NISSAN NOTE 2016 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 2031 of 3641

HA-6

< PRECAUTION >

PRECAUTIONS

• The air conditioner warranty is void if the vehicle is within the warranty period. Please contact Nissan Cus-tomer Affairs for further assistance.

COMPRESSOR

CAUTION:

• Cap or plug all openings to prevent moisture and fo reign matter from entering.

• Store it in the same way as it is when moun ted on the car when the compressor is removed.

• Follow “Maintenance of Oil Level” exactly when replacing or repairing compressor. Refer to HA-22,

"Description".

• Keep friction surfaces between clut ch and pulley clean. Wipe it off by using a clean waste cloth

moistened with thinner if the su rface is contaminated with oil.

• Turn the compressor shaft by hand more than five turns in both directions after compressor service

operation. This distributes oil e qually inside the compressor. Let the engine idle and operate the

compressor for one hour after the compressor is installed.

• Apply voltage to the new one and check for norma l operation after replacing the compressor magnet

clutch.

LEAK DETECTION DYE

CAUTION:

• The A/C system contains a fluorescent leak detect ion dye used for locating refrigerant leaks. An

ultraviolet (UV) lamp is required to il luminate the dye when inspecting for leaks.

• Always wear fluorescence enhancing UV safety goggles to protect eyes and enhance the visibility of the fluorescent dye.

• The fluorescent dye leak detector is not a replacement for an electrical l eak detector (SST: J-41995).

The fluorescent dye leak detector sh ould be used in conjunction with an electrical leak detector

(SST: J-41995) to pin-point refrigerant leaks.

• Read and follow all manufacture’s operating inst ructions and precautions prior to performing the

work for the purpose of safet y and customer’s satisfaction.

• A compressor shaft seal should not necessarily be repaired becau se of dye seepage. The compres-

sor shaft seal should only be repaired after confi rming the leak with an electrical leak detector (SST:

J-41995).

• Always remove any remaining dye from the leak area after repairs are completed to avoid a misdiag-

nosis during a future service.

• Do not allow dye to come into contact with painted body panels or interior components. Clean imme- diately with the approved dye cl eaner if dye is spilled. Fluorescent dye left on a surface for an

extended period of time cannot be removed.

• Do not spray the fluorescent dye cleaning agent on hot surfaces (engine exhaust manifold, etc.).

• Do not use more than one refrigerant dye bottle [1/4 ounce (7.4 cc)] per A/C system.

• Leak detection dyes for HFC-134a (R-134a) and CFC-12 (R-12) A/C systems are different. Do not use

HFC-134a (R-134a) leak detection dye in CFC-12 (R- 12) A/C system or CFC-12 (R-12) leak detection

dye in HFC-134a (R-134a) A/C system or A/C system damage may result.

• The fluorescent properties of the dye remains fo r three or more years unless a compressor malfunc-

tion occurs.

NOTE: Identification

• Vehicles with factory installed fluorescent dye have a green label.

• Vehicles without factory installed fluorescent dye have a blue label.

Service EquipmentINFOID:0000000012431988

RECOVERY/RECYCLING RECHARGING EQUIPMENT

Be certain to follow the manufacturer’s instructions for machine operation and machine maintenance. Do not

introduce any refrigerant other than that specified into the machine.

ELECTRONIC LEAK DETECTOR

Be certain to follow the manufacturer’s instruct ions for tester operation and tester maintenance.

VACUUM PUMP

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2032 of 3641

PRECAUTIONSHA-7

< PRECAUTION >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

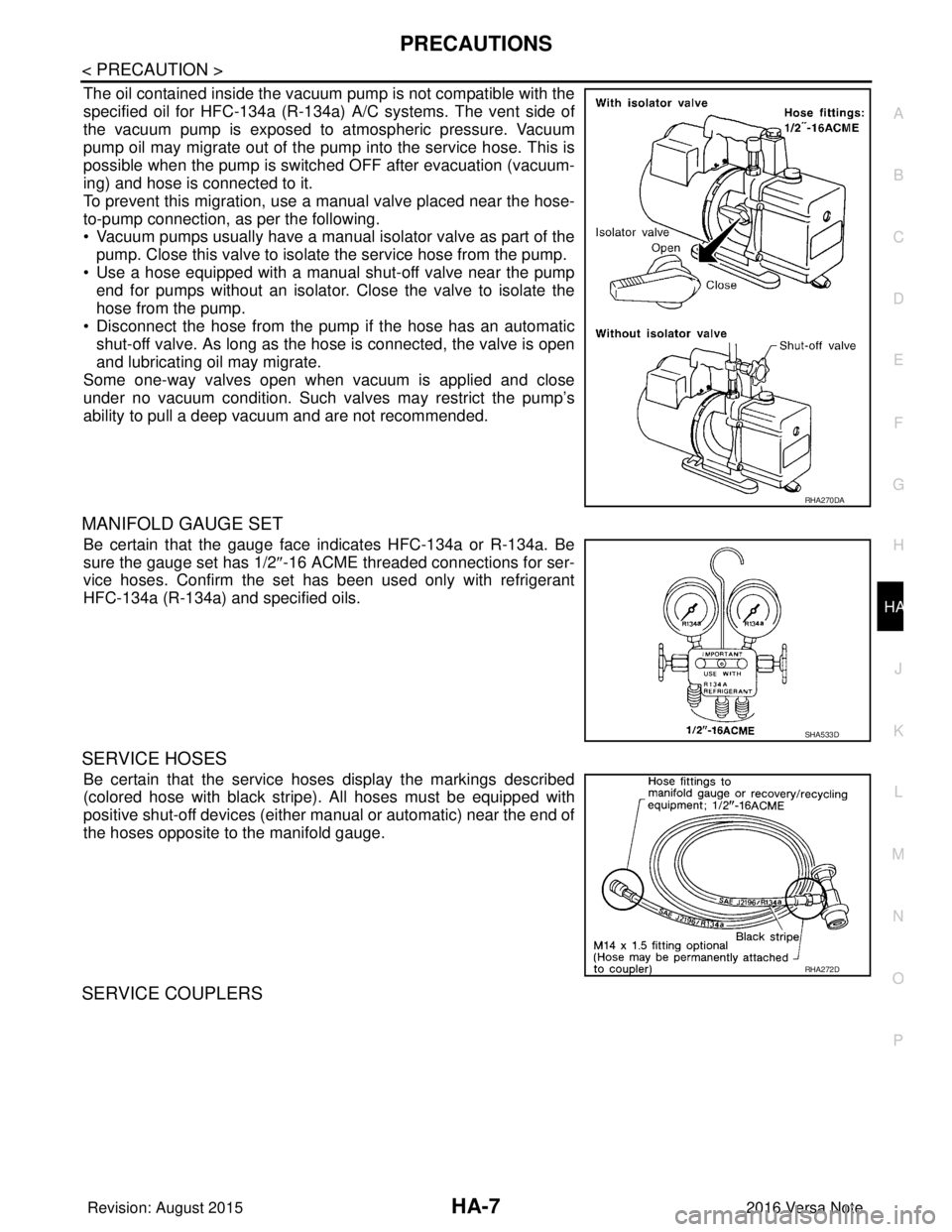

The oil contained inside the vacuum pump is not compatible with the

specified oil for HFC-134a (R-134a) A/C systems. The vent side of

the vacuum pump is exposed to atmospheric pressure. Vacuum

pump oil may migrate out of the pump into the service hose. This is

possible when the pump is switc hed OFF after evacuation (vacuum-

ing) and hose is connected to it.

To prevent this migration, use a manual valve placed near the hose-

to-pump connection, as per the following.

• Vacuum pumps usually have a manual isolator valve as part of the

pump. Close this valve to isolate the service hose from the pump.

• Use a hose equipped with a manual shut-off valve near the pump end for pumps without an isolator. Close the valve to isolate the

hose from the pump.

• Disconnect the hose from the pump if the hose has an automatic shut-off valve. As long as the hose is connected, the valve is open

and lubricating oil may migrate.

Some one-way valves open when vacuum is applied and close

under no vacuum condition. Such valves may restrict the pump’s

ability to pull a deep vacuum and are not recommended.

MANIFOLD GAUGE SET

Be certain that the gauge face indicates HFC-134a or R-134a. Be

sure the gauge set has 1/2 ″-16 ACME threaded connections for ser-

vice hoses. Confirm the set has been used only with refrigerant

HFC-134a (R-134a) and specified oils.

SERVICE HOSES

Be certain that the service hoses display the markings described

(colored hose with black stripe) . All hoses must be equipped with

positive shut-off devices (either manual or automatic) near the end of

the hoses opposite to the manifold gauge.

SERVICE COUPLERS

RHA270DA

SHA533D

RHA272D

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2033 of 3641

HA-8

< PRECAUTION >

PRECAUTIONS

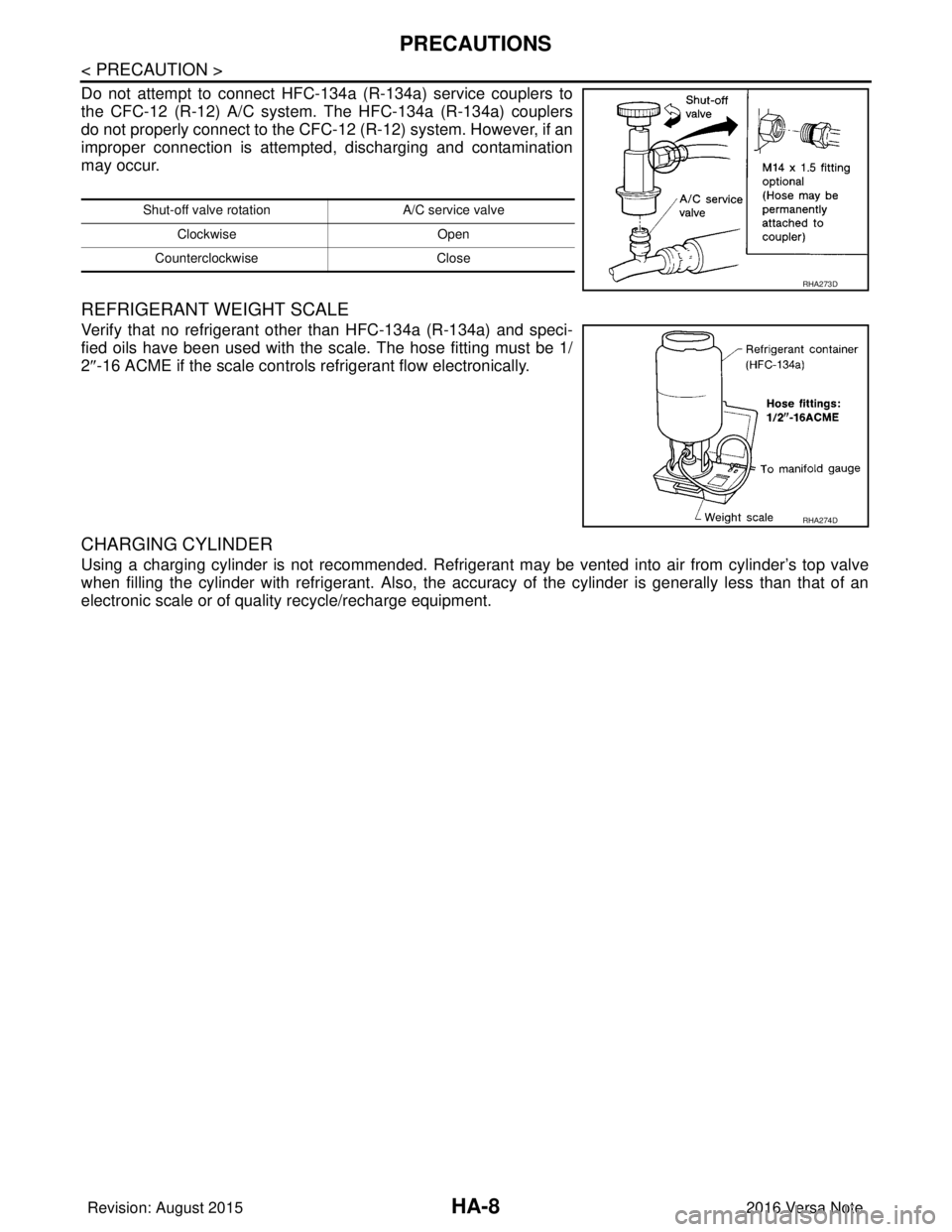

Do not attempt to connect HFC-134a (R-134a) service couplers to

the CFC-12 (R-12) A/C system. The HFC-134a (R-134a) couplers

do not properly connect to the CFC-12 (R-12) system. However, if an

improper connection is attempted, discharging and contamination

may occur.

REFRIGERANT WEIGHT SCALE

Verify that no refrigerant other than HFC-134a (R-134a) and speci-

fied oils have been used with the scale. The hose fitting must be 1/

2 ″-16 ACME if the scale controls refrigerant flow electronically.

CHARGING CYLINDER

Using a charging cylinder is not recommended. Refrigerant may be vented into air from cylinder’s top valve

when filling the cylinder with refrigerant. Also, the accuracy of the cylinder is generally less than that of an

electronic scale or of quality recycle/recharge equipment.

Shut-off valve rotati on A/C service valve

Clockwise Open

Counterclockwise Close

RHA273D

RHA274D

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2034 of 3641

PREPARATIONHA-9

< PREPARATION >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

PREPARATION

PREPARATION

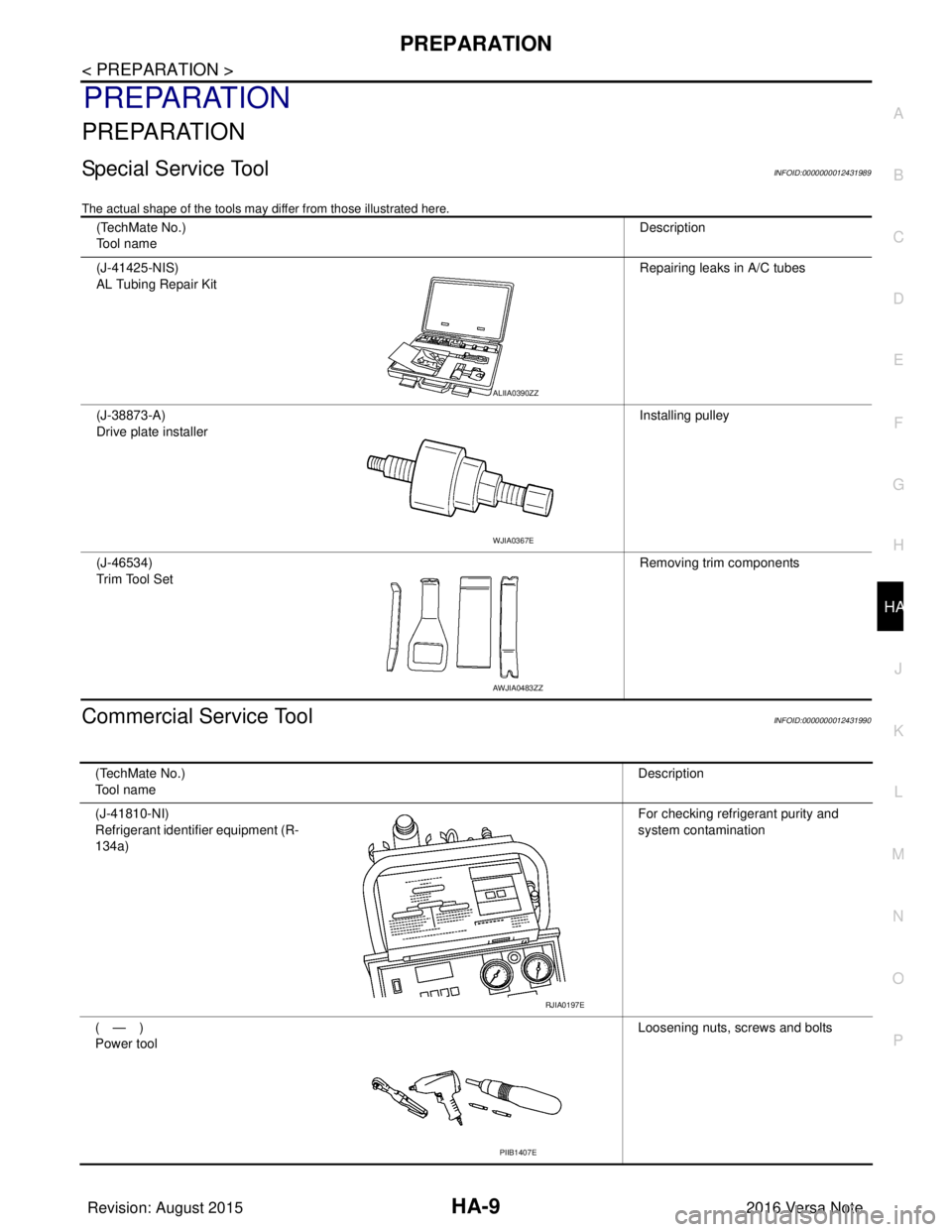

Special Service ToolINFOID:0000000012431989

The actual shape of the tools may di ffer from those illustrated here.

Commercial Service ToolINFOID:0000000012431990

(TechMate No.)

Tool name Description

(J-41425-NIS)

AL Tubing Repair Kit Repairing leaks in A/C tubes

(J-38873-A)

Drive plate installer Installing pulley

(J-46534)

Trim Tool Set Removing trim components

ALIIA0390ZZ

WJIA0367E

AWJIA0483ZZ

(TechMate No.)

Tool nameDescription

(J-41810-NI)

Refrigerant identifier equipment (R-

134a) For checking refrigerant purity and

system contamination

(—)

Power tool Loosening nuts, screws and bolts

RJIA0197E

PIIB1407E

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2035 of 3641

HA-10

< PREPARATION >

PREPARATION

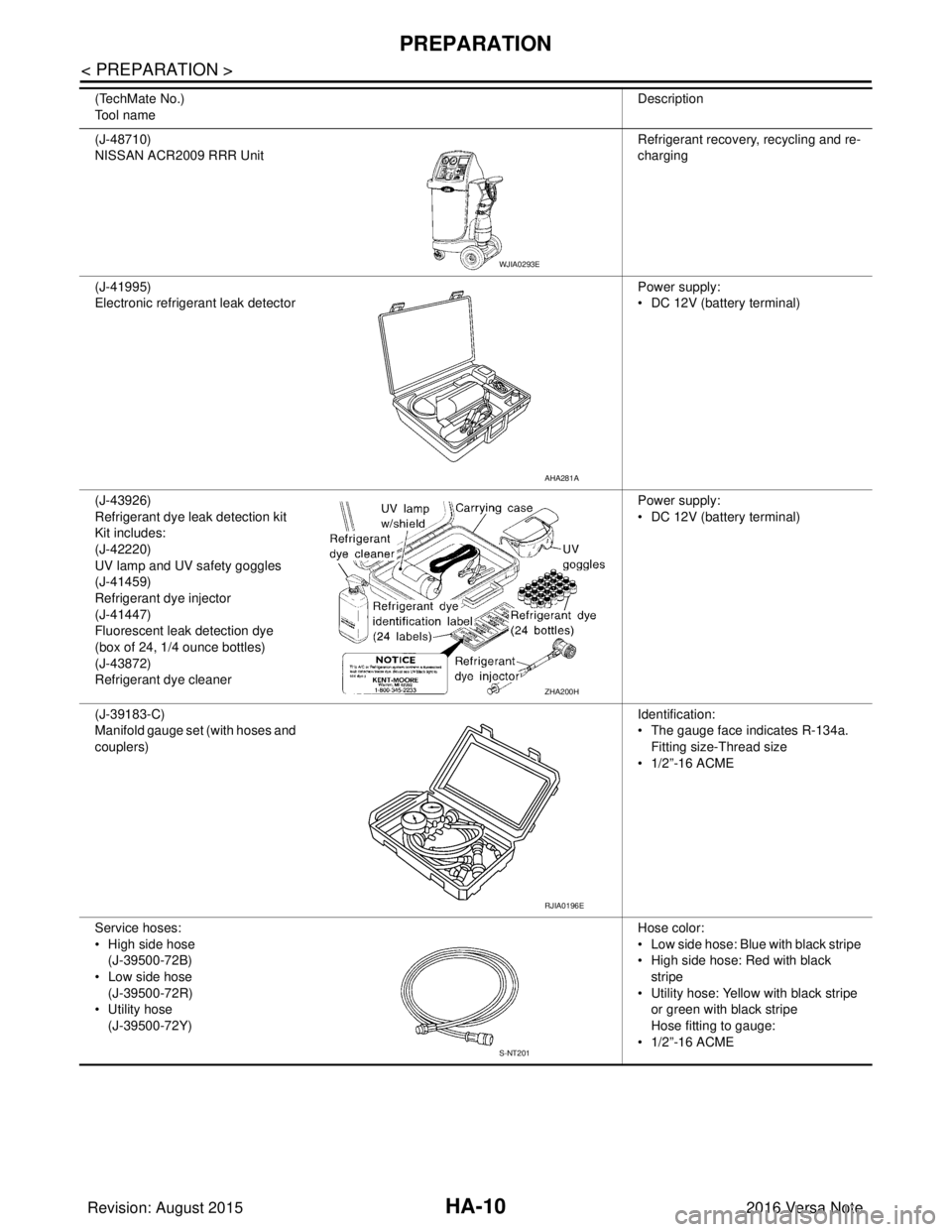

(J-48710)

NISSAN ACR2009 RRR UnitRefrigerant recovery

, recycling and re-

charging

(J-41995)

Electronic refrigerant leak detector Power supply:

• DC 12V (battery terminal)

(J-43926)

Refrigerant dye leak detection kit

Kit includes:

(J-42220)

UV lamp and UV safety goggles

(J-41459)

Refrigerant dye injector

(J-41447)

Fluorescent leak detection dye

(box of 24, 1/4 ounce bottles)

(J-43872)

Refrigerant dye cleaner Power supply:

• DC 12V (battery terminal)

(J-39183-C)

Manifold gauge set (with hoses and

couplers) Identification:

• The gauge face indicates R-134a.

Fitting size-Thread size

• 1/2”-16 ACME

Service hoses:

• High side hose (J-39500-72B)

• Low side hose (J-39500-72R)

• Utility hose (J-39500-72Y) Hose color:

• Low side hose: Blue with black stripe

• High side hose: Red with black

stripe

• Utility hose: Yellow with black stripe

or green with black stripe

Hose fitting to gauge:

• 1/2”-16 ACME

(TechMate No.)

Tool name

Description

WJIA0293E

AHA281A

ZHA200H

RJIA0196E

S-NT201

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2036 of 3641

PREPARATIONHA-11

< PREPARATION >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

Sealant and/or OilINFOID:0000000012431991

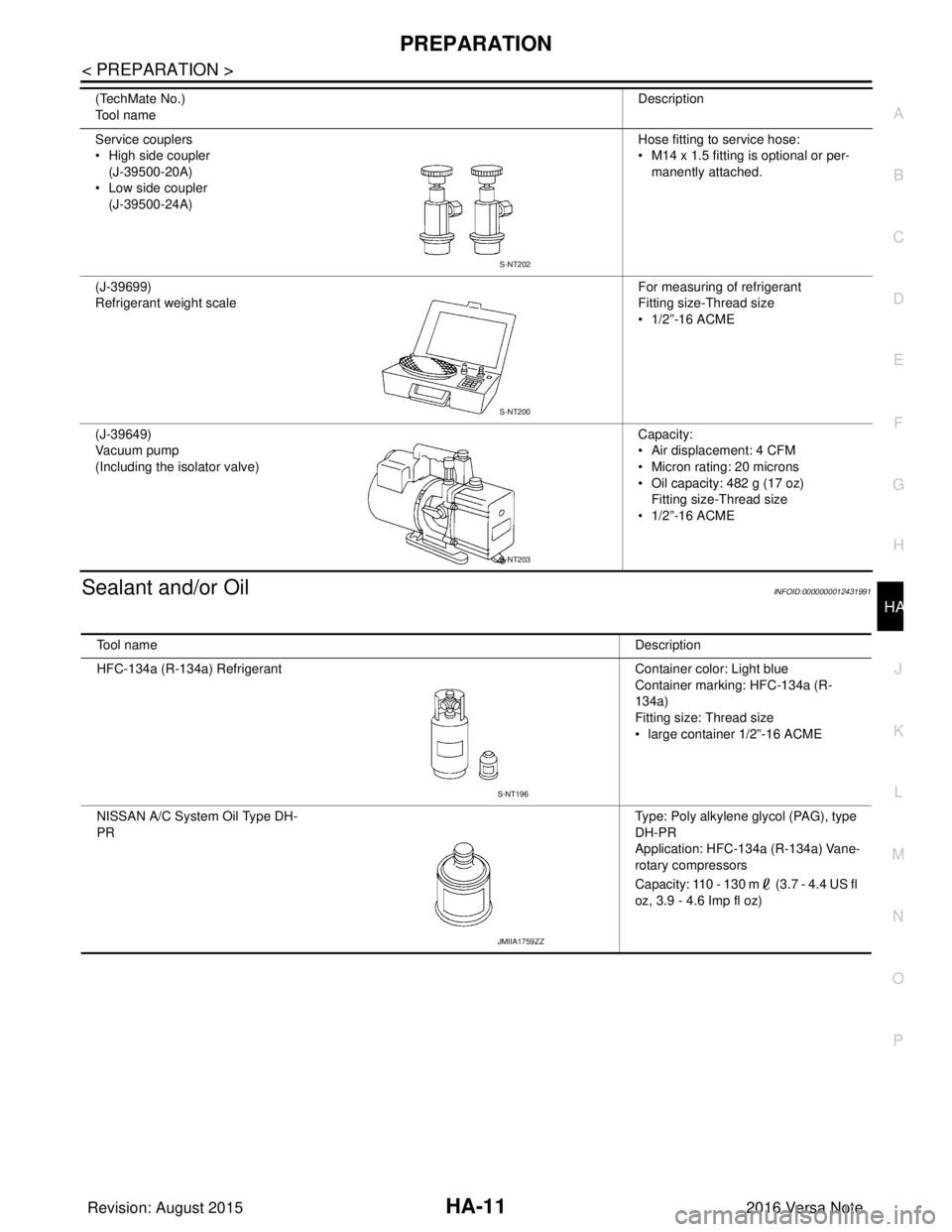

Service couplers

• High side coupler (J-39500-20A)

• Low side coupler

(J-39500-24A) Hose fitting to service hose:

• M14 x 1.5 fitting is optional or per-

manently attached.

(J-39699)

Refrigerant weight scale For measuring of refrigerant

Fitting size-Thread size

• 1/2”-16 ACME

(J-39649)

Vacuum pump

(Including the isolator valve) Capacity:

• Air displacement: 4 CFM

• Micron rating: 20 microns

• Oil capacity: 482 g (17 oz)

Fitting size-Thread size

• 1/2”-16 ACME

(TechMate No.)

Tool name

Description

S-NT202

S-NT200

S-NT203

Tool name

Description

HFC-134a (R-134a) Refrigerant Container color: Light blue

Container marking: HFC-134a (R-

134a)

Fitting size: Thread size

• large container 1/2”-16 ACME

NISSAN A/C System Oil Type DH-

PR Type: Poly alkylene glycol (PAG), type

DH-PR

Application: HFC-134a (R-134a) Vane-

rotary compressors

Capacity: 110 - 130 m (3.7 - 4.4 US fl

oz, 3.9 - 4.6 Imp fl oz)

S-NT196

JMIIA1759ZZ

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2037 of 3641

HA-12

< SYSTEM DESCRIPTION >

COMPONENT PARTS

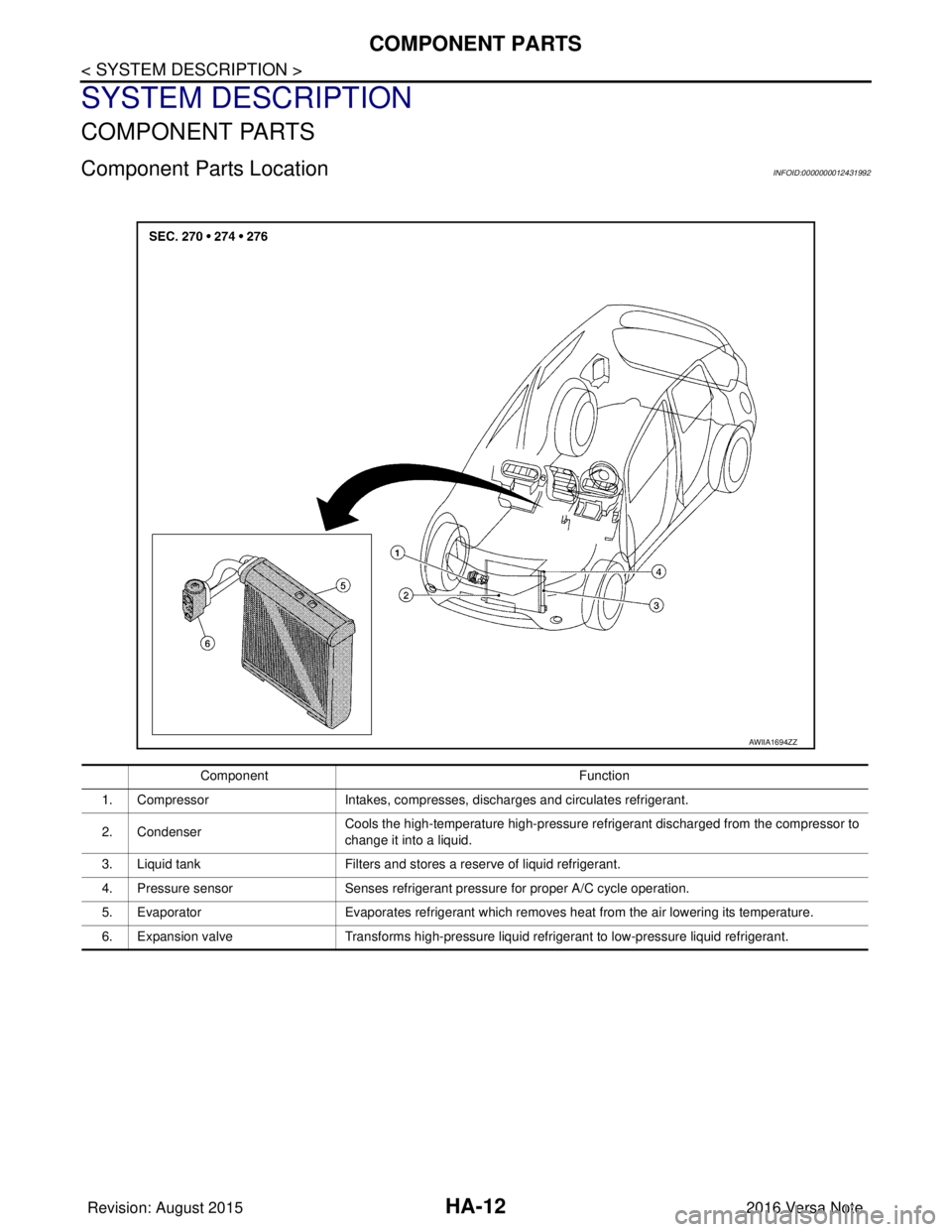

SYSTEM DESCRIPTION

COMPONENT PARTS

Component Parts LocationINFOID:0000000012431992

AWIIA1694ZZ

ComponentFunction

1. Compressor Intakes, compresses, discharges and circulates refrigerant.

2. Condenser Cools the high-temperature high-pressure refrigerant discharged from the compressor to

change it into a liquid.

3. Liquid tank Filters and stores a reserve of liquid refrigerant.

4. Pressure sensor Senses refrigerant pressure for proper A/C cycle operation.

5. Evaporator Evaporates refrigerant which removes heat from the air lowering its temperature.

6. Expansion valve Transforms high-pressure liquid refrigerant to low-pressure liquid refrigerant.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2038 of 3641

DIAGNOSIS AND REPAIR WORKFLOWHA-13

< BASIC INSPECTION >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

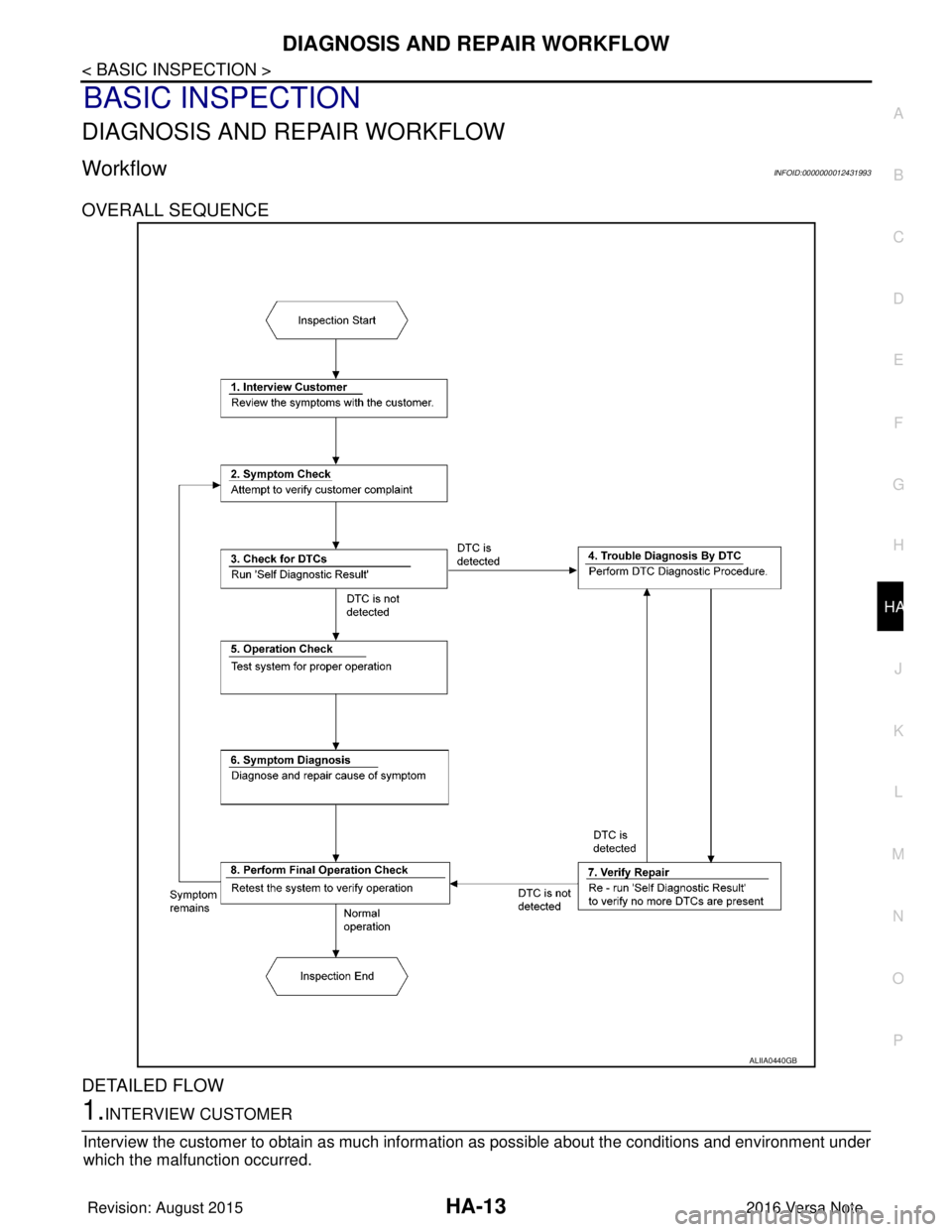

WorkflowINFOID:0000000012431993

OVERALL SEQUENCE

DETAILED FLOW

1.INTERVIEW CUSTOMER

Interview the customer to obtain as much informa tion as possible about the conditions and environment under

which the malfunction occurred.

ALIIA0440GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2039 of 3641

HA-14

< BASIC INSPECTION >

DIAGNOSIS AND REPAIR WORKFLOW

>> GO TO 2.

2.SYMPTOM CHECK

Verify symptoms.

>> GO TO 3.

3.CHECK FOR DTCS

With CONSULT

1. Turn ignition switch ON.

2. Select “Self Diagnostic Result” of “BCM”.

3. Check DTC.

Is any DTC detected?

YES >> GO TO 4.

NO >> GO TO 5.

4.PERFORM DTC DIAGNOSTIC PROCEDURE

Perform the diagnostic procedure fo r the detected DTC. Refer to BCS-49, "

DTCInspectionPriorityChart"

(with Intelligent Key system) or BCS-115, "DTCInspectionPriorityChart" (without Intelligent Key system).

>> GO TO 7.

5.OPERATION CHECK

Perform the operation check. Refer to HAC-30, "

Work Procedure".

>> GO TO 6.

6.SYMPTOM DIAGNOSIS

Check the symptom diagnosis table. Refer to HA-15, "

Symptom Table".

>> GO TO 8.

7.VERIFY REPAIR.

With CONSULT

1. Turn ignition switch ON.

2. Select “Self Diagnostic Result” of “BCM”.

3. Check DTC.

Is any DTC detected?

YES >> GO TO 4.

NO >> GO TO 8.

8.PERFORM FINAL OPERATION CHECK

Perform the operation check. Refer to HAC-30, "

Work Procedure".

Does it operate normally?

YES >> Inspection End.

NO >> GO TO 2.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2040 of 3641

REFRIGERATION SYSTEM SYMPTOMSHA-15

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

SYMPTOM DIAGNOSIS

REFRIGERATION SYSTEM SYMPTOMS

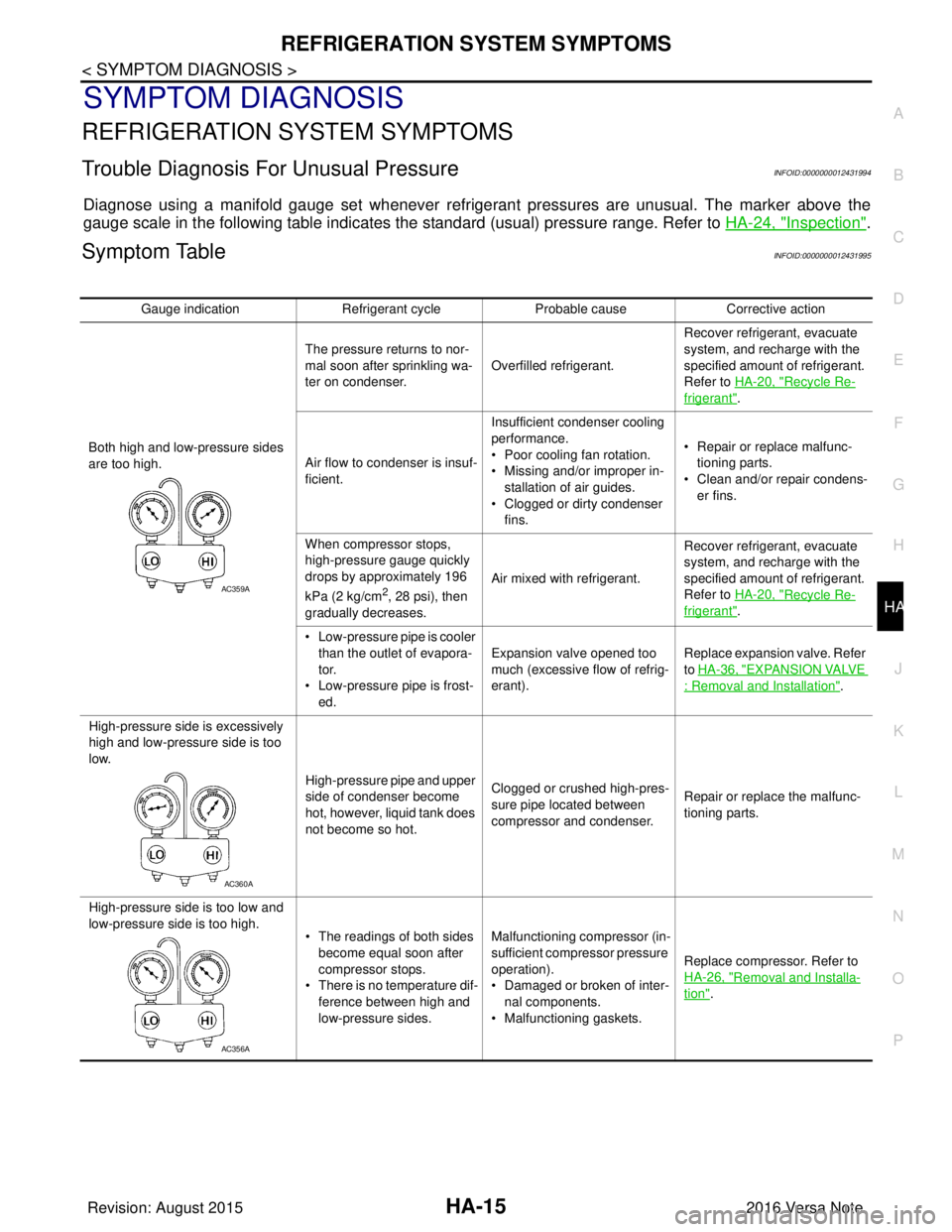

Trouble Diagnosis For Unusual PressureINFOID:0000000012431994

Diagnose using a manifold gauge set whenever refrigerant pressures are unusual. The marker above the

gauge scale in the following table indicates the standard (usual) pressure range. Refer to HA-24, "

Inspection".

Symptom TableINFOID:0000000012431995

Gauge indicationRefrigerant cycleProbable causeCorrective action

Both high and low-pressure sides

are too high. The pressure returns to nor-

mal soon after sprinkling wa-

ter on condenser.

Overfilled refrigerant. Recover refrigerant, evacuate

system, and recharge with the

specified amount of refrigerant.

Refer to HA-20, "

Recycle Re-

frigerant".

Air flow to condenser is insuf-

ficient. Insufficient condenser cooling

performance.

• Poor cooling fan rotation.

• Missing and/or improper in-

stallation of air guides.

• Clogged or dirty condenser fins. • Repair or replace malfunc-

tioning parts.

• Clean and/or repair condens- er fins.

When compressor stops,

high-pressure gauge quickly

drops by approximately 196

kPa (2 kg/cm

2, 28 psi), then

gradually decreases. Air mixed with refrigerant.

Recover refrigerant, evacuate

system, and recharge with the

specified amount of refrigerant.

Refer to HA-20, "Recycle Re-

frigerant".

• Low-pressure pipe is cooler than the outlet of evapora-

tor.

• Low-pressure pipe is frost- ed. Expansion valve opened too

much (excessive flow of refrig-

erant).

Replace expansion valve. Refer

to

HA-36, "

EXPANSION VALVE

: Removal and Installation".

High-pressure side is excessively

high and low-pressure side is too

low. High-pressure pipe and upper

side of condenser become

hot, however, liquid tank does

not become so hot.Clogged or crushed high-pres-

sure pipe located between

compressor and condenser.

Repair or replace the malfunc-

tioning parts.

High-pressure side is too low and

low-pressure side is too high. • The readings of both sides

become equal soon after

compressor stops.

• There is no temperature dif-

ference between high and

low-pressure sides. Malfunctioning compressor (in-

sufficient compressor pressure

operation).

• Damaged or broken of inter-

nal components.

• Malfunctioning gaskets. Replace compressor. Refer to

HA-26, "

Removal and Installa-

tion".

AC359A

AC360A

AC356A

Revision: August 2015

2016 Versa Note

cardiagn.com