NISSAN ALMERA TINO 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 1381 of 3051

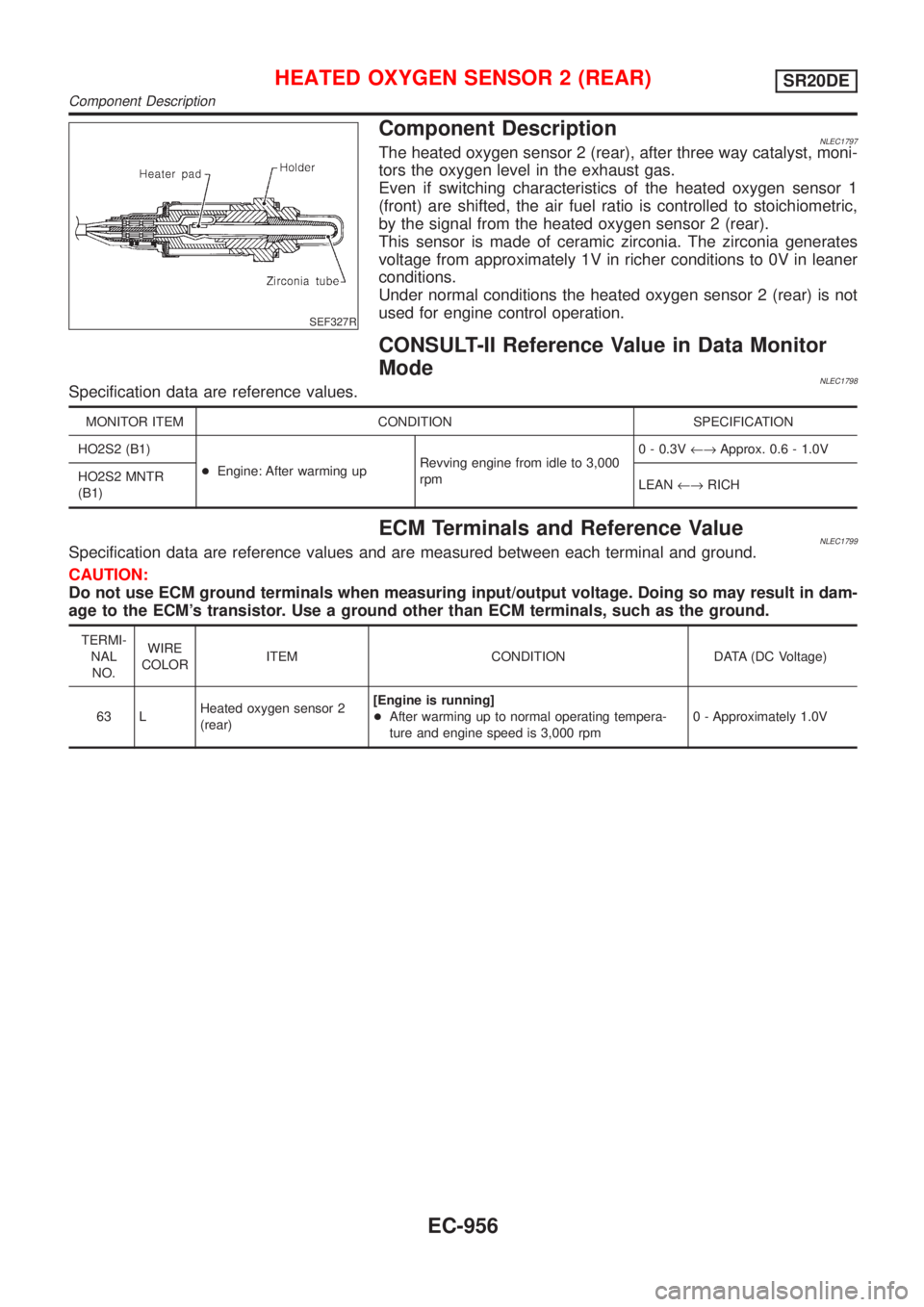

SEF327R

Component DescriptionNLEC1797The heated oxygen sensor 2 (rear), after three way catalyst, moni-

tors the oxygen level in the exhaust gas.

Even if switching characteristics of the heated oxygen sensor 1

(front) are shifted, the air fuel ratio is controlled to stoichiometric,

by the signal from the heated oxygen sensor 2 (rear).

This sensor is made of ceramic zirconia. The zirconia generates

voltage from approximately 1V in richer conditions to 0V in leaner

conditions.

Under normal conditions the heated oxygen sensor 2 (rear) is not

used for engine control operation.

CONSULT-II Reference Value in Data Monitor

Mode

NLEC1798Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

HO2S2 (B1)

+Engine: After warming upRevving engine from idle to 3,000

rpm0 - 0.3V¨Approx. 0.6 - 1.0V

HO2S2 MNTR

(B1)LEAN¨RICH

ECM Terminals and Reference ValueNLEC1799Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

63 LHeated oxygen sensor 2

(rear)[Engine is running]

+After warming up to normal operating tempera-

ture and engine speed is 3,000 rpm0 - Approximately 1.0V

HEATED OXYGEN SENSOR 2 (REAR)SR20DE

Component Description

EC-956

Page 1382 of 3051

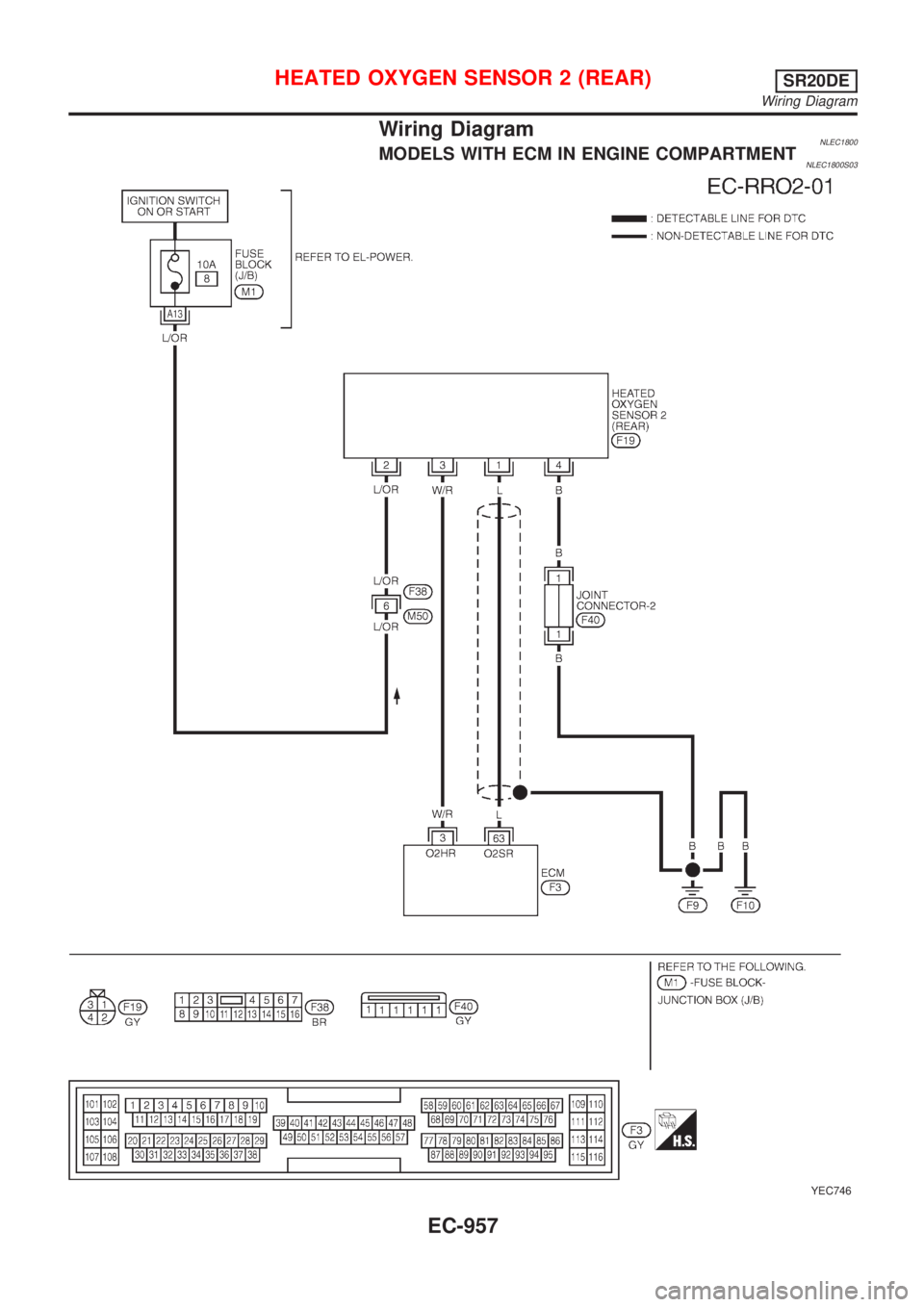

Wiring DiagramNLEC1800MODELS WITH ECM IN ENGINE COMPARTMENTNLEC1800S03

YEC746

HEATED OXYGEN SENSOR 2 (REAR)SR20DE

Wiring Diagram

EC-957

Page 1383 of 3051

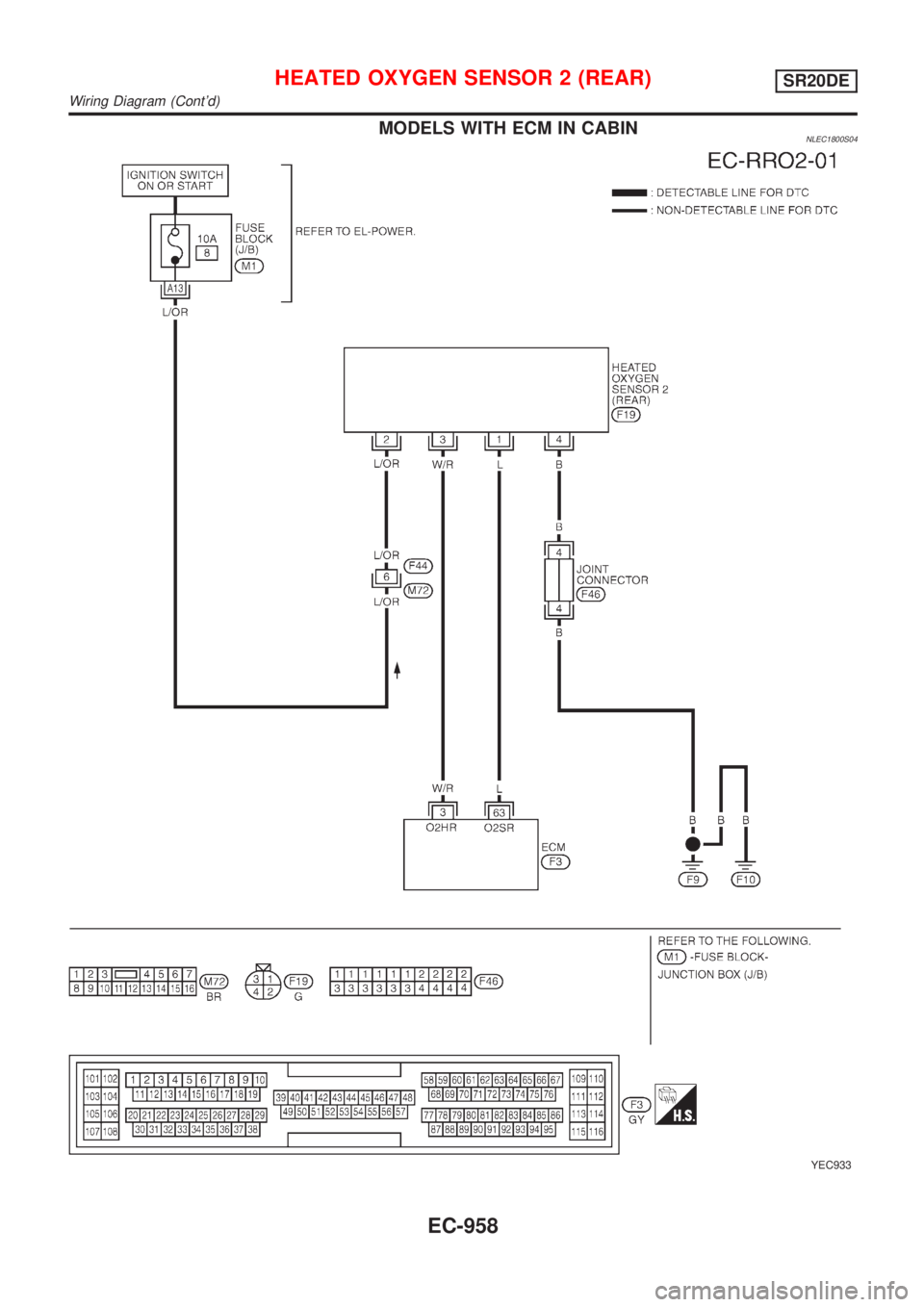

MODELS WITH ECM IN CABINNLEC1800S04

YEC933

HEATED OXYGEN SENSOR 2 (REAR)SR20DE

Wiring Diagram (Cont'd)

EC-958

Page 1384 of 3051

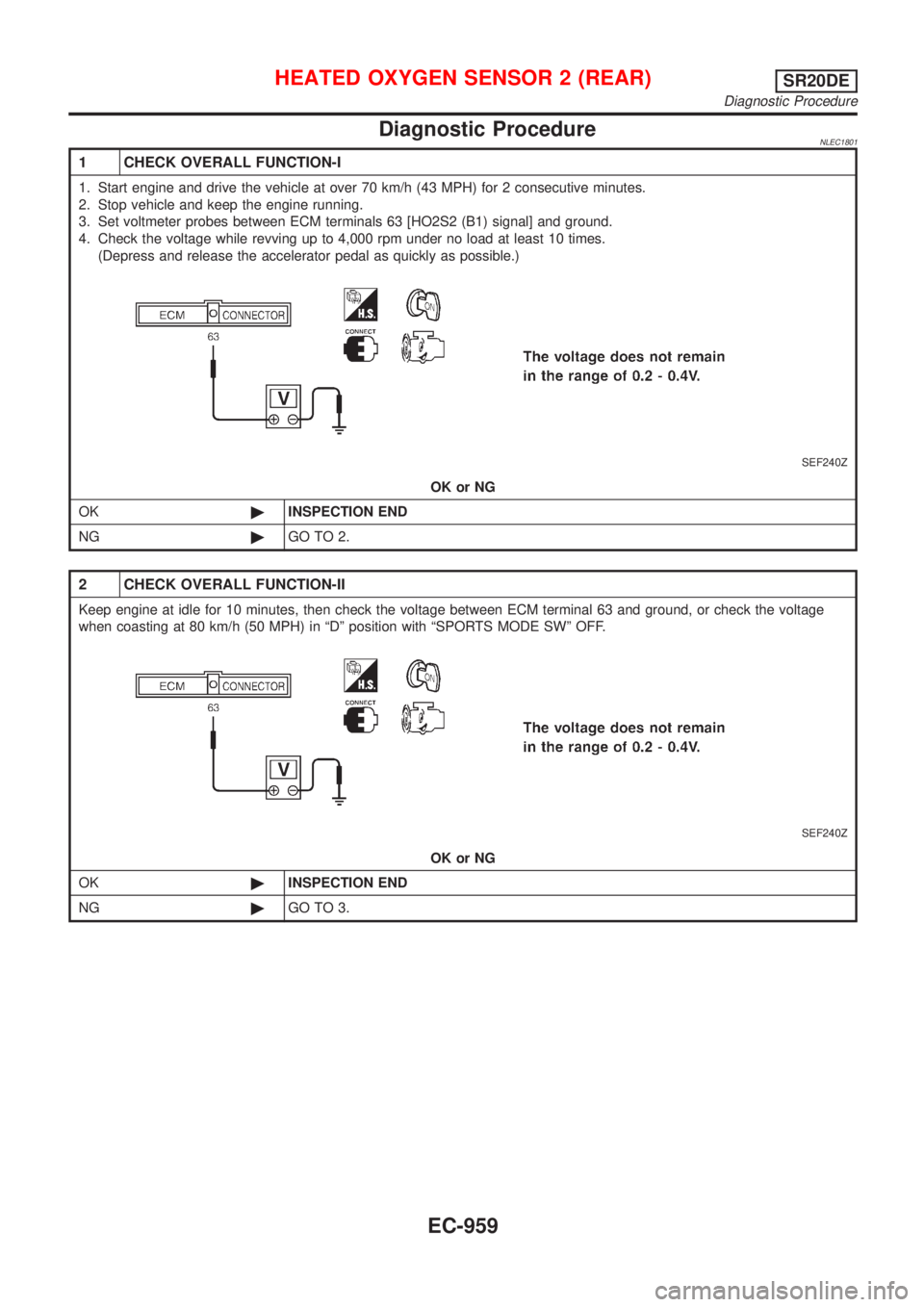

Diagnostic ProcedureNLEC1801

1 CHECK OVERALL FUNCTION-I

1. Start engine and drive the vehicle at over 70 km/h (43 MPH) for 2 consecutive minutes.

2. Stop vehicle and keep the engine running.

3. Set voltmeter probes between ECM terminals 63 [HO2S2 (B1) signal] and ground.

4. Check the voltage while revving up to 4,000 rpm under no load at least 10 times.

(Depress and release the accelerator pedal as quickly as possible.)

SEF240Z

OK or NG

OK©INSPECTION END

NG©GO TO 2.

2 CHECK OVERALL FUNCTION-II

Keep engine at idle for 10 minutes, then check the voltage between ECM terminal 63 and ground, or check the voltage

when coasting at 80 km/h (50 MPH) in ªDº position with ªSPORTS MODE SWº OFF.

SEF240Z

OK or NG

OK©INSPECTION END

NG©GO TO 3.

HEATED OXYGEN SENSOR 2 (REAR)SR20DE

Diagnostic Procedure

EC-959

Page 1385 of 3051

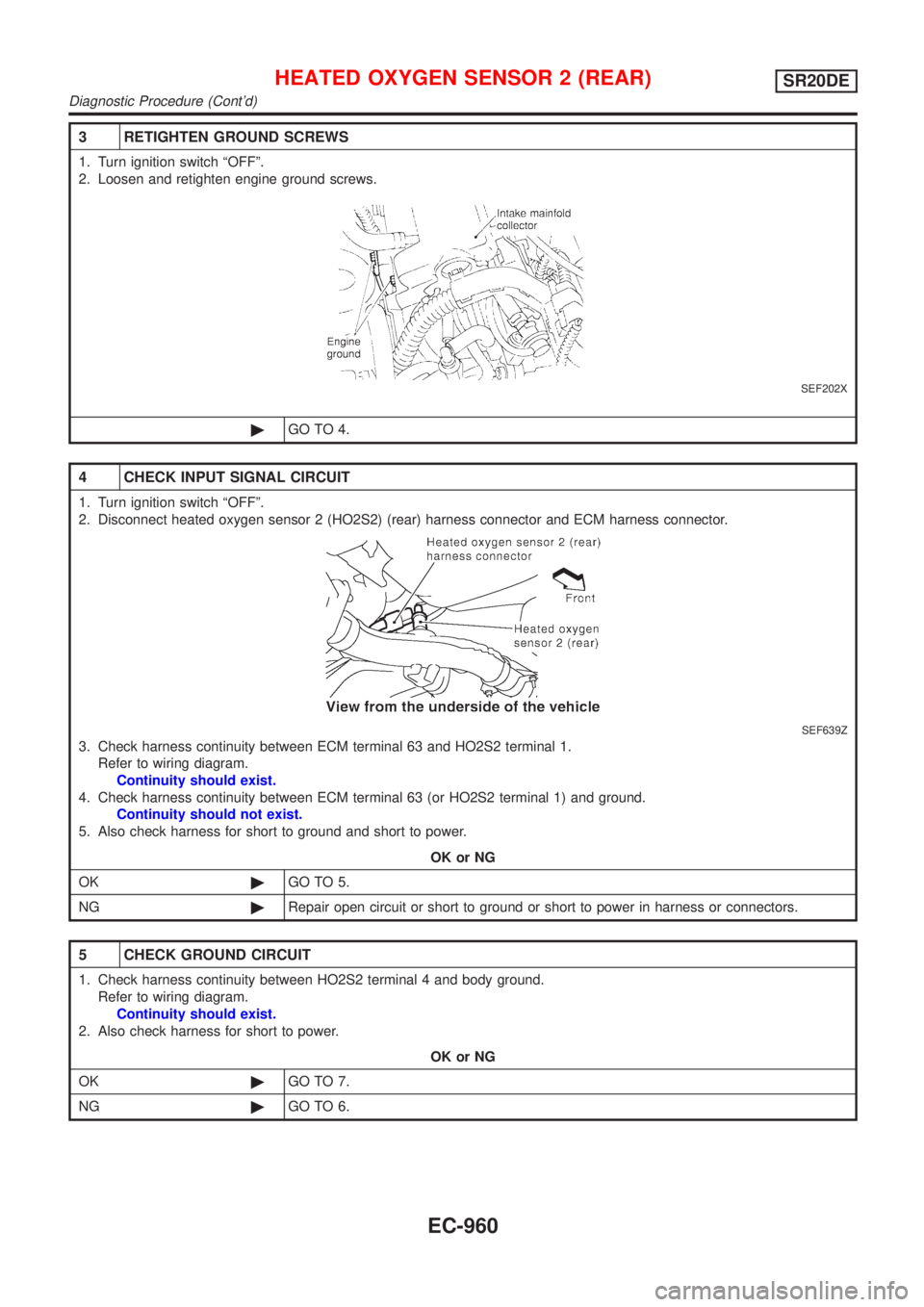

3 RETIGHTEN GROUND SCREWS

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screws.

SEF202X

©GO TO 4.

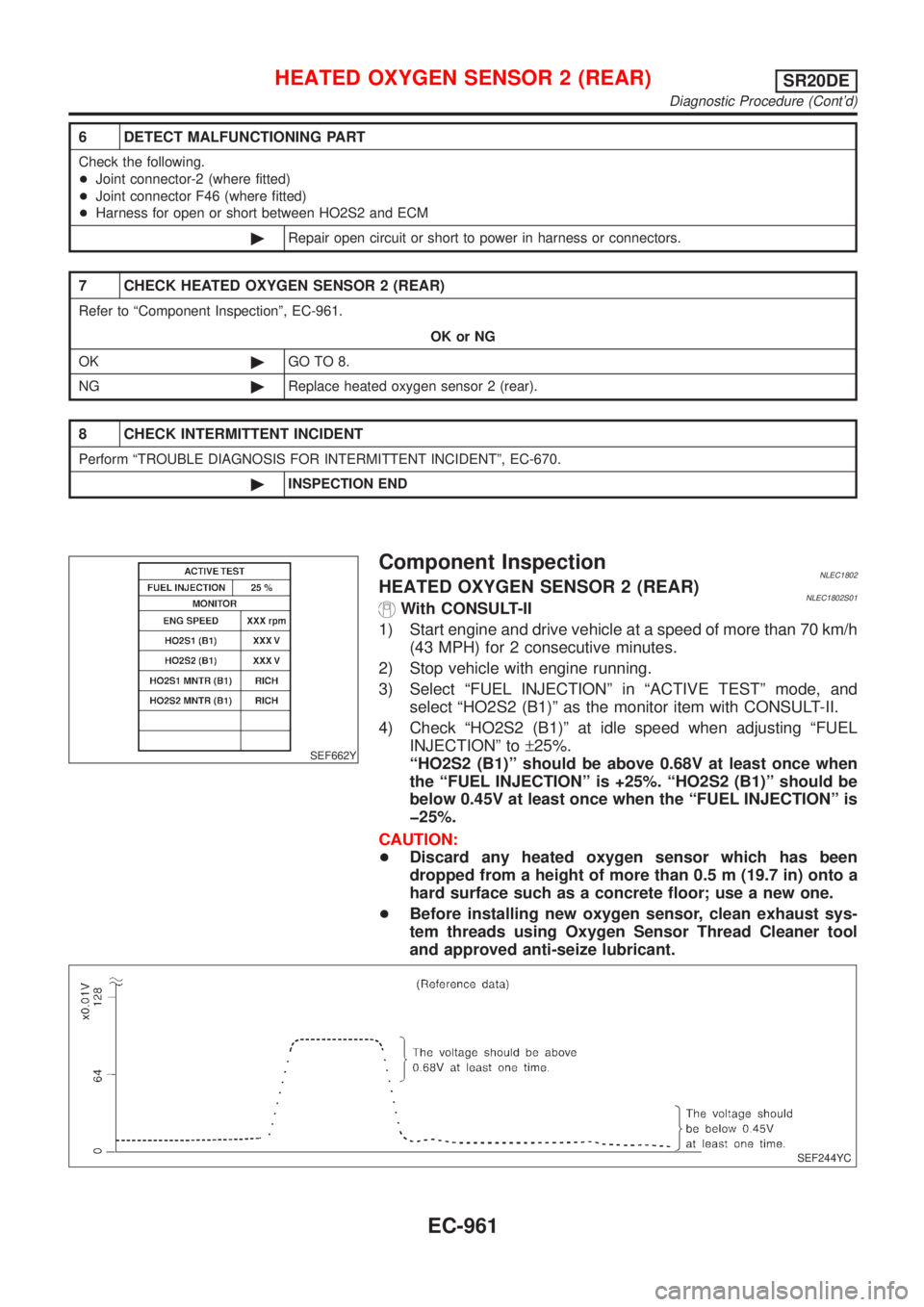

4 CHECK INPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect heated oxygen sensor 2 (HO2S2) (rear) harness connector and ECM harness connector.

SEF639Z

3. Check harness continuity between ECM terminal 63 and HO2S2 terminal 1.

Refer to wiring diagram.

Continuity should exist.

4. Check harness continuity between ECM terminal 63 (or HO2S2 terminal 1) and ground.

Continuity should not exist.

5. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

5 CHECK GROUND CIRCUIT

1. Check harness continuity between HO2S2 terminal 4 and body ground.

Refer to wiring diagram.

Continuity should exist.

2. Also check harness for short to power.

OK or NG

OK©GO TO 7.

NG©GO TO 6.

HEATED OXYGEN SENSOR 2 (REAR)SR20DE

Diagnostic Procedure (Cont'd)

EC-960

Page 1386 of 3051

6 DETECT MALFUNCTIONING PART

Check the following.

+Joint connector-2 (where fitted)

+Joint connector F46 (where fitted)

+Harness for open or short between HO2S2 and ECM

©Repair open circuit or short to power in harness or connectors.

7 CHECK HEATED OXYGEN SENSOR 2 (REAR)

Refer to ªComponent Inspectionº, EC-961.

OK or NG

OK©GO TO 8.

NG©Replace heated oxygen sensor 2 (rear).

8 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-670.

©INSPECTION END

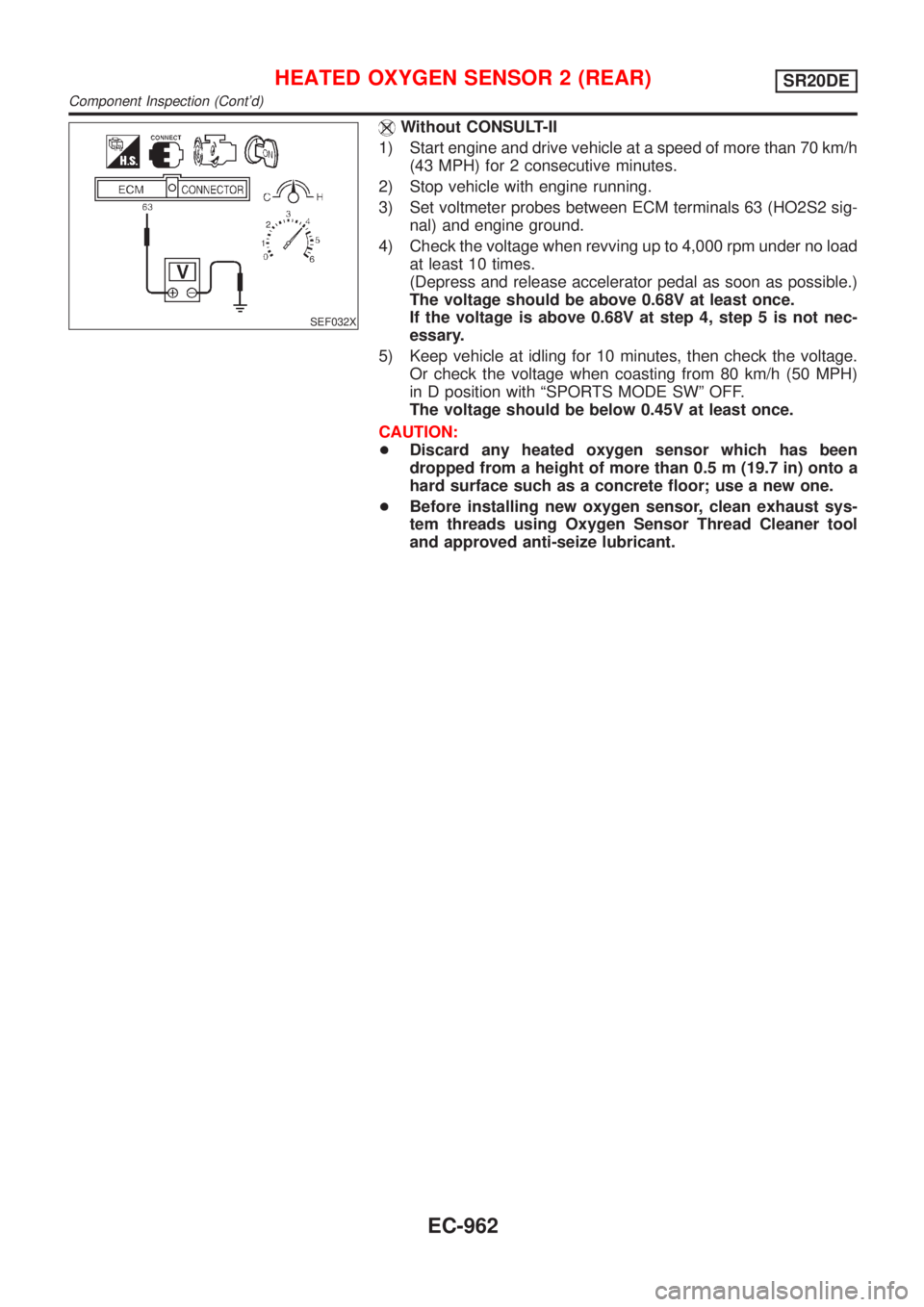

SEF662Y

Component InspectionNLEC1802HEATED OXYGEN SENSOR 2 (REAR)NLEC1802S01With CONSULT-II

1) Start engine and drive vehicle at a speed of more than 70 km/h

(43 MPH) for 2 consecutive minutes.

2) Stop vehicle with engine running.

3) Select ªFUEL INJECTIONº in ªACTIVE TESTº mode, and

select ªHO2S2 (B1)º as the monitor item with CONSULT-II.

4) Check ªHO2S2 (B1)º at idle speed when adjusting ªFUEL

INJECTIONº to±25%.

ªHO2S2 (B1)º should be above 0.68V at least once when

the ªFUEL INJECTIONº is +25%. ªHO2S2 (B1)º should be

below 0.45V at least once when the ªFUEL INJECTIONº is

þ25%.

CAUTION:

+Discard any heated oxygen sensor which has been

dropped from a height of more than 0.5 m (19.7 in) onto a

hard surface such as a concrete floor; use a new one.

+Before installing new oxygen sensor, clean exhaust sys-

tem threads using Oxygen Sensor Thread Cleaner tool

and approved anti-seize lubricant.

SEF244YC

HEATED OXYGEN SENSOR 2 (REAR)SR20DE

Diagnostic Procedure (Cont'd)

EC-961

Page 1387 of 3051

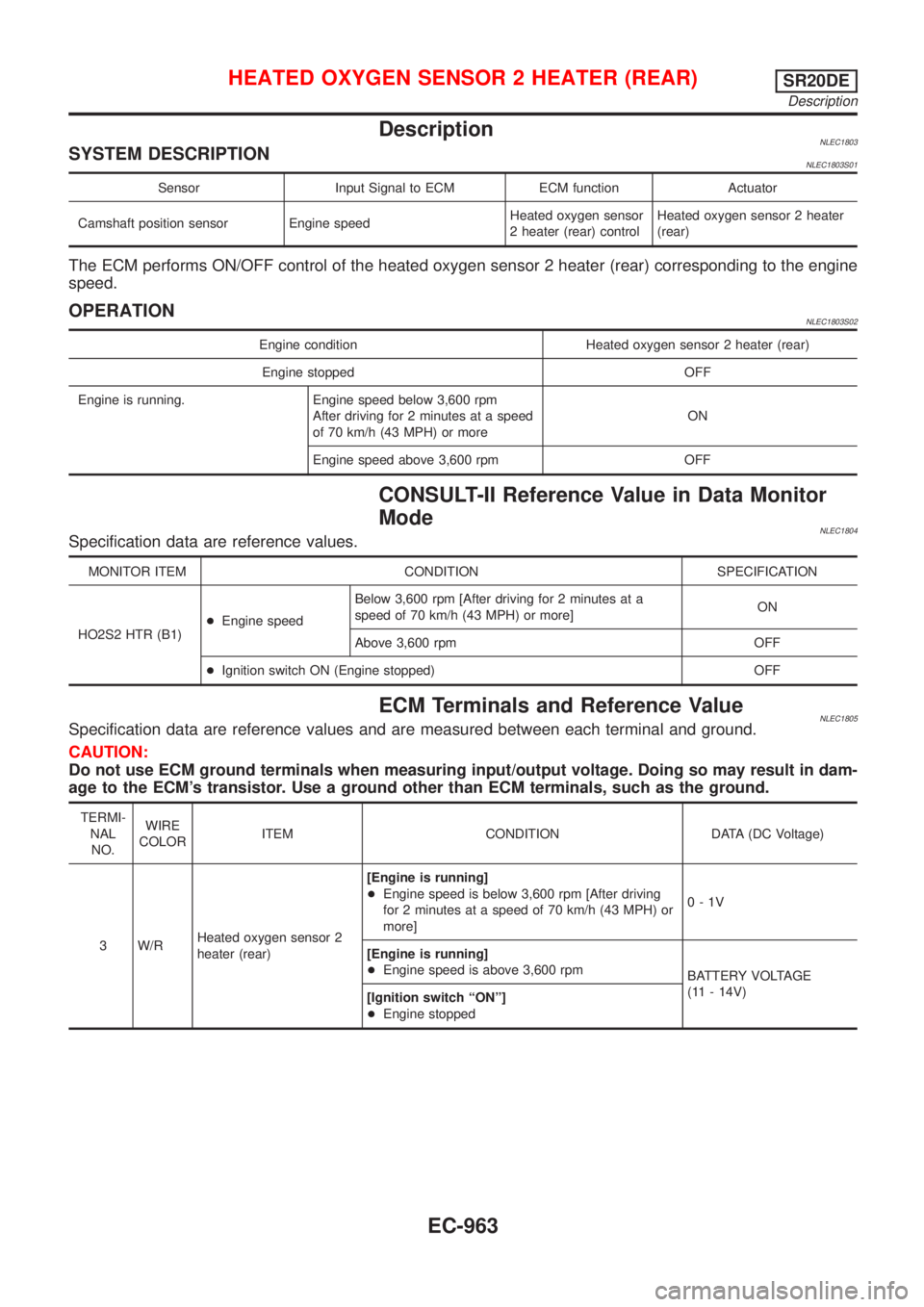

SEF032X

Without CONSULT-II

1) Start engine and drive vehicle at a speed of more than 70 km/h

(43 MPH) for 2 consecutive minutes.

2) Stop vehicle with engine running.

3) Set voltmeter probes between ECM terminals 63 (HO2S2 sig-

nal) and engine ground.

4) Check the voltage when revving up to 4,000 rpm under no load

at least 10 times.

(Depress and release accelerator pedal as soon as possible.)

The voltage should be above 0.68V at least once.

If the voltage is above 0.68V at step 4, step 5 is not nec-

essary.

5) Keep vehicle at idling for 10 minutes, then check the voltage.

Or check the voltage when coasting from 80 km/h (50 MPH)

in D position with ªSPORTS MODE SWº OFF.

The voltage should be below 0.45V at least once.

CAUTION:

+Discard any heated oxygen sensor which has been

dropped from a height of more than 0.5 m (19.7 in) onto a

hard surface such as a concrete floor; use a new one.

+Before installing new oxygen sensor, clean exhaust sys-

tem threads using Oxygen Sensor Thread Cleaner tool

and approved anti-seize lubricant.

HEATED OXYGEN SENSOR 2 (REAR)SR20DE

Component Inspection (Cont'd)

EC-962

Page 1388 of 3051

DescriptionNLEC1803SYSTEM DESCRIPTIONNLEC1803S01

Sensor Input Signal to ECM ECM function Actuator

Camshaft position sensor Engine speedHeated oxygen sensor

2 heater (rear) controlHeated oxygen sensor 2 heater

(rear)

The ECM performs ON/OFF control of the heated oxygen sensor 2 heater (rear) corresponding to the engine

speed.

OPERATIONNLEC1803S02

Engine condition Heated oxygen sensor 2 heater (rear)

Engine stopped OFF

Engine is running. Engine speed below 3,600 rpm

After driving for 2 minutes at a speed

of 70 km/h (43 MPH) or moreON

Engine speed above 3,600 rpm OFF

CONSULT-II Reference Value in Data Monitor

Mode

NLEC1804Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

HO2S2 HTR (B1)+Engine speedBelow 3,600 rpm [After driving for 2 minutes at a

speed of 70 km/h (43 MPH) or more]ON

Above 3,600 rpm OFF

+Ignition switch ON (Engine stopped) OFF

ECM Terminals and Reference ValueNLEC1805Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

3 W/RHeated oxygen sensor 2

heater (rear)[Engine is running]

+Engine speed is below 3,600 rpm [After driving

for 2 minutes at a speed of 70 km/h (43 MPH) or

more]0-1V

[Engine is running]

+Engine speed is above 3,600 rpm

BATTERY VOLTAGE

(11 - 14V)

[Ignition switch ªONº]

+Engine stopped

HEATED OXYGEN SENSOR 2 HEATER (REAR)SR20DE

Description

EC-963

Page 1389 of 3051

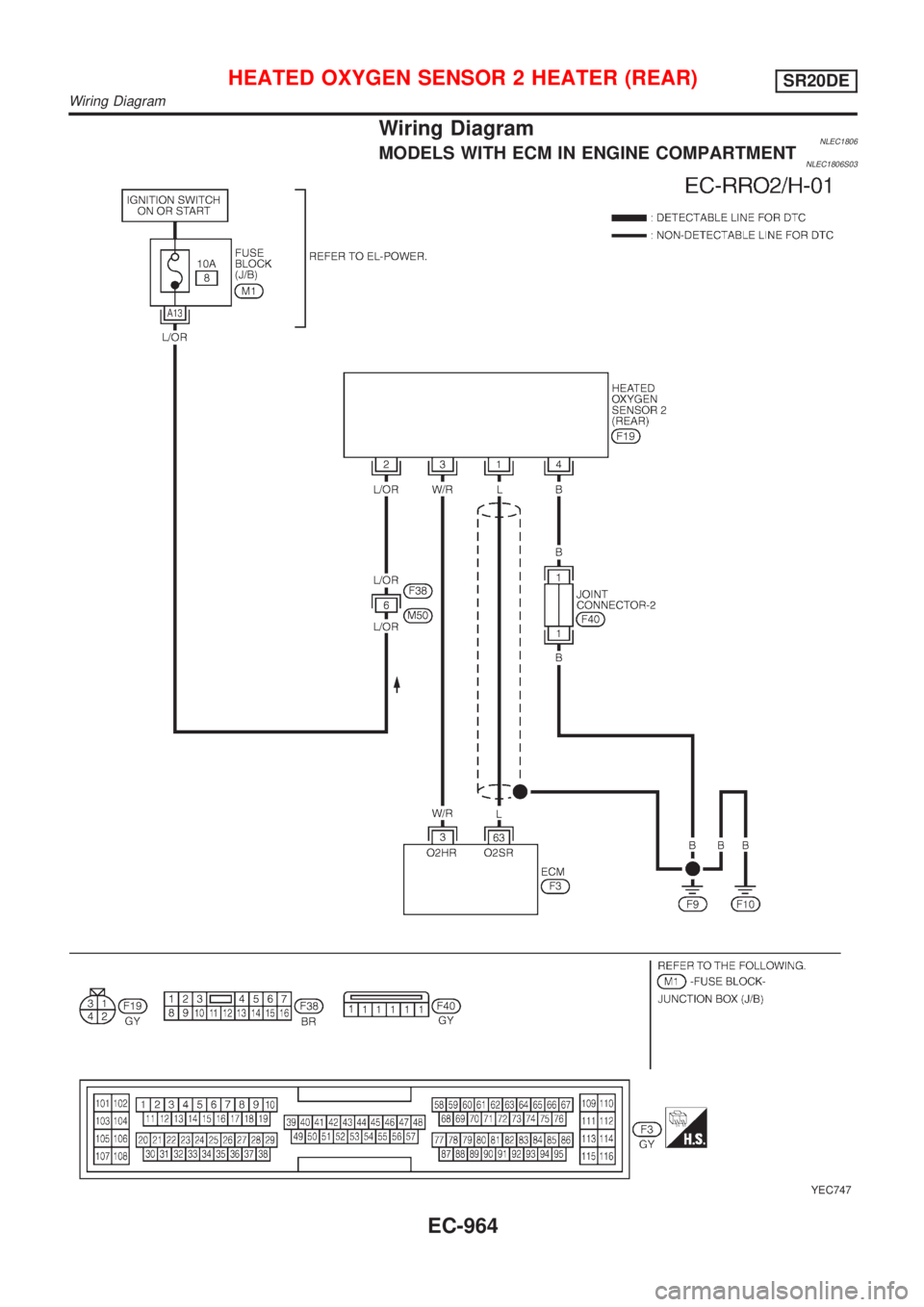

Wiring DiagramNLEC1806MODELS WITH ECM IN ENGINE COMPARTMENTNLEC1806S03

YEC747

HEATED OXYGEN SENSOR 2 HEATER (REAR)SR20DE

Wiring Diagram

EC-964

Page 1390 of 3051

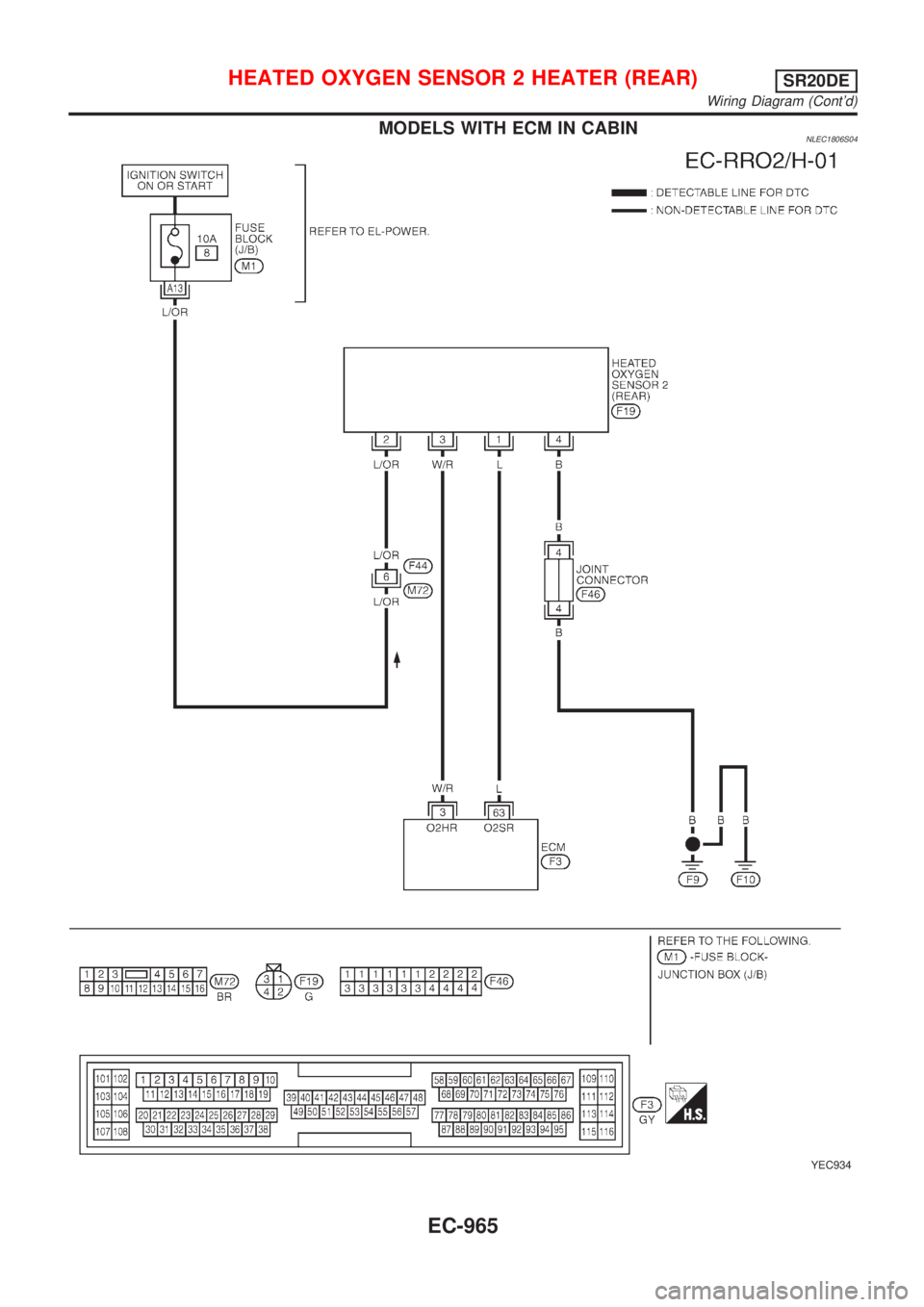

MODELS WITH ECM IN CABINNLEC1806S04

YEC934

HEATED OXYGEN SENSOR 2 HEATER (REAR)SR20DE

Wiring Diagram (Cont'd)

EC-965