NISSAN ALMERA TINO 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 2791 of 3051

ASSEMBLY.............................................................42

Final Drive..................................................................47

PRE-INSPECTION...................................................47

DISASSEMBLY........................................................48

INSPECTION...........................................................49

ASSEMBLY.............................................................49

Shift Control Components .........................................51

INSPECTION...........................................................51

ASSEMBLY....................................................................52

Clutch Housing ..........................................................52

Transaxle Case ..........................................................56

RS5F50A

OVERHAUL...................................................................62

Case Components .....................................................62

Gear Components .....................................................63

Shift Control Components .........................................64

DISASSEMBLY..............................................................65

REPAIR FOR COMPONENT PARTS...........................68

Input Shaft and Gears ...............................................68

DISASSEMBLY........................................................68

INSPECTION...........................................................69

ASSEMBLY.............................................................70

Mainshaft and Gears .................................................73

DISASSEMBLY........................................................73

INSPECTION...........................................................74

ASSEMBLY.............................................................75

Final Drive..................................................................77

DISASSEMBLY........................................................77

INSPECTION...........................................................77

ASSEMBLY.............................................................78

Shift Control Components .........................................79

INSPECTION...........................................................79

Case Components .....................................................79

REMOVAL AND INSTALLATION...............................79

ADJUSTMENT...............................................................81

Input Shaft End Play and Differential Side

Bearing Preload .........................................................81

DIFFERENTIAL SIDE...............................................81

INPUT SHAFT SIDE.................................................82

Mainshaft Bearing Preload ........................................82

ASSEMBLY....................................................................84

RS5F70A

SERVICE DATA AND SPECIFICATIONS (SDS).........88

General Specifications ...............................................88

TRANSAXLE...........................................................88

FINAL GEAR...........................................................88

Gear End Play ...........................................................89

Clearance Coupling Sleeve .......................................89

1ST, 2ND, 3RD, 4TH, 5TH & REVERSE

COUPLING SLEEVE

................................................89

Clearance Between Baulk Ring and Gear ................89

3RD, 4TH, 5TH, REVERSE BAULK RING..................89

1ST AND 2ND DOUBLE BAULK RING......................89

Available Snap Rings ................................................90

SNAP RING.............................................................90

Available C-rings........................................................90

4TH INPUT GEAR C-RING.......................................90

5TH INPUT GEAR REAR C-RING.............................90

MAINSHAFT C-RING...............................................91

Available Adjusting Shims .........................................92

INPUT SHAFT REAR BEARING ADJUSTING

SHIM

......................................................................92

MAINSHAFT ADJUSTING SHIM................................93

MAINSHAFT REAR BEARING ADJUSTING SHIM......93

Available Thrust Washer............................................94

MAINSHAFT THRUST WASHER...............................94

Available Washers .....................................................94

DIFFERENTIAL SIDE GEAR THRUST WASHER........94

Available Shims - Differential Side Bearing

Preload and Adjusting Shim ......................................95

BEARING PRELOAD...............................................95

DIFFERENTIAL SIDE BEARING ADJUSTING

SHIMS

....................................................................95

RS5F50A

SERVICE DATA AND SPECIFICATIONS (SDS).........96

General Specifications ...............................................96

TRANSAXLE...........................................................96

FINAL GEAR...........................................................96

Gear End Play ...........................................................97

Clearance Between Baulk Ring and Gear ................97

3RD, 4TH & 5TH BAULK RING.................................97

1ST AND 2ND DOUBLE BAULK RING......................97

REVERSE BAULK RING..........................................97

Available Snap Rings ................................................98

1ST & 2ND SYNCHRONIZER HUB (AT

MAINSHAFT)

...........................................................98

3RD & 4TH SYNCHRONIZER HUB (AT INPUT

SHAFT)

...................................................................98

5TH MAIN GEAR (AT MAINSHAFT)..........................98

Available Thrust Washer............................................98

4TH INPUT GEAR (AT INPUT SHAFT)......................98

DIFFERENTIAL SIDE GEAR THRUST WASHER........98

Available Shims .........................................................99

BEARING PRELOAD AND END PLAY......................99

TOTAL TURNING TORQUE (NEW BEARING)............99

MAINSHAFT BEARING ADJUSTING SHIM................99

TABLE FOR SELECTING MAINSHAFT BEARING

ADJUSTING SHIM(S)

...............................................99

INPUT SHAFT BEARING ADJUSTING SHIM...........100

TABLE FOR SELECTING INPUT SHAFT BEARING

ADJUSTING SHIM(S)

.............................................100

DIFFERENTIAL SIDE BEARING ADJUSTING

SHIM

....................................................................100

TABLE FOR SELECTING DIFFERENTIAL SIDE

BEARING ADJUSTING SHIM(S)

.............................101

CONTENTS(Cont’d)

MT-2

Page 2792 of 3051

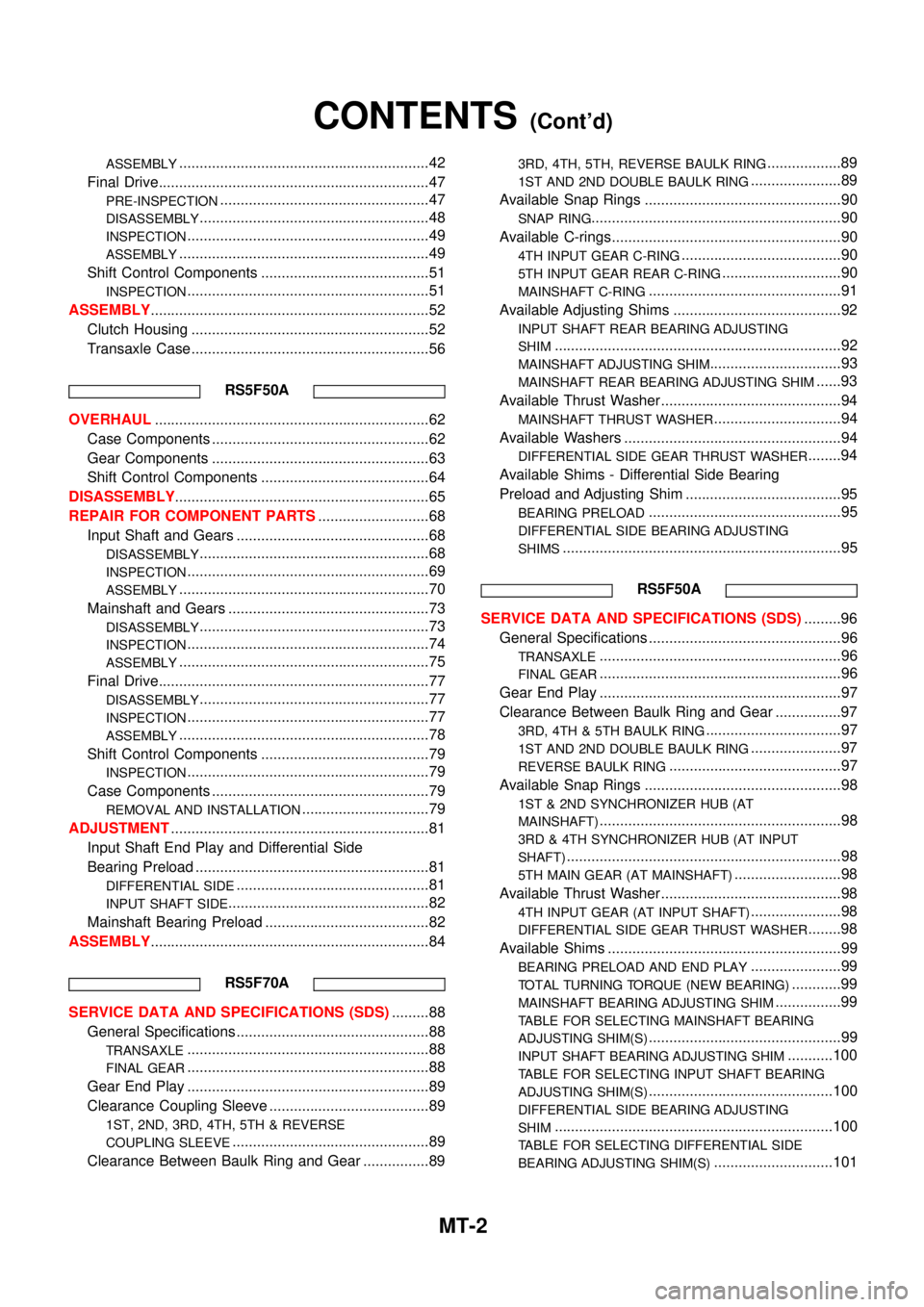

Special Service ToolsNLMT0032

Tool number

Tool nameDescription

KV38107700

Preload adapter

NT087

Measuring turning torque of final drive assembly

Measuring total turning torque

Measuring clearance between side gear and differ-

ential case with washer

Selecting differential side bearing adjusting shim

(Use with KV38106000.)

KV38106000

Height gauge adapter

(differential side bearing)

NT418

Selecting differential side bearing adjusting shim

(Use with KV38107700.)

a: 140 mm (5.51 in)

b: 40 mm (1.57 in)

c: 16 mm (0.63 in) dia.

d: M8 x 1.25P

KV32101000

Pin punch

NT410

Removing and installing retaining pin

Removing and installing lock pin

Removing selector shaft

Removing welch plug

a: 4 mm (0.16 in) dia.

KV31100300

Pin punch

NT410

Removing and installing retaining pin

a: 4.5 mm (0.177 in) dia.

ST30031000

Puller

NT411

Removing 3rd, 5th input gear

Removing 3rd & 4th and 5th & Rev synchronizer

hub

Removing mainshaft rear bearing

Removing 2nd gear, 5th gear bush

Removing 1st & 2nd synchronizer hub, 1st and

4th main gear

Removing and installing differential side bearing

a: 90 mm (3.54 in) dia.

b: 50 mm (1.97 in) dia.

ST30021000

Puller

NT411

Removing input shaft front and rear bearing

Installing input shaft front and rear bearing

Installing 5th input gear, 3rd main gear and 4th

main gear

Installing 1st & 2nd, 3rd & 4th and 5th & Rev syn-

chronizer hub

Installing 2nd gear bush, 5th gear bush, Rev gear

bush

Installing mainshaft rear bearing

a: 110 mm (4.33 in) dia.

b: 68 mm (2.68 in) dia.

PREPARATIONRS5F70A

Special Service Tools

MT-3

Page 2793 of 3051

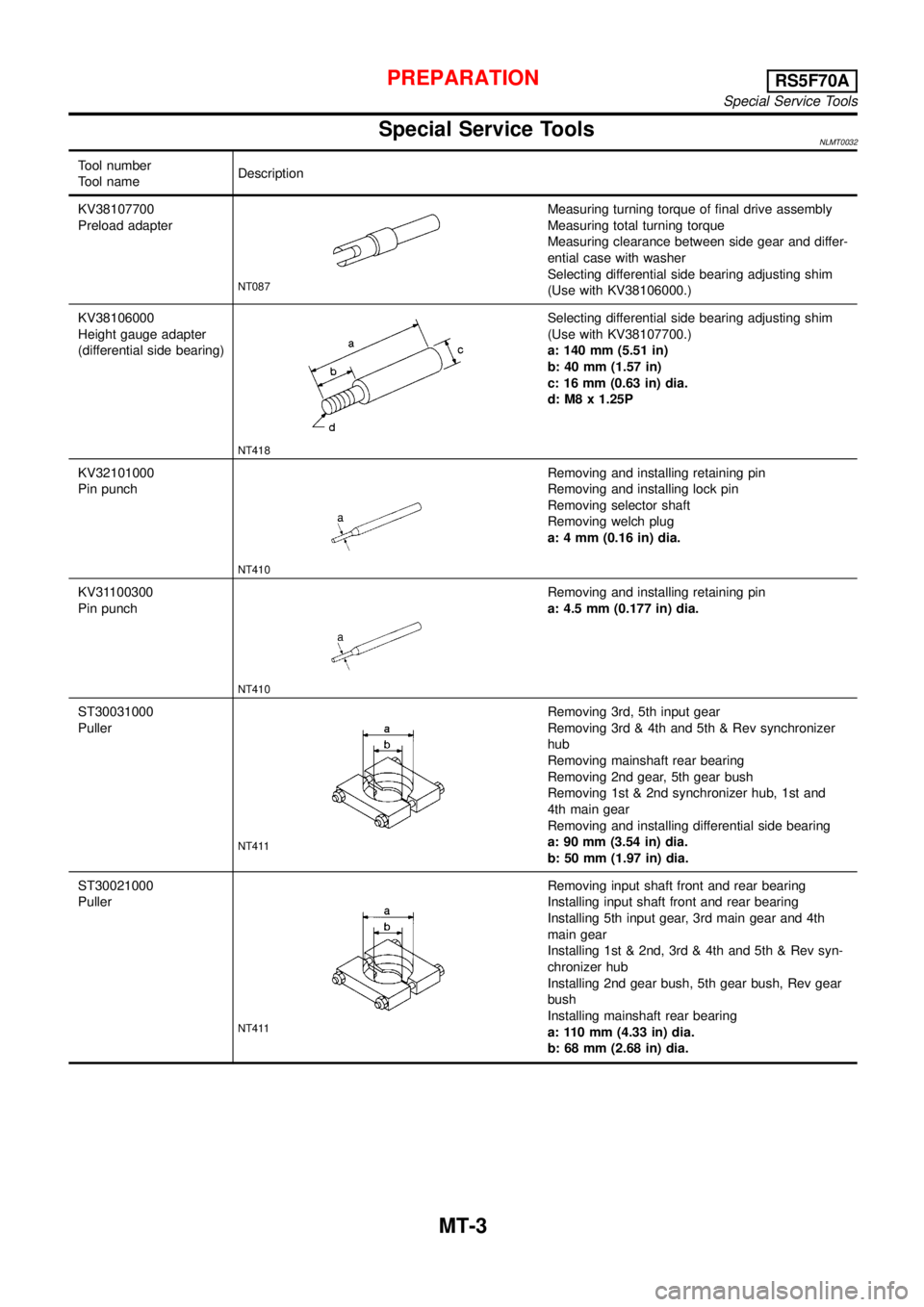

Tool number

Tool nameDescription

ST33290001

Puller

NT414

Removing idler gear bearing outer race

a: 250 mm (9.84 in)

b: 160 mm (6.30 in)

ST33230000

Drift

NT084

Removing differential oil seal

Installing differential side bearing

a: 51 mm (2.01 in) dia.

b: 28.5 mm (1.122 in) dia.

ST30720000

Drift

NT115

Installing differential side bearing outer race

a: 77 mm (3.03 in) dia.

b: 55.5 mm (2.185 in) dia.

ST22350000

Drift

NT065

Installing input shaft front and rear bearing

a: 34 mm (1.34 in) dia.

b: 28 mm (1.10 in) dia.

ST22452000

Drift

NT065

Installing 3rd and 4th main gear

Installing 5th gear bush

Installing 5th & Rev synchronizer hub

Installing Rev gear bush

Installing mainshaft rear bearing

a: 45 mm (1.77 in) dia.

b: 36 mm (1.42 in) dia.

ST37750000

Drift

NT065

Installing input shaft oil seal

Installing 5th synchronizer

Installing mainshaft rear bearing

Installing 5th main gear

Installing 3rd & 4th synchronizer hub

Installing striking rod oil seal

Installing clutch housing dust seal

a: 40 mm (1.57 in) dia.

b: 31 mm (1.22 in) dia.

PREPARATIONRS5F70A

Special Service Tools (Cont’d)

MT-4

Page 2794 of 3051

Commercial Service ToolsNLMT0033

Tool name Description

Drift

NT065

Installing welch plug

a: 12 mm (0.47 in) dia.

b: 10 mm (0.39 in) dia.

Drift

NT065

Removing input shaft rear bearing

Removing mainshaft rear bearing

a: 22 mm (0.87 in) dia.

b: 16 mm (0.63 in) dia.

Drift

NT065

Installing differential oil seal

a: 58 mm (2.28 in) dia.

b: 50 mm (1.97 in) dia.

Drift

NT065

Installing differential oil seal

a: 54 mm (2.13 in) dia.

b: 50 mm (1.97 in) dia.

Drift

NT065

Installing 2nd gear bush

a: 38 mm (1.50 in) dia.

b: 33 mm (1.30 in) dia.

Drift

NT065

Installing 3rd & 4th and 1st & 2nd synchronizer

hub

Installing mainshaft front bearing

a: 50 mm (1.97 in) dia.

b: 41 mm (1.61 in) dia.

Drift

NT065

Installing input shaft oil seal

Installing 5th input gear

a: 39 mm (1.54 in) dia.

b: 30 mm (1.18 in) dia.

PREPARATIONRS5F70A

Commercial Service Tools

MT-5

Page 2795 of 3051

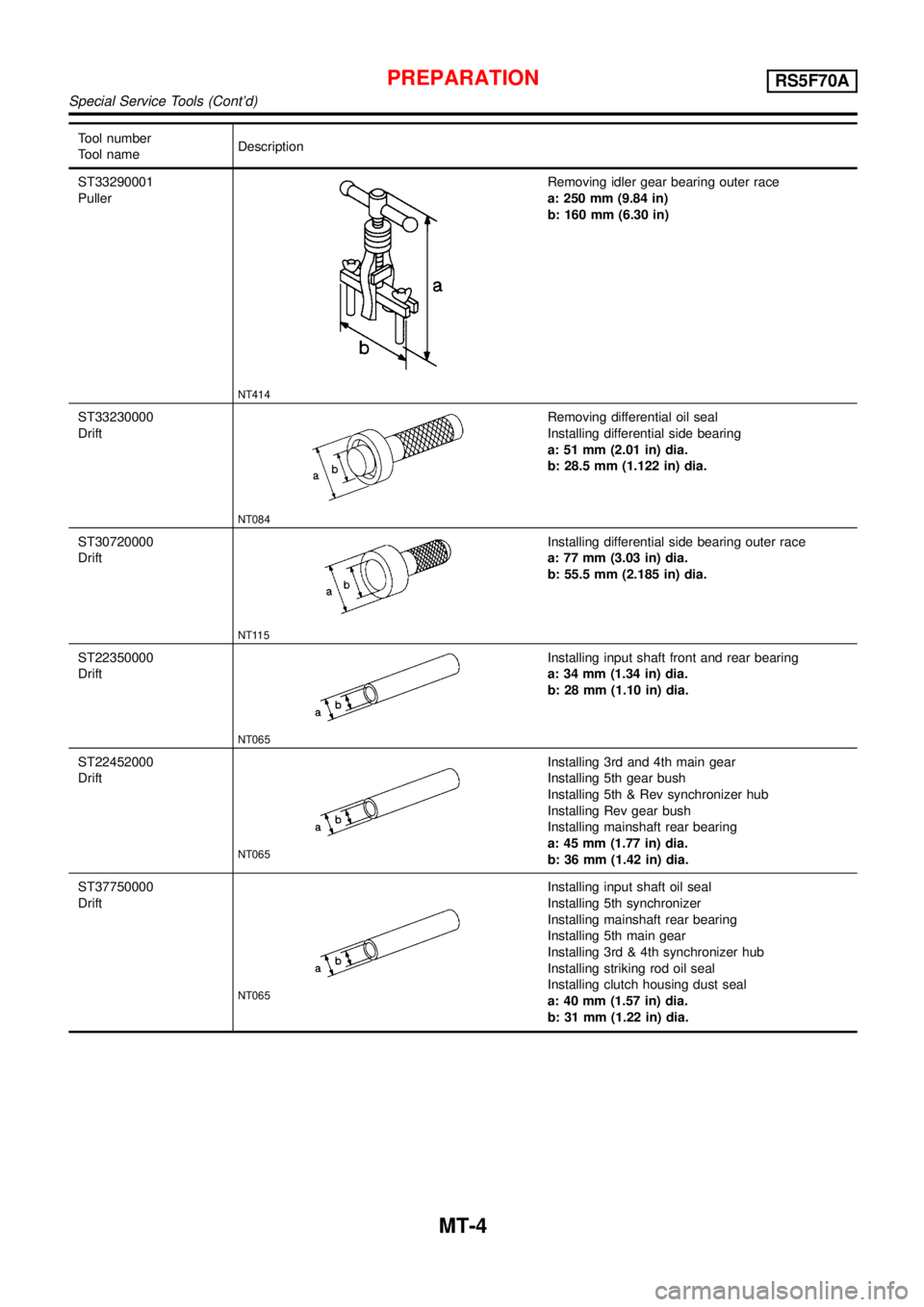

Special Service ToolsNLMT0001

Tool number

Tool nameDescription

KV38105210

Preload adapter

NT075

Measuring turning torque of final drive assembly

Measuring total turning torque

KV32101000

Pin punch

NT410

Removing and installing retaining pin

a: 4 mm (0.16 in) dia.

ST22730000

Puller

NT411

Removing mainshaft front and rear bearing inner

race

a: 82 mm (3.23 in) dia.

b: 30 mm (1.18 in) dia.

ST30031000

Puller

NT411

Removing input shaft front and rear bearing

Removing 4th & 5th main gear

a: 90 mm (3.54 in) dia.

b: 50 mm (1.97 in) dia.

ST30021000

Puller

NT411

Removing 5th synchronizer

Removing 3rd & 4th synchronizer

Removing 2nd & 3rd main gear

a: 110 mm (4.33 in) dia.

b: 68 mm (2.68 in) dia.

ST3306S001

Differential side bearing

puller set

1 ST33051001

Puller

2 ST33061000

Adapter

NT675

Removing differential side bearing inner race

a: 38 mm (1.50 in) dia.

b: 28.5 mm (1.122 in) dia.

c: 130 mm (5.12 in)

d: 135 mm (5.31 in)

e: 100 mm (3.94 in)

PREPARATIONRS5F50A

Special Service Tools

MT-6

Page 2796 of 3051

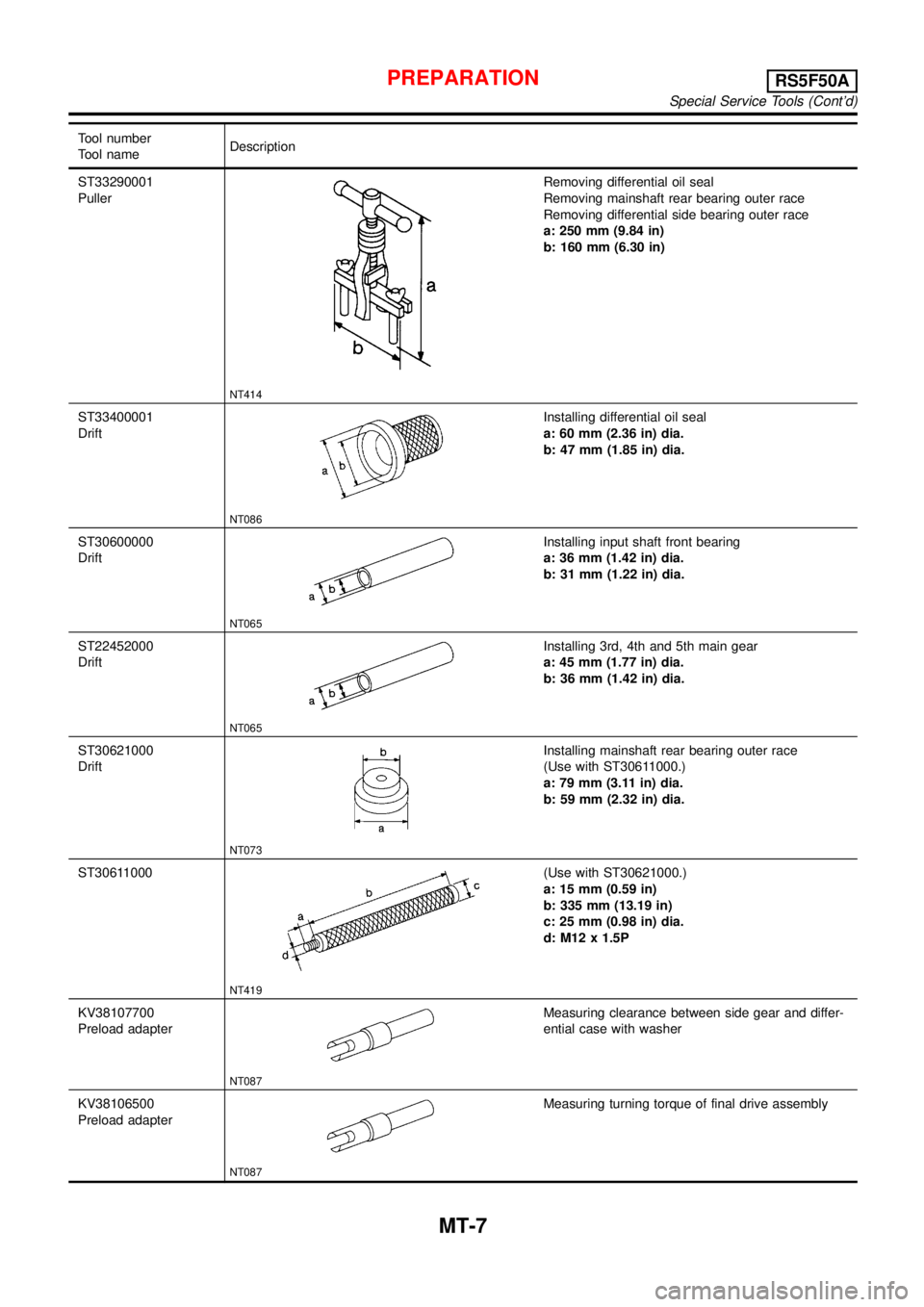

Tool number

Tool nameDescription

ST33290001

Puller

NT414

Removing differential oil seal

Removing mainshaft rear bearing outer race

Removing differential side bearing outer race

a: 250 mm (9.84 in)

b: 160 mm (6.30 in)

ST33400001

Drift

NT086

Installing differential oil seal

a: 60 mm (2.36 in) dia.

b: 47 mm (1.85 in) dia.

ST30600000

Drift

NT065

Installing input shaft front bearing

a: 36 mm (1.42 in) dia.

b: 31 mm (1.22 in) dia.

ST22452000

Drift

NT065

Installing 3rd, 4th and 5th main gear

a: 45 mm (1.77 in) dia.

b: 36 mm (1.42 in) dia.

ST30621000

Drift

NT073

Installing mainshaft rear bearing outer race

(Use with ST30611000.)

a: 79 mm (3.11 in) dia.

b: 59 mm (2.32 in) dia.

ST30611000

NT419

(Use with ST30621000.)

a: 15 mm (0.59 in)

b: 335 mm (13.19 in)

c: 25 mm (0.98 in) dia.

d: M12 x 1.5P

KV38107700

Preload adapter

NT087

Measuring clearance between side gear and differ-

ential case with washer

KV38106500

Preload adapter

NT087

Measuring turning torque of final drive assembly

PREPARATIONRS5F50A

Special Service Tools (Cont’d)

MT-7

Page 2797 of 3051

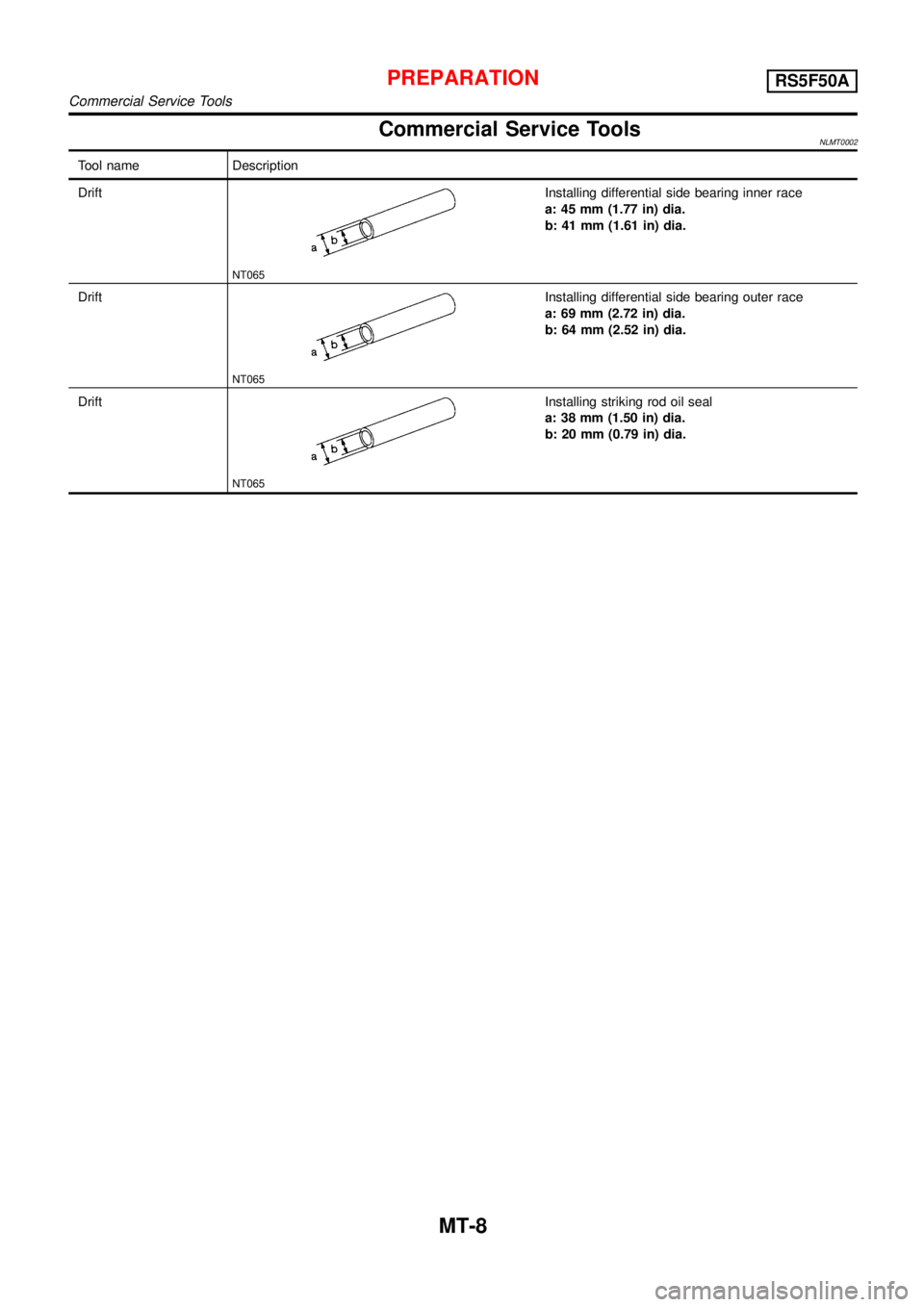

Commercial Service ToolsNLMT0002

Tool name Description

Drift

NT065

Installing differential side bearing inner race

a: 45 mm (1.77 in) dia.

b: 41 mm (1.61 in) dia.

Drift

NT065

Installing differential side bearing outer race

a: 69 mm (2.72 in) dia.

b: 64 mm (2.52 in) dia.

Drift

NT065

Installing striking rod oil seal

a: 38 mm (1.50 in) dia.

b: 20 mm (0.79 in) dia.

PREPARATIONRS5F50A

Commercial Service Tools

MT-8

Page 2798 of 3051

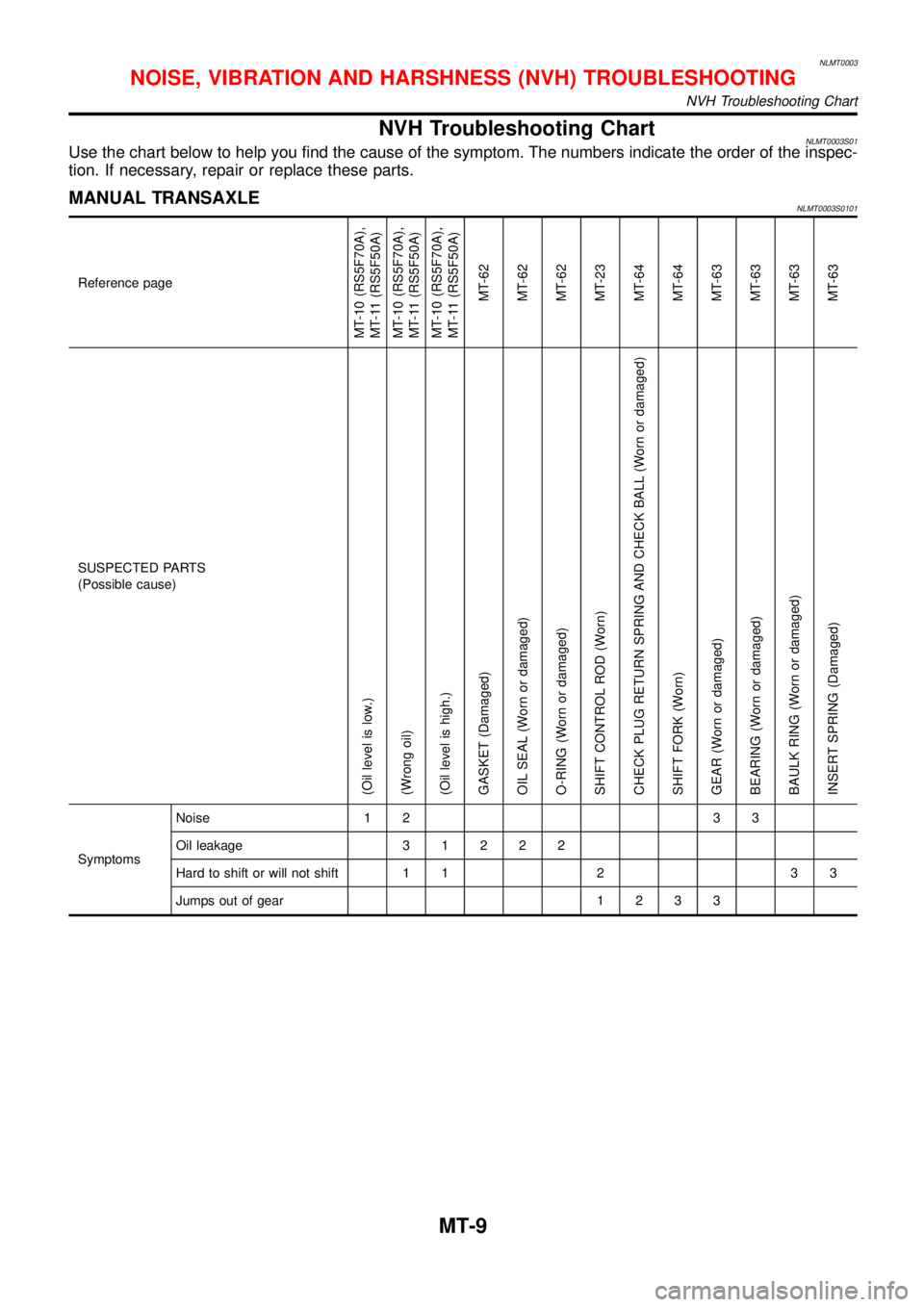

NLMT0003

NVH Troubleshooting ChartNLMT0003S01Use the chart below to help you find the cause of the symptom. The numbers indicate the order of the inspec-

tion. If necessary, repair or replace these parts.

MANUAL TRANSAXLENLMT0003S0101

Reference page

MT-10 (RS5F70A),

MT-11 (RS5F50A)

MT-10 (RS5F70A),

MT-11 (RS5F50A)

MT-10 (RS5F70A),

MT-11 (RS5F50A)

MT-62

MT-62

MT-62

MT-23

MT-64

MT-64

MT-63

MT-63

MT-63

MT-63

SUSPECTED PARTS

(Possible cause)

(Oil level is low.)

(Wrong oil)

(Oil level is high.)

GASKET (Damaged)

OIL SEAL (Worn or damaged)

O-RING (Worn or damaged)

SHIFT CONTROL ROD (Worn)

CHECK PLUG RETURN SPRING AND CHECK BALL (Worn or damaged)

SHIFT FORK (Worn)

GEAR (Worn or damaged)

BEARING (Worn or damaged)

BAULK RING (Worn or damaged)

INSERT SPRING (Damaged)

SymptomsNoise 1 2 3 3

Oil leakage31222

Hard to shift or will not shift 1 1 2 3 3

Jumps out of gear1233

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart

MT-9

Page 2799 of 3051

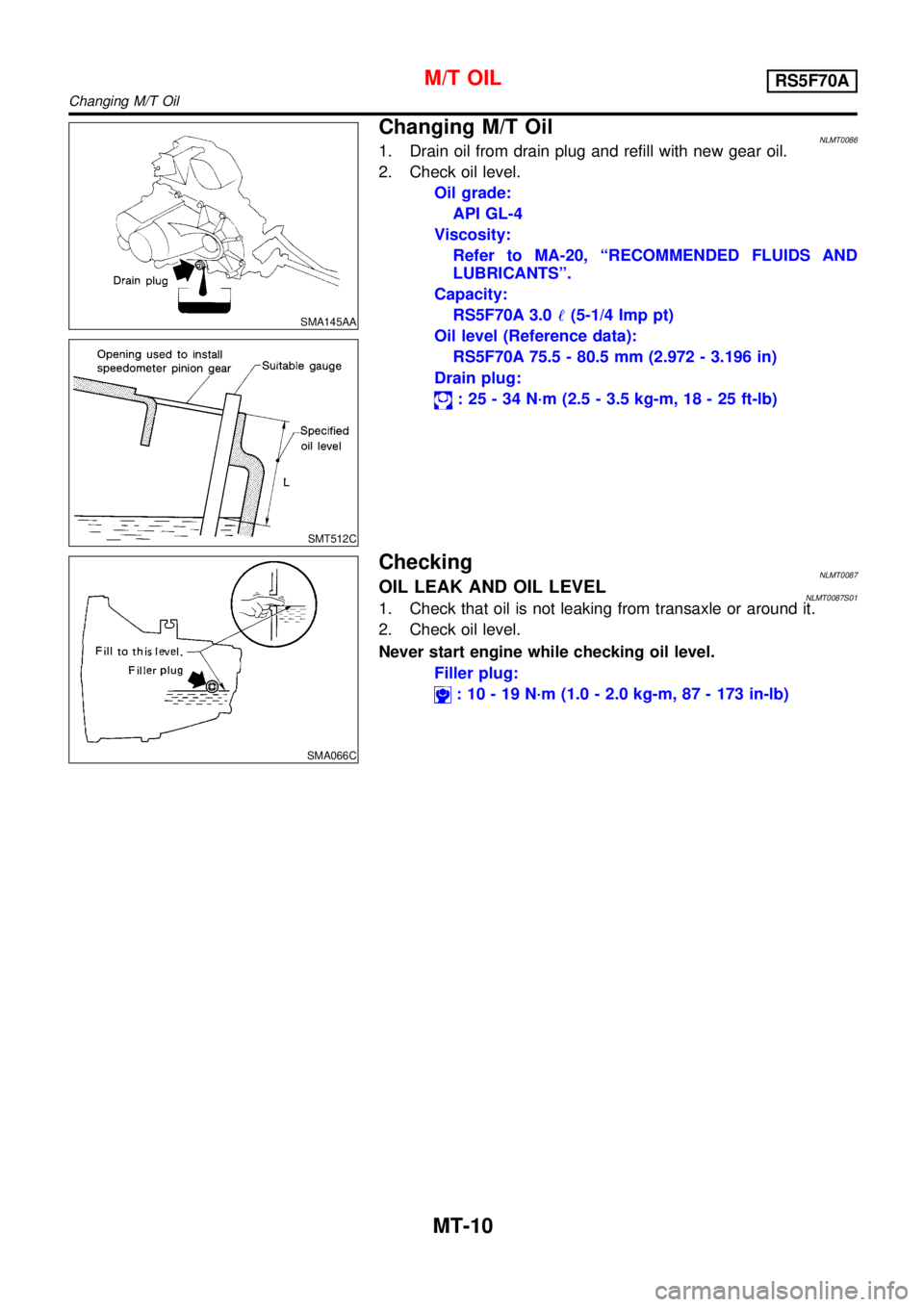

SMA145AA

SMT512C

Changing M/T OilNLMT00861. Drain oil from drain plug and refill with new gear oil.

2. Check oil level.

Oil grade:

API GL-4

Viscosity:

Refer to MA-20,“RECOMMENDED FLUIDS AND

LUBRICANTS”.

Capacity:

RS5F70A 3.0!(5-1/4 Imp pt)

Oil level (Reference data):

RS5F70A 75.5 - 80.5 mm (2.972 - 3.196 in)

Drain plug:

:25-34N·m (2.5 - 3.5 kg-m, 18 - 25 ft-lb)

SMA066C

CheckingNLMT0087OIL LEAK AND OIL LEVELNLMT0087S011. Check that oil is not leaking from transaxle or around it.

2. Check oil level.

Never start engine while checking oil level.

Filler plug:

:10-19N·m (1.0 - 2.0 kg-m, 87 - 173 in-lb)

M/T OILRS5F70A

Changing M/T Oil

MT-10

Page 2800 of 3051

SMA067C

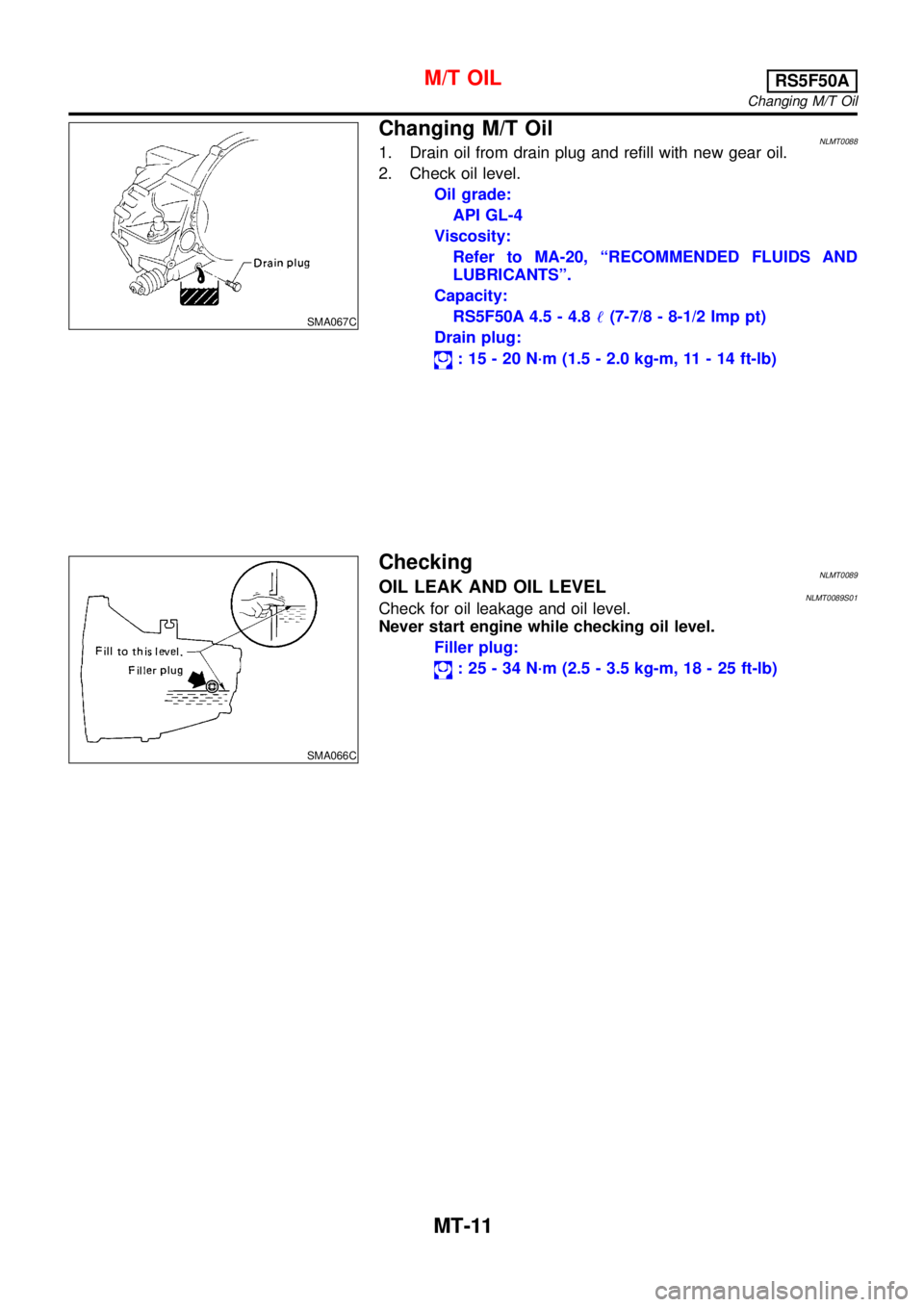

Changing M/T OilNLMT00881. Drain oil from drain plug and refill with new gear oil.

2. Check oil level.

Oil grade:

API GL-4

Viscosity:

Refer to MA-20,“RECOMMENDED FLUIDS AND

LUBRICANTS”.

Capacity:

RS5F50A 4.5 - 4.8!(7-7/8 - 8-1/2 Imp pt)

Drain plug:

:15-20N·m (1.5 - 2.0 kg-m, 11 - 14 ft-lb)

SMA066C

CheckingNLMT0089OIL LEAK AND OIL LEVELNLMT0089S01Check for oil leakage and oil level.

Never start engine while checking oil level.

Filler plug:

:25-34N·m (2.5 - 3.5 kg-m, 18 - 25 ft-lb)

M/T OILRS5F50A

Changing M/T Oil

MT-11