NISSAN ALMERA N15 1995 Service Manual

ALMERA N15 1995

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57349/w960_57349-0.png

NISSAN ALMERA N15 1995 Service Manual

Trending: belt, water pump, interior light, oil temperature, glove box, fog light, oil change

Page 151 of 1701

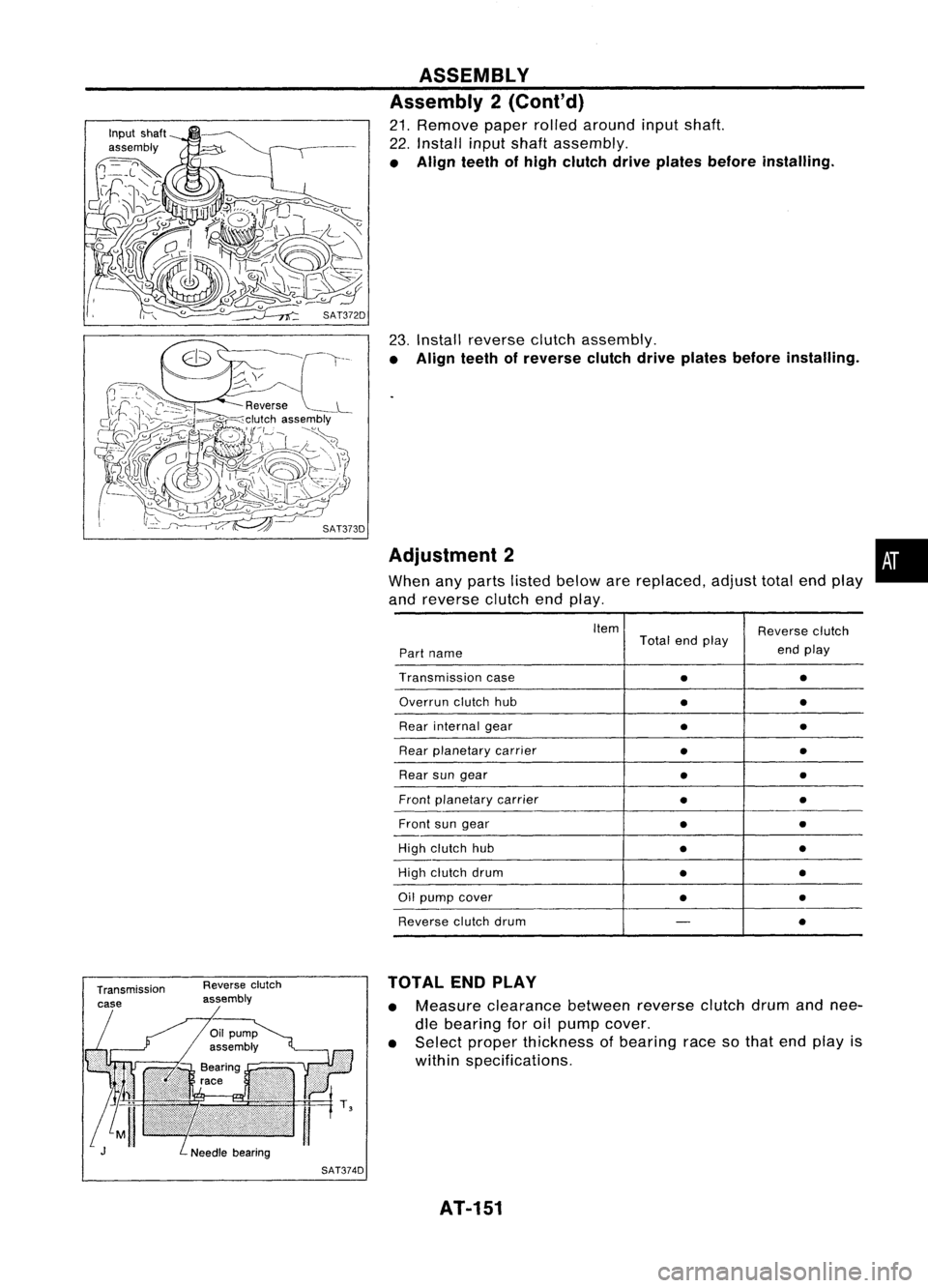

Reverseclutch

assembly

SAT374DASSEMBLY

Assembly 2(Cont'd)

21. Remove paperrolledaround inputshaft.

22. Install inputshaft assembly.

• Align teethofhigh clutch driveplates before installing.

23. Install reverse clutchassembly.

• Align teethofreverse clutchdriveplates before installing.

Adjustment 2 •

When anyparts listed below arereplaced, adjusttotalendplay

and reverse clutchendplay.

Item Reverseclutch

Total endplay

endplay

Part name

Transmission case

•

•

Overrun clutchhub

••

Rear internal gear

••

Rear planetary carrier

•

•

Rear sungear

•

•

Front planetary carrier

•

•

Front sungear

•

•

High clutch hub

••

High clutch drum

••

Oil pump cover

••

Reverse clutchdrum

-

•

TOTAL ENDPLAY

• Measure clearance betweenreverseclutchdrumandnee-

dle bearing foroilpump cover.

• Select proper thickness ofbearing racesothat endplay is

within specifications.

AT-151

Page 152 of 1701

Transmissioncase SAT375DASSEMBLY

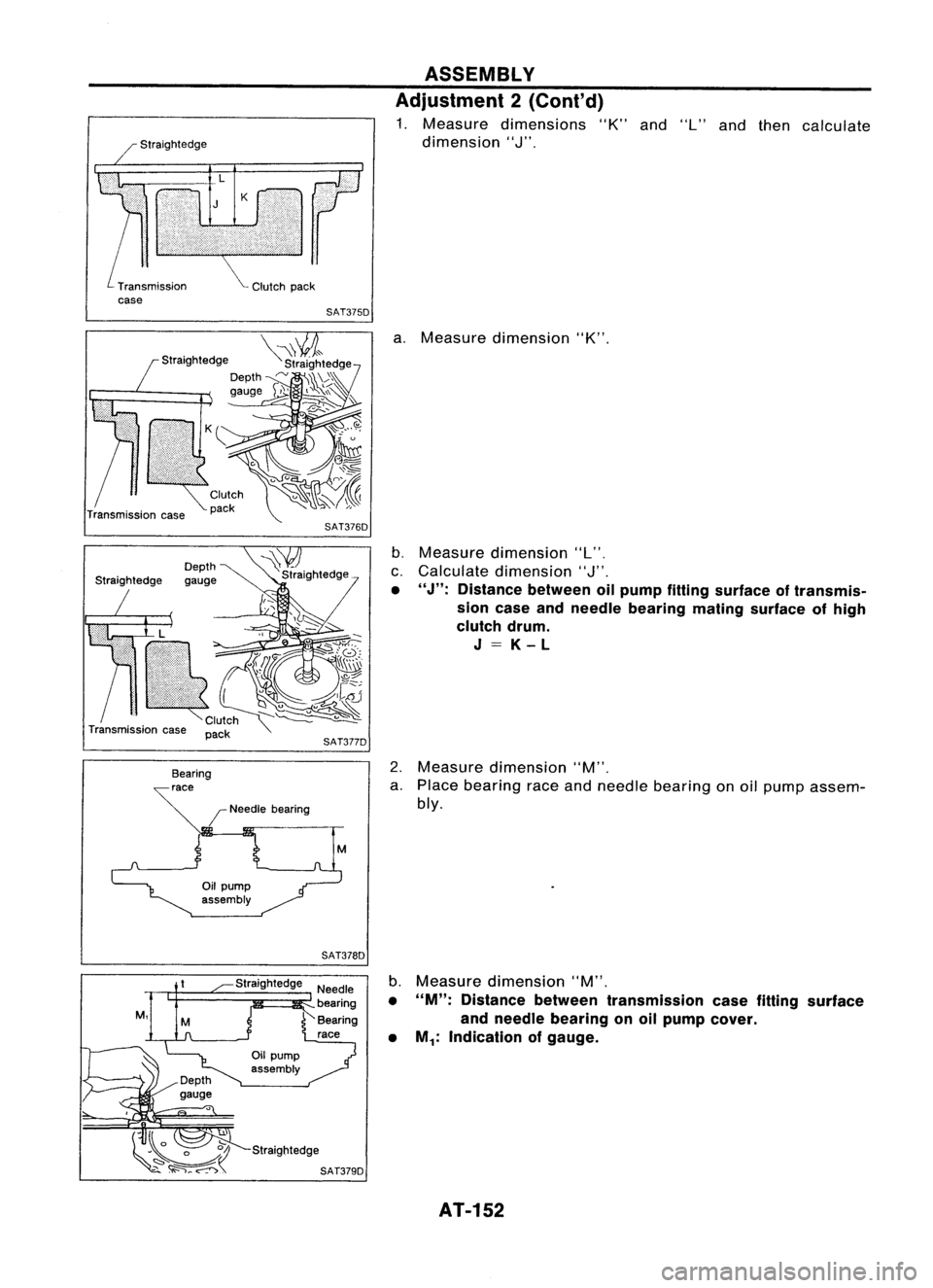

Adjustment 2(Cont'd)

1. Measure dimensions "K"and"L"and then calculate

dimension

"J".

Transmission case

Depth

gauge

/Needle bearing SAT376D

SAT377D

a.

Measure dimension "K".

b. Measure dimension "L",

c. Calculate dimension

"J".

• "J":

Distance betweenoilpump fitting surface oftransmis-

sion case andneedle bearing matingsurface ofhigh

clutch drum.

J=K-L

2. Measure dimension "M".

a. Place bearing raceandneedle bearing onoil pump assem-

bly.

SAT378D

Straightedge

Straightedge SAT379D

b.

Measure dimension "M".

• "M":

Distance betweentransmission casefitting surface

and needle bearing onoilpump cover.

• M

1:

Indication ofgauge.

AT-152

Page 153 of 1701

ASSEMBLY

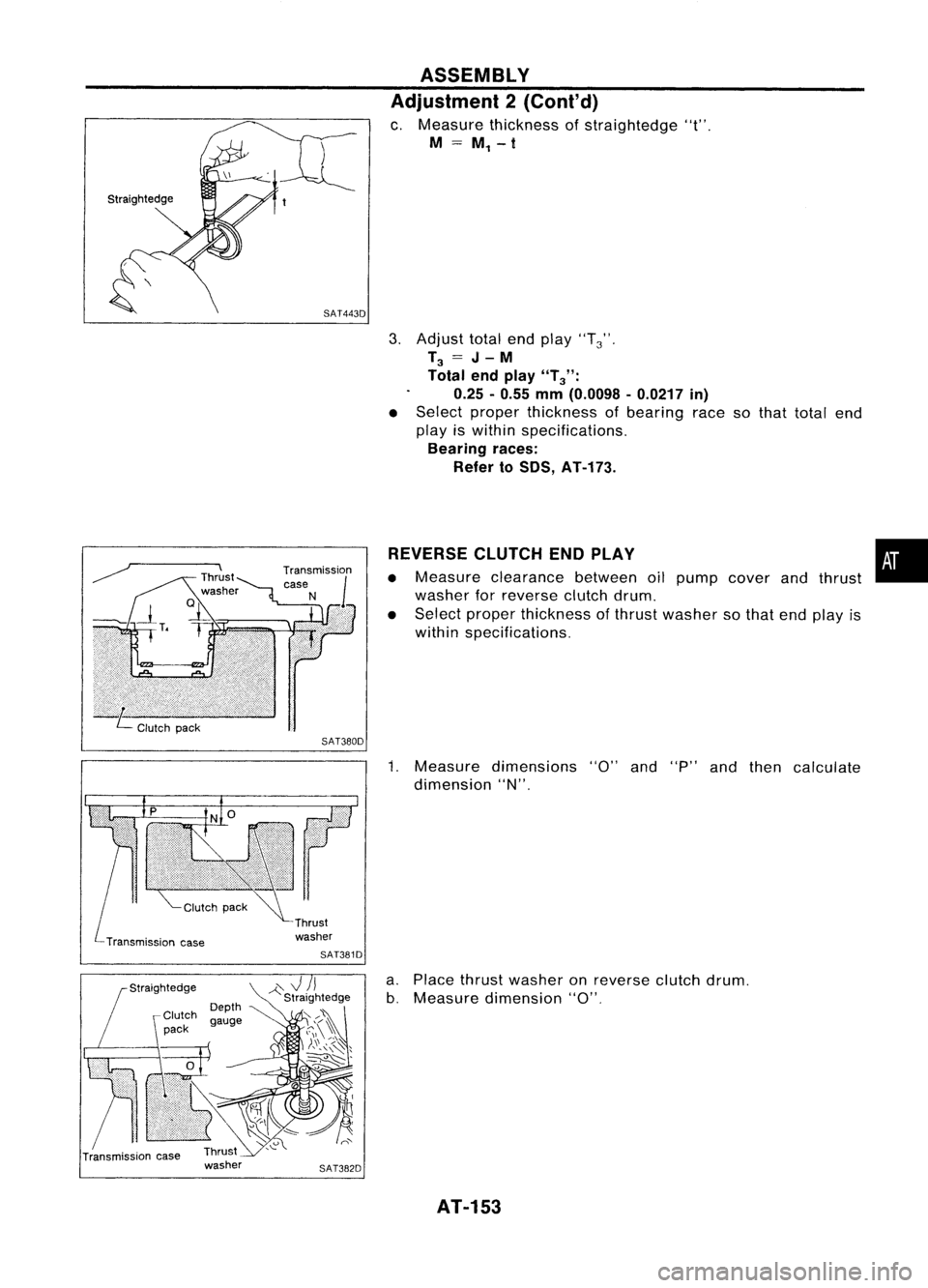

Adjustment 2(Cont'd)

c. Measure thickness ofstraightedge "t".

M

=

M

1 -

t

3. Adjust totalendplay "T

3'"

T

3

=

J-

M

Total endplay

"T

3":

0.25 -0.55 mm(0.0098 -0.0217 in)

• Select proper thickness ofbearing racesothat total end

play iswithin specifications.

Bearing races:

Refer toSOS, AT-173.

Transmission case SAT380D

SAT381D REVERSE

CLUTCHENDPLAY

• Measure clearance betweenoilpump cover andthrust

washer forreverse clutchdrum.

• Select proper thickness ofthrust washer sothat endplay is

within specifications.

1. Measure dimensions "0"and"P"andthen calculate

dimension "N".

•

a. Place thrust washer onreverse clutchdrum.

b. Measure dimension "0".

AT-153

Page 154 of 1701

-Straightedge

Depth

gauge ASSEMBLY

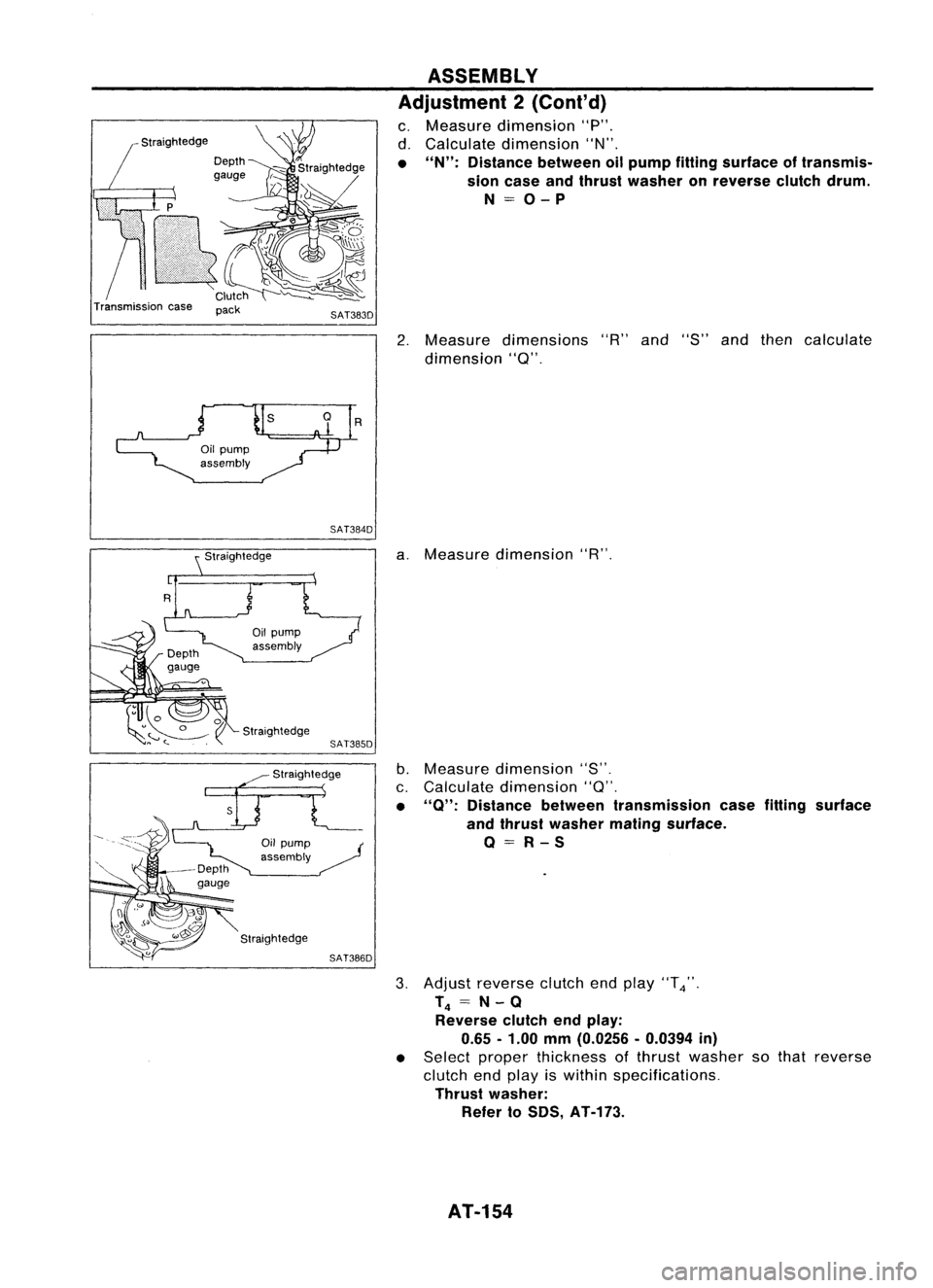

Adjustment 2(Cont'd)

c. Measure dimension "P".

d. Calculate dimension "N".

• "N": Distance betweenoilpump fittingsurface oftransmis-

sion case andthrust washer onreverse clutchdrum.

N=O-P

Transmission case

pack

SAT383D

2.Measure dimensions "R"and "S"andthen calculate

dimension

"Q".

R

SAT384D

Straightedge

a.

Measure dimension "R".

b. Measure dimension "S".

c. Calculate dimension

"Q".

• "0": Distance betweentransmission casefitting surface

and thrust washer matingsurface.

O=R-S

3. Adjust reverse clutchendplay "T

4".

T

4

=

N-0

Reverse clutchendplay:

0.65 -1.00

mm

(0.0256 -0.0394

in)

• Select proper thickness ofthrust washer sothat reverse

clutch endplay iswithin specifications.

Thrust washer:

Refer toSDS, AT-173.

AT-154

Page 155 of 1701

Bearingrace

Thrustwasher SAT158E ASSEMBLY

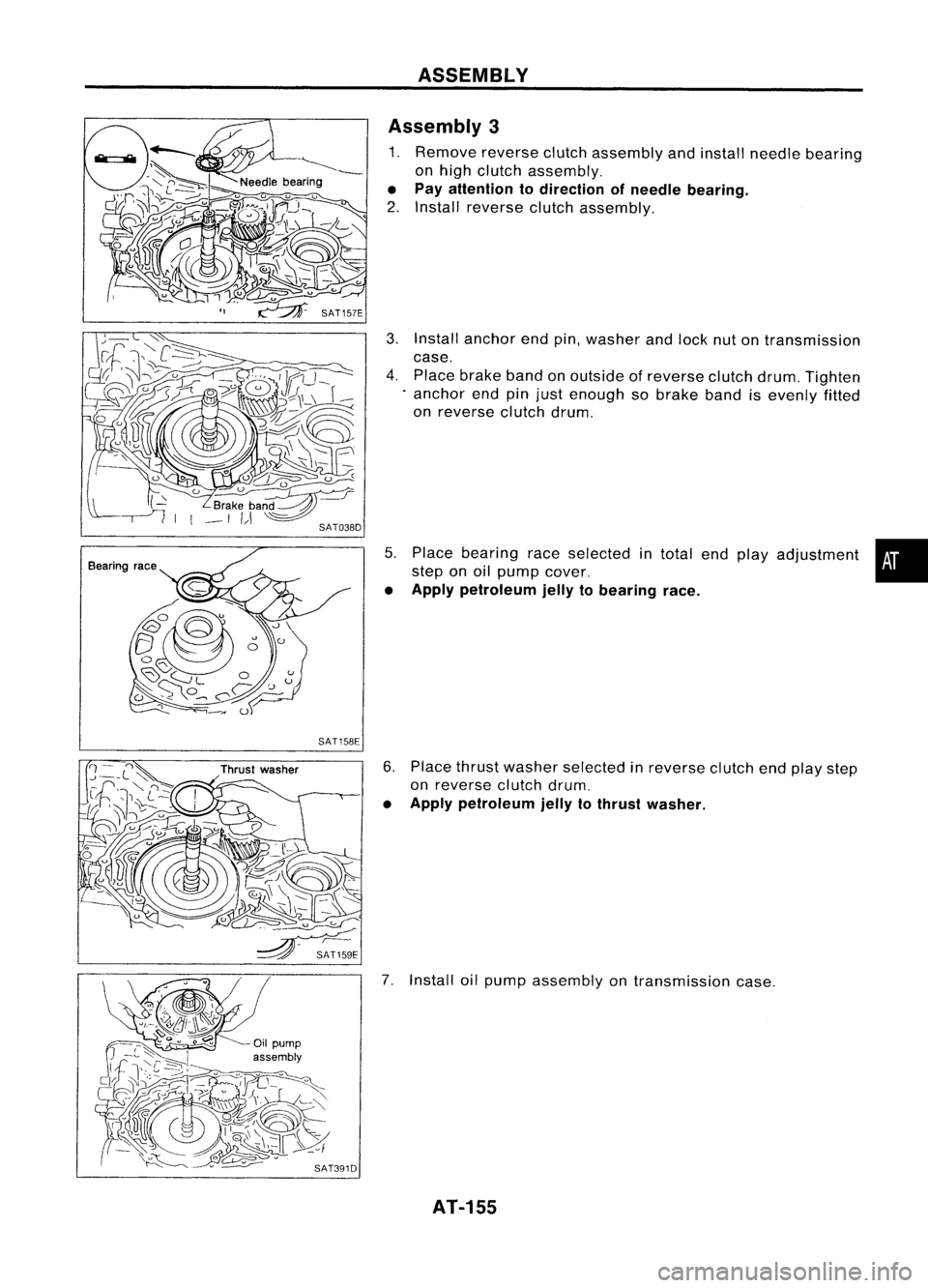

Assembly 3

1. Remove reverseclutchassembly andinstall needle bearing

on high clutch assembly.

• Pay attention todirection ofneedle bearing.

2. Install reverse clutchassembly.

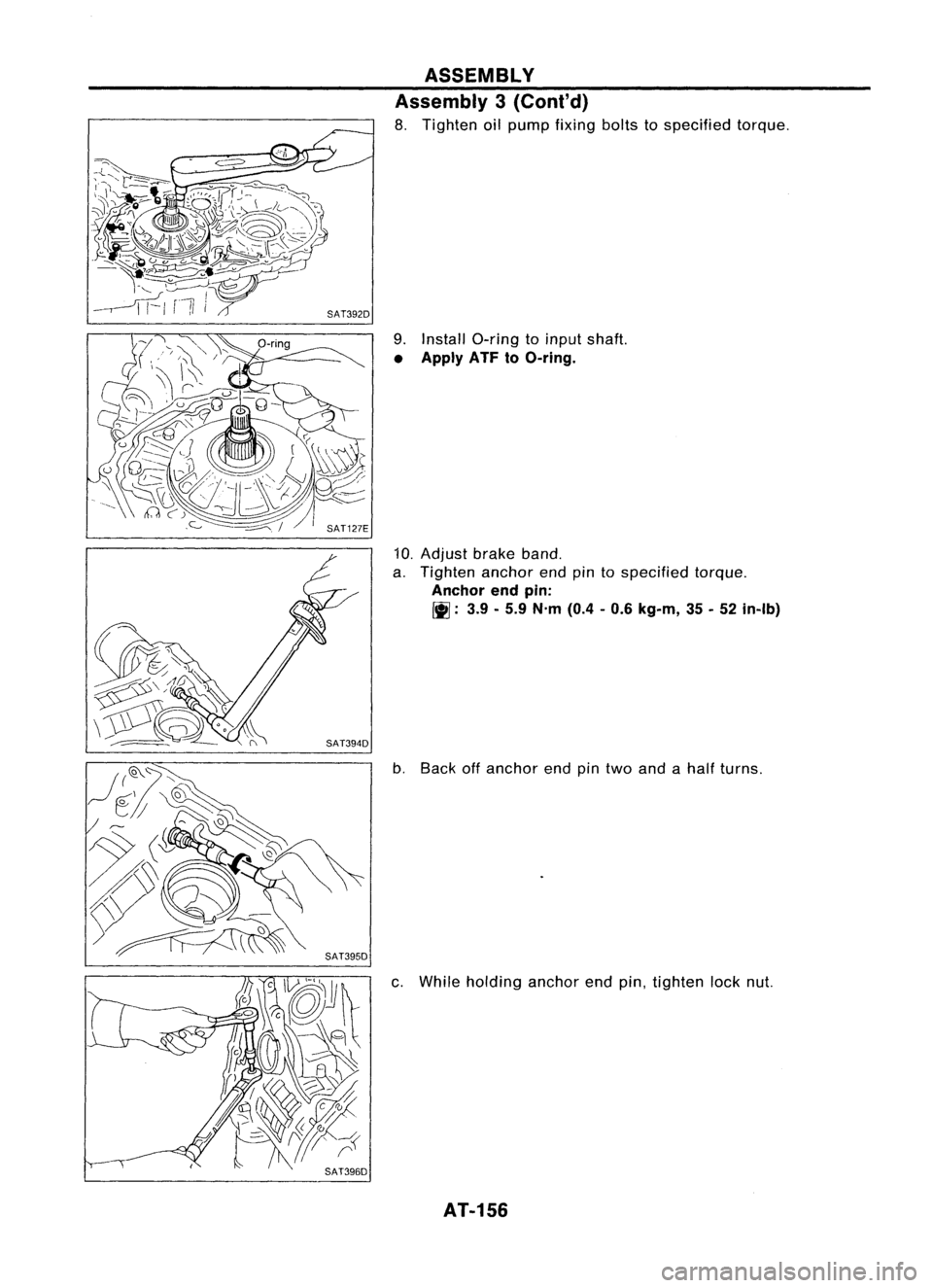

3. Install anchor endpin,washer andlock nutontransmission

case.

4. Place brake bandonoutside ofreverse clutchdrum.Tighten

. anchor endpinjust enough sobrake bandisevenly fitted

on reverse clutchdrum.

5. Place bearing raceselected intotal endplay adjustment •

step onoil pump cover.

• Apply petroleum jellytobearing race.

6. Place thrust washer selected inreverse clutchendplay step

on reverse clutchdrum.

• Apply petroleum jellytothrust washer.

7. Install oilpump assembly ontransmission case.

AT-155

Page 156 of 1701

ASSEMBLY

Assembly 3(Cont'd)

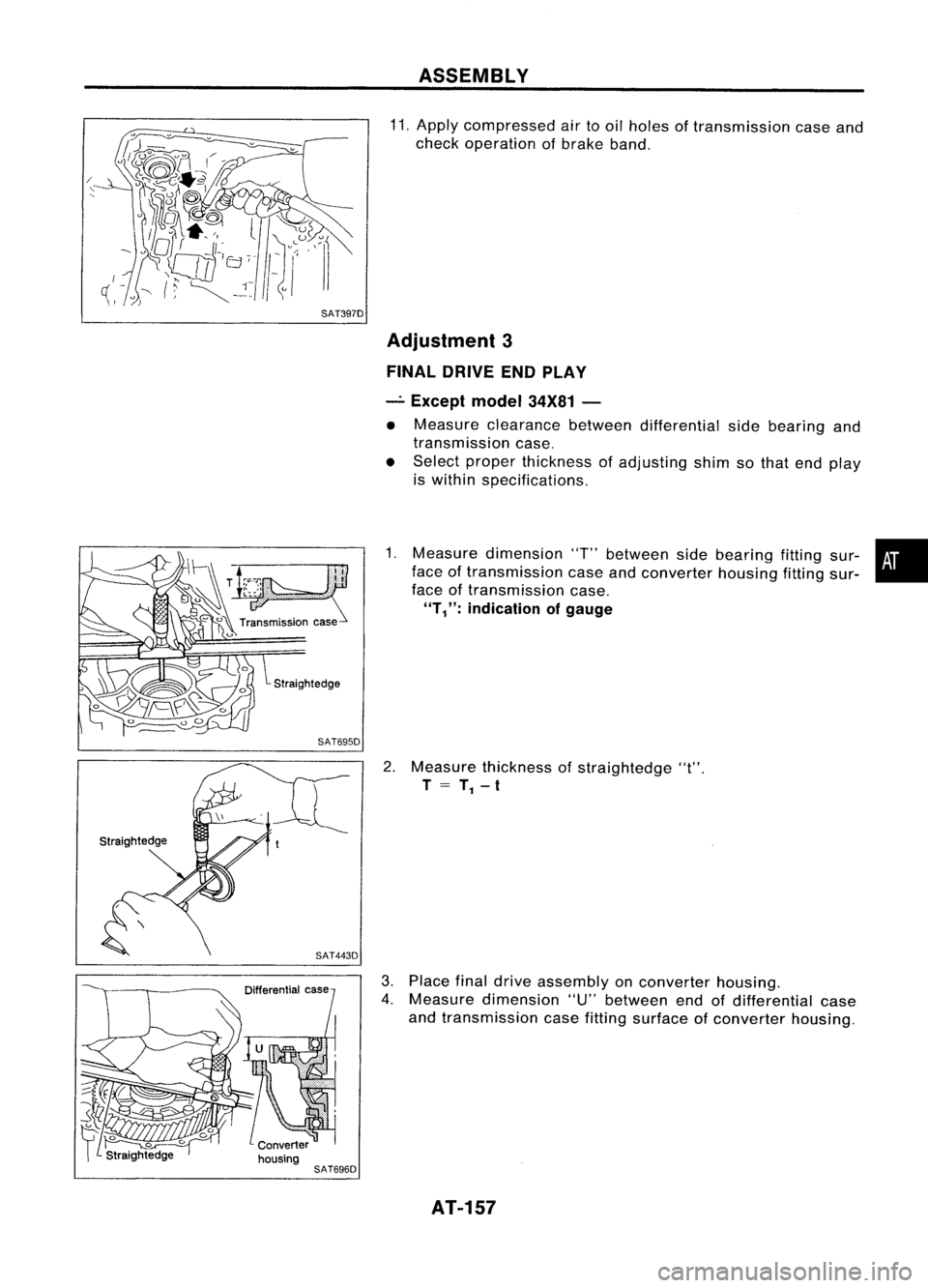

8. Tighten oilpump fixing boltstospecified torque.

9. Install O-ring toinput shaft.

• Apply ATFtoO-ring.

10. Adjust brakeband.

a. Tighten anchorendpintospecified torque.

Anchor endpin:

Ill:

3.9-5.9 N.m (0.4-0.6 kg-m, 35-52 in-Ib)

b. Back offanchor endpintwo and ahalf turns.

c. While holding anchorendpin,tighten locknut.

AT-156

Page 157 of 1701

SAT397D

Straightedge SAT695D

SAT696D ASSEMBLY

11. Apply compressed airtooil holes oftransmission caseand

check operation ofbrake band.

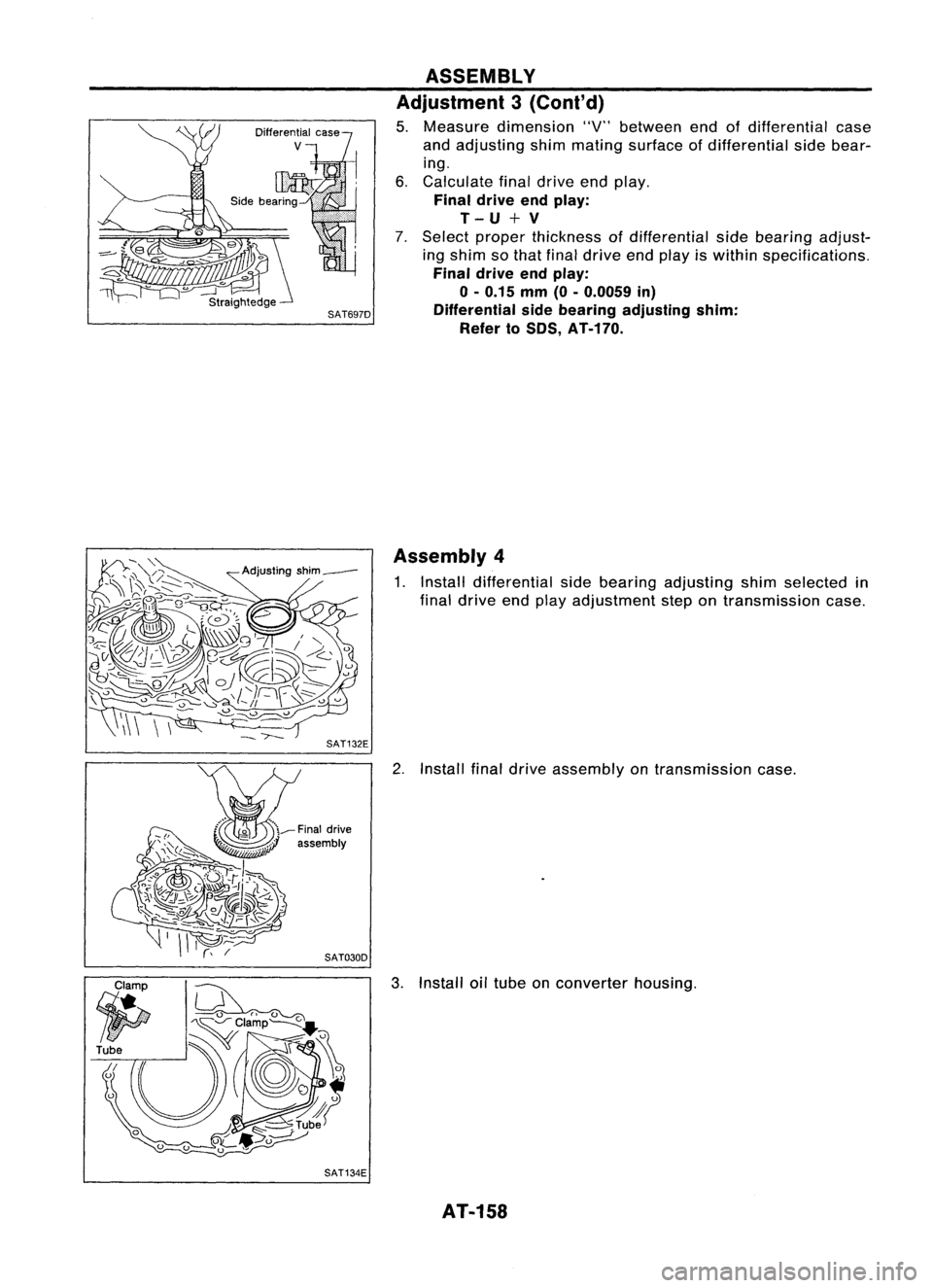

Adjustment 3

FINAL DRIVE ENDPLAY

_. Except model34X81-

• Measure clearance betweendifferential sidebearing and

transmission case.

• Select proper thickness ofadjusting shimsothat end play

is within specifications.

1. Measure dimension 'T"between sidebearing fittingsur-•

face oftransmission caseandconverter housingfittingsur-

face oftransmission case.

"T/':

indication ofgauge

2. Measure thickness ofstraightedge "t".

T

= T

1 -

t

3. Place finaldrive assembly onconverter housing.

4. Measure dimension "U"between endofdifferential case

and transmission casefitting surface ofconverter housing.

AT-157

Page 158 of 1701

ASSEMBLY

Adjustment 3

(Co nt'd)

5. Measure dimension "V"between endofdifferential case

and adjusting shimmating surface ofdifferential sidebear-

ing.

6. Calculate finaldrive endplay.

Final drive endplay:

T-U+V

7. Select proper thickness ofdifferential sidebearing adjust-

ing shim sothat final drive endplay iswithin specifications.

Final drive endplay:

0-

0.15

mm

(0-0.0059

in)

SAT697D Differentialsidebearing adjusting shim:

Refer to80S, AT-170.

Assembly 4

1. Install differential sidebearing adjusting shimselected in

final drive endplay adjustment stepontransmission case.

2. Install finaldrive assembly ontransmission case.

3. Install oiltube onconverter housing.

SAT134E AT-158

Page 159 of 1701

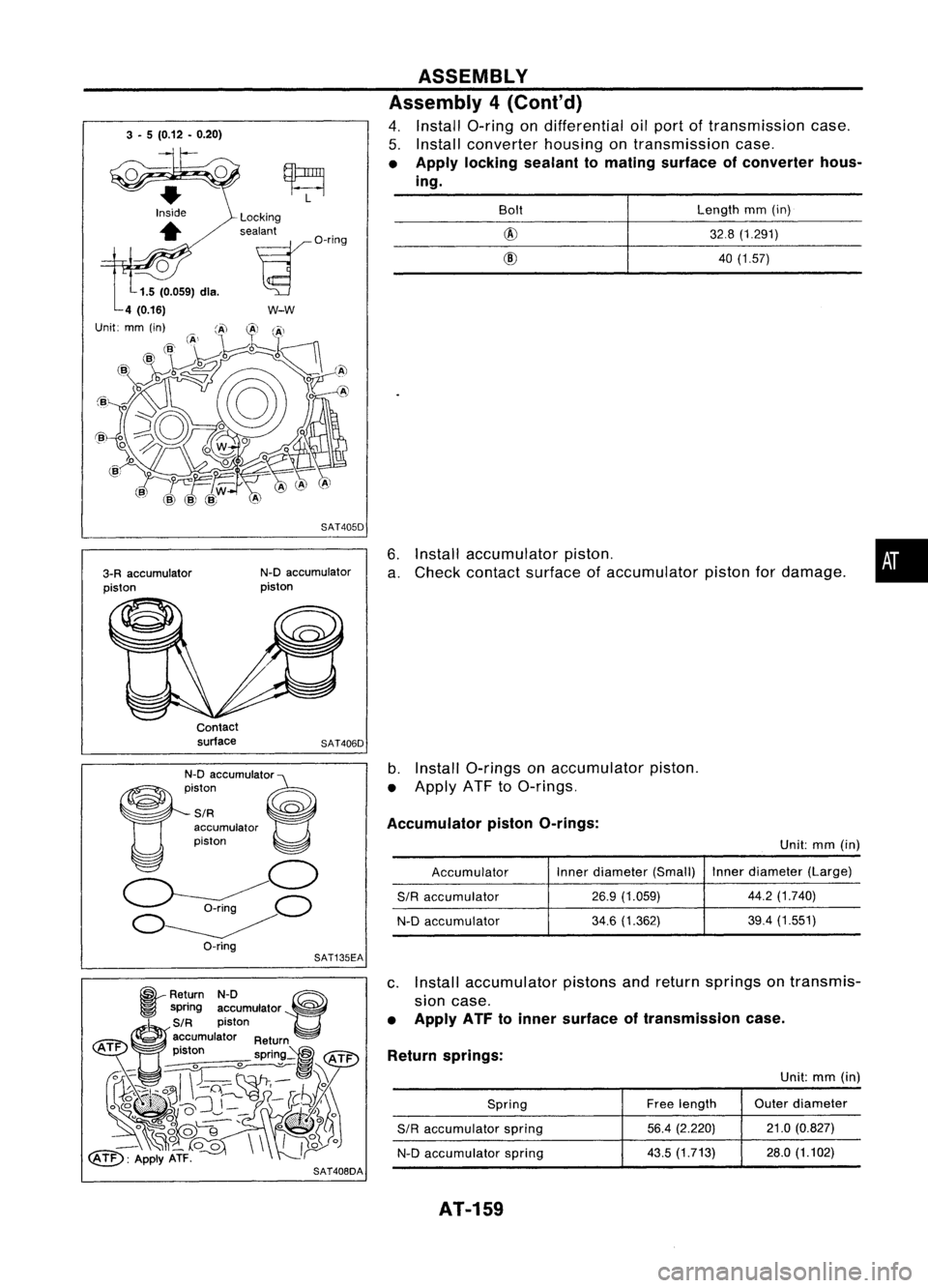

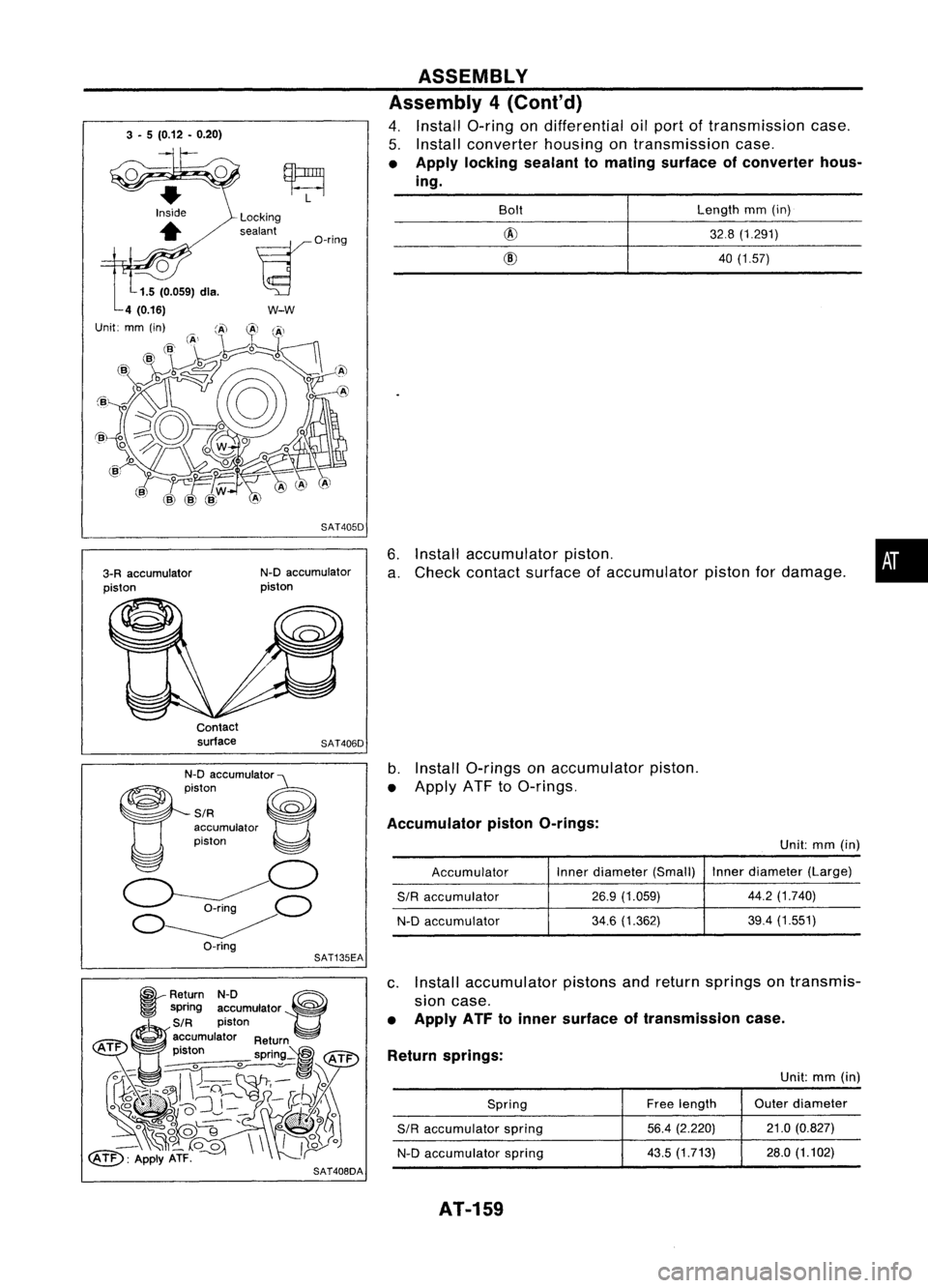

3-5 (0.12 •0.20)

6.Install accumulator piston.

a. Check contact surface ofaccumulator pistonfordamage.

ASSEMBLY

Assembly 4(Cont'd)

4. Install a-ring ondifferential oilport oftransmission case.

5. Install converter housingontransmission case.

• Apply locking sealant tomating surface ofconverter hous-

ing.

•

Length

mm(in)

32.8 (1.291)

40 (1.57)

@

@

Bolt

SAT405D

w-w

N-D accumulator

piston

Locking

sealant

~O'i"9

3-R accumulator

piston

Unit:

Contactsurface

SAT406D

N-D accumUlato'e

~iston ~

SIR ~

accumulator

piston

o

~C)

O~

O-ring

b.

Install a-rings onaccumulator piston.

• Apply ATFtoa-rings.

Accumulator pistonO-rings:

Unit:mm(in)

Accumulator Inner

diameter (Small) Inner

diameter (Large)

SIR

accumulator

26.9

(1.059) 44.2

(1.740)

N-D accumulator

34.6

(1.362) 39.4

(1.551)

SAT135EA

~ Return N-D ~

~ spring accumulator ~

~S/R piston

@)

accumulator Return

ATF .

t

pIS on spring~

tATi="

~~ ~~'\\~

~~U~~~-1C .....~.~ ..

}~y)~:

° ~~~'

o*lf

_~o_

00\\

II~o

~: ApplyATF.

r

c.

Install accumulator pistonsandreturn springs ontransmis-

sion case.

• Apply ATFtoinner surface oftransmission case.

Return springs:

Unit:mm(in)

Spring Free

length Outer

diameter

SIR

accumulator spring

56.4

(2.220) 21.0

(0.827)

N-D accumulator spring

43.5

(1.713) 28.0(1.102)

SAT408DA

AT-159

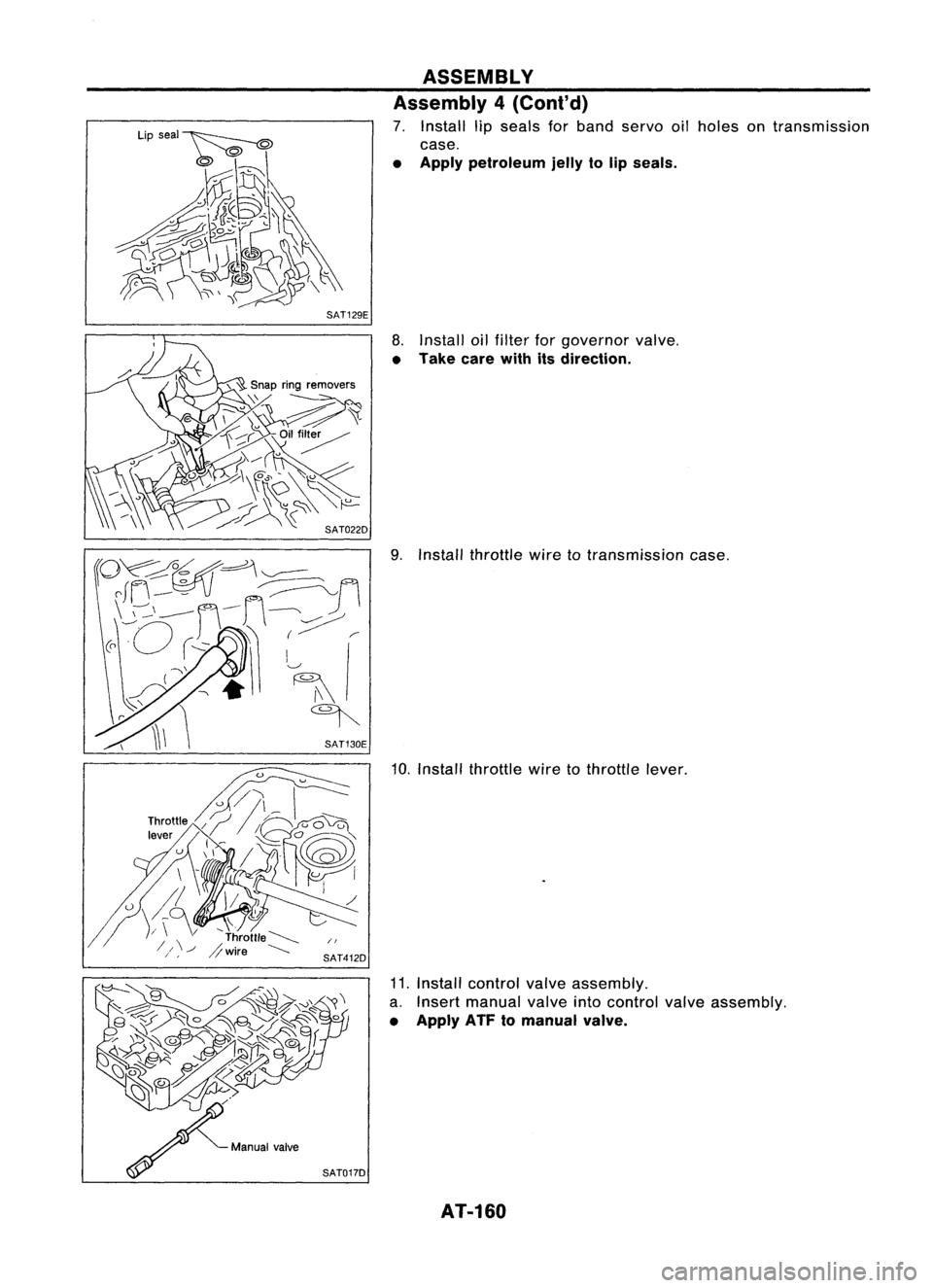

Page 160 of 1701

Installthrottle .

wIre totransm'

.

ISSlon case.

10.

Install th

rattle wiretothrattle lever.

11. I

nstall control

a. Insert manu valveassembl

• Apply ATF

t:I~:~v:alinto conir~1valve

valve.

assembly.

holes

ontransmiss'

Ion

ASSEMBLY

Assembly 4(C

7. Install ,.

ont'd)

case

tp

seals forband

• A . servooil

pply petroleum jellyto lip seals.

8. Install oilfilt

• Take carew~~

f.otr9?VernOr valve

I

s

dIrection. .

AT.160

Trending: engine oil, airbag off, oil type, fuse box location, radio, spare wheel, Check engine light wiring