NISSAN ALMERA TINO 2001 Service Repair Manual

ALMERA TINO 2001

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57352/w960_57352-0.png

NISSAN ALMERA TINO 2001 Service Repair Manual

Trending: window, coolant reservoir, mirror, fuse box location, oil, light, Reset service

Page 2801 of 3051

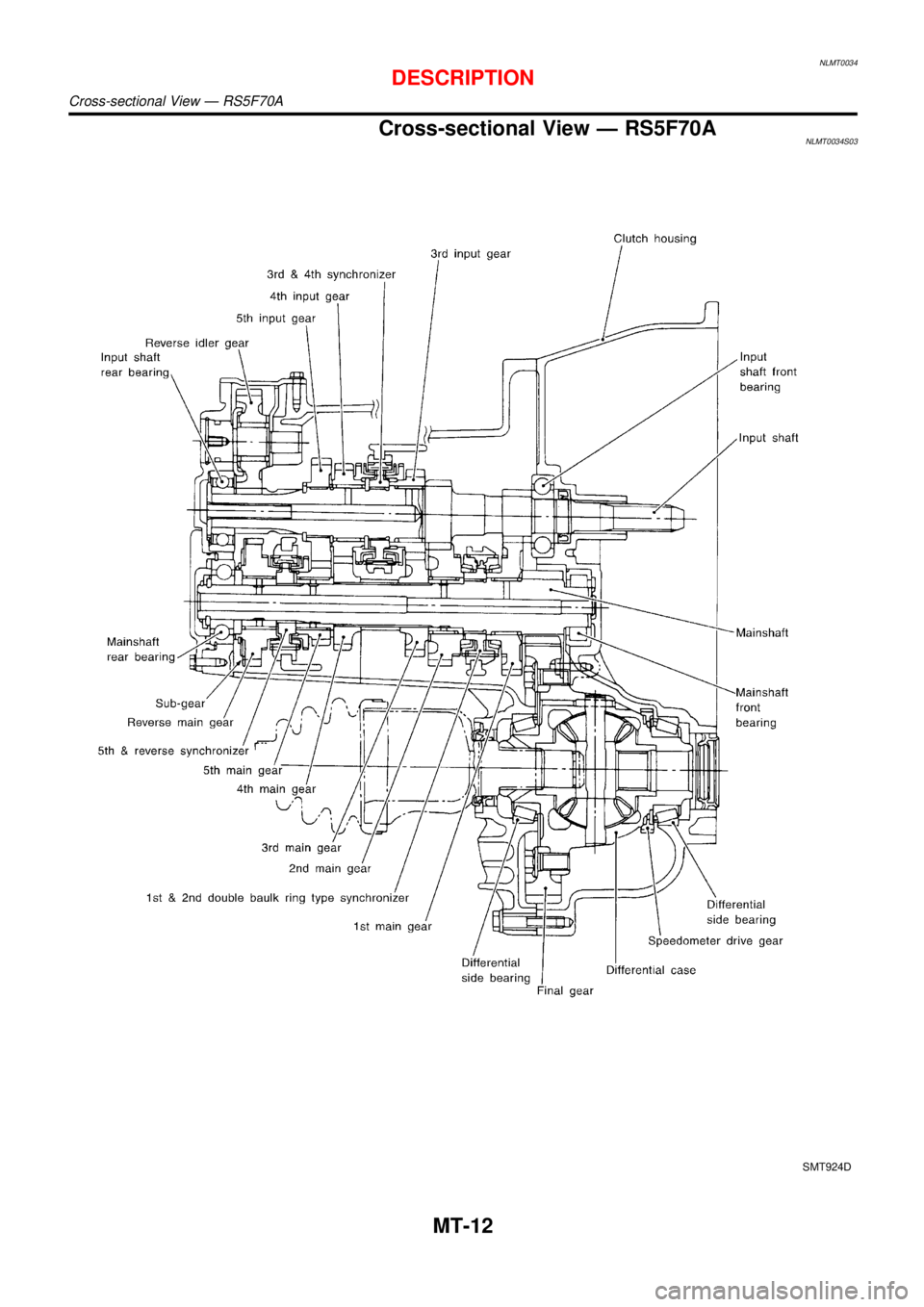

NLMT0034

Cross-sectional View—RS5F70ANLMT0034S03

SMT924D

DESCRIPTION

Cross-sectional View—RS5F70A

MT-12

Page 2802 of 3051

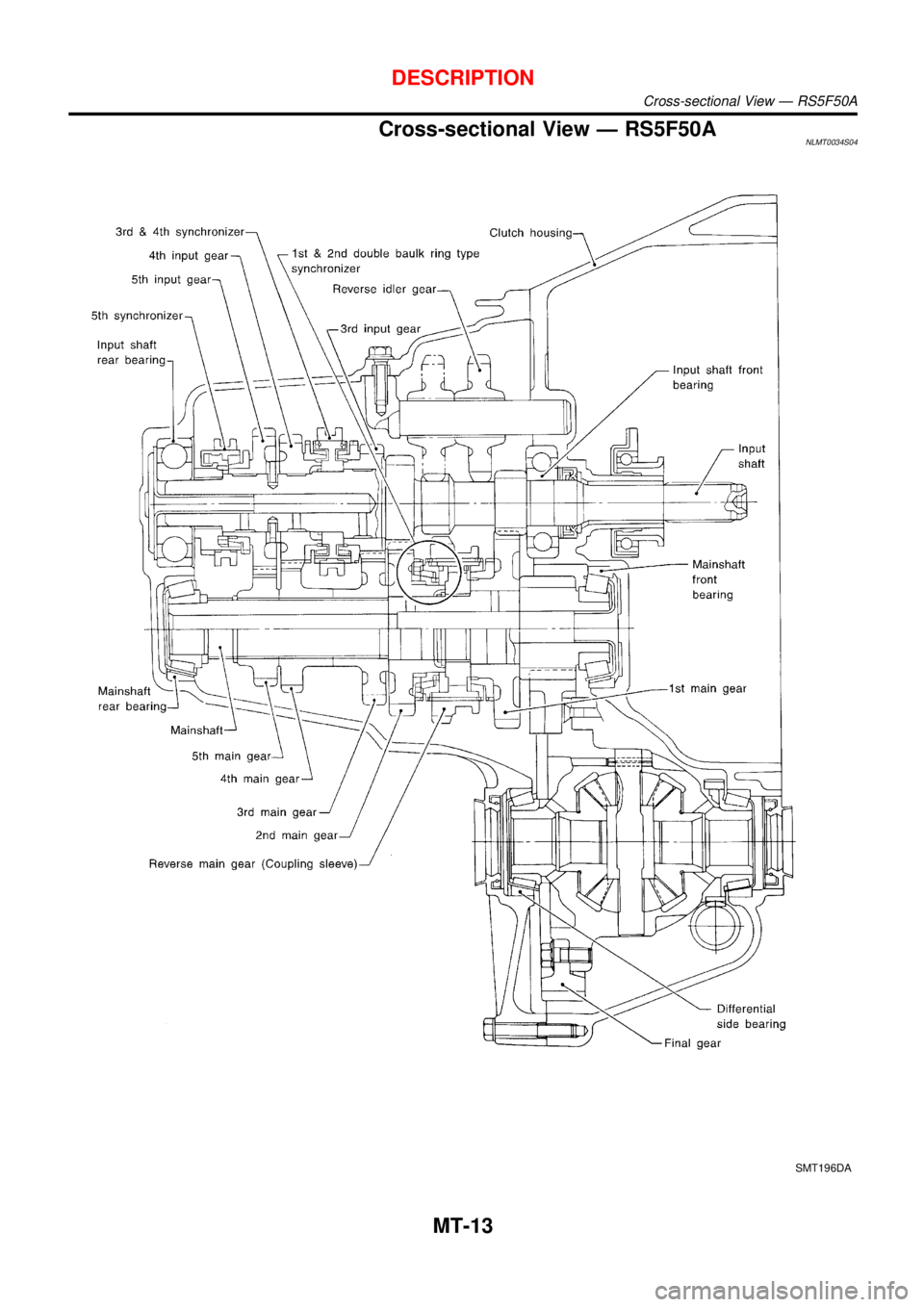

Cross-sectional View—RS5F50ANLMT0034S04

SMT196DA

DESCRIPTION

Cross-sectional View—RS5F50A

MT-13

Page 2803 of 3051

SMT837DA

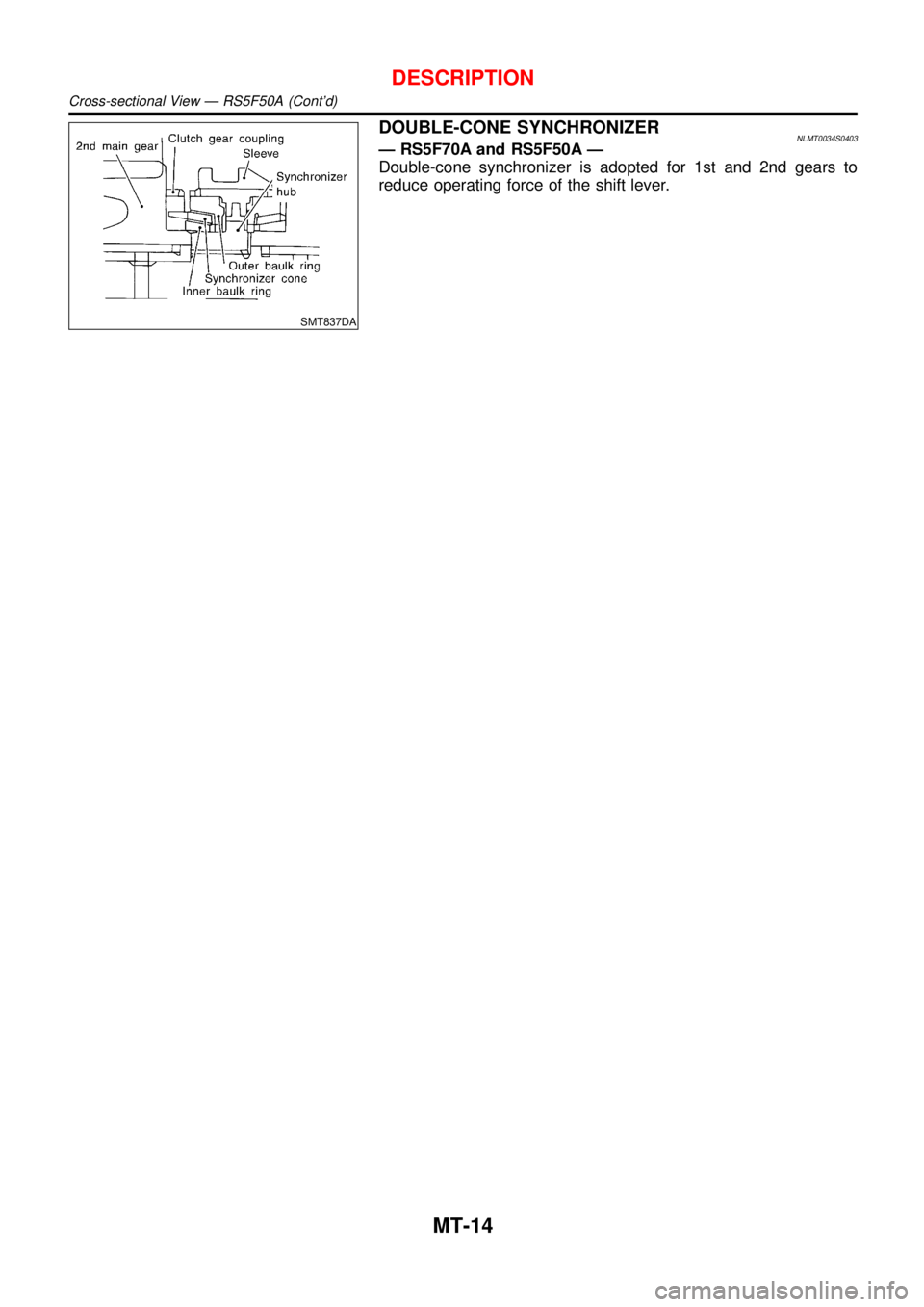

DOUBLE-CONE SYNCHRONIZERNLMT0034S0403—RS5F70A and RS5F50A—

Double-cone synchronizer is adopted for 1st and 2nd gears to

reduce operating force of the shift lever.

DESCRIPTION

Cross-sectional View—RS5F50A (Cont’d)

MT-14

Page 2804 of 3051

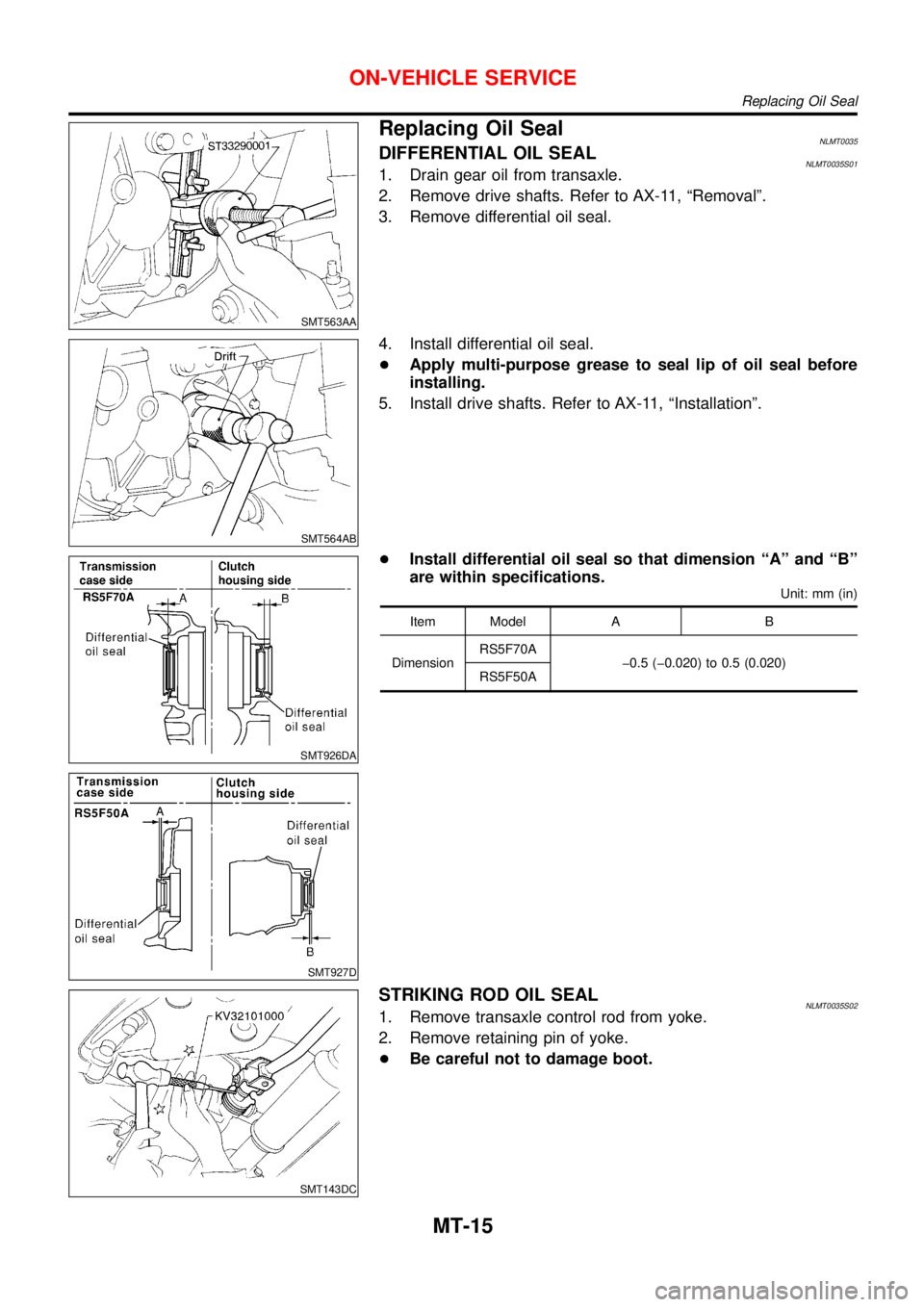

SMT563AA

Replacing Oil SealNLMT0035DIFFERENTIAL OIL SEALNLMT0035S011. Drain gear oil from transaxle.

2. Remove drive shafts. Refer to AX-11, “Removal”.

3. Remove differential oil seal.

SMT564AB

4. Install differential oil seal.

+Apply multi-purpose grease to seal lip of oil seal before

installing.

5. Install drive shafts. Refer to AX-11, “Installation”.

SMT926DA

SMT927D

+Install differential oil seal so that dimension“A”and“B”

are within specifications.

Unit: mm (in)

Item Model A B

DimensionRS5F70A

�0.5 (�0.020) to 0.5 (0.020)

RS5F50A

SMT143DC

STRIKING ROD OIL SEALNLMT0035S021. Remove transaxle control rod from yoke.

2. Remove retaining pin of yoke.

+Be careful not to damage boot.

ON-VEHICLE SERVICE

Replacing Oil Seal

MT-15

Page 2805 of 3051

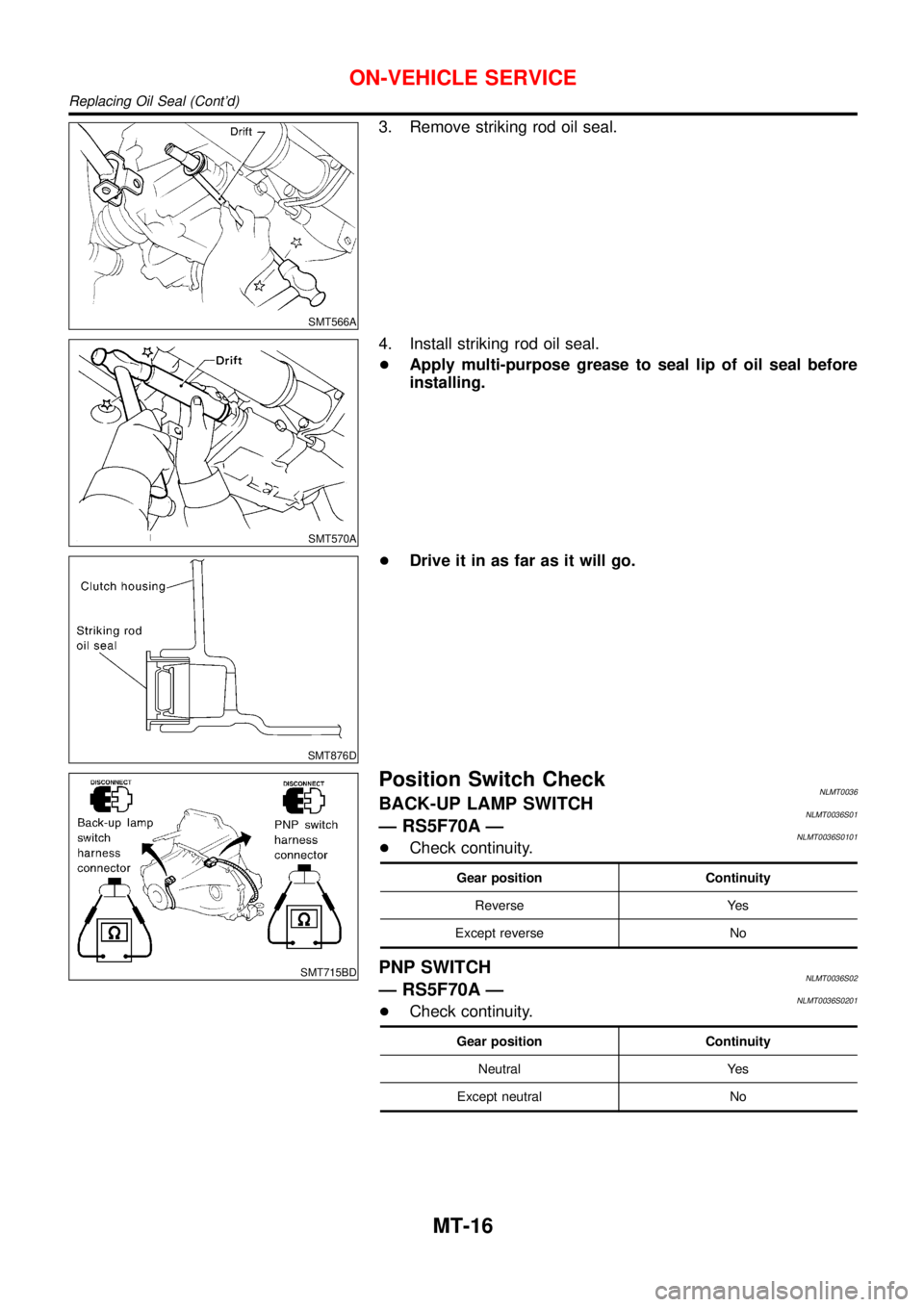

SMT566A

3. Remove striking rod oil seal.

SMT570A

4. Install striking rod oil seal.

+Apply multi-purpose grease to seal lip of oil seal before

installing.

SMT876D

+Drive it in as far as it will go.

SMT715BD

Position Switch CheckNLMT0036BACK-UP LAMP SWITCHNLMT0036S01—RS5F70A—NLMT0036S0101+Check continuity.

Gear position Continuity

Reverse Yes

Except reverse No

PNP SWITCHNLMT0036S02—RS5F70A—NLMT0036S0201+Check continuity.

Gear position Continuity

Neutral Yes

Except neutral No

ON-VEHICLE SERVICE

Replacing Oil Seal (Cont’d)

MT-16

Page 2806 of 3051

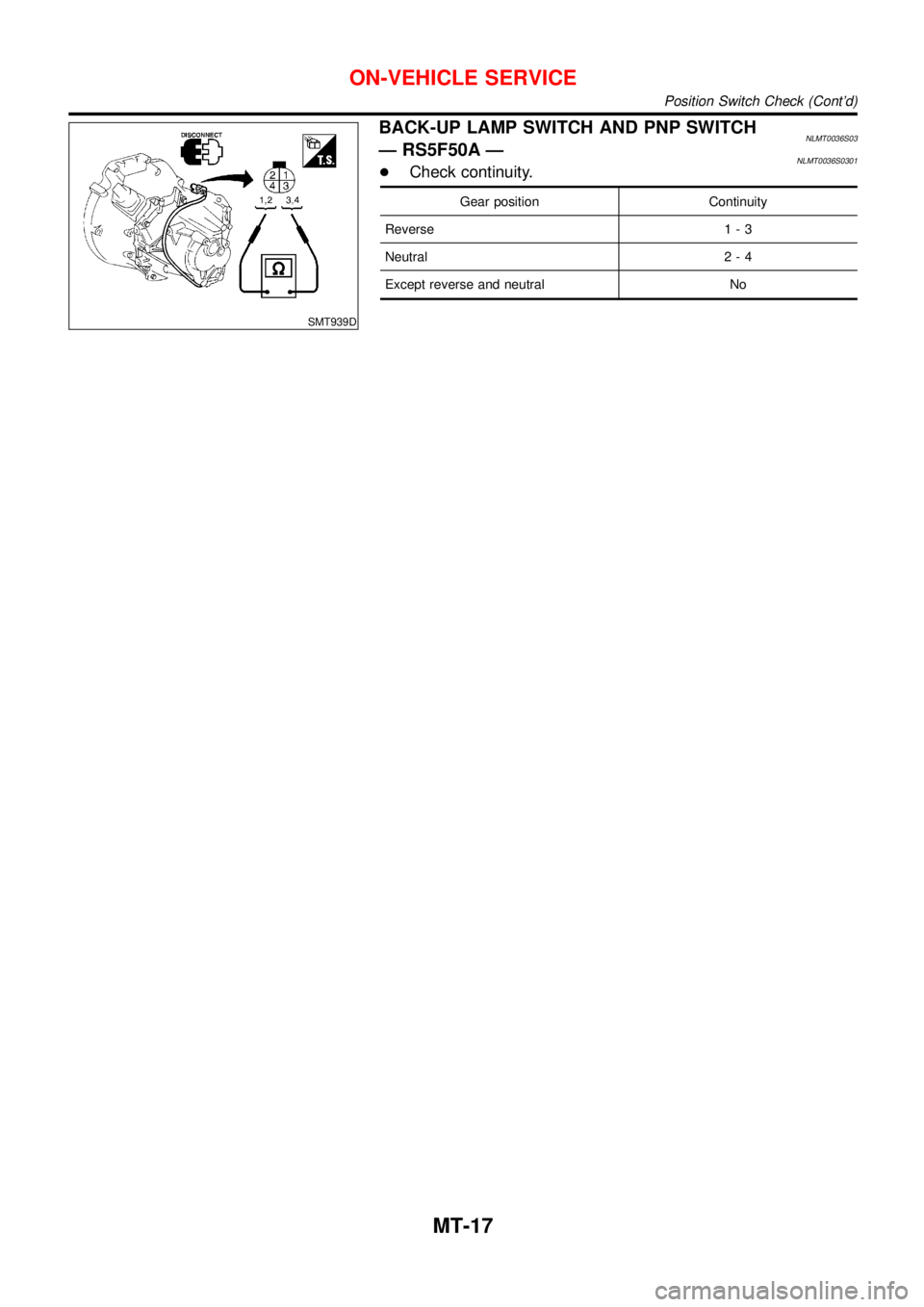

SMT939D

BACK-UP LAMP SWITCH AND PNP SWITCHNLMT0036S03—RS5F50A—NLMT0036S0301+Check continuity.

Gear position Continuity

Reverse 1 - 3

Neutral 2 - 4

Except reverse and neutral No

ON-VEHICLE SERVICE

Position Switch Check (Cont’d)

MT-17

Page 2807 of 3051

NLMT0008

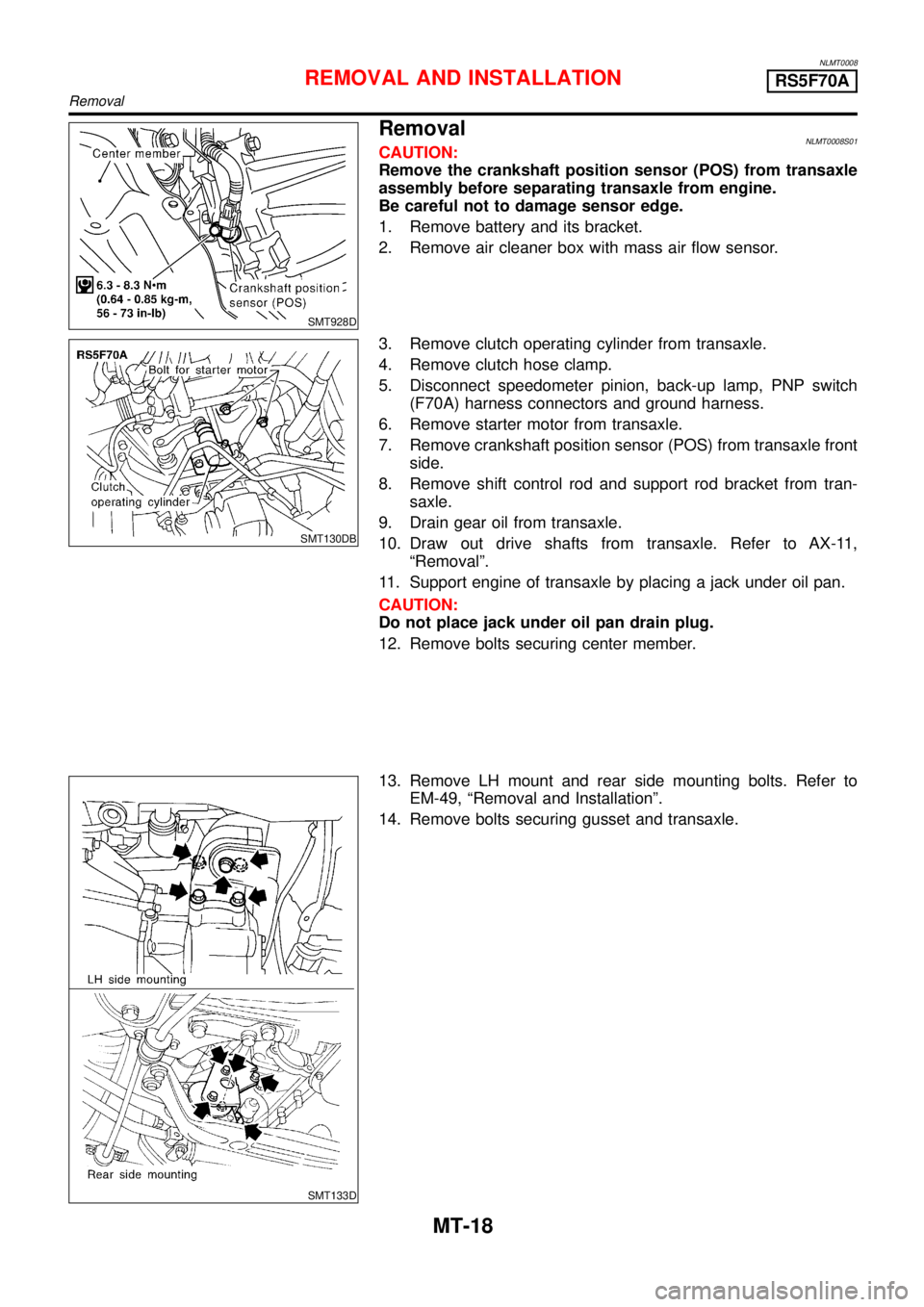

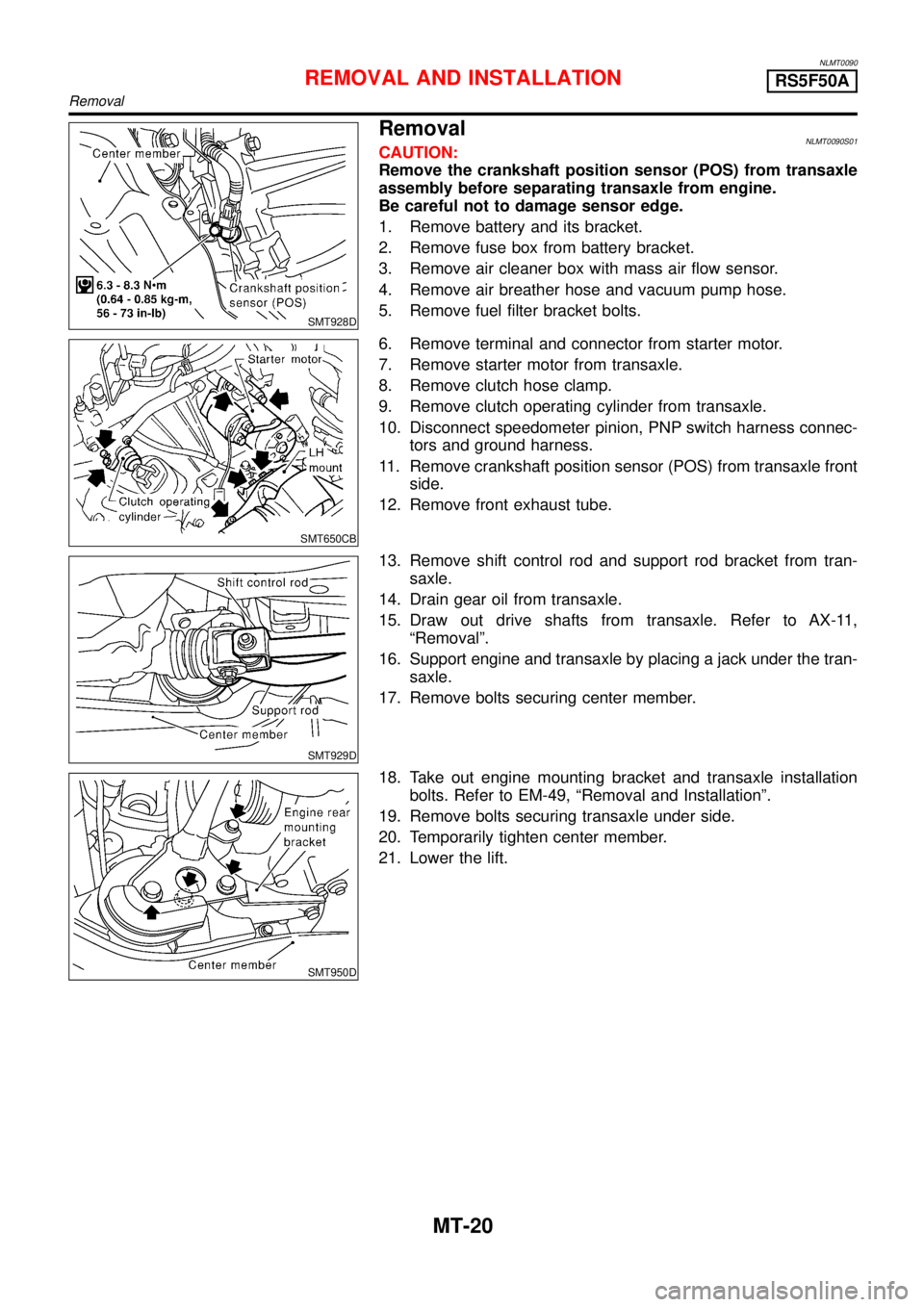

SMT928D

RemovalNLMT0008S01CAUTION:

Remove the crankshaft position sensor (POS) from transaxle

assembly before separating transaxle from engine.

Be careful not to damage sensor edge.

1. Remove battery and its bracket.

2. Remove air cleaner box with mass air flow sensor.

SMT130DB

3. Remove clutch operating cylinder from transaxle.

4. Remove clutch hose clamp.

5. Disconnect speedometer pinion, back-up lamp, PNP switch

(F70A) harness connectors and ground harness.

6. Remove starter motor from transaxle.

7. Remove crankshaft position sensor (POS) from transaxle front

side.

8. Remove shift control rod and support rod bracket from tran-

saxle.

9. Drain gear oil from transaxle.

10. Draw out drive shafts from transaxle. Refer to AX-11,

“Removal”.

11. Support engine of transaxle by placing a jack under oil pan.

CAUTION:

Do not place jack under oil pan drain plug.

12. Remove bolts securing center member.

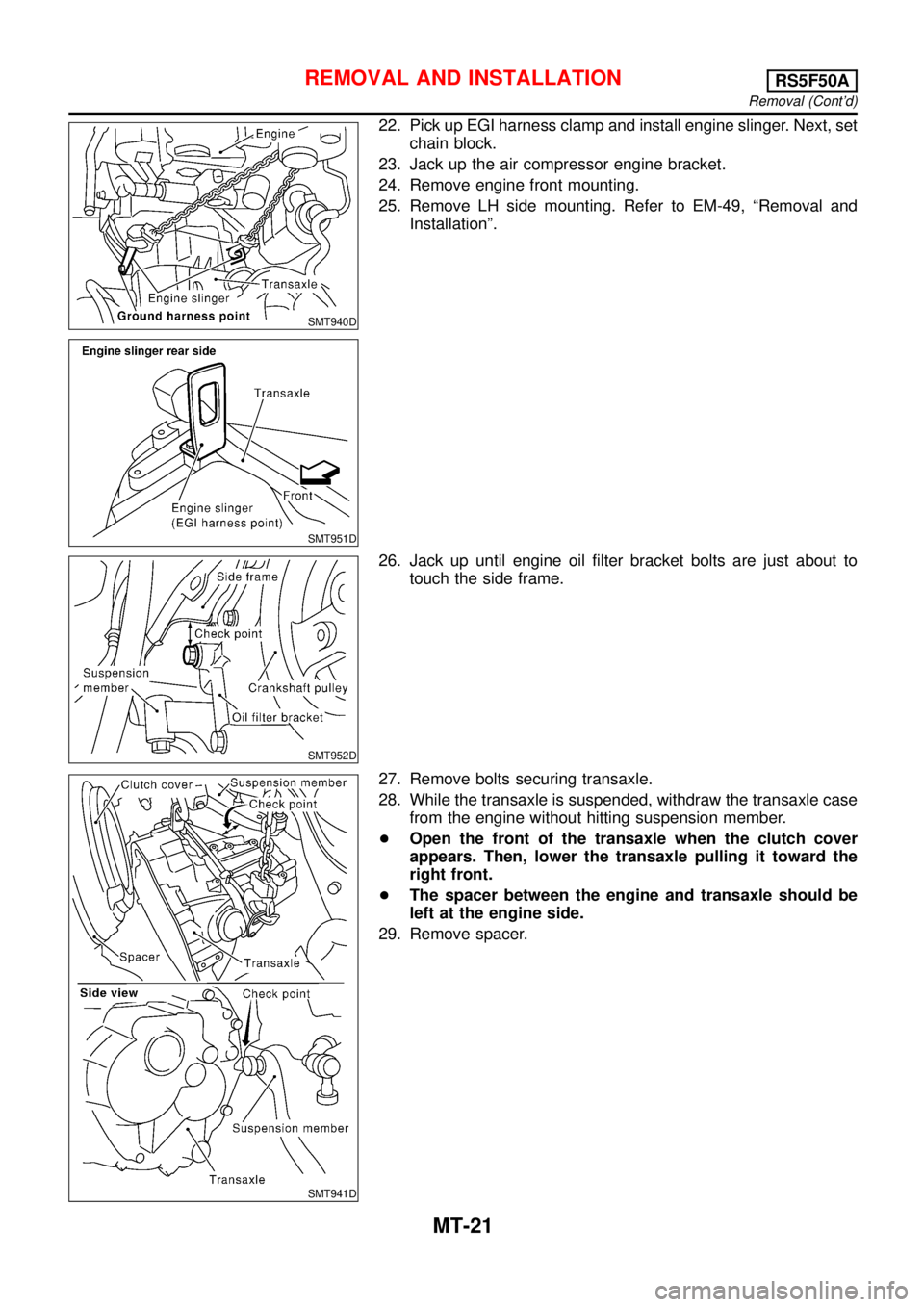

SMT133D

13. Remove LH mount and rear side mounting bolts. Refer to

EM-49,“Removal and Installation”.

14. Remove bolts securing gusset and transaxle.

REMOVAL AND INSTALLATIONRS5F70A

Removal

MT-18

Page 2808 of 3051

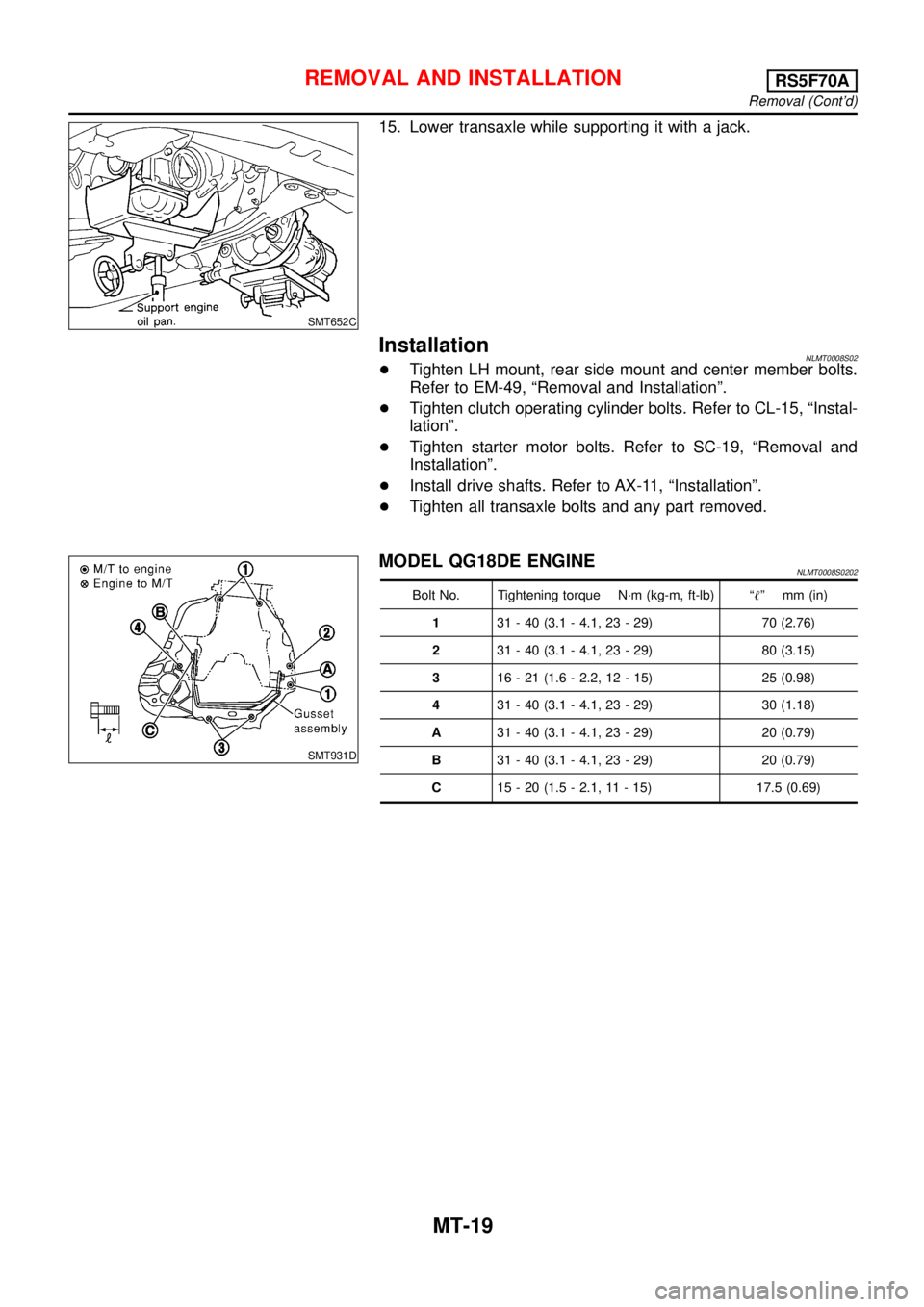

SMT652C

15. Lower transaxle while supporting it with a jack.

InstallationNLMT0008S02+Tighten LH mount, rear side mount and center member bolts.

Refer to EM-49,“Removal and Installation”.

+Tighten clutch operating cylinder bolts. Refer to CL-15,“Instal-

lation”.

+Tighten starter motor bolts. Refer to SC-19,“Removal and

Installation”.

+Install drive shafts. Refer to AX-11,“Installation”.

+Tighten all transaxle bolts and any part removed.

SMT931D

MODEL QG18DE ENGINENLMT0008S0202

Bolt No. Tightening torque N·m (kg-m, ft-lb)“!”mm (in)

131 - 40 (3.1 - 4.1, 23 - 29) 70 (2.76)

231 - 40 (3.1 - 4.1, 23 - 29) 80 (3.15)

316 - 21 (1.6 - 2.2, 12 - 15) 25 (0.98)

431 - 40 (3.1 - 4.1, 23 - 29) 30 (1.18)

A31 - 40 (3.1 - 4.1, 23 - 29) 20 (0.79)

B31 - 40 (3.1 - 4.1, 23 - 29) 20 (0.79)

C15 - 20 (1.5 - 2.1, 11 - 15) 17.5 (0.69)

REMOVAL AND INSTALLATIONRS5F70A

Removal (Cont’d)

MT-19

Page 2809 of 3051

NLMT0090

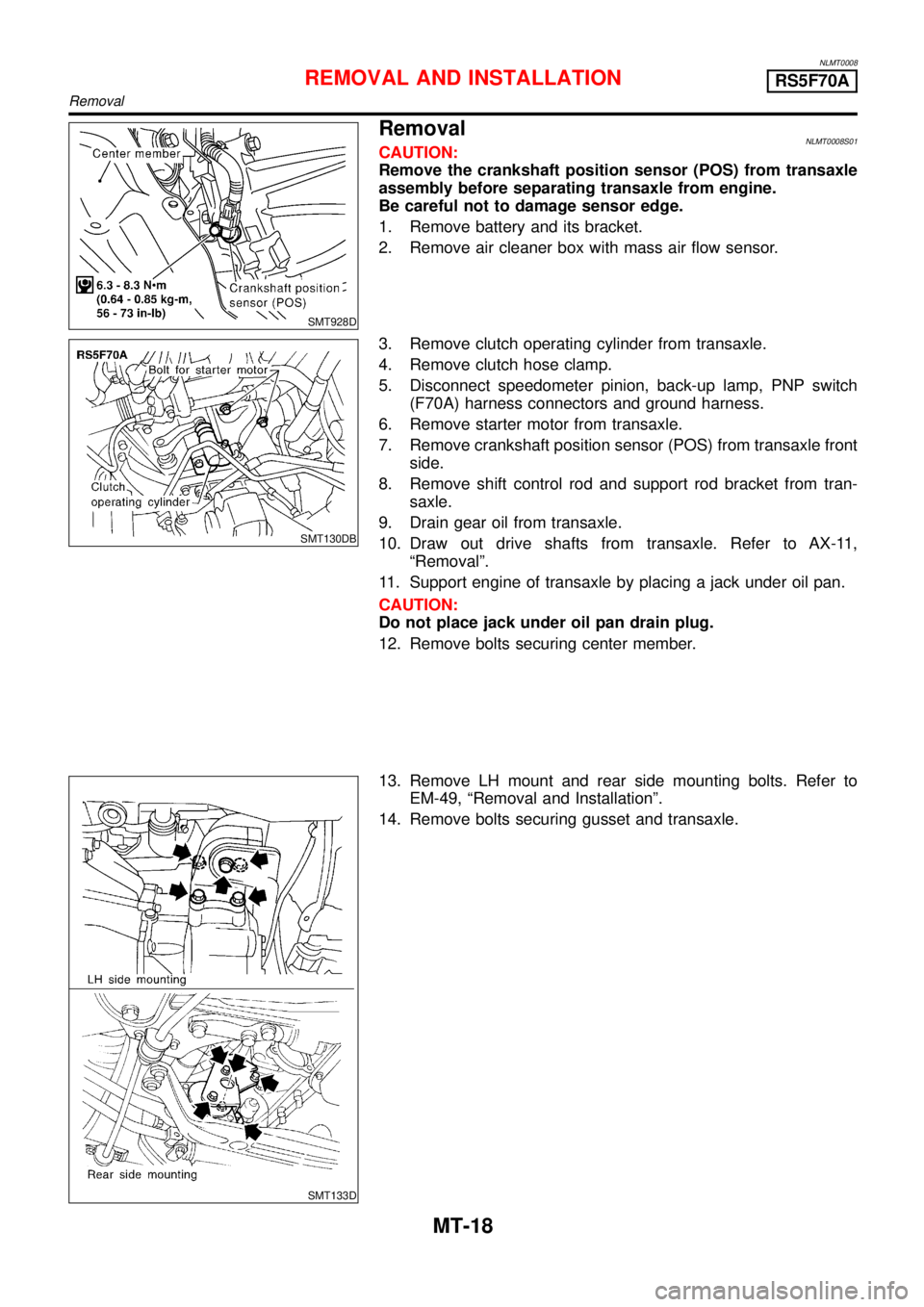

SMT928D

RemovalNLMT0090S01CAUTION:

Remove the crankshaft position sensor (POS) from transaxle

assembly before separating transaxle from engine.

Be careful not to damage sensor edge.

1. Remove battery and its bracket.

2. Remove fuse box from battery bracket.

3. Remove air cleaner box with mass air flow sensor.

4. Remove air breather hose and vacuum pump hose.

5. Remove fuel filter bracket bolts.

SMT650CB

6. Remove terminal and connector from starter motor.

7. Remove starter motor from transaxle.

8. Remove clutch hose clamp.

9. Remove clutch operating cylinder from transaxle.

10. Disconnect speedometer pinion, PNP switch harness connec-

tors and ground harness.

11. Remove crankshaft position sensor (POS) from transaxle front

side.

12. Remove front exhaust tube.

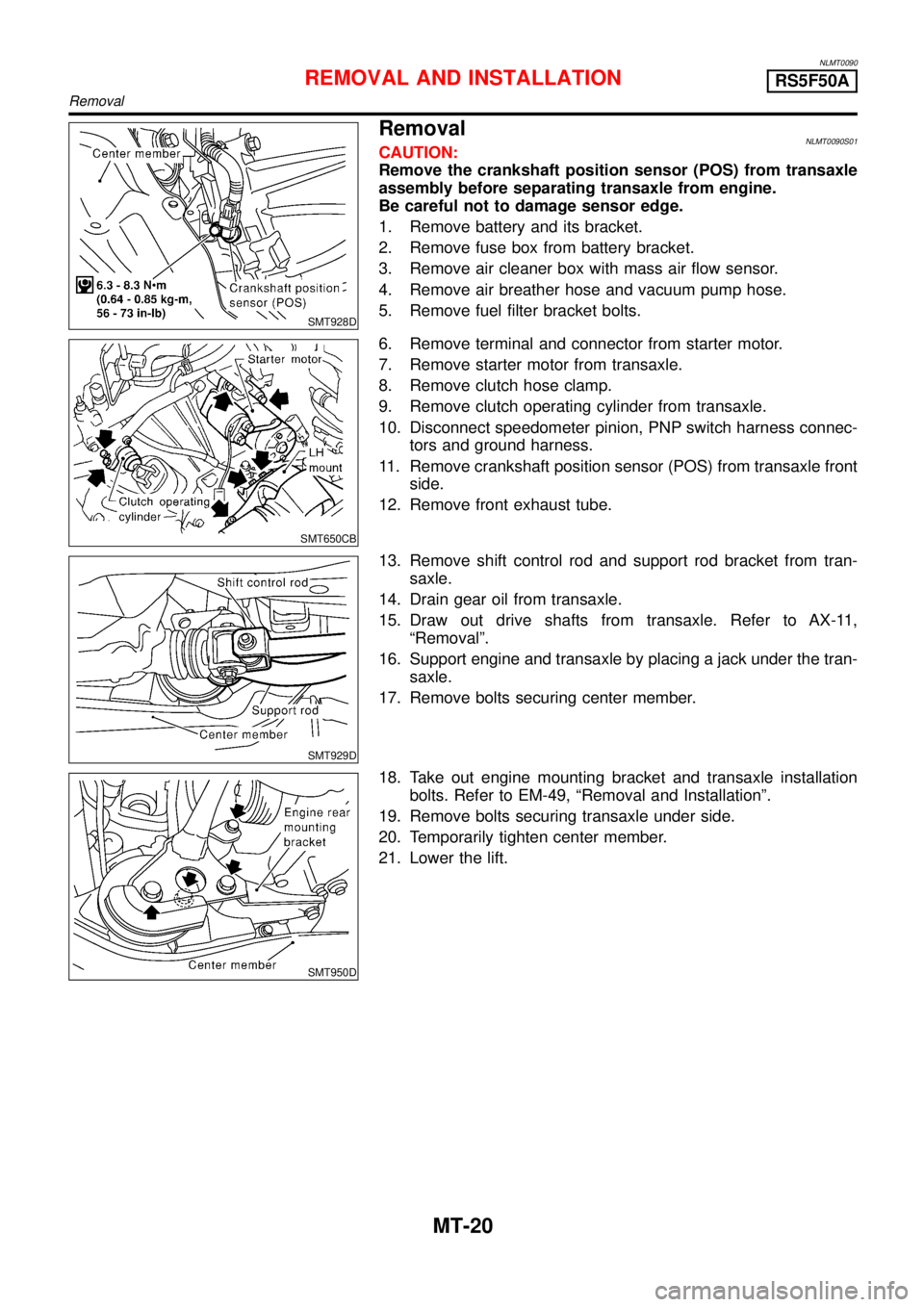

SMT929D

13. Remove shift control rod and support rod bracket from tran-

saxle.

14. Drain gear oil from transaxle.

15. Draw out drive shafts from transaxle. Refer to AX-11,

“Removal”.

16. Support engine and transaxle by placing a jack under the tran-

saxle.

17. Remove bolts securing center member.

SMT950D

18. Take out engine mounting bracket and transaxle installation

bolts. Refer to EM-49,“Removal and Installation”.

19. Remove bolts securing transaxle under side.

20. Temporarily tighten center member.

21. Lower the lift.

REMOVAL AND INSTALLATIONRS5F50A

Removal

MT-20

Page 2810 of 3051

SMT940D

SMT951D

22. Pick up EGI harness clamp and install engine slinger. Next, set

chain block.

23. Jack up the air compressor engine bracket.

24. Remove engine front mounting.

25. Remove LH side mounting. Refer to EM-49,“Removal and

Installation”.

SMT952D

26. Jack up until engine oil filter bracket bolts are just about to

touch the side frame.

SMT941D

27. Remove bolts securing transaxle.

28. While the transaxle is suspended, withdraw the transaxle case

from the engine without hitting suspension member.

+Open the front of the transaxle when the clutch cover

appears. Then, lower the transaxle pulling it toward the

right front.

+The spacer between the engine and transaxle should be

left at the engine side.

29. Remove spacer.

REMOVAL AND INSTALLATIONRS5F50A

Removal (Cont’d)

MT-21

Trending: oil, auxiliary battery, immobilizer, octane, Dash, maintenance schedule, brake rotor