MITSUBISHI SPYDER 1990 Service Repair Manual

SPYDER 1990

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57345/w960_57345-0.png

MITSUBISHI SPYDER 1990 Service Repair Manual

Trending: child lock, four wheel drive, CD player, instrument panel, radiator cap, wiring, oil

Page 1011 of 2103

AUTOMATIC TRANSAXLE ENGINE . .

(TURBO) ENGINE> General Information’ .

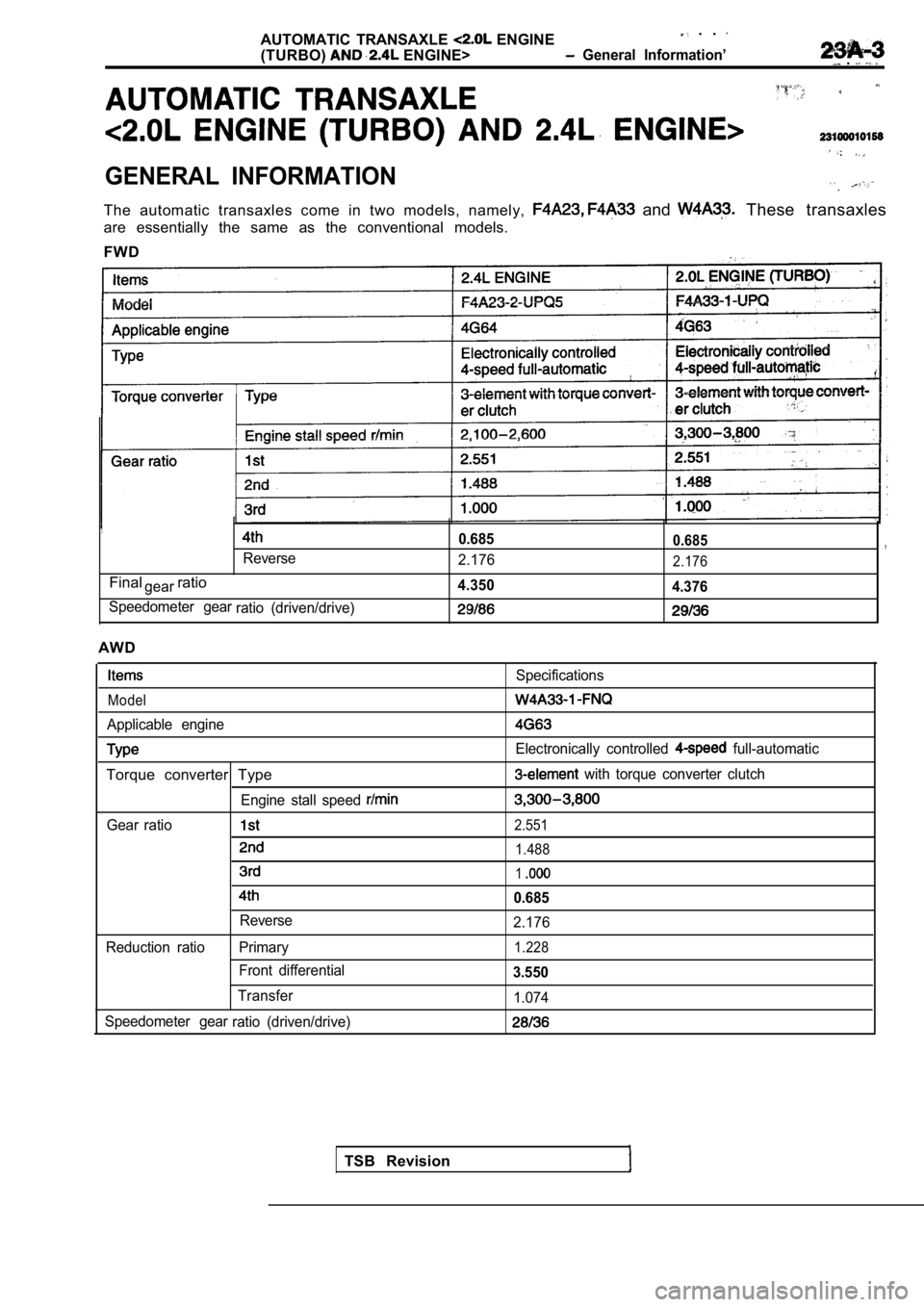

GENERAL INFORMATION

The automatic transaxles come in two models, namely, and These transaxles

are essentially the same as the conventional models .

FWD

Reverse

Final ratiogear

Speedometer gear ratio (driven/drive)

AWD

Model

Applicable engine

Torque converter Type

Engine stall speed

Gear ratio

Reverse

Reduction ratio Primary Front differential

Transfer

Speedometer gear ratio (driven/drive)

0.6850.685,

2.1762.176

4.350

4.376

Specifications

Electronically controlled full-automatic

with torque converter clutch

2.551

1.488

1

0.685

2.176

1.228

3.550

1.074

TSB Revision

Page 1012 of 2103

AUTOMATIC TRANSAXLE ENGINE

(TURBO) AND

ENGINE> General Information

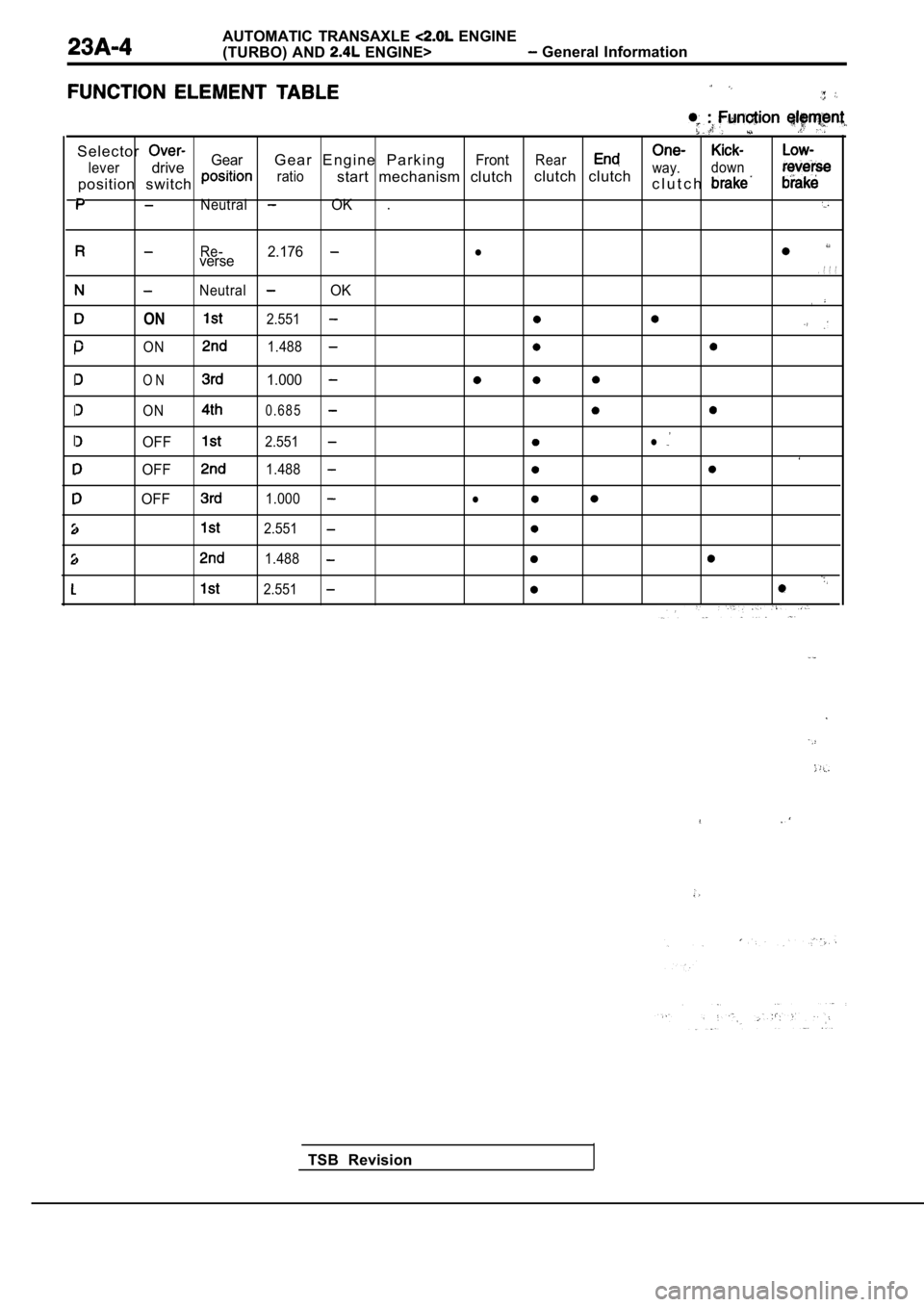

S e l e c t o rGearG e a r E n g i n e P a r k i n gFrontRearleverdrive . .

position switch ratiostart mechanism clutch clutch clutchway.down

c l u t c h

NeutralOK.

Re-2.176lverse . . .

NeutralOK,

ON2.551

ON1.488

I I

I

O N1.000

ON0 . 6 8 5

OFF2.551l

OFF1.488

OFF1.000l

2.551

1.488

2.551

TSB Revision

Page 1013 of 2103

AUTOMATIC TRANSAXLE ENGINE

(TURBO) AND ENGINE> General tnformation

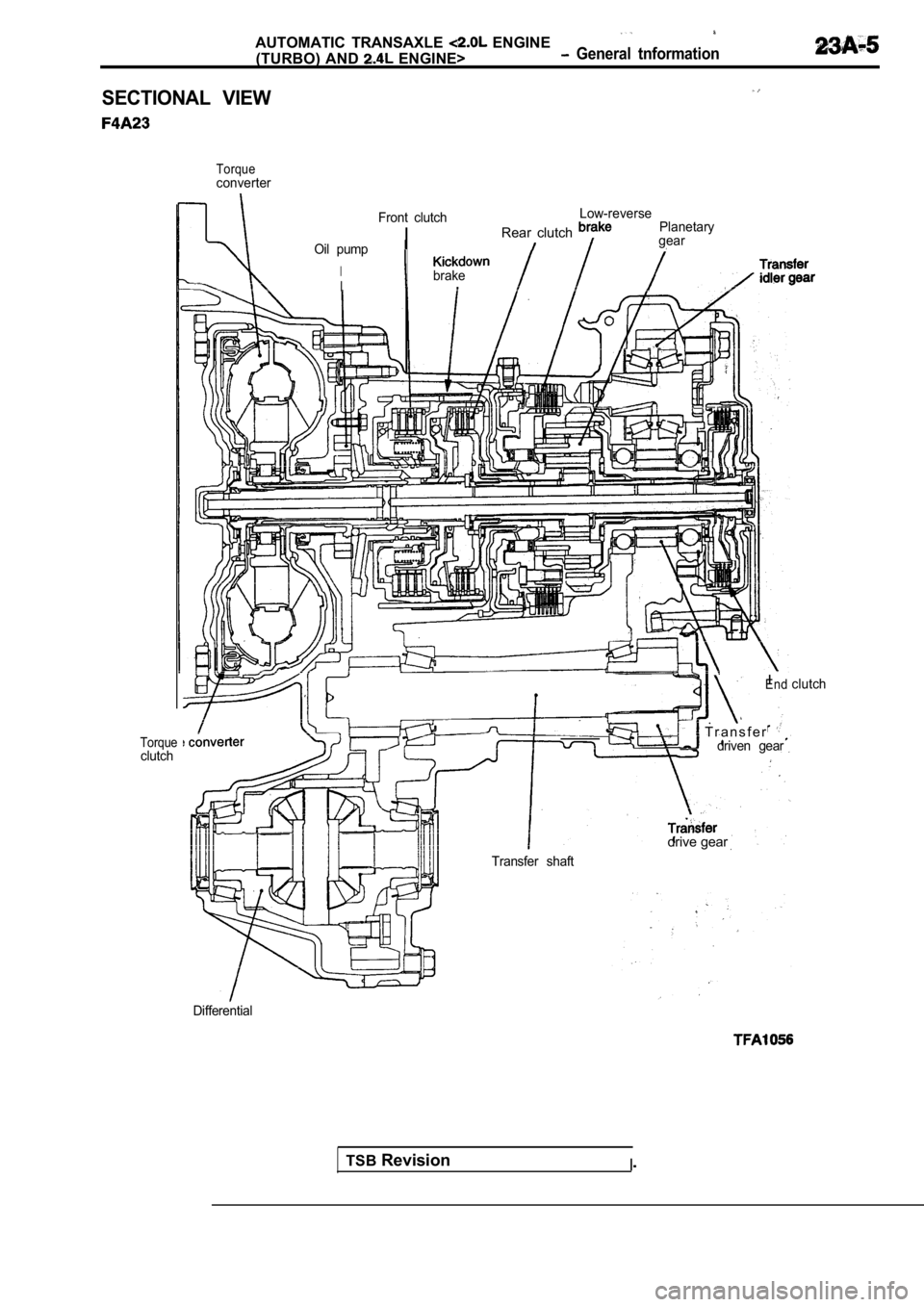

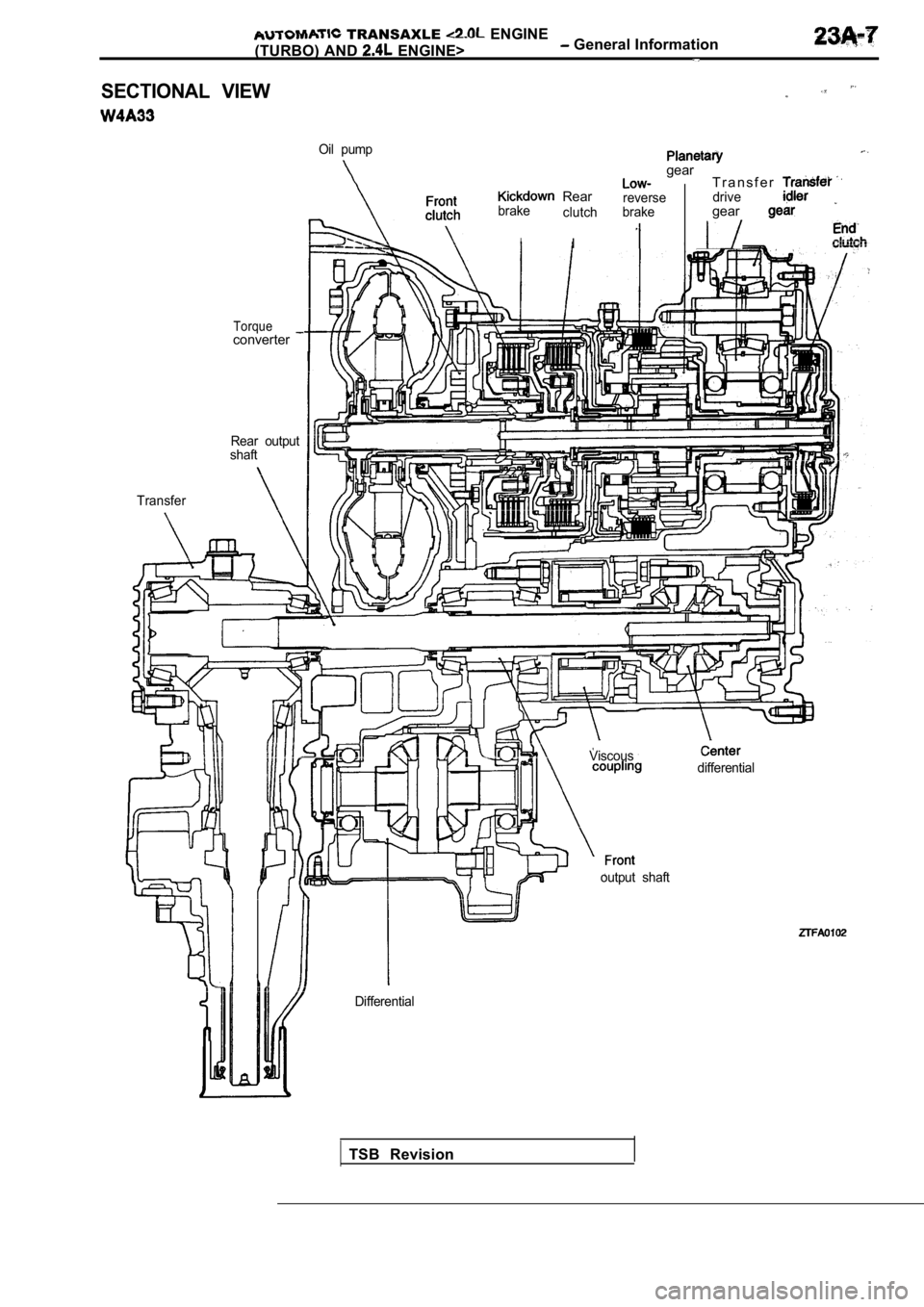

SECTIONAL VIEW

TorqueconverterOil pump

I

Front clutch

I

Low-reverse

Rear clutch Planetarygear

Ibrake

Torqueclutch

TSBRevisionI-

End

T r a n s f e rdriven gear

drive gear

Transfer shaft

Differential

clutch

Page 1014 of 2103

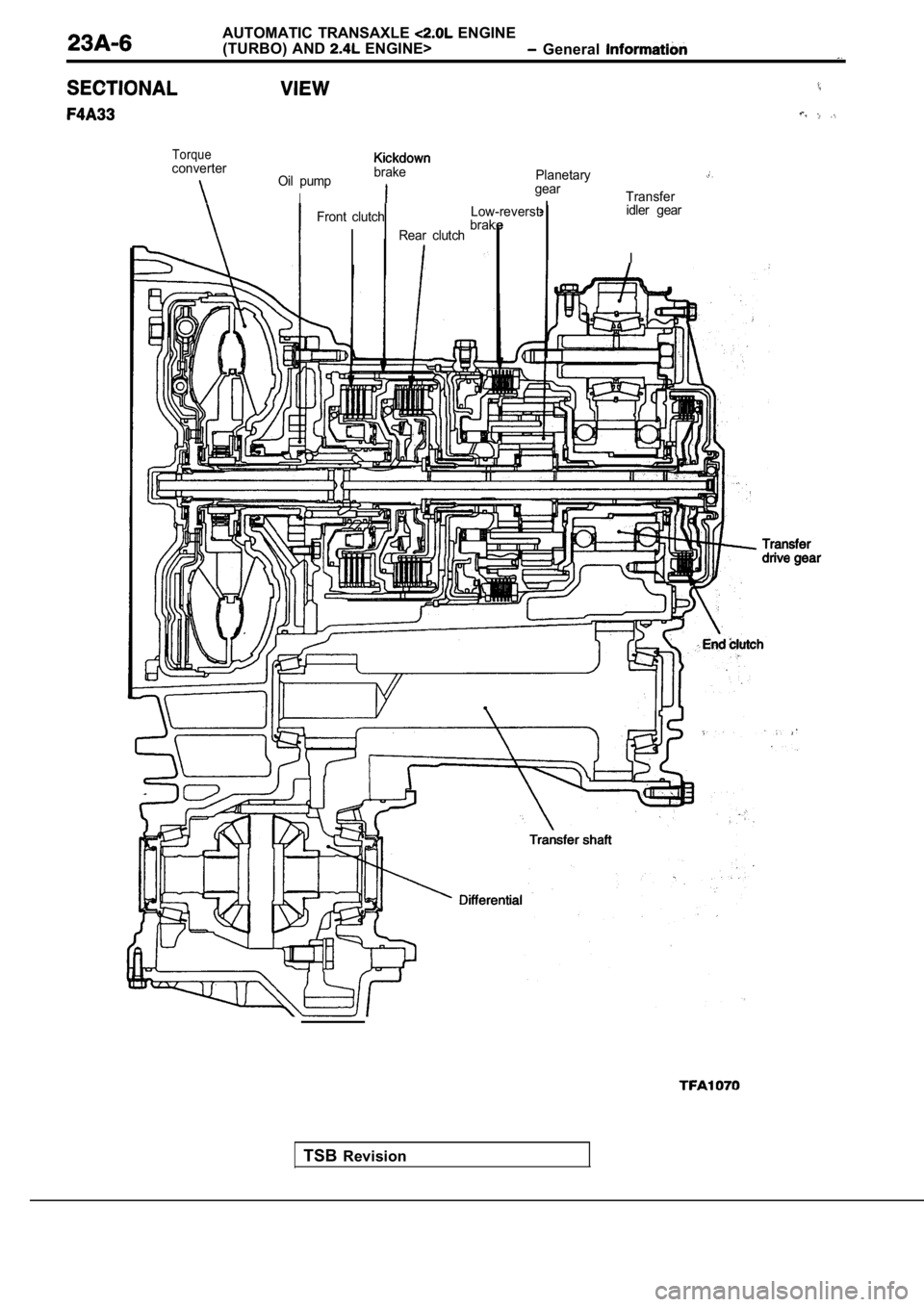

AUTOMATIC TRANSAXLE ENGINE

(TURBO) AND

ENGINE> General

TorqueconverterOil pump

I

brakePlanetary

gear Transfer ,

Front clutch Low-reverst

I

Rear clutchbrak

idler gear

I

TSB Revision

Page 1015 of 2103

TRANSAXLE ENGINE

(TURBO) AND

ENGINE> General Information

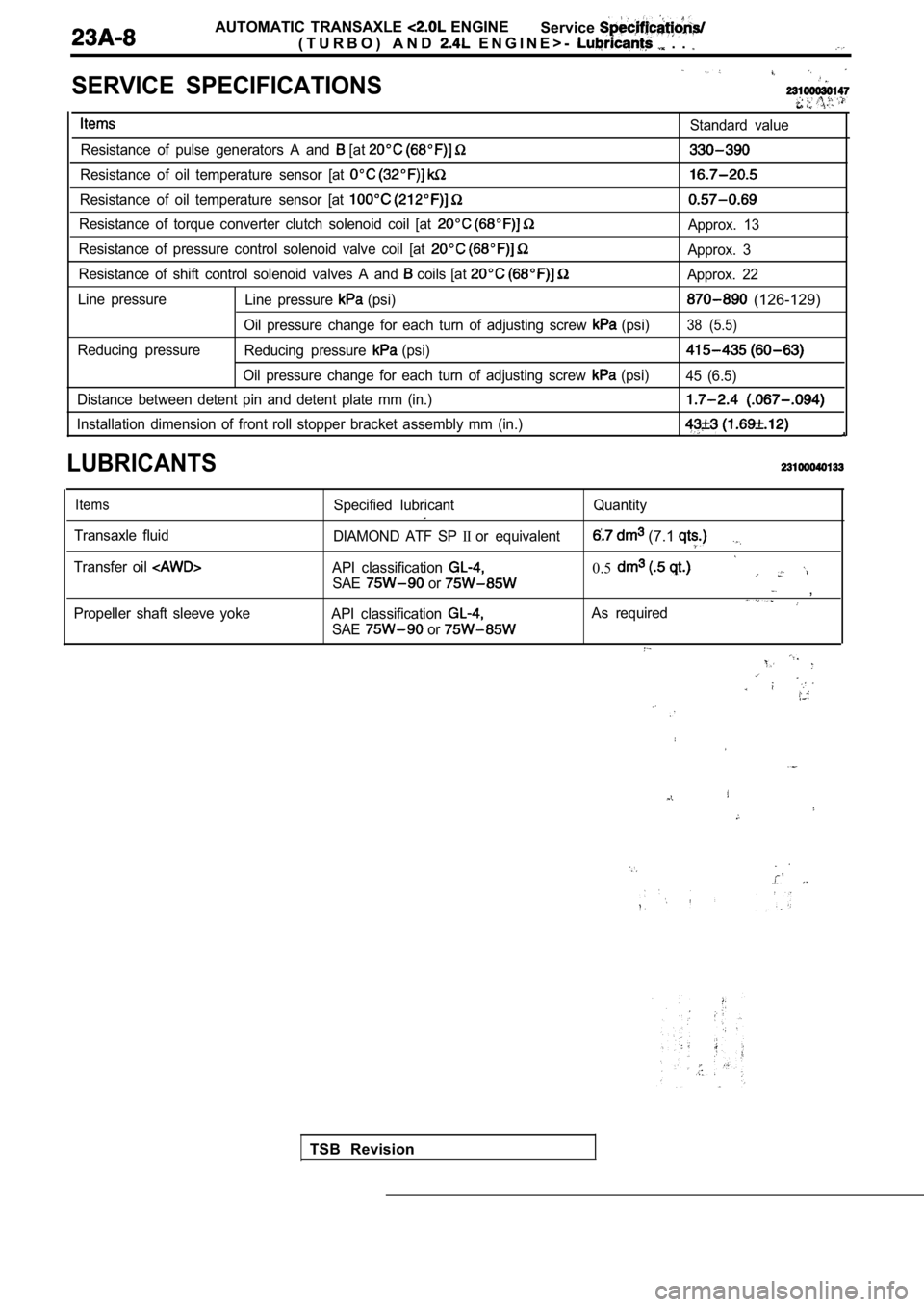

SECTIONAL VIEW

Torqueconverter

Rear output

shaft

Transfer Oil pump

gear

RearreverseT r a n s f e rdrive

brake clutchbrakegear

II

TSB Revision

differential

output shaft

Differential Viscous

Page 1016 of 2103

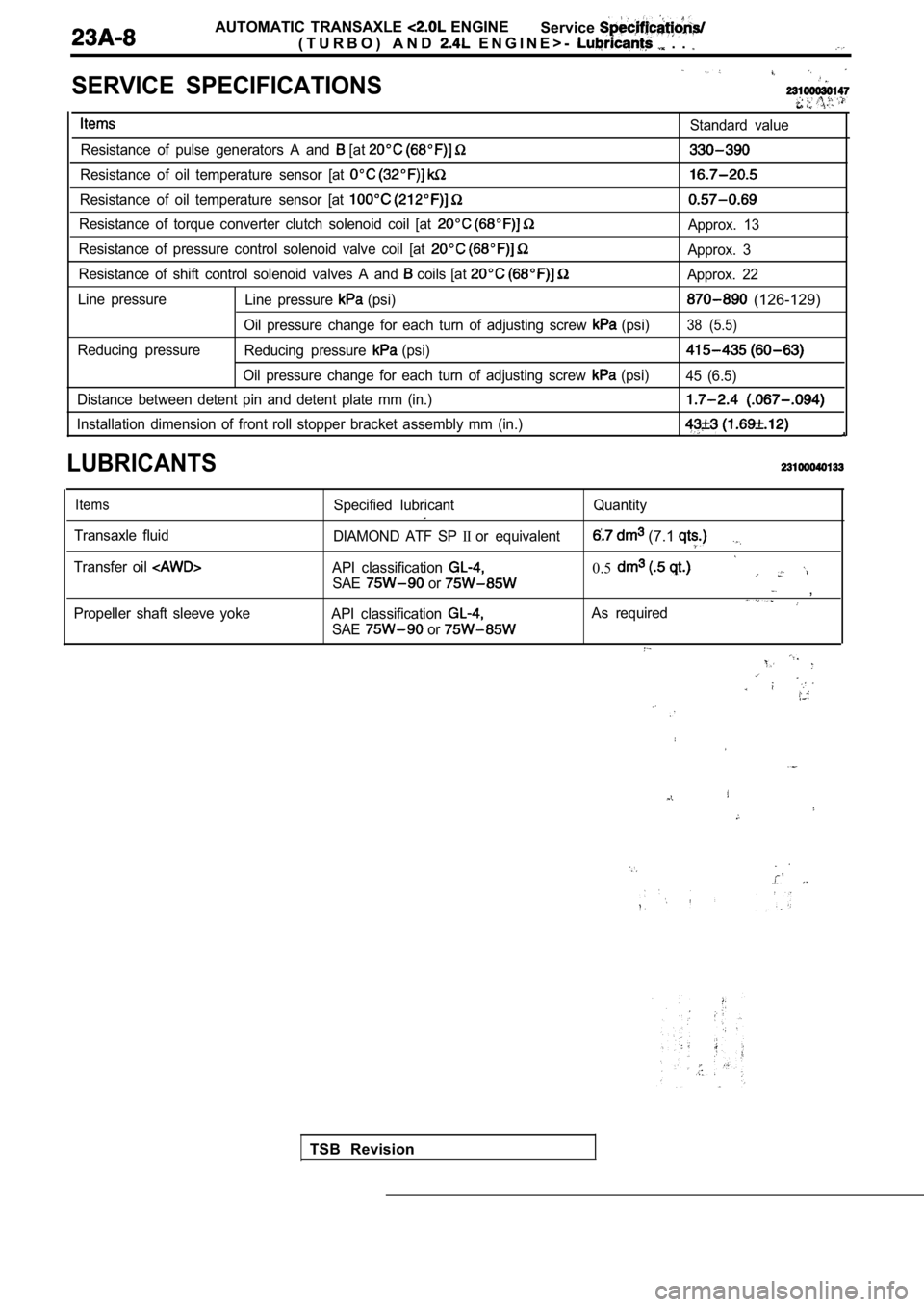

AUTOMATIC TRANSAXLE ENGINEService

( T U R B O ) A N D E N G I N E > - . .

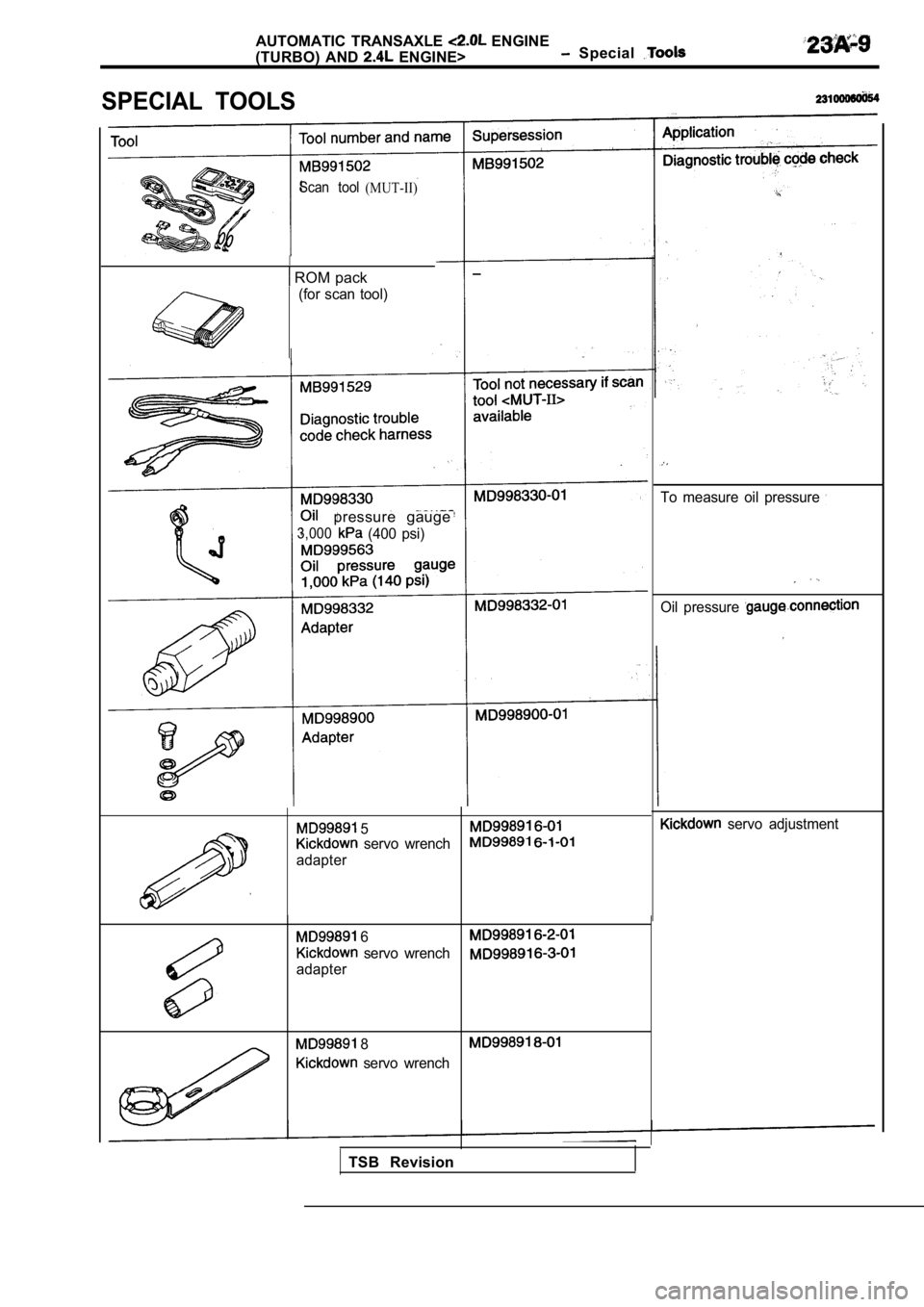

SERVICE SPECIFICATIONS

Standard value

Resistance of pulse generators A and

[at

Resistance of oil temperature sensor [at

Resistance of oil temperature sensor [at

Resistance of torque converter clutch solenoid coil [at Approx. 13

Resistance of pressure control solenoid valve coil [at

Approx. 3

Resistance of shift control solenoid valves A and

coils [at Approx. 22

Line pressure Line pressure

(psi) (126-129)

Oil pressure change for each turn of adjusting scre w (psi)38 (5.5)

Reducing pressure

Reducing pressure (psi)

Oil pressure change for each turn of adjusting scre w (psi)

45 (6.5)

Distance between detent pin and detent plate mm (in .)

Installation dimension of front roll stopper bracket assembly mm (in.)

LUBRICANTS

Items

Transaxle fluid

Transfer oil

Propeller shaft sleeve yoke Specified lubricant

Quantity

DIAMOND ATF SP

IIor equivalent (7.1

API classification 0.5SAE or ,

API classification As required

SAE

or

TSB Revision

Page 1017 of 2103

AUTOMATIC TRANSAXLE ENGINE

(TURBO) AND

ENGINE> Special

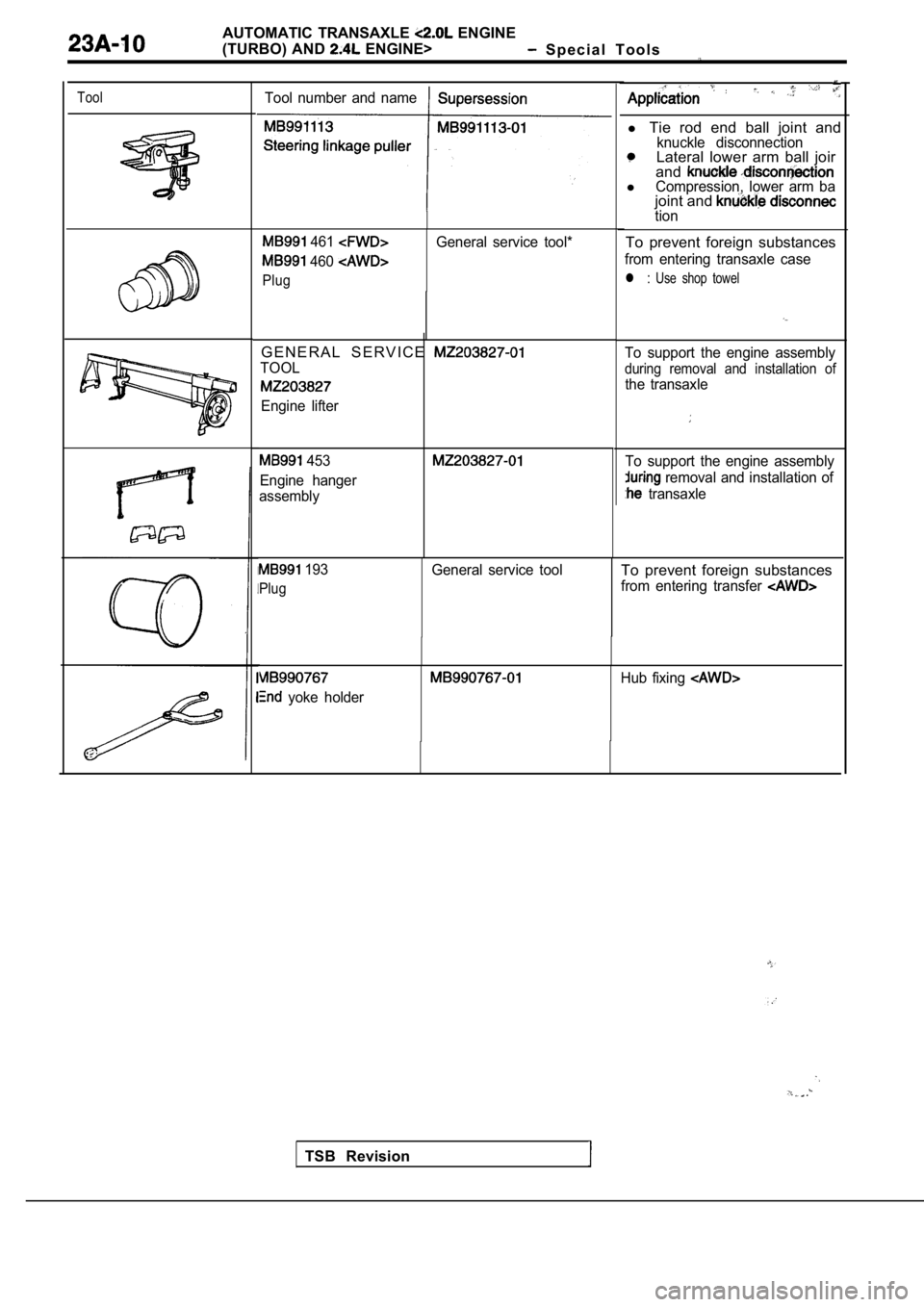

SPECIAL TOOLS

Scan tool(MUT-II)

I

ROM pack

(for scan tool)

pressure gauge

3,000 (400 psi)

5 servo wrench

adapter To measure oil pressure

Oil pressure

servo adjustment

6

servo wrench

adapter

8

servo wrench

TSB Revision

Page 1018 of 2103

AUTOMATIC TRANSAXLE ENGINE

(TURBO) AND

ENGINE> S p e c i a l T o o l s

ToolTool number and name

461

460

Plug

General service tool*

G E N E R A L S E R V I C E

TOOL

Engine lifter

453

Engine hanger

assembly

TSB Revision

l Tie rod end ball joint andknuckle disconnectionLateral lower arm ball joir

and

lCompression, lower arm bajoint and tion

To prevent foreign substances

from entering transaxle case

l : Use shop towel

To support the engine assembly

during removal and installation of

the transaxle

To support the engine assembly

removal and installation of

transaxle

193

Plug

General service toolTo prevent foreign substances

from entering transfer

yoke holder

Hub fixing

Page 1019 of 2103

AUTOMATIC TRANSAXLE

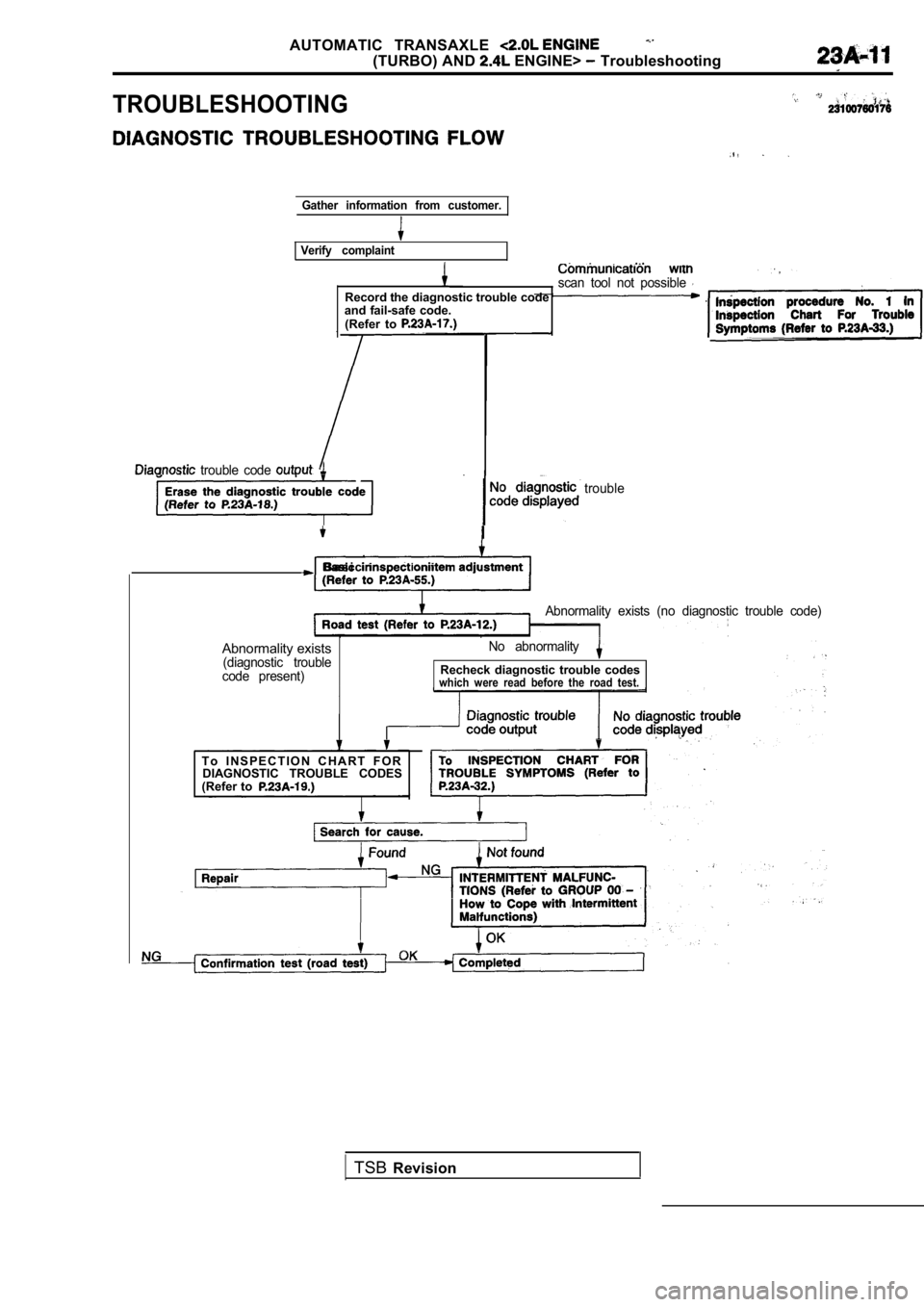

(TURBO) AND ENGINE> Troubleshooting

TROUBLESHOOTING

Gather information from customer.

Verify complaint

scan tool not possible Record the diagnostic trouble code and fail-safe code.(Refer to

trouble code

trouble

B a s i c

Abnormality exists (no diagnostic trouble code)

Abnormality exists(diagnostic trouble

code present) No abnormalityRecheck diagnostic trouble codeswhich were read before the road test.

T o I N S P E C T I O N C H A R T F O R

DIAGNOSTIC TROUBLE CODES

(Refer to

TSB Revision

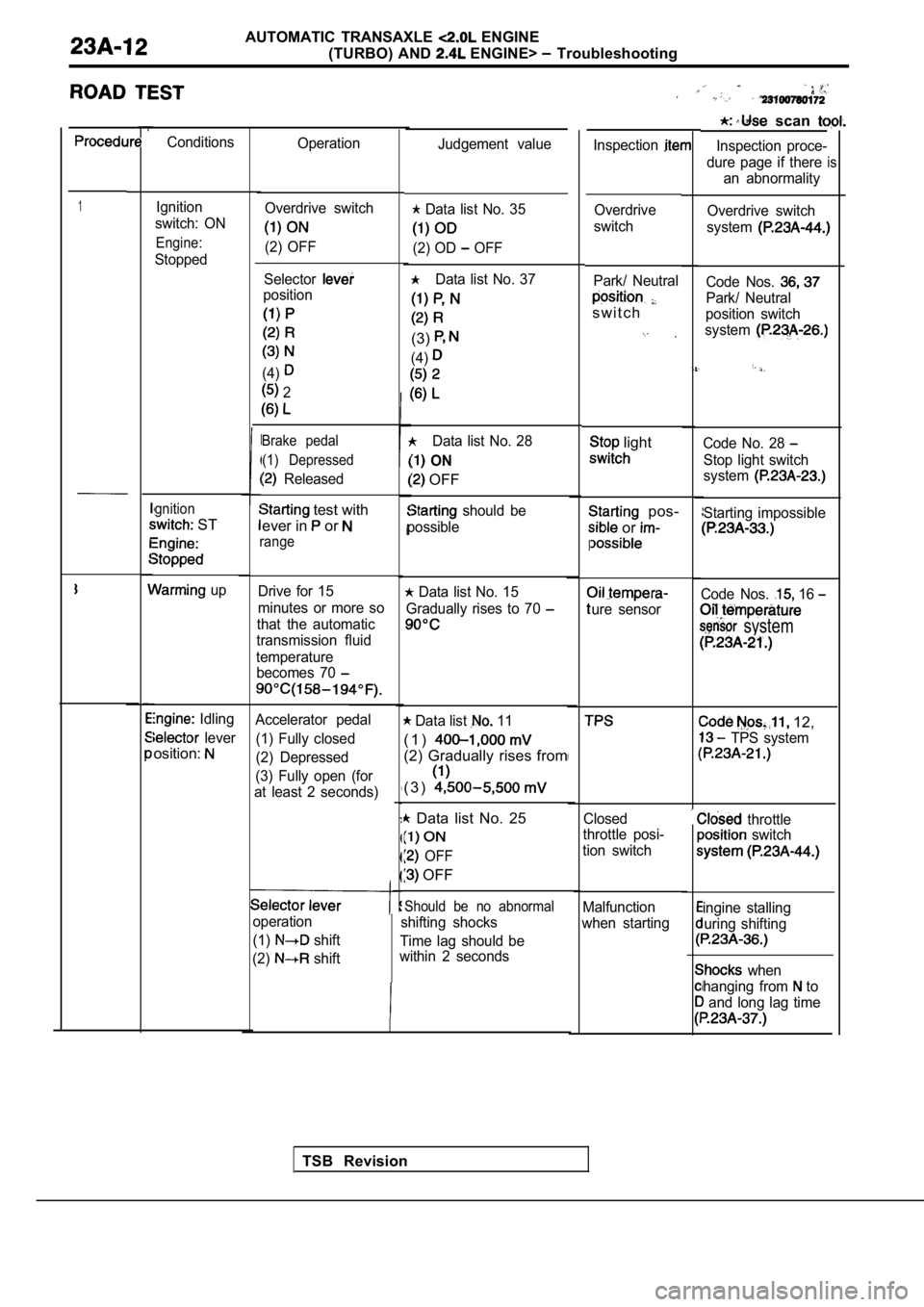

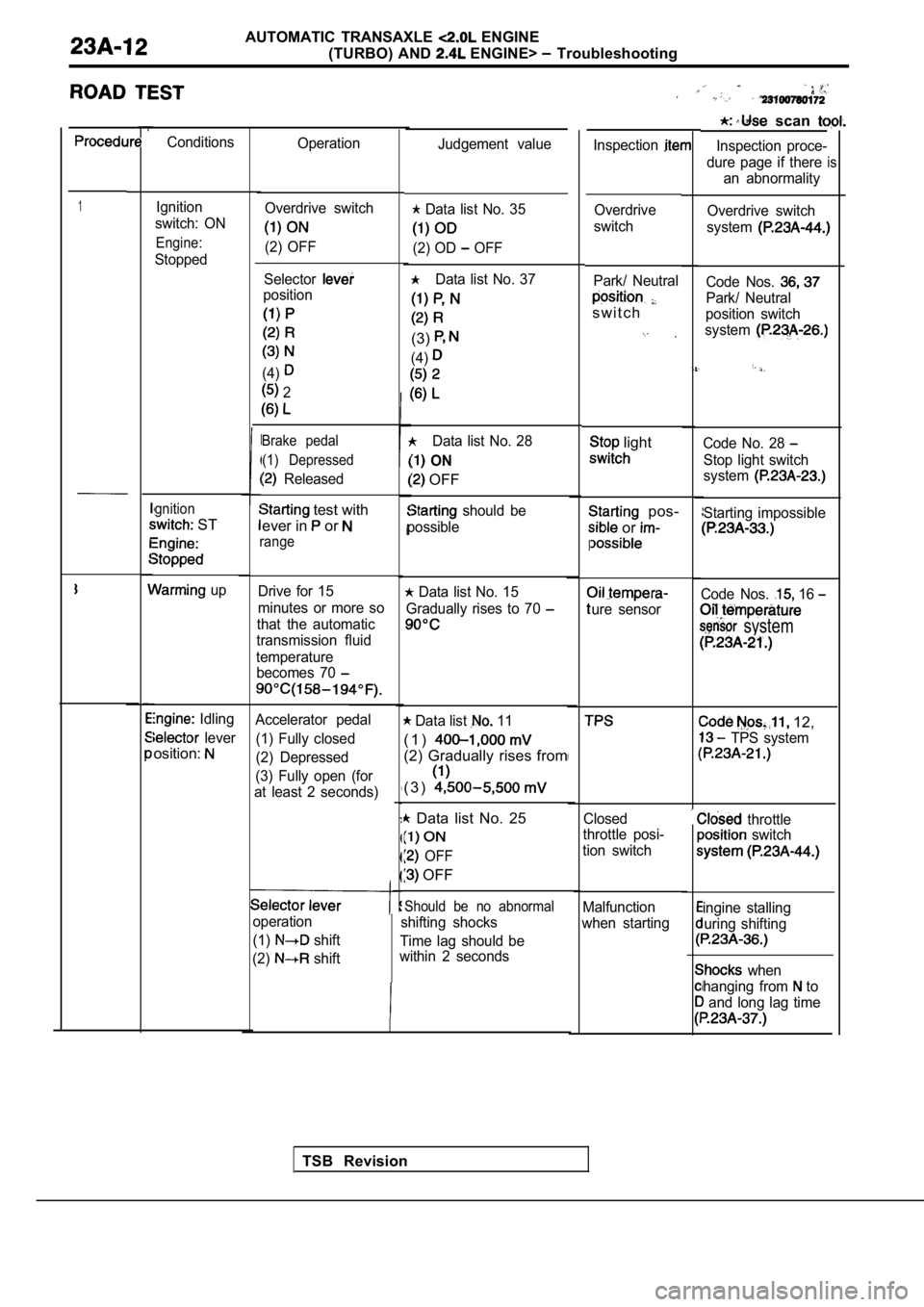

Page 1020 of 2103

AUTOMATIC TRANSAXLE ENGINE

(TURBO) AND

ENGINE> Troubleshooting

scan

Inspection proce-

dure page if there an abnormality

is

Conditions Operation

Inspection

1Ignition

switch: ON

Engine:

Stopped

gnition

ST

up

Idling

lever

osition:

Judgement value

Overdrive switch

system

Code Nos.

Park/ Neutral

position switch

system

Code No. 28

Stop light switch

system

Starting impossible

Code Nos. 16

system

12,

TPS system

throttle switch

ingine stalling

uring shifting

when

hanging from

to

and long lag time

Overdrive switch

(2) OFF

Data list No. 35

(2) OD OFF

Data list No. 37

(3)

(4)

Data list No. 28

ON

OFF

should be

possible Overdrive

switch

Selector

position

(4)

2

Park/ Neutral

s w i t c h

Brake pedal (1) Depressed

Released

light

pos-

or

I

ure sensor

test with

ever in

or

range

Drive for 15

minutes or more so

that the automatic

transmission fluid

temperature becomes 70 Data list No. 15

Gradually rises to 70

Accelerator pedal

(1) Fully closed

(2) Depressed

(3) Fully open (for

at least 2 seconds) Data list 11

( 1 )

(2) Gradually rises from

( 3 )

Data list No. 25

OFF

OFF

Closed

throttle posi-

tion switch

Should be no abnormal

shifting shocks

Time lag should be

within 2 seconds Malfunction

when starting

operation

(1)

shift

(2)

shift

TSB Revision

Trending: stop start, engine overheat, timing belt, wiper blades, washer fluid, driver seat adjustment, wheel bolts