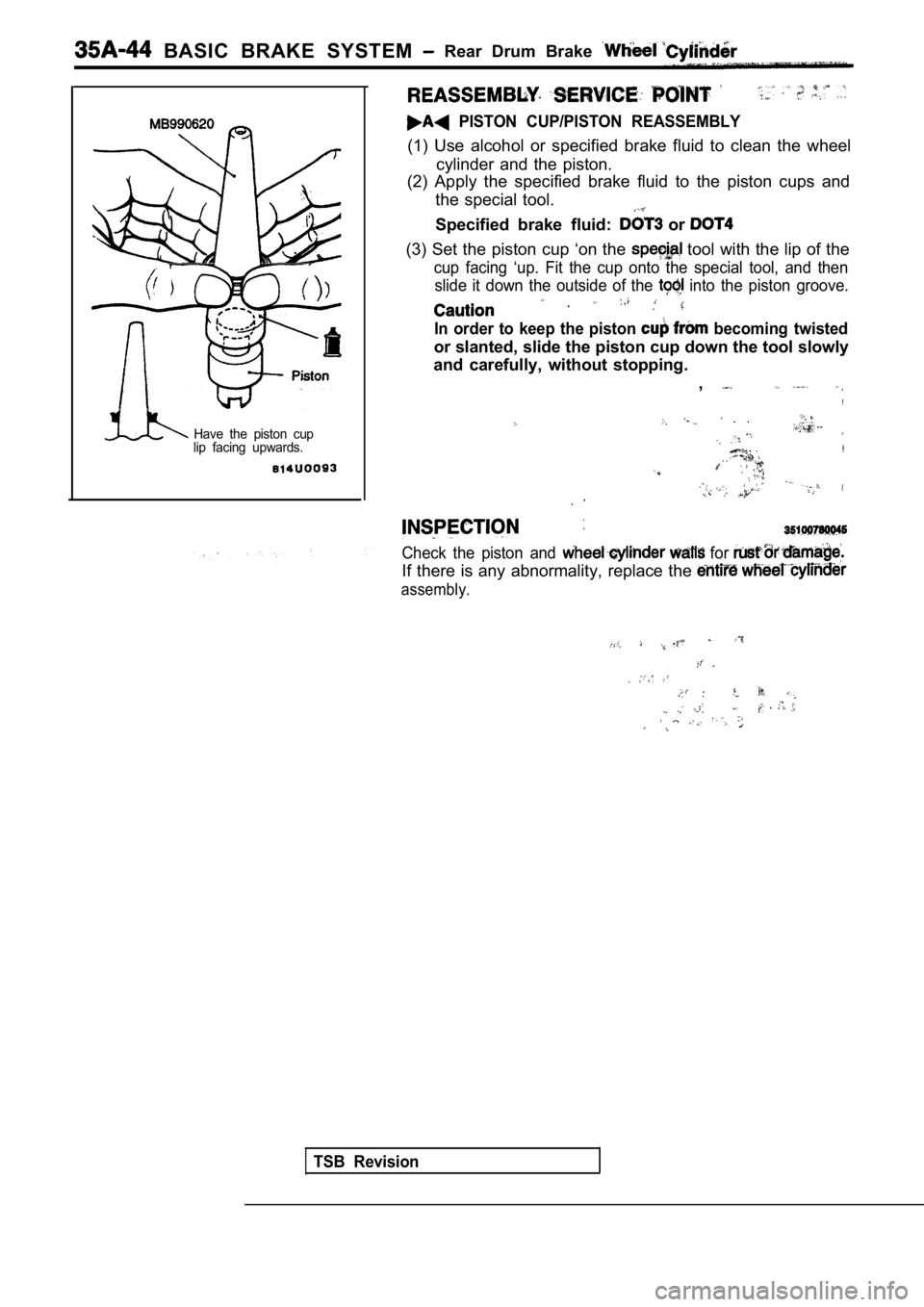

PISTON CUP/PISTON REASSEMBLY

(1) Use alcohol or specified brake fluid to clean the wheel

cylinder and the piston.

(2) Apply the specified brake fluid to the piston c ups and

the special tool.

Specified brake fluid: or

(3) Set the piston cup ‘on the tool with the lip of the

cup facing ‘up. Fit the cup onto the special tool, and then

slide it down the outside of the

into the piston groove.

In order to keep the piston becoming twisted

or slanted, slide the piston cup down the tool slow ly

and carefully, without stopping.

,

Have the piston cup

lip facing upwards.

. . --

. .

,

Check the piston and for

If there is any abnormality, replace the

assembly.

TSB Revision

Page 1683 of 2103

BASIC BRAKE SYSTEM Rear Disc Brake

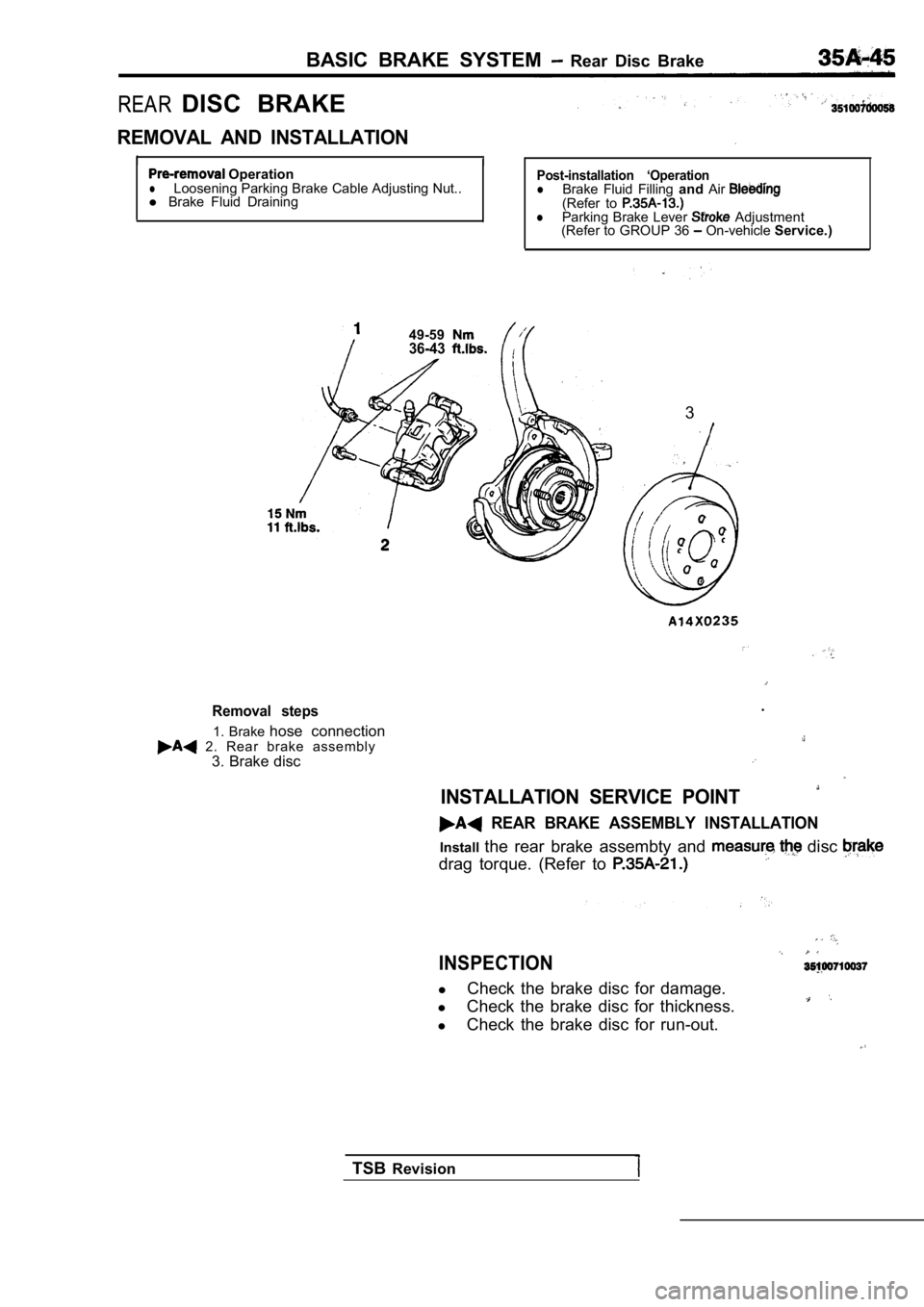

REAR DISC BRAKE

REMOVAL AND INSTALLATION

I

I OperationlLoosening Parking Brake Cable Adjusting Nut..

l Brake Fluid DrainingPost-installation ‘OperationlBrake Fluid Filling andAir(Refer to lParking Brake Lever Adjustment

(Refer to GROUP 36 On-vehicle Service.)

49-59

36-43

3

Removal steps

1. Brake hose connection 2. Rear brake assembly

3. Brake disc .

INSTALLATION SERVICE POINT

REAR BRAKE ASSEMBLY INSTALLATION

Install

the rear brake assembty and disc

drag torque. (Refer to

INSPECTION

lCheck the brake disc for damage.

l Check the brake disc for thickness.

l Check the brake disc for run-out.

TSB Revision

Page 1684 of 2103

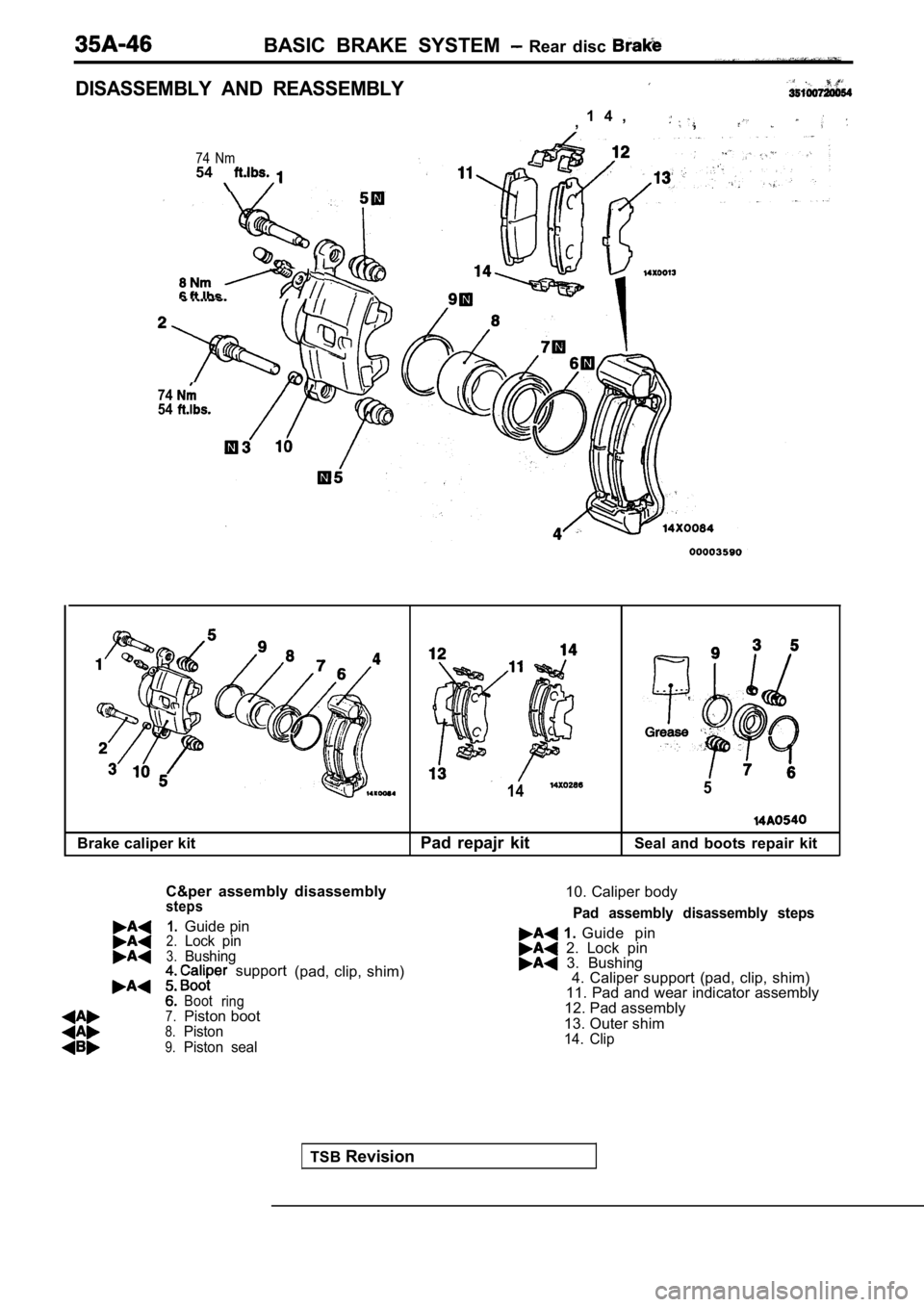

BASIC BRAKE SYSTEM Rear disc

DISASSEMBLY AND REASSEMBLY

1 4 ,

,,

74 Nm54

7454

Brake caliper kit

14

Pad repajr kit

5

Seal and boots repair kit

TSB Revision

C&per assembly disassembly

10. Caliper body

steps

1.Guide pin2.Lock pin3.Bushing support

Bootring7.Piston boot8.Piston

9.Piston seal

(pad, clip, shim)

Pad assembly disassembly steps

1. Guide pin 2. Lock pin 3. Bushing

4. Caliper support (pad, clip, shim)

11. Pad and wear indicator assembly

12. Pad assembly

13. Outer shim

14. Clip

Page 1685 of 2103

BASICB R AKE SYSTEM Rear Disc

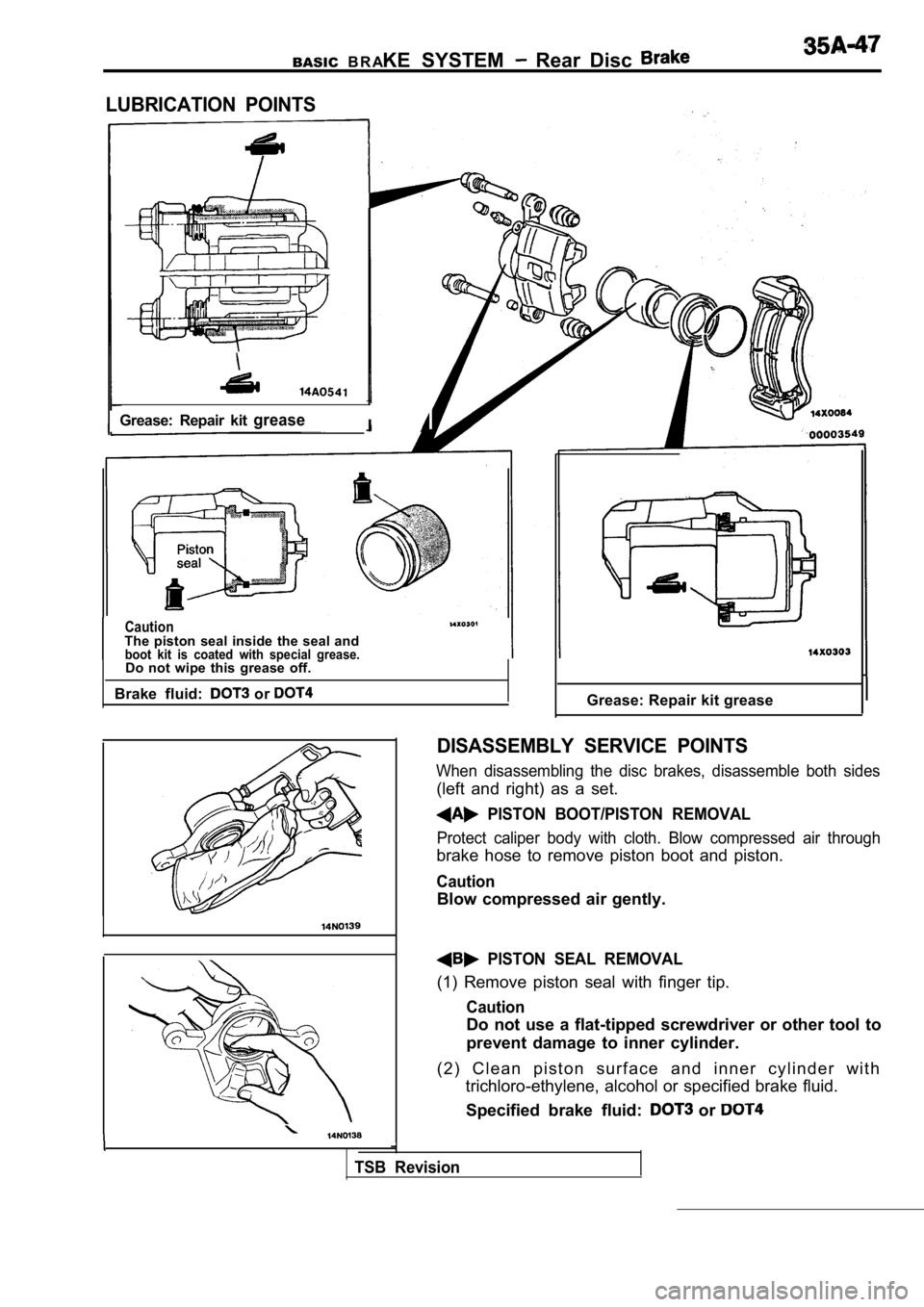

LUBRICATION POINTS

IGrease: Repair kit greaseI

CautionThe piston seal inside the seal andboot kit is coated with special grease.Do not wipe this grease off.

Brake fluid:

or

TSB Revision

Grease: Repair kit grease

DISASSEMBLY SERVICE POINTS

When disassembling the disc brakes, disassemble bot h sides

(left and right) as a set.

PISTON BOOT/PISTON REMOVAL

Protect caliper body with cloth. Blow compressed air through

brake hose to remove piston boot and piston.

Caution

Blow compressed air gently.

PISTON SEAL REMOVAL

(1) Remove piston seal with finger tip.

Caution

Do not use a flat-tipped screwdriver or other tool to

prevent damage to inner cylinder.

( 2 ) C l e a n p i s t o n s u r f a c e a n d i n n e r c y l i n d e r w i t h trichloro-ethylene, alcohol or specified brake flui d.

Specified brake fluid:

or

Page 1686 of 2103

BASICBRAKESYSTEM Rear Disc Brake

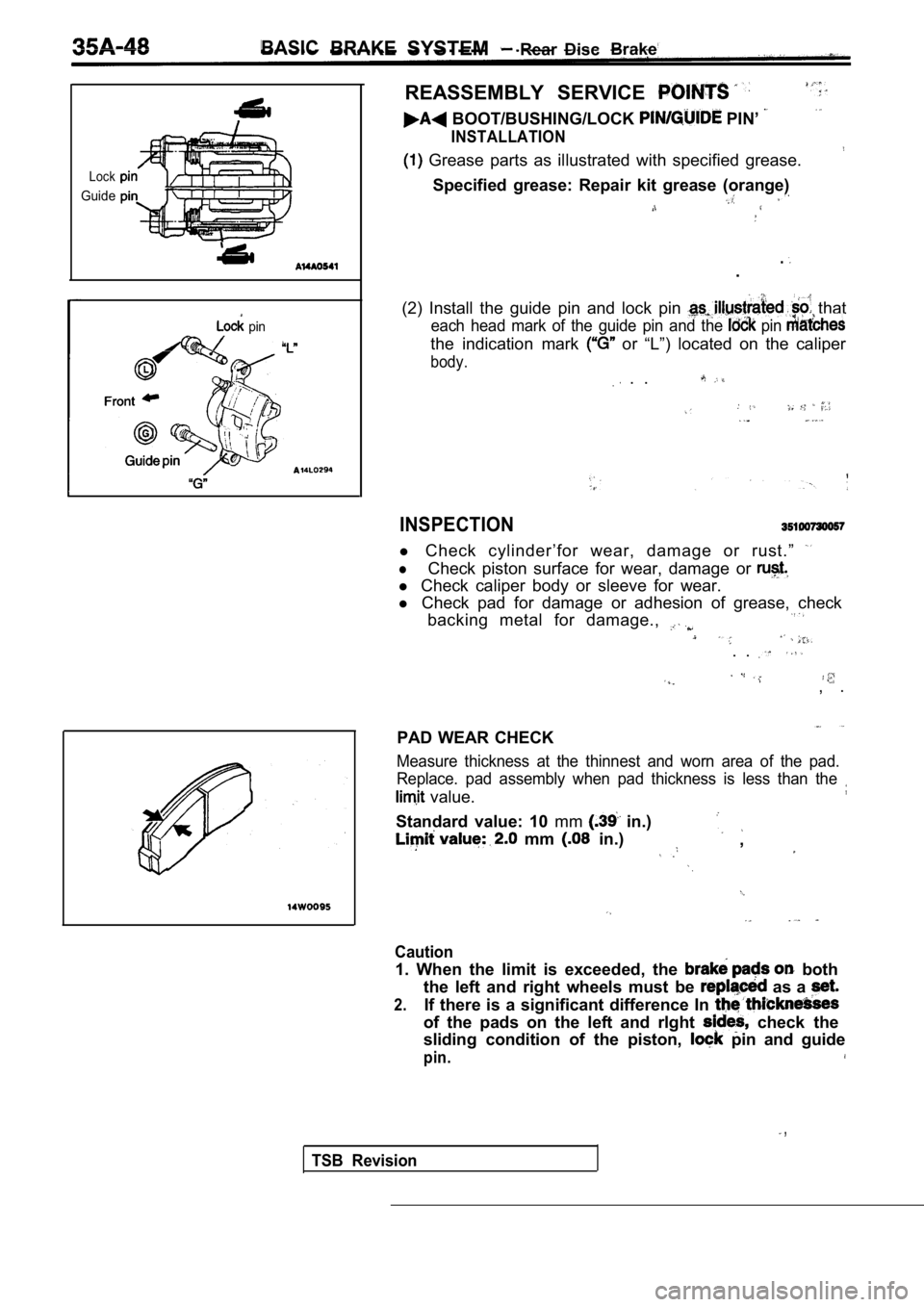

Lock

Guide

pin

REASSEMBLY SERVICE

BOOT/BUSHING/LOCK PIN’

INSTALLATION

Grease parts as illustrated with specified grease.

Specified grease: Repair kit grease (orange)

..

(2) Install the guide pin and lock pin

that

each head mark of the guide pin and the pin

the indication mark or “L”) located on the caliper

body.

. .

INSPECTION

l Check cylinder’for wear, damage or rust.”

lCheck piston surface for wear, damage or

l Check caliper body or sleeve for wear.

l Check pad for damage or adhesion of grease, check

backing metal for damage.,

. .

, .

PAD WEAR CHECK

Measure thickness at the thinnest and worn area of the pad.

Replace. pad assembly when pad thickness is less th an the

value.

Standard value: 10 mm in.)

mm in.),

Caution

1. When the limit is exceeded, the both

the left and right wheels must be

as a

2.If there is a significant difference In

of the pads on the left and rlght check the

sliding condition of the piston,

pin and guide

pin.

,

TSB Revision

Page 1687 of 2103

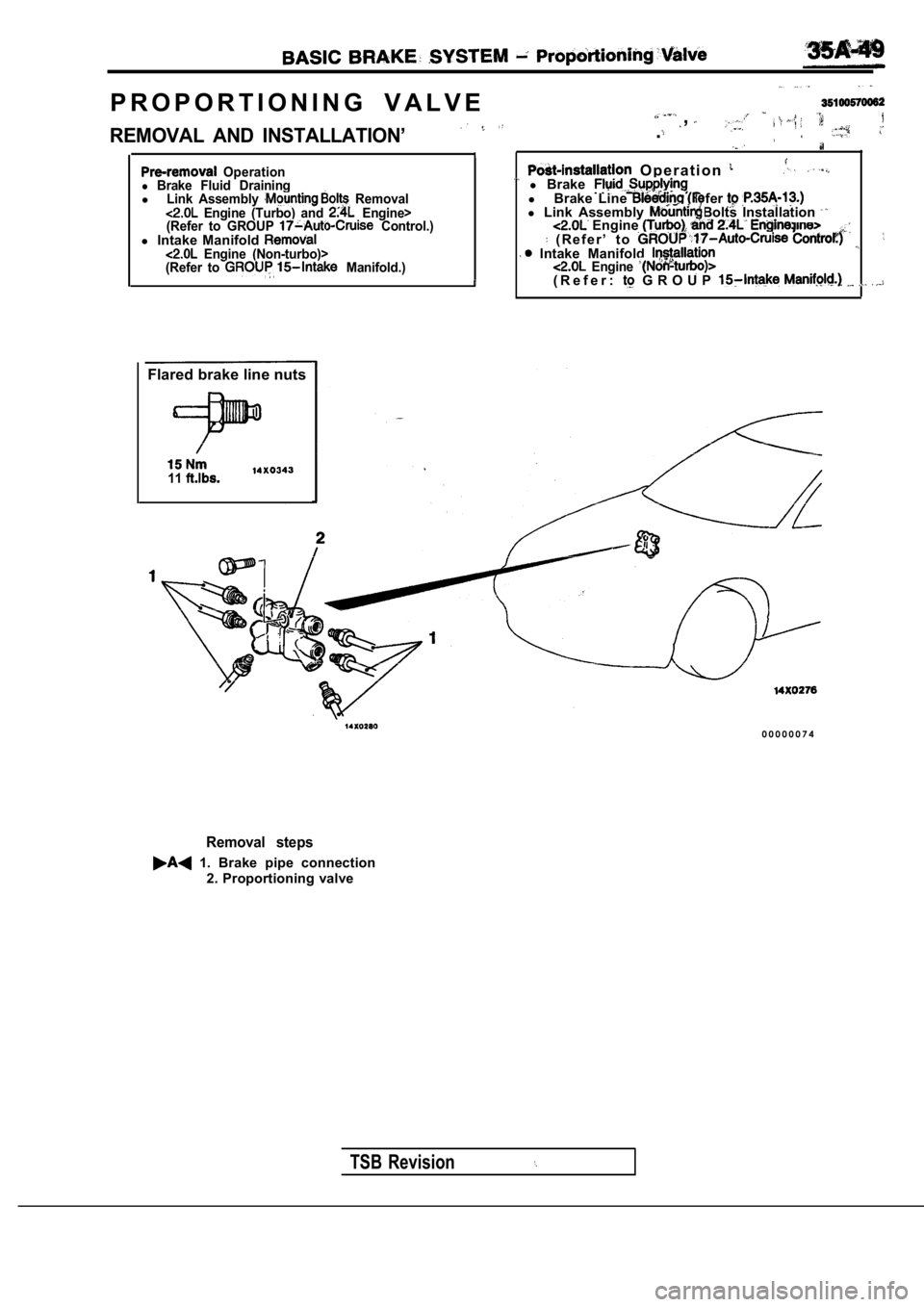

P R O P O R T I O N I N G V A L V E,

REMOVAL AND INSTALLATION’.

O p e r a t i o n Operationl Brake Fluid DrainingLink Assembly Removal l Brakel l Engine (Turbo) and Engine>Brake Line fer l

Link Assembly Bolts Installation (Refer to GROUP Control.) Engine l Intake Manifold ( R e f e r ’ t o Engine (Non-turbo)> Intake Manifold (Refer to Manifold.) Engine ( R e f e r : G R O U P

Flared brake line nuts

11

TSB Revision

Removal steps

1. Brake pipe connection

2. Proportioning valve

0 0 0 0 0 0 7 4

Page 1688 of 2103

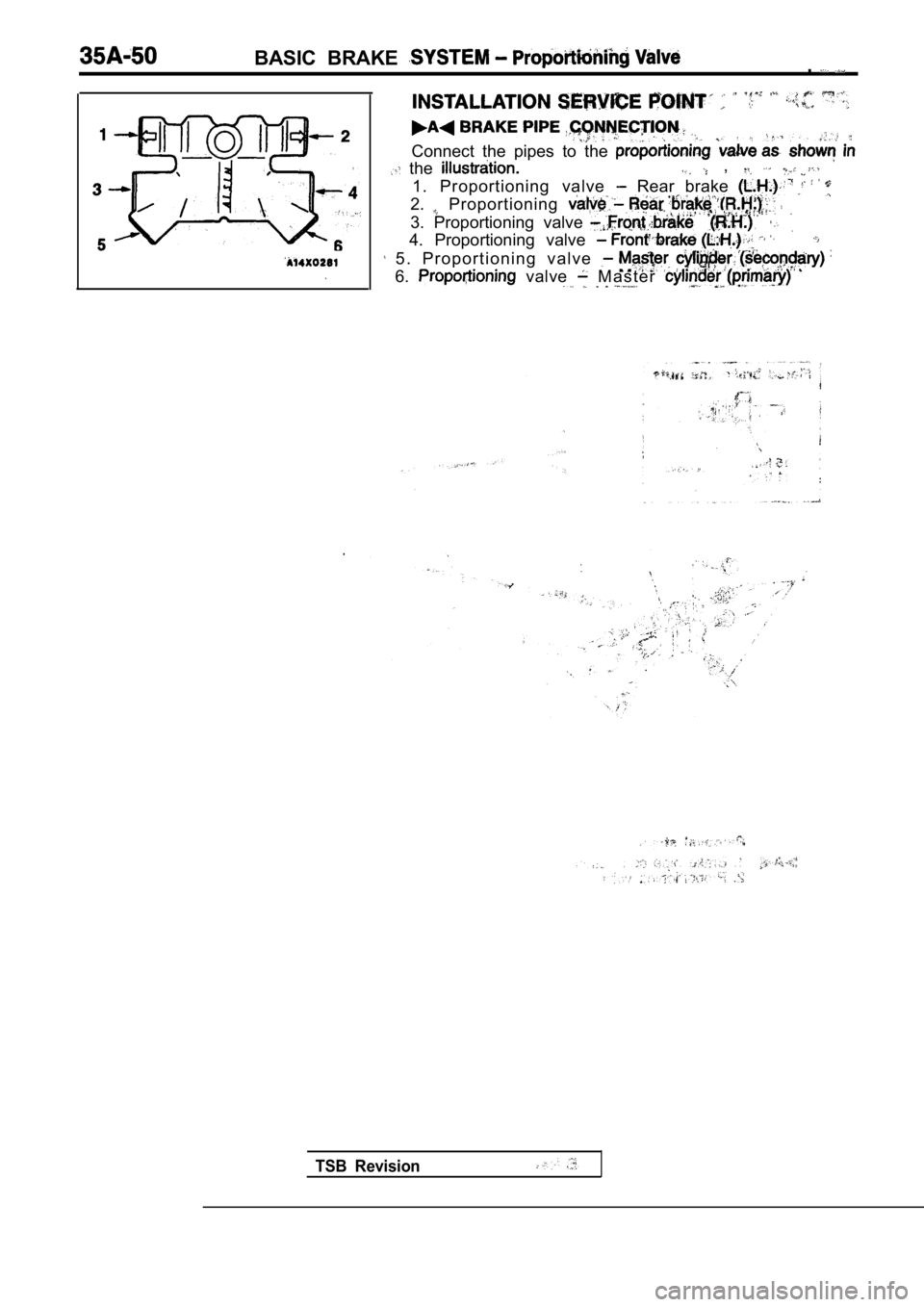

BASIC BRAKE ,

Connect the pipes to the

the ,

1. Proportioning valve Rear brake

2. Proportioning

3. Proportioning valve

4. Proportioning valve

5 . P r o p o r t i o n i n g v a l v e

6. valve M a s t e r

TSB Revision

Page 1689 of 2103

CONTENTS

ABS-ECU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41 VALVE. . . . . . . . . . . . . . . . .

GENERAL INFORMATION. . . . . . . . . . . . . . . . .2SERVICE SPECIFICATIONS.. . . . . . . . . . . . . .3

HYDRAULIC UNIT . . . . . . . . . . . . . . . . . . . . . . . . .36SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . .3

MASTER CYLINDER ANDTROUBLESHOOTING.. . . . . . . . . .. . . . . . . . .4

BRAKE BOOSTER. . . . . . . . . . . . . . . . . . . . . . . . .32..

W H E E L S P E E D .. . . .... . . . . . . . . . . . .38

ON-VEHICLE SERVICE24.... . . . . . . . . . . . . . . . . . . .

ABS Operation Check . . . . . . . . . . . . . . . . . . . . . . .

24

Bleeding

. . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Refer to GROUP for the following items.

BRAKE PEDAL

FRONT DISC BRAKE

LUBRICANTS

REAR DISC BRAKE

REAR DRUM BRAKE SHOE

REAR DRUM BRAKE WHEEL CYLINDER

ON-VEHICLE SERVICE

Brake Booster Operating Test

Brake Drum inside Diameter Check

Brake Fluid Level Sensor Check

Brake Lining and Brake Drum Contact Check

Brake Lining Thickness Check

Brake Pedal Check and Adjustment

Check Valve Operation Check

Front Brake Disc Run-out Check

Front Brake Disc Run-out Correction

Front Brake Disc Thickness Check

Front Disc Brake Pad Check and Replacement

Front Disc Brake Rotor Check

Proportioning Valve Function Test

Rear Brake Disc Run-out

Rear Brake Disc Run-out

Rear Brake Disc Thickness

Rear Disc Brake Pad and Replacement

S t o p L i g h t S w i t c h

Page 1690 of 2103

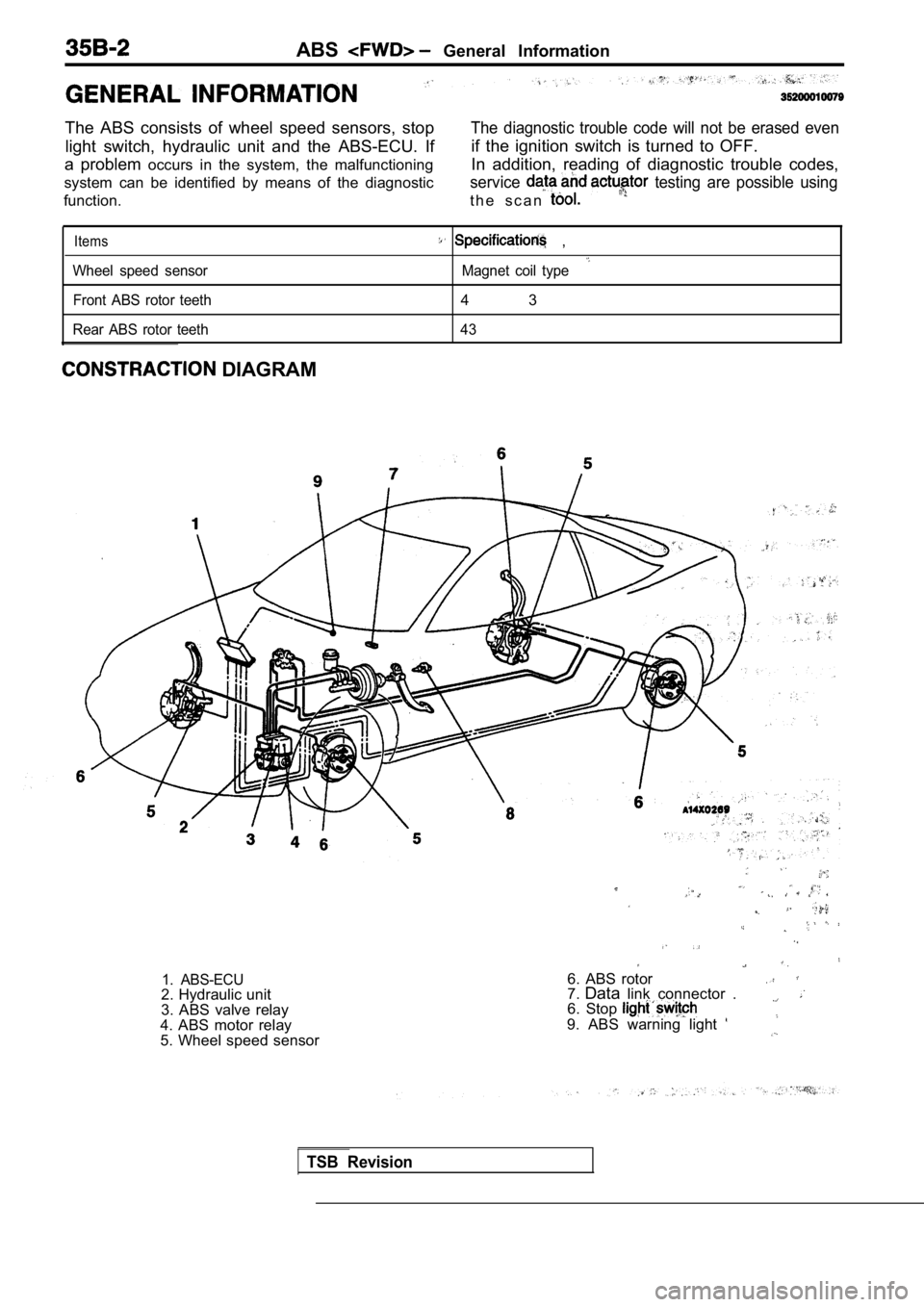

ABS General Information

The ABS consists of wheel speed sensors, stop light switch, hydraulic unit and the ABS-ECU. If

a problem occurs in the system, the malfunctioning

system can be identified by means of the diagnostic

function.

The diagnostic trouble code will not be erased even

if the ignition switch is turned to OFF.

In addition, reading of diagnostic trouble codes,

service testing are possible using

t h e s c a n

Items

Wheel speed sensor

Front ABS rotor teeth

Rear ABS rotor teeth

,

Magnet coil type

4 3

43

DIAGRAM

1. ABS-ECU6. ABS rotor7. Data link connector .

6. Stop

9. ABS warning light

2. Hydraulic unit

3. ABS valve relay

4. ABS motor relay

5. Wheel speed sensor

TSB Revision