NISSAN ALMERA N15 1995 Service Manual

Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1281 of 1701

SEM141FA

jPiSIOn healer

SEM877S CYLINDER

BLOCK

CAUTION:

• When installing slidingparts(bearings, pistons,etc.),apply

new engine oiltothe sliding surfaces.

• Place removed partssuchasbearings andbearing capsin

their proper orderanddirection.

• Apply newengine oiltobolt thread andseat surfaces when

tightening thefollowing: Connecting rodbolts andmain

bearing capbolts.

• Donot allow anymagnetic materials tocontact thering gear

teeth offlywheel/drive plate.

Disassembly

PISTON ANDCRANKSHAFT

1. Place engine onawork stand.

2. Remove cylinder head.

Refer to"Removal" in"TIMING CHAIN"(EM-69).

3. Remove oilpan.

Refer to"Removal" in"OIL PAN" (EM-63).

4. Remove timingchain.

Refer to"Removal" in"TIMING CHAIN"(EM-69).

5. Remove pistonswithconnecting rods.

• When disassembling pistonandconnecting rod,remove

snap ringfirst. Then heatpiston to60 to70°C (140to158°F),

or use piston pinpress stand atroom temperature.

6. Remove rearoilseal retainer.

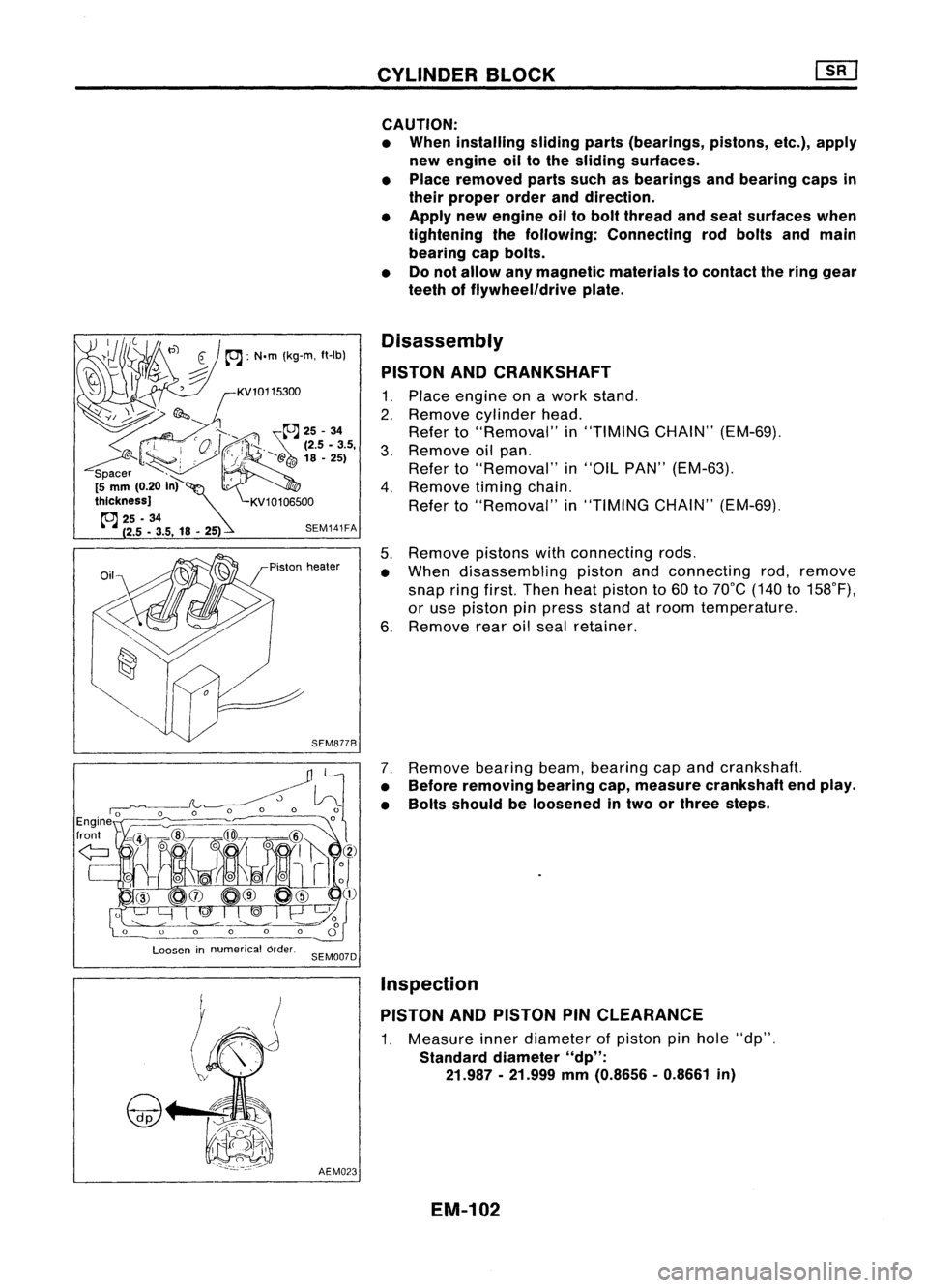

7. Remove bearingbeam,bearing capand crankshaft.

• Before removing bearingcap,measure crankshaft endplay.

• Bolts should beloosened intwo orthree steps.

Loosen innumerical order.

SEM007D

AEM023

Inspection

PISTON ANDPISTON PINCLEARANCE

1. Measure innerdiameter ofpiston pinhole "dp".

Standard diameter"dp":

21.987 -21.999

mm

(0.8656 -0.8661

in)

EM-102

Page 1282 of 1701

![NISSAN ALMERA N15 1995 Service Manual

Micrometer

AEM024

NG

F •• ~K

gauge

OK

~-

Feelergauge

SEM024AA

P;""A

pre.it

Feeler

~

gauge

Ring

Measuring point

SEM822B

Bend

SEM003FCYLINDER

BLOCK [][]

Inspection (Cont'd)

NISSAN ALMERA N15 1995 Service Manual

Micrometer

AEM024

NG

F •• ~K

gauge

OK

~-

Feelergauge

SEM024AA

P;""A

pre.it

Feeler

~

gauge

Ring

Measuring point

SEM822B

Bend

SEM003FCYLINDER

BLOCK [][]

Inspection (Cont'd)](/img/5/57349/w960_57349-1281.png)

Micrometer

AEM024

NG

F •• ~K

gauge

OK

~-

Feelergauge

SEM024AA

P;""A

pre.it

Feeler

~

gauge

Ring

Measuring point

SEM822B

Bend

SEM003FCYLINDER

BLOCK [][]

Inspection (Cont'd)

2. Measure outerdiameter ofpiston pin"Dp".

Standard diameter "Op":

21.989 -22.001 mm(0.8657 -0.8662 in)

3. Calculate pistonpinclearance.

dp -Op

=

-0.004 to0mm (-0.0002 to0in)

If itexceeds theabove value, replace pistonassembly with

pin.

PISTON RINGSIDECLEARANCE

Side clearance:

Top ring 0.045-0.080 mm(0.0018 -0.0031 in)

2nd ring 0.030-0.065 (0.0012 -0.0026 in)

Max. limitofside clearance:

0.2 mm (0.008 in)

If out ofspecification, replacepistonand/or pistonringassem-

bly.

PISTON RINGENDGAP

End gap:

Top ring 0.20-0.30 mm(0.0079 -0.0118 in)

2nd ring 0.35-0.50 mm(0.0138 -0.0197 in)

Oil ring 0.20-0.60 mm(0.0079 -0.0236 in)

Max. limitofring gap:

1.0 mm (0.039 in)

If out ofspecification, replacepistonring.Ifgap stillexceeds

the limit even withanew ring, dothe following. Reborecylin-

der and useover-sized pistonandpiston rings.

Refer to50S (EM-168).

• When replacing thepiston, inspect cylinder blocksurface

for scratches orseizure. Ifscratches orseizure arefound,

hone orreplace thecylinder block.

CONNECTING RODBEND ANDTORSION

Bend:

Limit 0.15mm(0.0059 in)

per 100 mm (3.94 in)length

Torsion: Limit 0.30mm(0.0118 in)

per 100 mm (3.94 in)length

If itexceeds thelimit, replace connecting rodassembly.

EM-103

•

Page 1283 of 1701

SEM123CCYLINDER

BLOCK ~

Inspection (Cont'd)

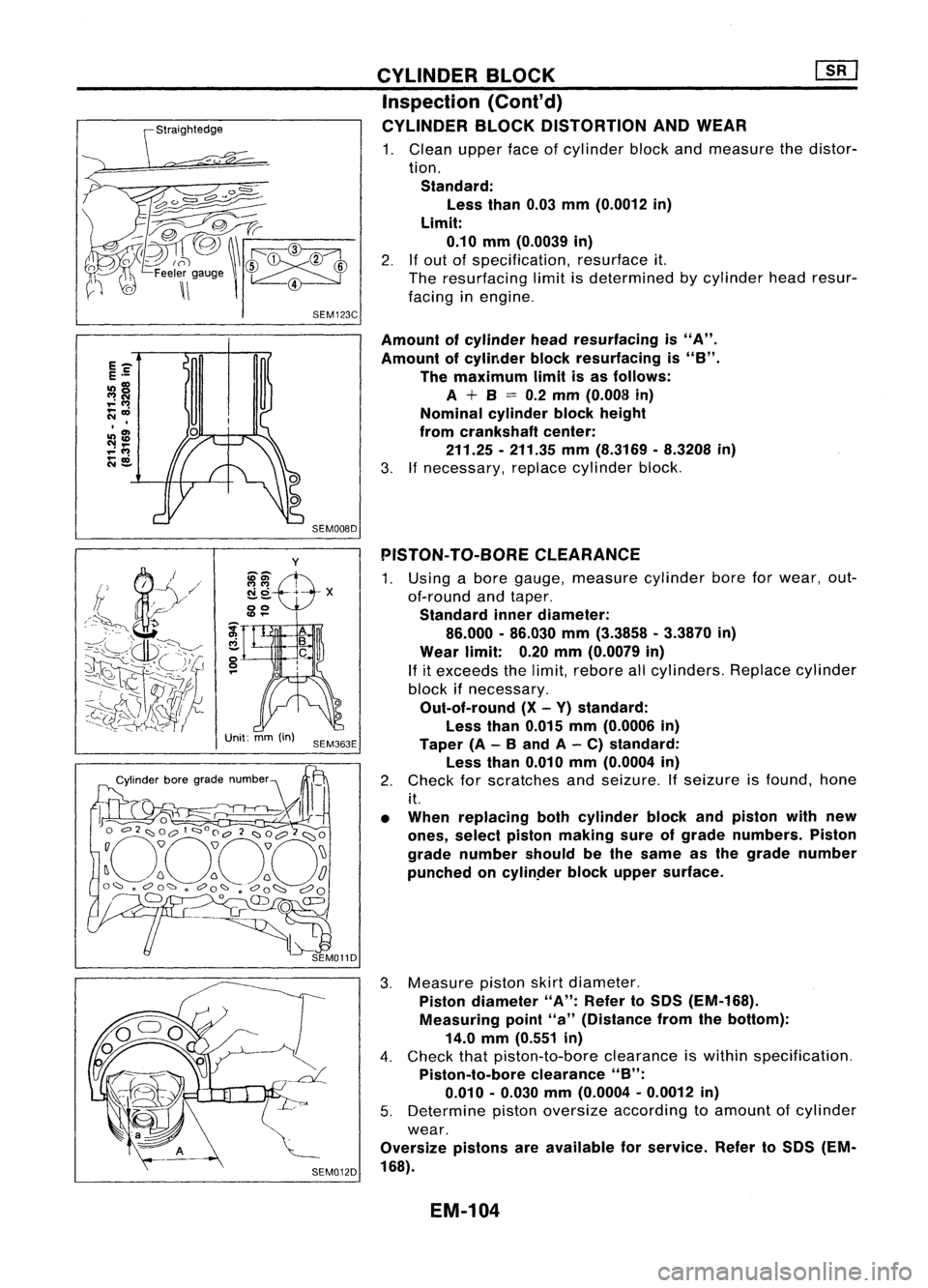

CYLINDER BLOCKDISTORTION ANDWEAR

1. Clean upperfaceofcylinder blockandmeasure thedistor-

tion. Standard: Less than0.03mm(0.0012 in)

Limit: 0.10 mm(0.0039 in)

2.

If

out ofspecification, resurfaceit.

The resurfacing limitisdetermined bycylinder headresur-

facing inengine.

SEM008D

Amount

ofcylinder headresurfacing is"A".

Amount ofcylinder blockresurfacing is

"8".

The maximum limitisas follows:

A

+

8

=

0.2 mm (0.008 in)

Nominal cylinderblockheight

from crankshaft center:

211.25 -211.35 mm(8.3169 -8.3208 in)

3. Ifnecessary, replacecylinder block.

y

ii-El)'

N 0+ -X

--

00

Unit: mm(in)

SEM363E PISTON-

TO-BORE CLEARANCE

1. Using abore gauge, measure cylinderboreforwear, out-

of-round andtaper.

Standard innerdiameter:

86.000 -86.030 mm(3.3858 -3.3870 in)

Wear limit: 0.20mm(0.0079 in)

If

itexceeds thelimit, rebore allcylinders. Replacecylinder

block ifnecessary.

Out-of-round (X-Y) standard:

Less than0.015 mm(0.0006 in)

Taper (A-

8

and A-C) standard:

Less than0.010 mm(0.0004 in)

2. Check forscratches andseizure. Ifseizure isfound. hone

it.

• When replacing bothcylinder blockandpiston withnew

ones, select piston making sureofgrade numbers. Piston

grade number shouldbethe same asthe grade number

punched oncylinper blockupper surface.

3. Measure pistonskirtdiameter.

Piston diameter "A":Refer toSDS (EM-168).

Measuring point"a"(Distance fromthebottom):

14.0 mm(0.551 in)

4. Check thatpiston-to-bore clearanceiswithin specification.

Piston-to-bore clearance"B":

0.010 -0.030 mm(0.0004 -0.0012 in)

5. Determine pistonoversize according toamount ofcylinder

wear.

Oversize pistonsareavailable forservice. RefertoSDS (EM-

168).

EM-104

Page 1284 of 1701

AB

Taper:A-B

Out-at-round: X-

y

y

SEM316A CYLINDER

BLOCK ~

Inspection (Cont'd)

6. Cylinder boresizeisdetermined byadding piston-to-bore

clearance topiston diameter "A".

Rebored sizecalculation:

D=A+B-C where,

D: Bored diameter

A: Piston diameter asmeasured •

B: Piston-to-bore clearance

C: Honing allowance 0.02mm(0.0008 in)

7. Install mainbearing caps,andtighten tothe specified

torque.

• Otherwise, cylinderboresmaybedistorted infinal assem-

bly.

8. Cut cylinder bores.

• When anycylinder needsboring, allother cylinders must

also bebored.

• Donot cuttoo much outofcylinder boreatatime. Cutonly

0.05 mm(0.0020 in)orso indiameter atatime.

9. Hone cylinders toobtain specified piston-to-bore clearance.

10. Measure finishedcylinder boreforout-of-round andtaper.

• Measurement shouldbedone aftercylinder borecools

down.

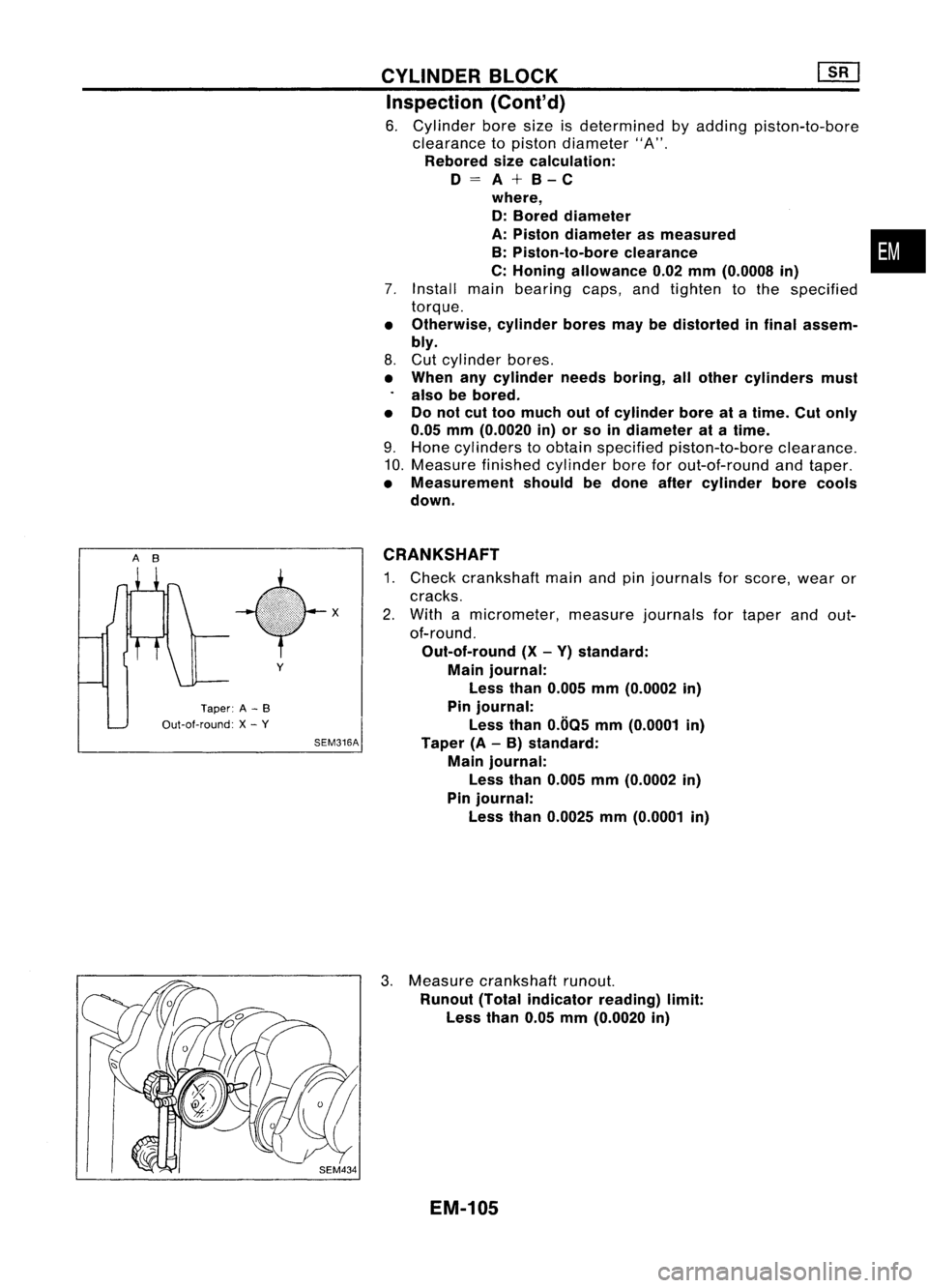

CRANKSHAFT

1. Check crankshaft mainandpinjournals forscore, wearor

cracks.

2. With amicrometer, measurejournalsfortaper andout-

of-round.

Out-of-round (X-Y) standard:

Main journal:

Less than0.005 mm(0.0002 in)

Pin journal:

Less than0.005 mm(0.0001 in)

Taper (A-B) standard:

Main journal:

Less than0.005 mm(0.0002 in)

Pin journal:

Less than0.0025 mm(0.0001 in)

3. Measure crankshaft runout.

Runout (Totalindicator reading)limit:

Less than0.05mm(0.0020 in)

EM-105

Page 1285 of 1701

#5

#4 ~

~i1

hole #3~~ \)

#2 ~~,

#1~~~ ~~

12 ~~

Engine front~

SEM685D

SEM964

SEM313D CYLINDER

BLOCK

Inspection (Cont'd)

BEARING CLEARANCE

• Use either ofthe following twomethods, however, method

"A" gives morereliable resultsandispreferred.

Method A(Using boregauge

&

micrometer)

Main bearing

1. Set main bearings intheir proper positions oncylinder

block andmain bearing cap.

2. Install mainbearing capand main bearing beamtocylinder

block.

Tighten allbolts incorrect orderintwo orthree stages.

3. Measure innerdiameter "A"ofeach main bearing.

4. Measure outerdiameter "Om"ofeach crankshaft main

journal.

5. Calculate mainbearing clearance.

Main bearing clearance

=

A-Om

Standard: 0.004•0.022 mm(0.0002 •0.0009 in)

Limit: 0.050mm(0.0020 in)

6. Ifitexceeds thelimit, replace bearing.

7. Ifclearance cannotbeadjusted withinthestandard ofany

bearing, grindcrankshaft journalanduseundersized bear-

ing.

a. When grinding crankshaft journal,confirmthat"L"dimen-

sion infillet rollismore thanthespecified limit.

"L":

0.1mm (0.004 in)

b. Refer toSOS forgrinding crankshaft andavailable service

parts.

8. Ifcrankshaft isreused, measure mainbearing clearances

and select thickness ofmain bearings.

If crankshaft isreplaced withanew one, select thickness of

main bearings asfollows:

a. Grade number ofeach cylinder blockmainjournal is

punched onthe respective cylinderblock.These numbers

are punched ineither Arabic orRoman numerals.

EM-106

Page 1286 of 1701

Crankshaft

front view

Crankshaft

front view

•

Crankshaft

Cylinderblockmainjournal gradenumber

main journal

grade num-

0 12

3

ber

012

3

0

(A,Black) (B,

Brown) (C,

Green) (0,Yellow)

.

12

3

4

1

(B,Brown) (C,Green) (0,

Yellow) (E,Blue)

2

3

4

5

2

(C,Green) (0,

Yellow) (E,Blue) (F,Pink)

3

4

5

6

3

(0,Yellow) (E,

Blue) (F,

Pink) (G,Nocolor)

For example:

Main journal gradenumber: 1

Crankshaft journalgradenumber: 2

Main bearing gradenumber =1+ 2

=

3(D, Yellow)

CYLINDER

BLOCK ~

Inspection (Conl'd)

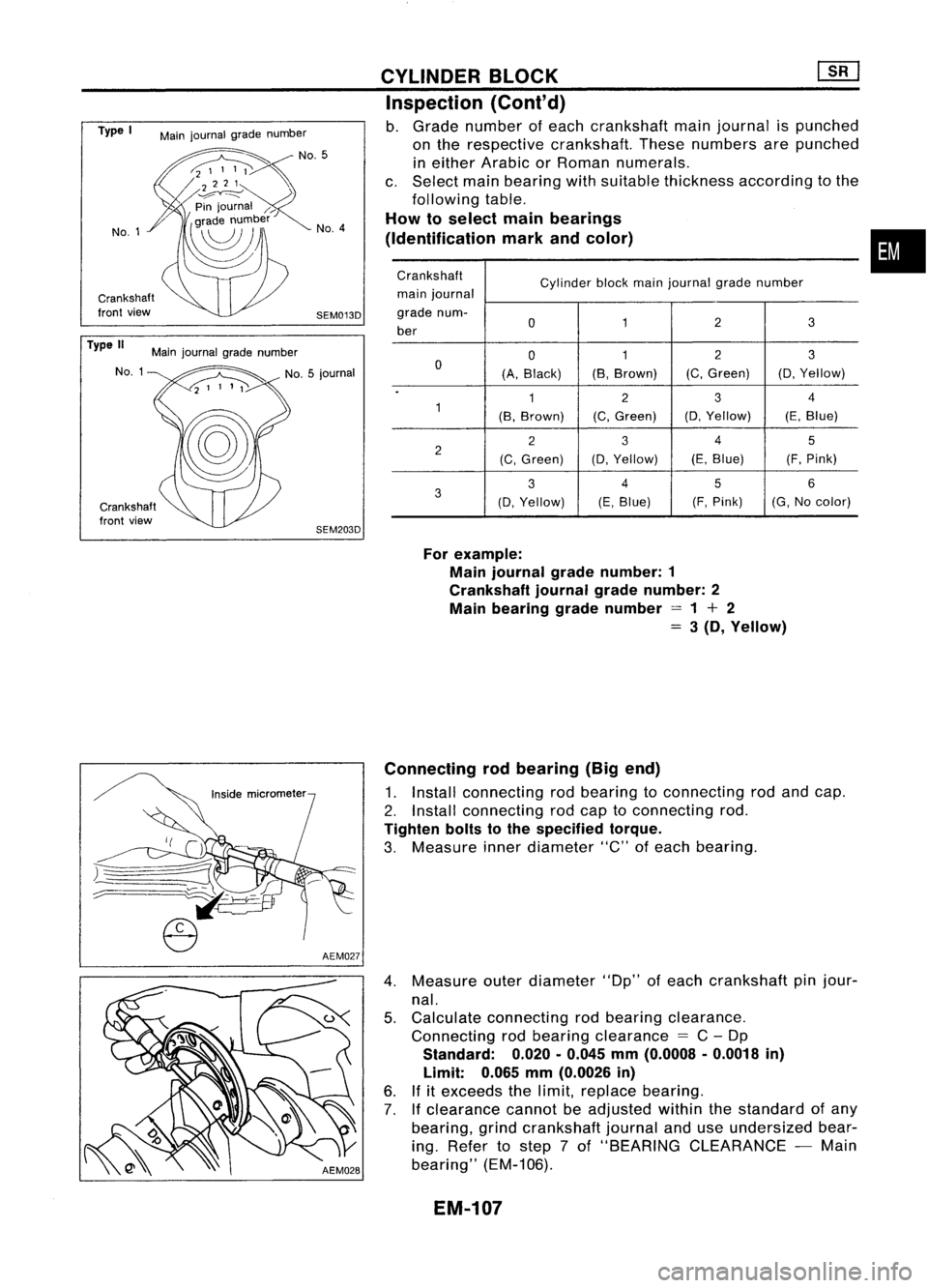

b. Grade number ofeach crankshaft mainjournal ispunched

on the respective crankshaft. Thesenumbers arepunched

in either Arabic orRoman numerals.

c. Select mainbearing withsuitable thickness according tothe

following table.

How toselect mainbearings

(Identification markandcolor)

SEM013D No.

4

SEM203D

Main

journal gradenumber

No.5

Main journal gradenumber

NO.1

Type

I

No.1

Type II

Connectingrodbearing (Bigend)

1. Install connecting rodbearing toconnecting rodand cap.

2. Install connecting rodcap toconnecting rod.

Tighten boltstothe specified torque.

3. Measure innerdiameter "C"ofeach bearing.

4. Measure outerdiameter "Dp"ofeach crankshaft pinjour-

nal.

5. Calculate connecting rodbearing clearance.

Connecting rodbearing clearance

=

C-Dp

Standard:

0.020.0.045

mm

(0.0008 .0.0018

in)

Limit:

0.065

mm

(0.0026

in)

6. Ifitexceeds thelimit, replace bearing.

7.

If

clearance cannotbeadjusted withinthestandard ofany

bearing, grindcrankshaft journalanduseundersized bear-

ing. Refer tostep 7of "BEARING CLEARANCE -Main

bearing" (EM-106).

EM-107

Page 1287 of 1701

Connectingrodbearing grade

number

o

1

2

o

1

2

Crank

pingrade number

Identification color:

Grade 0;No color

Grade 1;Black

Grade 2;Brown

Method B(Using plastigage)

CAUTION: • Donot turn crankshaft orconnecting rodwhile plastigage is

being inserted.

• When bearing clearance exceedsthespecified limit,ensure

that theproper bearing hasbeen installed.

If

incorrect bear-

ing clearance exists,useathicker orundersized mainbear-

ing toensure specified clearance.

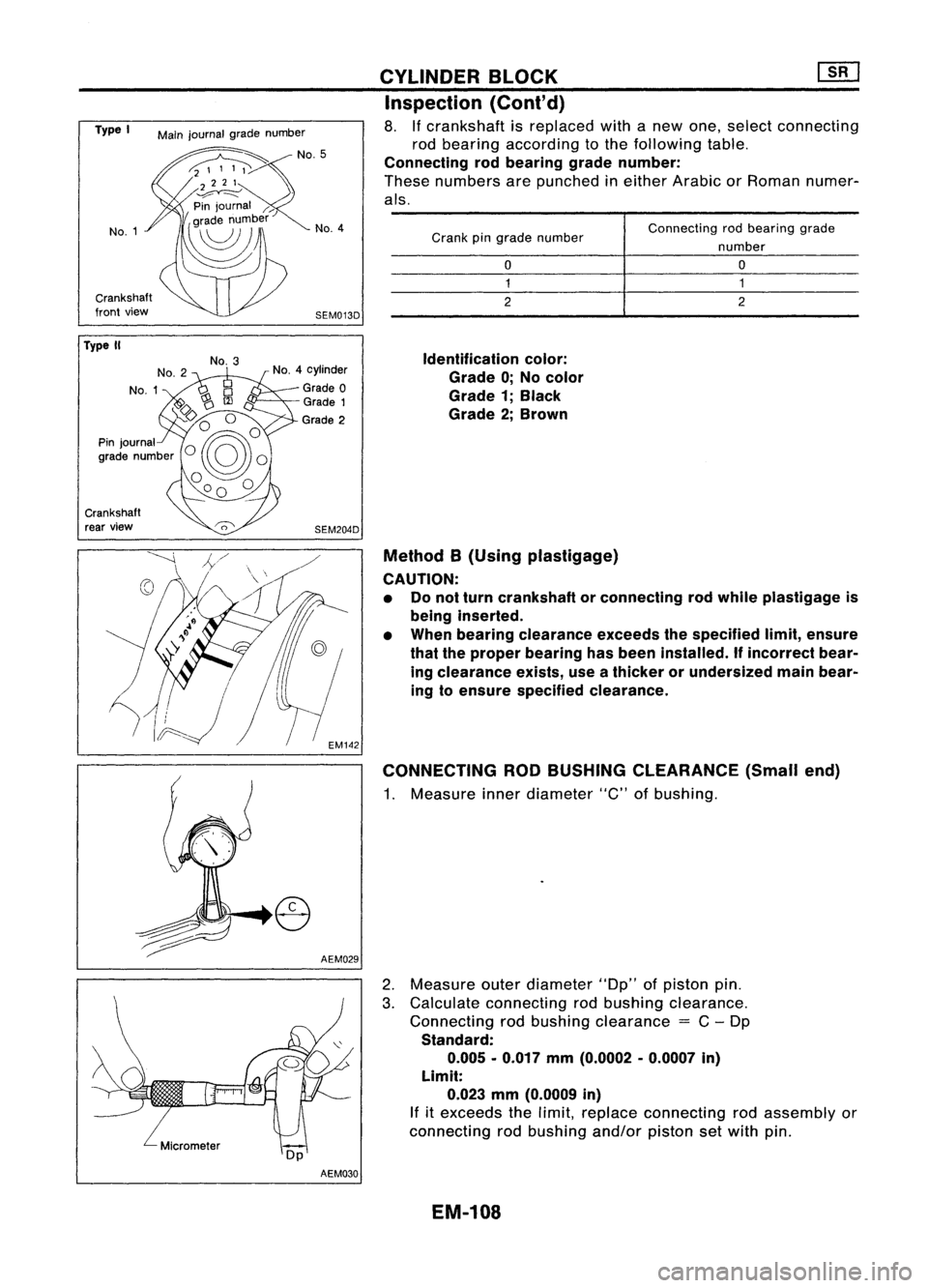

CONNECTING RODBUSHING CLEARANCE (Smallend)

1. Measure innerdiameter "C"ofbushing.

CYLINDER

BLOCK ~

Inspection (Cont'd)

8. Ifcrankshaft isreplaced withanew one, select connecting

rod bearing according tothe following table.

Connecting rodbearing gradenumber:

These numbers arepunched ineither Arabic orRoman numer-

als.

AEM029

SEM013D

No.

4

SEM204D

No.

4cylinder

Grade 0

Grade 1

Grade 2

No.

3

Main

journal gradenumber

No.1

Crankshaft

front view

Type

I

Crankshaft rear view

Type

II

2.Measure outerdiameter "Dp"ofpiston pin.

3. Calculate connecting rodbushing clearance.

Connecting rodbushing clearance

=

C-Dp

Standard: 0.005 -0.017 mm(0.0002 -0.0007 in)

Limit: 0.023 mm(0.0009 in)

If

itexceeds thelimit, replace connecting rodassembly or

connecting rodbushing and/orpistonsetwith pin.

AEM030

EM-108

Page 1288 of 1701

![NISSAN ALMERA N15 1995 Service Manual

M/T

Crankshaft

side

AIT

SEM062A

SEM163B CYLINDER

BLOCK [][]

Inspection (Conl'd)

REPLACEMENT OFCONNECTING RODBUSHING (Small

end)

1. Drive insmall endbushing untilitis flush withendsurface

of r NISSAN ALMERA N15 1995 Service Manual

M/T

Crankshaft

side

AIT

SEM062A

SEM163B CYLINDER

BLOCK [][]

Inspection (Conl'd)

REPLACEMENT OFCONNECTING RODBUSHING (Small

end)

1. Drive insmall endbushing untilitis flush withendsurface

of r](/img/5/57349/w960_57349-1287.png)

M/T

Crankshaft

side

AIT

SEM062A

SEM163B CYLINDER

BLOCK [][]

Inspection (Conl'd)

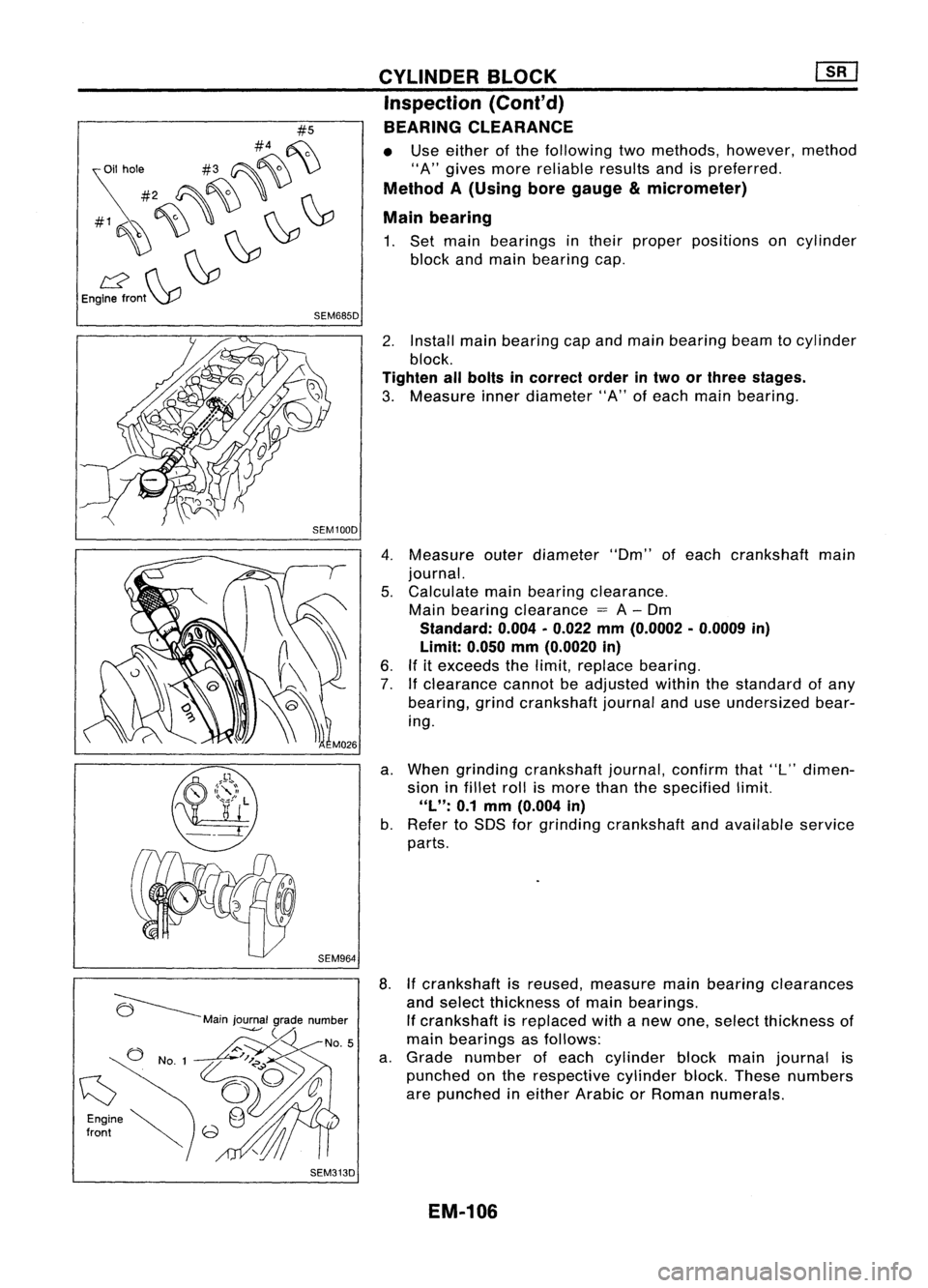

REPLACEMENT OFCONNECTING RODBUSHING (Small

end)

1. Drive insmall endbushing untilitis flush withendsurface

of rod.

Be sure toalign theoilholes.

2. After driving insmall endbushing, reamthebushing. This

is to ensure theclearance betweenconnecting rodbushing

and piston pinisthe specified value.

Clearance betweenconnecting rodbushing andpiston

pin: 0.005 -0.017 mm(0.0002 -0.0007 in)

REPLACEMENT OFPILOT BUSHING

(M/T)

ORPILOT

CONVERTER

(A/T)

1. Remove pilotbushing orpilot converter usingToolorsuit-

. able tool.

2. Install pilotbushing orpilot converter asshown.

•

FLYWHEEL/DRIVE PLATERUNOUT

Runout (Totalindicator reading):

Flywheel (MfTmodel)

Less than0.15mm(0.0059 in)

Drive plate(AfTmodel)

Less than0.20mm(0.0079 in)

CAUTION: Do not allow anymagnetic materials tocontact thering gear

teeth.

AssemblyPISTON

1. Install newsnap ringonone side ofpiston pinhole.

EM-109

Page 1289 of 1701

![NISSAN ALMERA N15 1995 Service Manual Frontmark

Oil hole

Engine

front Piston

grade

number

Cylindernumber

SEM946C

Top

Oil

SEM199F CYLINDER

BLOCK []:[J

Assembly (Conl'd)

2. Heat piston to60 to70°C (140to158°F) andassemble piston,

p NISSAN ALMERA N15 1995 Service Manual Frontmark

Oil hole

Engine

front Piston

grade

number

Cylindernumber

SEM946C

Top

Oil

SEM199F CYLINDER

BLOCK []:[J

Assembly (Conl'd)

2. Heat piston to60 to70°C (140to158°F) andassemble piston,

p](/img/5/57349/w960_57349-1288.png)

Frontmark

Oil hole

Engine

front Piston

grade

number

Cylindernumber

SEM946C

Top

Oil

SEM199F CYLINDER

BLOCK []:[J

Assembly (Conl'd)

2. Heat piston to60 to70°C (140to158°F) andassemble piston,

piston pin,connecting rodand new snap ring.

• Align thedirection ofpiston andconnecting rod.

• Numbers stampedonconnecting rodand capcorrespond to

each cylinder.

• After assembly, makesureconnecting rodswings

smoothly.

3. Set piston ringsasshown.

CAUTION:

• When piston ringsarenotreplaced, makesurethatpiston

rings aremounted intheir original positions.

• When replacing pistonrings,thosewithout punchmarks can

be mounted witheither sideup.

Oil ring

expander

*v

Engine!/

front

(:J

#5

#4 ~

~il hole #3~~ \)

#2 ~~ ,

#1~~~ ~~

12 ~~

Engine front~

SEM685DCRANKSHAFT

1. Set main bearings intheir proper positions oncylinder

block andmain bearing cap.

• Confirm thatcorrect mainbearings areused. Referto

"Inspection" ofthis section.

• Apply newengine oiltobearing surfaces.

EM-110

Page 1290 of 1701

![NISSAN ALMERA N15 1995 Service Manual Tighteninnumerical order.

'::::::-.... Alignoilhole.

~~

'~~-

SEM015D

SEM159B CYLINDER

BLOCK [][]

Assembly (Cont'd)

2. Install crankshaft andmain bearing capsandtighten bolts

to the spec NISSAN ALMERA N15 1995 Service Manual Tighteninnumerical order.

'::::::-.... Alignoilhole.

~~

'~~-

SEM015D

SEM159B CYLINDER

BLOCK [][]

Assembly (Cont'd)

2. Install crankshaft andmain bearing capsandtighten bolts

to the spec](/img/5/57349/w960_57349-1289.png)

Tighteninnumerical order.

'::::::-.... Alignoilhole.

~~

'~~-

SEM015D

SEM159B CYLINDER

BLOCK [][]

Assembly (Cont'd)

2. Install crankshaft andmain bearing capsandtighten bolts

to the specified torque.

• Apply newengine oiltothread ofbearing capbolts.

• Prior totightening bearingcapbolts, shiftcrankshaft back

and forth toproperly seatthebearing cap.

• Tightening procedure

a. Tighten allbolts to26 to32 N'm (2.7to3.3 kg-m, 20to24 •

in-Ib).

b. Turn allbolts 75to80 degrees clockwise withTool orsuit-

able angle wrench.

c. Loosen allbolts completely.

d. Tighten allbolts to32 to38 N'm (3.3to3.9 kg-m, 24to28

ft-Ib).

e. Turn allbolts 45to50 degrees clockwise withTool orsuit-

able angle wrench.

• Ifan angle wrench isnot available, markallbearing cap

bolts onthe side facing engine rear.Then, turneach bolt

specified degreesclockwise. Confirmangleofdegrees with

a graduator, notbyeye-measurement.

• After securing bearingcapbolts, makesurecrankshaft

turns smoothly byhand.

3. Measure crankshaft endplay.

Crankshaft endplay:

Standard

0.10 -0.26 mm(0.0039 -0.0102 in)

Limit

0.30 mm(0.0118 in)

If beyond thelimit, replace thrustbearings withnewones.

4. Install connecting rodbearings inconnecting rodsandcon-

necting rodcaps.

• Confirm thatcorrect bearings areused. Referto

"I nspection" .

• Install bearings sothat oilhole inconnecting rodaligns with

oil hole ofbearing.

• Apply newengine oiltobolt threads andbearing surfaces.

5. Install pistons withconnecting rods.

a. Install themintocorresponding cylinderswithTool.

• Becareful nottoscratch cylinder wallbyconnecting rod.

• Arrange sothat front mark onpiston headfaces toward

front ofengine.

• Apply newengine oiltopiston ringsandsliding surface of

piston.

EM-111