NISSAN ALMERA N15 1995 Service Manual

Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 201 of 1701

__________ BODYALIGNMENT _

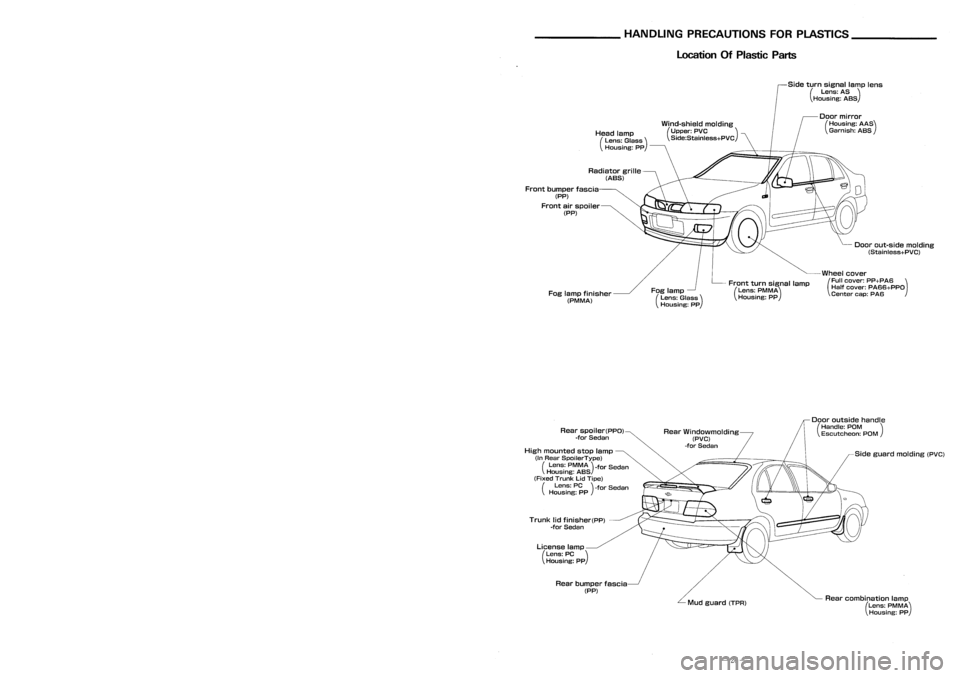

_HANDLINGPRECAUTIONS FORPLASTICS _

Passenger Compartment Sedan

5-door Hatchback Location

OfPlastic Parts

Side turnsignal lamplens

(Lens: AS)

Housing: ASS

Wind-shield molding

(Upper: PVC )

Side:Stainless+PVC

Doorout-side molding

(Stainless+PVC)

Wheel cover

(Full cover: PP+PA6 )

Half cover: PA66+PPO

Center cap:PA6

Door

mirror

(Housing: AAS)

Garnish: ASS

Front turnsignal lamp

(Lens: PMMA)

Housing: PP

Fog

lamp

(Lens: Glass)

Housing: PP

Head

lamp

(Lens: Glass)

Housing: pp

Radiator grille

(ABS)

Fog lamp finisher

(PM MA)

Front

bumper fascia

(PP)

Front airspoiler

(PP)

Point

Dimension

@-@

1228

CB-

@-@

1366

(8)-{6)

1159

CD--cD

1387

Q)-{J) 1367

@--@

1156

(b)--{[)

1385

~-4iV

1370

@~

1364

@~

1364

C'e)--@

1598

@--@

989*

@-{E)

918*

@~

1156*

@--{[)

917*

@~@

975*

@~(b)

757*

@~

1004*

@--@

723*

,

... ._MEASURMENT _

Figures marked witha

*

show symmetrically identical

dimensions onboth right andlefthand sides ofthe

vehicle.

Unit:

mm

@ :

Cowl tophole center (5dia.)

CB>

:

Front roofflange endatcenter

Positioning mark ~~

~}Outer frontpillarjoggle

Sideguard molding (PVC)

Rear combination lamp

(Lens: PMMA)

Housing: PP

Door

outside handle

(Handle: POM )

Escutcheon: POM

Mud guard (TPR)

Rear

Windowmolding

(PVC)

-for Sedan

Rear bumper fascia

(PP)

License

lamp

(Lens: PC)

Housing: PP

Trunk

lidfinisher(pp)

-for Sedan

Rear

spoiler(PPO)

-for Sedan

High mounted stoplamp

(In Rear SpoilerType)

(Lens: PMMA)-for Sedan

Housing: ASS

(Fixed Trunk LidTipe)

(Lens: PC)-for Sedan

Housing: PP

(f3),Cfi),Q),CD,@,@,CD,CD,~,@ :

Outer center pillarindention

CDCD :

Outer center pillarstandard hole

center

CBCD:

}

~@:

Outerfrontpillar indention

@@

:

Dash upper flange endcorner

-19- -26-

Page 202 of 1701

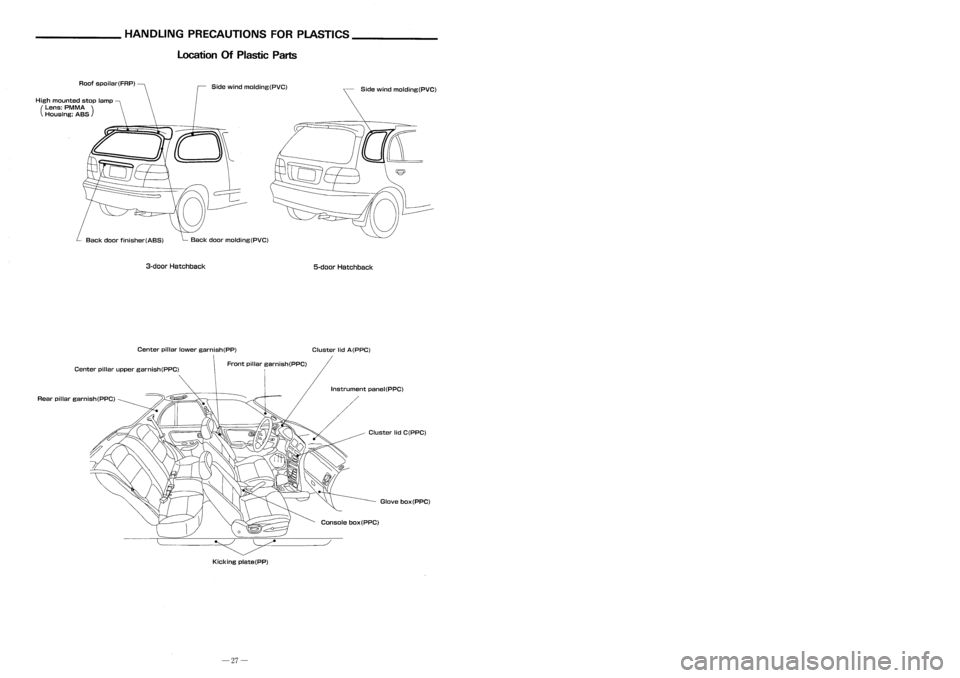

______ HANDLINGPRECAUTIONS FORPLASTICS __

BODYALIGNMENT _

Location OfPlastic Parts

Underbody

Kicking plate(PP)

Front

@,

076

dia.

Rear

@,@

62 dia.

Front

Rear

coordinates: coordinates:

@,@ @,@@

X :250

X:393.5

X:475

V :-632

V:1,460

V:3,082

Z :224.8

Z:126.9

Z:336.8

@,@

(8),

@

@

X :492 X

:572

X:-542

V :-450 V

:1,940

V:3,082

Z :355 Z

:200

Z:336.8

@,@

CD,

CD

X :406

X:600

V :64

V:2,035

Z :172

Z:235.2

@,@

Q)

X :352.7 X

:150

V :69 V

:2,442.9

Z :240 Z

:241

@,

@

@

X :432

X:300

V :338

V:2,480

Z :128

Z:381.8

(f),

CD

@

X :395

X:-300

V :515

V:2,480

Z :129.2

Z:405.8

@,

@)

X :393

Y :2,560

Z :365

@

X :470

Y :2,911

Z :339.6

@

X :-539

Y :2,911

Z :339.6

Unit: mm

Coordinates:

@,0

X :522.2

V :18.1

Z :571.7

@,@ X :465

V :2,456.4

Z :522

Front

andrear strut tower centers

I

~t-~

Rear

(f

••@

LH side

RHside

Q

Q

Bottom

view of

,1

vehicle

__

MEASURMENT POINTS__

Glove box(PPC)

Side

wind molding(PVC)

Cluster lidC(PPC)

Instrument

panel(PPC)

Console box(PPC)

5-door

Hatchback

Cluster lidA(PPC)

~----_/

Front

pillargarnish(PPC)

Side

wind molding(PVC)

Back doorfinisher(ABS)

Roof

spoilar(FRP)

3-doorHatchback

Center pillarlower garnish(PP)

Center pillarupper garnish(PPC)

Rear pillar garnish(PPC)

High

mounted stoplamp

(Lens: PMMA )

Housing: ABS

FrontSBT097

-27-

-18-

Page 203 of 1701

__________ BODYALIGNMENT ___________

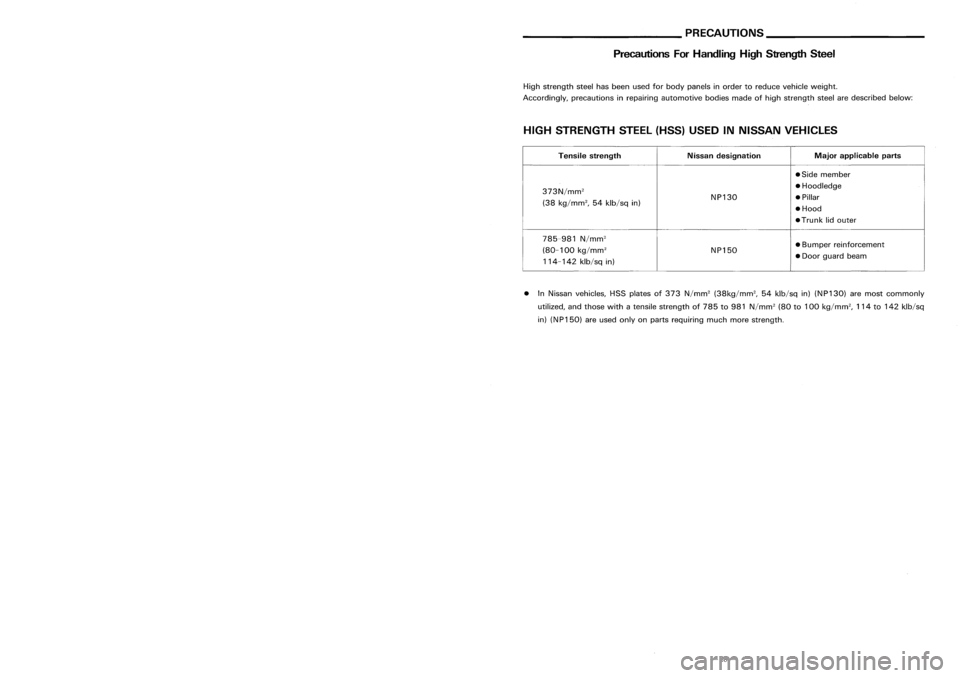

PRECAUTIONS _

Underbody Precautions

ForHandling HighStrength Steel

• InNissan vehicles, HSSplates of373 N/mm

2

(38kg/mm

2,

54klb/sq in)(NP130) aremost commonly

utilized, andthose withatensile strength of785 to981 N/mm

2

(80to100 kg/mm

2,

114to142 klb/sq

in) (NP150) areused onlyonparts requiring muchmorestrength.

HIGH

STRENGTH STEEL(HSS)USED INNISSAN VEHICLES

High

strength steelhasbeen usedforbody panels inorder toreduce vehicle weight.

Accordingly, precautionsinrepairing automotive bodiesmadeofhigh strength steelaredescribed below:

Tensile strength Nissan designation Major

applicable parts

• Side member

373N/mm

2

•

Hoodledge

(38 kg/mm

2,

54klb/sq in) NP130

•

Pillar

• Hood

.Trunk lidouter

785-981 N/mm

2

•Bumper reinforcement

(80-100 kg/mm

2

NP150

114-142 klb/sqin) •

Door guard beam

E

E

127

@>@)

235

~200

ee

@@

o

It)

CD

N

.. CD

.. 00

~ N~

It)

CD

CD

It)

C!.

~

CD

It)

It)

en

N

It)

CD CD

IIIlI:t'

(ij

Q)

er:

iJ

--------

en

It)

C!.

N

~ en

co

____

MEASURMENT _

..

o

.. It)

0)

It)

o

I'

..

.. 0

CD CD

en~

0) .,

~

129

@8

@@

@)@)

225

SBT096

-17- -28-

Page 204 of 1701

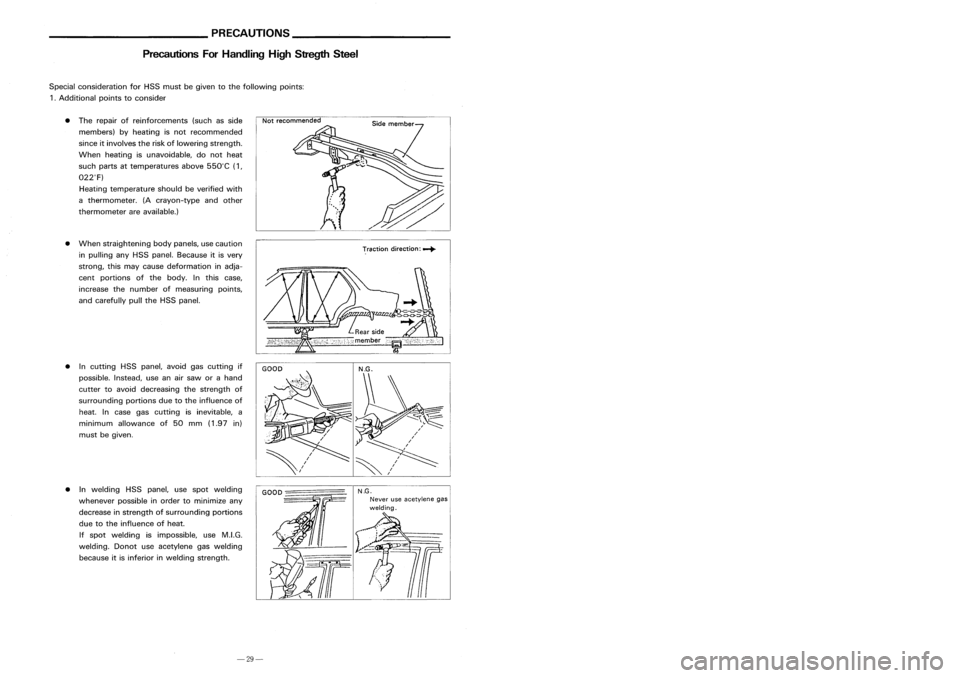

__________ PRECAUTIONS ___________

BODYALIGNMENT _

Precautions ForHandling HighStregth Steel Engine

Compartment

__ MEASURMENT POINTS__

Unit:mm

Front side

SBT088

Traction direction: ...

Not

recommended

• The repair ofreinforcements (suchasside

members) byheating isnot recommended

since itinvolves theriskoflowering strength.

When heating isunavoidable, donot heat

such parts attemperatures above550°C (1,

022°F)

Heating temperature shouldbeverified with

a thermometer. (Acrayon-type andother

thermometer areavailable.)

• When straightening bodypanels, usecaution

in pulling anyHSS panel. Because itis very

strong, thismay cause deformation inadja-

cent portions ofthe body. Inthis case,

increase thenumber ofmeasuring points,

and carefully pulltheHSS panel.

Special

consideration forHSS must begiven tothe following points:

1 .Additional pointstoconsider

• Incutting HSSpanel, avoidgascutting if

possible. Instead,useanairsaw orahand

cutter toavoid decreasing thestrength of

surrounding portionsduetothe influence of

heat. Incase gascutting isinevitable, a

minimum allowance of50 mm (1.97 in)

must begiven.

SBT090

Radiator

coresupport lower

•

(b)

11

dia.

SBT094

• Inwelding HSSpanel, usespot welding

whenever possibleinorder tominimize any

decrease instrength ofsurrounding portions

due tothe influence ofheat.

If spot welding isimpossible, useM.LG.

welding. Donotuseacetylene gaswelding

because itis inferior inwelding strength.

GOOD

-================

N.G.

Never useacetylene .gas

welding.

Radiator

coresupport uppercenter

SBT091

-29-

-16-

Page 205 of 1701

__________ BODYALIGNMENT _

_ PRECAUTIONS _

Description PrecautionsForHandling HighStrength Steel

• Alldimensions indicatedinfigures areactual ones.

• When usingatracking gauge,adjustbothpointers toequal length. Thencheck thepointers andgauge

itself tomake surethere isno free play.

• When ameasuring tapeisused, check tobe sure there isno elongation, twistingorbending.

• Measurements shouldbetaken atthe center ofthe mounting holes.

• Anasterisk

(*)

following thevalue atthe measuring pointindicates thatthemeasuring pointonthe other

side issymmetrically thesame value.

• The coordinates ofthe measurement pointsarethe distances measured fromthestandard lineof"X", "V"

and "Z".

EngineCompartment

D=2T+3(mm)

D=2T+O.12 (in)

•

The electrode tipdiameter mustbereformed

properly according tothe panels thickness.

•

The spot ungget onHSS panel isharder than

that ofan ordinary steelpanel.

Therefore, forspot cutting HSSpanel, ahigh

torque drillofalow speed (1,000 to1,200

rpm) maybeused tomaintain itsdurability

and facilitate theoperation.

• HSS panels withatensile strength of785 to981 N/mm

2

(80to100 kg/mm

2,

114to142 klb/sq in),

used asreinforcement inthe door guard barand inthe bumper, istoo high intensile strength touse

for general repairs.Whenthesepanels aredamaged, theouter panels alsosustain consequential

damage; therefore, thesepanels arenever remedied withoutreplacing thedoor assembly orbumper

assembly.

2. Precautions inspot welding

This work should beperformed understandard workconditions. However,workcontrol mustbeexercised

as folloows:

SBF8?4GB

"Z":

Imaginary baseline

[200 mmbelow datum line

("OZ" atdesign plan)]

Front axlecenter

/

y (_)

(0)

Incorrect

Incorrect

Correct

D==Tip+diameter

T

,::=T====p=la::t_e=-=-_t_h=i_C=k=_n=_e_s=s= __,-- ~

• The panel surfaces mustbefitted toeach

other, leaving nogaps.

____

MEASURMENT _

SBT08?

-15- -30-

Page 206 of 1701

__________ PRECAUTIONS _

_ BODYALIGNMENT _

Precautions ForHandling HighStrength Steel

PanelPartsMatching Marks

~ViewE

3-Door Hatchback

and 5-Door Hatchback

A

mark hasbeen placed oneach partofthe body toindicate thepanel partsmatching positions.Whenrepairing

parts damaged byan accident whichmightaffectthevehicle frame(members, pillars,etc.)more accurate,

effective repairwillbepossible byusing these marks together wi~hbody alignment data.

Welding

current

Pressure

Unit:mrr

(C•

Thickness

(t)

Minimum pitch(

Q )

0.6 (0.024)

I

10 (0.39)

orover

0.8 (0.031) 12(0.47)

orover

1.0 (0.039) 18(0.71)

orover

1.2 (0.047) 20(0.79)

orover

1.6 (0.063) 27(1.06)

orover

~71) 31

11.221

orover

•

Follow established specifications forthe

appropriate pressurelevel,current leveland

weld time.

• Follow thespecifications forthe proper

welding pitch.

• After welding, weldingstrength mustbe

tested.

J

Type

W:

@----- ~

Et

Type V:~----- ~

View A ViewS

ViewC

View D-1 View

D-2

ViewE

Sedan and5-door Hatchback 3-door

Hatchback

3-door

Hatchback and5-door Hatchback

/w-..IE

+-W

II (-

'- r )

o

-31- -14-

Page 207 of 1701

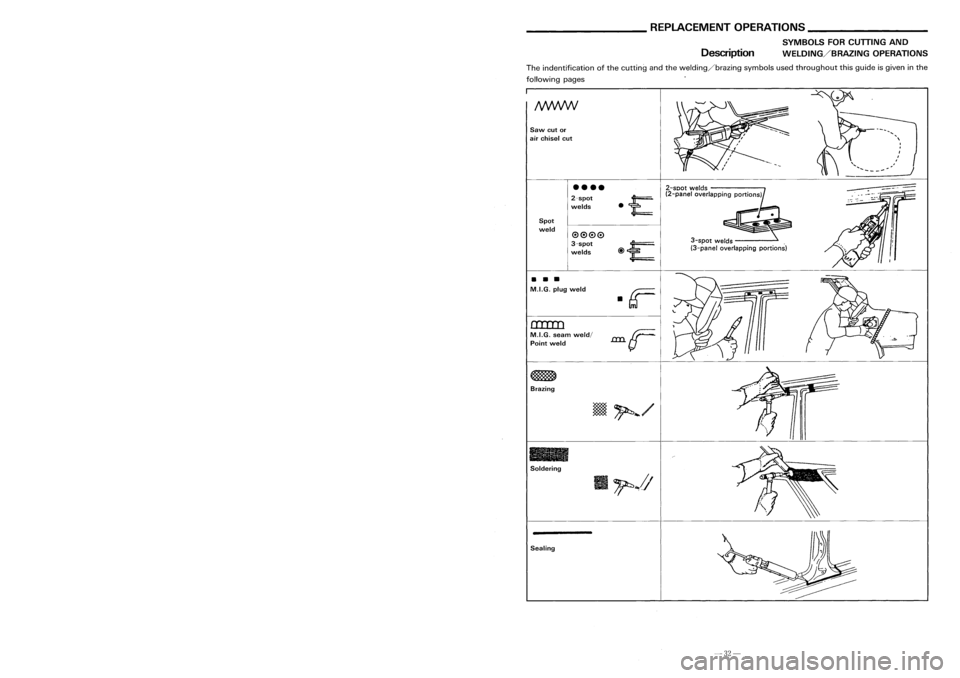

Description

_________

BODYALIGNMENT _

Body Center Marks ________

REPLACEMENTOPERATIONS _

SYMBOLS FORCUITING AND

WELDING/BRAZING OPERATIONS

..J

3-spot welds

(3-panel overlapping portions)

2-SDOt

welds

(2-panel overlapping portions)

••••

2-spot

welds

0000

3-spot

welds

Spot

weld

Brazing

Soldering

(ItIlI)

M.LG. seamweld/

Point weld

Saw

cutor

air chisel cut

•

•

•

M.LG. plugweld

-

The

indentification ofthe cutting andthewelding/brazing symbolsusedthroughout thisguide isgiven inthe

following pages

Portion F

Portion

C

Unit:

mm

Porton

H

3-Door Hatchback

and 5-Door Hatchback

• Front roof

• Second crossmember

Portion

D-Sedan

Portion E

-Sedan

Portion F

Portion E

Portion

8

Portion

G

~

Slot(7X 11)

/~/

• Rear waist panelslot

•

Cowl top

Portion

BPortion

C

Hole(4

dial

Portion

A

Portion D

Portion

A

• Rear roof

•

Upper radiator coresupport

A

mark hasbeen placed oneach partofthe body toindicate thevehicle center.Whenrepairing partsdamaged

by an accident whichmightaffectthevehicle frame(members, pillars,etc.)more accurate, effectiverepairwill

be possible byusing these marks together withbody alignment data.

Portion G

3-door and5-door Hatchback

Lozenge

mark

Portion

H

3-door and5-door Hatchback Sealing

• Rear roof •

Rear panel

-13- -32-

Page 208 of 1701

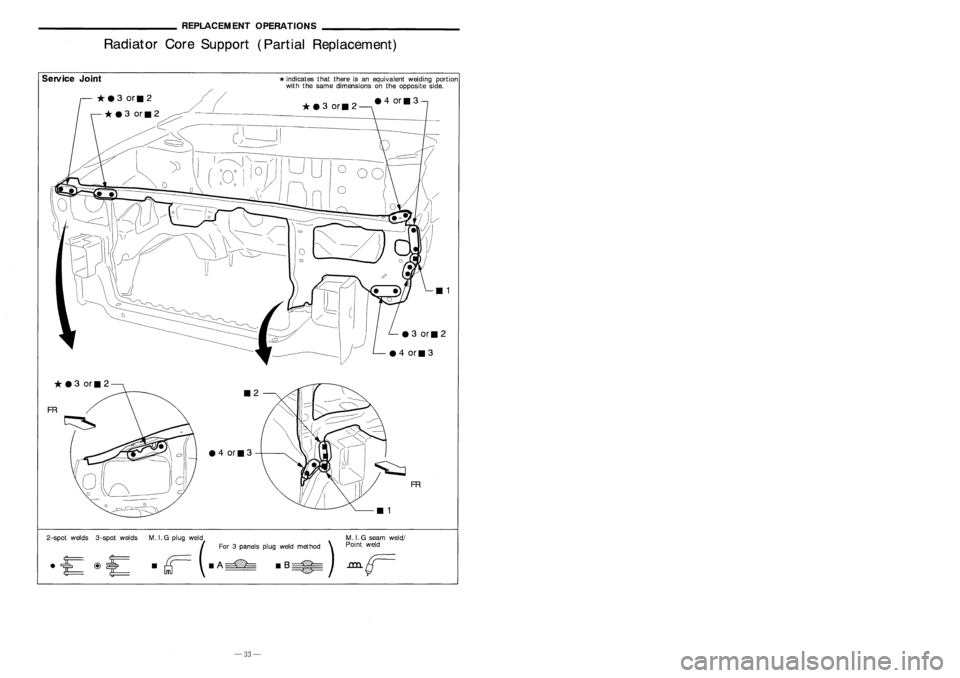

REPLACEMENTOPERATIONS _

------------

RadiatorCoreSupport (PartialReplacement) BODY

CONSTRUCTION _

-----------

BodyConstruction

\

Section

L-L:

Section P-P:

Section

D-D:

Section H-H:

Section K-K:

Section

C-C:

Section G-G:

Section 0-0:

Section

J-J:

Section

F-F:

Section

8-8:

. Section N-N:

Section

I-I:

Section

E-E:

Section

A-A:

Section M-M:

_1

FR

(

e

4orll3 *

indicates thatthere isan equivalent wel~ing.portion

with thesame dimensions onthe opposite Side.

o

*

e

3

or 112

FR

Service

Joint

Section

0-0:

Section

R-R:

2-spot welds 3-spotwelds

M.1.Gplug weld )M.I.Gseam weld/

(Point weld

For 3panels plugweld m.ethod

· r ·

A

=='*= •

B

===:=

.an

F

-33- -12-

Page 209 of 1701

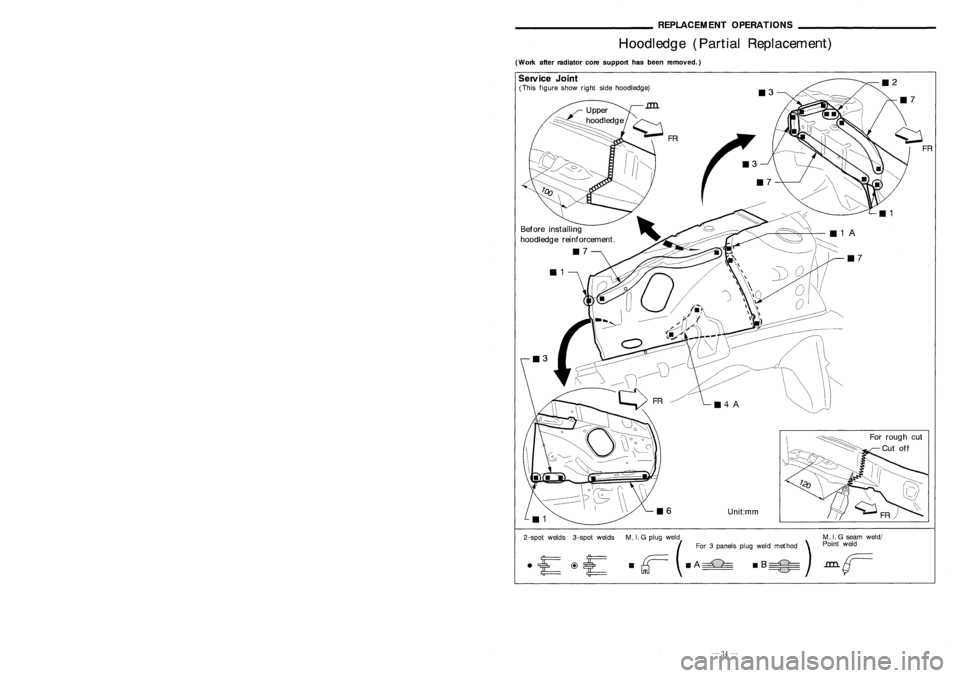

BODYCONSTRUCTION _

------------

BodyConsb"uction. REPLACEMENT

OPERATIONS _

------------

Hoodledge(PartialReplacement)

(Work afterradiator coresupport hasbeen removed.)

114AUnit:mm

Before

installing

hoodledge reinforcement.

117

Service

Joint

(This figure showrightsidehoodledge)

Sedan

3-d oar Hatchback

5-door Hatchback 2-spot

welds 3-spotwelds

M.1.

Gplug weld )

M.I.

Gseam weld/

(For 3panels plugweld method. Pointweld

· r

.A~ .B~

.an.F

-34-

-11-

Page 210 of 1701

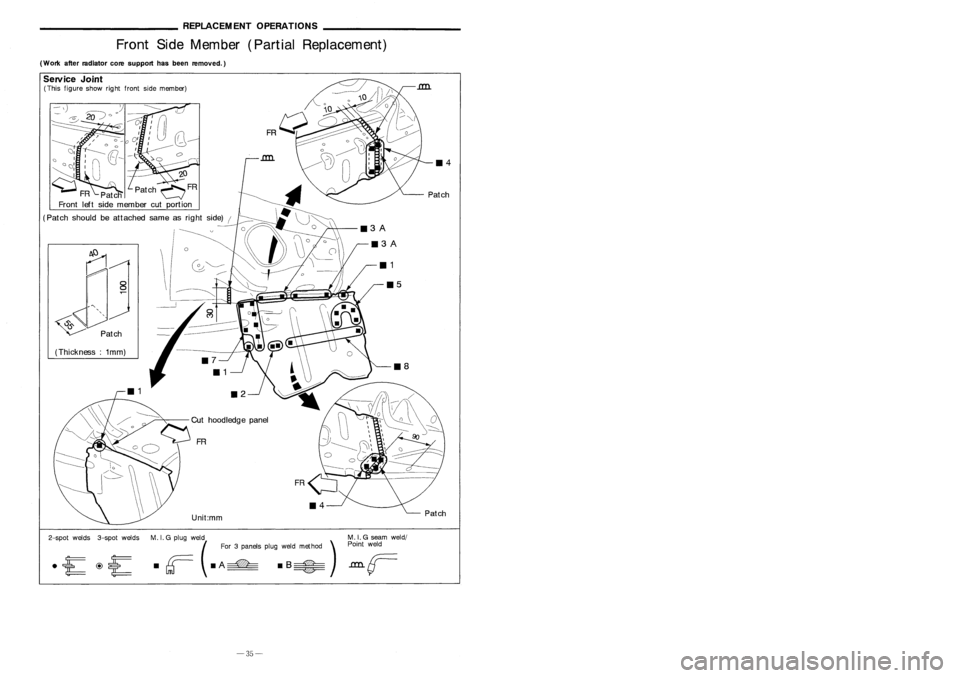

REPLACEMENTOPERATIONS

Front SideMember (PartialReplacement)

(Work afterradiator coresupport hasbeen removed.) ________

CORROSIONPROTECTION _

Stone Guard Coat

SectionB-B

Section

A-A

--r':":'

To

prevent damage causedbystones, thelower outerbodypanels (fender, door,etc.)have anadditional layer

of Stone Guard CoatovertheEDprimer coating. Thus,when replacing orrepairing thesepanels, apply

undercoat tothe same portions asbefore. Useacoat which isrust preventive, durable,shockresistant andhas

a long shelf life.

~mm1111i :

Indicates stoneguard coated portions

114

Patch

118

111

115

114

hoodledge

panel

117

111

Unit:mm

8

Patch

""

"

"

(Thickness: 1mm)

-\

Service

Joint

(This figure showrightfront sidemember)

2-spot welds 3-spotwelds M.1.

Gplug weld MIG seam weld/

(For 3panels plugweld method )P1ID.~irit

F

weld

• rr=

.A=-= .B~

G1J --- ~

Section

C-C

-35- -10-