MITSUBISHI SPYDER 1990 Service Repair Manual

SPYDER 1990

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57345/w960_57345-0.png

MITSUBISHI SPYDER 1990 Service Repair Manual

Trending: child seat, headlights, brake pads, coolant level, transmission oil, change wheel, refrigerant type

Page 671 of 2103

E N G I N E ( T U R B O )

AND ENGINE>

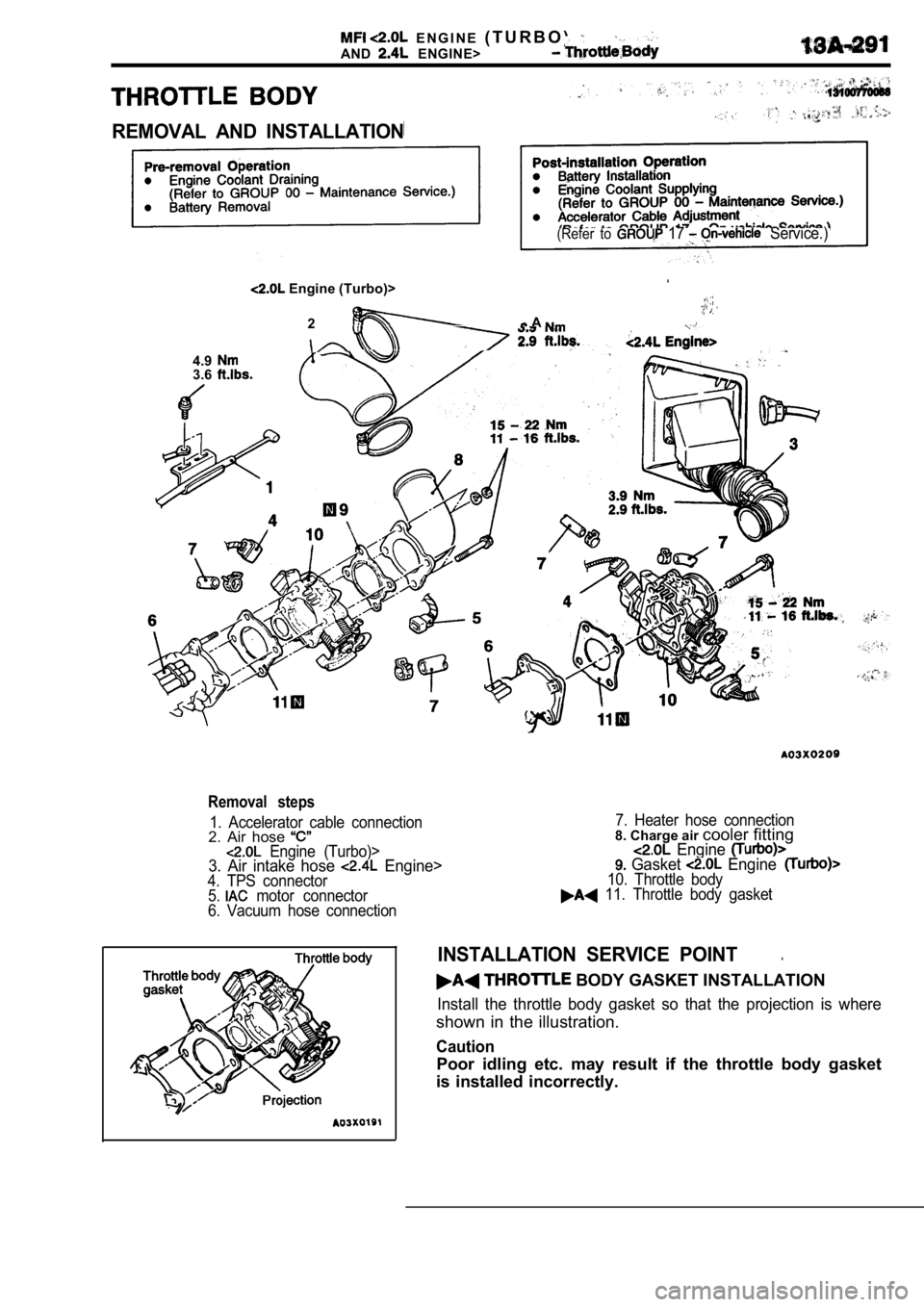

REMOVAL AND INSTALLATION

(Refer to 17 Service.)

Engine (Turbo)>

2 A . .

4.93.6

Removal steps

1. Accelerator cable connection2. Air hose Engine (Turbo)>3. Air intake hose Engine>4. TPS connector

5. motor connector

6. Vacuum hose connection 7. Heater hose connection

8. Charge air

cooler fitting Engine Gasket Engine10. Throttle body 11. Throttle body gasket

INSTALLATION SERVICE POINT.

BODY GASKET INSTALLATION

Install the throttle body gasket so that the projec tion is where

shown in the illustration.

Caution

Poor idling etc. may result if the throttle body ga sket

is installed incorrectly.

Page 672 of 2103

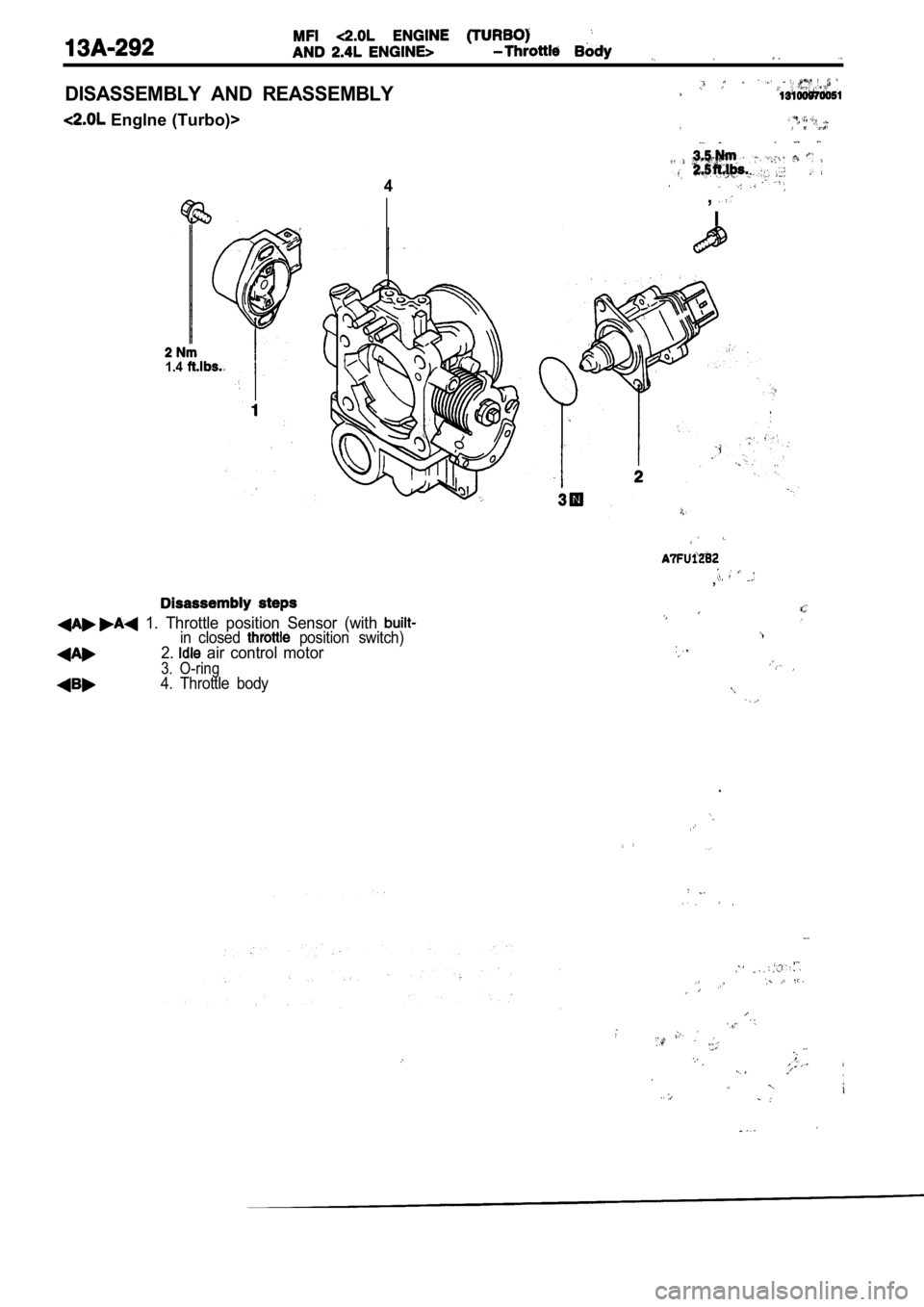

DISASSEMBLY AND REASSEMBLY

Englne (Turbo)>

4

1.4

,

I

1. Throttle position Sensor (with in closed position switch)2. air control motor

3. O-ring4. Throttle body

,

Page 673 of 2103

1.4

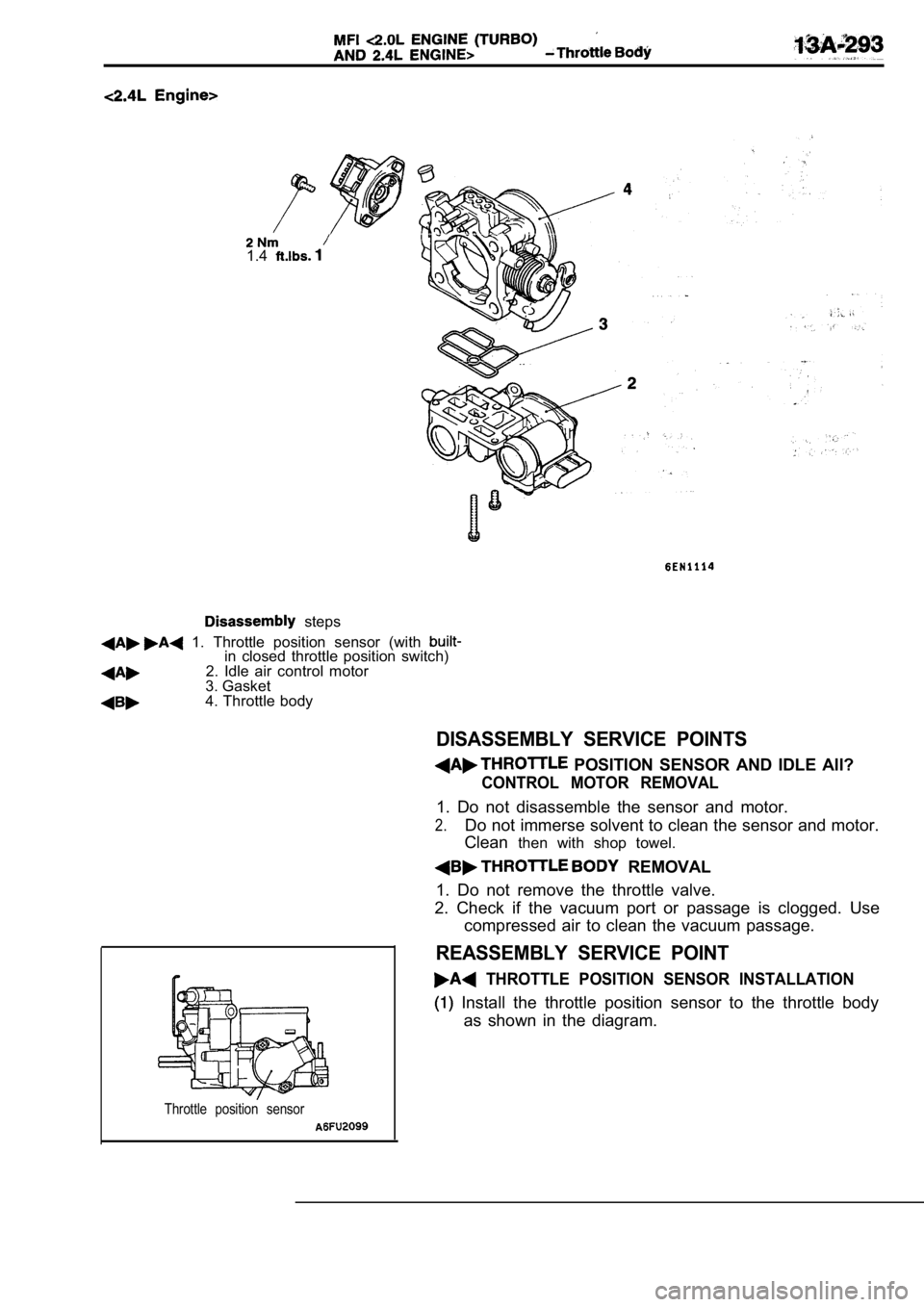

steps

1. Throttle position sensor (with in closed throttle position switch)2. Idle air control motor

3. Gasket

4. Throttle body

DISASSEMBLY SERVICE POINTS

POSITION SENSOR AND IDLE All?

CONTROL MOTOR REMOVAL

1. Do not disassemble the sensor and motor.

2.Do not immerse solvent to clean the sensor and moto r.

Clean then with shop towel.

REMOVAL

1. Do not remove the throttle valve.

2. Check if the vacuum port or passage is clogged. Use

compressed air to clean the vacuum passage.

REASSEMBLY SERVICE POINT

THROTTLE POSITION SENSOR INSTALLATION

Install the throttle position sensor to the thrott le body

as shown in the diagram.

Throttle position sensor

Page 674 of 2103

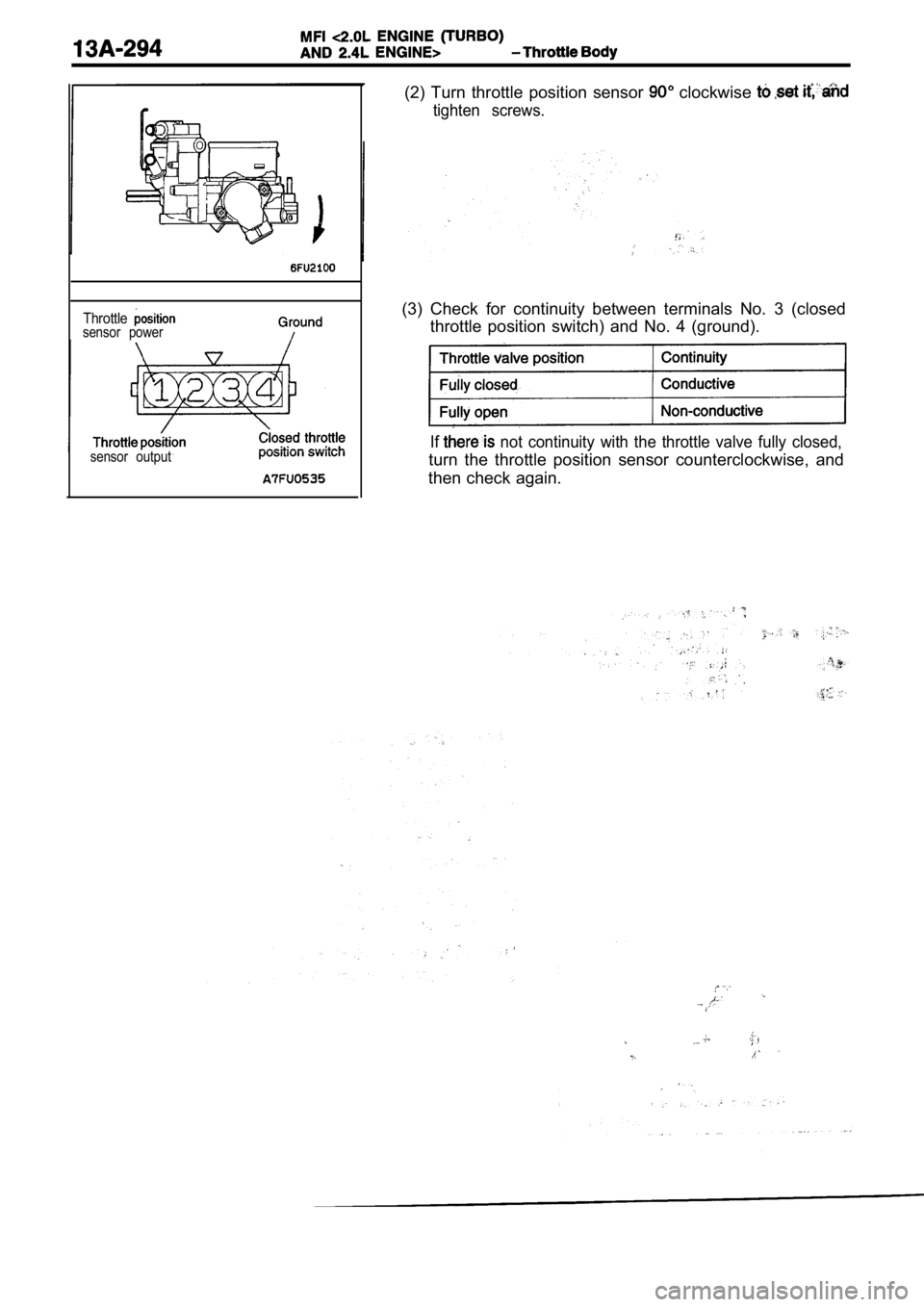

Throttlesensor powersensor output

(2) Turn throttle position sensor clockwise

tighten screws.

(3) Check for continuity between terminals No. 3 (c losed

throttle position switch) and No. 4 (ground).

If not continuity with the throttle valve fully close d,

turn the throttle position sensor counterclockwise, and

then check again.

Page 675 of 2103

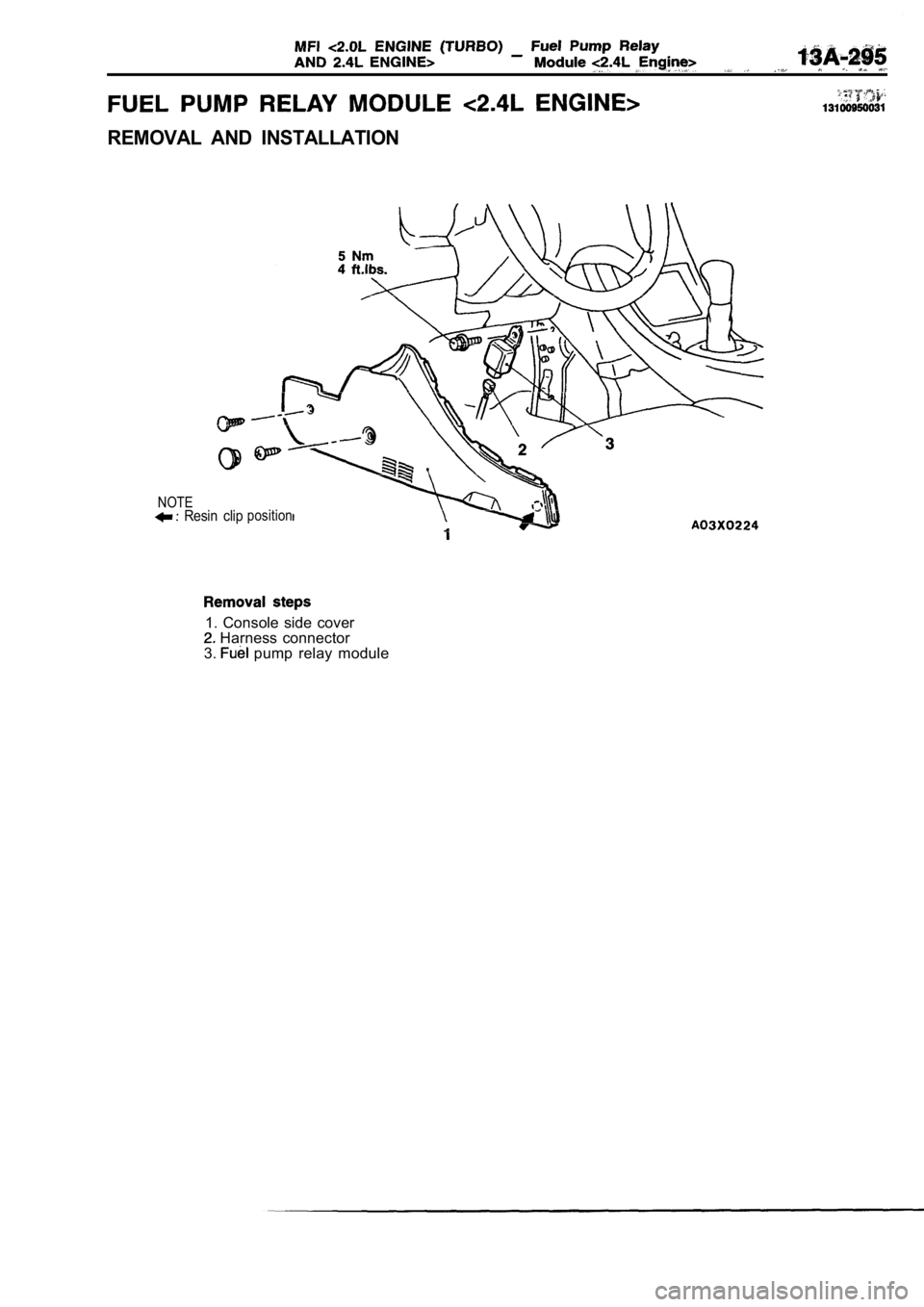

REMOVAL AND INSTALLATION

NOTE Resin clipposition

1. Console side cover Harness connector

3. pump relay module

Page 676 of 2103

Page 677 of 2103

, ,

CONTENTS

FUEL FILTER . . . . . . . . . . . . . . . . . . . . . . 12SERVICE . . . . .

FUEL TANK. . . . . . . . . . . . . . . . . . . . . . . . 2SPECIAL TOOL. . . . . . . . . , . . . . . , . . . . . . ‘2

FUEL TANK4. . . . . . . . . . . . . . . . . . . . .3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL INFORMATION . . . . . . . . . . . . . . . . 2

Page 678 of 2103

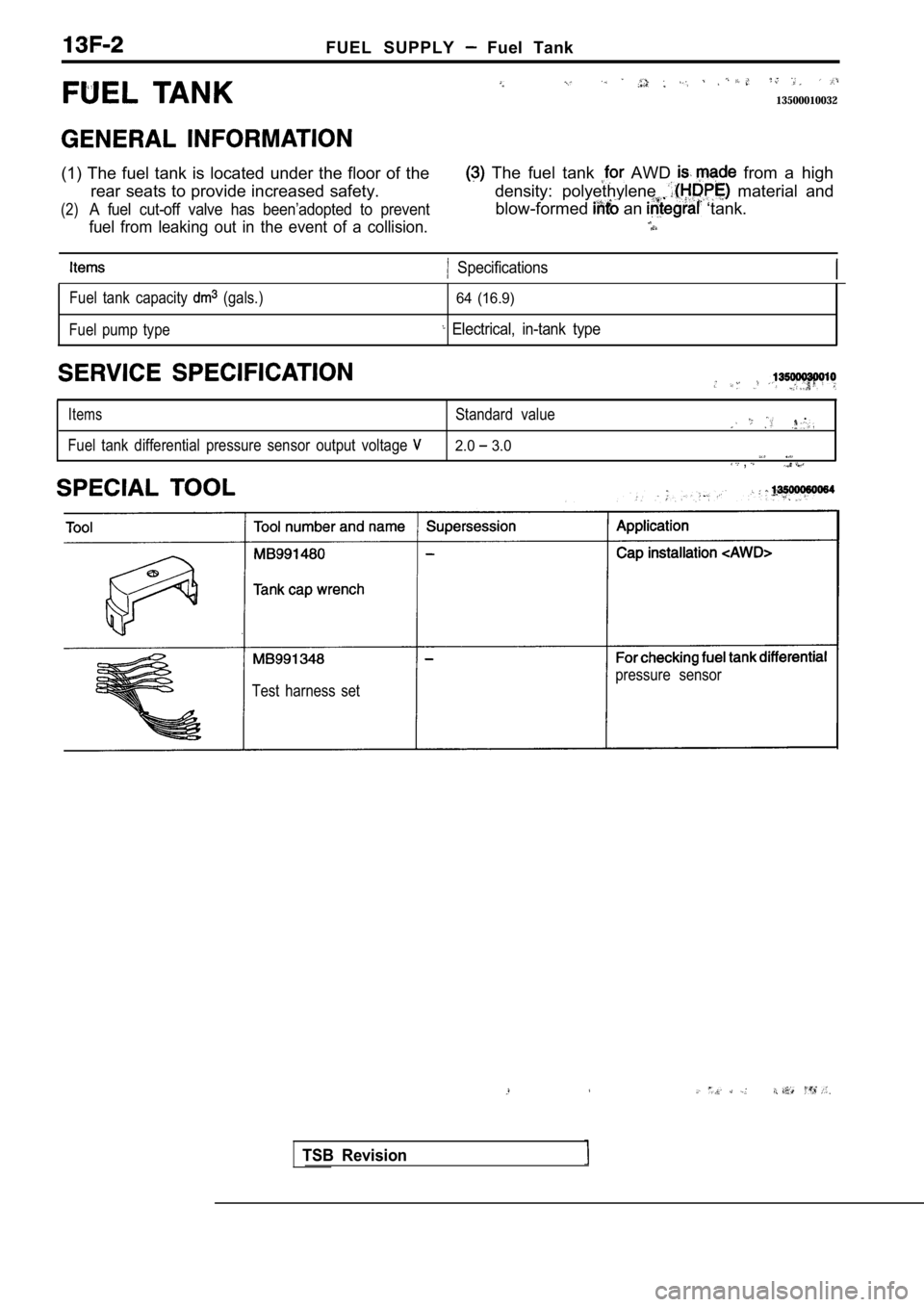

FUEL SUPPLY Fuel Tank

13500010032

(1) The fuel tank is located under the floor of the The fuel tank AWD from a high

rear seats to provide increased safety. density: pol yethylene

material and

(2)A fuel cut-off valve has been’adopted to preventblow-formed an ‘tank.

fuel from leaking out in the event of a collision.

Specifications

Fuel tank capacity (gals.)

Fuel pump type64 (16.9)

Electrical, in-tank type

ItemsStandard value.

Fuel tank differential pressure sensor output volta ge 2.0 3.0 ,

Test harness set pressure sensor

TSB Revision

Page 679 of 2103

FUEL SUPPLY -‘Fuel Tank

SymptomProbable cause

Engine malfunctions

Bent or kinked fuel pipe or hose Repair or replace

due to insufficient fuelClogged fuel pipe or hoseClean or replace

Clogged fuel filter or in-tank fuel filter

Water in fuel filter

Dirty or rusted fuel tank interior

Replace. .

Replace the fuel filter or clean the fuel

tank and fuel line

Clean or replace

Malfunctioning fuel pump

(Clogged filter in the pump)

Evaporative emission Mispiping of vapor line .

control system mal-

functions Disconnected vapor line piping joint

(When tank filler tube

cap is removed, pres-

Folded, bent, cracked or clogged vapor line

sure releasing noise is

heard)Faulty fuel tank filler tube cap Replace

Correct

CorrectReplace

Revision I

Page 680 of 2103

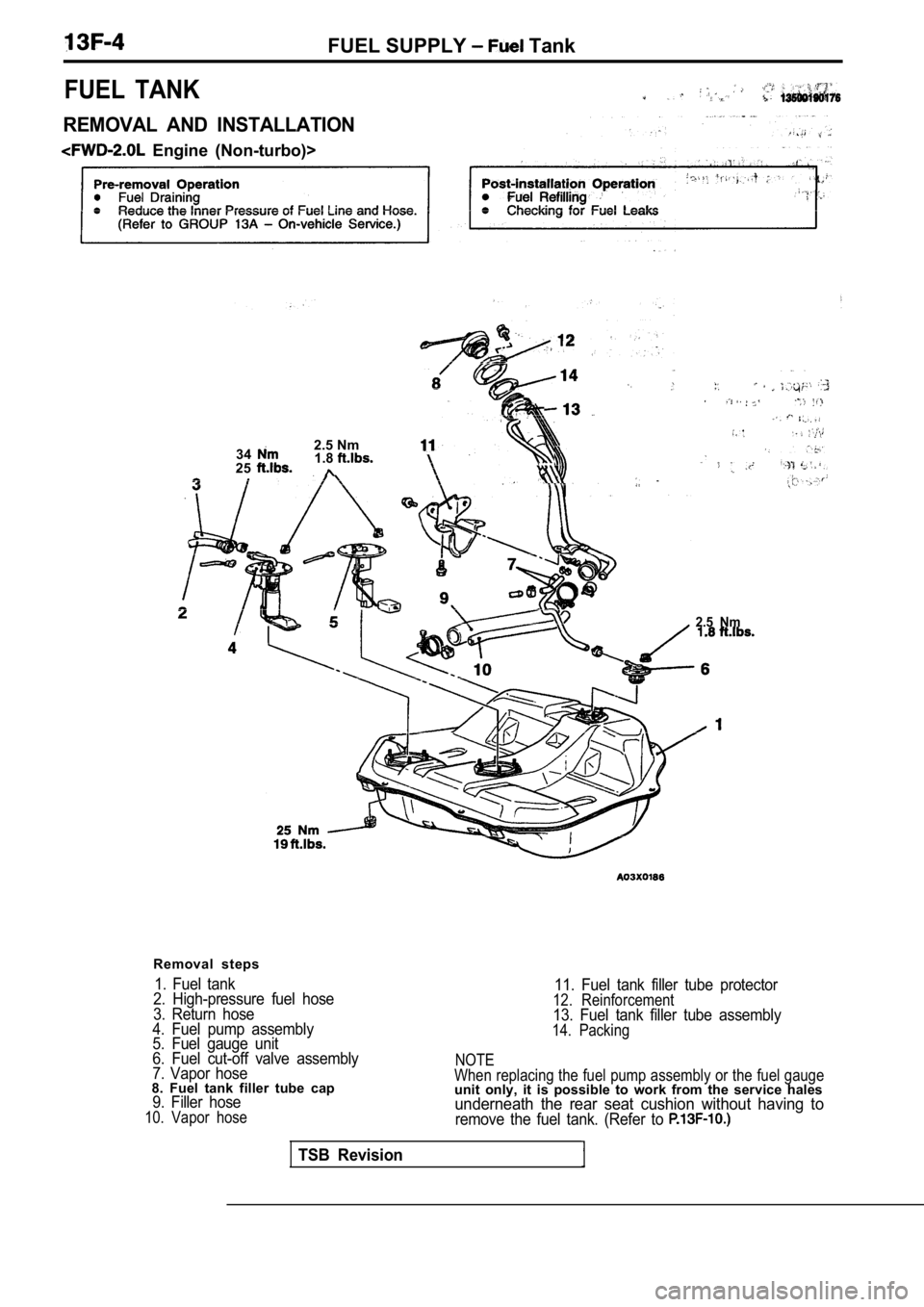

FUEL SUPPLY Tank

FUEL TANK

REMOVAL AND INSTALLATION

Engine (Non-turbo)>34

2.5 Nm

251.8

2.5 Nm

Removal steps

1. Fuel tank

2. High-pressure fuel hose

3. Return hose

4. Fuel pump assembly

5. Fuel gauge unit

6. Fuel cut-off valve assembly

7. Vapor hose

8. Fuel tank filler tube cap9. Filler hose10. Vapor hose

TSB Revision

11. Fuel tank filler tube protector12. Reinforcement13. Fuel tank filler tube assembly14. Packing

NOTE

When replacing the fuel pump assembly or the fuel g auge

unit only, it is possible to work from the service halesunderneath the rear seat cushion without having toremove the fuel tank. (Refer to

Trending: clock reset, clutch, brake pads replacement, air conditioning, air bleeding, horn, battery