NISSAN ALMERA N15 1995 Service Manual

Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1311 of 1701

![NISSAN ALMERA N15 1995 Service Manual

I

Recess

I

diameter

W: Refer toSOS.

I

SEM795A

SEMB76

SEM877

SEM635AA CYLINDER

HEAD

[£Q]

Inspection (Cont'd)

VALVE SEATREPLACEMENT

1. Bore outoldseat untilitcollapses.

Set machine depthst NISSAN ALMERA N15 1995 Service Manual

I

Recess

I

diameter

W: Refer toSOS.

I

SEM795A

SEMB76

SEM877

SEM635AA CYLINDER

HEAD

[£Q]

Inspection (Cont'd)

VALVE SEATREPLACEMENT

1. Bore outoldseat untilitcollapses.

Set machine depthst](/img/5/57349/w960_57349-1310.png)

I

Recess

I

diameter

W: Refer toSOS.

I

SEM795A

SEMB76

SEM877

SEM635AA CYLINDER

HEAD

[£Q]

Inspection (Cont'd)

VALVE SEATREPLACEMENT

1. Bore outoldseat untilitcollapses.

Set machine depthstopsothat boring cannot contact bot-

tom face ofseat recess incylinder head.

2. Ream thecylinder headrecess.

Reaming boreforservice valveseat

[Oversize 0.5mm (0.020 in)]:

Intake 41.432 -41.454 mm(1.6312 -1.6320 in)

Exhaust 35.432-35.454 mm(1.3950 -1.3958 in)

Use thevalve gUide center forreaming toensure valveseatwill

have thecorrect fit.

3. Heat cylinder headtoatemperature of150 to160°C (302to

320°F) andpress fitseat untilitseats onthe bottom.

4. Install valveseats.

When replacing valveseat,valve should bereplaced aswell.

5. Cut orgrind valve seatusing asuitable toolatthe specified

dimensions asshown inSOS (EM-172).

The cutting shouldbedone withboth hands toobtain auniform

and concentric finish.

6. Apply asmall amount offine grinding compound tothe

valve's contacting faceandputthe valve intoitsguide.

Lap valve against itsseat untilproper valveseating is

obtained.

7. Check valveseating condition.

EM-132

Page 1312 of 1701

![NISSAN ALMERA N15 1995 Service Manual

T(Margin thickness)

II

~a

.

,

I

T(Th)

D

L

CYLINDER

HEAD @Q]

Inspection (Cont'd)

VALVE DIMENSIONS

1. Check dimensions ofeach valve. Fordimensions, referto

SDS (EM-171).

2. Correct orrepla NISSAN ALMERA N15 1995 Service Manual

T(Margin thickness)

II

~a

.

,

I

T(Th)

D

L

CYLINDER

HEAD @Q]

Inspection (Cont'd)

VALVE DIMENSIONS

1. Check dimensions ofeach valve. Fordimensions, referto

SDS (EM-171).

2. Correct orrepla](/img/5/57349/w960_57349-1311.png)

T(Margin thickness)

II

~a

.

,

I

T(Th)

D

L

CYLINDER

HEAD @Q]

Inspection (Cont'd)

VALVE DIMENSIONS

1. Check dimensions ofeach valve. Fordimensions, referto

SDS (EM-171).

2. Correct orreplace anyvalve thatisfaulty .

d •

L-~

SEM188A

3.Valve faceorvalve stemendsurface shouldberefaced by

using avalve grinder.

When valveheadhasbeen worn down to0.5 mm (0.020 in)in

margin thickness, replacethevalve.

Grinding allowance torvalve stemtipis0.5 mm (0.020 in)or

less.

VALVE SPRING SQUARENESS

Check valvespring forsquareness usingasteel square andflat

surface plate.

If

spring isout ofsquare "S"more thanspecified limit,replace

with newone.

Out-at-square: OuterLess than2.1mm (0.083 in)

Inner less than1.9mm (0.075 in)

•

SEM333

VALVE SPRING PRESSURE LOAD

Measure thefree length andthetension ofeach spring. Ifthe

measured valueexceeds thespecified limit,replace spring.

Refer toSDS (EM-172).

EM113 HYDRAULIC VALVELIFTER

1. Check contact andsliding surfaces forwear orscratches .

SEM7238 EM-133

Page 1313 of 1701

SEM724B

SEM720B

WKOO"'P;O

Notch

~~~ SEM721BCYLINDER

HEAD

Inspection (Cont'd)

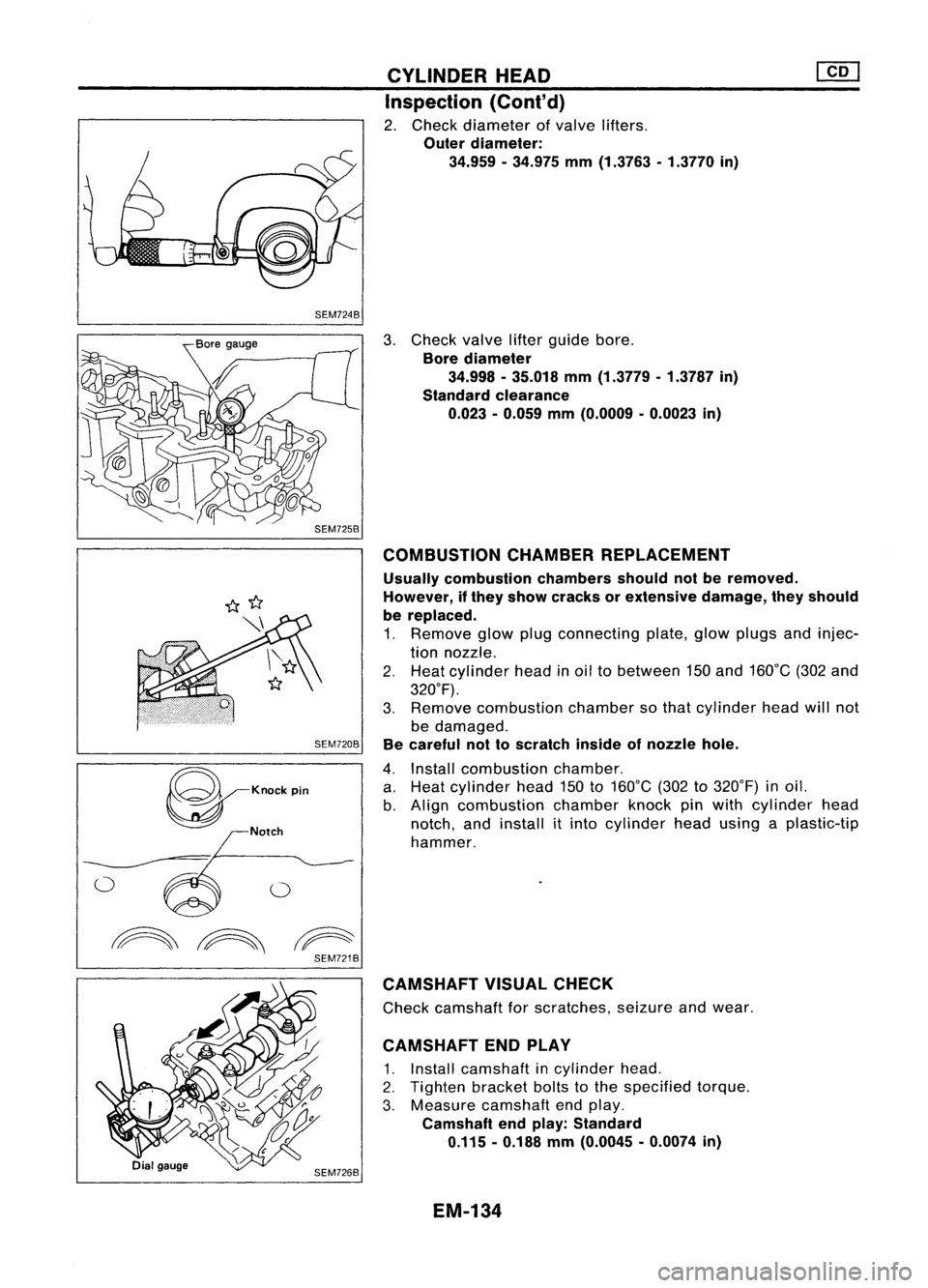

2. Check diameter ofvalve lifters.

Outer diameter:

34.959 -34.975 mm(1.3763 -1.3770 in)

3. Check valvelifterguide bore.

Bore diameter

34.998 -35.018 mm(1.3779 -1.3787 in)

Standard clearance

0.023 -0.059 mm(O.0009 -0.0023 in)

COMBUSTION CHAMBERREPLACEMENT

Usually combustion chambersshouldnotberemoved.

However, ifthey show cracks orextensive damage,theyshould

be replaced.

1. Remove glowplugconnecting plate,glowplugs andinjec-

tion nozzle.

2. Heat cylinder headinoil tobetween 150and 160°C (302and

320°F).

3. Remove combustion chambersothat cylinder headwillnot

be damaged.

Be careful nottoscratch insideofnozzle hole.

4. Install combustion chamber.

a. Heat cylinder head150to160°C (302to320°F) inoil.

b. Align combustion chamberknockpinwith cylinder head

notch, andinstall itinto cylinder headusing aplastic-tip

hammer.

CAMSHAFT VISUALCHECK

Check camshaft forscratches, seizureandwear.

CAMSHAFT ENDPLAY

1. Install camshaft incylinder head.

2. Tighten bracketboltstothe specified torque.

3. Measure camshaft endplay.

Camshaft endplay: Standard

0.115 -0.188 mm(O.0045 -0.0074 in)

EM-134

Page 1314 of 1701

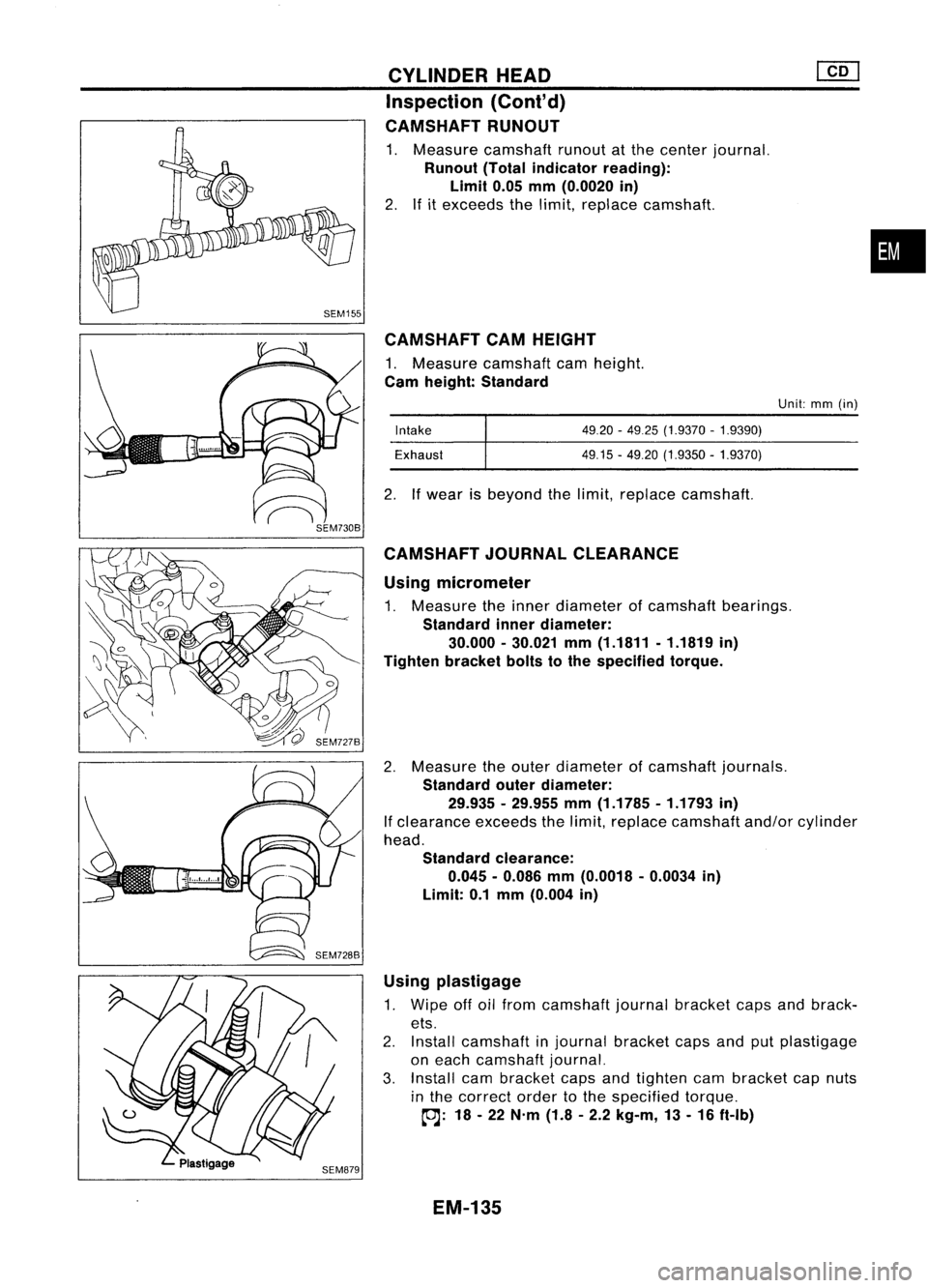

CAMSHAFTCAMHEIGHT

1. Measure camshaft camheight.

Cam height: Standard

Using micrometer

1. Measure theinner diameter ofcamshaft bearings.

Standard innerdiameter:

30.000 -30.021 mm(1.1811 -1.1819 in)

Tighten bracketboltstothe specified torque.

2. Measure theouter diameter ofcamshaft journals.

Standard outerdiameter:

29.935 -29.955 mm(1.1785 -1.1793 in)

If clearance exceedsthelimit, replace camshaft and/orcylinder

head.

Standard clearance:

0.045 -0.086 mm(0.0018 -0.0034 in)

Limit: 0.1mm (0.004 in)

•

Unit: mm(in)

49.20 -4925 (1.9370 -1.9390)

49.15 -49.20 (1.9350 -1.9370)

Intake

Exhaust

2. Ifwear isbeyond thelimit, replace camshaft.

CYLINDER

HEAD

Inspection (Cont'd)

CAMSHAFT RUNOUT

1. Measure camshaft runoutatthe center journal.

Runout (Totalindicator reading):

Limit 0.05mm(0.0020 in)

2. Ifitexceeds thelimit, replace camshaft.

CAMSHAFT JOURNALCLEARANCE

Using plastigage

1. Wipe offoilfrom camshaft journalbracket capsandbrack-

ets.

2. Install camshaft injournal bracket capsandputplastigage

on each camshaft journal.

3. Install cambracket capsandtighten cambracket capnuts

in the correct ordertothe specified torque.

~: 18-22 N'm (1.8-2.2 kg-m, 13-16 ft-Ib)

EM-135

Page 1315 of 1701

![NISSAN ALMERA N15 1995 Service Manual SEM202

SEM731BA

Grade number

Tightening sequence

r

1

@@

~.~.~

o

,..0

W

@

@ @

Facing frontofengine

(position 2)

SEM528DCYLINDER

HEAD

[£Q]

Inspection {Cont'd)

4. Remove cambracket capsan NISSAN ALMERA N15 1995 Service Manual SEM202

SEM731BA

Grade number

Tightening sequence

r

1

@@

~.~.~

o

,..0

W

@

@ @

Facing frontofengine

(position 2)

SEM528DCYLINDER

HEAD

[£Q]

Inspection {Cont'd)

4. Remove cambracket capsan](/img/5/57349/w960_57349-1314.png)

SEM202

SEM731BA

Grade number

Tightening sequence

r

1

@@

~.~.~

o

,..0

W

@

@ @

Facing frontofengine

(position 2)

SEM528DCYLINDER

HEAD

[£Q]

Inspection {Cont'd)

4. Remove cambracket capsandmeasure maximum widthof

plastigage. Camshaft bearingclearance:

Limit

0.1 mm (0.004 in)

5. Ifclearance appearstoexceed thelimit, replace camshaft

or cylinder head.

• Which partstobe replaced shouldbedecided uponafter

measuring thediameters ofthe parts concerned.

Assembly

1. Install valvecomponent parts.

Install valvespring withitsnarrow pitchsidetoward cylinder

head side.

• Always installnewvalve oilseals.

Refer tooil seal replacement.

• Before installing oilseal, install valve-spring seat.

• When installing valve,applyengine oilonthe valve stem

and lipofvalve oilseal.

• Check whether thevalve faceisfree from foreign matter.

• Install valvespring retainers onthe intake sideandvalve

rotators onthe exhaust side.

• Valve rotators cannotbedisassembled.

2. Install camshaft andbrackets andtighten bracket nutstothe

specified torqueintwo orthree stages.

Camshaft-bracket nuts:

~: 18-22 N'm (1.8-2.2 kg-m, 13-16 ft-Ib)

• Tighten bracketfromcenter tooutside.

• Apply sealant tobrackets No.1and No.5.

• When installing "brackets, setcamshaft sothat thepinof

camshaft fronthead isuppermost.

• Install newcamshaft oilseals.

Refer tooil seal replacement.

17.5 (0.689)

o

o

13.0

(0.512)

NO.1 journal bracket No.5journal bracket

Unit: mm(in)

SEM676D

EM-136

Page 1316 of 1701

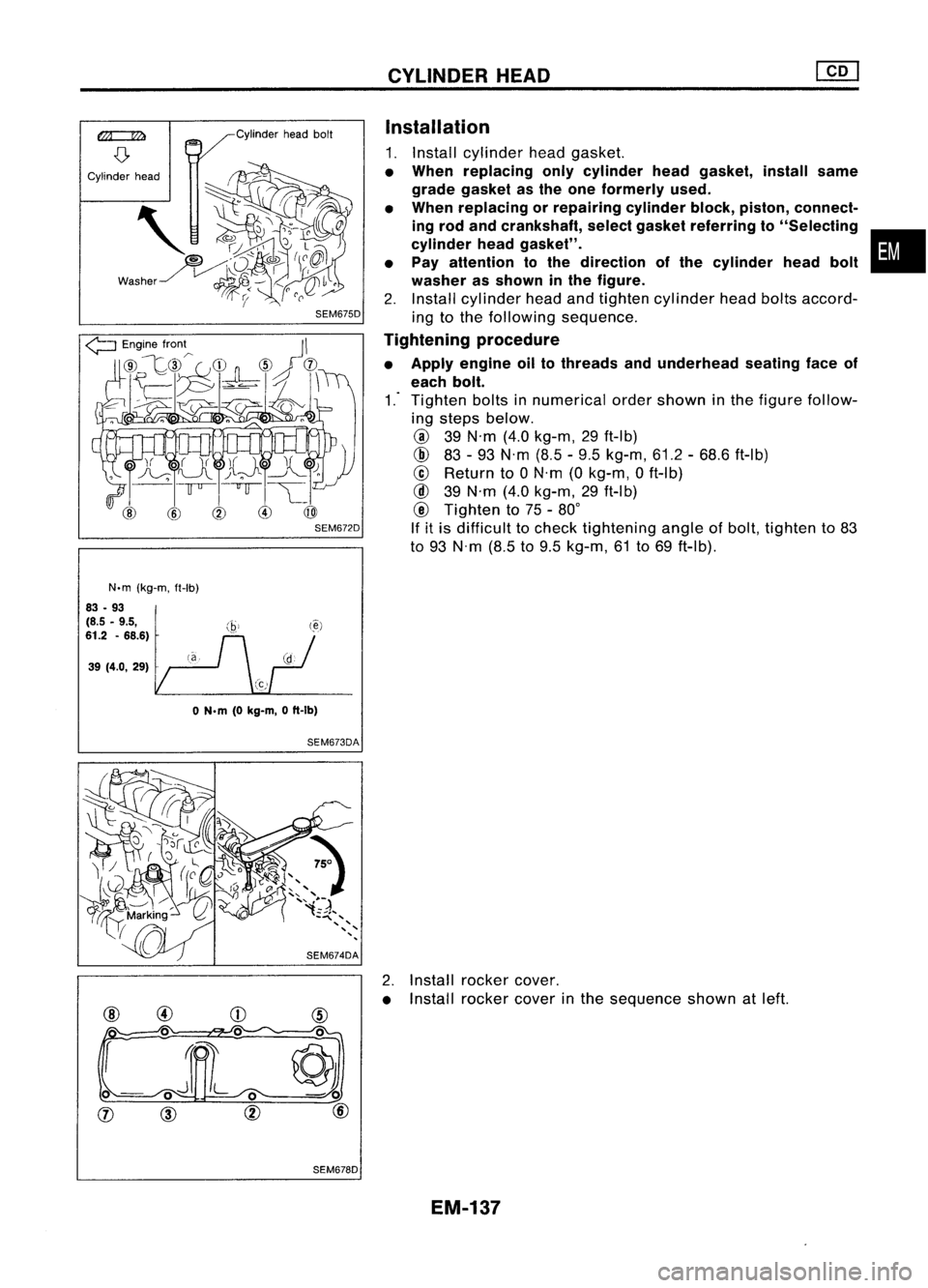

Cylinderheadbolt

N.m (kg-m, ft-Ib)

83 -93

(8.5 -9.5,

(Iii(~)

61.2 -68.6)

39 (4.0, 29)

o

N.m (0kg-m, 0ft-Ib)

SEM673DA

SEM678D CYLINDER

HEAD

Installation

1. Install cylinder headgasket.

• When replacing onlycylinder headgasket, installsame

grade gasket asthe one formerly used.

• When replacing orrepairing cylinderblock,piston, connect-

ing rod and crankshaft, selectgasket referring to"Selecting •

cylinder headgasket".

• Pay attention tothe direction ofthe cylinder headbolt

washer asshown inthe figure.

2. Install cylinder headandtighten cylinder headboltsaccord-

ing tothe following sequence.

Tightening procedure

• Apply engine oiltothreads andunderhead seatingfaceof

each bolt.

1.-

Tighten boltsinnumerical ordershown inthe figure follow-

ing steps below.

@

39N'm (4.0kg-m, 29ft-Ib)

@

83-93 N'm (8.5-9.5 kg-m, 61.2-68.6 ft-Ib)

@

Return to0N'm (0kg-m, 0ft-Ib)

@

39N'm (4.0kg-m, 29ft-Ib)

@

Tighten to75 -80°

If itis difficult tocheck tightening angleofbolt, tighten to83

to 93 N'm (8.5to9.5 kg-m, 61to69 ft-Ib).

2. Install rocker cover.

• Install rocker coverinthe sequence shownatleft.

EM-137

Page 1317 of 1701

![NISSAN ALMERA N15 1995 Service Manual

Unit:mm(in)

SEM529DCYLINDER

HEAD

@[]

Installation (Cont'd)

• Apply sealing compound (THREE-BOND No.10or equiva-

lent) toboth ends ofbrackets No.1andNo.5.

Selecting cylinderheadgasket

When NISSAN ALMERA N15 1995 Service Manual

Unit:mm(in)

SEM529DCYLINDER

HEAD

@[]

Installation (Cont'd)

• Apply sealing compound (THREE-BOND No.10or equiva-

lent) toboth ends ofbrackets No.1andNo.5.

Selecting cylinderheadgasket

When](/img/5/57349/w960_57349-1316.png)

Unit:mm(in)

SEM529DCYLINDER

HEAD

@[]

Installation (Cont'd)

• Apply sealing compound (THREE-BOND No.10or equiva-

lent) toboth ends ofbrackets No.1andNo.5.

Selecting cylinderheadgasket

When replacing onlycylinder headgasket, installthesame

grade (Number ofnotches) gasketasthe one formerly used.

Step 1

Measure projection ofpiston tocylinder headsurface.

a) Set dial gauge andneedle oncylinder blockandadjust dial

gauge tozero.

b) Set dial gauge needle atmeasuring pointonpiston, taking

care nottodisturb itszero setting.

c) Rotate crankshaft aroundthetopdead center position.

d) Read andwrite down themaximum value.

e) Reset dialgauge oncylinder blockandconfirm thatzero

setting hasnotbeen disturbed duringmeasurement.

f) Repeat stepsbthrough dfor allmeasuring pointsasillus-

trated andforeach cylinder.

• Besure thatpiston whose projection isbeing measured is

at its TDC.

Step 2

Calculate theaverage valueofmeasurements takenforeach

piston.

Step 3

Calculate theaverage valueofmeasurements forallpistons

from thevalues obtained fromstep2.

Step 4

Round offthe value obtained.

Step 5

Determine requiredthickness ofgasket, referring tochart

A.

EM-138

Page 1318 of 1701

![NISSAN ALMERA N15 1995 Service Manual

SEM530D

CYLINDER

HEAD

[£[]

Installation (Cont'd)

Relation between pistonaverage projection andcylinder head

gasket (ChartA)

Average valueof

Gasketthickness Grade

piston projec-

mm(in) (Number NISSAN ALMERA N15 1995 Service Manual

SEM530D

CYLINDER

HEAD

[£[]

Installation (Cont'd)

Relation between pistonaverage projection andcylinder head

gasket (ChartA)

Average valueof

Gasketthickness Grade

piston projec-

mm(in) (Number](/img/5/57349/w960_57349-1317.png)

SEM530D

CYLINDER

HEAD

[£[]

Installation (Cont'd)

Relation between pistonaverage projection andcylinder head

gasket (ChartA)

Average valueof

Gasketthickness Grade

piston projec-

mm(in) (Number

of

tions notches)

mm (in)

Newparts

Inassembly

1.25 (0.0492) 1.1~gg~

0

Less than

0.505 (0.0433

~ggg;~)

(0.0199) 1.15_+gg~

1.30 (0.0512)

(0.0453~ggg~g) 1

0.505 -0.555

1.35(0.0931) 1.20_+gg~

(0.0199 -0.0219)

(0.0472~ggg~g ) 2

.

Over

0.555 1.25_+gg~

(0.0219) 1.40

(0.0551)

(0.0492~ggg~g ) 3

Step 6

Check ifthe average valueofeach projection obtainedfrom

step 2is larger thanthemax. value ofthe standard projection

(of selected gasket)incremented by0.05 mm(0.0020 in).

If so, use gasket thatis1grade thicker. Ifnot so,use gasket as

selected instep 4.

•

Example

Unit:mm(in)

Step Cylinder

No.

1 2 34

Item

M1M2M3 M4M1 M2M3 M4M1

M2M3

.

M4 M1

M2M3M4

1. Measured

value 0.53

0.560.53 0.560.59 0.55 0.59

0550.53 0.580.57

0.54

0.58 0.51052 0.57

(0.0209) (0.0220)(0.0209)(0.0220)

(0.0232)(0.0217)

(0.0232)(0.0217)(0.0209)(0.0228)(0.0224)(0.0213)(0.0228) (0.0201)(0.0205) (0.0224)

Average 0.545 0.57

0.555 0.545

2 value

ofeach

(0.0215) (0.0224)-(0.0219)

(0.0215)

piston

Average

3 value

ofall 055375(0.02180)

pistons

4. Round

off

0.554(0.0218)'1

value

Determined

5. gasket

thick-

120(0.0472) (Grade8)

ness (Tempo-

rarily)

X: Maximum valueofstandard projection ofselected gasket...0.555 (0.0219) (inchart A)

+

0.05 (0.0020)

=

0.605 (0.0238)

6. Y:Maximum valueinstep 2

=

0.57 (0.0224)

The relationship betweenXand Yis "X

>

Y.... 2

Determined

7. gasket thick- 1.20(0.0472) (Grade8)'2

ness (Finally)

*1: IIthe average value

01

projections lorallpistons is,lor example, 0.553(7)5,as shown inthe table above, itshould berounded oilasfol-

lows:

II the digit inthe forth decimal place(which isenclosed byacircle inthis case) issmaller than5,the average valueshould beregarded

as 0.553 mm(0.0218 in);ilitis larger than5,the average valueshould beregarded as0.554 mm(0.0218 in).

*2: IIX

<

Y, then thethicker gradeCgasket mustbeused.

EM-139

Page 1319 of 1701

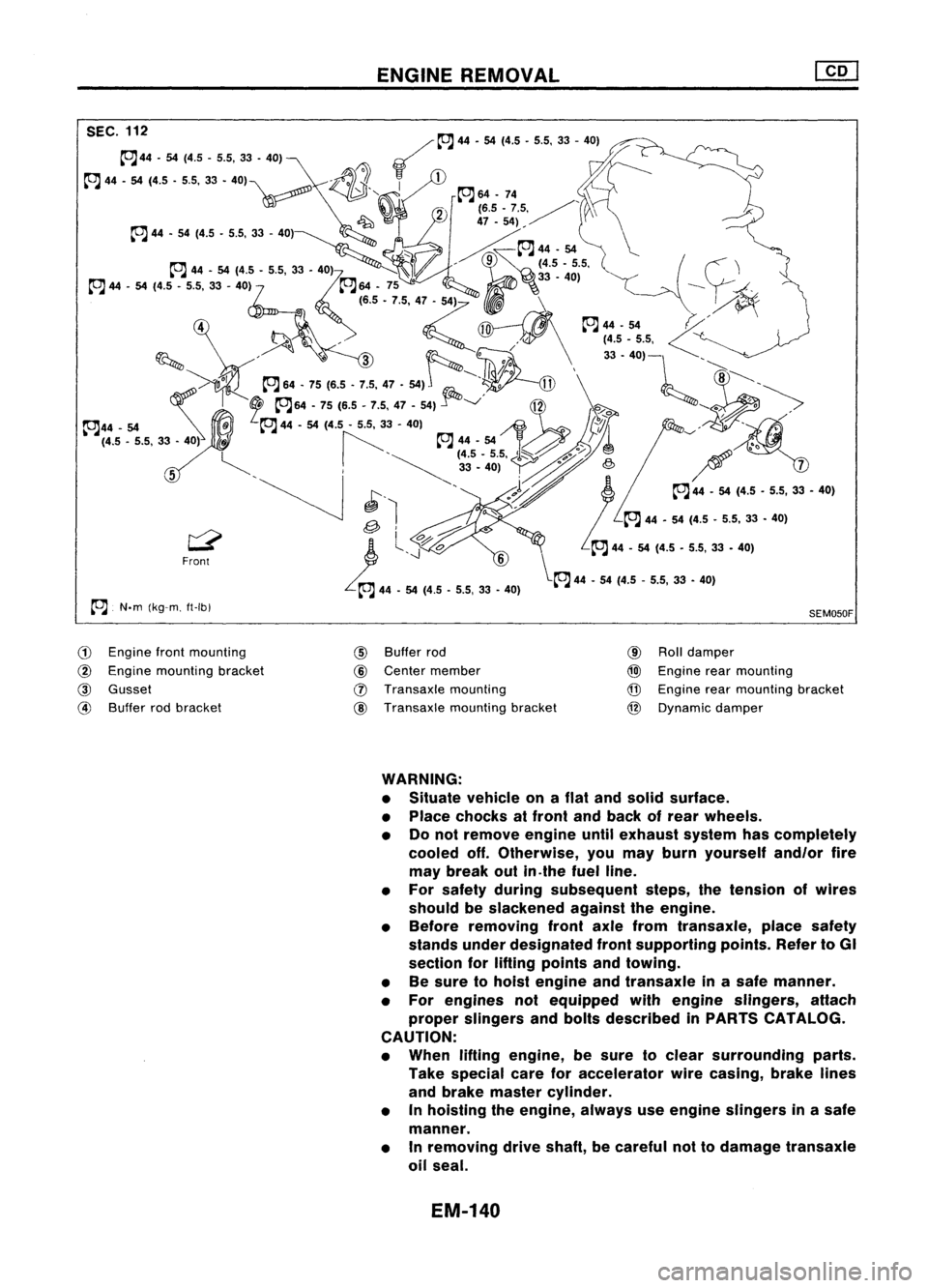

SEC.112 ENGINE

REMOVAL

~~ 44.54(4.5.5.5,33 -40)

~44 .54 (4.5 .5.5, 33.40) ~~

~ 44•54 (4.5 .5.5, 33•40)"\ ~

-~1J.

~1

~~' ~64.74,

_' 2

(6.5.7.5, / \

~ 47.54),/'

rJ44. 54(4.5.5.5,33 -40) ~\

'" ~~~44.54 \....

.- ,9

(4.5.5.5,

ttJJ 44-54 (4.5 •5.5, 33-40)

7

ttJJ64.75 ------~

@--."

('.5•7.5, 4~' \

y~

~~.~~ ~~f;fi\

~~~'~i':-l~"

k(j' --.

II!~o' ~

/'Oolk..,

ttJJ64.75 (6.5•7.5, 47•54) ~

~'o

@\

8,.'~

~- I

2

rJ64. 75(6.5 .7.5,47.54)..1"""-../

~2ft -."~

°

>

~44. 54

~@

ttJJ44.54(4.5 -5.5, 33. 40)

j~~~1 ~-/.~/

(4.5 -5.5, 33•40)

ti ~~

44•54

~'@

A

5~'

!-'~

~35'-4~.)5'~ ~/

,0

7

~ I~. '

.Vi

rJ44.54(4.5.5.5,33.40)

~ ~l

ttJJ44•54 (4.5 •5.5, 33•40)

~ 'l

o.o~

I...",;S'"

1.

..J'-;:7o

6

ttJJ44.54 (4.5 •5.5, 33•40)

~l \

'LrJ 44•54 (4.5 -5.5, 33•40)

ttJJ 44.54 (4.5 .5_5, 33.40)

rJ

N.m(kg-m. ft-Ibl

G)

Engine frontmounting

@

Engine mounting bracket

@

Gusset

@

Buffer rodbracket

@

Buffer rod

@

Center member

(J)

Transaxle mounting

@

Transaxle mountingbracket

SEM050F

@

Rolldamper

@)

Engine rearmounting

@

Engine rearmounting bracket

@

Dynamic damper

WARNING:

• Situate vehicle onaflat and solid surface.

• Place chocks atfront andback ofrear wheels.

• Donot remove engineuntilexhaust systemhascompletely

cooled off.Otherwise, youmay burn yourself and/orfire

may break outin.the fuel line.

• For safety during subsequent steps,thetension ofwires

should beslackened againsttheengine.

• Before removing frontaxlefrom transaxle, placesafety

stands underdesignated frontsupporting points.RefertoGI

section forlifting points andtowing.

• Besure tohoist engine andtransaxle inasafe manner.

• For engines notequipped withengine slingers, attach

proper slingers andbolts described inPARTS CATALOG.

CAUTION:

• When liftingengine, besure toclear surrounding parts.

Take special careforaccelerator wirecasing, brakelines

and brake master cylinder.

• Inhoisting theengine, alwaysuseengine slingers inasafe

manner.

• Inremoving driveshaft, becareful nottodamage transaxle

oil seal.

EM-140

Page 1320 of 1701

Drainplug(Radiator)

SFA110A

SFA 1538

SEM534D ENGINE

REMOVAL

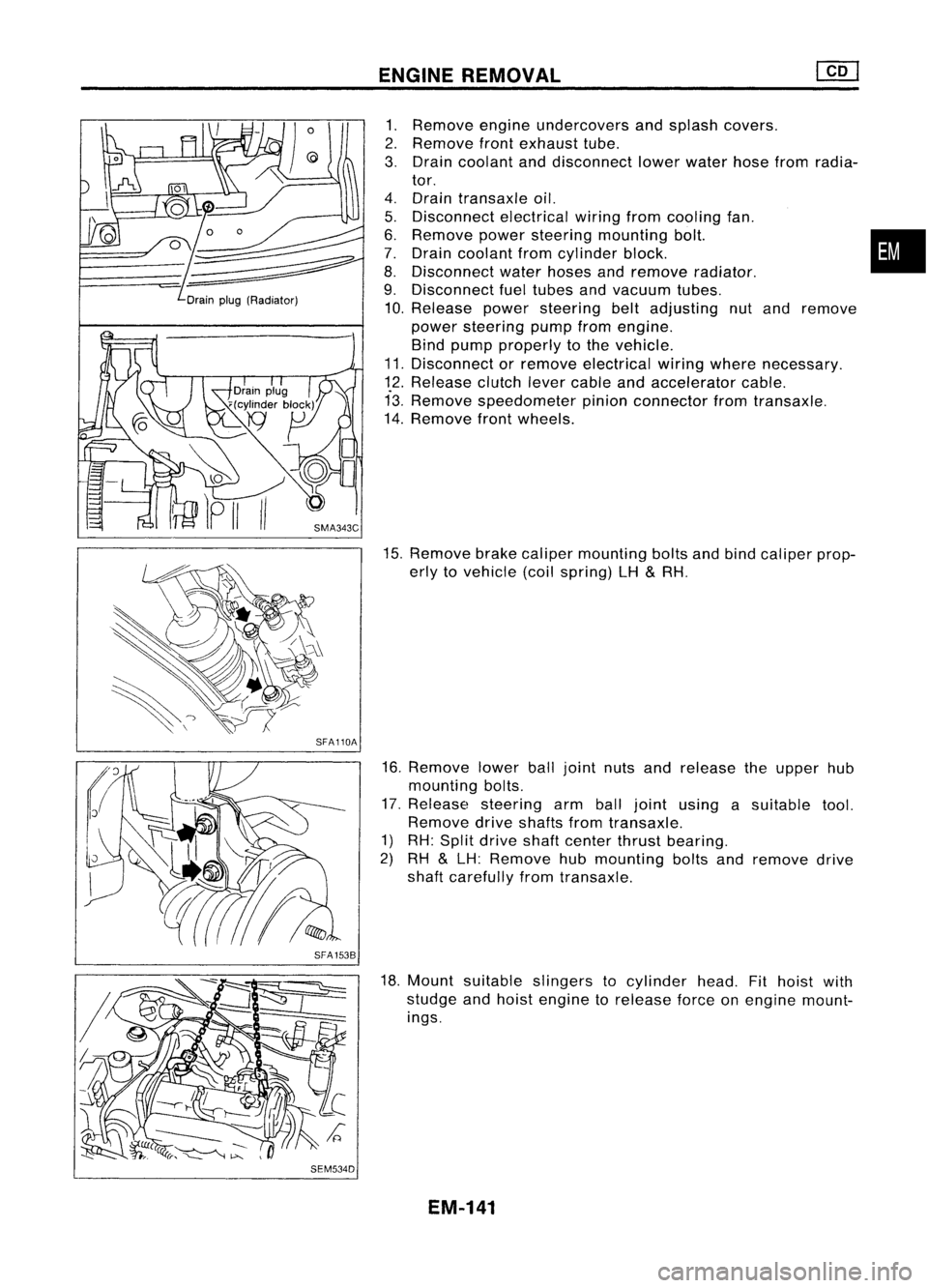

1. Remove engineundercovers andsplash covers.

2. Remove frontexhaust tube.

3. Drain coolant anddisconnect lowerwater hosefromradia-

tor.

4. Drain transaxle oil.

5. Disconnect electricalwiringfromcooling fan.

6. Remove powersteering mounting bolt. •

7. Drain coolant fromcylinder block.

8. Disconnect waterhoses andremove radiator.

9. Disconnect fueltubes andvacuum tubes.

10. Release powersteering beltadjusting nutand remove

power steering pumpfromengine.

Bind pump properly tothe vehicle.

11. Disconnect orremove electrical wiringwhere necessary.

12. Release clutchlevercable andaccelerator cable.

13. Remove speedometer pinionconnector fromtransaxle.

14. Remove frontwheels.

15. Remove brakecaliper mounting boltsandbind caliper prop-

erly tovehicle (coilspring) LH

&

RH.

16. Remove lowerballjoint nutsandrelease theupper hub

mounting bolts.

17. Release steering armballjoint using asuitable tool.

Remove driveshafts fromtransaxle.

1) RH: Split drive shaftcenter thrustbearing.

2) RH

&

LH: Remove hubmounting boltsandremove drive

shaft carefully fromtransaxle.

18. Mount suitable slingers tocylinder head.Fithoist with

studge andhoist engine torelease forceonengine mount-

ings.

EM-141