MITSUBISHI SPYDER 1990 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 691 of 2103

CONTENTS

GENERAL INFORMATION. . . . . . . . . . . . . . . . . .2SERVICE SPECIFICATIONS . . . . . . . . . . . . . . . . . 3

LUBRICANT3THERMOSTAT. . . . . . . . . . . . . . . . . . . . . . . . . . . .13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ON-VEHICLE SERVICE. . . . . . . . . . . . . . . . . . . . .7TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . .4

Engine Coolant Concentration Test. . . . . . . . . . . .7.

Engine Coolant Leak Check . . . . . . . . . . . . . . . . . .

7WATER HOSE ‘AND PIPE

. . . . . . . . .

Engine Coolant Replacement. . . . . . . . . . . . . . . . .7 AND

Radiator Cap Valve Opening Pressure CheckENGINE>. . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . .22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7WATER PUMP

RADIATOR. . . . . . . . . .18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 ENGINE (NON-TURBO)>

ENGINE (TURBO) AND , , S E A L A N T

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3ENGINE>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Page 692 of 2103

14-2ENGINE COOLING General Information

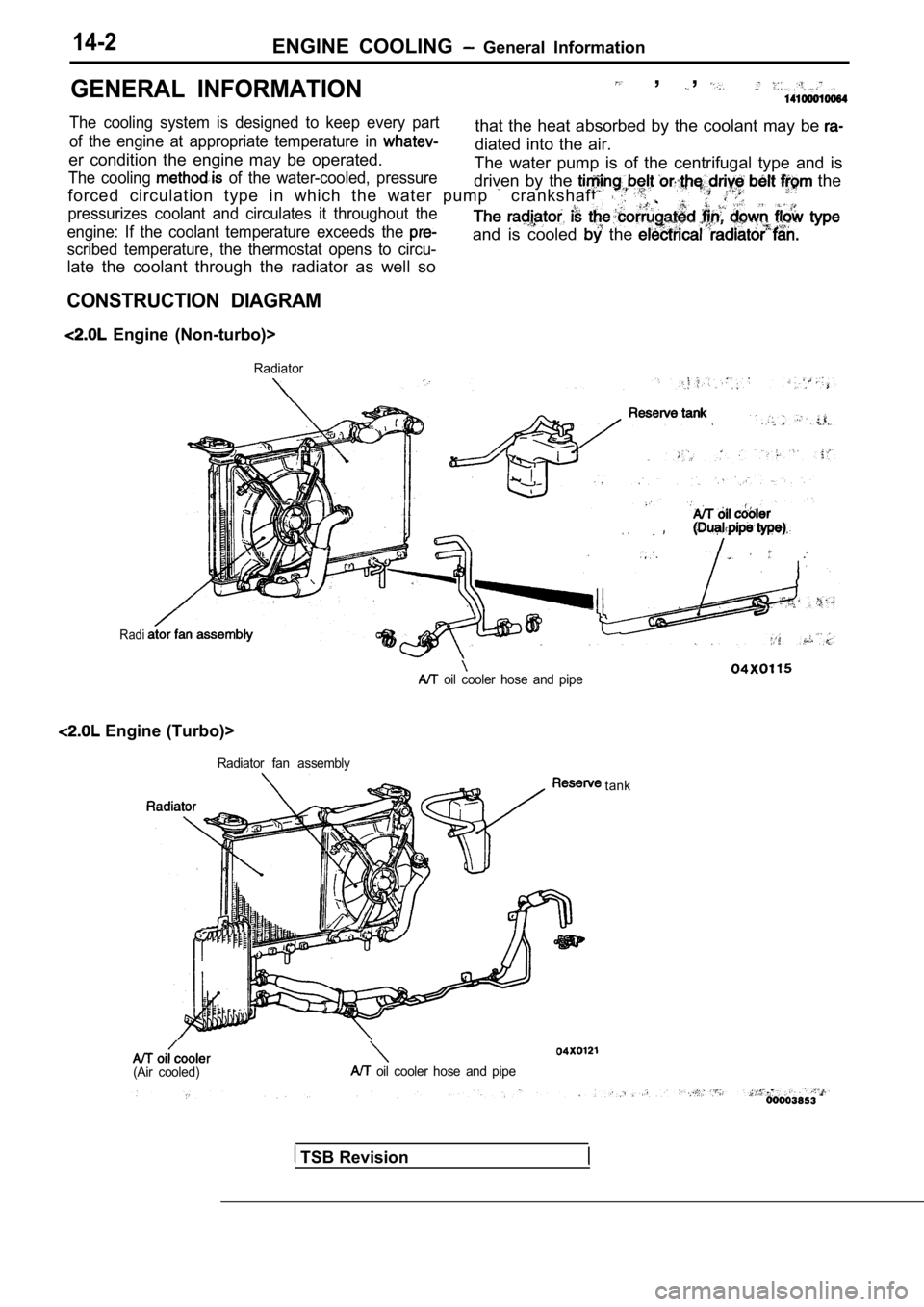

GENERAL INFORMATION , ,

The cooling system is designed to keep every partthat the heat absorbed by the coolant may be of the engine at appropriate temperature in diated into the air.

er condition the engine may be operated.

The cooling of the water-cooled, pressureThe water pump is of the centrifugal type and is

driven by the

the

forced circulation type in which the water pump crankshaft. .

pressurizes coolant and circulates it throughout th e

engine: If the coolant temperature exceeds the

scribed temperature, the thermostat opens to circu-

late the coolant through the radiator as well so

and is cooled the

CONSTRUCTION DIAGRAM

Engine (Non-turbo)>

Radiator

Radi

.

oil cooler hose and pipe

Engine (Turbo)>

Radiator fan assembly

(Air cooled) oil cooler hose and pipetank

TSB Revision

Page 693 of 2103

G e n e r a l

ENGINE COOLING

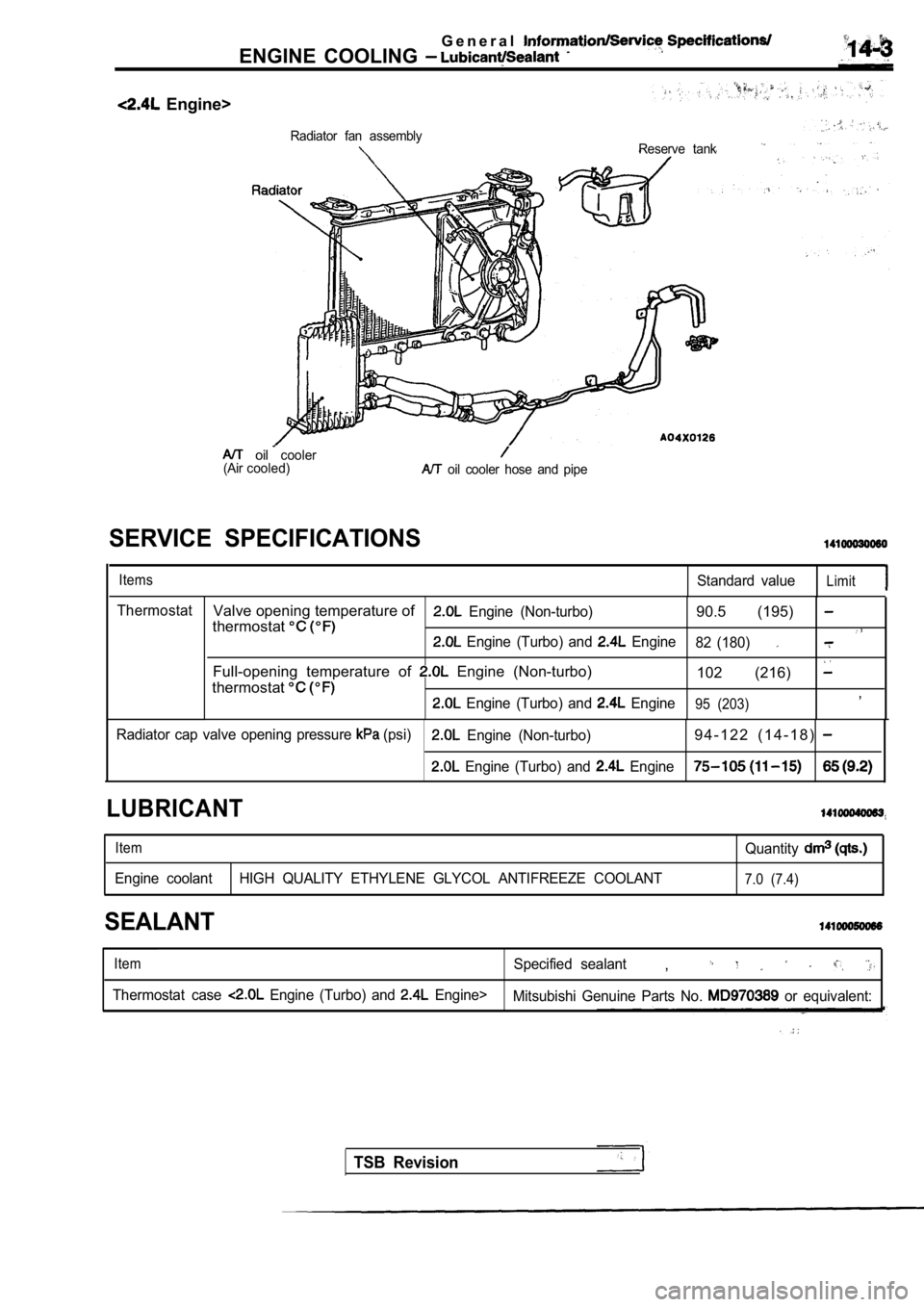

Engine>

Radiator fan assemblyReserve tank

(Airoilcooler

cooled) oil cooler hose and pipe

SERVICE SPECIFICATIONS

ItemsStandard valueLimit

ThermostatValve opening temperature of Engine (Non-turbo)90.5 (195) thermostat Engine (Turbo) and Engine 82 (180)

Full-opening temperature of Engine (Non-turbo)

102 (216)

thermostat

Engine (Turbo) and Engine95 (203),

Radiator cap valve opening pressure (psi) Engine (Non-turbo)9 4 - 1 2 2 ( 1 4 - 1 8 )

Engine (Turbo) and Engine

LUBRICANT

ItemQuantity

Engine coolant HIGH QUALITY ETHYLENE GLYCOL ANTIFREE ZE COOLANT7.0 (7.4)

SEALANT

ItemSpecified sealant,

Thermostat case Engine (Turbo) and Engine>

Mitsubishi Genuine Parts No. or equivalent:

TSB Revision

Page 694 of 2103

E N G I N E C O O L I N G

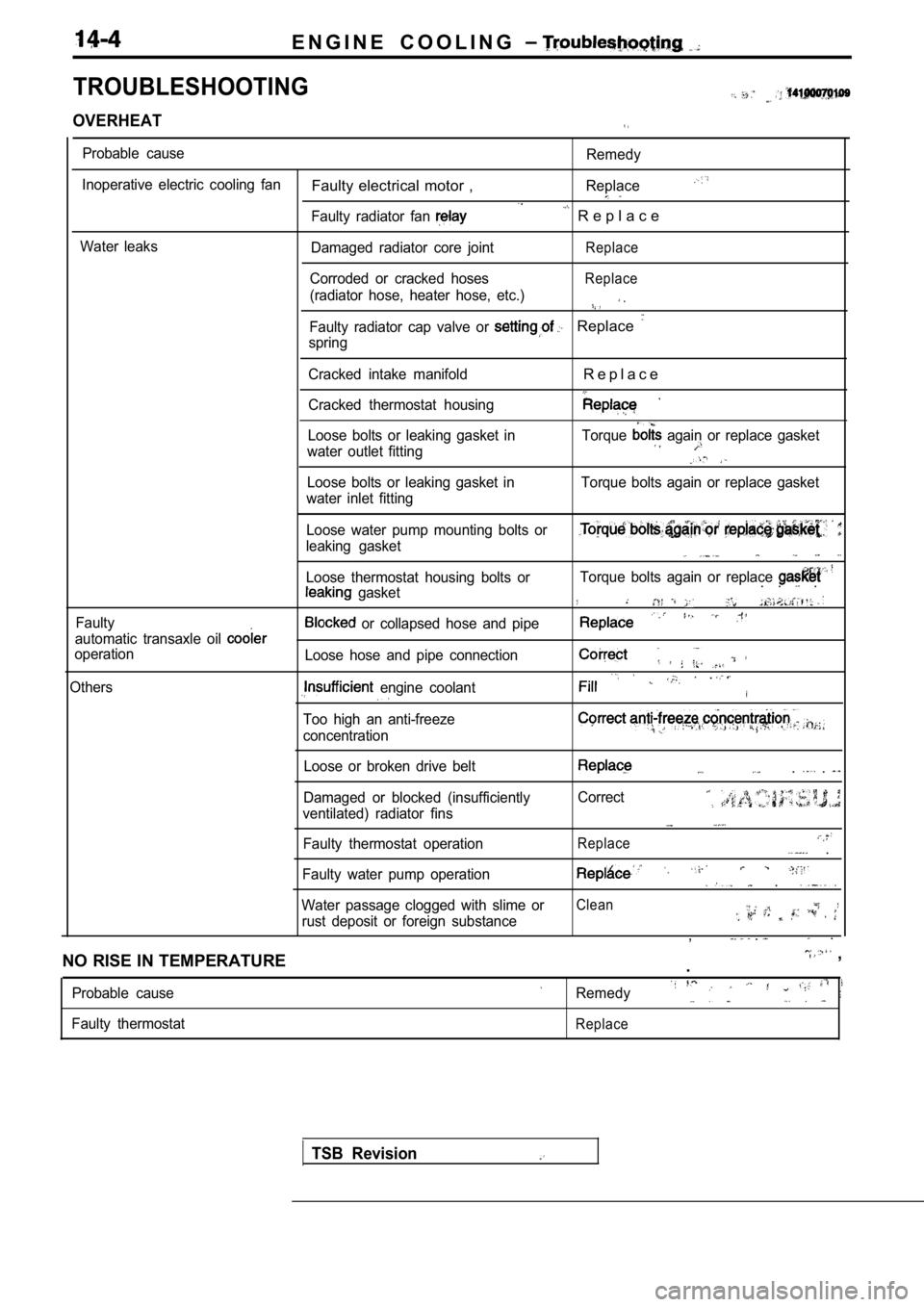

TROUBLESHOOTING

OVERHEAT

Probable cause

Inoperative electric cooling fan

Water leaks

Faulty electrical motor ,

Faulty radiator fan

Damaged radiator core joint

Corroded or cracked hoses

(radiator hose, heater hose, etc.)

Remedy

Replace

R e p l a c e

Replace

Replace

.

Faulty radiator cap valve or Replace

spring

Cracked intake manifold

Cracked thermostat housing

R e p l a c e

Loose bolts or leaking gasket in

water outlet fitting Torque again or replace gasket

Loose bolts or leaking gasket in

water inlet fitting Torque bolts again or replace gasket

Faulty Loose water pump mounting bolts or

leaking gasket

Loose thermostat housing bolts or

gasket

automatic transaxle oil

operation

Others

or collapsed hose and pipe

Loose hose and pipe connection

engine coolant

Too high an anti-freeze

concentration

Torque bolts again or replace . . .

.

Loose or broken drive belt

Damaged or blocked (insufficiently

ventilated) radiator fins

Faulty thermostat operation. .

Correct

Replace .

Faulty water pump operation .

Water passage clogged with slime orClean

rust deposit or foreign substance, . .

NO RISE IN TEMPERATURE

,

.

Probable cause

Faulty thermostatRemedy

Replace

TSB Revision

Page 695 of 2103

ENGINE COOLING Troubleshooting

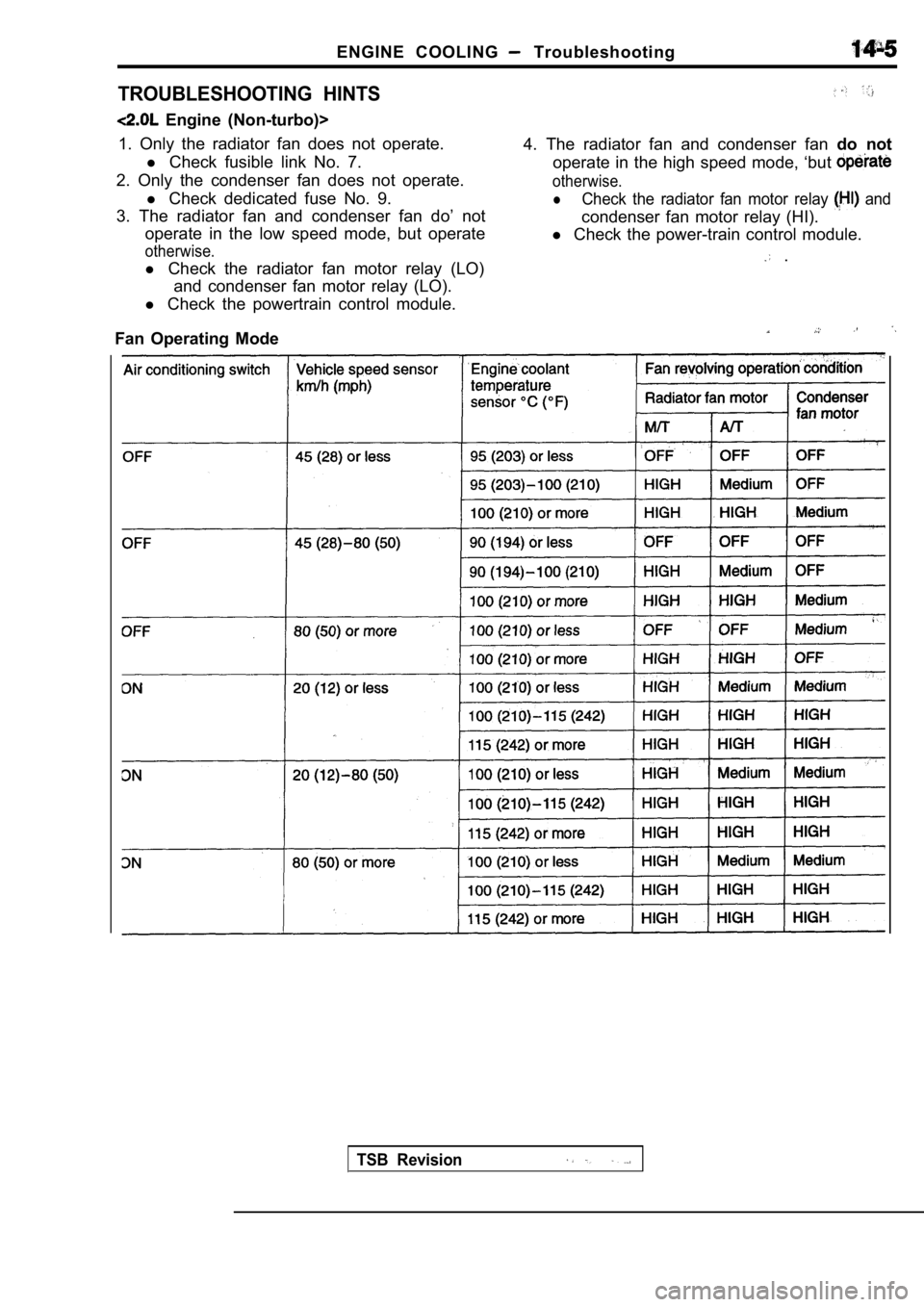

TROUBLESHOOTING HINTS

Engine (Non-turbo)>

1. Only the radiator fan does not operate. l Check fusible link No. 7.

2. Only the condenser fan does not operate. l Check dedicated fuse No. 9.

3. The radiator fan and condenser fan do’ not operate in the low speed mode, but operate

otherwise.

4. The radiator fan and condenser fan do not

operate in the high speed mode, ‘but

otherwise.

lCheck the radiator fan motor relay and

condenser fan motor relay (HI).

l Check the power-train control module.

l Check the radiator fan motor relay (LO)

and condenser fan motor relay (LO).

l Check the powertrain control module.

Fan Operating Mode

.

TSB Revision

Page 696 of 2103

14-6ENGINE COOLING

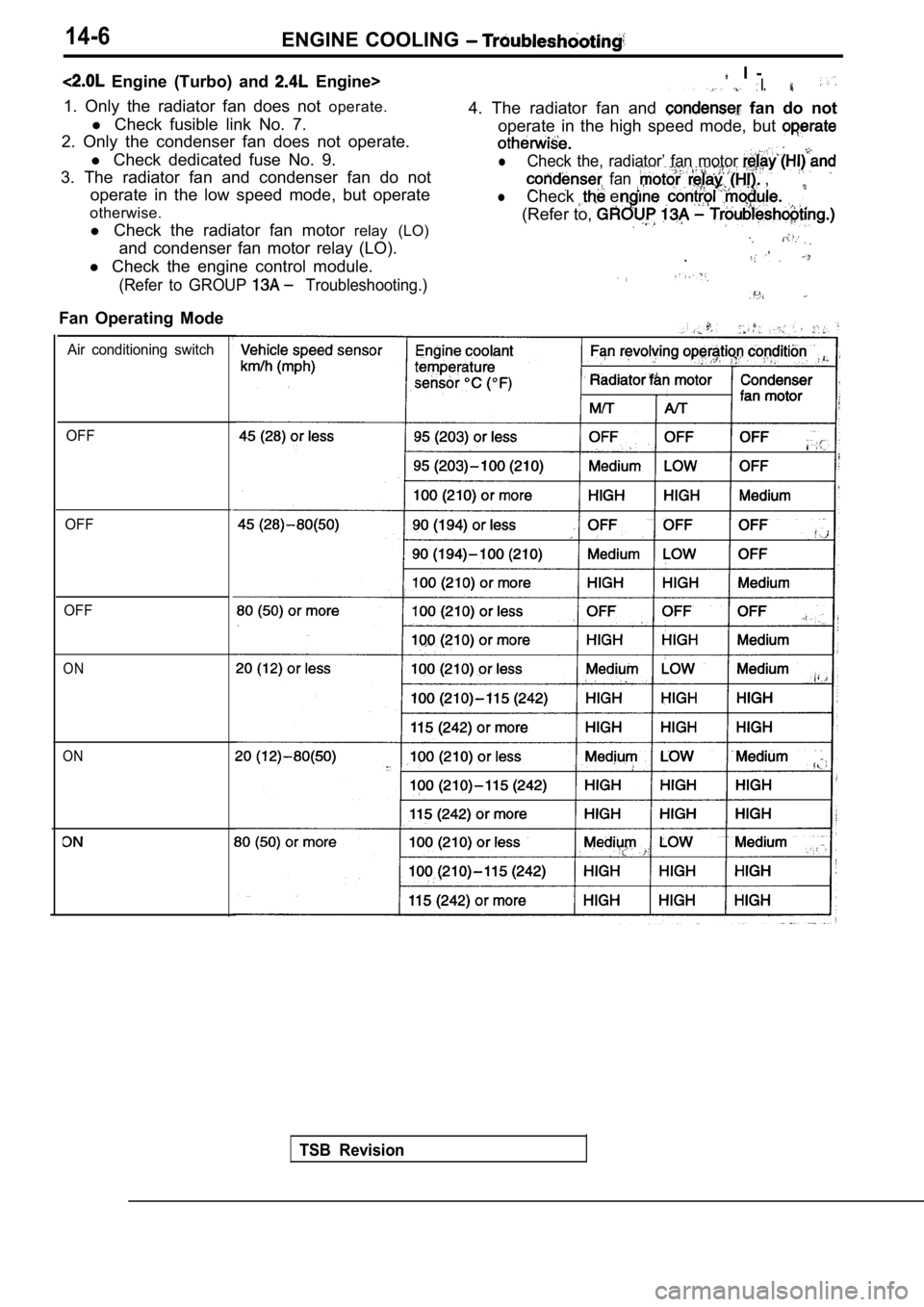

Engine (Turbo) and Engine>

1. Only the radiator fan does not operate.

l Check fusible link No. 7.

2. Only the condenser fan does not operate.

l Check dedicated fuse No. 9.

3. The radiator fan and condenser fan do not operate in the low speed mode, but operate

otherwise.

l Check the radiator fan motor relay (LO)

and condenser fan motor relay (LO).

l Check the engine control module.

(Refer to GROUP Troubleshooting.)

I -* I.

4. The radiator fan and fan do not

Fan Operating Mode operate in the high speed mode, but

lCheck the, radiator’ fan motor

fan ,

lCheck en

(Refer to,

.

Air conditioning switch

OFF

OFF

OFF

ON

ON

TSB Revision

Page 697 of 2103

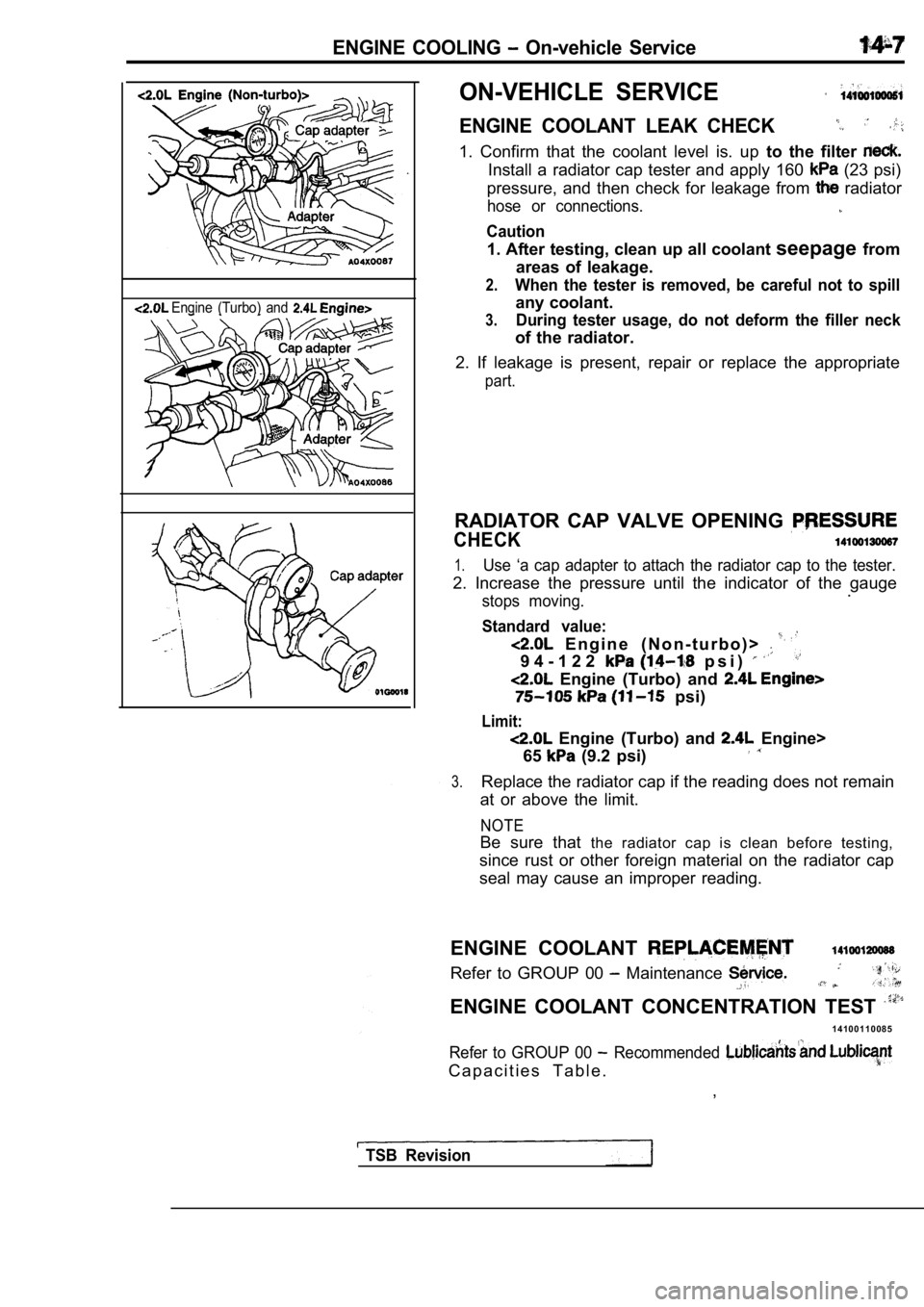

ENGINE COOLING On-vehicle Service

Engine (Turbo) and

ON-VEHICLE SERVICE

ENGINE COOLANT LEAK CHECK

1. Confirm that the coolant level is. up to the filter

Install a radiator cap tester and apply 160 (23 psi)

pressure, and then check for leakage from

radiator

hose or connections.

Caution

1. After testing, clean up all coolant seepagefrom

areas of leakage.

2.When the tester is removed, be careful not to spill

any coolant.

3.During tester usage, do not deform the filler neck

of the radiator.

2. If leakage is present, repair or replace the app ropriate

part.

RADIATOR CAP VALVE OPENING

CHECK

1.Use ‘a cap adapter to attach the radiator cap to the tester.

2. Increase the pressure until the indicator of the gauge

stops moving..

Standard value:

E n g i n e ( N o n - t u r b o ) >

9 4 - 1 2 2 p s i )

Engine (Turbo) and

psi)

Limit:

Engine (Turbo) and Engine>

65

(9.2 psi)

3.Replace the radiator cap if the reading does not re main

at or above the limit.

NOTE

Be sure that the radiator cap is clean before testing,

since rust or other foreign material on the radiato r cap

seal may cause an improper reading.

ENGINE COOLANT

Refer to GROUP 00 Maintenance

ENGINE COOLANT CONCENTRATION TEST

1 4 1 0 0 1 1 0 0 8 5

Refer to GROUP 00 Recommended

C a p a c i t i e s T a b l e . ,

TSB Revision

Page 698 of 2103

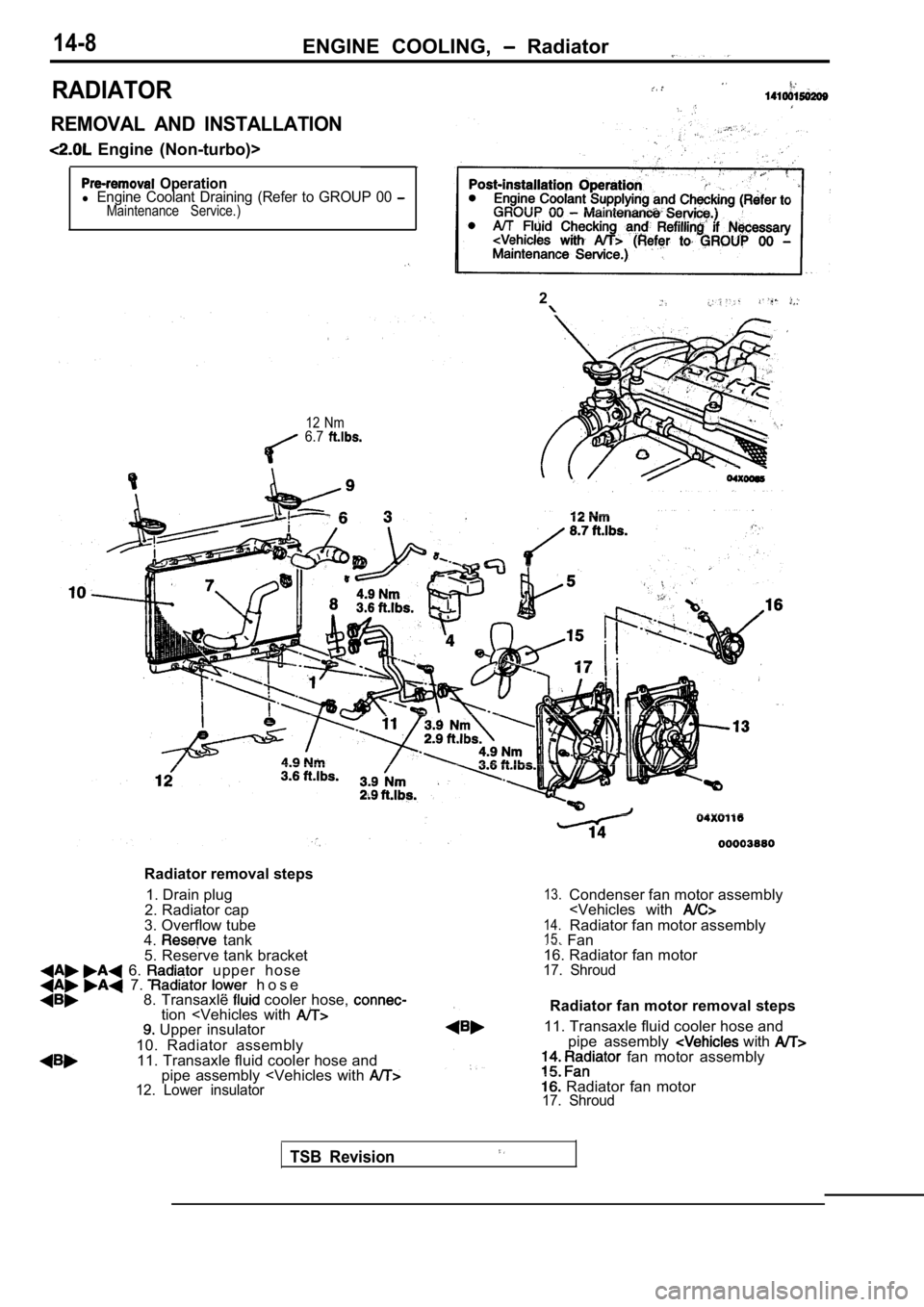

14-8ENGINE COOLING, Radiator

RADIATOR

REMOVAL AND INSTALLATION

Engine (Non-turbo)>

Operationl Engine Coolant Draining (Refer to GROUP 00 Maintenance Service.)

2

12 Nm6.7

Radiator removal steps1. Drain plug

2. Radiator cap

3. Overflow tube

4.

tank

5. Reserve tank bracket

6. upper hose 7. h o s e

8. Transaxle cooler hose, tion

11. Transaxle fluid cooler hose and pipe assembly

13.Condenser fan motor assembly

16. Radiator fan motor

17. Shroud

Radiator fan motor removal steps

11. Transaxle fluid cooler hose and pipe assembly

with fan motor assembly

Radiator fan motor17. Shroud

TSB Revision

Page 699 of 2103

ENGINE

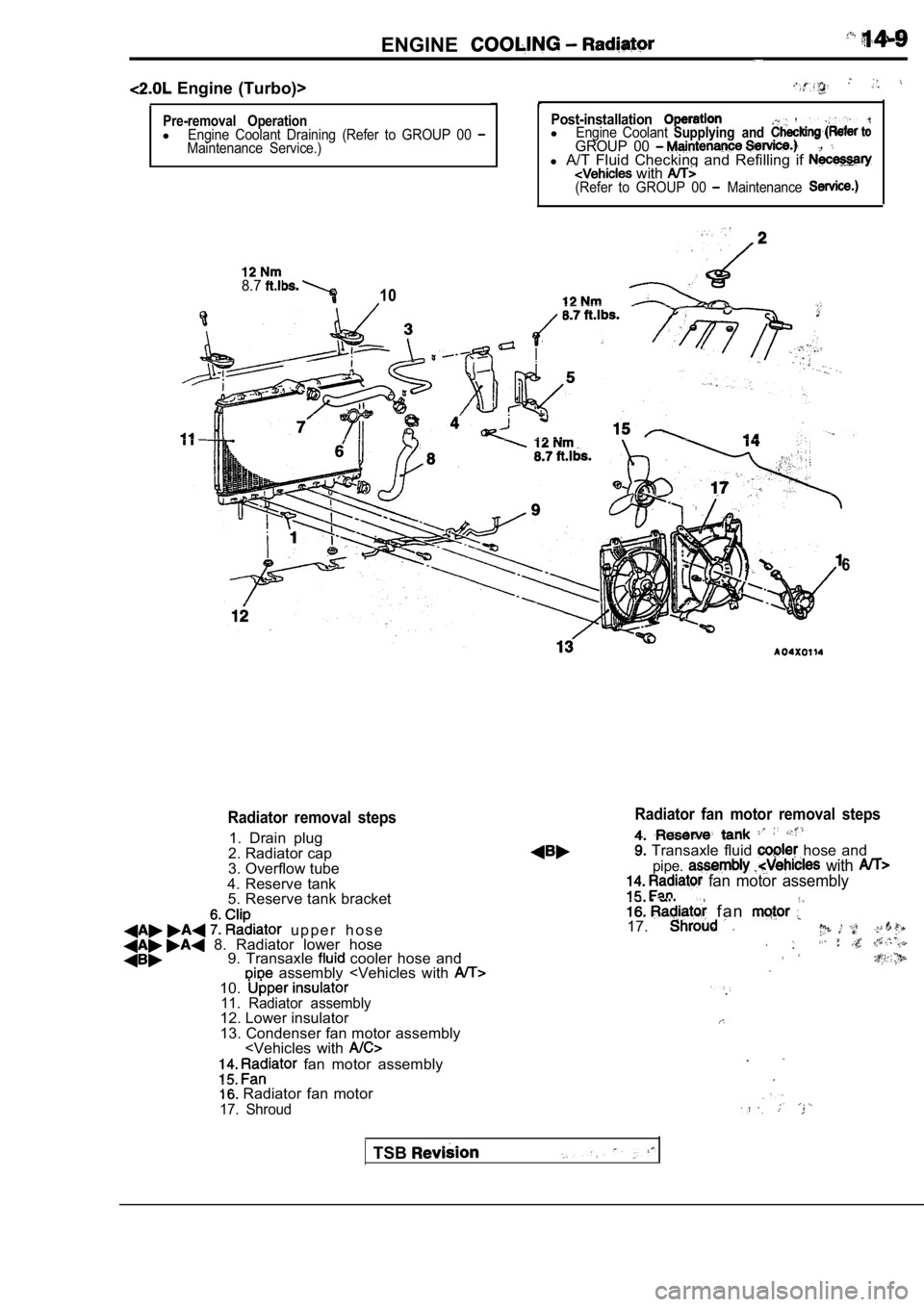

Engine (Turbo)>

Pre-removal OperationlEngine Coolant Draining (Refer to GROUP 00 Maintenance Service.)

Post-installation.

lEngine Coolant Supplying and GROUP 00 l A/T Fluid Checking and Refilling if with (Refer to GROUP 00 Maintenance

8.710

6

Radiator removal steps

1. Drain plug

2. Radiator cap

3. Overflow tube

4. Reserve tank 5. Reserve tank bracket

u p p e r h o s e 8. Radiator lower hose 9. Transaxle cooler hose and assembly

Radiator fan motor

17. Shroud

Radiator fan motor removal steps

Transaxle fluid hose and

pipe. with fan motor assembly

f a n 17.

.

.

TSB

Page 700 of 2103

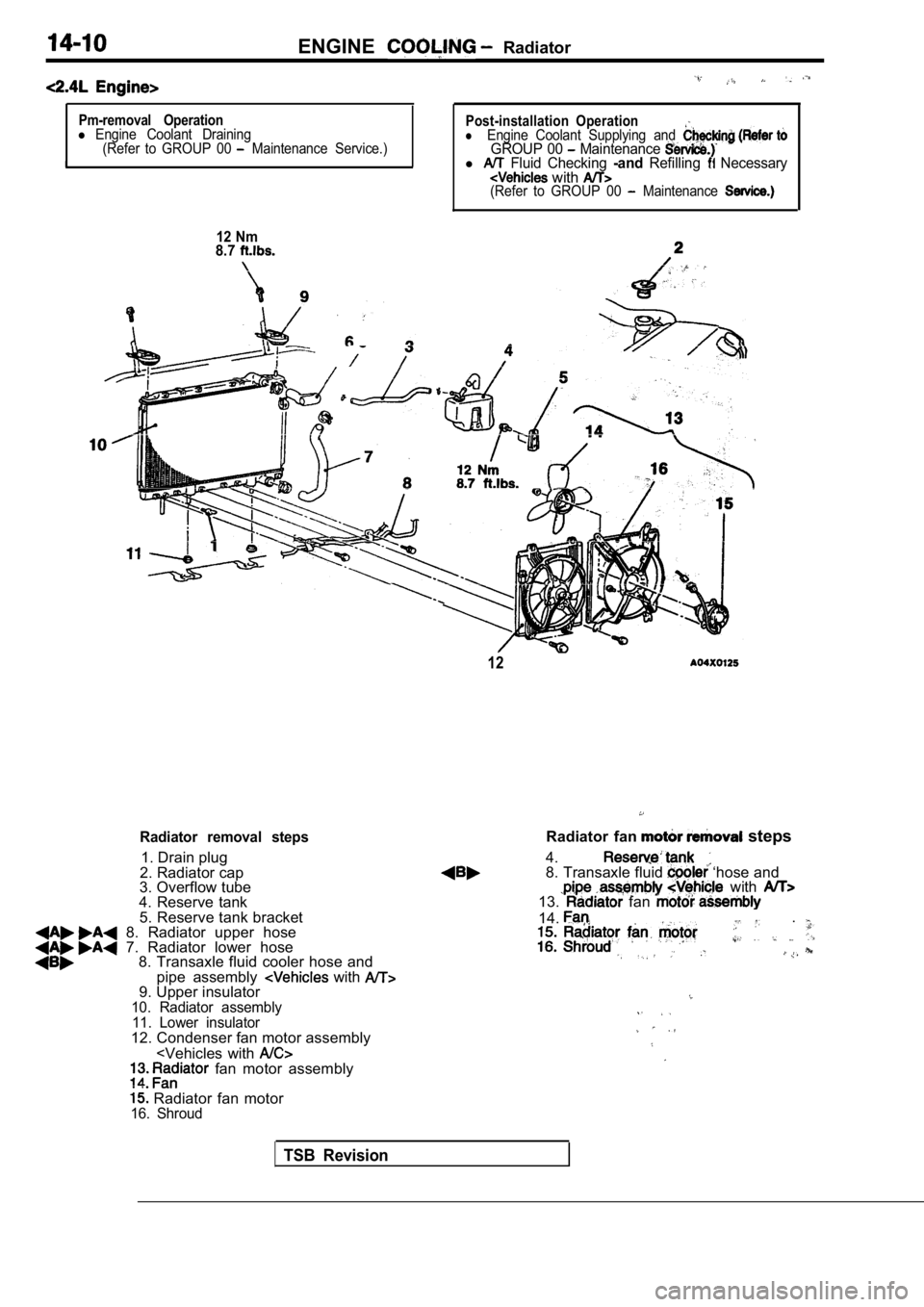

ENGINE Radiator

Pm-removal Operationl Engine Coolant Draining(Refer to GROUP 00 Maintenance Service.)II

Post-installation OperationlEngine Coolant Supplying and GROUP 00 Maintenance l Fluid Checking -andRefilling Necessary with (Refer to GROUP 00 Maintenance

12 Nm8.7

Radiator removal steps

1. Drain plug

2. Radiator cap

3. Overflow tube

4. Reserve tank

5. Reserve tank bracket

8. Radiator upper hose 7. Radiator lower hose8. Transaxle fluid cooler hose and pipe assembly with 9. Upper insulator10. Radiator assembly11. Lower insulator

12. Condenser fan motor assembly

Radiator fan motor16. Shroud

12

Radiator fan steps

4.

8. Transaxle fluid ‘hose and with 13. fan

14..

.

TSB Revision