tires NISSAN NOTE 2016 Service Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 2741 of 3641

REAR SUSPENSION BEAMRSU-13

< REMOVAL AND INSTALLATION >

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

REAR SUSPENSION BEAM

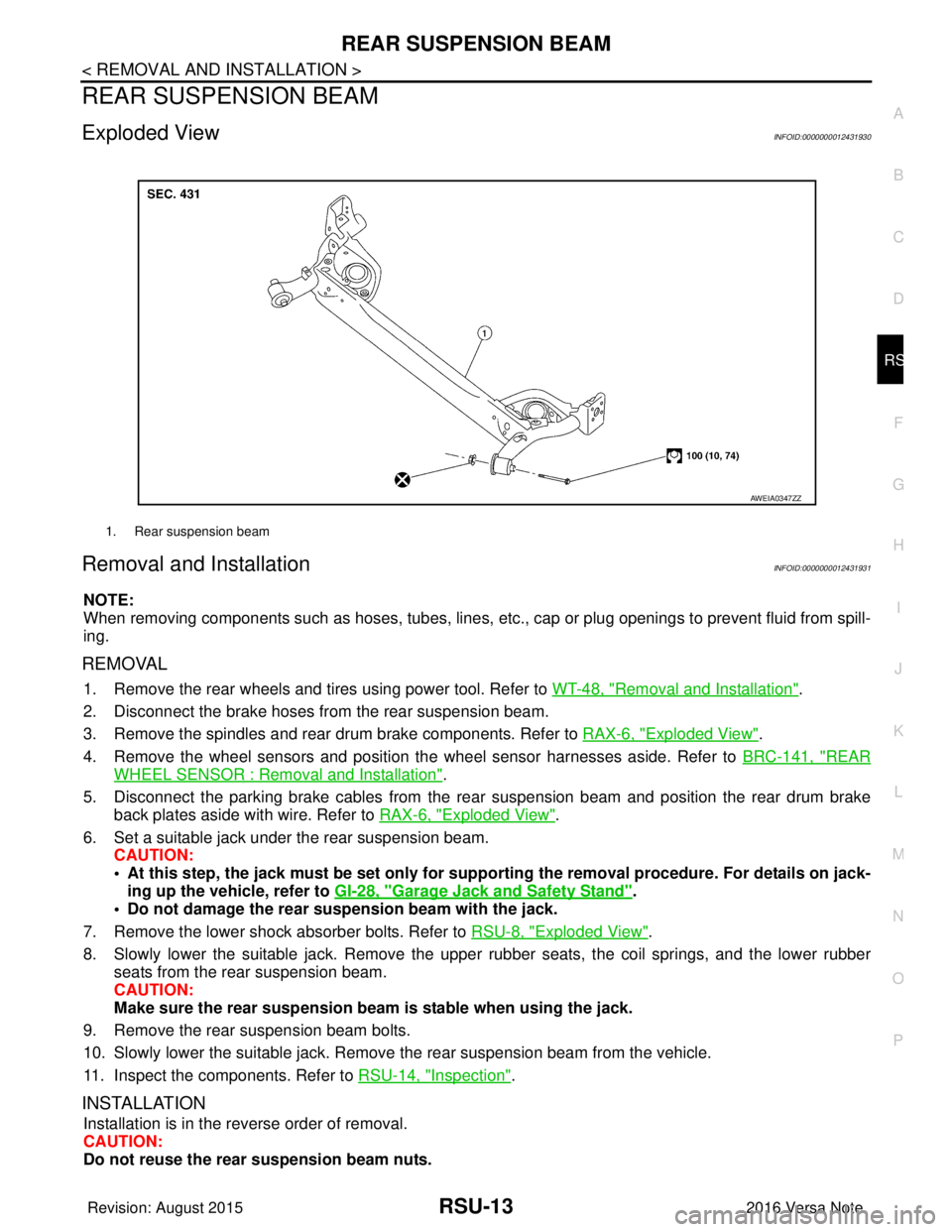

Exploded ViewINFOID:0000000012431930

Removal and InstallationINFOID:0000000012431931

NOTE:

When removing components such as hoses, tubes, lines, etc. , cap or plug openings to prevent fluid from spill-

ing.

REMOVAL

1. Remove the rear wheels and tires using power tool. Refer to WT-48, "Removal and Installation".

2. Disconnect the brake hoses from the rear suspension beam.

3. Remove the spindles and rear drum brake components. Refer to RAX-6, "

Exploded View".

4. Remove the wheel sensors and position the wheel sensor harnesses aside. Refer to BRC-141, "

REAR

WHEEL SENSOR : Removal and Installation".

5. Disconnect the parking brake cables from the rear suspension beam and position the rear drum brake

back plates aside with wire. Refer to RAX-6, "

Exploded View".

6. Set a suitable jack under the rear suspension beam. CAUTION:

• At this step, the jack must be set only for suppo rting the removal procedure. For details on jack-

ing up the vehicle, refer to GI-28, "

Garage Jack and Safety Stand".

• Do not damage the rear su spension beam with the jack.

7. Remove the lower shock absorber bolts. Refer to RSU-8, "

Exploded View".

8. Slowly lower the suitable jack. Remove the upper rubber seats, the coil springs, and the lower rubber seats from the rear suspension beam.

CAUTION:

Make sure the rear susp ension beam is stable when using the jack.

9. Remove the rear suspension beam bolts.

10. Slowly lower the suitable jack. Remove the rear suspension beam from the vehicle.

11. Inspect the components. Refer to RSU-14, "

Inspection".

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Do not reuse the rear suspension beam nuts.

1. Rear suspension beam

AWEIA0347ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2742 of 3641

RSU-14

< REMOVAL AND INSTALLATION >

REAR SUSPENSION BEAM

• Perform the final tightening of the rear suspension beam nuts and bolts under unladen conditions with thetires on level ground.

• Adjust the parking brake. Refer to PB-4, "

Inspection and Adjustment".

• Fill the hydraulic brake system. Refer to BR-12, "

Refilling".

• Bleed the hydraulic brake system. Refer to BR-13, "

Bleeding Brake System".

• Complete the inspection. Refer to BR-12, "

Inspection".

InspectionINFOID:0000000012431932

INSPECTION AFTER REMOVAL

Check the rear suspension beam for deformation, cracks or damage. Replace the parts if necessary.

INSPECTION AFTER INSTALLATION

1. Check the wheel sensor harness to be sure the connectors are fully seated.

2. Check the neutral position of the steering angle sensor. Refer to BRC-55, "

ADJUSTMENT OF STEERING

ANGLE SENSOR NEUTRAL POSITION : Description".

3. Check the wheel alignment. Refer to RSU-6, "

Inspection".

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2744 of 3641

WT-1

SUSPENSION

C

DF

G H

I

J

K L

M

SECTION WT

A

B

WT

N

O PCONTENTS

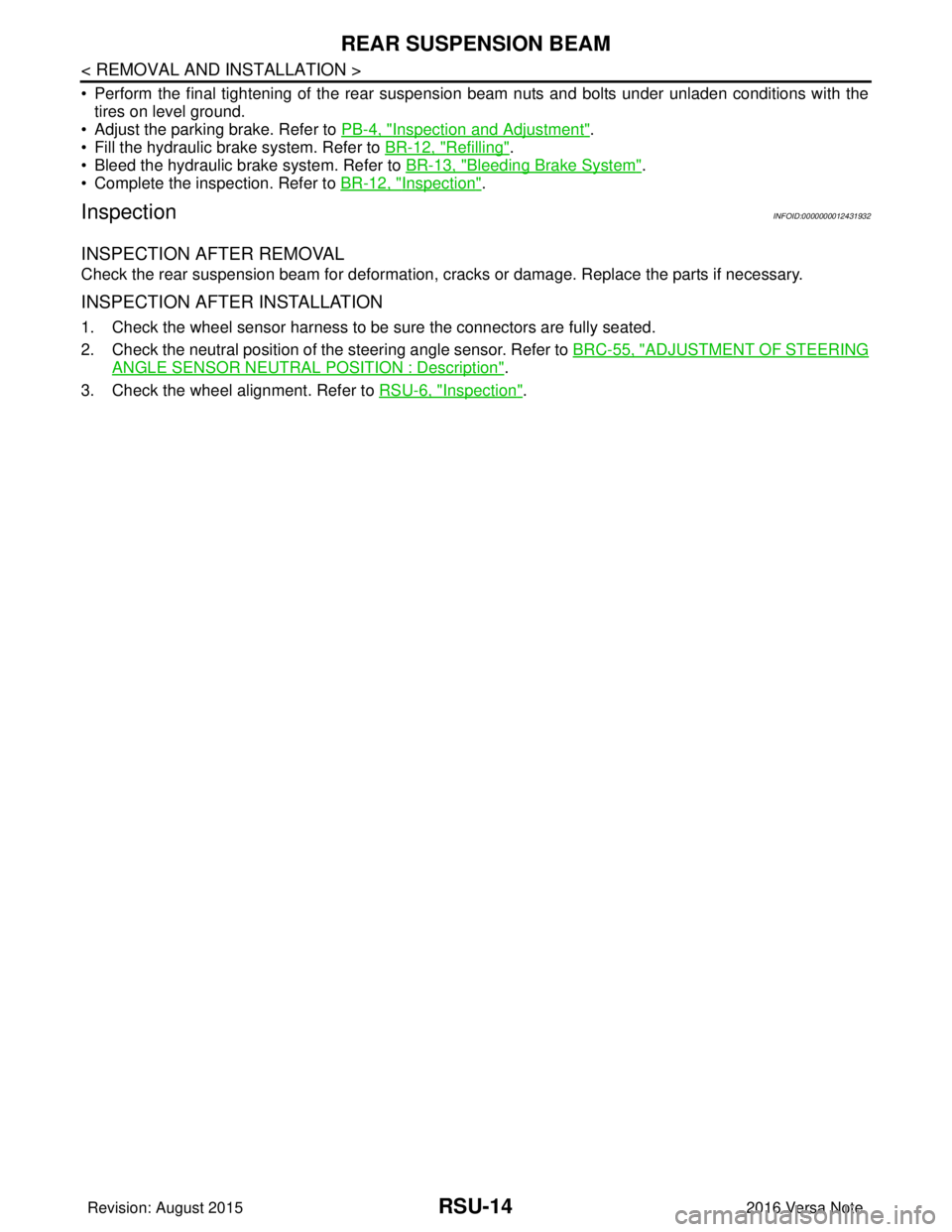

ROAD WHEELS & TIRES

PRECAUTION ....... ........................................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Service Notice and Precautions for TPMS ................3

Service Notice and Precautions for Road Wheel ......3

PREPARATION ............................................5

PREPARATION .............................................. .....5

Special Service Tool ........................................... ......5

Commercial Service Tool ..........................................5

SYSTEM DESCRIPTION ..............................6

COMPONENT PARTS ................................... .....6

Component Parts Location .................................. ......6

Component Description .............................................6

BCM ..........................................................................6

Remote Keyless Entry Receiver ...............................6

Transmitter ................................................................7

Low Tire Pressure Warning Lamp .............................7

SYSTEM ......................................................... .....8

TIRE PRESSURE MONITORING SYSTEM .......... ......8

TIRE PRESSURE MONITORING SYSTEM : Sys-

tem Diagram ..............................................................

8

TIRE PRESSURE MONITORING SYSTEM : Sys-

tem Description .........................................................

8

TIRE PRESSURE MONITORING SYSTEM :

Easy Fill Tire Alert Function ......................................

8

DIAGNOSIS SYSTEM (BCM) ............................10

WITH INTELLIGENT KEY ..................................... ....10

WITH INTELLIGENT KEY : CONSULT Function

(BCM - COMMON ITEM) ........................................

10

WITH INTELLIGENT KEY : CONSULT Function

(BCM - AIR PRESSURE MONITOR) ......................

11

WITHOUT INTELLIGENT KEY .............................. ....11

WITHOUT INTELLIGENT KEY : CONSULT Func-

tion (BCM - COMMON ITEM) ..................................

11

WITHOUT INTELLIGENT KEY : CONSULT Func-

tion (BCM - AIR PRESSURE MONITOR) ...............

12

ECU DIAGNOSIS INFORMATION ..............14

BCM ...................................................................14

List of ECU Reference ......................................... ....14

WIRING DIAGRAM ......................................15

TIRE PRESSURE MONITORING SYSTEM ......15

Wiring Diagram - With Inte lligent Key ......................15

Wiring Diagram - Without Intelligent Ke y .................18

BASIC INSPECTION ....... ............................21

DIAGNOSIS AND REPAIR WORK FLOW .......21

Work Flow ............................................................ ....21

ID REGISTRATION PROCEDURE ...................22

Description ...............................................................22

Work Procedure .......................................................22

DTC/CIRCUIT DIAGNOSIS .........................25

C1704, C1705, C1706, C1707 LOW TIRE

PRESSURE .......................................................

25

DTC Logic ............................................................ ....25

Diagnosis Procedure ...............................................25

C1708, C1709, C1710, C1711 TRANSMITTER

(NO DATA) ........................................................

27

DTC Logic ............................................................ ....27

Diagnosis Procedure ...............................................27

C1716, C1717, C1718, C1719 TRANSMITTER

(PRESSURE DATA) ..........................................

30

DTC Logic ............................................................ ....30

Diagnosis Procedure ...............................................30

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2752 of 3641

SYSTEMWT-9

< SYSTEM DESCRIPTION >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

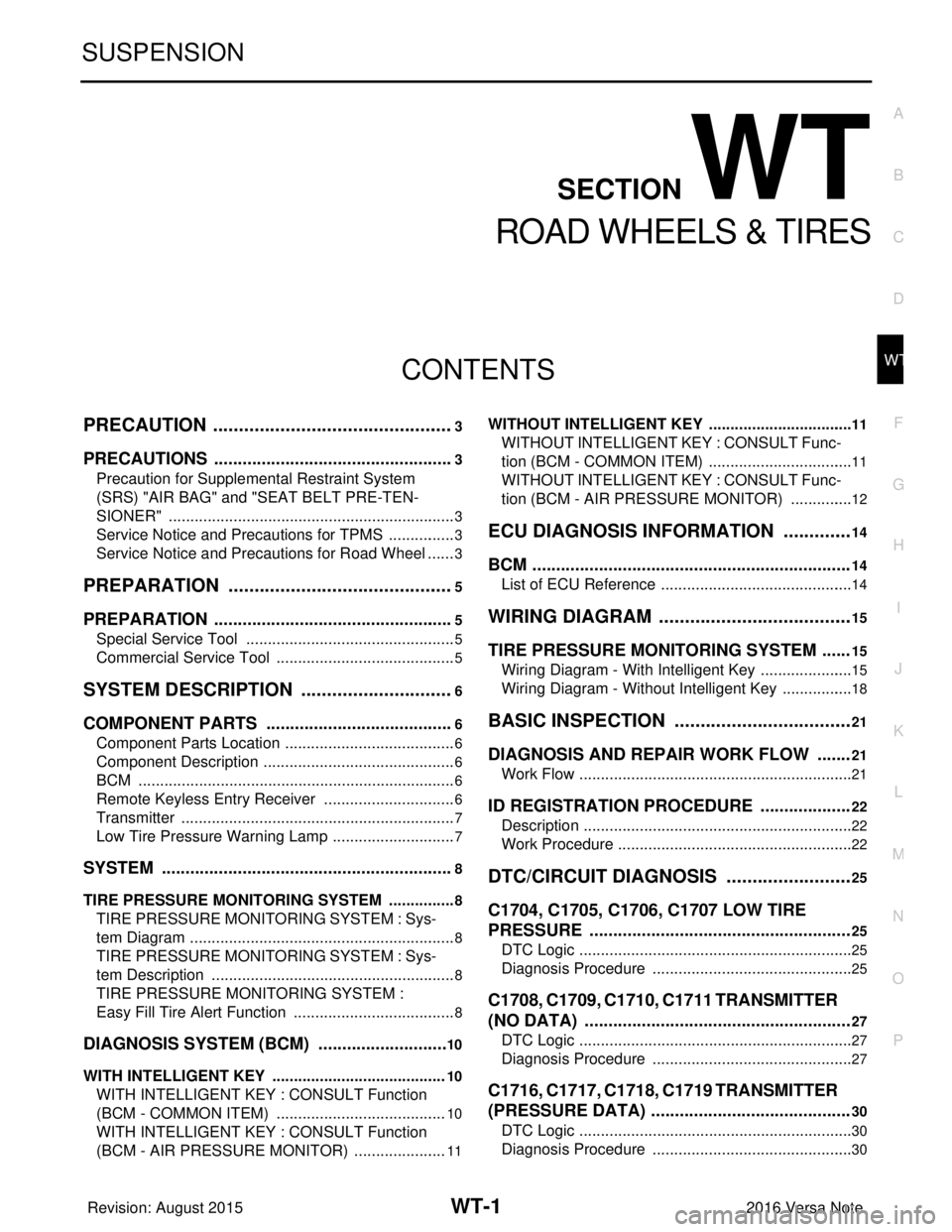

• This function informs the driver of the satisfaction of the recom- mended COLD tire pressure.

The hazard warning lamp blinks when reaching the recommended

COLD tire pressure during radio wave reception. After reaching the

recommended COLD tire pressure, the horn sounds once and the

hazard warning lamp stops blinking.

• When tire pressure becomes a value equal to or more than 30 kPa

(0.31 kg/cm

2, 4 psi) more than the recommended COLD tire pres-

sure, the hazard warning lamp and the horn operates three times.

After deflating the tire and reaching the recommended COLD tire

pressure, the horn sounds only once and the hazard warning lamp

stops blinking.

NOTE:

• After starting to inflate the tire, it takes a fe w seconds for the easy fill tire alert to function.

• If there is no response for approximately 15 seconds or mo re after inflating the tires, cancel the use of the

easy fill tire alert function or move the vehicle approximately 1 m (3.2 ft) backward or forward to try again.

The air filler pressure may be weak or out of service area.

JSEIA0214GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2765 of 3641

WT-22

< BASIC INSPECTION >

ID REGISTRATION PROCEDURE

ID REGISTRATION PROCEDURE

DescriptionINFOID:0000000012432443

This procedure must be performed after replacing wheels, transmitters or the BCM.

Work ProcedureINFOID:0000000012432444

TPMS ID registration can be performed using one of the following procedures:

• Transmitter Activation tool [KV48105501 (J-45295-A)] with CONSULT (preferred method)

• Signal Tech II tool [- (J- 50190)] with CONSULT (preferred method)

• Signal Tech II tool [- (J-50190)] without CONSULT

• CONSULT only

TPMS REGISTRATION WITH TRANSMITTER ACTIVATION TOOL [KV48105501 (J-45295-A)]

With CONSULT

1. Turn the ignition switch ON.

2. Using CONSULT, select “WORK SUPPORT” in “AIR PRESSURE MONITOR” of “BCM”. Then, select “ID

REGIST.”

3. Select “Start” on “ID REGIST” screen.

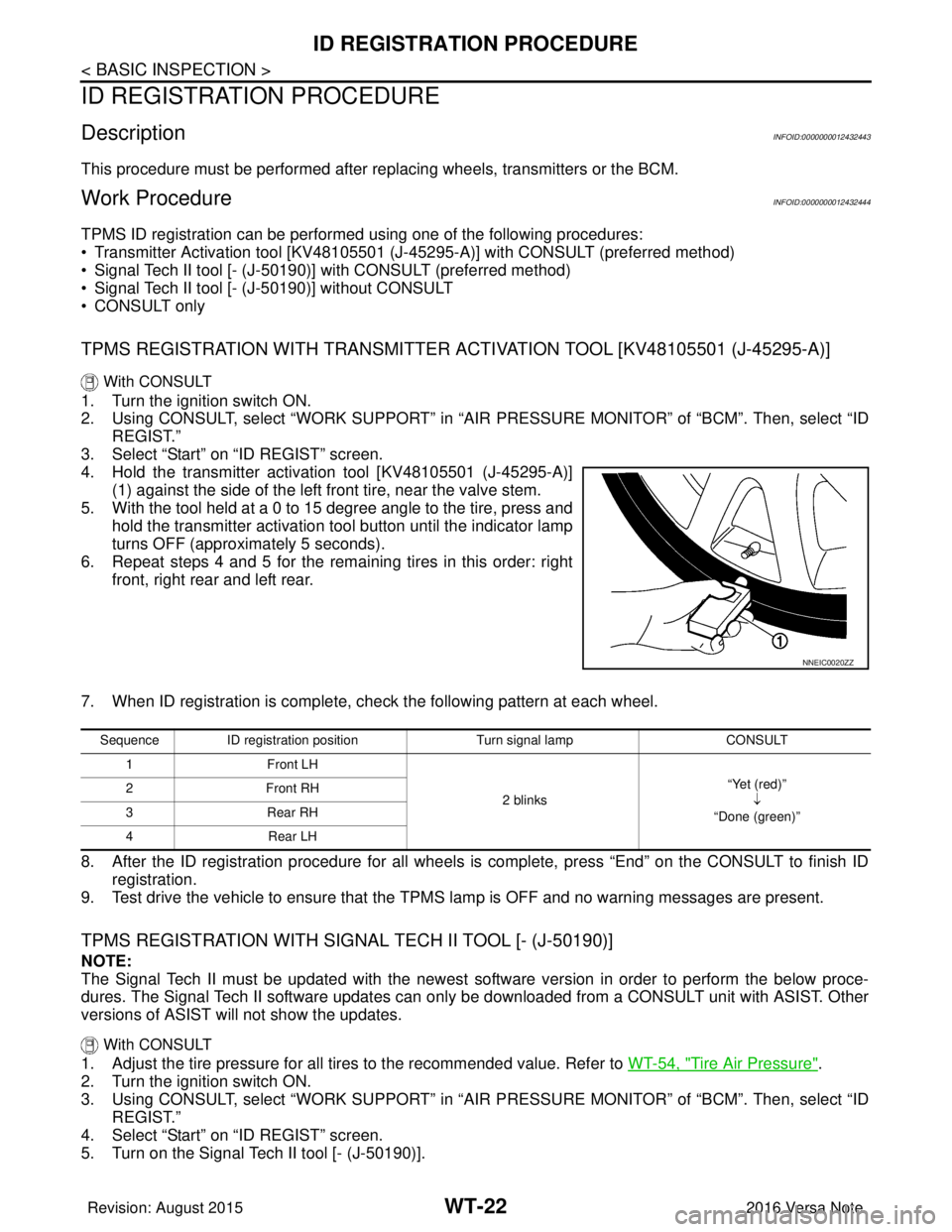

4. Hold the transmitter activation tool [KV48105501 (J-45295-A)] (1) against the side of the left front tire, near the valve stem.

5. With the tool held at a 0 to 15 degree angle to the tire, press and hold the transmitter activation tool button until the indicator lamp

turns OFF (approximately 5 seconds).

6. Repeat steps 4 and 5 for the remaining tires in this order: right front, right rear and left rear.

7. When ID registration is complete, check the following pattern at each wheel.

8. After the ID registration procedure for all wheels is complete, press “End” on the CONSULT to finish ID registration.

9. Test drive the vehicle to ensure that the TPMS lamp is OFF and no warning messages are present.

TPMS REGISTRATION WITH SIGNAL TECH II TOOL [- (J-50190)]

NOTE:

The Signal Tech II must be updated with the newest software version in order to perform the below proce-

dures. The Signal Tech II software updates can onl y be downloaded from a CONSULT unit with ASIST. Other

versions of ASIST wil l not show the updates.

With CONSULT

1. Adjust the tire pressure for all tires to the recommended value. Refer to WT-54, "Tire Air Pressure".

2. Turn the ignition switch ON.

3. Using CONSULT, select “WORK SUPPORT” in “AIR PRESSURE MONITOR” of “BCM”. Then, select “ID

REGIST.”

4. Select “Start” on “ID REGIST” screen.

5. Turn on the Signal Tech II tool [- (J-50190)].

NNEIC0020ZZ

Sequence ID registration position Turn signal lamp CONSULT

1F ro nt L H

2 blinks “Yet (red)”

↓

“Done (green)”

2F

ro nt R H

3R ea r R H

4R ear L H

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2766 of 3641

ID REGISTRATION PROCEDUREWT-23

< BASIC INSPECTION >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

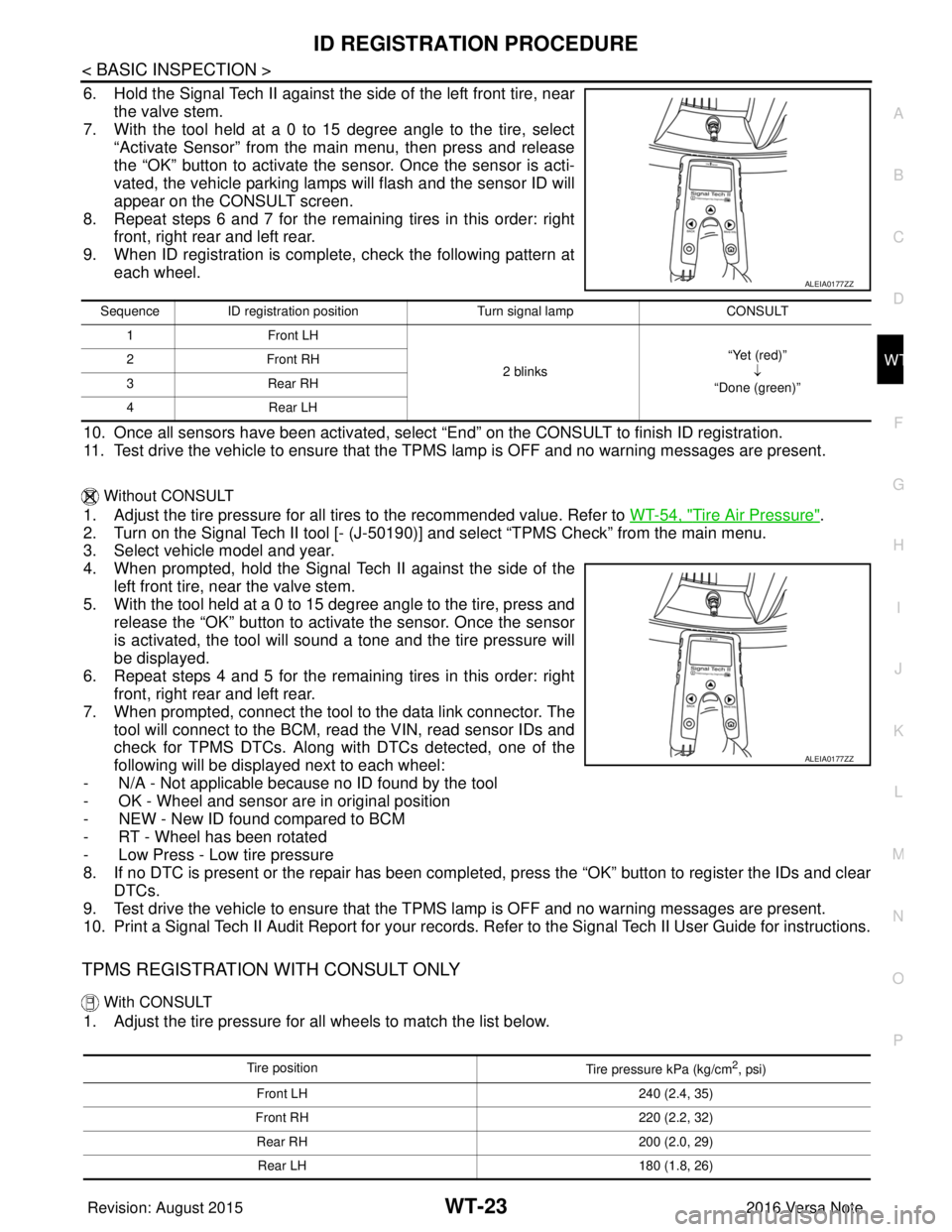

6. Hold the Signal Tech II against the side of the left front tire, near the valve stem.

7. With the tool held at a 0 to 15 degree angle to the tire, select

“Activate Sensor” from the main menu, then press and release

the “OK” button to activate the s ensor. Once the sensor is acti-

vated, the vehicle parking lamps will flash and the sensor ID will

appear on the CONSULT screen.

8. Repeat steps 6 and 7 for the remaining tires in this order: right front, right rear and left rear.

9. When ID registration is complete, check the following pattern at each wheel.

10. Once all sensors have been activated, select “End” on the CONSULT to finish ID registration.

11. Test drive the vehicle to ensure that the TPMS lamp is OFF and no warning messages are present.

Without CONSULT

1. Adjust the tire pressure for all tires to the recommended value. Refer to WT-54, "Tire Air Pressure".

2. Turn on the Signal Tech II tool [- (J-50190) ] and select “TPMS Check” from the main menu.

3. Select vehicle model and year.

4. When prompted, hold the Signal Te ch II against the side of the

left front tire, near the valve stem.

5. With the tool held at a 0 to 15 degree angle to the tire, press and release the “OK” button to activate the sensor. Once the sensor

is activated, the tool will sound a tone and the tire pressure will

be displayed.

6. Repeat steps 4 and 5 for the remaining tires in this order: right front, right rear and left rear.

7. When prompted, connect the tool to the data link connector. The tool will connect to the BCM, read the VIN, read sensor IDs and

check for TPMS DTCs. Along wit h DTCs detected, one of the

following will be displayed next to each wheel:

- N/A - Not applicable because no ID found by the tool

- OK - Wheel and sensor ar e in original position

- NEW - New ID found compared to BCM

- RT - Wheel has been rotated

- Low Press - Low tire pressure

8. If no DTC is present or the repair has been complet ed, press the “OK” button to register the IDs and clear

DTCs.

9. Test drive the vehicle to ensure that the TPMS lamp is OFF and no warning messages are present.

10. Print a Signal Tech II Audit Report for your records. Refer to the Signal Tech II User Guide for instructions.

TPMS REGISTRATION WITH CONSULT ONLY

With CONSULT

1. Adjust the tire pressure for all wheels to match the list below.

ALEIA0177ZZ

Sequence ID registration position Turn signal lamp CONSULT

1 Front LH

2 blinks“Yet (red)”

↓

“Done (green)”

2F

ro nt R H

3 Rear RH

4 Rear LH

ALEIA0177ZZ

Tire position

Tire pressure kPa (kg/cm2, psi)

Front LH 240 (2.4, 35)

Front RH 220 (2.2, 32)

Rear RH 200 (2.0, 29)

Rear LH 180 (1.8, 26)

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2767 of 3641

WT-24

< BASIC INSPECTION >

ID REGISTRATION PROCEDURE

2. Turn the ignition switch ON.

3. Using CONSULT, select “WORK SUPPORT” in “AIR PRESSURE MONITOR” of “BCM”. Then, select “ID

REGIST.”

4. Select “Start” on “ID REGIST” screen.

5. Drive the vehicle at a speed greater than 40 km/h (25 MPH) for 3 minutes or more.

6. After ID registration for all wheels is complete, press “End” on the CONSULT to finish ID registration.

7. Adjust the tire pressures for all tires to the recommended value. Refer to WT-54, "

Tire Air Pressure".

8. Test drive the vehicle to ensure that the TPMS lamp is OFF and no warning messages are present.

ID registration position CONSULT

Front LH “Yet (red)”↓

“Done (green)”

Front RH

Rear RHRear LH

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2783 of 3641

WT-40

< SYMPTOM DIAGNOSIS >

EASY FILL TIRE ALERT DOES NOT ACTIVATE

EASY FILL TIRE ALERT DOES NOT ACTIVATE

DescriptionINFOID:0000000012432461

The easy fill tire alert does not function while inflating a tire when the select lever position is in P-range with the

ignition switch ON.

NOTE:

• After starting to inflate the tire, it takes a few seconds for the easy fill tire alert to function.

• If there is no response for approximately 15 seconds or mo re after inflating the tires, cancel the use of the

easy fill tire alert function or move the vehicle approximately 1 m (3.2 ft) backward or forward to try again.

The air filler pressure may be weak or out of service area.

• For easy fill tire alert, Refer to WT-8, "

TIRE PRESSURE MONITORING SYST EM : Easy Fill Tire Alert Func-

tion".

Diagnosis ProcedureINFOID:0000000012432462

1. LOCATION CHANGE

Move the vehicle to other area and repeat the procedure of the easy fill tire alert function. Refer to WT-8,

"TIRE PRESSURE MONITORING SYSTEM : Easy Fill Tire Alert Function".

Is the function normal?

YES >> Normal (the easy fill tire alert may not operate, depending on reception condition.)

NO >> GO TO 2.

2.PERFORM BCM SELF-DIAGNOSIS

With CONSULT

Perform self-diagnosis for “AIR PRESSURE MONITOR”.

Is any DTC detected?

YES >> Perform trouble diagnosis for detected DTC. Refer to BCS-50, "DTCIndex" (with Intelligent Key

system) or BCS-115, "

DTCIndex" (without Intelligent Key system).

NO >> GO TO 3.

3.CHECK HAZARD WARNING LAMP OPERATION

Check hazard warning lamp operation with hazard switch.

Does the hazard warning lamp blink?

YES >> GO TO 4.

NO >> Perform trouble diagnosis for the hazard warning lamp. Refer to EXL-85, "

Diagnosis Procedure" .

4.PERFORM TCM SELF-DIAGNOSIS

With CONSULT

Perform self-diagnosis for “TRANSMISSION”.

Is any DTC detected?

YES >> Check malfunctioning circuit. Refer to TM-110, "DTC Index".

NO >> GO TO 5.

5.CHECK HORN OPERATION

Check horn operation. Refer to HRN-3, "

Wiring Diagram".

Is the operation normal?

YES >> GO TO 6.

NO >> Repair or replace error-detected parts.

6.PERFORM BCM SELF-DIAGNOSIS

With CONSULT

1. Drive for 10 minutes at a speed of 40 km/h (25 MPH) or more.

CAUTION:

Total time driving at a speed of 40 km/h (25 MPH) or more must be 10 minutes.

2. Stop the vehicle.

3. Perform self-diagnosis for “AIR PRESSURE MONITOR”.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2786 of 3641

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGWT-43

< SYMPTOM DIAGNOSIS >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

NOISE, VIBRATION AND HARSHN ESS (NVH) TROUBLESHOOTING

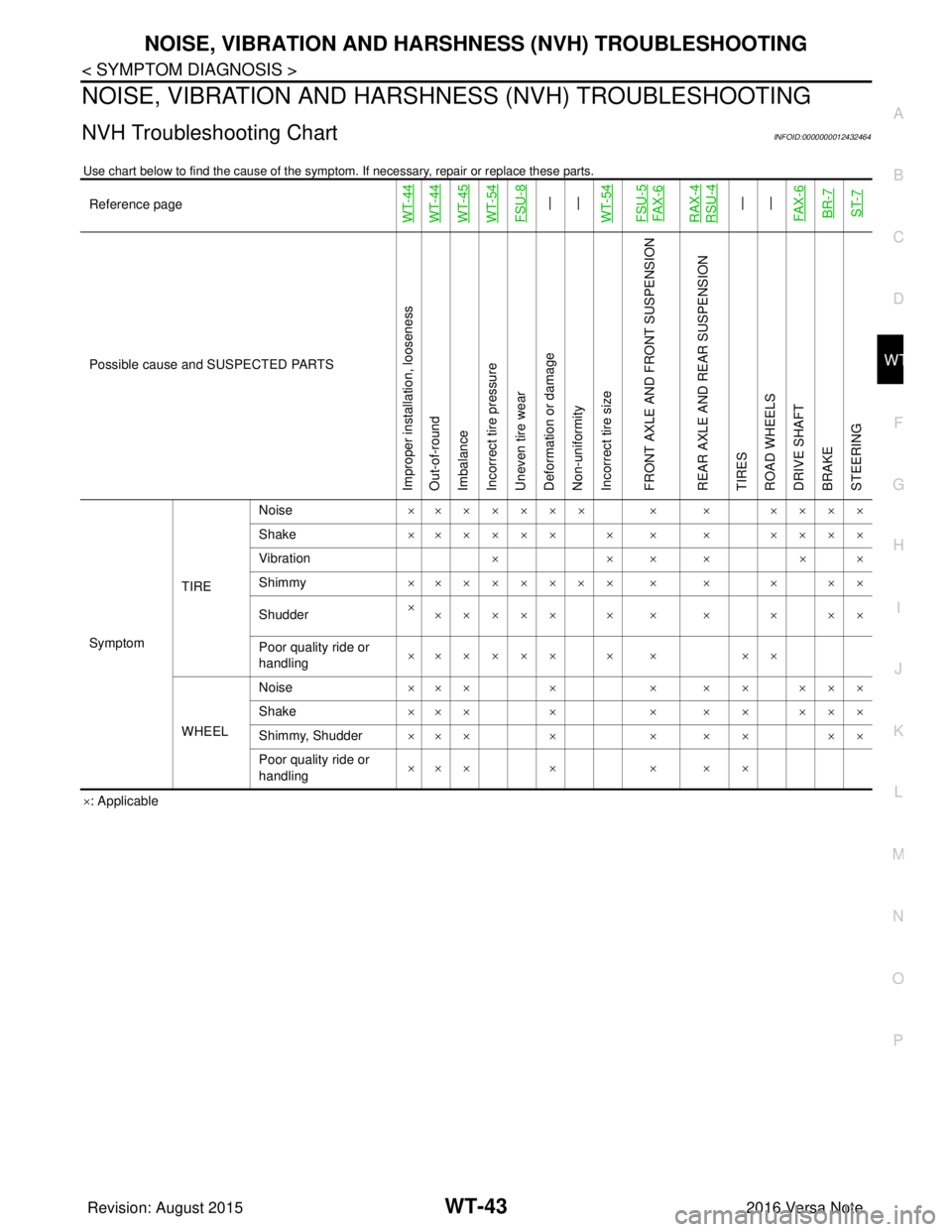

NVH Troubleshooting ChartINFOID:0000000012432464

Use chart below to find the cause of the symptom . If necessary, repair or replace these parts.

×: Applicable

Reference page

WT-44WT-44WT-45WT-54FSU-8—

—

WT-54FSU-5FA X - 6RAX-4RSU-4—

—

FA X - 6BR-7ST-7

Possible cause and SUSPECTED PARTS

Improper installation, looseness

Out-of-round

Imbalance

Incorrect tire pressure

Uneven tire wear

Deformation or damage

Non-uniformity

Incorrect tire size

FRONT AXLE AND FRONT SUSPENSION

REAR AXLE AND REAR SUSPENSION

TIRES

ROAD WHEELS

DRIVE SHAFT

BRAKE

STEERING

Symptom TIRENoise

××××××× × × ××××

Shake ×××××× × × × ××××

Vibration ××××××

Shimmy ×××××××× × × × ××

Shudder ×

××××× × × × × ××

Poor quality ride or

handling ×××××× × × ××

WHEEL Noise

××× × × × × ×××

Shake ××× × × × × ×××

Shimmy, Shudder ×××× ×××××

Poor quality ride or

handling ×× × ×

× × ×

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2787 of 3641

WT-44

< PERIODIC MAINTENANCE >

WHEEL

PERIODIC MAINTENANCE

WHEEL

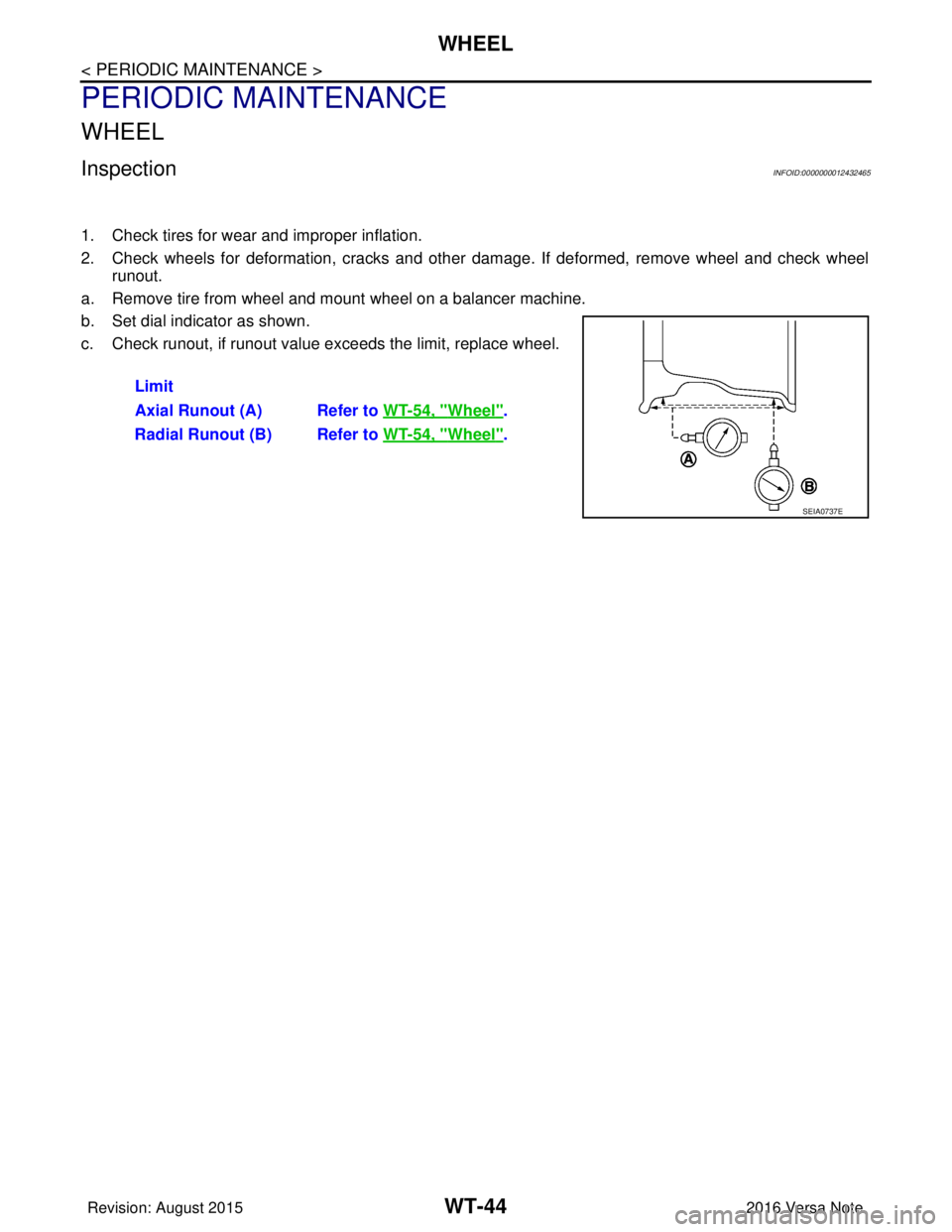

InspectionINFOID:0000000012432465

1. Check tires for wear and improper inflation.

2. Check wheels for deformation, cracks and other damage. If deformed, remove wheel and check wheel

runout.

a. Remove tire from wheel and mount wheel on a balancer machine.

b. Set dial indicator as shown.

c. Check runout, if runout value exceeds the limit, replace wheel.

Limit

Axial Runout (A) Refer to WT-54, "

Wheel".

Radial Runout (B) Refer to WT-54, "

Wheel".

SEIA0737E

Revision: August 2015 2016 Versa Note

cardiagn.com