NISSAN ALMERA N15 1995 Service Manual

Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 191 of 1701

__________ PRECAUTIONS ___________

BODYALIGNMENT _

Precautions ForHandling HighStregth Steel Engine

Compartment

__ MEASURMENT POINTS__

Unit:mm

Front side

SBT088

Traction direction: ...

Not

recommended

• The repair ofreinforcements (suchasside

members) byheating isnot recommended

since itinvolves theriskoflowering strength.

When heating isunavoidable, donot heat

such parts attemperatures above550°C (1,

022°F)

Heating temperature shouldbeverified with

a thermometer. (Acrayon-type andother

thermometer areavailable.)

• When straightening bodypanels, usecaution

in pulling anyHSS panel. Because itis very

strong, thismay cause deformation inadja-

cent portions ofthe body. Inthis case,

increase thenumber ofmeasuring points,

and carefully pulltheHSS panel.

Special

consideration forHSS must begiven tothe following points:

1 .Additional pointstoconsider

• Incutting HSSpanel, avoidgascutting if

possible. Instead,useanairsaw orahand

cutter toavoid decreasing thestrength of

surrounding portionsduetothe influence of

heat. Incase gascutting isinevitable, a

minimum allowance of50 mm (1.97 in)

must begiven.

SBT090

Radiator

coresupport lower

•

(b)

11

dia.

SBT094

• Inwelding HSSpanel, usespot welding

whenever possibleinorder tominimize any

decrease instrength ofsurrounding portions

due tothe influence ofheat.

If spot welding isimpossible, useM.LG.

welding. Donotuseacetylene gaswelding

because itis inferior inwelding strength.

GOOD

-================

N.G.

Never useacetylene .gas

welding.

Radiator

coresupport uppercenter

SBT091

-29-

-16-

Page 192 of 1701

__________ BODYALIGNMENT ___________

PRECAUTIONS _

Underbody Precautions

ForHandling HighStrength Steel

• InNissan vehicles, HSSplates of373 N/mm

2

(38kg/mm

2,

54klb/sq in)(NP130) aremost commonly

utilized, andthose withatensile strength of785 to981 N/mm

2

(80to100 kg/mm

2,

114to142 klb/sq

in) (NP150) areused onlyonparts requiring muchmorestrength.

HIGH

STRENGTH STEEL(HSS)USED INNISSAN VEHICLES

High

strength steelhasbeen usedforbody panels inorder toreduce vehicle weight.

Accordingly, precautionsinrepairing automotive bodiesmadeofhigh strength steelaredescribed below:

Tensile strength Nissan designation Major

applicable parts

• Side member

373N/mm

2

•

Hoodledge

(38 kg/mm

2,

54klb/sq in) NP130

•

Pillar

• Hood

.Trunk lidouter

785-981 N/mm

2

•Bumper reinforcement

(80-100 kg/mm

2

NP150

114-142 klb/sqin) •

Door guard beam

E

E

127

@>@)

235

~200

ee

@@

o

It)

CD

N

.. CD

.. 00

~ N~

It)

CD

CD

It)

C!.

~

CD

It)

It)

en

N

It)

CD CD

IIIlI:t'

(ij

Q)

er:

iJ

--------

en

It)

C!.

N

~ en

co

____

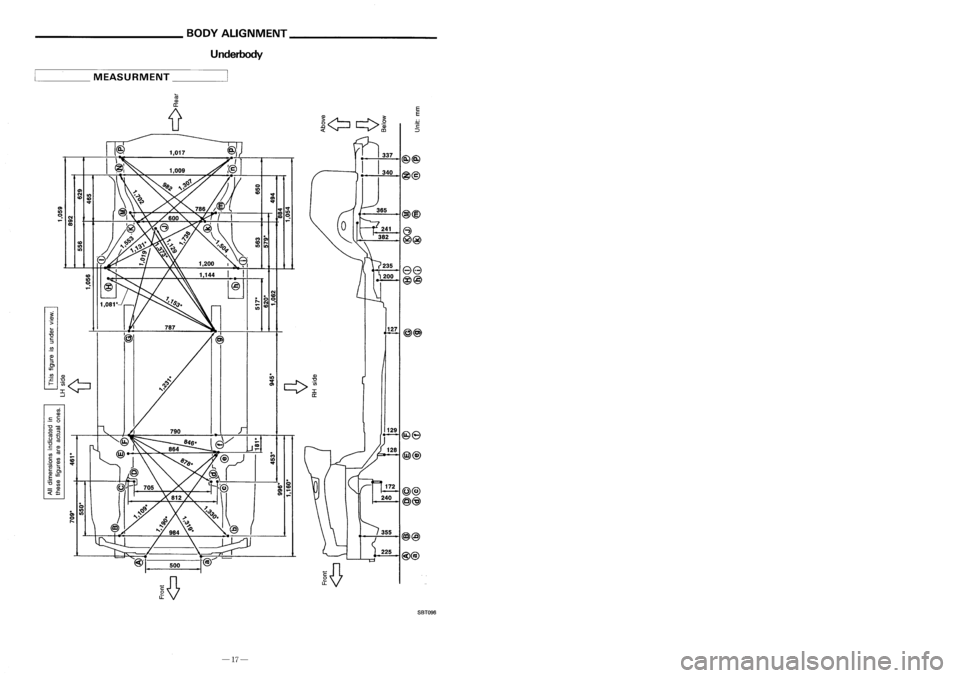

MEASURMENT _

..

o

.. It)

0)

It)

o

I'

..

.. 0

CD CD

en~

0) .,

~

129

@8

@@

@)@)

225

SBT096

-17- -28-

Page 193 of 1701

______ HANDLINGPRECAUTIONS FORPLASTICS __

BODYALIGNMENT _

Location OfPlastic Parts

Underbody

Kicking plate(PP)

Front

@,

076

dia.

Rear

@,@

62 dia.

Front

Rear

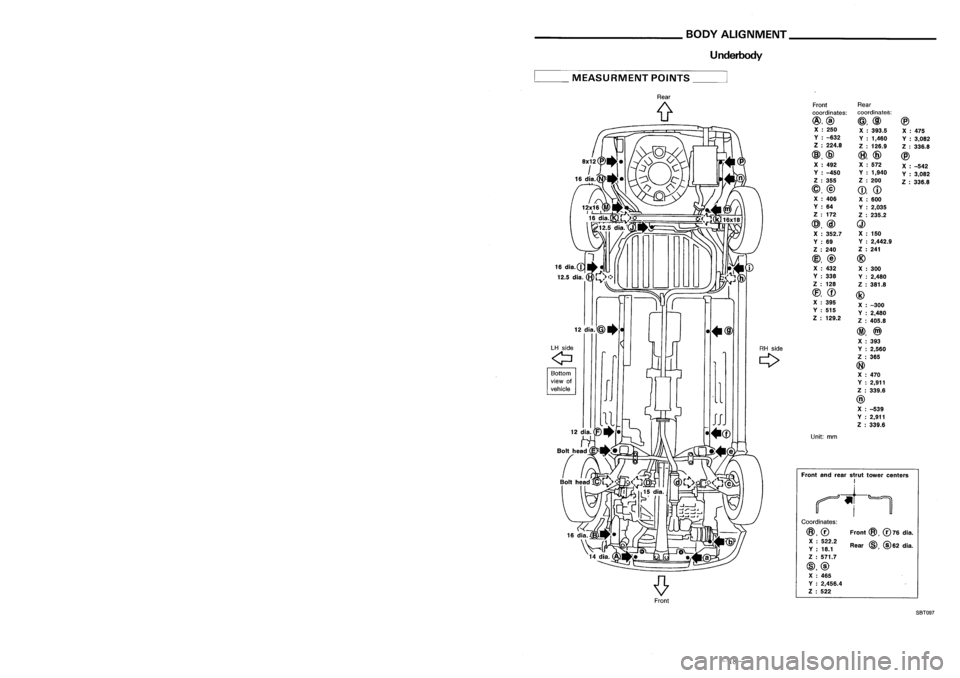

coordinates: coordinates:

@,@ @,@@

X :250

X:393.5

X:475

V :-632

V:1,460

V:3,082

Z :224.8

Z:126.9

Z:336.8

@,@

(8),

@

@

X :492 X

:572

X:-542

V :-450 V

:1,940

V:3,082

Z :355 Z

:200

Z:336.8

@,@

CD,

CD

X :406

X:600

V :64

V:2,035

Z :172

Z:235.2

@,@

Q)

X :352.7 X

:150

V :69 V

:2,442.9

Z :240 Z

:241

@,

@

@

X :432

X:300

V :338

V:2,480

Z :128

Z:381.8

(f),

CD

@

X :395

X:-300

V :515

V:2,480

Z :129.2

Z:405.8

@,

@)

X :393

Y :2,560

Z :365

@

X :470

Y :2,911

Z :339.6

@

X :-539

Y :2,911

Z :339.6

Unit: mm

Coordinates:

@,0

X :522.2

V :18.1

Z :571.7

@,@ X :465

V :2,456.4

Z :522

Front

andrear strut tower centers

I

~t-~

Rear

(f

••@

LH side

RHside

Q

Q

Bottom

view of

,1

vehicle

__

MEASURMENT POINTS__

Glove box(PPC)

Side

wind molding(PVC)

Cluster lidC(PPC)

Instrument

panel(PPC)

Console box(PPC)

5-door

Hatchback

Cluster lidA(PPC)

~----_/

Front

pillargarnish(PPC)

Side

wind molding(PVC)

Back doorfinisher(ABS)

Roof

spoilar(FRP)

3-doorHatchback

Center pillarlower garnish(PP)

Center pillarupper garnish(PPC)

Rear pillar garnish(PPC)

High

mounted stoplamp

(Lens: PMMA )

Housing: ABS

FrontSBT097

-27-

-18-

Page 194 of 1701

__________ BODYALIGNMENT _

_HANDLINGPRECAUTIONS FORPLASTICS _

Passenger Compartment Sedan

5-door Hatchback Location

OfPlastic Parts

Side turnsignal lamplens

(Lens: AS)

Housing: ASS

Wind-shield molding

(Upper: PVC )

Side:Stainless+PVC

Doorout-side molding

(Stainless+PVC)

Wheel cover

(Full cover: PP+PA6 )

Half cover: PA66+PPO

Center cap:PA6

Door

mirror

(Housing: AAS)

Garnish: ASS

Front turnsignal lamp

(Lens: PMMA)

Housing: PP

Fog

lamp

(Lens: Glass)

Housing: PP

Head

lamp

(Lens: Glass)

Housing: pp

Radiator grille

(ABS)

Fog lamp finisher

(PM MA)

Front

bumper fascia

(PP)

Front airspoiler

(PP)

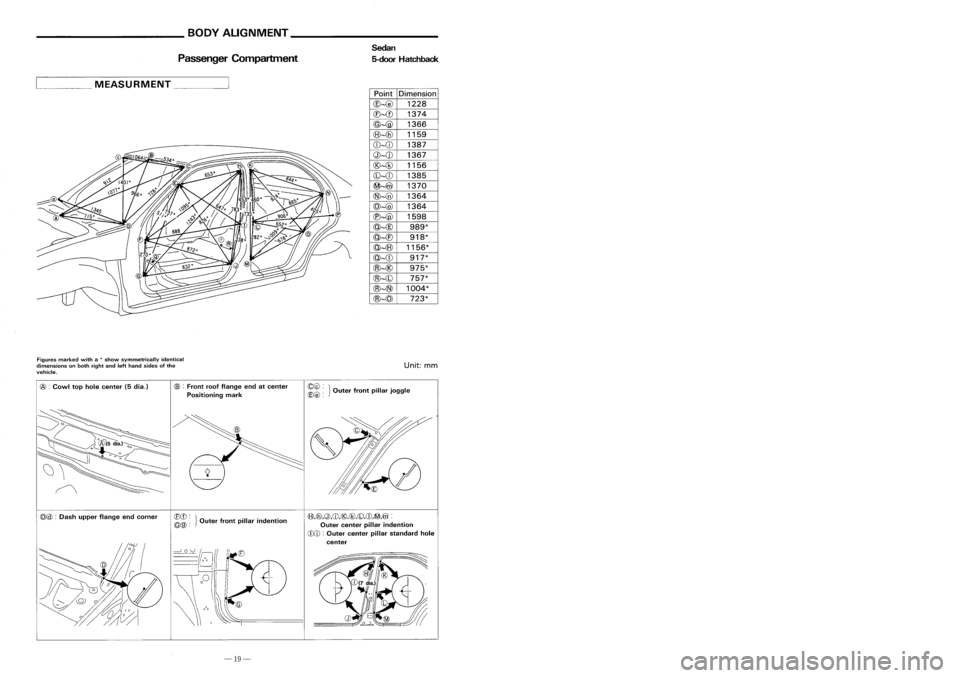

Point

Dimension

@-@

1228

CB-

@-@

1366

(8)-{6)

1159

CD--cD

1387

Q)-{J) 1367

@--@

1156

(b)--{[)

1385

~-4iV

1370

@~

1364

@~

1364

C'e)--@

1598

@--@

989*

@-{E)

918*

@~

1156*

@--{[)

917*

@~@

975*

@~(b)

757*

@~

1004*

@--@

723*

,

... ._MEASURMENT _

Figures marked witha

*

show symmetrically identical

dimensions onboth right andlefthand sides ofthe

vehicle.

Unit:

mm

@ :

Cowl tophole center (5dia.)

CB>

:

Front roofflange endatcenter

Positioning mark ~~

~}Outer frontpillarjoggle

Sideguard molding (PVC)

Rear combination lamp

(Lens: PMMA)

Housing: PP

Door

outside handle

(Handle: POM )

Escutcheon: POM

Mud guard (TPR)

Rear

Windowmolding

(PVC)

-for Sedan

Rear bumper fascia

(PP)

License

lamp

(Lens: PC)

Housing: PP

Trunk

lidfinisher(pp)

-for Sedan

Rear

spoiler(PPO)

-for Sedan

High mounted stoplamp

(In Rear SpoilerType)

(Lens: PMMA)-for Sedan

Housing: ASS

(Fixed Trunk LidTipe)

(Lens: PC)-for Sedan

Housing: PP

(f3),Cfi),Q),CD,@,@,CD,CD,~,@ :

Outer center pillarindention

CDCD :

Outer center pillarstandard hole

center

CBCD:

}

~@:

Outerfrontpillar indention

@@

:

Dash upper flange endcorner

-19- -26-

Page 195 of 1701

______ HANDLINGPRECAUTIONS FORPLASTICS __________

BODYALIGNMENT _

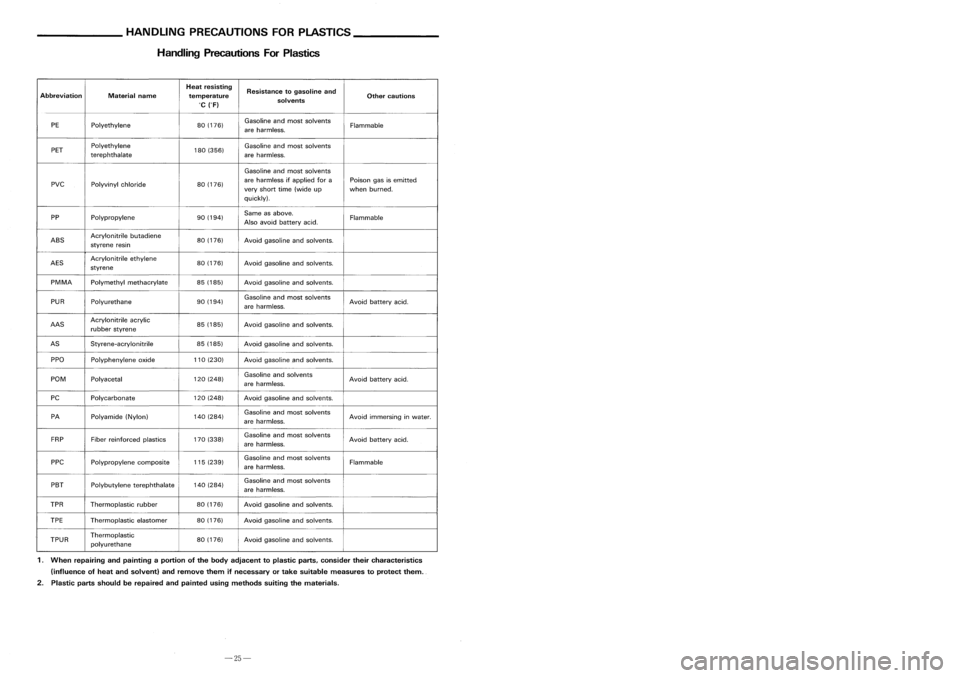

Handling Precautions ForPlastics

Heat resisting

Resistancetogasoline and

Abbreviation Materialname

temperature Othercautions

QC rF)

solvents

PE Polyethylene

80

(176)

Gasoline

andmost solvents

Flammable

are harmless.

PET Polyethylene

180(356)

Gasoline

andmost solvents

terephthalate areharmless.

Gasoline andmost solvents

PVC Polyvinylchloride

80

(176)

are

harmless ifapplied fora

Poison gasisemitted

very short time(wide up

whenburned.

quickly).

pp

Polypropylene

90

(194)

Same

asabove.

Flammable

Also avoid battery acid.

ABS Acrylonitrile

butadiene

80(176)

Avoidgasoline andsolvents.

styrene resin

AES Acrylonitrile

ethylene

80(176)

Avoidgasoline andsolvents.

styrene

PMMA Polymethylmethacrylate

85

(185)

Avoidgasoline andsolvents.

PUR Polyurethane

90

(194)

Gasoline

andmost solvents

Avoidbattery acid.

are harmless.

AAS Acrylonitrile

acrylic

85(185)

Avoidgasoline andsolvents.

ru bber styrene

AS Styrene-a crylo nitri Ie

85

(185)

Avoidgasoline andsolvents.

PPO Polyphenylene oxide

110

(230)

Avoidgasoline .andsolvents.

POM Polyacetal

120

(248)

Gasoline

andsolvents

Avoidbattery acid.

are harmless.

PC Polycarbonate

120

(248)

Avoidgasoline andsolvents.

PA Polyamide(Nylon)

140

(284)

Gasoline

andmost solvents

Avoidimmersing inwater.

are harmless.

FRP Fiberreinforced plastics

170

(338)

Gasoline

andmost solvents

Avoidbattery acid.

are harmless.

PPC Polypropylene composite

115

(239)

Gasoline

andmost solvents

Flammable

are harmless.

PBT Polybutylene terephthalate

140

(284)

Gasoline

andmost solvents

are harmless.

TPR Thermoplastic rubber

80

(176)

Avoidgasoline andsolvents.

TPE Thermoplastic elastomer

80

(176)

Avoidgasoline andsolvents.

TPUR Thermoplastic

80(176)

Avoidgasoline andsolvents.

polyurethane

1 . When repairing andpainting aportion ofthe body adjacent toplastic parts,consider theircharacteristics

(influence ofheat andsolvent) andremove themifnecessary ortake suitable measures toprotect them._

2. Plastic partsshould berepaired andpainted usingmethods suitingthematerials.

-25-

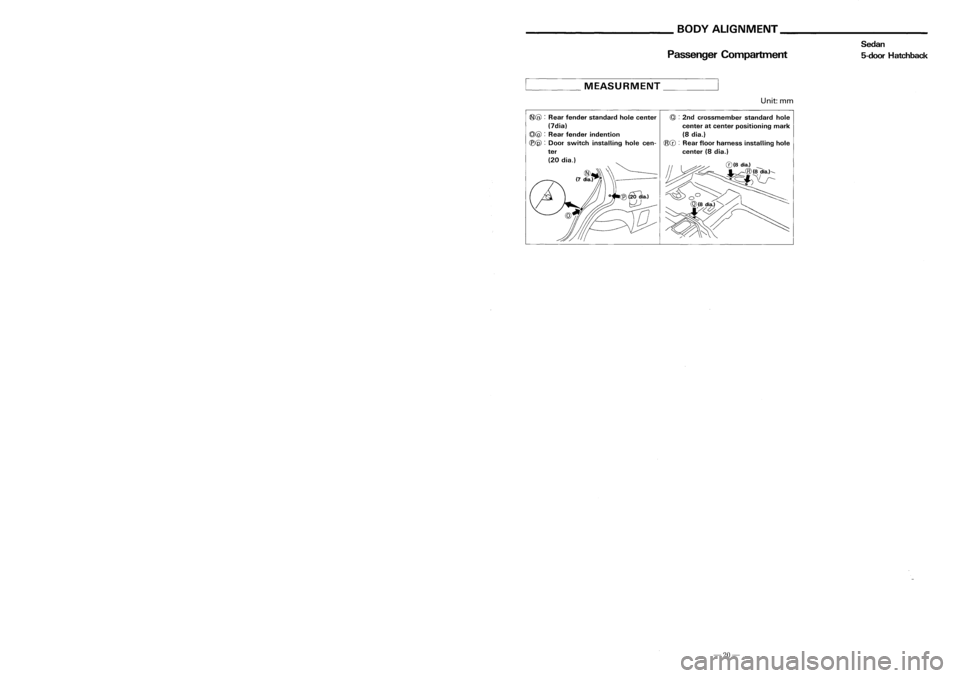

Passenger

Compartment

____ MEASURMENT _

Unit:mm

~@ :

Rear fender standard holecenter

@:

2nd crossmember standardhole

(7dia) centeratcenter positioning mark

(Q)@ :

Rear fender indention (8dia.)

(B@ :

Door switch installing holecen-

@([):

Rearfloor harness installing hole

ter center(8dia.)

(20 dia.) ~

(D<)

~~ ~~'---- ~ k@(fdiaol",

(7 diajj \\1 ~;..·

C')\U--

~ ~O"~Wiaol ~

-Z

J

D~

-20-

Sedan

5-door Hatchback

Page 196 of 1701

__________ BODYALIGNMENT ___________

BODYALIGNMENT _

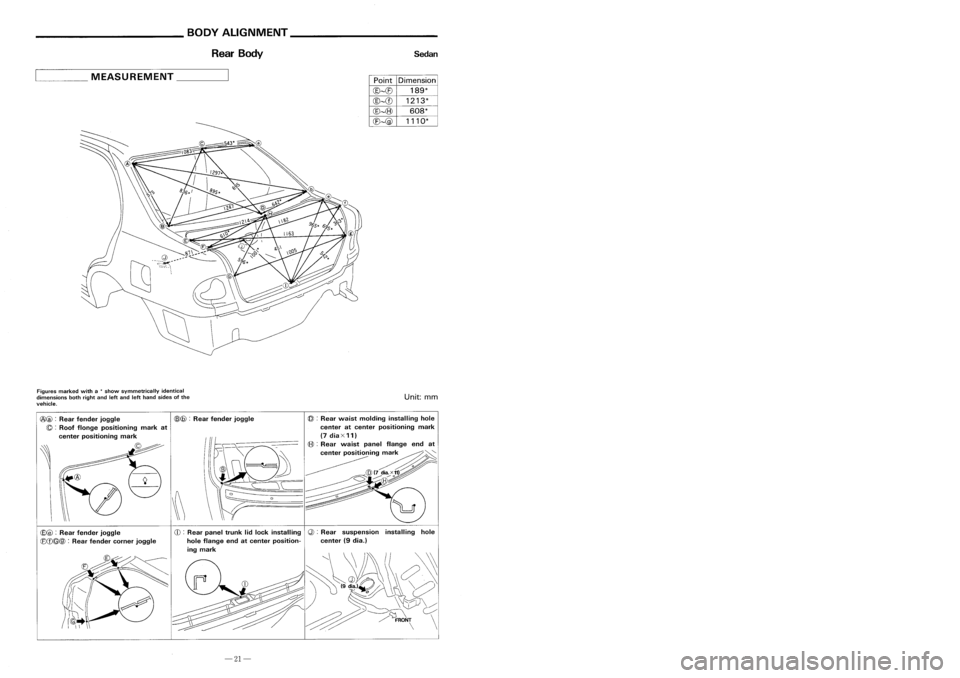

Rear Body Sedan

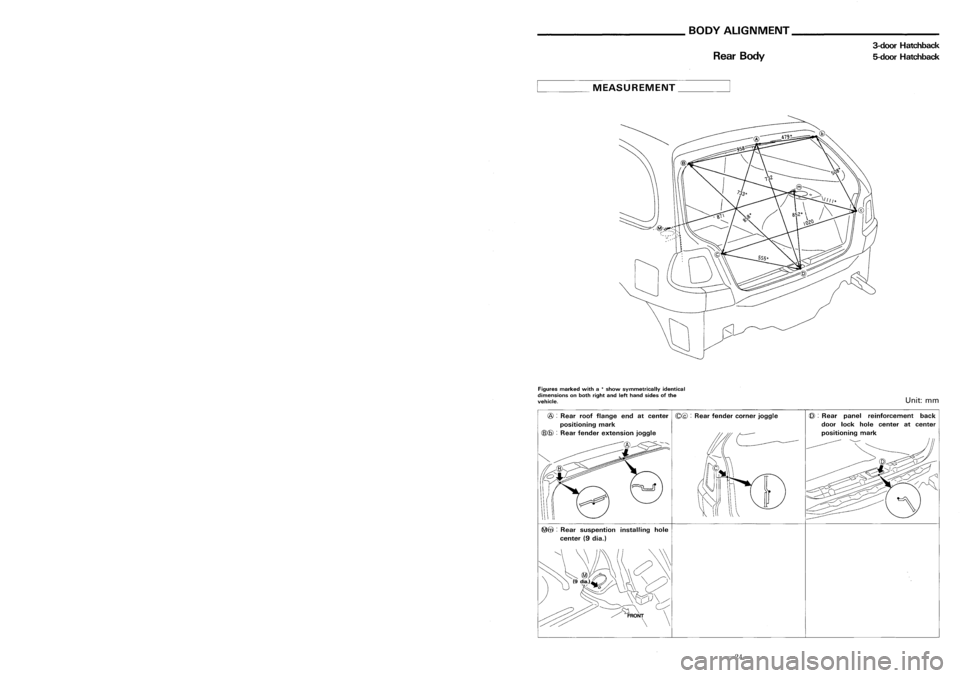

RearBody 3-door

Hatchback

5-door Hatchback

____ MEASUREMENT _

PointDimension

@~(E)

189*

@~CD

1213*

@~(8)

608*

(E)~@

1110*

~

MEASUREMENT _

Figures marked witha

*

show symmetrically identical

dimensions bothright andleftand lefthand sides ofthe

vehicle.

Unit:

mm

Figures

marked witha

*

show symmetrically identical

dimensions onboth right andlefthand sides ofthe

vehicle.

Unit:

mm

@ :

Rear panel reinforcement back

door lockhole center atcenter

~@ :

Rear suspention installinghole

center (9dia.)

@

:

Rear roofflange endatcenter

(Q@:

Rearfender cornerjoggle

positioning mark

(6)@ :

Rear fender extension joggle

CD :

Rear panel trunklidlock installing

Q):

Rear suspension installinghole

hole flange endatcenter position- center(9dia.)

ing mark

\~

CE)@ :

Rear fender joggle

(8(f)

@@

:

Rear fender joggle

(6)@:

Rear fender joggle

(Q :

Roof flonge positioning markat

center positioning mark

-21-

-24-

Page 197 of 1701

_________ BODYALIGNMENT __________

BODYALIGNMENT _

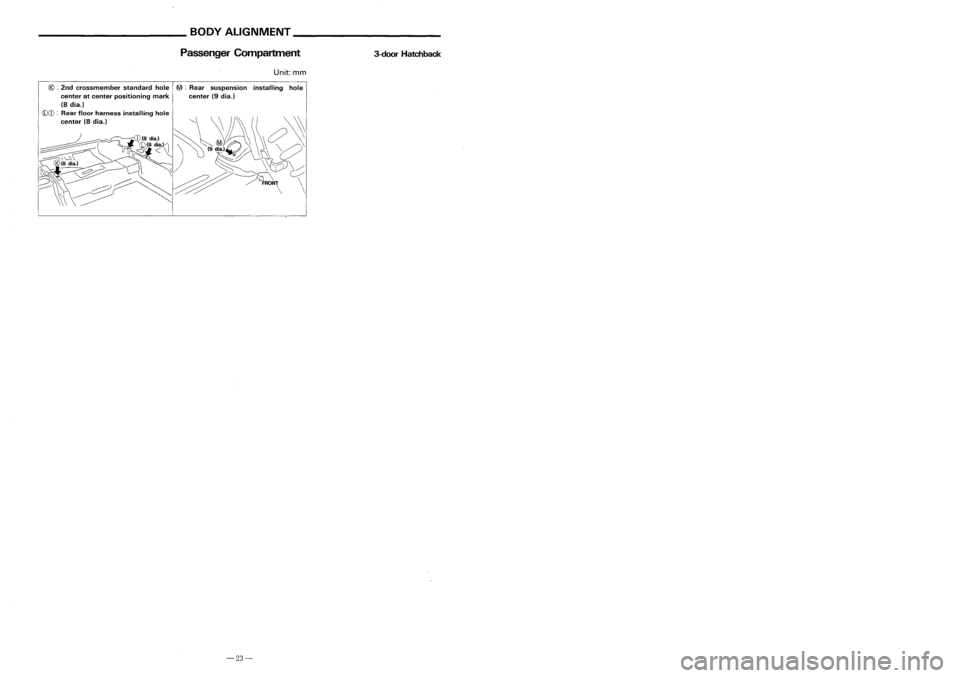

Passenger Compartment

3-doorHatchback Passenger

Compartment 3-door

Hatchback

Unit: mm

@ :

2nd crossmember standardhole~:Rear suspension installinghole

center atcenter positioning markcenter(9dia.)

(a

dia.)

CDCD :

=:::e~I~~rd~:~)ness installinghole "\\\

}J\ (/ ~

~cp(8

dia.),~

~Yb::~ \\

c?

~~--:q~

,\'I~I~

~~~~ /~FRONT\

- \\\y~ ~ \

____

MEASUREMENT -'

PointDimension

@~

1228

Cf)~

1374

C8},{5)

1094

Q)~

1388

Q)~

1558

(8)~

871

@~@

989*

@--{f)

918*

@~(8)

1193*

@~Q)

1043*

(b)~C8)

1017*

(b)~

655*

Figures marked witha

*

show symmetrically identical

dimensions onboth right andlefthand sides ofthe

vehicle.

Unit:

mm

@ :

Cowl tophole center (5dia.)

(6):

Front roofflange endatcenter

Positioning mark

~@:

}

(B@:

Outerfrontpillar joggle

q:])@ :

Rear fender joggle

CDCD :

Rear fender indention

Q)(D :

Door switch installing holecen-

ter (7dia.) ofnut

(BeD:

}

0

f

"11"d"

~@ :

uter rontpiarIn entlon

@@

:

Dash upper flange endcorner

-23-

-22-

Page 198 of 1701

_________ BODYALIGNMENT __________

BODYALIGNMENT _

Passenger Compartment

3-doorHatchback Passenger

Compartment 3-door

Hatchback

Unit: mm

@ :

2nd crossmember standardhole~:Rear suspension installinghole

center atcenter positioning markcenter(9dia.)

(a

dia.)

CDCD :

=:::e~I~~rd~:~)ness installinghole "\\\

}J\ (/ ~

~cp(8

dia.),~

~Yb::~ \\

c?

~~--:q~

,\'I~I~

~~~~ /~FRONT\

- \\\y~ ~ \

____

MEASUREMENT -'

PointDimension

@~

1228

Cf)~

1374

C8},{5)

1094

Q)~

1388

Q)~

1558

(8)~

871

@~@

989*

@--{f)

918*

@~(8)

1193*

@~Q)

1043*

(b)~C8)

1017*

(b)~

655*

Figures marked witha

*

show symmetrically identical

dimensions onboth right andlefthand sides ofthe

vehicle.

Unit:

mm

@ :

Cowl tophole center (5dia.)

(6):

Front roofflange endatcenter

Positioning mark

~@:

}

(B@:

Outerfrontpillar joggle

q:])@ :

Rear fender joggle

CDCD :

Rear fender indention

Q)(D :

Door switch installing holecen-

ter (7dia.) ofnut

(BeD:

}

0

f

"11"d"

~@ :

uter rontpiarIn entlon

@@

:

Dash upper flange endcorner

-23-

-22-

Page 199 of 1701

__________ BODYALIGNMENT ___________

BODYALIGNMENT _

Rear Body Sedan

RearBody 3-door

Hatchback

5-door Hatchback

____ MEASUREMENT _

PointDimension

@~(E)

189*

@~CD

1213*

@~(8)

608*

(E)~@

1110*

~

MEASUREMENT _

Figures marked witha

*

show symmetrically identical

dimensions bothright andleftand lefthand sides ofthe

vehicle.

Unit:

mm

Figures

marked witha

*

show symmetrically identical

dimensions onboth right andlefthand sides ofthe

vehicle.

Unit:

mm

@ :

Rear panel reinforcement back

door lockhole center atcenter

~@ :

Rear suspention installinghole

center (9dia.)

@

:

Rear roofflange endatcenter

(Q@:

Rearfender cornerjoggle

positioning mark

(6)@ :

Rear fender extension joggle

CD :

Rear panel trunklidlock installing

Q):

Rear suspension installinghole

hole flange endatcenter position- center(9dia.)

ing mark

\~

CE)@ :

Rear fender joggle

(8(f)

@@

:

Rear fender joggle

(6)@:

Rear fender joggle

(Q :

Roof flonge positioning markat

center positioning mark

-21-

-24-

Page 200 of 1701

______ HANDLINGPRECAUTIONS FORPLASTICS __________

BODYALIGNMENT _

Handling Precautions ForPlastics

Heat resisting

Resistancetogasoline and

Abbreviation Materialname

temperature Othercautions

QC rF)

solvents

PE Polyethylene

80

(176)

Gasoline

andmost solvents

Flammable

are harmless.

PET Polyethylene

180(356)

Gasoline

andmost solvents

terephthalate areharmless.

Gasoline andmost solvents

PVC Polyvinylchloride

80

(176)

are

harmless ifapplied fora

Poison gasisemitted

very short time(wide up

whenburned.

quickly).

pp

Polypropylene

90

(194)

Same

asabove.

Flammable

Also avoid battery acid.

ABS Acrylonitrile

butadiene

80(176)

Avoidgasoline andsolvents.

styrene resin

AES Acrylonitrile

ethylene

80(176)

Avoidgasoline andsolvents.

styrene

PMMA Polymethylmethacrylate

85

(185)

Avoidgasoline andsolvents.

PUR Polyurethane

90

(194)

Gasoline

andmost solvents

Avoidbattery acid.

are harmless.

AAS Acrylonitrile

acrylic

85(185)

Avoidgasoline andsolvents.

ru bber styrene

AS Styrene-a crylo nitri Ie

85

(185)

Avoidgasoline andsolvents.

PPO Polyphenylene oxide

110

(230)

Avoidgasoline .andsolvents.

POM Polyacetal

120

(248)

Gasoline

andsolvents

Avoidbattery acid.

are harmless.

PC Polycarbonate

120

(248)

Avoidgasoline andsolvents.

PA Polyamide(Nylon)

140

(284)

Gasoline

andmost solvents

Avoidimmersing inwater.

are harmless.

FRP Fiberreinforced plastics

170

(338)

Gasoline

andmost solvents

Avoidbattery acid.

are harmless.

PPC Polypropylene composite

115

(239)

Gasoline

andmost solvents

Flammable

are harmless.

PBT Polybutylene terephthalate

140

(284)

Gasoline

andmost solvents

are harmless.

TPR Thermoplastic rubber

80

(176)

Avoidgasoline andsolvents.

TPE Thermoplastic elastomer

80

(176)

Avoidgasoline andsolvents.

TPUR Thermoplastic

80(176)

Avoidgasoline andsolvents.

polyurethane

1 . When repairing andpainting aportion ofthe body adjacent toplastic parts,consider theircharacteristics

(influence ofheat andsolvent) andremove themifnecessary ortake suitable measures toprotect them._

2. Plastic partsshould berepaired andpainted usingmethods suitingthematerials.

-25-

Passenger

Compartment

____ MEASURMENT _

Unit:mm

~@ :

Rear fender standard holecenter

@:

2nd crossmember standardhole

(7dia) centeratcenter positioning mark

(Q)@ :

Rear fender indention (8dia.)

(B@ :

Door switch installing holecen-

@([):

Rearfloor harness installing hole

ter center(8dia.)

(20 dia.) ~

(D<)

~~ ~~'---- ~ k@(fdiaol",

(7 diajj \\1 ~;..·

C')\U--

~ ~O"~Wiaol ~

-Z

J

D~

-20-

Sedan

5-door Hatchback