NISSAN ALMERA N15 1995 Service Manual

Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1331 of 1701

![NISSAN ALMERA N15 1995 Service Manual SEM550

SEM703D CYLINDER

BLOCK

@[]

Inspection (Cont'd)

Using feeler gauge

1. Set piston andfeeler gauge withspring scale.

2. Measure extracting forcewhile pulling upscale slowly.

Feeler gaugeuse NISSAN ALMERA N15 1995 Service Manual SEM550

SEM703D CYLINDER

BLOCK

@[]

Inspection (Cont'd)

Using feeler gauge

1. Set piston andfeeler gauge withspring scale.

2. Measure extracting forcewhile pulling upscale slowly.

Feeler gaugeuse](/img/5/57349/w960_57349-1330.png)

SEM550

SEM703D CYLINDER

BLOCK

@[]

Inspection (Cont'd)

Using feeler gauge

1. Set piston andfeeler gauge withspring scale.

2. Measure extracting forcewhile pulling upscale slowly.

Feeler gaugeused:

0.05 -0.07 mm(0.0020 -0.0028 in)

Extracting force:

7.8 -14.7 N(0.8 -1.5 kg, 1.8-3.3 Ib)

Assembly

PISTON

• Numbers stampedonconnecting rodand capcorrespond to

each cylinder. Careshould betaken toavoid awrong com-

bination including bearingandconnecting roddirection.

KV101070S0

EM156

•

Install newsnap ringonone side ofpiston pinhole.

• When assembling pistonandconnecting rodwith piston pin,

heat piston tobetween 60and 80°C (140and176°F) and

install piston pinwith asuitable tool.

• Install newsnap ring.

• After assembling, ascertainthatpiston swings smoothly.

• Install

piston

ringswithasuitable tool.

Selective topring; When installing newtopring orreplacing

cylinder block,selecttopring toadjust ringgap.

Punch

marksideup

~r~~

~ Tetl~ntubesetposition

~ ,0

Ql

0

SEM251D

Top

ring grade No. Cylinder

boregrade

1,2,3

No mark 4,

5

S

SEM617

CRANKSHAFT

1. Set main bearings inthe proper position oncylinder block

and main bearing caps.

• Ifeither crankshaft, cylinderblockormain bearing isreused

again, itis necessary tomeasure mainbearing clearance.

• Upper bearings (cylinderblockside)haveoilgroove.

• Apply newengine oiltobearing surfaces.

EM-152

Page 1332 of 1701

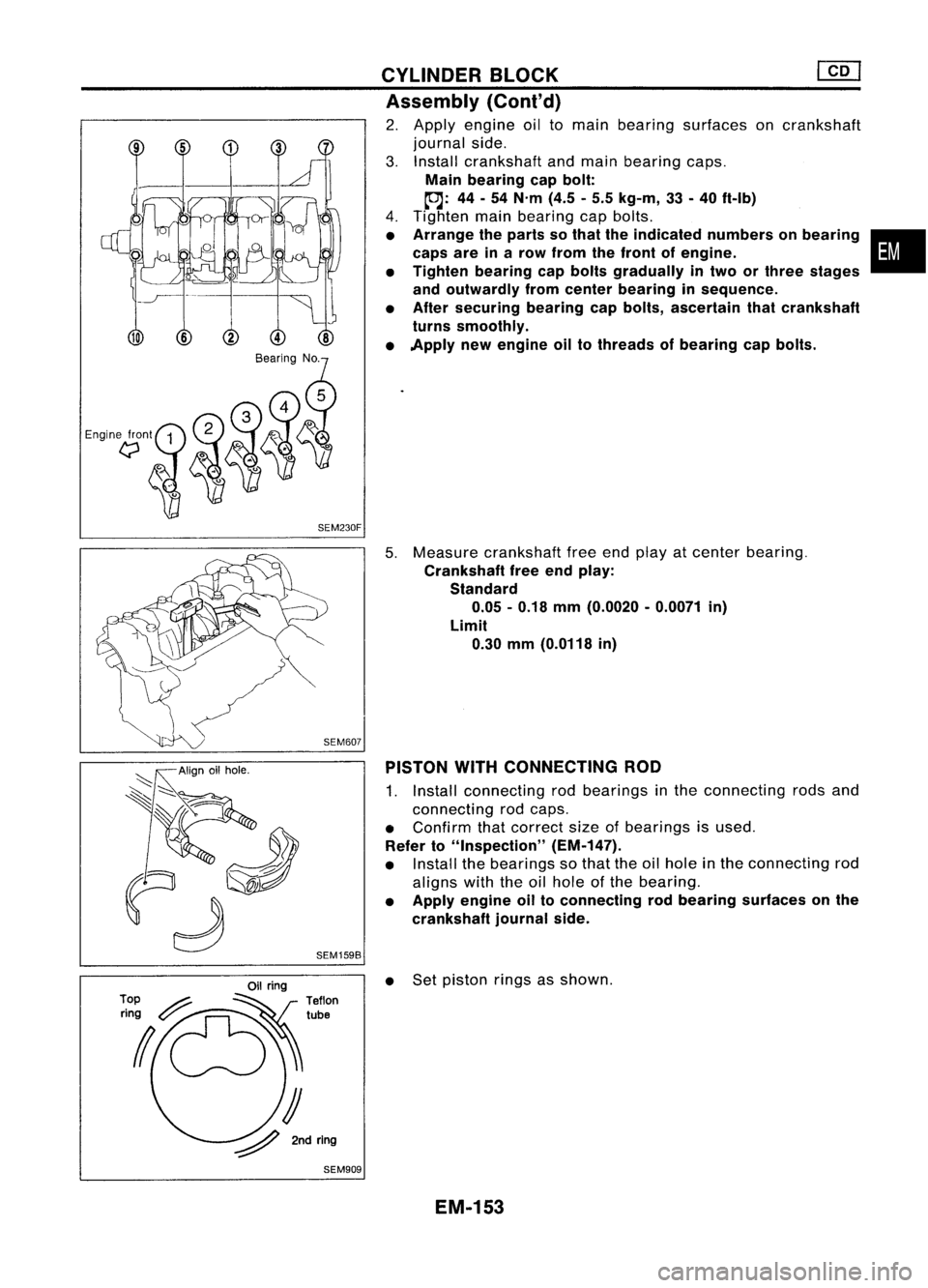

Enginefront1

t;J

SEM230F

~~~:::~"

IJ

~ 2ndring

SEM909 CYLINDER

BLOCK

[ill

Assembly (Cont'd)

2. Apply engine oiltomain bearing surfaces oncrankshaft

journal side.

3. Install crankshaft andmain bearing caps.

Main bearing capbolt:

~: 44-54 N'm (4.5-5.5 kg-m, 33-40 ft-Ib)

4. Tighten mainbearing capbolts.

• Arrange theparts sothat theindicated numbersonbearing •

caps areinarow from thefront ofengine.

• Tighten bearing capbolts gradually intwo orthree stages

and outwardly fromcenter bearing insequence.

• After securing bearingcapbolts, ascertain thatcrankshaft

turns smoothly.

• Apply newengine oiltothreads ofbearing capbolts.

5. Measure crankshaft freeendplay atcenter bearing.

Crankshaft freeendplay:

Standard 0.05 -0.18 mm(0.0020 -0.0071 in)

Limit 0.30 mm(0.0118 in)

PISTON WITHCONNECTING ROD

1. Install connecting rodbearings inthe connecting rodsand

connecting rodcaps.

• Confirm thatcorrect sizeofbearings isused.

Refer to"Inspection" (EM-147).

• Install thebearings sothat theoilhole inthe connecting rod

aligns withtheoilhole ofthe bearing.

• Apply engine oiltoconnecting rodbearing surfaces onthe

crankshaft journalside.

• Set piston ringsasshown.

EM-153

Page 1333 of 1701

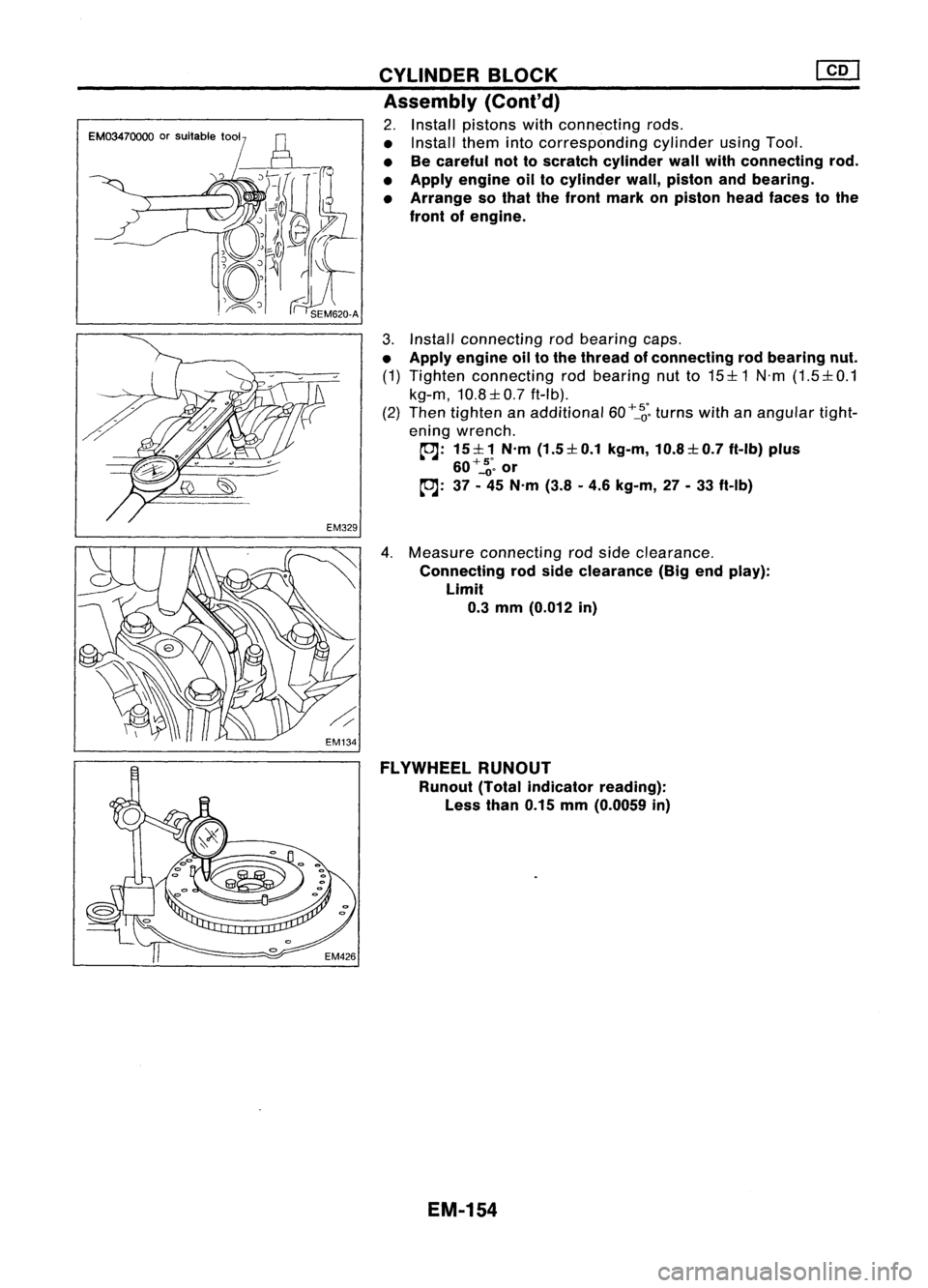

EM03470000orsuitable tool CYLINDER

BLOCK

lliJ

Assembly

(Conl'd)

2. Install pistons withconnecting rods.

• Install themintocorresponding cylinderusingTool.

• Becareful nottoscratch cylinder wallwithconnecting rod.

• Apply engine oiltocylinder wall,piston andbearing.

• Arrange sothat thefront mark onpiston headfaces tothe

front ofengine.

3. Install connecting rodbearing caps.

• Apply engine oiltothe thread ofconnecting rodbearing nut.

(1) Tighten connecting rodbearing nutto15:1:1 N'm(1.5:1:0.1

kg-m, 10.8:1:0.7ft-Ib).

(2) Then tighten anadditional 60

+_~'.

turns withanangular tight-

ening wrench.

~: 15:1:1 N'm(1.5:1:0.1 kg-m,10.8:1:0.7 ft-Ib)plus

60+'::;.

or

~: 37-45 N'm (3.8-4.6 kg-m, 27-33 ft-Ib)

4. Measure connecting rodside clearance.

Connecting rodside clearance (Bigendplay):

Limit

0.3

mm (0.012 in)

FLYWHEEL RUNOUT

Runout (Totalindicator reading):

Less than0.15mm(0.0059 in)

EM-154

Page 1334 of 1701

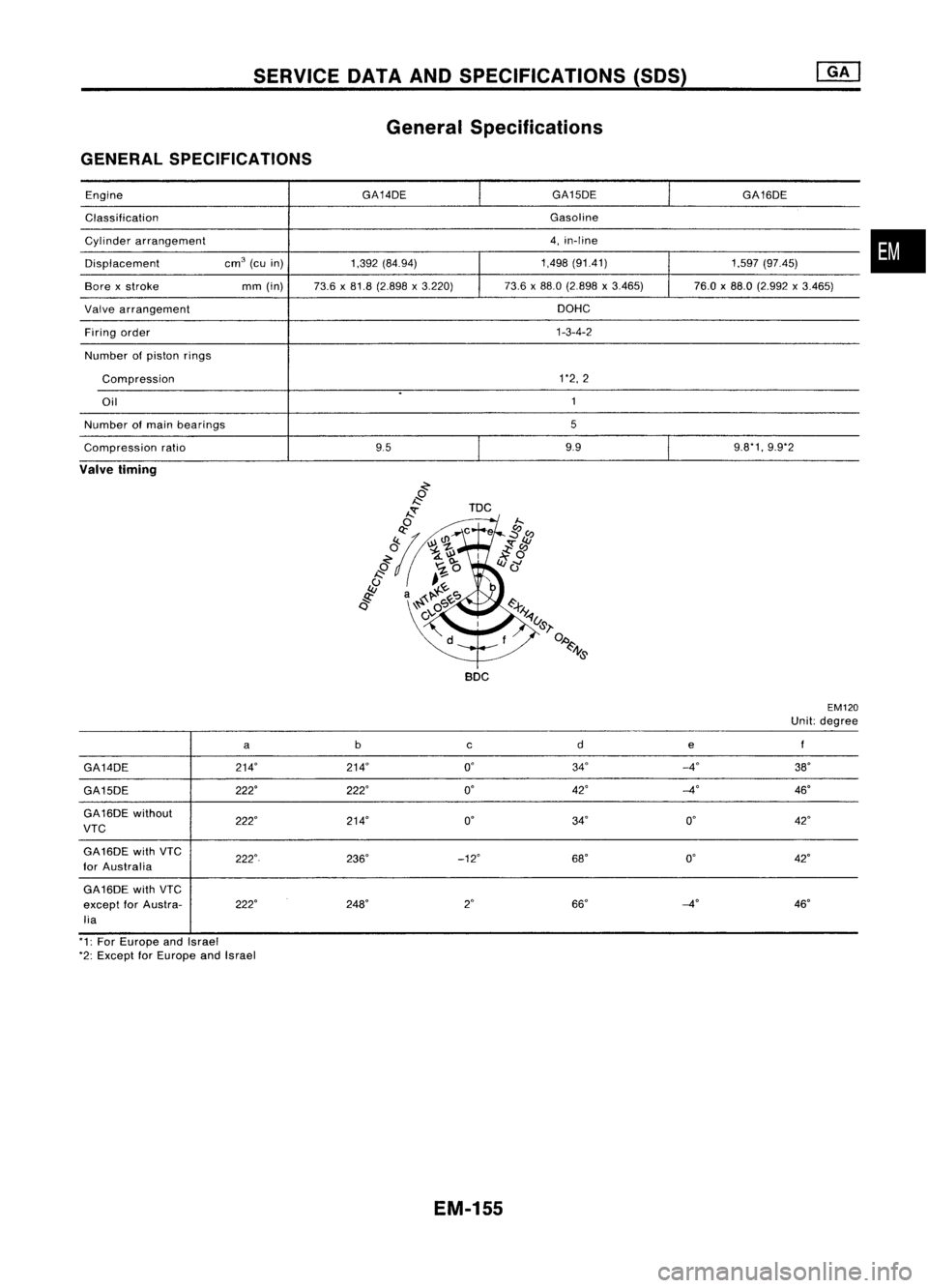

SERVICEDATAANDSPECIFICATIONS (SOS)

General Specifications

GENERAL SPECIFICATIONS

Engine GA14DE

GA15DE

GA16DE

Classification Gasoline

Cylinder arrangement 4,

in-line

Displacement cm

3

(cuin) 1,392(84.94) 1,498

(91.41)

1.597(97.45)

Bore xstroke mm(in) 73.6x81.8 (2.898 x3.220) 73.6

x88.0 (2.898 x3.465) 76.0x88.0 (2.992 x3.465)

Valve arrangement DOHC

Firing order 1-3-4-2

Number ofpiston rings

Compression 1'2,2

.

Oil 1

Number ofmain bearings 5

Compression ratio 959.9

9.8'1,9.9'2

Valve timing

~-r-y'

~U&l'

f

0,0

~J}&

BOC

EM120

Unit: degree

a b

cde

GA14DE 214"214° 0°

34° _4°

38°

GA15DE 222°

222° 0"

42°

-40

46°

GA16DE without

222° 214° 0°

34° 0°

VTC 42°

GA16DE withVTC

222" 236°_12°

68°0°42"

for Australia

GA16DE withVTC

except forAustra- 222°

248° 2"

66°

-4"

46"

lia

'1: For Europe andIsrael

'2: Except forEurope andIsrael

EM-155

•

Page 1335 of 1701

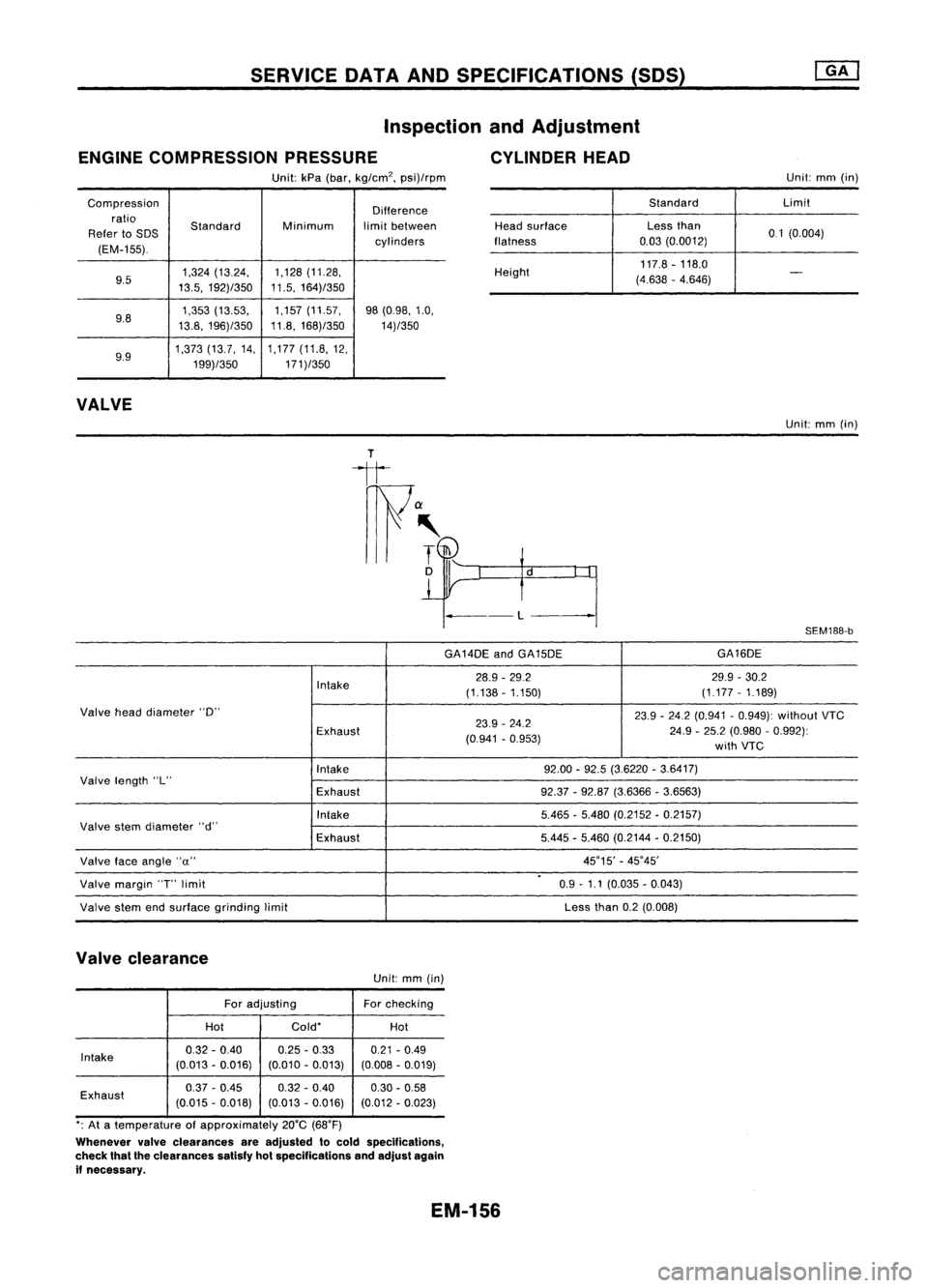

SERVICEDATAANDSPECIFICATIONS (50S)

Inspection andAdjustment

ENGINE COMPRESSION PRESSURE CYLINDERHEAD

Unit: kPa(bar, kg/cm

2,

psi)/rpm Unit:

mm(in)

Compression Difference

ratio Standard Minimumlimitbetween

Refer toSDS

cylinders

(EM-155).

9.5 1,324

(13.24, 1,128

(11.28,

13.5, 192)/350 11.5,

164)/350

9.8 1,353

(13.53, 1,157

(11.57,

98(0.98, 1.0,

13.8, 196)/350 11.8,

168)/350

14)/350

9.9 1,373

(13.7,14, 1,177

(11.8,12,

199)/350 171)/350

VALVE

Standard

Limit

Head surface Lessthan

0.1(0.004)

flatness 0.03

(0.0012)

Height 117.8

-118.0

(4.638 -4.646)

-

Unit: mm(in)

---L

SEM188-b

GA14DE andGA15DE GA16DE

Intake 28.9

-29.2 29.9-30.2

(1.138 -1.150) (1.177

-1.189)

Valve headdiameter "0"

23.9-24.2 (0.941 -0.949): without VTC

Exhaust 23.9

-24.2

24.9-25.2 (0.980 -0.992):

(0.941 -0.953)

withVTC

Intake 92.00

-92.5 (3.6220 -3.6417)

Valve length "L"

Exhaust 92.37-92.87 (3.6366 -3.6563)

Intake 5.465-5.480 (0.2152 -0.2157)

Valve stemdiameter "d"

Exhaust 5.445

-5.460 (0.2144 -0.2150)

Valve faceangle "u" 45°15'

-45°45'

.

Valve margin

'T'

limit 0.9-1.1 (0.035 -0.043)

Valve stemendsurface grinding limit Less

than0.2(0.008)

Valve clearance

Unit:mm(in)

For adjusting Forchecking

Hot Cold*

Hot

Intake 0.32

-0.40 0.25

-0.33

0.21-0.49

(0.013 -0.016) (0.010-0.013) (0.008-0.019)

Exhaust 0.37

-0.45 0.32-0.40

0.30-0.58

(0.015 -0.018) (0.013-0.016) (0.012-0.023)

*: At atemperature ofapproximately 20°C(68°F)

Whenever valveclearances areadjusted tocold specifications,

check thattheclearances satisfyhotspecifications andadjust again

if necessary.

EM-156

Page 1336 of 1701

SERVICEOATAAND SPECIFICATIONS (SOS)

Inspection andAdjustment (Cont'd)

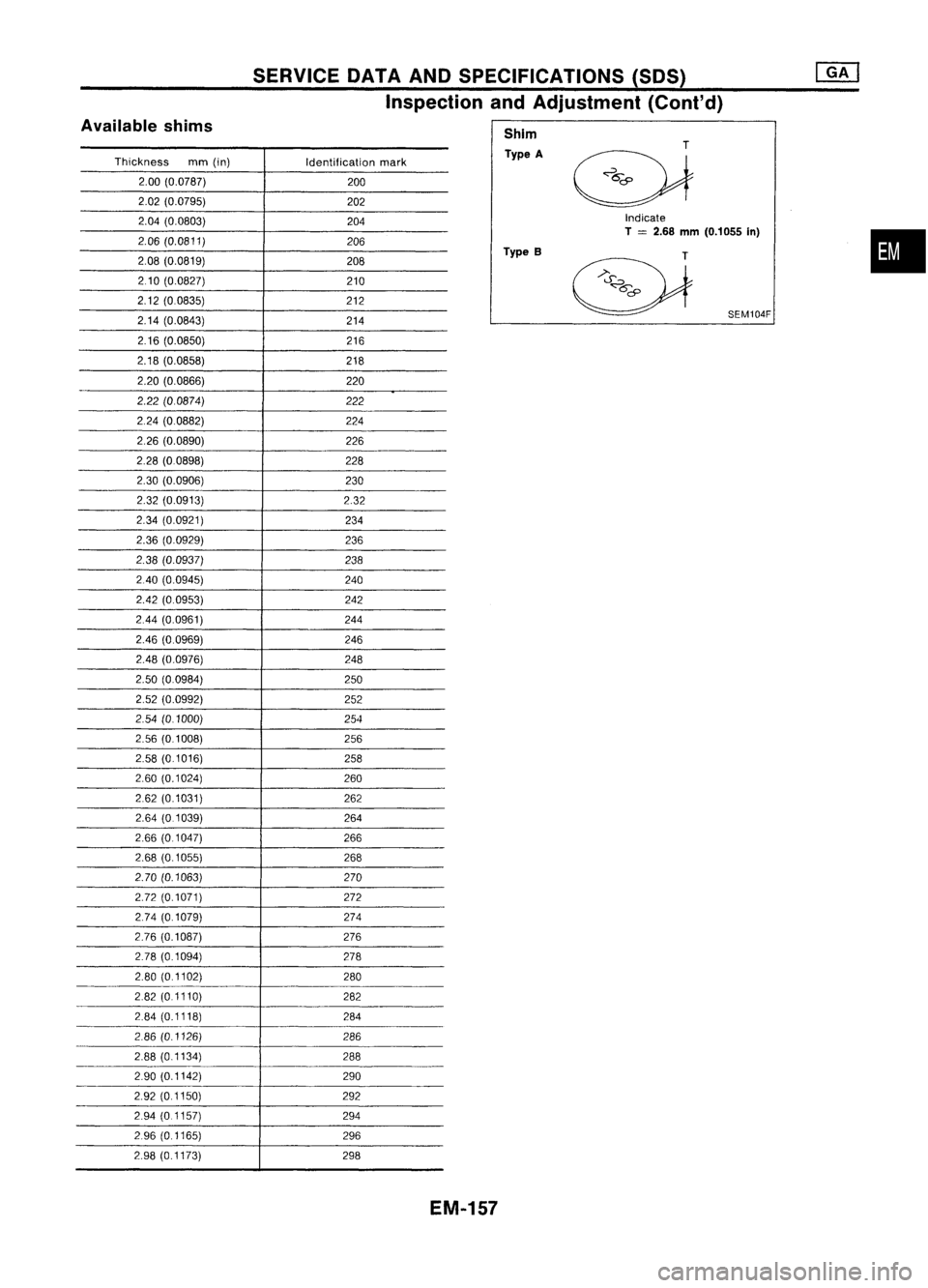

Indicate

T

=

2.68

mm

(0.1055 In)

Available

shims

Thickness mm(in)

Identificationmark

2.00 (0.0787)

200

2.02 (0.0795)

202

2.04 (0.0803)

204

2.06 (0.0811)

206

2.08 (0.0819)

208

210 (0.0827)

210

2.12 (00835)

212

2.14 (0.0843)

214

216 (0.0850)

216

2.18 (0.0858) 218

2.20 (0.0866) 220

2.22 (00874) 222

224 (00882)

224

2.26 (0.0890)

226

2.28 (0.0898) 228

2.30 (0.0906)

230

2.32 (0.0913) 2.32

2.34 (0.0921)

234

2.36 (0.0929)

236

2.38 (0.0937)

238

240 (0.0945)

240

2.42 (0.0953) 242

2.44 (0.0961) 244

2.46 (0.0969)

246

2.48 (0.0976) 248

2.50 (00984)

250

2.52 (0.0992) 252

2.54 (0.1000)

254

2.56 (01008) 256

2.58 (0.1016) 258

2.60 (0.1024)

260

262 (0.1031) 262

2.64 (0.1039) 264

2.66 (0.1047)

266

2.68 (0.1055) 268

2.70 (0.1063) 270

2.72 (0.1071) 272

2.74 (0.1079) 274

2.76 (0.1087) 276

278 (0.1094)

278

2.80 (01102) 280

282 (01110) 282

284 (0.1118)

284

286 (0.1126) 286

2.88 (01134)

288

290 (0.1142) 290

2.92 (0.1150) 292

294 (0.1157)

294

296 (0.1165) 296

2.98 (0.1173) 298Shim

Type A

Type B

SEM104F

•

EM-157

Page 1337 of 1701

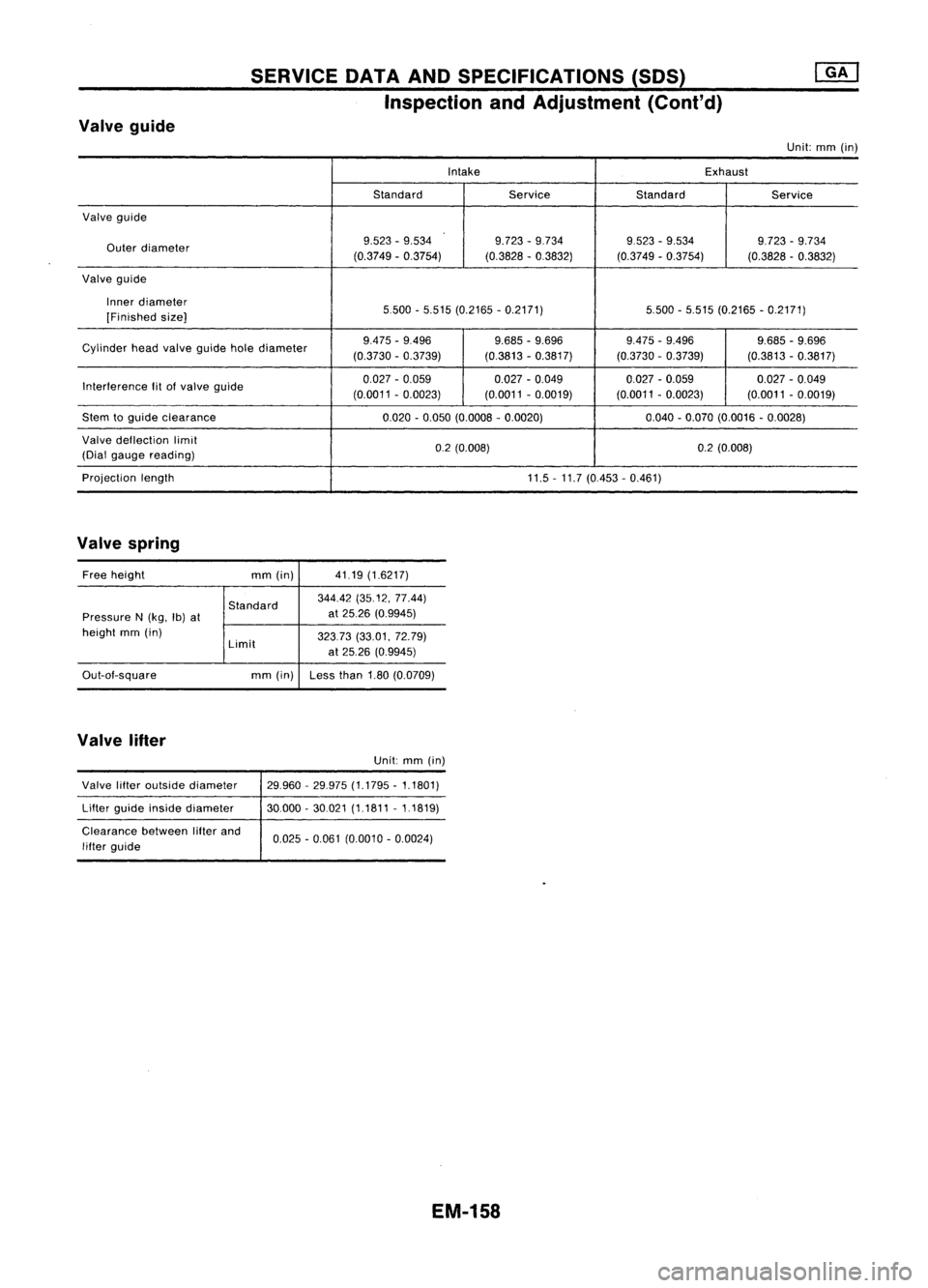

Valveguide SERVICE

DATAANDSPECIFICATIONS (50S)

Inspection andAdjustment (Cont'd)

Unit:mm(in)

Intake Exhaust

Standard ServiceStandard

Service

Valve gUide

Outer diameter 9.523

-9.534 9.723-9.734 9523-9.534

9.723-9.734

(0.3749 -0.3754) (0.3828-03832)

(0.3749-0.3754) (0.3828-0.3832)

Valve guide

Inner diameter

5500-5.515 (0.2165 -0.2171) 5.500-5.515 (0.2165 -0.2171)

[Finished size]

Cylinder headvalve guide holediameter 9.475

-9.496

9.685-9.696 9.475-9.496 9.685-9.696

(0.3730 -0.3739) (0.3813-0.3817)

(0.3730-0.3739) (0.3813-0.3817)

Interference fit

01

valve guide 0.027

-0.059 0.027-0.049 0.027-0.059 0.027-0.049

(0.0011 -0.0023)

(0.0011-0.0019) (0.0011

-0.0023) (0.0011-0.0019)

Stem toguide clearance

0.020-0.050 (0.0008 -0.0020) 0.040-0.070 (0.0016 -0.0028)

Valve deflection limit

0.2(0.008) 0.2(0.008)

(Dial gauge reading)

Projection length

11.5-11.7 (0.453 -0.461)

Valve spring

Free height

mm(in) 41.19

(1.6217)

Standard 344.42

(35.12, 77.44)

Pressure N(kg, Ib)at at

25.26 (0.9945)

height mm(in)

32373(33.01. 72.79)

Limit

at25.26 (0.9945)

Out-aI-square mm(in) Lessthan1.80(0.0709)

Valve lifter

Unit:mm(in)

Valve lifteroutside diameter

Lifter guide inside diameter

Clearance betweenlifterand

lifter guide 29.960

-29.975 (1.1795 -1.1801)

30000 -30.021 (1.1811 -1.1819)

0.025 -0.061 (0.0010 -0.0024)

EM-158

Page 1338 of 1701

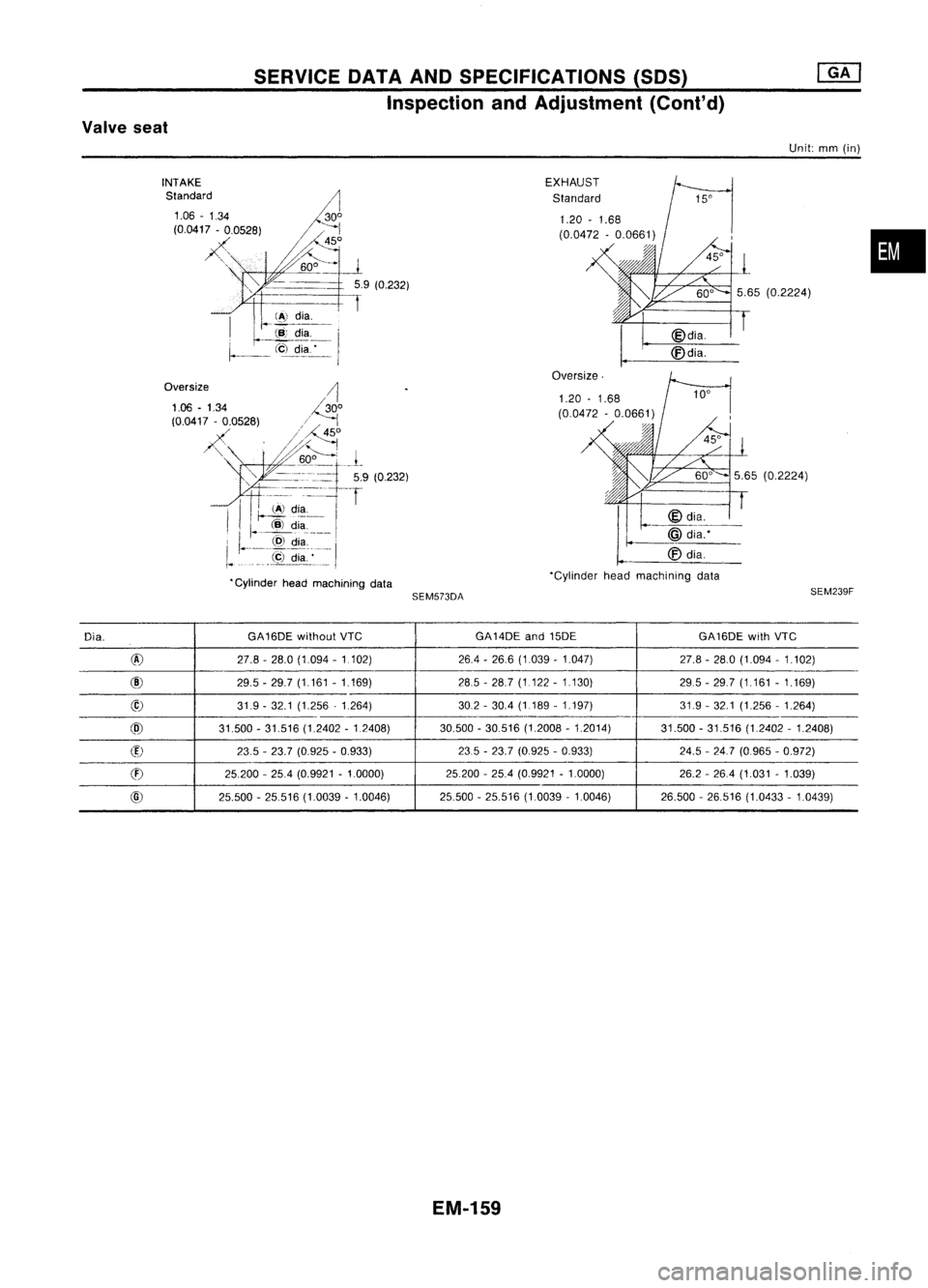

SERVICEDATAANDSPECIFICATIONS (50S)

Inspection andAdjustment (Cont'd)

Valve seat

Unit:mm(in)

•

SEM239F

5.65

(0.2224)

5.65 (0.2224)

Oversize.

@dia.

~dia~.-'--

'Cylinder headmachining data

EXHAUST

Standard

SEM573DA

•

Cylinder headmachining data

INTAKE

Standard

Dia. GA16DE

withoutVTe GA14DE

and15DE

GA16DEwithVTe

@ 27.8-28.0 (1094 -1 102) 26.4-26.6 (1.039 -1.047) 27.8-28.0 (1.094 -1.102)

@ 29.5-29.7 (1.161 -1.169) 285

-28.7 (1.122 -1.130)

29.5-29.7 (1.161 -1.169)

@ 319-32.1 (1.256 -1.264) 302-30.4 (1.189 -1.197) 31.9-32.1 (1.256 -1.264)

@ 31.500-31.516 (1.2402 -1.2408) 30.500

-30.516 (1.2008 -1.2014) 31.500-31.516 (1.2402 -1.2408)

(f)

23.5-23.7 (0.925 -0.933) 235

-23.7 (0.925 -0.933) 24.5-247 (0.965 -0.972)

CD

25.200

-25.4 (0.9921 -1.0000) 25.200-25.4 (0.9921 -1.0000) 26.2-26.4 (1.031 -1.039)

@ 25.500-25516 (1.0039 -1.0046) 25.500-25.516 (1.0039 -1.0046) 26.500-26.516 (1.0433 -1.0439)

EM-159

Page 1339 of 1701

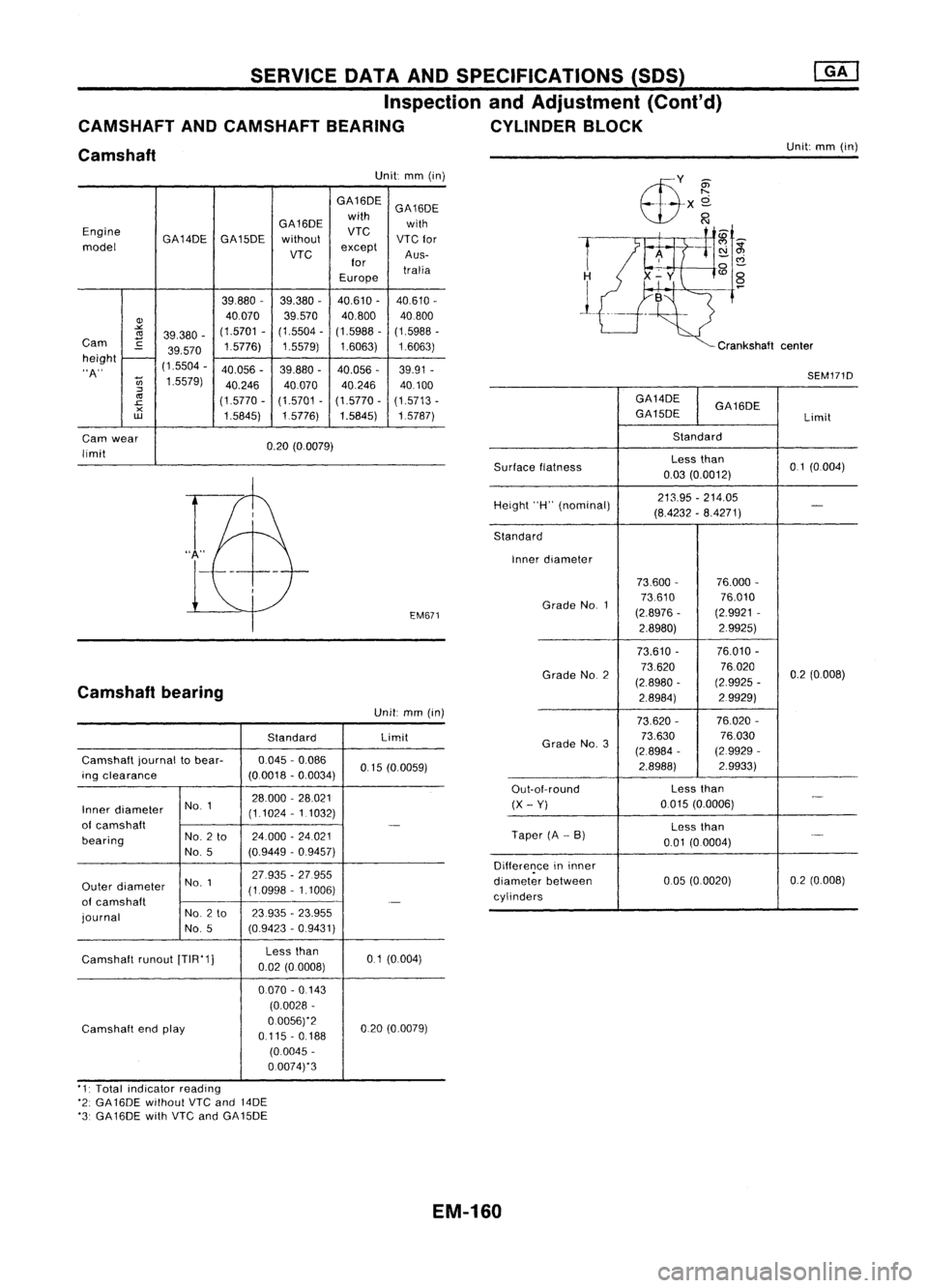

SERVICEOATAAND SPECIFICATIONS (SOS)

Inspection andAdjustment (Cont'd)

CAMSHAFT ANDCAMSHAFT BEARING CYLINDERBLOCK

Camshaft

Unit:

mm(in)

Unit: mm(in)

GA16DE GA16DE

GA16DE with

with

Engine GA14DEGA15DE without

VTC

VTC

for

model

VTC

except

Aus-

for tralia

Europe

39,880 -

39,380 -40,610

-

40,610 -

Q)

40070

39,570

40,800

40800

""

(1.5701

-(1.5504 -(1.5988 -(1.5988 -

<1l

39,380 -

Cam

C

1.5776)1.5579)1.6063) 1.6063)

39.570

height

-

"A" (1,5504

-

40.056 -39.880 -

40.056 -39.91

-

U;

1.5579)

40.24640,07040.246 40.100

:::l

<1l

(1.5770-(1.5701-(1.5770 -(1.5713 -

.c

x

1,5845)1,5776)

1.5845) 1,5787)

w

Cam wear

0.20(0.0079)

limit

EM671

Camshaft bearing

Unit:mm(in)

Standard Limit

Camshaft journaltobear- 0,045

-0.086

0,15(0.0059)

ing clearance (00018-0.0034)

NO.1 28.000

-28,021

Inner diameter

(1.1024-1 1032)

of camshaft

-

bearing No.

2to 24,000

-24021

No, 5 (0.9449

-0.9457)

NO.1 27.935

-27.955

Outer diameter

(1,0998-1.1006)

of camshaft

.-

journal No.

2to 23935

-23.955

No, 5 (0,9423

-0,9431)

Camshaft runout[TIR'1] Less

than

01(0,004)

0.02 (0.0008)

0070 -0 143

(0,0028 -

Camshaft endplay 0.0056)'2

020(0,0079)

0,115 -0,188

(0.0045 -

0.0074)'3

T

1

Crankshaftcenter

SEM171D

GA14DE GA16DE

GA15DE Limit

Standard

Surface flatness Less

than

0,1(0,004)

0,03 (0.0012)

Height "H"(nominal) 213.95

-214.05

-

(8.4232 -8.4271)

Standard Inner diameter

73.600- 76.000-

Grade No.1 73,610

76,010

(2.8976 -(2,9921

-

2.8980) 2.9925)

73.610 - 76.010

-

Grade NO.2 73,620

76020

0.2(0,008)

(2.8980 -(2.9925

-

2.8984) 2.9929)

73,620 - 76.020-

Grade No.3 73.630

76.030

(2,8984 -(2.9929 -

2.8988) 2,9933)

Out-ot-round Less

than

-

(X -Yi

0,015

(0.0006)

Less than

Taper (A-B)

._-

0.01 (0.0004)

Difference ininner

diameter between 005

(0,0020) 0,2

(0.008)

cylinders

'1: Total indicator reading

'2: GA 16DE without

VTC

and 14DE

'3: GA16DE withVTC andGA15DE

EM-160

Page 1340 of 1701

•

Unit:

mm(in)

Standard Limit

Top 0.040

-0.080

Side (0.0016

-0.0031)

clearance 0.2

(0.008)

2nd' 0.030

-0.070

(0.0012 -0.0028)

Top 0.20

-0.35

(0.0079 -0.0138)

End gap 2nd' 0.37

-0.52

1.0(0.039)

(0.0146 -0.0205)

Oil 0.20

-0.60

(0.0079 -0.0236)

Unit:

mm(in)

SERVICE

OATAAND SPECIFICATIONS (SDS)

Inspection andAdjustment (Cont'd)

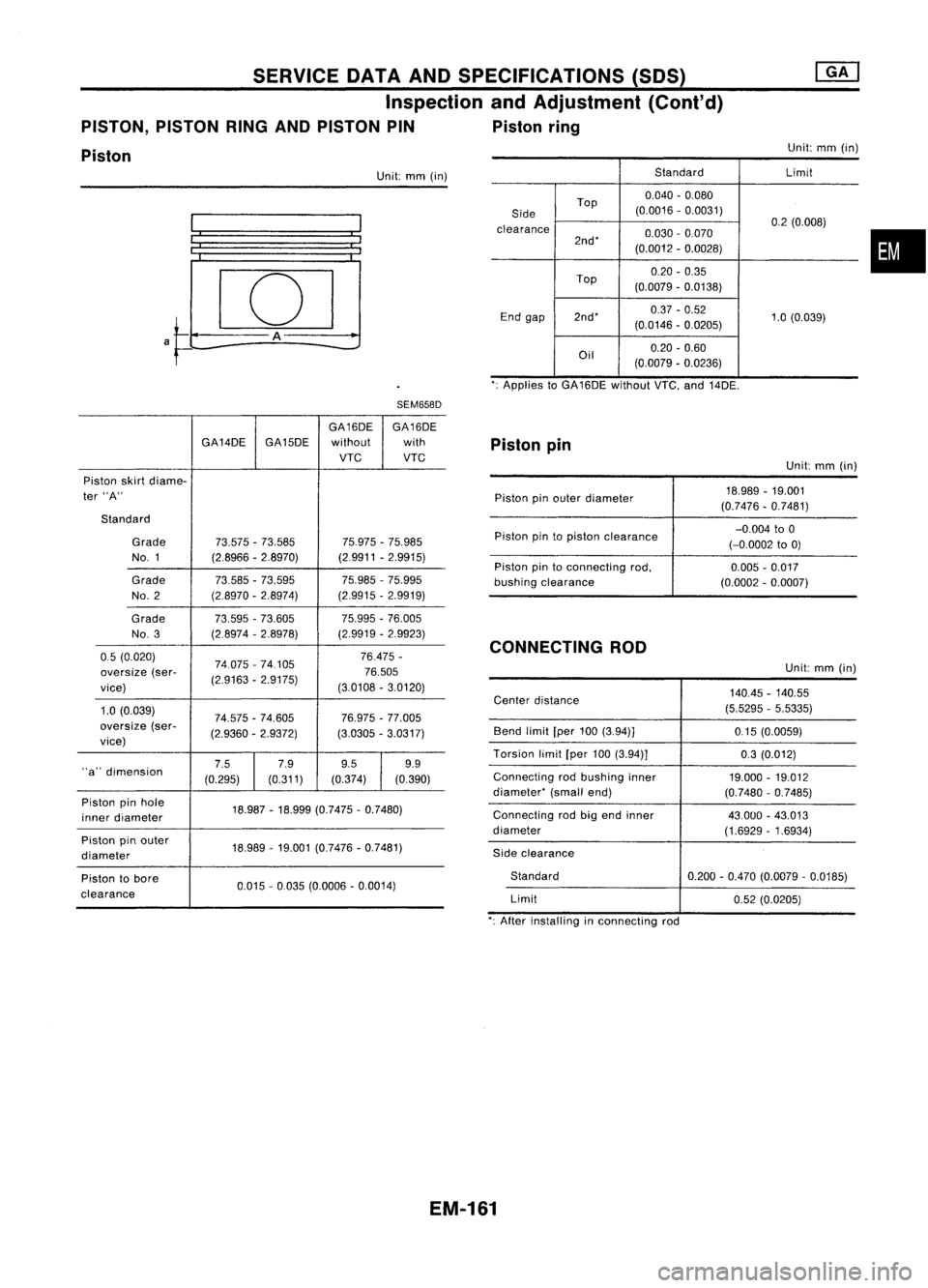

PISTON, PISTONRINGANDPISTON PIN Pistonring

Piston

':Applies toGA16DE withoutVTC,and14DE.

SEM658D

Centerdistance 140.45

-140.55

(5.5295 -5.5335)

Bend limit[per100(3.94)]

0.15(0.0059)

Torsion limit[per100(3.94)]

0.3(0.012)

Connecting rodbushing inner

19.000-19.012

diameter' (smallend)

(0.7480-0.7485)

Connecting rodbigend inner

43.000-43.013

diameter (1.6929-1.6934)

Side clearance

Standard 0.200-0.470 (0.0079 -0.0185)

Limit 0.52(0.0205)

Piston

pin

GA16DE

GA16DE

GA14DE GA15DE without with

VTC VTC

Piston skirtdiame-

ter "A"

Standard

Grade 73.575-73.585 75.975-75.985

NO.1 (2.8966-2.8970) (29911

-2.9915)

Grade 73.585-73.595 75.985

-75.995

No. 2 (2.8970

-2.8974) (2.9915-2.9919)

Grade 73.595-73.605 75.995-76.005

No. 3 (2.8974-2.8978) (2.9919

-2.9923)

05 (0.020)

74.075-74105 76.475

-

oversize (ser-

(2.9163-2.9175) 76.505

vice) (3.0108

-3.0120)

1.0 (0.039)

74.575-74.605 76.975-77.005

oversize (ser-

(2.9360-2.9372) (3.0305

-3.0317)

vice)

"a" dimension 7.5

7.99.5 9.9

(0.295) (0.311)

(0.374) (0.390)

Piston pinhole

18.987-18.999 (0.7475 -0.7480)

inner diameter

Piston pinouter

18.989-19.001 (0.7476 -0.7481)

diameter

Piston tobore

0.015-0035 (0.0006 -0.0014)

clearance Piston

pinouter diameter

Piston pintopiston clearance

Piston pintoconnecting rod,

bushing clearance

CONNECTING ROD Unit:

mm(in)

18.989 -19.001

(0.7476 -0.7481)

-0.004 to0

(-0.0002 to0)

0.005 -0.017

(0.0002 -0.0007)

Unit: mm(in)

': After installing inconnecting rod

EM-161